Preparation is the key to success in any interview. In this post, we’ll explore crucial Roof Bolter Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Roof Bolter Operation Interview

Q 1. Describe the different types of roof bolts used in mining.

Roof bolts are crucial for supporting mine roofs and preventing collapses. Different types are selected based on ground conditions and the specific needs of the mine. Common types include:

- Expansion Bolts: These bolts expand once installed, creating a strong grip within the rock. They’re relatively simple to install and are effective in many rock types. Think of them like an incredibly strong, expanding screw anchoring itself into the roof.

- Resin-Grouted Bolts: These utilize a resin to fill the hole around the bolt, creating a composite support system that distributes stress more effectively. The resin acts like glue, significantly strengthening the bond between the bolt and the rock, suitable for weaker or fractured ground.

- Friction Bolts: These rely on friction between the bolt and the rock to create stability. Installation involves carefully tightening the bolt to achieve the required friction. They are often used in stronger, more competent rock masses.

- Cable Bolts: These use steel cables anchored into the rock, often with resin or grout. This system is excellent for supporting large areas or handling significant stress. They’re like a strong net spreading stress over a larger area.

- Reinforced Bolts: These incorporate reinforcing elements, such as steel bars, to further enhance strength and load-bearing capacity. They’re particularly beneficial in challenging ground conditions.

The choice of bolt type is a crucial engineering decision, often determined by a geotechnical assessment of the mine’s specific conditions.

Q 2. Explain the process of installing roof bolts, including drilling, bolting, and grouting.

Roof bolt installation is a precise and safety-critical process. It typically involves these steps:

- Drilling: A specialized drill rig, often mounted on a roof bolter machine, is used to drill holes of the correct diameter and depth into the mine roof. The drilling angle is crucial and is determined by the geological survey of the area and is usually done at a slight angle to maximize stability.

- Bolting: Once the hole is drilled, the chosen roof bolt is inserted. For expansion bolts, this involves simply driving the bolt into the hole until it expands. Resin-grouted bolts require injecting the resin into the hole around the bolt before setting. For friction bolts, careful tightening is required to achieve sufficient friction.

- Grouting (if applicable): For resin-grouted bolts and some other types, a high-strength grout or resin is pumped into the hole to completely fill it. This ensures that the bolt is fully supported and effectively transfers stress to the surrounding rock. The curing time of the resin is crucial and needs to be carefully monitored, often requiring specific climate controls within the mine.

Modern roof bolters often incorporate automated systems to aid in drilling and bolting, improving efficiency and safety.

Q 3. What are the safety precautions you take when operating a roof bolter?

Safety is paramount in roof bolting. My routine includes:

- Pre-shift Inspections: Checking the roof bolter equipment for any mechanical faults or damage before commencing work.

- Personal Protective Equipment (PPE): Always wearing a hard hat, safety glasses, hearing protection, and high-visibility clothing. Depending on the mine, additional protective equipment may be needed.

- Ground Control Measures: Ensuring that proper ground control measures are in place, including regular roof inspections and scaling (removing loose rock) before and during bolting.

- Communication: Maintaining clear and constant communication with my team and supervisor. Using designated communication channels is essential, especially in noisy environments.

- Following procedures: Adhering strictly to the mine’s safety procedures and operating manuals.

- Emergency Procedures: Being fully aware of emergency procedures and evacuation routes in case of accidents or ground instability.

I never compromise on safety, even under pressure to meet production targets.

Q 4. How do you identify and address potential hazards related to roof bolting?

Identifying and addressing hazards is a proactive approach I always take. This involves:

- Regular Roof Inspections: Visually inspecting the roof for signs of weakness, such as cracks, loose rocks, or bulging. Regular monitoring is done using established procedures.

- Geological Surveys: Working closely with geologists to understand the geological conditions and identify potential hazards.

- Ground Monitoring: Using ground monitoring instruments, such as convergence meters, to detect movement and instability in the roof. This allows for early warning and preventive measures.

- Risk Assessment: Conducting thorough risk assessments before starting any bolting operation, identifying and mitigating potential hazards. This will include assessments of the equipment, personnel, and environmental factors.

