The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Rope Coiling and Handling interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Rope Coiling and Handling Interview

Q 1. Describe the different types of rope commonly used in your field and their applications.

Rope selection is crucial for safety and effectiveness. Different ropes are designed for specific tasks and conditions. Here are some common types:

- Nylon: Strong, lightweight, and stretches under load, making it ideal for rescue operations and climbing where shock absorption is needed. It’s also relatively resistant to abrasion but can be prone to UV degradation over time.

- Polyester: High strength-to-weight ratio, less stretch than nylon, excellent resistance to abrasion and UV degradation. Frequently used in sailing and heavy-duty applications.

- Polypropylene: Floats on water, resists mildew, and is inexpensive. However, it’s weaker than nylon or polyester and has a lower melting point. It’s commonly used for mooring lines and docklines.

- Manila (Natural Fiber): Biodegradable, strong, and relatively inexpensive, it’s still used in some applications, especially where its natural properties are advantageous, such as absorbing shocks during docking. However, it’s susceptible to rot and mildew and loses strength when wet.

- Kevlar: Extremely strong and lightweight, known for its high tensile strength, used in high-performance applications such as high-speed water sports and safety harnesses, where incredible strength is critical.

The choice depends heavily on the intended application. For instance, a rescue team would prioritize nylon’s shock-absorbing properties, while a sailboat might use polyester for its durability and low stretch.

Q 2. Explain the proper techniques for coiling different types of rope.

Proper coiling is essential for preventing tangles, kinks, and damage to the rope. The method varies slightly depending on the rope type and diameter, but the general principle is to create a neat, organized coil that can be easily deployed.

- Overhand Coil (for most ropes): Holding one end, coil the rope over your hand, creating a series of overlapping loops. Keep the coils tight and even to prevent snags. Once you reach the end, tuck the final end neatly into the coil.

- Figure Eight Coil (for thicker ropes): Similar to the overhand coil, but you create a figure-eight pattern with each loop, resulting in a more stable and less prone-to-tangles coil.

- Helical Coil (for long lengths): This involves coiling the rope in a spiral around a central axis, forming a tight, compact coil. This is effective for longer lengths of thinner rope.

Remember: Always coil the rope in the same direction to avoid creating stress points that may weaken the fiber over time. Think of it like winding a clock: consistency is key.

Q 3. What are the safety considerations when handling different types of rope?

Safety is paramount when handling ropes. Here are crucial considerations:

- Eye Protection: Wear safety glasses to protect your eyes from flying debris, especially when working with stiff or worn ropes.

- Gloves: Use gloves to prevent cuts and abrasions from rough or sharp ropes. Gloves provide better grip and reduce hand fatigue.

- Proper Technique: Always use proper coiling, knotting, and handling techniques to avoid accidental snags or entanglement.

- Load Limits: Never exceed a rope’s weight or breaking strength. Always use a rope with a safety factor appropriate for the load.

- Environmental Factors: Be aware of environmental conditions. Wet ropes can be weaker and more slippery, while UV exposure can degrade the rope’s strength over time.

- Sharp Objects: Keep ropes away from sharp objects to avoid cuts and fraying.

Ignoring these safety measures can lead to serious injuries or equipment damage. Remember: Safety first.

Q 4. How do you inspect rope for damage or wear?

Regular inspection is vital for identifying potential problems before they become hazards. Inspect ropes for:

- Fraying or Broken Strands: Look closely for any broken or frayed fibers, especially at the ends and in areas that have seen significant wear.

- Cuts or Abrasions: Check for any cuts, gouges, or abrasions in the rope’s surface. These can significantly reduce strength.

- Kinks or Knots: Persistent kinks or knots can weaken the rope at these points, making them prone to failure.

- UV Degradation: Look for signs of fading or discoloration, particularly in ropes that are exposed to sunlight for extended periods.

- Stiffness or Brittleness: Over time, ropes can become stiff and brittle, which will make them more vulnerable to breakage. A flexible rope is a safer rope.

If you find any of these problems, replace the rope immediately. Remember, a damaged rope is an unsafe rope.

Q 5. Explain the importance of proper rope storage.

Proper storage is essential for extending the lifespan of your ropes and maintaining their strength and integrity. Improper storage can lead to damage, deterioration, and decreased effectiveness. Here’s how to store ropes properly:

- Dry and Cool Location: Store ropes in a dry, cool, and well-ventilated area to avoid moisture damage and prevent mildew or rot.

- Away from Sunlight: Direct sunlight can degrade many rope types, weakening them and reducing their lifespan. Shield from direct sunlight whenever possible.

- Off the Ground: Elevate ropes off the ground to keep them clean and prevent moisture absorption.

- Coiled Properly: Always coil ropes neatly and securely to prevent tangles and kinks that may weaken the fibers.

- Labeled and Organized: Label ropes clearly with their type, diameter, and strength rating for easy identification and efficient management.

Consider these tips as essential practices to ensure your valuable ropes remain in optimal condition for years to come. A well-maintained rope is a safe and reliable rope.

