The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Rigging and Trussing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Rigging and Trussing Interview

Q 1. Explain the different types of rigging hardware.

Rigging hardware encompasses a wide array of components crucial for safely suspending and controlling loads. Think of it as the nuts and bolts – literally and figuratively – of any rigging system. These components are designed to withstand significant stress and are categorized based on their function.

- Shackles: These U-shaped components with a pin through the bow are used to connect various rigging elements. They come in different strengths and materials (e.g., forged steel, alloy steel) and have a Working Load Limit (WLL) clearly stamped on them. Imagine them as strong links in a chain.

- Turnbuckles: These allow for precise adjustment of cable tension. They consist of a threaded rod within a housing, allowing for shortening or lengthening of a cable or wire rope. Think of them as adjustable tensioners.

- Wire Rope Clips (Clamps): These are used to secure the ends of wire ropes, preventing unraveling and ensuring proper load distribution. It’s crucial to use the correct number of clips and apply them correctly. A common mistake is to not have enough clips leading to potential wire rope failure.

- Eye Bolts: These are threaded bolts with a loop at one end, used to create secure anchor points. They are essential for connecting components to structures or other elements in a rigging system. Always ensure they are rated appropriately for the intended load.

- Carabiners: While generally used in climbing, certain heavy-duty carabiners may be used (with caution and expert knowledge) in some rigging applications. They are quick-connect devices but must be chosen carefully based on strength and type.

- Swivels: These allow for rotation of one rigging element relative to another, preventing twisting of cables and reducing wear. They prevent the cable from twisting, especially essential with long cables.

Selecting the right hardware is paramount; always check the WLL rating before use and inspect for damage before each application. Using substandard or damaged hardware can result in catastrophic failure.

Q 2. Describe the process of calculating load capacity for a truss.

Calculating the load capacity of a truss is a critical safety aspect. It involves considering several factors to ensure the structure can safely support the intended weight. It’s not a simple calculation, it requires engineering knowledge and often software.

The process typically involves:

- Determining the total load: This includes the weight of the truss itself, lighting fixtures, speakers, and any other equipment suspended from it. It also needs to take into account wind load and potential dynamic loads (movement during shows).

- Analyzing the truss structure: This involves understanding the geometry of the truss, including the type, members, and connections. This often requires Finite Element Analysis (FEA) software to accurately model the stress distribution.

- Calculating member forces: Using engineering principles (like statics and mechanics of materials), individual member forces (tension and compression) are calculated for each component. These calculations are often performed by engineering software.

- Determining the safety factor: A safety factor (typically 5:1 or higher) is applied to the calculated load capacities to account for uncertainties and unforeseen circumstances. This ensures the truss can withstand unexpected stresses.

- Checking against material strength: The calculated stresses are compared against the yield strength of the truss material (usually aluminum or steel) to ensure that the truss will not deform or fail under load.

Ignoring these steps can lead to catastrophic failures. It’s crucial to consult a structural engineer when working with trusses, especially for large-scale installations.

Q 3. What are the different types of trusses and their applications?

Trusses come in various configurations, each suited for specific applications. The choice depends on factors like span, load capacity, and aesthetic considerations.

- Triangle Truss: The most common type, featuring a triangular arrangement of members. Its strength comes from the inherent stability of the triangle. Used widely in concerts, theatre, and exhibitions.

- Box Truss: Consists of two triangle trusses connected to form a square or rectangular tube. Offers increased stiffness and torsional resistance compared to a single triangle truss, making them better for longer spans and heavier loads.

- Roof Truss: Designed specifically for roof structures, featuring an arch-like configuration which efficiently transfers the weight. Usually seen in large constructions.

- Space Truss: Three-dimensional structure with members arranged in a lattice form, often used for large-scale structures and complex geometries.

- Circular Truss: Used to create circular structures or supports; often employed in large-scale installations or special set designs.

Each truss type has its load-bearing capabilities and optimal applications. Misusing a truss can compromise structural integrity and safety. The choice of truss is always determined by the loading and configuration needs. Expert calculations are necessary for the design of all trusses.

Q 4. How do you ensure the safety of rigging operations?

Ensuring safety in rigging operations is paramount. It’s not just about following procedures; it’s about a safety-first mindset from planning to execution. This is achieved through a multi-pronged approach:

- Proper planning and risk assessment: This involves identifying potential hazards, developing mitigation strategies, and creating a detailed rigging plan. This includes analyzing the load, the rigging hardware, and the environment.

- Regular inspection of equipment: All rigging hardware must be inspected for damage, wear, or corrosion before each use. This reduces the risk of failure during operation.

- Competent personnel: Only trained and certified riggers should handle rigging operations. They are knowledgeable in safe practices and techniques. This requires training and certification.

- Use of appropriate equipment: The rigging equipment must be correctly selected and rated for the intended load. Overloading equipment is a major cause of accidents.

