Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Robotics Control interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Robotics Control Interview

Q 1. Explain the difference between open-loop and closed-loop control systems in robotics.

Imagine you’re teaching a dog a trick. In open-loop control, you show the dog what to do once and hope it performs correctly. There’s no feedback mechanism to check if the dog actually followed your instructions. In robotics, this means sending a command to a motor to move a certain distance or angle without checking if it actually reached the target. The robot just executes the command blindly. This is simple to implement but highly susceptible to errors from unforeseen disturbances like friction or external forces. For example, instructing a robotic arm to move 10 degrees without any feedback mechanism might result in a slightly different final position due to variations in the motor’s performance or load on the arm.

Closed-loop control, on the other hand, is like teaching a dog with treats and corrections. You show the dog the trick, check its performance, and provide feedback (treats for success, corrections for mistakes). In robotics, this involves using sensors to monitor the robot’s actual state (position, velocity, etc.) and comparing it to the desired state. The controller then adjusts the commands to minimize the difference. This is much more robust and accurate, compensating for uncertainties and disturbances. A classic example is using a position sensor (e.g., encoder) on a robotic joint to measure its angle, compare it to the target angle, and adjust the motor’s torque accordingly until the target is reached.

Q 2. Describe different types of robot manipulators and their control challenges.

Robot manipulators come in various forms, each posing unique control challenges. Articulated robots, resembling human arms, have revolute joints and offer great dexterity but complex kinematics and potential singularities (points where the robot loses degrees of freedom). Controlling them requires sophisticated algorithms to handle inverse kinematics and singularity avoidance.

Cartesian robots, with linear joints, move along three Cartesian axes (X, Y, Z). They’re simpler to control since the relationship between joint positions and end-effector position is straightforward. However, they lack the dexterity of articulated robots.

SCARA robots are a compromise, offering a combination of rotary and linear motion. They excel in tasks requiring planar motion and are often easier to control than articulated robots but more complex than Cartesian ones.

Parallel robots have multiple arms supporting a single end-effector, providing high stiffness and accuracy. However, their complex kinematics can make control a significant challenge, especially in handling workspace limitations and redundancies.

Control challenges vary depending on the manipulator’s type: for articulated arms, it’s mainly the complexity of kinematics and singularity avoidance. For Cartesian robots, precise positioning and speed control are paramount. SCARA robots need efficient control algorithms to handle the combination of rotary and linear motion. Parallel robots require robust control strategies to deal with their complex kinematics and redundancy.

Q 3. What are PID controllers and how are they tuned for robotic systems?

PID controllers are widely used in robotics due to their simplicity and effectiveness. They adjust a control signal based on three terms: Proportional (P), Integral (I), and Derivative (D). The proportional term considers the current error (difference between the desired and actual state). The integral term considers the accumulated error over time, addressing persistent errors. The derivative term considers the rate of change of the error, anticipating future errors. The output of the PID controller is a weighted sum of these three terms:

u(t) = Kp * e(t) + Ki * ∫e(t)dt + Kd * de(t)/dt

where:

u(t)is the control signale(t)is the errorKp,Ki, andKdare the tuning gains

Tuning involves finding optimal values for Kp, Ki, and Kd to achieve desired performance (fast response, minimal overshoot, and good stability). This is often done empirically, experimenting with different values until satisfactory results are obtained. Techniques like Ziegler-Nichols method provide a systematic approach. Poorly tuned PID controllers can lead to oscillations, slow response, or instability. For example, a high Kp might lead to oscillations, while a high Ki might result in overshoot. Finding the right balance is key to achieving optimal performance.

Q 4. Explain the concept of Jacobian matrix in robot kinematics and its role in control.

The Jacobian matrix in robot kinematics is a crucial tool for relating joint velocities to end-effector velocities. It maps changes in joint angles to corresponding changes in the end-effector’s position and orientation. Imagine a robotic arm with multiple joints. The Jacobian matrix essentially tells you how much the end-effector will move in Cartesian space if you slightly change the angle of each joint. This is critical for robot control because it allows for transformation between the joint space (angles of each joint) and the operational space (position and orientation of the end-effector). It’s used in several applications:

- Inverse kinematics: Finding the joint angles required to achieve a desired end-effector pose.

- Velocity control: Calculating the required joint velocities to achieve a desired end-effector velocity.

- Force control: Transforming forces applied to the end-effector into joint torques.

Mathematically, the Jacobian is a matrix whose entries are partial derivatives of the end-effector position and orientation with respect to the joint angles. The size of the Jacobian depends on the number of degrees of freedom of the robot and the representation of the end-effector pose. It’s a powerful tool for understanding and controlling the robot’s motion in Cartesian space.