Q 6. Describe different knot-tying techniques and their applications.

Many knots exist, each with specific applications. Here are a few examples:

- Bowline: Forms a strong, reliable loop that won’t slip. Excellent for attaching a rope to a ring or forming a secure harness loop.

- Clove Hitch: A simple, quick hitch used to attach a rope to a post or ring. It’s easy to tie and untie, but it’s not as secure as a bowline for heavy loads.

- Figure Eight Knot: Forms a secure loop useful at the end of a rope to prevent it from running through a pulley system.

- Sheet Bend: Used to join two ropes of similar diameter.

- Reef Knot (Square Knot): A common knot used for joining two ropes, particularly with smaller diameters, but prone to slipping under load unless reinforced. Only use the reef knot for light duties

Choosing the right knot is crucial for safety and effectiveness. Practice tying these knots until you can do so quickly and efficiently under pressure.

Q 7. What are the limitations of different types of rope?

Every rope type has limitations. Understanding these limits is crucial for safe and effective use.

- Nylon: While strong, it stretches significantly under load, which can be a problem in applications requiring precise positioning or where excessive stretch could be dangerous.

- Polyester: Less stretchy than nylon, but can be more susceptible to abrasion in certain environments.

- Polypropylene: Low melting point, weaker than nylon or polyester, and can be damaged easily by UV exposure.

- Manila: Susceptible to rot and mildew, loses strength when wet, and is less durable than synthetic ropes.

- Kevlar: Very expensive and difficult to work with compared to other ropes.

Always consider the specific limitations of the rope you are using and select the appropriate type for the job. Using a rope beyond its limitations can lead to failure and potentially dangerous situations.

Q 8. How do you determine the appropriate rope diameter and strength for a specific task?

Determining the correct rope diameter and strength involves carefully considering the load’s weight, the working environment, and the required safety factor. Think of it like choosing the right size of rope for climbing; a thin rope wouldn’t hold a heavy climber, just as a weak rope won’t support a heavy load. We need to consider the Working Load Limit (WLL), which is the maximum safe load a rope can handle. This is usually a fraction of the rope’s breaking strength, typically 1/5th, accounting for wear, tear, and unexpected stresses.

For example, if you’re lifting a 1000 kg load, you wouldn’t just choose a rope with a breaking strength of 1000kg. You’d want a rope with a WLL significantly higher, perhaps a rope with a breaking strength of 5000kg to ensure a 5:1 safety factor. The diameter is chosen based on the required strength; a larger diameter generally translates to higher strength.

The environment also plays a vital role. A rope used in harsh, abrasive conditions needs to be thicker and more robust than one used in a clean, controlled environment. Finally, you need to consider the type of rope – different materials (e.g., nylon, polypropylene, steel) offer varying strength and properties.

Q 9. Explain the process of selecting the appropriate rope for a given application.

Selecting the right rope involves a multi-step process. First, assess the task – what is the load, what are the environmental conditions, and how will the rope be used (lifting, towing, securing)? Consider factors such as the load’s weight, shape, and potential for shifting. Next, determine the required strength and diameter as discussed previously, ensuring a suitable safety factor.

Then, research different rope types. Nylon is known for its strength and elasticity, polypropylene for its buoyancy and resistance to rot, while steel wire rope provides extreme strength but can be susceptible to corrosion. Match the rope’s properties to the needs of your application. Finally, always check the rope for any signs of wear or damage before use. Don’t hesitate to replace it if needed; your safety is paramount.

For instance, for lifting delicate equipment, a softer, more flexible rope with a high WLL is better than a stiff, harsh one which could damage the equipment. Conversely, for heavy-duty towing in rough terrain, a high-tenacity, abrasion-resistant rope like a steel wire rope might be necessary. This decision-making process prioritizes both effectiveness and safety.

Q 10. How do you mitigate risks associated with rope usage?

Mitigating risks involves multiple layers of precaution. First, choose and inspect the correct rope, ensuring it’s free from damage (abrasions, cuts, fraying) and is properly stored before and after use. Always check its WLL and ensure it significantly exceeds the expected load.

- Proper Training: Ensure all personnel involved in rope handling are properly trained and understand the risks involved. This includes proper knot tying techniques and load securing procedures.

- Regular Inspection: Inspect the rope before and after each use. Look for wear and tear, UV degradation, and any other signs of damage.

- Safety Factor: Always use a substantial safety factor to account for unexpected stresses and wear.

- Protective Gear: Use appropriate personal protective equipment (PPE), such as gloves and eye protection.

- Safe Handling Procedures: Follow safe handling procedures – avoid sharp edges, kinks, and excessive strain on the rope.

- Environmental Considerations: Be aware of environmental factors that may degrade the rope, such as UV light, chemicals, or extreme temperatures.

By following these guidelines, you significantly reduce the likelihood of accidents and failures associated with rope usage. Think of it like driving a car – regular maintenance, adherence to traffic laws, and careful driving reduces accidents.

Q 11. What are the different types of rope failures and their causes?