- Immediate Action: If any hazard is identified, I immediately stop work and report it to my supervisor. No one proceeds until the hazard is addressed and it is deemed safe to continue.

Proactive hazard identification is crucial for preventing accidents and ensuring a safe working environment.

Q 5. What are the signs of roof instability, and what actions should be taken?

Signs of roof instability can be subtle or obvious. They include:

- Cracks or Fractures: The appearance of cracks in the roof or walls is a major warning sign.

- Loose Rocks: Loose rocks hanging from the roof pose an immediate danger.

- Bulging or Swelling: A bulging or swelling roof indicates that pressure is building up.

- Noise or Sounds: Unusual noises, such as cracking or popping sounds, can indicate stress in the rock mass.

- Convergence: Measurements showing the roof and floor are moving closer together.

If any of these signs are observed, immediate action should be taken. This includes:

- Stopping Work Immediately: Evacuate the area immediately to prevent potential injuries.

- Reporting to Supervisor: Notify the supervisor or mine official immediately.

- Implementing Support Measures: Depending on the severity, this may involve additional bolting, shoring, or other support systems.

- Geotechnical Assessment: A detailed geotechnical assessment may be required to determine the cause of instability and develop a remediation plan.

Q 6. Describe your experience with different types of roof bolter equipment.

Throughout my career, I’ve worked with various roof bolter models, from older, more manual machines to sophisticated, automated systems. My experience includes:

- Hydraulic Roof Bolters: These are common and use hydraulic power for drilling and bolting, providing good power and control.

- Electric Roof Bolters: These offer quieter operation and potentially lower maintenance, and are suitable for certain mine environments.

- Mobile and Boom-Mounted Bolters: Different mounting types allow for access to various areas of the mine roof.

- Automated Bolters: These machines offer increased efficiency and precision through automation of many functions.

Understanding the capabilities and limitations of each type of equipment is essential for safe and efficient operation. Adapting to various systems and technologies has enhanced my problem-solving skills and safety awareness.

Q 7. How do you maintain and troubleshoot a roof bolter?

Maintaining and troubleshooting a roof bolter is crucial for safe and efficient operation. My maintenance routine includes:

- Daily Inspections: Checking all components for wear, damage, or leaks before starting work.

- Regular Servicing: Following the manufacturer’s recommended servicing schedule for hydraulic systems, drilling components, and other parts.

- Lubrication: Regular lubrication of moving parts to prevent wear and tear.

- Component Replacement: Promptly replacing worn or damaged components.

Troubleshooting involves systematic problem-solving:

- Identify the Problem: Determine the exact nature of the problem, observing symptoms and gathering data.

- Check Basic Systems: Start with simple checks: hydraulic fluid levels, electrical connections, and fuel levels (if applicable).

- Consult Manuals: Refer to the equipment’s operating and maintenance manuals for troubleshooting guides and diagrams.

- Isolate Faults: If the problem isn’t immediately apparent, systematically check components to isolate the faulty part.

- Repair or Replace: Repair the fault or replace the damaged component. If unable to solve the problem, seek assistance from a qualified technician.

Regular maintenance and effective troubleshooting prevent unexpected breakdowns and ensure the roof bolter operates safely and efficiently.

Q 8. What are the common causes of roof bolt failure, and how can they be prevented?

Roof bolt failure can stem from various issues, broadly categorized as geological, design, and installation problems. Geologically, weaknesses like poor rock quality (fractures, bedding planes, soft seams), unstable strata, or unexpected geological features like voids can lead to failure. Design flaws include insufficient bolt length, inappropriate bolt type for the rock mass, or inadequate support pattern. Installation errors encompass improper bolt placement, insufficient grouting, or damage to the bolt during installation.