Q 5. How do you handle singularities in robot control?

Singularities in robot kinematics are configurations where the robot loses one or more degrees of freedom. Imagine trying to extend your arm straight out while keeping your elbow locked – you lose the ability to move your hand in certain directions. In robots, this manifests as a situation where the Jacobian matrix becomes singular (non-invertible). This means an infinitely large joint velocity might be required to produce a small end-effector velocity. Such situations are problematic as they lead to unpredictable behavior and can damage the robot.

Several strategies are used to handle singularities:

- Singularity avoidance: Planning robot trajectories to avoid regions of the workspace near singularities.

- Redundancy resolution: Using redundant degrees of freedom to navigate around singularities.

- Pseudo-inverse Jacobian: Using a pseudo-inverse instead of the regular inverse of the Jacobian to resolve the singularity. This approach finds a solution that minimizes joint velocities while achieving the desired end-effector velocity.

- Damped least squares method: This method adds damping to the pseudo-inverse calculation, making it less sensitive to singularity.

The choice of method depends on the specific robot and application. Careful trajectory planning and the use of appropriate control algorithms are critical for successful singularity avoidance or resolution.

Q 6. What are the advantages and disadvantages of using different robot coordinate systems?

Robots often use different coordinate systems to represent their position and orientation. Joint coordinates represent the angles or positions of the robot’s joints. World coordinates represent the robot’s position and orientation relative to a fixed frame in the environment. End-effector coordinates describe the position and orientation of the robot’s end-effector. Each system has advantages and disadvantages:

- Joint coordinates are simple to control directly but lack intuitive understanding of the end-effector’s position in the environment.

- World coordinates provide a clear representation of the robot’s position in the environment, but transformations between joint space and world space can be complex.

- End-effector coordinates directly reflect the desired position and orientation of the task, making programming easier but requiring complex transformations to joint space.

The choice of coordinate system depends on the task and control strategy. For instance, a simple pick-and-place task might be easier to program using end-effector coordinates, while complex assembly operations may benefit from a combined approach utilizing all three coordinate systems. Effective coordinate transformations are crucial to seamlessly switch between these coordinate systems.

Q 7. Explain the concept of forward and inverse kinematics in robotics.

Forward kinematics refers to the process of determining the end-effector’s pose (position and orientation) from the known joint angles. Think of it as knowing the angles of each joint of a robotic arm and calculating where the hand ends up. It’s a relatively straightforward calculation, often involving a series of matrix transformations (homogeneous transformations) to map joint angles to end-effector position and orientation in a chosen coordinate frame.

Inverse kinematics is the inverse problem: given a desired end-effector pose, find the required joint angles. This is significantly more challenging because it involves solving a set of nonlinear equations. Multiple solutions may exist, and the robot’s configuration must be considered to choose an appropriate solution. Numerical methods (e.g., Newton-Raphson) are commonly used to find a solution iteratively, but this process can be computationally expensive and sensitive to the initial guess. Inverse kinematics is crucial for tasks that require the robot to reach a specific position and orientation, such as grasping an object or performing a welding operation.

Q 8. Describe different robot programming languages and their applications.

Robot programming languages bridge the gap between human instructions and robot actions. They vary greatly depending on the robot’s complexity and the task at hand.

- Proprietary Languages: Many robot manufacturers provide their own programming languages, often tailored to their specific hardware. These languages might be simpler to learn for a particular robot but lack portability. An example would be RAPID for ABB robots.

- ROS (Robot Operating System): This is a more powerful and widely used framework rather than a language itself. It provides tools and libraries allowing programmers to write code in various languages (like Python, C++) to control complex robotic systems. ROS simplifies inter-process communication and handles things like sensor data fusion and motion planning. Its versatility makes it popular in research and industry.

- MATLAB/Simulink: These tools excel at simulation and prototyping. They offer a high-level environment to develop algorithms and control systems before deploying them to physical robots. Simulink’s graphical programming is particularly useful for visualizing robot dynamics.

- Python: Becoming increasingly popular in robotics due to its ease of use, vast libraries (like NumPy and SciPy), and strong community support. It’s used for everything from simple scripts to complex AI algorithms guiding robot behavior.

The choice of language depends heavily on the application. For a simple pick-and-place task in a factory, a proprietary language might suffice. For a more advanced system like autonomous navigation or collaborative robotics, ROS or Python with specialized libraries are more suitable.

Q 9. Explain different robot motion planning algorithms (e.g., A*, RRT).

