Are you ready to stand out in your next interview? Understanding and preparing for Rug Cutting interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Rug Cutting Interview

Q 1. What types of cutting tools are used in rug cutting?

The choice of cutting tools in rug cutting depends heavily on the rug material and the desired cut. We use a variety of tools, categorized primarily by their cutting mechanism:

- Electric Shears: These are excellent for precise cutting of various materials, especially delicate ones like silk or wool. They offer good control and speed. I often use these for intricate designs or when trimming fringes.

- Rotary Cutters: These are ideal for cutting large areas quickly and efficiently, particularly with thicker rugs like those made of heavy wool or synthetic materials. They’re very effective for straight cuts and creating consistent shapes.

- Craft Knives (Utility Knives): These are essential for detail work and trimming hard-to-reach areas. Their precision makes them useful for intricate patterns or repairing minor damages.

- Specialized Shears: For specific tasks like fringe trimming or cutting very thick pile, specialized shears with extra-strong blades are necessary. These often have ergonomic handles for comfort during extended use.

The selection process always involves considering the material’s thickness, density, and the desired precision of the cut.

Q 2. Explain the different cutting techniques used for various rug materials.

Cutting techniques vary significantly depending on the rug material. For instance:

- Wool Rugs: Wool is relatively easy to cut but requires sharp blades to prevent fraying. I often use electric shears for smoother cuts and rotary cutters for larger sections. Precision is crucial to maintain the integrity of the fibers.

- Silk Rugs: Silk is incredibly delicate. Here, sharp, fine-tipped shears are essential to avoid snagging or damaging the fibers. Slow, careful cutting is paramount.

- Synthetic Rugs: These rugs are often easier to cut than natural fibers due to their consistency. Rotary cutters or electric shears are suitable, depending on the desired finish.

- Hand-Knotted Rugs: These require meticulous precision, often utilizing craft knives for trimming and shaping fringes or repairing small sections. It’s essential to maintain a very sharp blade to ensure clean cuts, preserving the integrity of the knots.

The key is to adapt the technique to the specific challenges of each material. Experience helps anticipate potential issues, such as material stretching or fraying.

Q 3. How do you ensure precision and accuracy in rug cutting?

Precision and accuracy are paramount. I achieve this through a combination of techniques:

- Sharp Blades: Dull blades lead to uneven cuts and potential damage. Regular sharpening and blade maintenance are vital.

- Precise Measurements: Accurate measurements are taken before any cutting begins, using measuring tapes and rulers. For complex designs, templates or patterns are created and used as a guide.

- Cutting Aids: Cutting mats, straight edges, and self-healing cutting surfaces are used to keep the rug stable and prevent slippage during the cut.

- Slow & Steady Technique: Rushing the process almost always leads to errors. A slow, deliberate approach allows for better control and accuracy.

- Consistent Blade Angle: Maintaining a consistent angle while cutting ensures uniform cuts and avoids uneven edges.

Experience plays a huge role in developing a feel for the blade and the material, allowing for intuitive adjustments to maintain precision.

Q 4. What safety precautions are essential when operating rug cutting machinery?

Safety is my top priority. When using rug cutting machinery, these precautions are always followed:

- Proper Training: Thorough training is essential before operating any cutting machinery.

- Eye Protection: Safety glasses or goggles must be worn to protect against flying debris.

- Protective Clothing: Long sleeves and closed-toe shoes are worn to protect skin from sharp blades.

- Machine Maintenance: Regular maintenance and inspections of the equipment are crucial to prevent malfunctions and accidents.

- Proper Handling: Always maintain a firm grip on the cutting tool and avoid reaching over blades.

- Keep Hands Clear: Keep fingers and hands away from the cutting area.

- Sharp Blade Disposal: Dispose of used blades safely, according to regulations.

A safe work environment is not just about following rules; it’s about cultivating a mindset of carefulness and attentiveness.

Q 5. Describe your experience with different types of cutting machines.

My experience spans a variety of cutting machines. I’ve worked extensively with:

- Electric Shears (various models): From basic models to high-end professional shears with adjustable speed and blade settings, I’ve found their versatility indispensable for many projects. I prefer those with ergonomic handles for comfort.

- Rotary Cutters (different blade sizes): These have proved invaluable for quick, large-scale cuts and creating consistent shapes. I adapt the blade size to the rug’s thickness and the size of the cut.

- Oscillating Knife Cutters: I’ve used these for more complex shapes where sharp curves are needed. This technology offers good control for intricate designs.