- Communication and teamwork: Clear communication between all team members is essential. Everyone should understand the rigging plan and their responsibilities.

- Emergency procedures: Clear emergency procedures should be in place and practiced regularly to deal with unforeseen circumstances. This includes emergency contact information and evacuation plans.

Neglecting any of these steps can lead to serious accidents. Safety should never be compromised.

Q 5. Explain the importance of load testing in rigging.

Load testing in rigging is a crucial step to validate the structural integrity of the system and ensure it can handle the intended load. It’s not just about calculations; it’s about real-world verification.

Load testing involves applying a controlled load to the rigging system, typically exceeding the intended working load. This allows for visual inspection for deformations and verifies that the system remains within safety limits. The load is gradually applied and monitored using calibrated instruments.

The importance of load testing lies in:

- Verification of calculations: It confirms the accuracy of load calculations and design specifications. It accounts for any unexpected factors.

- Identifying weak points: Load testing can reveal weaknesses in the system that might not be apparent through calculations alone. This allows for corrective actions.

- Ensuring safety: It provides a tangible demonstration of the system’s ability to withstand the intended load and helps to reduce the risk of failure.

- Compliance: Many safety regulations mandate load testing for specific rigging applications.

Proper load testing requires certified equipment and personnel capable of conducting safe and accurate tests and recording the results. This data is essential for documentation.

Q 6. What are the different types of knots used in rigging?

Several knots are used in rigging, each designed for specific purposes and load-bearing characteristics. The choice of knot depends on the application and the type of rope being used.

- Bowline: Creates a fixed loop that doesn’t slip easily. Excellent for creating a secure loop at the end of a rope.

- Clove Hitch: A simple, easily tied knot that forms a loop around a post or other object. Useful for temporary attachments.

- Figure Eight Knot: A simple knot to secure the end of a rope and is essential for safety. It’s easy to tie and untie. Used in climbing and similar applications.

- Running Bowline: Similar to a bowline but allows the loop to move along the rope. The slip-knot feature of this knot is useful for hoisting operations.

- Fisherman’s Knot: Used to join two ropes of similar diameter. It’s strong but can be difficult to untie after being subjected to heavy loads.

Improper knot tying can lead to catastrophic failure. Riggers must be proficient in tying various knots and understand the limitations of each. It is extremely important to only use the appropriate knots for each application and to know how to tie them correctly. In professional rigging, the choice of knot is a critical decision.

Q 7. Describe the proper methods for attaching a load to a truss.

Attaching a load to a truss requires careful consideration of several factors, ensuring the load is distributed evenly and the connection is secure. This involves using appropriate hardware and techniques.

- Use of shackles or other connecting hardware: Direct attachment to the truss is generally not recommended. Shackles provide a strong and reliable connection, allowing easy attachment and detachment. The correct shackle size and rating is critical to the operation.

- Even weight distribution: Ensure the load is evenly distributed across multiple attachment points on the truss. This minimizes stress concentration on any single point and prevents the truss from being overloaded in any specific area. This is often achieved using multiple chains or wire ropes.

- Correct placement of attachment points: Attachment points should be selected strategically on the truss to minimize bending moments and maximize load-bearing capacity. Avoid attaching to points that may be weaker in the truss.

- Use of load-rated hardware: All hardware used for attachment must have a working load limit (WLL) that exceeds the total load. The WLL of each component must be checked prior to use.

- Avoid sharp bends or kinks: Sharp bends in cables or ropes can significantly reduce their load-bearing capacity and lead to failure. The angle and tension must be properly distributed. This requires planning and knowledge of the system.

Attaching a load to a truss is a critical part of the entire rigging process; improper attachment can lead to serious safety hazards. Proper planning and attention to detail are always required.

Q 8. How do you inspect rigging hardware for damage?

Inspecting rigging hardware is crucial for safety. It’s not just a visual check; it requires a systematic approach. Think of it like a doctor’s checkup for your equipment. We start with a thorough visual inspection, looking for any signs of wear and tear, such as:

- Corrosion: Rust, pitting, or any discoloration indicates weakening of the metal.

- Damage: Bent shackles, cracked hooks, or damaged threads are immediate red flags.

- Wear: Look for excessive wear on ropes, chains, or wire ropes – fraying, kinks, or broken strands are unacceptable.

- Deformation: Any unusual bends or twists in metal components.

- Missing parts: Check for any missing cotter pins, safety latches, or other crucial components.

Beyond visual inspection, we might use other methods. For example, we might use a load cell to verify the actual working load limit (WLL) of a component, or non-destructive testing (NDT) methods in critical situations to assess internal integrity. Remember, if in doubt, replace the component. Safety should always be the top priority.

Q 9. What are the regulations and safety standards you follow in rigging?