Robot motion planning algorithms determine the sequence of movements a robot must execute to reach a goal, avoiding obstacles. Here are a couple of prominent examples:

- A* (A-star): This is a graph search algorithm that finds a path from a starting point to a goal. It uses a heuristic function to estimate the distance to the goal, efficiently exploring the search space. It’s suitable for grid-based environments or situations where the robot’s workspace can be represented as a graph. Imagine planning a route on a map – A* is similar, intelligently choosing the best route based on distance and estimated remaining travel time.

- RRT (Rapidly-exploring Random Tree): This algorithm is particularly useful for high-dimensional spaces and complex environments with obstacles. It builds a tree of possible robot configurations by randomly sampling the configuration space. It then attempts to connect the newly sampled configuration to the nearest node in the existing tree. This allows it to find paths in environments with narrow passages or intricate geometry. Imagine a robot navigating a cluttered workshop; RRT is excellent at finding a viable path amidst the obstacles.

The choice between A* and RRT depends on the environment and planning requirements. A* is more efficient in structured, grid-like environments, while RRT excels in complex and unstructured spaces.

Q 10. How do you deal with sensor noise and uncertainty in robot control?

Sensor noise and uncertainty are inevitable in robotics. They can lead to inaccurate measurements and flawed control decisions. Effective strategies to mitigate their effects include:

- Sensor Fusion: Combining data from multiple sensors (e.g., camera, lidar, IMU) helps reduce noise. By comparing measurements, inconsistencies due to noise can be identified and minimized. This is akin to using multiple witnesses to corroborate a story – a more reliable understanding emerges.

- Kalman Filtering (discussed further below): This powerful algorithm estimates the true state of the robot by combining sensor measurements with a model of the robot’s dynamics.

- Robust Control Techniques: These methods are designed to function correctly even with significant uncertainties. For instance, sliding mode control or H-infinity control can maintain stability in the presence of noise and disturbances.

- Data Preprocessing: Techniques like smoothing (moving average filters) and outlier rejection can help reduce noise before it affects the control system. This is like cleaning up a messy data set before analyzing it.

Implementing a combination of these methods is crucial for building a robust and reliable robotic system.

Q 11. What are Kalman filters and how are they used in robotics?

Kalman filters are powerful algorithms that estimate the state of a dynamic system (like a robot) from a series of noisy measurements. It works by combining a prediction step, based on a model of the system’s dynamics, with a correction step, based on new sensor measurements. The core idea is to weigh the prediction and the measurement appropriately, giving more weight to the more reliable source.

In robotics, Kalman filters are widely used in:

- State Estimation: Estimating the robot’s pose (position and orientation) from sensor data like IMU and GPS.

- Sensor Fusion: Integrating data from multiple sensors, as previously mentioned, to obtain a more accurate and reliable estimate.

- Navigation: Determining the robot’s trajectory and position in an environment.

- Control: Providing a more accurate estimate of the robot’s state for better control performance.

Imagine a self-driving car using GPS and wheel encoders to determine its location. GPS readings are often noisy, while wheel encoders can drift over time. A Kalman filter can combine these data sources to produce a much more accurate position estimate.

Q 12. Explain different methods for robot path planning and trajectory generation.

Robot path planning and trajectory generation are crucial for ensuring smooth and efficient movement. The process generally involves two steps: path planning, which finds a collision-free path from start to goal, and trajectory generation, which creates a smooth time-parametrized path that’s executable by the robot.

- Path Planning Algorithms: We’ve already discussed A* and RRT. Other algorithms include Dijkstra’s algorithm, potential fields methods, and sampling-based methods like PRM (Probabilistic Roadmap).

- Trajectory Generation Techniques: Once a path is determined, a trajectory is generated. This involves specifying the robot’s position, velocity, and acceleration as a function of time. Common techniques include polynomial interpolation, spline interpolation, and Bézier curves. These methods ensure smooth transitions between waypoints, preventing jerky movements and minimizing wear and tear on the robot.

For example, a robotic arm picking and placing objects needs a trajectory that is smooth to avoid collisions and ensure accurate placement. Similarly, a mobile robot navigating a corridor needs a path that avoids obstacles and a trajectory that ensures smooth turns and avoids excessive acceleration or deceleration.

Q 13. Describe different types of robot sensors and their applications in control.

Robots rely on a variety of sensors for perception and interaction with their environment. The choice of sensors depends heavily on the specific application.

- Cameras: Provide visual information, enabling robots to ‘see’ their surroundings. They’re used in object recognition, navigation, and visual servoing. Stereo cameras provide depth information.