Prevention involves a multi-pronged approach. Thorough geological investigation before mining commences is crucial to identify potential weak zones. This might involve core drilling, geophysical surveys, and detailed mapping. The design of the roof bolting system should be tailored to the specific geological conditions, using appropriate software and engineering expertise to determine optimal bolt length, diameter, type (e.g., fully grouted, resin-anchored), and spacing. Rigorous quality control during installation is paramount, including regular inspections of equipment, adherence to specified procedures, and the use of qualified personnel. Regular roof monitoring and maintenance, including visual inspections and convergence monitoring, can help detect early signs of deterioration and prevent catastrophic failure.

- Example: I once worked on a site where a seemingly solid rock mass exhibited unexpected weakness due to hidden bedding planes. This led to several bolt failures until we adjusted the bolting pattern and utilized longer, higher-strength bolts, along with a more robust grouting procedure.

Q 9. Explain the importance of proper ground control in mining operations.

Proper ground control in mining is paramount for ensuring the safety of personnel and the stability of the mining operation. It involves a series of techniques and measures to manage and control the behavior of the surrounding rock mass, preventing falls, collapses, and other hazards. This includes not just roof bolting, but also other methods like pillar design, cable bolting, shotcreting, and rock reinforcement. Effective ground control minimizes risks, increases operational efficiency by reducing downtime caused by ground instability, and maximizes resource extraction by allowing access to previously inaccessible areas.

Consider this analogy: Imagine building a house without a proper foundation. The structure would be unstable and prone to collapse. Similarly, in mining, without adequate ground control, the entire operation becomes vulnerable to unpredictable ground movements.

Q 10. How do you ensure the accuracy and effectiveness of roof bolt installation?

Accuracy and effectiveness in roof bolt installation are achieved through a combination of careful planning, precise execution, and robust quality control. Before installation, the exact location of each bolt should be determined based on the design plan. This often involves marking the roof surface using lasers or surveying equipment. During installation, the chosen drilling method (e.g., top-hammer, DTH) must be appropriate for the rock type and bolt diameter. The hole depth must be accurately monitored, ensuring it matches the planned bolt length. The bolt should be correctly inserted and fully grouted or resin-anchored, as per the design specifications. After installation, the bolts should be tested to verify the achieved load capacity. Regular checks and inspections, including visual assessments and periodic load tests, are crucial to confirm continued stability.

Example: We utilize specialized tools like bolt tensioners and torque wrenches to ensure that each bolt achieves the necessary tension. Regular calibration of these tools is a critical part of maintaining accuracy and effectiveness.

Q 11. What are the regulatory requirements and safety standards related to roof bolting?

Regulatory requirements and safety standards related to roof bolting are stringent and vary somewhat depending on the jurisdiction. However, common themes include adherence to nationally recognized codes and standards (e.g., MSHA in the USA, similar bodies in other countries), mandatory training and certification for roof bolting personnel, detailed site-specific risk assessments prior to any bolting activity, regular inspections and maintenance of equipment and the support system, thorough documentation of all bolting operations, and incident reporting and investigation procedures. Failure to comply with these regulations can lead to significant penalties and endanger the lives of mine workers.

Example: All our personnel must undergo mandatory training on safe roof bolting procedures and emergency response plans before working on site. Their certifications are regularly reviewed and renewed.

Q 12. Describe your experience with different rock types and their impact on roof bolting techniques.

Experience with diverse rock types significantly impacts roof bolting techniques. Hard, competent rocks typically require less frequent bolting compared to softer, more fractured rocks. The type of bolt (e.g., fully grouted, resin-anchored) and the support pattern (e.g., regularly spaced, localized reinforcement) will vary accordingly. For example, very hard rocks might only necessitate fully grouted bolts at wider spacings, whereas highly fractured rocks could necessitate a denser pattern of resin-anchored bolts for enhanced stability. The presence of water can also significantly influence the choice of grout or resin and the overall bolting strategy. Knowledge of rock mechanics principles is essential to understand and accommodate these differences.

Example: I’ve worked with everything from strong quartzite to weak shale. In quartzite, we use longer, fully grouted bolts spaced further apart, while in shale, we employ shorter resin-anchored bolts in a much denser pattern to counteract the higher degree of fracturing.

Q 13. How do you handle unexpected situations or equipment malfunctions during roof bolting?