Rope failures can stem from several causes, leading to different types of failures. Think of it like a chain; its strength is only as good as its weakest link. Rope failure can be catastrophic, so understanding the causes is critical.

- Abrasion: Wear and tear due to friction against surfaces, leading to thinning and weakening of the rope.

- Cutting: Sharp objects severing the rope fibers.

- Crushing: Excessive load concentrated on a small area of the rope.

- Overloading: Exceeding the rope’s working load limit, leading to sudden breakage.

- Knot Failure: Improper knot tying or weak knots resulting in failure under load.

- UV Degradation: Prolonged exposure to sunlight weakens the fibers, reducing strength.

- Chemical Degradation: Exposure to chemicals can weaken or destroy rope fibers.

Identifying the cause of failure is crucial to prevent future incidents. For example, if a rope fails due to abrasion, you might need to protect it with sleeves or use a different route to avoid the abrasive surface.

Q 12. How do you assess the working load limit of a rope?

The working load limit (WLL) is the maximum load a rope can safely handle. It’s typically found on the rope’s tag or in the manufacturer’s specifications. This is not a value to be casually interpreted. Never exceed it.

To assess the WLL, always refer to the manufacturer’s information. This is the definitive source. Never try to estimate it based on visual inspection or guesswork. The WLL is a critical safety parameter, and underestimating it can lead to catastrophic consequences. If you’re unsure about the WLL of a particular rope, it’s always better to err on the side of caution and use a stronger rope.

Remember, the WLL is usually a fraction (typically 1/5th) of the rope’s breaking strength, but relying solely on breaking strength is unsafe and inaccurate.

Q 13. What are the best practices for maintaining rope in optimal condition?

Maintaining rope in optimal condition is essential for safety and longevity. Regular inspection is key. Check for signs of wear, such as fraying, cuts, or kinks. Avoid sharp bends and twisting. Inspect for UV degradation, especially in ropes regularly exposed to sunlight. Clean the rope periodically to remove dirt and debris, using appropriate cleaning methods specific to the rope material.

Proper storage is also critical. Store the rope in a cool, dry place, away from direct sunlight, chemicals, and excessive moisture. Avoid coiling it too tightly, as this can put undue stress on the fibers. Use appropriate storage containers or racks to keep the rope organized and prevent tangling. Finally, regularly check for any signs of chemical damage or deterioration due to exposure to harsh conditions.

Think of it as car maintenance – regular checks and preventative measures drastically extend the lifespan and improve safety.

Q 14. Describe the process of securing a load using rope.

Securing a load with rope requires careful planning and execution. First, assess the load and choose the appropriate rope based on its weight and shape. Ensure the WLL is significantly higher than the load’s weight. Then, choose appropriate knots for the application. Some common knots include the bowline (for creating a loop), the clove hitch (for attaching to a post or ring), and the figure eight knot (for creating a secure stop). Ensure the knots are tied correctly and snugly; a poorly tied knot can lead to failure.

When securing the load, distribute the weight evenly across the rope to prevent overloading any single point. Avoid sharp bends, which can weaken the rope. Multiple securing points, where applicable, are safer than a single one. After securing, always inspect the setup to ensure stability and that the load is safely secured. Regular monitoring is vital, particularly if the load is being moved or exposed to external factors.

For instance, if securing a heavy crate, using multiple points of attachment and evenly distributing the load using appropriate knots and a sufficient safety margin is crucial for preventing accidental dropping or slippage.

Q 15. How do you handle a rope that has become entangled or fouled?

Dealing with an entangled or fouled rope requires patience and a systematic approach. Rushing can worsen the situation and lead to injury. First, I would assess the severity of the tangle. A minor knot can often be worked out by hand, carefully tracing the rope and untwisting it. For more complex tangles, I’d start by identifying the main lines and working from the outermost parts inwards, avoiding pulling aggressively. Think of it like untangling a ball of yarn – slow, steady, and methodical. If the rope is heavily fouled, perhaps around an obstacle, I might need to use specialized tools like a rope lubricant or even carefully cut the rope at the point of entanglement to free the rest, making sure to secure the loose end immediately. Safety is paramount – I’d always wear appropriate gloves to prevent cuts and abrasions.

For example, imagine a climbing rope tangled around a rock. Instead of yanking, I’d carefully work my way through the tangle, potentially using a karabiner to temporarily secure sections and prevent further entanglement. If the rope is severely damaged, it would be replaced immediately to prevent accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the procedures for rescuing someone who has fallen while using rope?

Rescuing someone who has fallen while using rope is a serious situation demanding immediate and coordinated action. My first priority is to assess the victim’s condition and the stability of the situation. I’d immediately call for emergency services. Then, depending on the circumstances and my training, I may employ a variety of rescue techniques. This could involve using a rope system to lower the injured person safely to the ground (if feasible and safe), or using specialized equipment like a rescue harness and pulley system to ascend to the victim and provide immediate care and then perform a controlled descent. Communication with the victim and the rescue team is critical, keeping everyone informed of the situation and the rescue plan.