- Lidar (Light Detection and Ranging): Uses lasers to create a 3D point cloud of the environment. This is crucial for autonomous navigation, obstacle avoidance, and mapping.

- IMU (Inertial Measurement Unit): Measures acceleration and angular velocity. It provides information about the robot’s motion, important for localization and stabilization.

- Encoders (Rotary and Linear): Measure the rotation or linear displacement of robot joints or wheels. Essential for precise motion control and feedback in closed-loop systems.

- Force/Torque Sensors: Measure forces and torques applied to the robot. Crucial for tasks requiring precise interaction with objects, such as assembly or delicate manipulation.

- Proximity Sensors (Ultrasonic, Infrared): Detect the presence of objects in close proximity. Used for obstacle avoidance and safe operation.

A robotic surgery system, for instance, might use high-resolution cameras, force/torque sensors, and sophisticated control algorithms to perform intricate procedures.

Q 14. How do you ensure the safety of a robotic system?

Ensuring the safety of a robotic system is paramount. It involves multiple layers of protection and careful consideration at all stages of design and implementation.

- Emergency Stop Mechanisms: Easily accessible emergency stop buttons and circuits must be incorporated to halt the robot immediately in case of unexpected events.

- Safety Sensors and Interlocks: Using sensors to detect potential hazards (e.g., proximity sensors to prevent collisions with humans) and interlocks to shut down the robot if a safety condition is violated is essential.

- Redundant Systems: Incorporating backup systems to prevent complete failure. For example, having two independent braking systems for a mobile robot.

- Risk Assessment and Mitigation: Conducting a thorough risk assessment to identify potential hazards and implement appropriate safety measures. This includes considering worst-case scenarios.

- Software Safety: Using robust software development practices, including thorough testing and validation, to ensure that the robot’s control software functions correctly and reliably. This involves techniques like fault tolerance and error recovery.

- Human-Robot Collaboration Protocols: For collaborative robots, designing safety protocols that allow safe interaction between humans and robots is crucial. This might involve speed limitations, force limitations, and safety zones.

Safety is not an afterthought but an integral part of the entire robot design and operation lifecycle.

Q 15. Explain the concept of robot workspace and its limitations.

A robot’s workspace defines the volume of space within which it can operate its end-effector (e.g., gripper, tool). Think of it as the robot’s ‘reach’. This is determined by its physical structure – the lengths of its links, the range of its joints, and any physical constraints in the environment. Limitations arise from several factors.

- Joint Limits: Each joint has a specific range of motion. Exceeding these limits can damage the robot. Imagine a human arm – you can’t bend your elbow backwards beyond a certain point.

- Self-Collision: The robot’s links might collide with each other during certain movements. This is a major design consideration and is addressed through workspace analysis and sophisticated control algorithms. Think of a robot arm with many segments – careful planning is needed to avoid the arm hitting itself.

- Environmental Constraints: Obstacles in the workspace – tables, walls, other robots – severely restrict reachable areas. This is similar to how a human’s workspace is limited by furniture or other people in a room.

- Singularity: Certain configurations of joints can cause a loss of dexterity or even make control impossible. Imagine trying to lift something heavy with your arm fully extended – it’s far weaker and less controlled than when your arm is closer to your body.

Understanding and modeling the workspace is crucial for task planning and path generation. Software tools simulate the workspace to ensure safe and efficient robot movements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the challenges in controlling multiple robots collaboratively?

Controlling multiple robots collaboratively presents significant challenges beyond controlling a single robot. The complexity grows exponentially with the number of robots involved.

- Coordination and Synchronization: Robots need to precisely coordinate their actions to avoid collisions, share resources (like workpieces), and achieve a common goal. Imagine multiple robots assembling a car – each needs to complete its tasks at the right time and in the right sequence.

- Communication and Data Fusion: Robots must communicate efficiently to share information about their positions, tasks, and the environment. This involves efficient communication protocols and algorithms to handle potential communication delays or failures.

- Robustness to Failures: If one robot fails, the entire system might be affected. Fault-tolerance and redundancy strategies are essential to ensure continuous operation.

- Task Allocation: Deciding which robot should perform which task efficiently is an optimization problem. This depends on factors like robot capabilities, task priorities, and current robot positions.

- Centralized vs. Decentralized Control: A centralized controller coordinates all robots, offering simplicity but is prone to single point of failure. Decentralized control allows for robustness but requires more complex communication.

Techniques like distributed control architectures, multi-agent systems, and task scheduling algorithms help overcome these challenges. Real-world examples include collaborative robots in assembly lines, warehouse automation, and search and rescue operations.