Rigging adheres to strict regulations and safety standards that vary by location and industry. In most places, these standards are based on national and international guidelines such as OSHA (Occupational Safety and Health Administration) in the US, or equivalent standards in other countries. These regulations cover various aspects, including:

- Equipment inspection and certification: Rigging hardware must be regularly inspected and certified by qualified professionals to ensure its continued safe operation. We utilize inspection checklists and documentation for meticulous tracking.

- Competent personnel: Only trained and qualified personnel should handle rigging operations. This includes possessing the necessary certifications and understanding all applicable safety regulations.

- Safe work practices: Detailed procedures and safe work practices must be followed, including proper rigging techniques, load handling, and emergency procedures.

- Load calculations: Accurate load calculations are critical. Overloading is a major cause of accidents. Calculations incorporate factors of safety and account for environmental conditions like wind.

- Risk assessment: Every rigging operation requires a thorough risk assessment before commencing work to identify and mitigate potential hazards.

Non-compliance can lead to severe consequences, including accidents, injuries, fines, and legal repercussions.

Q 10. Explain the concept of a rigging plan and its importance.

A rigging plan is a crucial document that details every aspect of a lifting operation, like a blueprint for a building. It outlines the specific equipment, procedures, and safety measures involved. Think of it as the roadmap that guides the entire process, ensuring a safe and efficient operation. Key elements include:

- Detailed drawings or diagrams: Show the placement of trusses, beams, supports and the suspended load.

- Equipment list: Specifying the type, size, and WLL of each piece of equipment used.

- Lifting procedures: A step-by-step guide for the lift, including assembly, lifting, and lowering procedures.

- Safety precautions: A list of all safety measures and emergency procedures.

- Personnel responsibilities: Clearly defining roles and responsibilities for each team member.

- Load calculations: Detailed calculations showing the forces involved and verifying the adequacy of the rigging system.

Without a comprehensive rigging plan, accidents become much more likely due to miscommunication, inadequate equipment, or unsafe practices. It protects everyone involved.

Q 11. How do you calculate the center of gravity for a suspended load?

Calculating the center of gravity (CG) for a suspended load is essential for safe and stable lifting. Imagine trying to balance a seesaw – the CG is the point where the load would balance perfectly. For complex loads, we can use several methods:

- Simple Shapes: For regularly shaped loads (e.g., a rectangular box), the CG is at the geometric center.

- Complex Shapes: For irregularly shaped loads, we often divide the load into smaller, simpler shapes, calculate the CG of each, and then find the overall CG using weighted averages.

- Measurement and Calculation: Direct measurement techniques involve using a plumb bob suspended from various points on the load to locate the CG.

- Software: Specialized rigging software simplifies CG calculations, especially for intricate loads.

Incorrect CG calculation can lead to unstable lifts, resulting in swinging loads, equipment damage, or even accidents. It’s crucial to take meticulous measurements and calculations to determine the CG accurately before the lift begins.

Q 12. What are the different types of lifting equipment used in rigging?

Numerous types of lifting equipment are employed in rigging, each suited for specific tasks and loads. Some common examples include:

- Chain Hoists: Hand-operated or electric chain hoists are used for lifting and moving moderate loads.

- Wire Rope Slings: Offer versatility and strength for lifting various objects. Different configurations exist (e.g., choker, bridle).

- Shackles: Strong metal links used to connect different parts of the rigging system.

- Eye Bolts and Hooks: Attachment points for slings and other rigging components.

- Load Cells: Used to precisely measure the weight of a load during lifting.

- Cranes: Large machinery used to lift heavy loads with high capacity.

- Jacks: Hydraulic or mechanical devices used for lifting or positioning heavy objects.

Choosing the right lifting equipment based on the load’s weight, shape, and material is vital for ensuring a safe and efficient lift. Using the wrong equipment can result in catastrophic failures.

Q 13. Describe the process of setting up a counterweight system.

Counterweight systems are essential for balancing loads in rigging, particularly in applications like theatrical stage rigging. Imagine a seesaw again: the counterweights act as the balancing weight on the other side. Setting up a system usually involves these steps:

- Assessment: Determine the weight of the load to be balanced.

- Counterweight Selection: Choose counterweights that are slightly heavier than the expected load, accounting for friction and other factors. Often sandbags or specialized weights are used.

- System Design: The counterweights are typically attached to a system of ropes, pulleys, and sheaves which will move opposite to the load to balance out its motion and weight.

- Installation and Adjustment: Install the system carefully. Precise adjustments are made to balance the load correctly.

- Testing and Refinement: Thoroughly test the counterweight system with a dummy load, making adjustments as needed. Final adjustments will ensure smooth operations.

A poorly set-up counterweight system can lead to unbalanced loads, unexpected movement, or even accidents. Careful planning and execution are vital for safety.

Q 14. How do you handle unexpected issues during a rigging operation?

Unexpected issues can arise during any rigging operation. The key is to be prepared, have a plan B, and act decisively but calmly. Procedures vary, but general steps include:

- Identify the problem: First assess the situation and determine the precise nature of the problem.