For instance, if someone falls while rappelling and is dangling, I wouldn’t attempt a solo rescue without proper training and equipment. I would secure the victim’s position, alert emergency services, and wait for assistance from trained professionals. Improvised rescues can lead to more serious injuries, emphasizing the importance of training and the appropriate safety equipment.

Q 17. Explain the use of different types of rope clamps and their applications.

Rope clamps are crucial for securing ropes and creating adjustable systems. Different types cater to various needs. Here are some examples:

- Figure-eight clamps: Simple, widely used, and relatively inexpensive. They are excellent for creating adjustable loops and tensioning ropes. However, they can only be effectively used on static ropes, not dynamic ones as they cause damage during use.

- Tibloc: A mechanical device providing excellent gripping power and reliable braking action. Frequently employed in rescue and climbing scenarios.

- Ascenders: Used for ascending ropes. They are designed to grip the rope effectively during upward movement and release when downward force is applied. They usually employ a cam-based mechanism.

- Rope Grabs: Similar to ascenders but typically more simplistic, and commonly used for light-duty work or temporary solutions.

The choice of clamp depends on the application. Figure-eight clamps might be suitable for simple rigging, while Tiblocs are preferred for more demanding rescue operations. Ascenders are essential for ascending ropes during climbing or rescue, while rope grabs might be used for temporary anchors.

Q 18. How do you ensure the safety of yourself and others when working at heights with rope?

Safety at heights with rope is paramount. It’s a combination of careful planning, proper equipment, and meticulous execution. Before any work begins, a thorough risk assessment is crucial. This includes identifying potential hazards, selecting appropriate safety equipment (harnesses, helmets, appropriate gloves), and establishing clear communication protocols. Using redundant safety systems, such as double ropes or backup anchors, drastically reduces the risk. Regular equipment inspections are mandatory to ensure that everything is in good working order. Furthermore, adherence to strict safety procedures and thorough training are essential. It’s vital to never work alone at heights, always having a competent spotter or partner.

For example, when working on a tall building, I’d always use a full-body harness, a lifeline connected to a secure anchor point, and a backup safety line. My partner would constantly monitor my safety, and we’d have pre-determined signals for communication. Every piece of equipment would be inspected before use, and we would have a clear escape plan in place.

Q 19. What are the regulations and standards governing the use of rope in your industry?

Regulations governing rope use vary depending on the industry and geographic location. However, common themes include compliance with relevant safety standards (e.g., ANSI, EN, or other regional standards) for rope materials, testing, and inspection. These standards define the requirements for rope strength, durability, and appropriate use in different situations. There are also regulations regarding the certification of personnel handling ropes, especially in high-risk environments. These certifications ensure that individuals possess the necessary training and skills to operate safely and effectively. Regular inspections of ropes and equipment are typically mandatory, along with detailed record-keeping of inspections and maintenance.

Failure to comply with these regulations can have serious consequences, potentially leading to accidents, fines, or legal action. Therefore, understanding and adhering to all relevant regulations is vital.

Q 20. How do you communicate effectively with your team when working with rope?

Clear and concise communication is fundamental when working with rope, especially in a team. We use a combination of verbal and non-verbal cues. Verbal communication often involves pre-determined commands, such as “taking up slack,” “holding,” or “lowering.” Non-verbal cues might include hand signals, which are particularly important in noisy environments or when it’s difficult to speak clearly. Regular briefings before starting work are important to clarify procedures and ensure everyone understands their role and responsibilities. After any incident, a debriefing session allows for identification of improvements in the safety protocols and efficiency of the operation.

For example, a simple hand signal could indicate to a teammate to stop pulling immediately. This prevents miscommunication and avoids potentially dangerous situations. Clear communication also includes the use of radio communication when working across a greater distance.

Q 21. Describe your experience with different types of rope access systems.

My experience encompasses a wide range of rope access systems, from simple single-rope techniques to more complex systems using multiple ropes, pulleys, and ascenders. I’m proficient in various techniques such as rappelling, ascending, and creating various anchor points. I have extensive experience with different types of ropes, including static ropes (for rigging and anchoring) and dynamic ropes (for climbing and controlled falls). I have practical experience with different types of harnesses and personal protection equipment (PPE), ensuring I’m confident in using them safely and effectively. My work has involved various applications, including industrial inspections, rescue operations, and specialized rigging for film and theatre productions.

Specifically, I’ve worked with both single-rope techniques (SRT), which are often used for inspections, and double-rope techniques (DRT), which offer increased redundancy and safety. This experience extends to using various rescue and hauling systems, employing block and tackle systems for lifting heavy loads, and dealing with various types of anchor points, from natural features to purpose-built anchor systems.

Q 22. How do you identify and avoid potential hazards when working with rope?

Identifying and avoiding hazards when working with ropes is paramount to safety. It involves a thorough pre-use inspection and understanding the working environment. This includes looking for:

- Wear and tear: Examine the rope for fraying, cuts, broken strands, or significant abrasion. Think of it like checking the tread on a tire – insufficient tread depth is a major hazard.

- Knots and kinks: These weaken the rope significantly and can create stress points that lead to failure. A simple kink can reduce the rope’s strength by up to 50%.