Q 17. How do you perform robot calibration and what are its benefits?

Robot calibration is the process of accurately determining the robot’s kinematic parameters – the geometric relationships between its links and joints. This involves measuring the physical dimensions of the robot and determining the offsets between the sensors and the robot’s coordinate system.

The process typically involves:

- Modeling: Creating a mathematical model of the robot’s kinematics.

- Measurement: Using specialized equipment like laser trackers or the robot itself to measure the positions and orientations of its joints and links. This may involve touching known points or using visual sensors.

- Parameter Identification: Using collected data to estimate the kinematic parameters using optimization algorithms. This involves minimizing the difference between the measured positions and the positions predicted by the model.

- Validation: Verifying the accuracy of the calibrated parameters by performing additional measurements and analyzing the results.

Benefits of Calibration:

- Improved Accuracy: Calibration reduces positioning errors, leading to more precise movements and better task performance. A poorly calibrated robot may miss its targets.

- Increased Repeatability: Consistent performance over time is ensured.

- Enhanced Safety: Accurate robot positioning reduces the risk of collisions with the environment or other robots.

Calibration is an essential step in deploying industrial robots and ensuring the quality of their work. For example, in precision manufacturing or surgery, accurate calibration is crucial.

Q 18. Explain the role of impedance control in robot manipulation.

Impedance control allows a robot to interact with its environment in a compliant way. Instead of rigidly following a pre-planned trajectory, the robot adjusts its motion in response to external forces. Think of it as giving the robot a sense of ‘touch’ and ‘feel’.

Instead of specifying position directly, impedance control specifies the desired relationship between force and position (or velocity). This relationship is described by an impedance model, often a combination of stiffness, damping, and inertia. A high stiffness means the robot resists changes in position, while high damping means it resists changes in velocity.

Example: Imagine a robot inserting a peg into a hole. With simple position control, a slight misalignment could lead to excessive force and damage. Impedance control would allow the robot to adapt its position based on the contact force, ensuring a smooth insertion even if there are small errors or unexpected forces.

Impedance control is crucial for tasks requiring interaction with unpredictable environments, such as assembly, human-robot collaboration, and manipulation of deformable objects.

Q 19. Describe different methods for robot force control.

Robot force control aims to regulate the forces exerted by the robot on its environment. Several methods exist, each with its strengths and weaknesses.

- Hybrid Force/Position Control: This approach divides the robot’s degrees of freedom into those controlled by force and those controlled by position. For example, a robot might control the force applied along a specific direction while controlling its position in other directions. This is commonly used in tasks requiring both precise positioning and controlled force, like inserting a peg into a hole.

- Force Sensing and Feedback Control: Force sensors at the robot’s end-effector measure the forces applied. This information is used in a feedback control loop to adjust the robot’s motion to achieve the desired force. This requires accurate force sensors and a well-tuned control system.

- Compliance Control: This method uses passive or active compliance mechanisms (e.g., springs, dampers) to control forces indirectly. The robot’s structure itself accommodates external forces. This method is often simpler to implement but may offer less precise force control.

- Adaptive Force Control: This approach incorporates learning and adaptation to handle variations in the environment or the object being manipulated. It’s useful in situations with uncertainty or varying contact conditions.

The choice of force control method depends on the specific application and the level of precision required.

Q 20. How do you handle robot collisions and unexpected events?

Handling robot collisions and unexpected events is crucial for safe and reliable robot operation. Strategies include:

- Collision Detection: Using sensors (e.g., proximity sensors, force/torque sensors) to detect collisions. This can trigger an immediate stop or a more sophisticated response.

- Reactive Control: Implementing control algorithms that respond appropriately to detected collisions. This could involve reducing speed, changing trajectory, or stopping the robot. This often employs reactive methods like potential fields or impedance control to ensure safety.

- Collision Avoidance: Planning robot paths that avoid obstacles in advance. This uses path planning algorithms that consider the robot’s physical dimensions and the environment’s geometry. This is a proactive strategy and far better than reactive control.

- Safety Systems: Implementing safety features like emergency stops, speed limits, and safety rated sensors to minimize the risk of harm to humans or equipment. These systems are critical in human-robot interaction.

- Recovery Strategies: Designing mechanisms for the robot to recover from unexpected situations or minor collisions. This might involve retrying the task or switching to a backup plan. Adaptive control is essential here.

A layered approach, combining collision avoidance during path planning, collision detection during execution, and reactive control to handle unexpected events, is generally needed for robust robot systems.