Each machine has its strengths and weaknesses, and choosing the right tool for the job is critical for efficiency and safety. Understanding the capabilities of each machine allows for optimized workflows.

Q 6. How do you handle damaged or defective rugs during the cutting process?

Dealing with damaged rugs requires a careful assessment. Minor damages like small holes or frayed edges can often be repaired during the cutting process. This may involve trimming away damaged sections and blending the edges seamlessly. For more extensive damage, the cutting process might need to be adapted, potentially sacrificing certain sections to salvage the rest of the rug. The approach always considers the extent of the damage, the rug’s overall condition, and the customer’s wishes.

In cases of significant defects, where repair isn’t feasible, the customer should be informed, and the cutting plan revised accordingly. Transparency is key in these situations.

Q 7. How do you maintain the sharpness and condition of your cutting tools?

Maintaining the sharpness of cutting tools is crucial for precision and safety. I employ several strategies:

- Regular Sharpening: Blades are sharpened regularly using appropriate honing tools, depending on the type of blade (e.g., electric shear blades require specialized sharpening).

- Blade Cleaning: After each use, blades are cleaned thoroughly to remove any debris that can dull the edges or cause corrosion.

- Proper Storage: Blades are stored in protective cases or sheaths to prevent damage or accidental cuts.

- Professional Sharpening: For more complex blades or when necessary, I use a professional sharpening service to ensure optimal sharpness and blade longevity.

Investing time in maintaining tools isn’t just about extending their lifespan; it’s about ensuring consistent quality and preventing costly mistakes due to dull blades.

Q 8. What are the common challenges faced in rug cutting, and how do you overcome them?

Rug cutting, while seemingly straightforward, presents several challenges. One major hurdle is maintaining consistent cut quality across diverse materials and designs. Variations in fiber density, thickness, and texture can significantly impact the precision of the cut. Another significant challenge is minimizing waste. Optimizing cutting patterns is crucial to reducing material loss, especially with expensive materials like silk. Finally, ensuring the safety of workers, using sharp blades and adhering to safety protocols, is paramount.

To overcome these, we employ a multi-pronged approach. This includes investing in high-precision cutting machines with adjustable settings to accommodate different materials. We meticulously plan cutting patterns using CAD software to minimize waste and optimize material usage. Regular machine maintenance and operator training are key to consistent quality and safety. Furthermore, we’ve implemented a rigorous quality control process at every stage, from material inspection to final product review.

Q 9. Explain your experience with different rug materials (e.g., wool, silk, synthetic).

My experience spans a wide range of rug materials, each presenting unique cutting characteristics. Wool, for instance, is relatively forgiving, offering some give under the blade, but requires careful attention to avoid fraying. Silk, being much more delicate, necessitates the use of specialized blades and slower cutting speeds to prevent damage or slippage. Synthetic materials, such as nylon or polyester, can be more challenging due to their tendency to melt or deform under excessive heat or pressure from the blade; requiring specific blade types and cooling techniques.

I’ve worked extensively with hand-knotted rugs, where the precise cutting of individual knots is critical to maintaining the design’s integrity. In machine-made rugs, the challenge shifts to achieving uniformity and speed across large production runs. For example, I once worked on a project involving a large, intricate silk rug where the subtlety of the design demanded the utmost precision. The delicate nature of the silk fibers necessitated a thorough understanding of blade angles, cutting speeds and the fiber characteristics of the material.

Q 10. How do you determine the optimal cutting pattern for a given rug design?

Determining the optimal cutting pattern is a crucial step in rug production. It involves a blend of artistry and technical skill. We begin by carefully analyzing the rug design, identifying repeating motifs and symmetrical elements. This allows us to create a cutting layout that minimizes waste and maximizes material efficiency. I typically utilize Computer-Aided Design (CAD) software, which allows me to digitally lay out the pattern, experiment with different arrangements, and calculate material usage before physically cutting the rug.

For example, in a rug with a complex floral pattern, I would carefully identify repeating sections to minimize the number of cuts needed, reducing waste. This also ensures that the pattern is consistently replicated across the entire rug. The software also allows me to simulate different cutting methods, like straight cuts or more intricate shapes, helping me choose the most efficient and accurate approach for the specific rug design.

Q 11. How do you ensure the consistent quality of cuts throughout a large production run?