- Chemical damage: Exposure to acids, solvents, or UV radiation can degrade the rope’s fibers. Look for discoloration or unusual stiffness.

- Environmental factors: Sharp objects, rough surfaces, and extreme temperatures can damage the rope. Consider the environment – a rope used in a construction site is subject to far more hazards than one used in a climbing gym.

- Proper storage: Improper storage can lead to damage. Ropes should be stored in a cool, dry place away from direct sunlight and sharp objects.

Avoiding hazards includes using the correct type of rope for the job, employing appropriate techniques for handling and coiling, and always wearing appropriate personal protective equipment (PPE) like gloves.

Q 23. Explain your experience with using different types of rope protection equipment.

My experience encompasses a wide range of rope protection equipment. I’ve worked extensively with:

- Fall arrest systems: Including harnesses, lanyards, shock absorbers, and anchors. I understand the critical importance of regular inspections and the specific requirements for different applications (e.g., working at heights).

- Rope guards: These protect ropes from abrasion and damage during use. I’ve used various types, from simple fabric sleeves to more robust metal or plastic protectors, selecting the appropriate type based on the application and environmental factors.

- Protective coverings: These are used to protect rope ends and prevent fraying. I’m familiar with various methods such as whipping, seizing, and using end caps. A well-protected end dramatically increases the lifespan of the rope.

- Load distribution devices: These are crucial for ensuring that the load is evenly distributed along the rope and to avoid concentration of stress at any point. I’m proficient in using such equipment according to manufacturer guidelines.

Throughout my career, selecting the correct PPE has been a crucial element in ensuring safety and efficiency. I always prioritize choosing equipment that is appropriately rated for the task and in perfect working condition.

Q 24. What are the different types of rope terminations and their applications?

Rope terminations are crucial for ensuring the safety and longevity of rope systems. Different applications call for different terminations:

- Whipping: This involves wrapping a thin cord tightly around the end of a rope to prevent fraying. It’s a simple, effective method for lighter ropes.

- Seizing: Similar to whipping but uses stronger material and multiple wraps for enhanced durability. Often used in demanding applications.

- Splicing: A more advanced technique where the rope ends are interwoven to create a seamless, strong termination. This is ideal for high-strength applications and maintains rope integrity.

- Eye splices: Create a loop at the end of the rope, suitable for attaching to shackles or other hardware. Their strength is crucial for safety.

- Soft shackles: A modern alternative to metal shackles, offering flexibility and reduced weight. They are increasingly popular but require careful selection and inspection.

The choice of termination depends on the rope material, its intended use, and the load it will bear. Improper termination can lead to catastrophic failure, so proper technique and appropriate materials are essential.

Q 25. Describe your experience with rope maintenance and inspection procedures.

Rope maintenance and inspection are critical for ensuring safety. My procedures include:

- Visual inspection: Thoroughly examine the entire length of the rope for any signs of wear, damage, or contamination before each use. This includes checking for fraying, cuts, kinks, and discoloration.

- Strength testing: While not always practical in the field, strength testing can be performed periodically to verify the rope’s integrity, especially for ropes used in critical applications.

- Cleaning: After each use, I clean the rope to remove dirt and debris that can accelerate wear. I use appropriate cleaning agents depending on the rope material.

- Drying: Proper drying is crucial, preventing mildew and rot. Avoid direct sunlight or high heat.

- Storage: Ropes should be stored in a cool, dry place, away from direct sunlight and sharp objects, in a manner that prevents kinking or damage.

A thorough maintenance program prolongs the lifespan of ropes and significantly reduces the risk of accidents. Documentation is critical, recording inspections and any maintenance performed.

Q 26. Explain how to properly inspect and maintain fall protection equipment.

Inspecting and maintaining fall protection equipment is a crucial aspect of safety. The process involves:

- Visual inspection: Check harnesses, lanyards, and anchors for cuts, tears, fraying, burns, or any signs of unusual wear. Look for corrosion on metal components.

- Component checks: Inspect buckles, carabiners, and other components for proper function and ensure they are free of damage. Test buckles and carabiners to make sure they latch and unlatch smoothly.

- Stitching and webbing: Examine all stitching and webbing for any signs of deterioration. Feel for any weakened or broken strands.

- Shock absorbers: Ensure that shock absorbers are not damaged or their indicators show signs of deployment.

- Documentation: Maintain detailed records of inspections, including dates, findings, and any corrective actions taken.

Following the manufacturer’s recommendations is essential. If any damage is found, the equipment should be immediately taken out of service and replaced. Regular inspections prevent catastrophic failures.

Q 27. What steps do you take to ensure the safe handling and storage of ropes?

Safe handling and storage of ropes is vital for preventing accidents and maximizing their lifespan. The following steps ensure this:

- Proper coiling: Ropes should be coiled neatly to prevent kinking and tangling. I use the figure-eight method for most applications.

- Clean and dry storage: Store ropes in a cool, dry, and well-ventilated area away from direct sunlight, extreme temperatures, and chemicals.