Q 21. What are the ethical considerations in designing and deploying robotic systems?

Ethical considerations in robotics are increasingly important as robots become more prevalent in society. Key concerns include:

- Safety and Risk Assessment: Robots should be designed and deployed to minimize risks to humans and the environment. Thorough safety testing and risk assessments are crucial.

- Job Displacement: Automation through robotics can displace workers. Mitigation strategies are necessary to ensure a just transition for affected individuals.

- Bias and Discrimination: AI algorithms used in robots can inherit biases from the data they are trained on, potentially leading to discriminatory outcomes. Careful attention to data selection and algorithm design is essential to prevent bias.

- Privacy and Surveillance: Robots equipped with cameras and sensors can collect personal data. Privacy safeguards and transparent data handling practices are essential.

- Accountability and Responsibility: Determining who is responsible when a robot causes harm is a complex legal and ethical question. Clear guidelines and regulations are needed.

- Autonomous Weapons Systems: The development and deployment of lethal autonomous weapons raise serious ethical concerns about accountability and the potential for unintended consequences.

Addressing these ethical issues requires interdisciplinary collaboration between roboticists, ethicists, policymakers, and the public to ensure the responsible development and deployment of robotic systems.

Q 22. Explain the role of computer vision in robot control.

Computer vision plays a crucial role in enabling robots to perceive and interact with their environment. It’s essentially the robot’s ‘eyesight,’ allowing it to understand its surroundings and make informed decisions. This involves capturing images or videos using cameras, processing them to extract meaningful information (like object recognition, depth perception, and motion estimation), and then using that information to guide its actions.

For example, in a robotic assembly line, computer vision allows a robot to identify specific parts, determine their orientation, and precisely grasp them. Without computer vision, the robot would be limited to pre-programmed tasks in a perfectly controlled environment, severely restricting its adaptability and flexibility. Imagine a self-driving car—computer vision is vital for detecting pedestrians, traffic lights, and other vehicles, enabling safe and efficient navigation.

The processing usually involves techniques like image segmentation, feature extraction (e.g., SIFT, SURF), object detection (e.g., using deep learning models like YOLO or Faster R-CNN), and 3D reconstruction. The extracted data is then integrated into the robot’s control system, often using techniques like sensor fusion to combine information from multiple sources.

Q 23. Describe your experience with ROS (Robot Operating System).

I have extensive experience with ROS (Robot Operating System), having used it in various projects ranging from autonomous navigation to robotic manipulation. I’m proficient in its core components, including topics, services, actions, and nodes. I’ve utilized ROS extensively for robot simulation, hardware abstraction, and multi-robot coordination.

For instance, in one project, I developed a ROS-based system for a mobile manipulator robot. This involved creating nodes for sensor data acquisition (LiDAR, cameras, IMU), localization using SLAM (Simultaneous Localization and Mapping) algorithms, path planning using A*, and control of the robot’s arm using inverse kinematics. The system leveraged ROS’s robust communication framework to facilitate seamless data exchange between different components.

Furthermore, I’m familiar with various ROS tools, including rqt for visualization and debugging, rviz for 3D visualization, and rosbag for data recording and replay. My proficiency extends to writing custom ROS nodes and packages in C++ and Python, enabling me to adapt and extend ROS functionality to meet specific project requirements.

//Example ROS node snippet (C++) #include int main(int argc, char **argv) { ros::init(argc, argv, "my_node"); ros::NodeHandle nh; // ... node functionality ... ros::spin(); return 0; } Q 24. What are some common challenges in real-time robot control?

Real-time robot control presents numerous challenges. A primary concern is maintaining the necessary computational speed to respond to sensor data and execute control commands within strict timing constraints. Delays can lead to instability and unsafe operation. This is especially critical in high-speed applications or those involving human-robot interaction.

- Computational constraints: Complex control algorithms or high-resolution sensor data can overwhelm the processing power of the robot’s controller, leading to missed deadlines.

- Sensor noise and uncertainty: Sensor readings are often noisy or imprecise, requiring sophisticated filtering and estimation techniques to extract reliable information.

- Unpredictable environments: Robots often operate in dynamic and uncertain environments, requiring robust control strategies that can handle unexpected events or disturbances.

- Hardware limitations: Actuator limitations (e.g., limited torque, speed, and range) can constrain the robot’s ability to execute desired movements.

- Safety: Ensuring safe operation is paramount, particularly when robots interact with humans or operate in hazardous environments. Robust safety mechanisms are essential to prevent accidents.

Addressing these challenges requires careful selection of hardware and software components, optimization of control algorithms, and the implementation of robust error handling and safety mechanisms.