- Communicate: Clearly communicate with the rigging crew, using standard communication protocols to inform everyone of the issue.

- Risk Assessment: Evaluate the risk associated with the problem. Do you need to stop the operation, or can you safely proceed with modifications?

- Implement corrective action: Based on the risk assessment, you may take steps to fix the problem, find a work-around, or stop the operation completely.

- Document: Meticulously document the problem, the corrective action taken, and the outcome of the incident.

For example, if a wire rope shows signs of excessive wear during the operation, we wouldn’t continue. We would immediately halt the operation, assess the damage, replace the damaged part, and fully inspect the rest of the system before resuming. Safety is paramount, and sometimes stopping the operation is the best solution.

Q 15. Explain the importance of communication in a rigging team.

Effective communication is the bedrock of safe and efficient rigging operations. Think of a rigging team like a finely tuned orchestra; each member plays a crucial role, and without clear communication, chaos ensues. In a rigging environment, miscommunication can lead to disastrous consequences, from minor delays to serious injury or equipment damage.

- Pre-Rigging Planning: Clear communication during the planning phase ensures everyone understands the load, the rigging points, the lifting method, and the safety protocols. A misunderstanding about the weight of a lighting fixture, for instance, could result in a catastrophic failure.

- Real-Time Coordination: During the rigging process itself, constant communication is vital. Hand signals, radio communication, and clear verbal instructions are essential for coordinating the actions of multiple team members, especially when working at heights or with heavy equipment. A simple misinterpretation of a hand signal can mean the difference between a successful lift and a dangerous situation.

- Post-Rigging Debriefing: After the operation, a thorough debriefing allows the team to identify any issues, near misses, or areas for improvement. This reflective process enhances team learning and prevents similar incidents from occurring in the future. This is like a post-game analysis for a sports team.

In my experience, utilizing a combination of pre-planned communication strategies and on-site real-time updates significantly reduces errors and enhances safety. A clear chain of command and designated communication channels are essential.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the potential hazards associated with rigging?

Rigging inherently involves significant hazards. These risks are amplified when working at heights or with heavy loads. Some of the most prevalent potential hazards include:

- Falls from Heights: This is perhaps the most significant risk, especially when working on elevated platforms or from suspended equipment. Improper use of fall protection systems or inadequate safety measures directly contribute to this risk.

- Crushing Injuries: Heavy loads, equipment malfunctions, or uncontrolled movements can cause serious crushing injuries. This highlights the importance of proper load calculations, secure rigging points, and a well-maintained system.

- Struck-by Hazards: Falling objects, swinging loads, or collapsing structures can result in serious injuries. Safe work practices, including proper spotting and securing of equipment, are crucial for mitigation.

- Electrocution: Working near energized electrical lines or equipment poses a significant electrocution risk. Maintaining appropriate clearances and employing qualified electricians is crucial.

- Equipment Failure: Improperly maintained or overloaded rigging hardware (chains, slings, shackles, etc.) can fail, leading to the catastrophic failure of the entire system.

The risk assessment and meticulous planning required to mitigate these hazards are paramount to ensuring a safe work environment.

Q 17. How do you mitigate the risks associated with working at heights?

Mitigating risks associated with working at heights is a multi-faceted process that involves engineering controls, administrative controls, and personal protective equipment (PPE). It’s not enough to just have a safety harness; a comprehensive approach is required.

- Engineering Controls: These focus on modifying the work environment to minimize the risk. Examples include using scaffold systems with appropriate guardrails, implementing robust anchor points for fall arrest systems, and using elevated work platforms. This proactive approach reduces the likelihood of falls.

- Administrative Controls: This involves implementing safe work procedures, providing comprehensive training to personnel, conducting regular inspections, and establishing clear communication protocols. A thorough risk assessment forms the foundation for this.

- Personal Protective Equipment (PPE): This includes full-body harnesses, appropriately rated lanyards, and fall arrest systems. Regular inspection and maintenance of PPE are critical. PPE acts as a last line of defense, but it’s far better to eliminate hazards in the first place.

A real-world example: Before commencing any work at height, we perform a thorough site-specific risk assessment, and implement the required engineering, administrative and PPE controls. We also ensure that all team members are appropriately trained and certified in working at heights procedures, and any specific equipment involved in the project.

Q 18. Describe your experience with different types of rigging systems.

My experience encompasses a wide range of rigging systems, including:

- Chain Hoists: I’m proficient in using various types and capacities of chain hoists, from manual hand-chain hoists to motorized electric chain hoists. Understanding their limitations and load capacities is crucial.

- Wire Rope Systems: I have extensive experience with wire rope slings, shackles, and other hardware, understanding their proper inspection and maintenance, including detecting signs of wear and tear.