Unexpected situations during roof bolting operations require a calm, methodical approach prioritizing safety. Equipment malfunctions, such as a drill malfunction or a bolt breakage, require immediate shutdown of the operation and assessment of the situation. If a geological hazard, like a void, is unexpectedly encountered, appropriate measures are implemented to mitigate the risk, often including further investigation to determine the extent of the problem and adaptation of the bolting plan. Communication is key; the team needs to be promptly informed of any change in the plan or unexpected circumstances. A thorough post-incident analysis is essential to prevent recurrence of the problem.

Example: Once, while drilling, we encountered a previously unknown void. We immediately halted work, reported the incident, and called in a geotechnical engineer to assess the situation. We then revised our plan to incorporate more extensive support in the affected area.

Q 14. What is your experience with pre-split bolting techniques?

Pre-split bolting is a technique used to create a controlled fracture zone in the rock mass before installing roof bolts. This is particularly valuable in areas where rock quality is poor or where there are significant discontinuities that could lead to instability. By creating a pre-determined fracture, we can improve the effectiveness of the roof bolts by better distributing the stress and reducing the likelihood of unpredictable failures. It’s often used in conjunction with other ground support methods. The process typically involves drilling a series of closely spaced holes and then using explosives to create the fracture. The bolts are then installed into the created fracture zone.

Example: I’ve utilized pre-split bolting in several projects where the rock mass exhibited significant fracturing. The controlled pre-split allowed for more effective and stable ground control compared to conventional bolting alone.

Q 15. What are the limitations of roof bolting, and what alternative support methods are available?

Roof bolting, while a highly effective ground support method, has limitations. Its effectiveness is heavily reliant on the geological conditions. For instance, in highly fractured or weak rock masses, the bolts may not provide sufficient support, especially in areas with high stress concentrations. Another limitation is the potential for bolt failure due to corrosion, improper installation, or unforeseen geological events like seismic activity. Finally, roof bolting may not be suitable for all mining geometries; extremely high or very low headings may pose challenges.

Alternative support methods include:

- Shotcrete: A sprayed concrete layer providing immediate and continuous support.

- Rock reinforcement with steel fiber: Adding strength to the existing rock mass by injecting steel fibers into fractures and voids.

- Cable bolting: Using long, high-strength steel cables anchored deep into the rock mass for support in large, unstable areas.

- Steel sets (timber sets): Traditional support systems using steel or timber beams to create a structural framework.

- Rock mass classification and design: Comprehensive geological investigations to tailor ground support solutions to the specific rock properties and stress conditions.

The choice of an alternative method depends on factors such as the rock mass quality, the mining geometry, the cost, and the required level of safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure communication and coordination with other mine personnel during roof bolting operations?

Effective communication and coordination are paramount to safe and efficient roof bolting operations. This begins with pre-shift planning meetings where the tasks, potential hazards, and emergency procedures are clearly outlined. During operations, we use a system of hand signals and radio communication to ensure clear instructions are relayed between the bolter operator, the drilling assistant, and the supervisor. We also utilize a designated spotter to monitor the area around the bolter, alerting the crew to potential dangers like falling rocks or equipment malfunctions. Regular communication ensures everyone is aware of the bolting progress and any necessary adjustments to the plan. Incident reporting is crucial for continuous improvement and safety enhancement. For example, if a bolt installation is unusually difficult, we communicate this to the supervisor to explore the possibility of an altered bolting pattern or support system.

Q 17. What are your experience with different types of drilling equipment used in roof bolting?

My experience encompasses a range of drilling equipment, from smaller, hydraulically powered roof bolters suitable for narrower tunnels to larger, more powerful units for wider excavations. I’ve worked with both crawler-mounted and boom-type bolters. Crawler-mounted bolters offer better stability on uneven terrain, while boom-type bolters provide more reach and flexibility. I’m proficient in operating both cable-feed and rod-feed drilling systems. Cable-feed systems are better for longer holes, while rod-feed systems are often preferred for shorter, more precise drilling. Regular maintenance and proper operation are key to ensuring the longevity and efficiency of these machines. For example, I meticulously check the hydraulic fluid levels, grease the moving parts, and ensure the drilling rods are in good condition to avoid equipment failure.