- Protection from sharp objects: Avoid storing ropes near sharp objects that could cut or abrade them.

- Labeling: Label ropes clearly with their type, strength, and date of last inspection.

- Regular inspection: Conduct regular inspections to identify any signs of wear and tear. Replace ropes that show significant damage.

By following these steps, you minimize the risk of rope damage and ensure the ropes are ready for safe and effective use when needed.

Q 28. Describe a situation where your rope handling skills were critical in preventing an accident.

During a challenging rescue operation in a confined space, a section of rope used for hauling equipment began to fray near a sharp edge. I immediately noticed the wear, stopped the operation, and secured the damaged section with additional rope and protective covering. This prevented a potentially catastrophic rope failure and ensured the safety of the rescue team and the person being rescued. My experience in identifying the hazard, swift action in implementing a solution, and proficiency in using appropriate techniques prevented a serious accident.

Key Topics to Learn for Your Rope Coiling and Handling Interview

- Rope Types and Properties: Understanding different rope materials (e.g., nylon, polyester, polypropylene), their strengths, weaknesses, and appropriate applications in various scenarios.

- Coiling Techniques: Mastering various coiling methods (e.g., figure-eight, butterfly, single-loop) for efficient storage, easy deployment, and preventing tangles. Practical application includes demonstrating proficiency in different coiling styles for diverse rope diameters and lengths.

- Safety Procedures and Regulations: Knowing and adhering to relevant safety regulations, including proper handling techniques to avoid injury and damage to equipment. This includes understanding load limits and recognizing signs of rope wear and tear.

- Knots and Hitches: Familiarity with essential knots and hitches used in rope handling, their applications, and their limitations. Practical application would involve demonstrating the ability to tie and untie various knots quickly and securely.

- Troubleshooting and Problem Solving: Ability to identify and resolve common issues related to rope handling, such as tangled ropes, damaged sections, or ineffective knot tying. This includes understanding the implications of using incorrect techniques and knowing how to recover from mistakes safely.

- Equipment and Tools: Knowledge of various tools used in conjunction with rope handling (e.g., winches, pulleys, shackles). Understanding their function, safe operation, and maintenance is crucial.

- Environmental Considerations: Understanding how environmental factors (e.g., weather, temperature) can impact rope performance and safety procedures.