- Lifting Beams and Spreader Beams: I’m skilled in utilizing lifting beams and spreader beams for distributing loads evenly, particularly when lifting large and unwieldy objects. This involves accurate load calculations and ensuring proper load distribution.

- Plywood Rigging: This is a very specialized type of rigging used for things like large set pieces or flying scenery. The specific techniques for creating strong, lightweight structures are quite nuanced and require an understanding of material science.

- Motorized Chain Hoists & Winches: I have worked extensively with motorized systems, emphasizing their safe operation and understanding their capabilities and limitations, including emergency stop procedures.

My experience extends beyond just the equipment itself; it includes a deep understanding of the load calculations, safety factors, and regulatory compliance required for each system.

Q 19. What software or tools are you familiar with for rigging design?

While I’m not a software developer, I’m proficient in using several software packages and tools commonly used in rigging design and analysis. This helps in accurate calculations and safe planning.

- AutoCAD: I utilize AutoCAD to create detailed drawings of rigging systems, including accurate measurements, load calculations, and detailed hardware specifications. This helps to visualize and communicate the setup to the team.

- Vectorworks: This software is excellent for designing theatrical rigging and staging, allowing me to model complex systems and simulate movements of scenery and lighting equipment.

- Spreadsheet Software (Excel, Google Sheets): I use spreadsheets for load calculations, creating rigging schedules, and maintaining detailed records of equipment inspections. This ensures consistent and accurate data tracking.

- Specialized Rigging Software (e.g., some proprietary software specific to the company or manufacturer): I have experience with some specialized rigging calculation software and modelling tools depending on the specific project.

I understand that the chosen software depends on the project scope and complexity, but my familiarity with these tools enhances my ability to effectively plan and execute rigging operations.

Q 20. How do you ensure proper documentation of rigging operations?

Proper documentation of rigging operations is not just a best practice; it’s a legal and safety imperative. This documentation provides a crucial audit trail and ensures accountability.

- Pre-Job Risk Assessments: Detailed risk assessments that identify potential hazards and outline mitigation strategies are crucial. These assessments document potential risks and the steps taken to prevent accidents.

- Rigging Diagrams and Calculations: Detailed drawings illustrating the rigging setup, including load calculations, hardware specifications, and safety factors. This ensures everyone understands the plan.

- Inspection Records: Meticulous records of equipment inspections, noting any signs of wear or damage, should be maintained. These provide proof of equipment suitability and responsible maintenance.

- Incident Reports: Thorough documentation of any incidents, near misses, or accidents, including a detailed account of the event and any corrective actions taken. This allows for continuous improvement.

- Post-Job Reports: Summarize the operation, note any challenges, and highlight areas for improvement. This helps maintain operational effectiveness and safety.

All documentation is kept in a secure, organized system, and readily accessible to relevant personnel. I ensure all documents are properly timestamped and signed off by the responsible parties.

Q 21. Describe your experience with troubleshooting rigging problems.

Troubleshooting rigging problems requires a systematic approach, combining practical experience, knowledge of physics, and a keen eye for detail. It’s like solving a puzzle, where each piece of information contributes to the overall solution.

- Identify the Problem: Clearly define the problem. Is the load not lifting? Is there unusual movement? Is there equipment malfunction? Precise identification is the first step.

- Gather Information: Collect data. What is the load weight? What type of rigging hardware is being used? What are the environmental conditions? This comprehensive approach will guide the diagnosis.

- Analyze the Situation: Apply your knowledge of physics and engineering principles. Are there any load imbalances? Are the rigging points correctly positioned? Is there any wear and tear on the equipment?

- Develop and Implement Solutions: Based on your analysis, propose and implement appropriate solutions. This may involve adjusting rigging points, replacing damaged equipment, or modifying lifting techniques. Safety is paramount at this stage.

- Document the Solution: Thoroughly document the problem, the troubleshooting process, and the solution implemented. This will prevent future occurrences of the same issue.

For example, if a load is swaying excessively during lifting, it might indicate a load imbalance, improperly positioned rigging points, or wind conditions. By systematically investigating these factors, and implementing solutions such as load redistribution or altering lifting techniques, the problem can be efficiently resolved.

Q 22. How do you calculate the safe working load for a rigging component?

Calculating the safe working load (SWL) of a rigging component is crucial for safety. It’s not a single calculation but rather a process involving several factors. You always start with the manufacturer’s specifications – the SWL is clearly stated on the component itself (e.g., a sling, shackle, or chain). However, this is just the starting point. We must then consider:

- Angle of the lift: Lifting at an angle reduces the SWL. A sling at 30 degrees from vertical will have a significantly lower capacity compared to a vertical lift. Many manufacturers provide angle correction charts.

- Component condition: Regular inspections are vital. Damage, corrosion, or wear significantly impacts SWL. A component showing signs of wear should be immediately removed from service.