Q 18. Explain the importance of regular inspections and maintenance of roof bolts.

Regular inspections and maintenance are vital for ensuring the long-term stability and safety of the roof bolting system. Neglecting this aspect can lead to bolt failure and potentially catastrophic roof collapses. Inspections involve visual checks for signs of corrosion, damage to the bolt heads or anchors, and any movement in the surrounding rock mass. We regularly use a sounding hammer to check bolt tightness and detect potential problems. Maintenance includes tightening loose bolts, replacing damaged components, and conducting regular lubrication of moving parts. The frequency of these inspections and maintenance activities depends on factors such as the geological conditions and the mining environment, typically ranging from daily checks to more thorough periodic evaluations. For example, following a blasting event, we carry out a comprehensive inspection of the entire bolted area to identify any damage caused by the vibrations. Documentation of every inspection and maintenance is critical for tracking the system’s health and anticipating potential issues.

Q 19. Describe your experience with cable bolting.

Cable bolting is a robust ground support technique, particularly effective in large, unstable rock masses. My experience with cable bolting includes installing and tensioning long steel cables anchored deeply into the rock mass to provide significant support. This involves drilling long holes, typically using specialized drilling equipment. The cables are then grouted into the holes and tensioned using hydraulic jacks to ensure proper load transfer to the rock. Cable bolting is generally used in situations where conventional roof bolting is insufficient due to the large span or weak geological conditions. The high tensile strength of the cables and their deep anchorage can significantly enhance stability in such environments. Precise placement of the cables is critical; I use detailed plans and surveys to locate them effectively to maximize the support they provide. Monitoring the tension in the cables after installation is crucial to guarantee continued effectiveness, and regular inspections are vital to detect any signs of damage or loosening.

Q 20. What are the different types of resin used in roof bolting and their applications?

Several resin types are used in roof bolting, each suited for specific applications and geological conditions. These include:

- Polyester resin: A common choice known for its fast curing time and relatively high strength. It’s well-suited for applications where quick installation is critical.

- Epoxy resin: Offers superior strength and durability compared to polyester, making it ideal for challenging geological conditions or environments with high temperatures or moisture. However, it’s typically more expensive and has a slower curing time.

- Vinyl ester resin: Possesses a good balance between strength, curing time, and cost, often used as a compromise between polyester and epoxy resin.

The choice of resin depends on factors such as the rock type, the required bond strength, the ambient temperature, and the curing time constraints. For example, in a wet environment, an epoxy resin would be a better choice than polyester to prevent premature degradation of the bond.

Q 21. How do you determine the appropriate bolt length and pattern for a given geological condition?

Determining the appropriate bolt length and pattern requires a thorough understanding of the geological conditions and the stress regime. This involves a combination of geological mapping, rock mass classification (e.g., using the Rock Mass Rating – RMR system), and geotechnical analysis. The bolt length needs to be sufficient to reach a competent rock mass and provide adequate anchorage. We often consult geotechnical reports and detailed rock mass characterization studies to aid in this decision-making process. The bolting pattern (spacing and orientation of the bolts) is designed to distribute the load effectively and account for the directional strength of the rock mass. For example, in areas with distinct weaknesses (joints, faults), the bolts might be oriented to reinforce these planes. Simulation software is often used to model the rock mass behavior and optimize the bolting pattern for maximum stability. The process combines experience-based judgement with the analysis of data obtained through several sources in order to avoid failures and ensure the integrity of the support system.

Q 22. What is your understanding of convergence monitoring and its relationship to roof bolting?

Convergence monitoring is the process of regularly measuring and tracking the movement of the mine roof and walls. It’s crucial for roof bolting because it helps us predict potential roof falls and adjust our support strategies accordingly. Think of it like constantly checking the structural integrity of a building – small movements might be normal, but significant changes signal a problem needing immediate attention. We use different instruments like convergence monitoring systems which measure the distance between points in the roof, and any increase signals potential instability. This information directly informs where and how many roof bolts we need to install or reinforce to maintain a safe working environment. For example, if we see increased convergence in a particular area, we might opt for a denser bolting pattern or switch to stronger bolts.