Next Steps

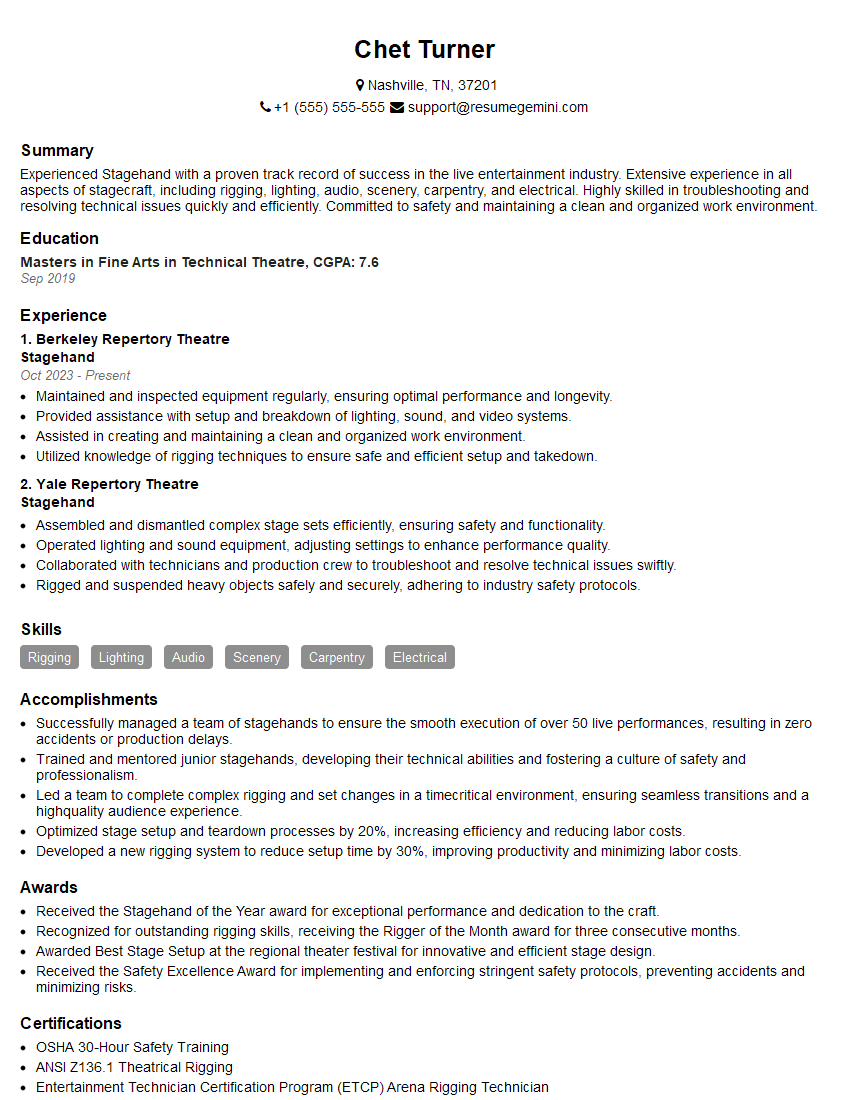

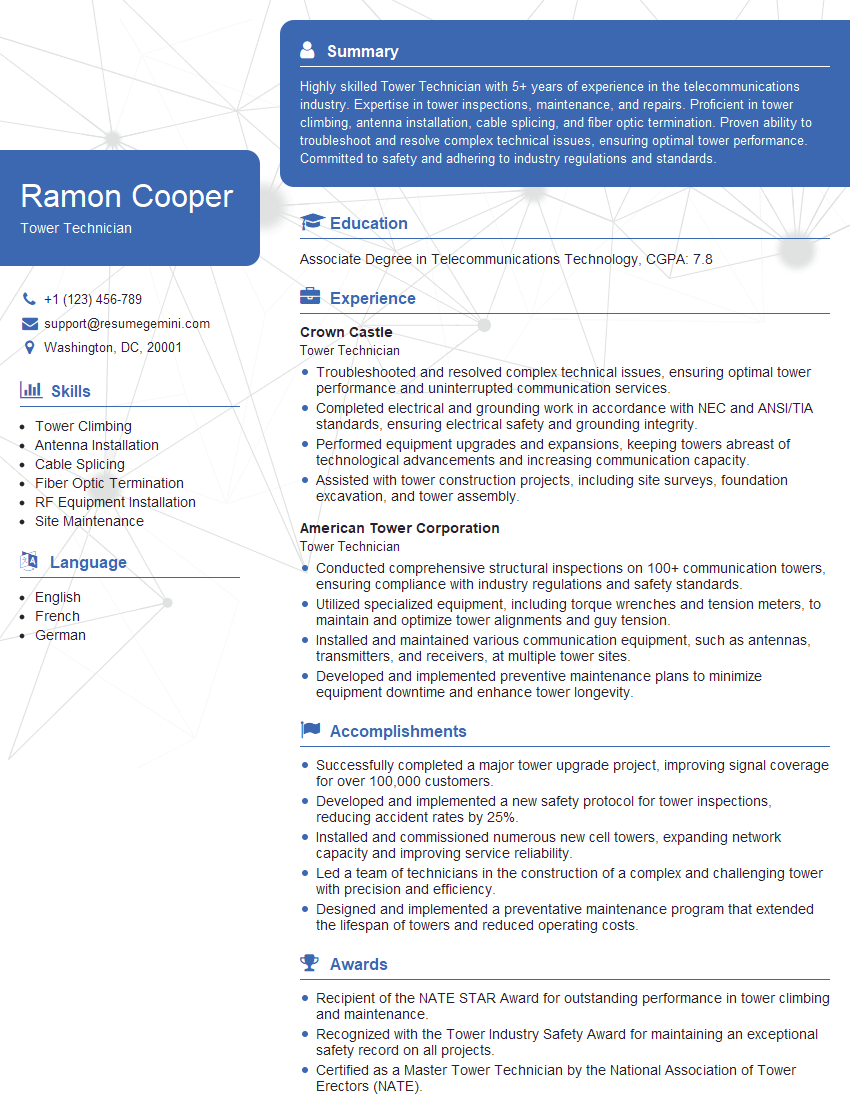

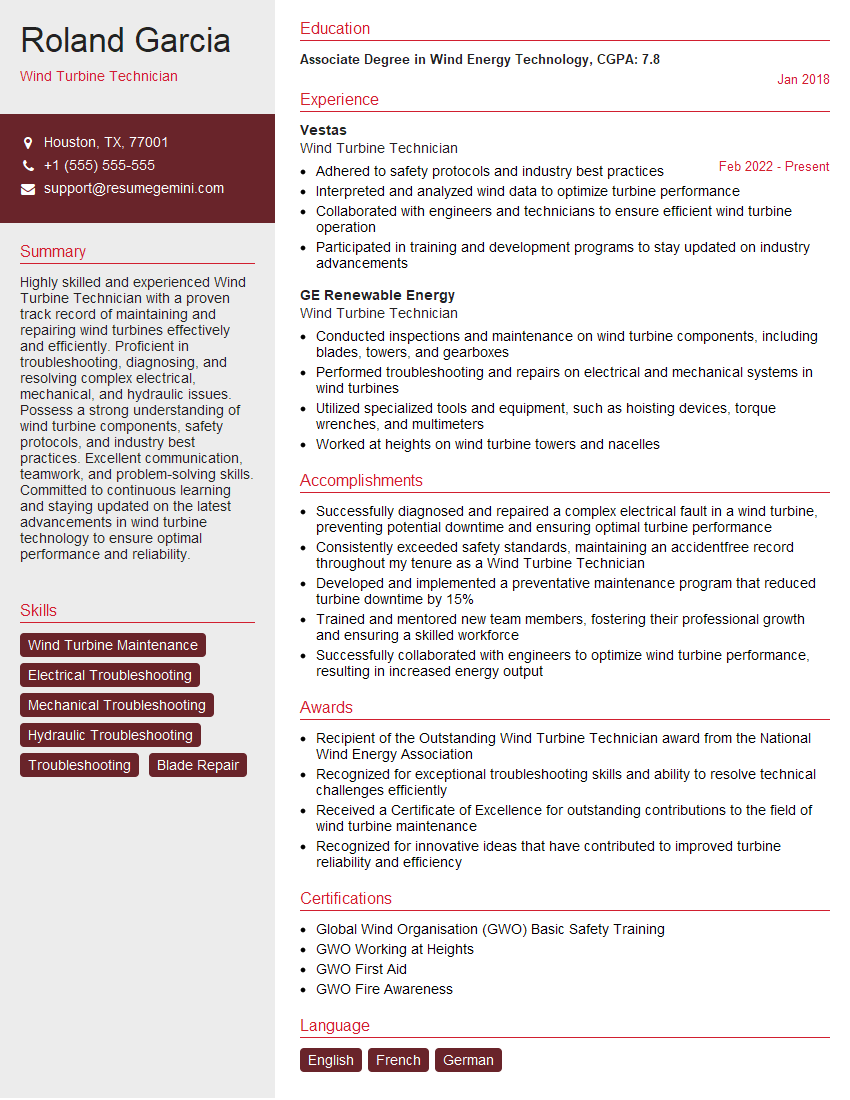

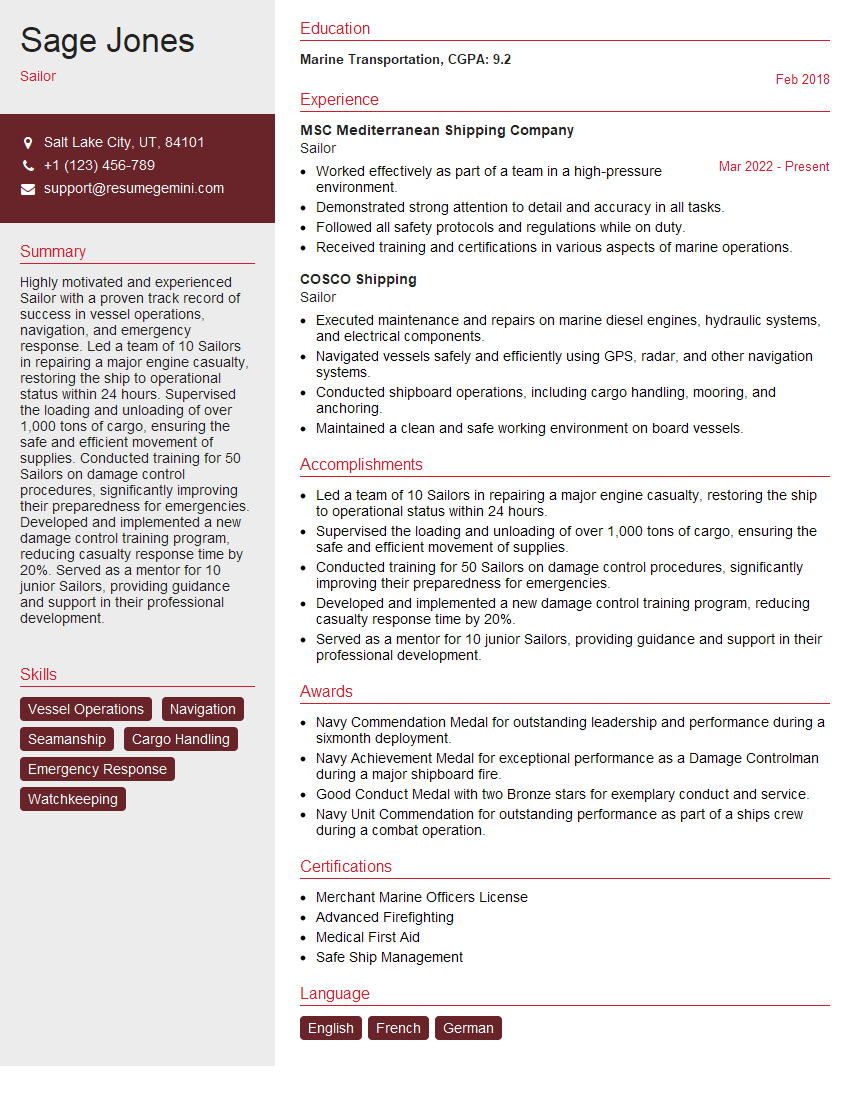

Mastering rope coiling and handling is a valuable skill that opens doors to diverse and rewarding career opportunities. Demonstrating proficiency in this area significantly enhances your employability and showcases your commitment to safety and efficiency. To further boost your job prospects, it’s crucial to create a professional and ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to your specific needs. We offer examples of resumes specifically designed for Rope Coiling and Handling professionals, providing you with a strong foundation to showcase your capabilities to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good