- Environmental factors: Extreme temperatures, chemical exposure, or other environmental conditions can weaken components and reduce their SWL.

- Safety factors: A safety factor is always applied. This means the SWL is significantly lower than the ultimate breaking strength to allow for unforeseen circumstances or unexpected loads.

Example: A sling is rated for 10,000 lbs SWL vertically. If used at a 45-degree angle, referencing the manufacturer’s chart might reduce the SWL to approximately 7000 lbs. If there’s even minor damage, it would be prudent to further reduce the working load or retire the sling altogether.

In short, calculating the safe working load involves more than just looking at a single number. It requires a thorough understanding of the equipment, its condition, and the specific lifting conditions.

Q 23. What is your experience with different types of rigging slings?

My experience encompasses a wide range of rigging slings, including:

- Polyester (Webbing) Slings: These are versatile, lightweight, and relatively inexpensive. They are suitable for a variety of lifting tasks but are susceptible to UV degradation and abrasion.

- Nylon Slings: Similar to polyester, but with slightly higher strength and elasticity. They offer a good balance of strength and flexibility.

- Chain Slings: Durable and robust, ideal for heavy lifting and harsh environments. Regular inspection for wear and damage is paramount.

- Wire Rope Slings: Extremely strong and suitable for very heavy loads. Proper lubrication and inspection for broken wires are crucial.

- Round Slings: Efficient for lifting round or cylindrical objects

- Endless Slings: Offer a more efficient way of lifting heavier loads.

I’m proficient in selecting the appropriate sling based on the load, the environment, and the characteristics of the object being lifted. This includes understanding the different sling configurations (e.g., choker hitch, basket hitch) and their impact on SWL.

Q 24. Explain the difference between static and dynamic rigging.

The key difference between static and dynamic rigging lies in the nature of the load and the equipment used.

- Static rigging involves lifting and securing loads that remain stationary or move very slowly. Think of setting up a stage for a concert. The primary focus is on stability and ensuring the load remains securely in place. Static rigging often utilizes stronger and more rigid components like chain, wire rope, and heavy-duty shackles.

- Dynamic rigging deals with loads that are in motion or subjected to significant shock loads. Consider the rigging of a camera crane on a film set. Here, we are anticipating movement, and the rigging needs to account for sudden acceleration and deceleration. Dynamic rigging typically utilizes more flexible components like synthetic slings, which can absorb some of the shock. The safety factor is typically higher for dynamic rigging.

The choice between static and dynamic rigging depends entirely on the application. Misusing static rigging in a dynamic situation can be extremely dangerous.

Q 25. How do you address issues related to rigging in adverse weather conditions?

Rigging in adverse weather conditions demands extra caution and planning. My approach involves:

- Assessment of the Weather: Checking weather forecasts and monitoring conditions on-site is paramount. High winds, heavy rain, snow, or ice significantly impact SWL and safety.

- Increased Safety Factors: I’d often apply a greater safety factor than usual to compensate for unpredictable weather conditions.

- Appropriate Equipment Selection: Selecting materials and equipment less affected by adverse weather is vital. This might mean opting for materials that are less susceptible to water damage or corrosion.

- Enhanced Inspection Procedures: More frequent inspections are necessary to catch any issues early. Ice or snow accumulation needs immediate attention.

- Wind Considerations: High winds increase the strain on the rigging system. Additional bracing or securing measures might be necessary, or the entire operation might need to be postponed.

- Communication: Clear and constant communication with the entire team is essential in managing a potentially dangerous situation.

In extreme conditions, work might be suspended completely. Safety is always the top priority.

Q 26. What are your experience with different types of chain and wire rope?

My experience includes working with various types of chain and wire rope, understanding their strengths, limitations, and proper maintenance.

- Chain: I’m familiar with various grades and strengths of chain, including alloy steel chains for high-strength applications and galvanized chain for corrosion resistance. Regular inspection for stretch, wear, and damage (e.g., cracks) is crucial. Proper lubrication is also essential for longevity.

- Wire Rope: Different wire rope constructions (e.g., 6×19, 6×36) have different flexibility and strength characteristics. I am experienced in identifying correct rope diameters for given applications. Regular inspection is critical, checking for broken wires, kinks, and overall wear. Proper lubrication is also vital.

The selection of chain or wire rope depends on factors like load capacity, working environment (e.g., corrosive environment needing galvanized chain), and the required flexibility. I always choose the appropriate grade and construction to ensure safety and reliability.

Q 27. Explain your understanding of fall protection systems in rigging.

Fall protection is paramount in rigging. The systems used will depend on the specific work being performed, but they should always comply with relevant safety regulations. Common fall protection systems in rigging include:

- Harnesses: Full body harnesses are essential for personnel working at heights.

- Anchor Points: Secure anchor points are critical for connecting safety lines and harnesses. These points should be independently assessed for their load bearing capacity.