Q 23. Explain your experience with different roof bolting patterns and their effectiveness.

My experience encompasses various roof bolting patterns, each suited to different geological conditions. We’ve used everything from simple, evenly spaced patterns in stable rock to complex, tailored layouts for challenging ground conditions. A common pattern is the ‘grid’ pattern, where bolts are installed in a regularly spaced grid. This is cost-effective for relatively stable ground. However, in areas with known weaknesses or high stress concentrations, we often use ‘cluster’ bolting, where a higher density of bolts is installed around the weak area. Another pattern we employ is ‘directional bolting’, where bolts are installed at an angle to counteract specific stress directions. The effectiveness of each pattern depends on factors like rock mass quality, stress conditions, and the type of bolts being used. In one project involving particularly fractured shale, we adapted a hybrid pattern combining cluster and directional bolting to effectively mitigate the risk of roof collapse, and it was significantly more successful than a standard grid pattern would have been in that situation.

Q 24. What safety equipment do you use while operating a roof bolter?

Safety is paramount. My standard safety equipment includes a hard hat, safety glasses, steel-toed boots, high-visibility clothing, and a self-retracting lifeline (SRL) when working at heights. I also use hearing protection due to the noise of the equipment and appropriate respiratory protection if dust levels are high. Crucially, I never operate the roof bolter without first ensuring proper ventilation and confirming the adequacy of roof support in the immediate vicinity. In areas with potential for methane or other gases, I would also utilize gas monitoring equipment and appropriate personal protective equipment.

Q 25. How do you conduct a pre-shift inspection of a roof bolter?

A pre-shift inspection is a critical step. I start by visually inspecting the entire roof bolter for any damage – checking hydraulic lines, hoses, the bolting mechanism, the electrics, and the overall structural integrity. I check fluid levels (hydraulic oil, etc.), ensuring they are within the acceptable range. I verify the functionality of all safety devices, such as emergency stops and warning lights. I then test all controls to confirm they’re responding properly and the machine is operating correctly. I also check the condition of the bolts I will be using, checking for defects or damage. Detailed records of the inspection are meticulously maintained, ensuring a history is kept in accordance with mine safety regulations.

Q 26. Explain your understanding of the principles of rock mechanics related to roof bolting.

Rock mechanics play a fundamental role in roof bolting. Understanding rock strength, stress conditions, and jointing patterns is key to designing effective support systems. We need to analyze factors like the rock mass rating (RMR) to assess rock stability. High stress zones need more robust support compared to zones with lower stress. The orientation of joints and fractures greatly influences the direction of stress and how the roof will behave. For example, understanding the orientation of weakness planes in the rock means we can install bolts in a way that reinforces the structure along the primary failure planes. Ignoring these principles can lead to insufficient support and potential roof failure.

Q 27. Describe your experience with the use of specialized tools and equipment during roof bolting.

My experience includes using a range of specialized tools and equipment beyond the roof bolter itself. This includes various types of roof bolts (e.g., resin-grouted bolts, fully threaded bolts, split sets), drill bits optimized for different rock types, and specialized setting tools to ensure proper bolt installation. I am familiar with using rock testing equipment to determine the characteristics of the rock mass before planning the bolting scheme. We frequently use surveying equipment to accurately assess the mine geometry, especially when dealing with irregular roof profiles or complex support layouts. In some projects, we also utilized ground radar and other geophysical techniques to analyze the subsurface conditions prior to bolting.

Q 28. How do you manage the risks associated with working at heights during roof bolting operations?

Working at heights presents significant risks. We strictly adhere to all safety protocols, including the use of appropriate fall protection equipment, such as harnesses, lanyards, and SRLs. Prior to commencing work, thorough risk assessments are conducted to identify potential hazards and develop control measures. We frequently use scaffolding or elevated work platforms whenever feasible. Regular inspections of all safety equipment are conducted to maintain their effectiveness. Continuous training and refresher courses ensure all personnel are adequately trained in safe work practices at heights and emergency procedures. Moreover, we have implemented a system of ‘buddy checks’ to ensure everyone is following safety protocols during operations, making it a collaborative safety effort.