Maintaining consistent quality throughout a large production run is critical. We achieve this through a combination of technology and process control. Firstly, we use precision cutting machinery calibrated and regularly maintained to ensure consistent cutting depth and speed. Secondly, we have a standardized operating procedure for our cutting technicians, ensuring all follow the same safety protocols and cutting techniques.

Regular quality checks during the production process are essential. We have a system of random sampling, where a percentage of rugs are inspected at different stages of production. This allows us to identify and correct any inconsistencies early, preventing large-scale defects. The use of automated measurement tools provides objective data, aiding in maintaining consistent quality throughout the process. For example, we might set tolerance limits on dimensions or cut angles for each piece, automatically flagging pieces outside of this range. Any deviations are investigated, and corrective actions are implemented.

Q 12. Describe your experience with quality control procedures in rug cutting.

Quality control is paramount in rug cutting. Our procedures begin with the incoming inspection of raw materials, verifying their quality and consistency. Throughout the cutting process, we conduct regular in-process inspections, checking for dimensional accuracy, consistent cut quality, and the absence of defects. This includes visual inspection as well as using measuring tools to check for deviations from the design specifications.

Following the cutting process, a final inspection is done where each rug undergoes a thorough examination for any defects. This might involve checking for inconsistencies in the cutting pattern, frayed edges, or any material imperfections. We maintain detailed records of all inspections, allowing for traceability and identification of any potential problem areas. This data is used to constantly refine our processes and improve quality control measures. Our team is trained on effective visual inspection techniques and regularly undergoes refresher training to maintain a high standard of consistent quality check.

Q 13. How do you identify and address defects in cut rugs?

Identifying and addressing defects is a crucial part of our process. Defects can range from minor inconsistencies in cutting to major flaws like inaccurate dimensions or damaged material. We utilize several methods for detection, beginning with visual inspection and followed by detailed measurements using calibrated tools.

Minor defects, such as slight variations in cutting, might be corrected through minor adjustments or trimming. More significant flaws, such as incorrect dimensions or damaged material, will require more involved repairs or even the rejection of the piece. We maintain a detailed log of all defects found, along with their causes and corrective actions. This data helps us identify recurring issues and implement preventative measures. For example, a consistent problem with frayed edges might lead us to adjust blade settings or implement a new finishing technique.

Q 14. What is your experience with different types of rug designs and patterns?

My experience encompasses a broad spectrum of rug designs and patterns, from traditional Persian and Oriental designs with their intricate knotting and detailed patterns to contemporary geometric and abstract styles. I’ve worked on rugs with various levels of complexity, from simple, solid-colored rugs to extremely intricate pieces with multiple layers of texture and pattern. The cutting techniques and precision required vary significantly depending on the complexity and style.

Working on a traditional Persian rug demands an extremely high level of precision and understanding of the historical context of the design. The intricacies of the patterns require careful planning and execution to ensure the final cut reflects the original artistry. In contrast, a contemporary geometric rug might necessitate different cutting techniques and tools to achieve clean lines and sharp angles. Each project demands adaptation and the ability to apply the appropriate skills and techniques.

Q 15. How do you calculate the material yield for a given rug project?

Calculating material yield in rug cutting is crucial for minimizing waste and maximizing profitability. It involves carefully considering the rug’s dimensions, the pattern’s layout, and the cutting method. We start by determining the total area of the rug. Let’s say we’re working with a rectangular rug measuring 10 feet by 12 feet, giving us a total area of 120 square feet.

Next, we account for the pattern. Some patterns require more material due to complex shapes or intricate designs. Let’s assume the pattern itself consumes 5% extra material for efficient cutting and minimizing waste. Therefore, we’ll adjust the calculation: 120 sq ft * 1.05 = 126 sq ft.

Finally, we account for cutting loss. This includes the unavoidable material wasted during the cutting process. With experience, you learn to minimize this loss, but a reasonable estimate for cutting loss is often around 10% – 15%. Let’s use 10% in this example: 126 sq ft * 0.10 = 12.6 sq ft. Adding this to the initial calculation: 126 sq ft + 12.6 sq ft = 138.6 sq ft. Therefore, to produce this rug, we need approximately 138.6 square feet of material. This process is adjusted based on the specific rug, pattern, and cutting method. Software can significantly help with these calculations, especially for complex designs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with computerized cutting systems.