- Safety Lines and Lanyards: These connect the harness to the anchor point, preventing falls. Proper length and type of lanyard must be chosen for the specific task.

- Shock Absorbers: Incorporated into lanyards or safety lines, shock absorbers reduce the impact force during a fall.

- Self-Retracting Lifelines (SRLs): SRLs automatically retract the lifeline, providing continuous fall protection.

Regular inspections of all fall protection equipment are mandatory. Damaged or worn-out equipment must be immediately replaced. Training on the proper use of fall protection systems is also crucial for every member of the rigging crew.

Q 28. Describe a challenging rigging project and how you overcame the difficulties.

One challenging project involved rigging a massive, irregularly shaped sculpture for an outdoor art installation. The sculpture’s unique shape and weight distribution made it difficult to find stable lifting points, and the on-site conditions – limited space and uneven terrain – added to the complexity. The high winds predicted for the day of installation presented additional hurdles.

To overcome these difficulties, we:

- Performed a thorough 3D model analysis: This allowed us to identify optimal lifting points that distributed the weight evenly, minimizing stress on the sculpture and the rigging system.

- Utilized specialized rigging equipment: This included custom-designed spreader beams to accommodate the sculpture’s irregular shape and multiple attachment points to allow us to distribute the load effectively and safely.

- Developed a comprehensive rigging plan: This included detailed diagrams, lift plans, and emergency procedures, anticipating and mitigating potential problems. The plan was then rigorously reviewed with the entire rigging crew.

- Employed additional bracing and securing mechanisms: Due to the high-wind prediction, we utilized extra bracing and tie-down points to secure the sculpture during the lift and after placement.

Through meticulous planning, the use of specialized equipment, and a strong focus on teamwork and safety, we successfully completed the installation without incident. This project highlighted the importance of thorough planning, adaptation to unforeseen challenges, and the value of a skilled and experienced team.

Key Topics to Learn for Your Rigging and Trussing Interview

- Load Calculations and Weight Distribution: Understanding how to accurately calculate and distribute weight across trusses and rigging systems is fundamental. Consider different load types and safety factors.

- Types of Rigging Hardware: Familiarize yourself with various shackles, slings, wire ropes, and other hardware, including their strengths, limitations, and proper inspection techniques. Practical application involves knowing when to use each piece of equipment safely and effectively.

- Truss Design and Construction: Grasp the principles behind different truss types (e.g., square, triangular) and their applications. Understanding the structural integrity and limitations of various designs is key.

- Rigging Techniques and Knots: Master essential knots and rigging techniques for safe and efficient load handling. Be prepared to discuss proper knot selection for different situations and their load-bearing capabilities.

- Safety Regulations and Best Practices: Demonstrate a thorough understanding of relevant safety standards and regulations in rigging and trussing. This includes fall protection, load limits, and emergency procedures.

- Troubleshooting and Problem Solving: Practice identifying potential hazards and developing solutions for common rigging and trussing challenges. Be ready to discuss your approach to problem-solving in a practical setting.

- Software and Technology: Familiarity with relevant software used for load calculations, design, or simulations is a valuable asset. Be prepared to discuss any experience you have in this area.