Q 25. How do you perform robot system diagnostics and troubleshooting?

Robot system diagnostics and troubleshooting involve a systematic approach to identify and resolve issues. This begins with careful observation of the robot’s behavior, analyzing sensor data, and checking for error messages. I typically follow these steps:

- Gather information: Observe the robot’s malfunction, collect relevant sensor data, and review log files for error messages.

- Isolate the problem: Systematically narrow down the potential causes by checking individual components (sensors, actuators, controllers, software modules). This might involve using diagnostic tools provided by the robot manufacturer or developing custom diagnostic routines.

- Verify hypotheses: Test potential solutions systematically. For example, if a sensor is suspected, try replacing or recalibrating it. If a software module is suspected, check its code for errors or update it to the latest version.

- Implement solutions: Once the root cause is identified, implement the appropriate solution, ensuring it doesn’t introduce new problems.

- Document findings: Maintain comprehensive records of the diagnosis and repair process for future reference. This aids in preventing similar issues in the future.

For example, if a robot arm is not moving correctly, I would first check for any obvious mechanical obstructions. Then, I’d examine the motor currents, encoder readings, and control signals to identify whether the problem originates in the motor, the controller, or the software.

Q 26. Explain your experience with different control architectures (e.g., hierarchical, decentralized).

I’ve worked with various control architectures, including hierarchical and decentralized approaches. Hierarchical control structures organize the control system into layers, each handling specific tasks at different levels of abstraction. For example, a high-level layer might handle path planning, while lower layers focus on motor control. This approach simplifies the design and implementation of complex robotic systems.

Decentralized control architectures distribute control functionality among multiple modules or agents, reducing the computational burden on a single controller. This is particularly useful for large-scale robotic systems or multi-robot systems. Each module has a specific role and communicates with others to coordinate their actions. This offers robustness and scalability; if one module fails, the others can continue operating.

In practice, I’ve often employed a hybrid approach, combining elements of both hierarchical and decentralized architectures to leverage the benefits of each. For instance, a mobile manipulation robot might use a hierarchical structure for arm control while using a decentralized approach for coordinating navigation and manipulation tasks in a shared workspace with other robots.

Q 27. Describe your experience with simulation tools used in robot control.

My experience with robot simulation tools is extensive. I’ve utilized Gazebo extensively, which provides a realistic physics engine for simulating robot dynamics and sensor data. This allows testing and validating control algorithms in a safe and controlled environment before deploying them on real robots. This significantly reduces the risk of damage to expensive hardware during testing.

I’ve also used other simulation tools like V-REP and Webots, depending on the specific requirements of the project. The choice of simulator often depends on factors such as the level of realism needed, the types of robots being simulated, and the availability of supporting tools and libraries. Simulation also allows for rapid prototyping and experimentation with different control strategies without the constraints and costs associated with real-world testing.

In one project, I used Gazebo to simulate a swarm of robots navigating a complex environment. This allowed us to test and refine our distributed control algorithms before deploying them on the actual robots. The simulation helped us identify and resolve issues early in the development process, saving significant time and resources.

Q 28. Explain the importance of testing and validation in robotics control.

Thorough testing and validation are crucial in robotics control to ensure safety, reliability, and performance. Testing involves verifying that the robot behaves as expected under various conditions, while validation confirms that the system meets its specified requirements. This involves a multi-stage process:

- Unit testing: Testing individual software modules or components in isolation.

- Integration testing: Testing the interaction between different modules.

- System testing: Testing the complete robotic system as a whole.

- Acceptance testing: Testing the system against pre-defined performance requirements.

Testing should encompass a wide range of scenarios, including nominal operation, boundary conditions, and fault conditions. Simulation plays a significant role, allowing for extensive testing without risking damage to real hardware. Real-world testing is also essential to validate the simulation results and account for real-world uncertainties.

Neglecting rigorous testing can lead to catastrophic failures, particularly in safety-critical applications. For example, inadequate testing of a surgical robot could lead to serious injuries. Therefore, a robust testing and validation process is not just good practice; it’s essential for ensuring the safety and reliability of robotic systems.

Key Topics to Learn for Robotics Control Interview

- Control System Design: Understanding feedback control loops (PID, etc.), state-space representation, and system stability analysis. Practical application: Designing a control system for a robotic arm to accurately pick and place objects.

- Robot Kinematics and Dynamics: Forward and inverse kinematics, Jacobian matrices, Lagrangian and Newton-Euler dynamics. Practical application: Calculating the joint angles needed for a robot to reach a specific point in space, considering its physical limitations.