My experience with computerized cutting systems spans over ten years. I’ve worked extensively with both CAD/CAM software and automated cutting machines, including laser cutters and CNC routers. These systems significantly improve precision and efficiency. I’m proficient in using the software to design, program and optimize cutting paths for various rug types and patterns. For instance, I’ve used software to create efficient nesting patterns, reducing waste by up to 20% compared to manual cutting. I can also program these systems for various cutting techniques, such as bevel cuts or shaped cuts. The software allows me to simulate the cutting process before production, ensuring that the output is perfect and minimizing potential errors.

Q 17. How do you troubleshoot malfunctions in cutting machinery?

Troubleshooting malfunctions in cutting machinery requires a systematic approach. I begin by identifying the nature of the problem – is it a mechanical issue, a software glitch, or a problem with the material itself? For mechanical problems, I start with basic checks: blade sharpness, lubrication, and power supply. I also inspect belts, gears, and motors for wear or damage. If the problem persists, I consult the machine’s manual and may need to call in a technician, depending on the complexity of the issue.

Software problems are often resolved through software diagnostics and updates. Sometimes it’s a simple issue like a misaligned setting, other times a more complex bug requires more in-depth troubleshooting. Material-related problems might involve material defects that need to be replaced. In all cases, careful documentation of the troubleshooting process and corrective actions are crucial to prevent future recurrences and to optimize the maintenance and longevity of our equipment.

Q 18. What is your knowledge of different types of rug backing materials?

Rug backing materials play a critical role in the overall quality and longevity of the rug. My knowledge encompasses a wide range of materials, including jute, cotton canvas, felt, and various synthetic options. Jute is a popular choice for its affordability and strength but can be prone to shrinking and moisture issues. Cotton canvas offers a good balance of strength, softness, and stability. Felt is softer and provides excellent cushioning. Synthetic backings, such as polypropylene, provide durability, water resistance, and are easy to clean.

The choice of backing material depends on factors like rug type, the intended use of the rug, cost considerations, and desired aesthetic qualities. For instance, a high-end rug might use a high-quality cotton canvas or a specialized backing with additional cushioning, whereas a more casual rug might opt for a less expensive jute backing. I always consider the properties of each material and its interaction with the rug’s face fibers to recommend the optimal backing.

Q 19. How do you adhere to safety regulations and protocols in the cutting room?

Adherence to safety regulations is paramount in the cutting room. We maintain a clean and organized workspace, ensuring all machinery is correctly grounded and regularly inspected. All employees are trained on the safe operation of the cutting machines and are provided with appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and cut-resistant gloves. Regular safety meetings reinforce safety procedures and address any potential hazards. We follow strict guidelines for handling sharp blades and materials to minimize the risk of accidents. Proper waste disposal protocols are also in place to manage sharp materials and chemical waste. Our adherence to OSHA standards and regular safety inspections ensures a safe and productive work environment.

Q 20. How do you handle large-scale rug cutting projects?

Large-scale rug cutting projects require meticulous planning and efficient execution. We begin by breaking down the project into smaller, manageable sections. This involves careful measurement and precise layout planning using CAD software to optimize material usage. We then utilize a combination of automated and manual cutting techniques, depending on the complexity of the design and the efficiency of using our available machinery. We implement a rigorous quality control system at each stage of the process, which includes regular checks for accurate dimensions and pattern consistency. For very large projects, we might use specialized cutting equipment to ensure efficiency and accuracy. Effective communication and coordination among the team are key to successful project completion on time and within budget.

Q 21. Explain your understanding of different cutting angles and their applications.

Understanding different cutting angles is essential for achieving precise cuts and creating various effects. A straight cut, at a 90-degree angle, is the most common, producing clean, sharp edges. Bevel cuts, at angles other than 90 degrees, can create decorative edges or facilitate easier joining of rug sections. These cuts can create a smoother transition in layered rugs or offer a distinctive aesthetic. The application of different cutting angles depends on the desired rug design and finishing techniques. For example, bevel cuts are often used to create decorative fringes or to miter corners for a seamless appearance. Accurate and consistent angles are crucial for achieving a high-quality finished product, and I utilize precise measuring tools and cutting equipment to ensure this.

Q 22. Describe your experience in working with different blade types and their maintenance.

My experience spans various blade types used in rug cutting, from traditional hand shears to electric rotary cutters and automated laser systems. Each type requires a unique approach to maintenance. Hand shears, for instance, need regular sharpening and lubrication to maintain their cutting edge and prevent damage to the rug fibers. I use a honing steel regularly and have them professionally sharpened every few months, depending on usage. Electric rotary cutters demand careful cleaning after each use to remove fibers and debris that can clog the blades and reduce their cutting efficiency. I also regularly check and replace the blade when necessary; dull blades lead to uneven cuts and increased risk of accidents. Laser cutting systems require less direct physical maintenance but demand regular calibration checks and preventative maintenance by a qualified technician to ensure precision and prevent breakdowns. This meticulous maintenance for all tools significantly impacts the quality and consistency of the cuts, minimizing waste and ensuring a high-quality end product.