Next Steps: Level Up Your Rigging and Trussing Career

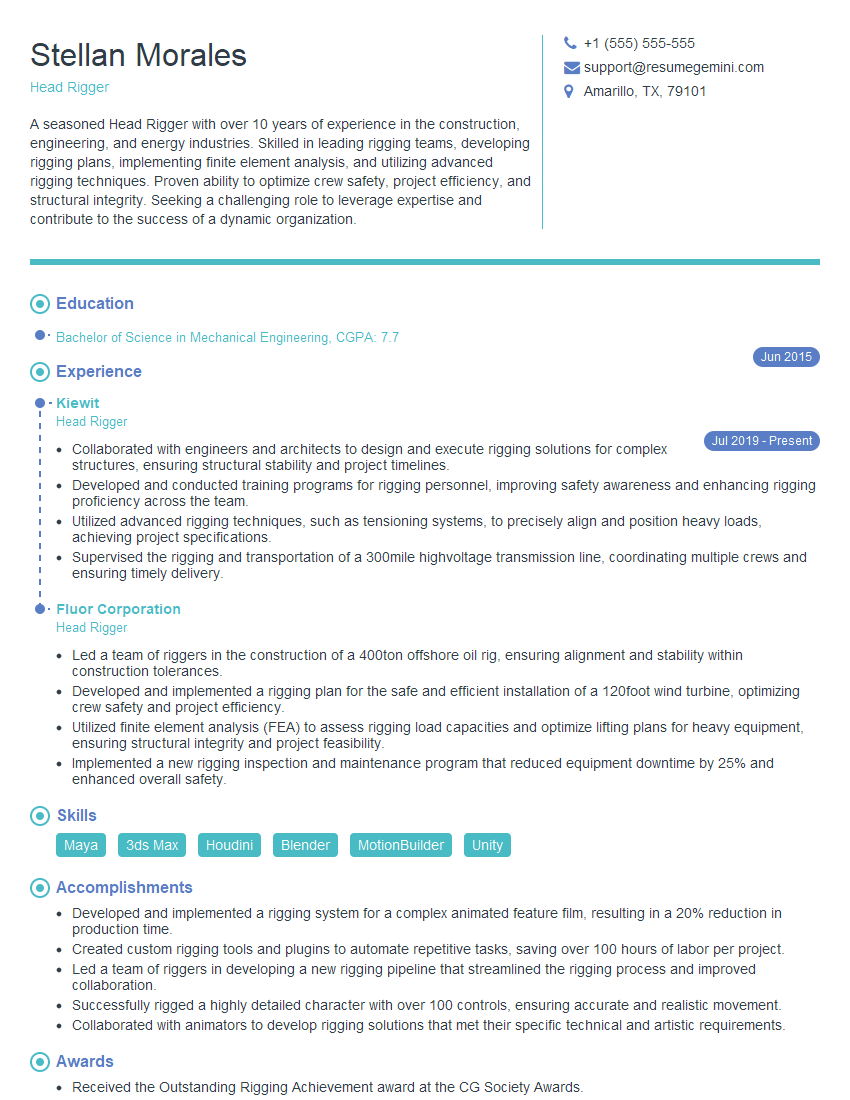

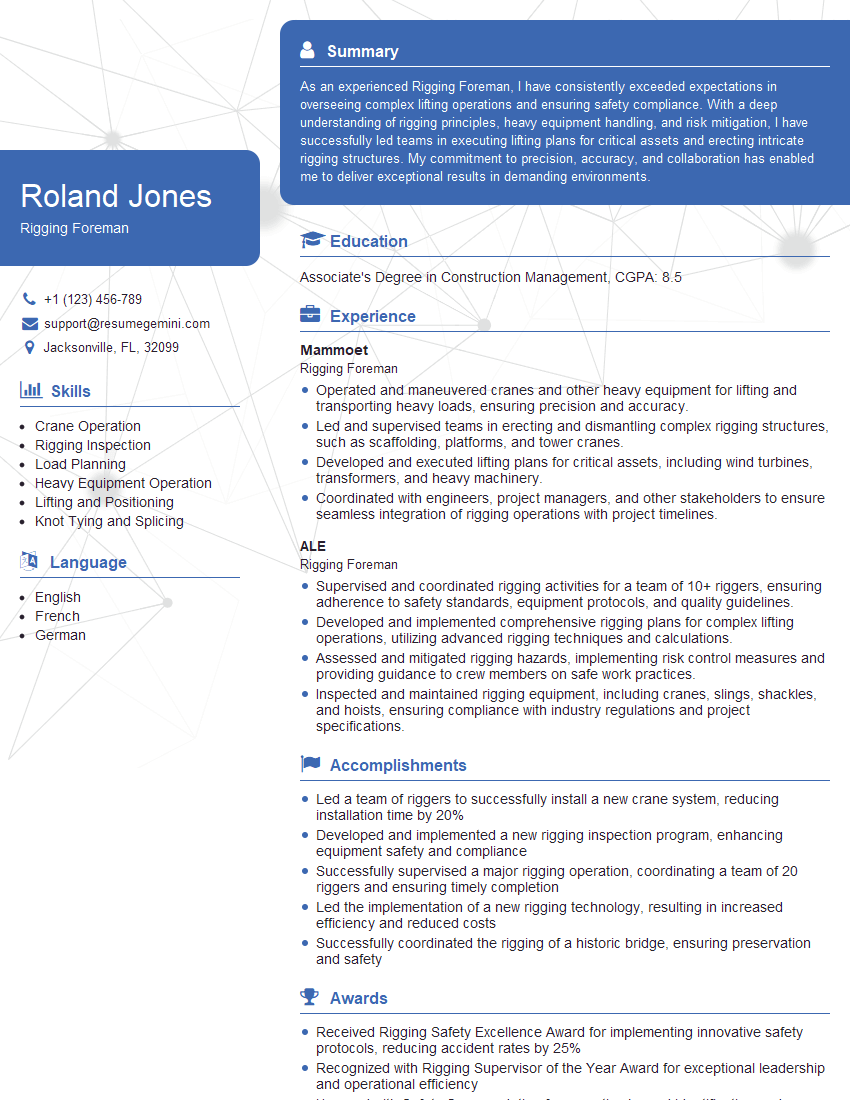

Mastering rigging and trussing opens doors to exciting career opportunities in the entertainment, construction, and industrial sectors. To stand out from the competition, a well-crafted resume is crucial. An ATS-friendly resume increases your chances of getting your application seen by recruiters. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. We even provide examples of resumes tailored specifically to the Rigging and Trussing industry to give you a head start. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good