- Motion Planning and Trajectory Generation: Path planning algorithms (e.g., A*, RRT), trajectory optimization techniques, and collision avoidance. Practical application: Programming a robot to navigate a complex environment without colliding with obstacles.

- Sensor Integration and Fusion: Working with various sensors (e.g., IMUs, cameras, LiDAR), sensor data processing, and sensor fusion techniques. Practical application: Implementing a system that allows a robot to accurately perceive its environment using multiple sensor inputs.

- Real-time Programming and Embedded Systems: Familiarity with real-time operating systems (RTOS), programming languages (e.g., C++, Python), and hardware interfacing. Practical application: Developing efficient and reliable control software for a robot operating in a real-world setting.

- Control Algorithms: Adaptive control, model predictive control (MPC), and robust control techniques. Practical application: Designing a control system that can adapt to changing environmental conditions or uncertainties.

- Robotics Software Frameworks: Experience with ROS (Robot Operating System) or other relevant frameworks. Practical application: Developing and deploying complex robotic applications using industry-standard tools.

Next Steps

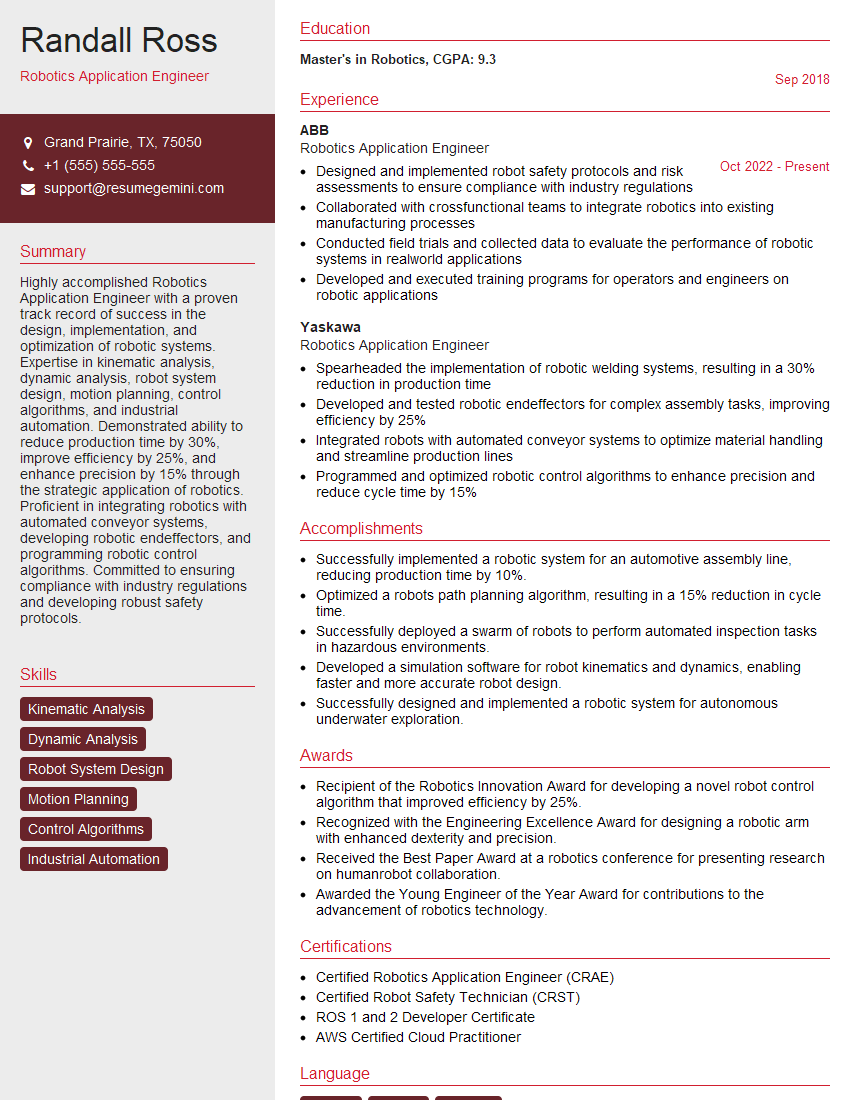

Mastering Robotics Control opens doors to exciting and impactful careers in automation, manufacturing, research, and more. Your expertise in this field is highly sought after! To maximize your job prospects, create an ATS-friendly resume that highlights your skills and accomplishments effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the Robotics Control field. We provide examples of resumes specifically designed for Robotics Control roles to guide you. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good