Q 23. How do you manage your time effectively in a high-pressure production environment?

In a high-pressure production environment, effective time management is paramount. My approach is a combination of planning, prioritization, and efficient workflow. I start by reviewing the day’s cutting schedule, identifying the most complex or time-sensitive orders. I then break down each task into smaller, manageable steps. This allows for better tracking of progress and easier identification of potential delays. I’ve also implemented a system of ‘batch processing’ where possible, grouping similar cutting tasks to optimize workflow and minimize machine setup time. Furthermore, I proactively communicate any potential delays to the team, ensuring everyone is informed and can adjust accordingly. Regular breaks help maintain focus and prevent burnout, contributing to a consistent and efficient output throughout the day.

Q 24. How do you prioritize tasks to meet deadlines in rug cutting?

Prioritizing tasks in rug cutting is crucial for meeting deadlines. I employ a combination of methods. Firstly, I use a Kanban-style system, visually tracking the progress of each order. This allows me to quickly identify bottlenecks and prioritize tasks that are closest to their deadline or have the highest urgency. Secondly, I consider the complexity of the cut: intricate designs require more time and therefore take precedence over simpler cuts when deadlines are tight. Thirdly, I assess the material: some rugs are more delicate and require extra care, impacting the task’s priority. By combining these elements, I develop a dynamic task list that ensures the most crucial cuts are completed on time, minimizing any potential delays and ensuring customer satisfaction.

Q 25. What are your strategies for preventing common cutting errors?

Preventing cutting errors is a critical aspect of my work. My strategy involves several key steps. Before starting any cut, I meticulously inspect the rug for any imperfections or inconsistencies that could affect the final outcome. I double-check measurements and ensure the rug is properly aligned on the cutting surface. Using clear and precise markings helps maintain accuracy and consistency. I always utilize the appropriate blade for the material and cutting technique. For example, using a sharp blade for delicate fabrics prevents fraying. Regularly maintaining equipment is essential for minimizing errors caused by dull or malfunctioning tools. Furthermore, taking regular breaks helps prevent fatigue-related errors. By consistently following these procedures, I ensure precise and accurate cuts every time.

Q 26. Describe your experience with manual and automated cutting techniques.

My experience encompasses both manual and automated cutting techniques. Manual cutting, using hand shears or rotary cutters, offers greater precision and control for intricate designs and smaller rugs, but is more time-consuming. I’m proficient in using various hand tools to achieve complex shapes and patterns. For example, I can skillfully create curved lines or intricate details that are impossible with automated systems. Automated cutting, utilizing laser or CNC cutting machines, excels in efficiency and speed for large-scale production and repetitive cuts. The accuracy is superb for straight lines and simple shapes. However, complex patterns or delicate materials may not be suitable for automated systems. I adapt my technique to the specifics of each project and the available resources, choosing the method that optimizes quality and efficiency.

Q 27. How do you ensure the proper alignment and positioning of rugs before cutting?

Precise alignment and positioning are critical for accurate rug cutting. Before cutting, I use a combination of techniques. I start by laying the rug flat on a stable, clean cutting surface, ensuring there are no wrinkles or folds. For large rugs, I may use weights or clamps to keep them secure. I then meticulously measure and mark the cutting lines using a precise measuring tool and tailor’s chalk or a marker appropriate for the rug material. I carefully align the rug according to the design template, paying close attention to symmetry and detail. Using alignment tools, like squares and rulers, helps maintain accuracy and prevents skewed cuts. This meticulous approach ensures the final product meets the highest standards of quality and precision.

Q 28. How do you contribute to a safe and efficient work environment in the cutting room?

Contributing to a safe and efficient work environment is a top priority. I consistently follow all safety regulations, including wearing appropriate personal protective equipment (PPE) such as safety glasses and cut-resistant gloves. I maintain a clean and organized workspace, reducing the risk of accidents caused by tripping hazards or misplaced tools. I regularly inspect cutting equipment for any damage or malfunction and report any issues promptly to prevent accidents. Furthermore, I actively participate in safety training and share best practices with colleagues. Proactive communication about potential hazards and collaborative problem-solving contribute to a safer and more efficient workflow for the entire team. By maintaining a culture of safety awareness, we minimize risks and maximize productivity.