Key Topics to Learn for Roof Bolter Operation Interview

- Machine Operation & Maintenance: Understanding the mechanical components, hydraulic systems, and electrical systems of a roof bolter. Knowing preventative maintenance schedules and troubleshooting common malfunctions is crucial.

- Safety Procedures & Regulations: Detailed knowledge of mine safety regulations, emergency protocols, and safe operating procedures specific to roof bolting. This includes understanding personal protective equipment (PPE) requirements and confined space entry procedures.

- Ground Control & Support: Understanding geological conditions, roof strata assessment, and the selection of appropriate bolting patterns and support systems based on site-specific conditions. This includes knowledge of different bolt types and installation techniques.

- Data Recording & Reporting: Accurately recording operational data, including bolt placement, equipment performance, and any safety incidents. Understanding the importance of clear and concise reporting for compliance and operational efficiency.

- Problem-Solving & Decision-Making: Demonstrating the ability to identify and troubleshoot mechanical issues, adapt to changing geological conditions, and make sound decisions regarding safety and operational effectiveness under pressure.

- Teamwork & Communication: Understanding the importance of effective communication within a team environment, including collaborating with other mine personnel, supervisors, and safety officers.

Next Steps

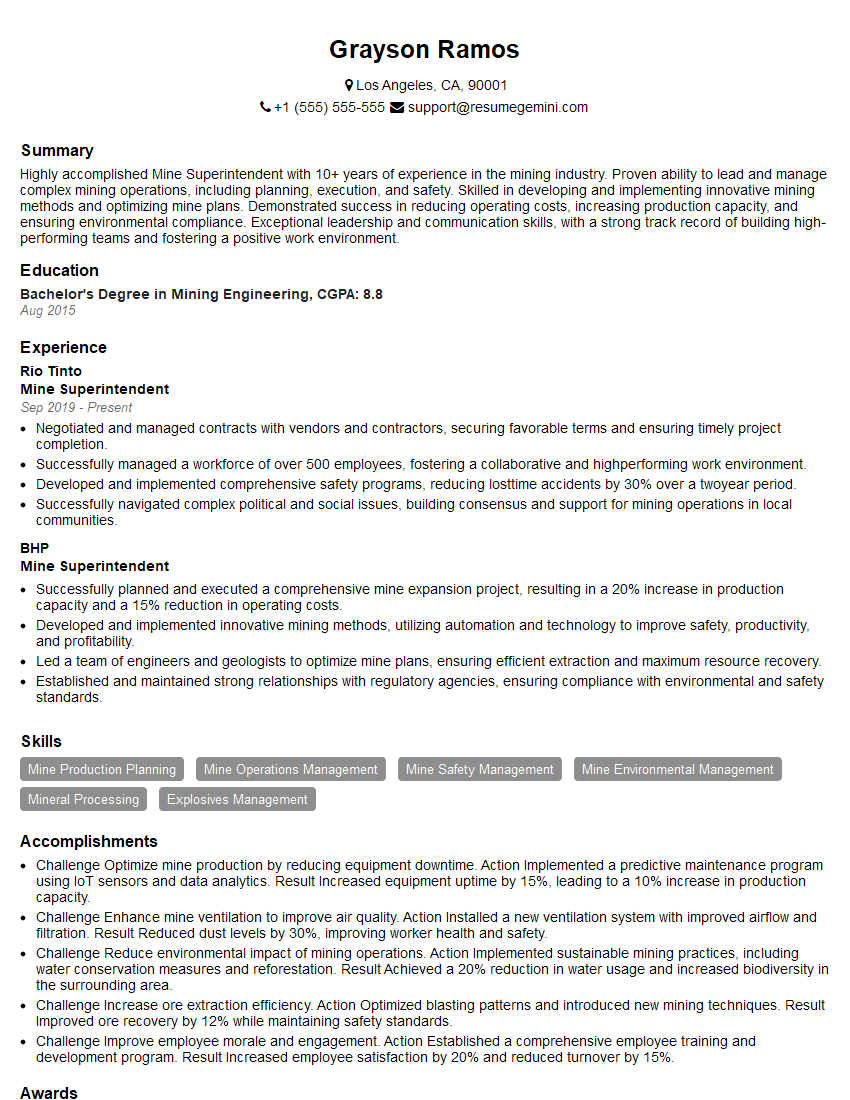

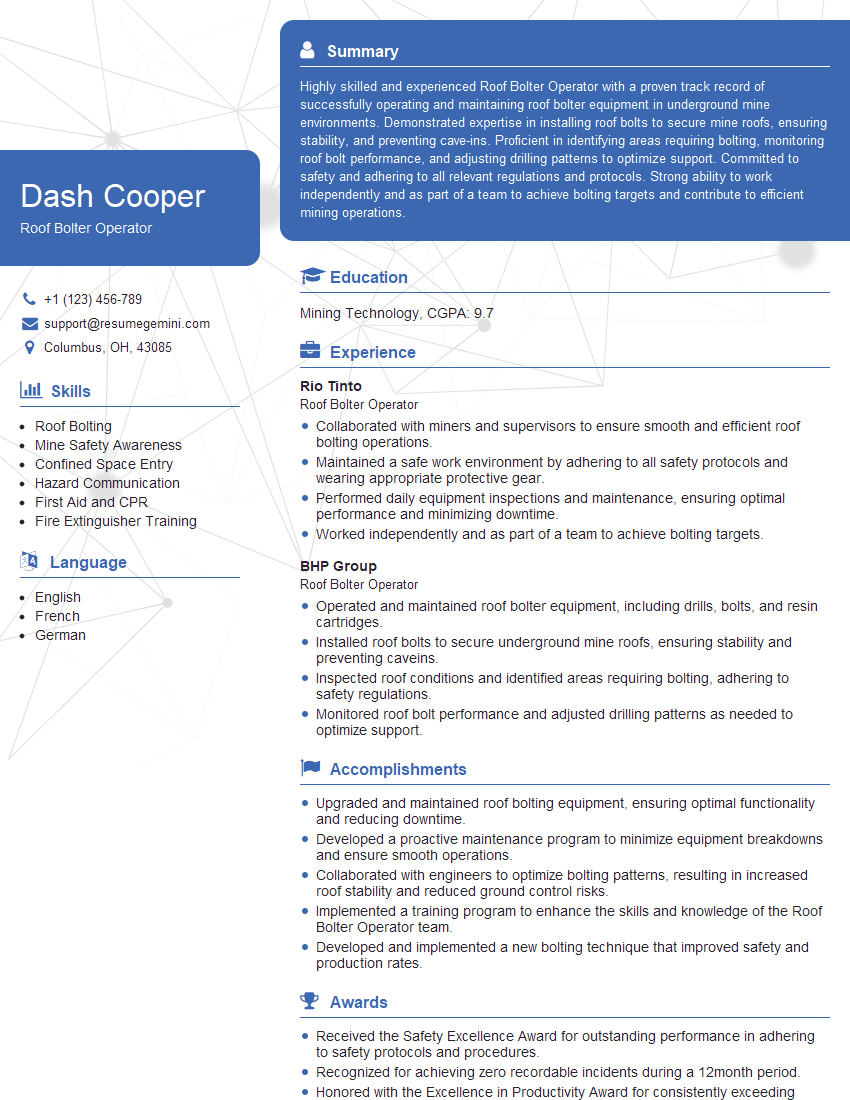

Mastering Roof Bolter Operation opens doors to a rewarding career with excellent growth potential in the mining industry. It signifies a commitment to safety, technical expertise, and operational efficiency – all highly valued skills. To maximize your job prospects, focus on creating a strong, ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Roof Bolter Operation to guide you through the process. Take the next step towards your dream job – build your best resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good