Key Topics to Learn for Rug Cutting Interview

- Understanding Fiber Types: Knowledge of different fiber compositions (wool, silk, synthetic) and their impact on cutting techniques and final product quality.

- Pattern Recognition and Design Implementation: Analyzing rug designs and translating them into precise cutting plans, considering factors like symmetry, knot density, and color transitions.

- Cutting Techniques and Precision: Mastering various cutting methods (e.g., hand cutting, machine cutting) and understanding the importance of accuracy to minimize waste and achieve clean edges.

- Quality Control and Inspection: Identifying defects and inconsistencies in cut pieces, understanding quality standards, and implementing corrective measures.

- Safety Procedures and Equipment Handling: Safe operation of cutting tools and machinery, adherence to safety regulations, and minimizing risks of injury.

- Production Efficiency and Optimization: Strategies for maximizing cutting efficiency, minimizing downtime, and optimizing workflow for large-scale production.

- Waste Management and Sustainability: Implementing strategies to reduce material waste, recycling practices, and environmentally conscious cutting methods.

- Troubleshooting and Problem-Solving: Identifying and resolving issues that arise during the cutting process, such as flawed materials or equipment malfunctions.

Next Steps

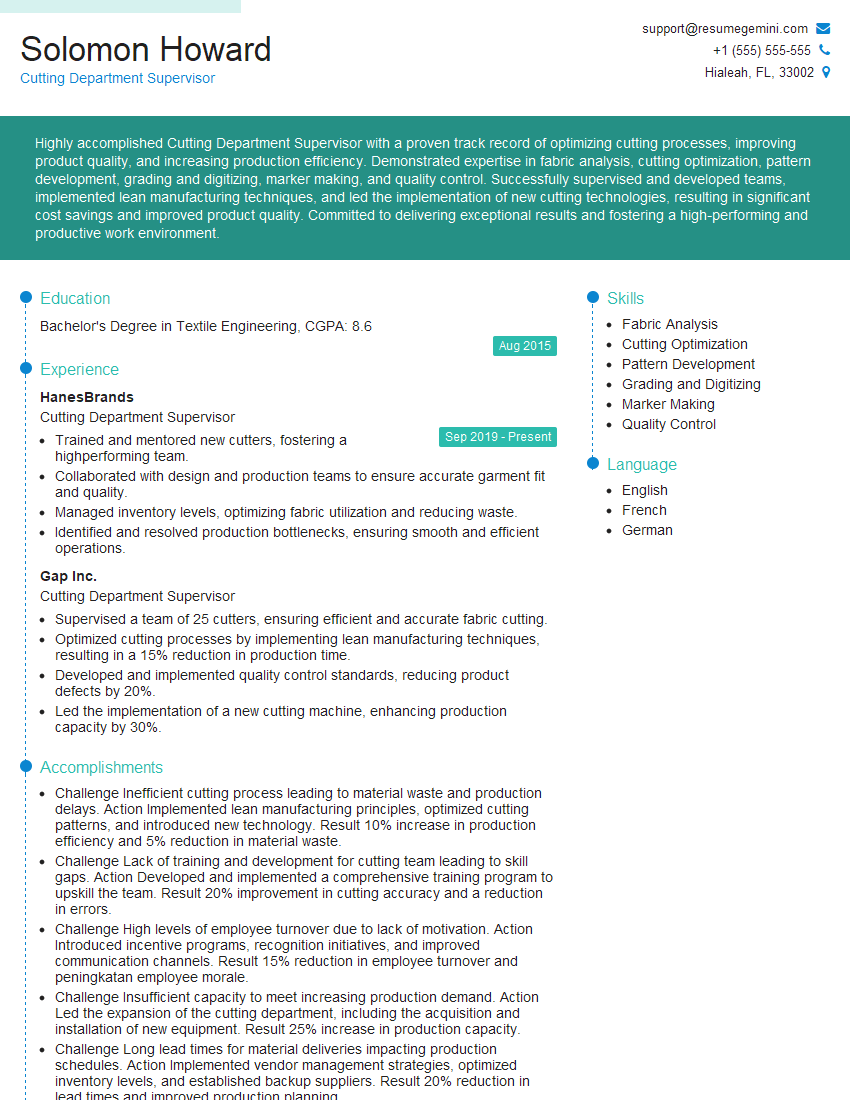

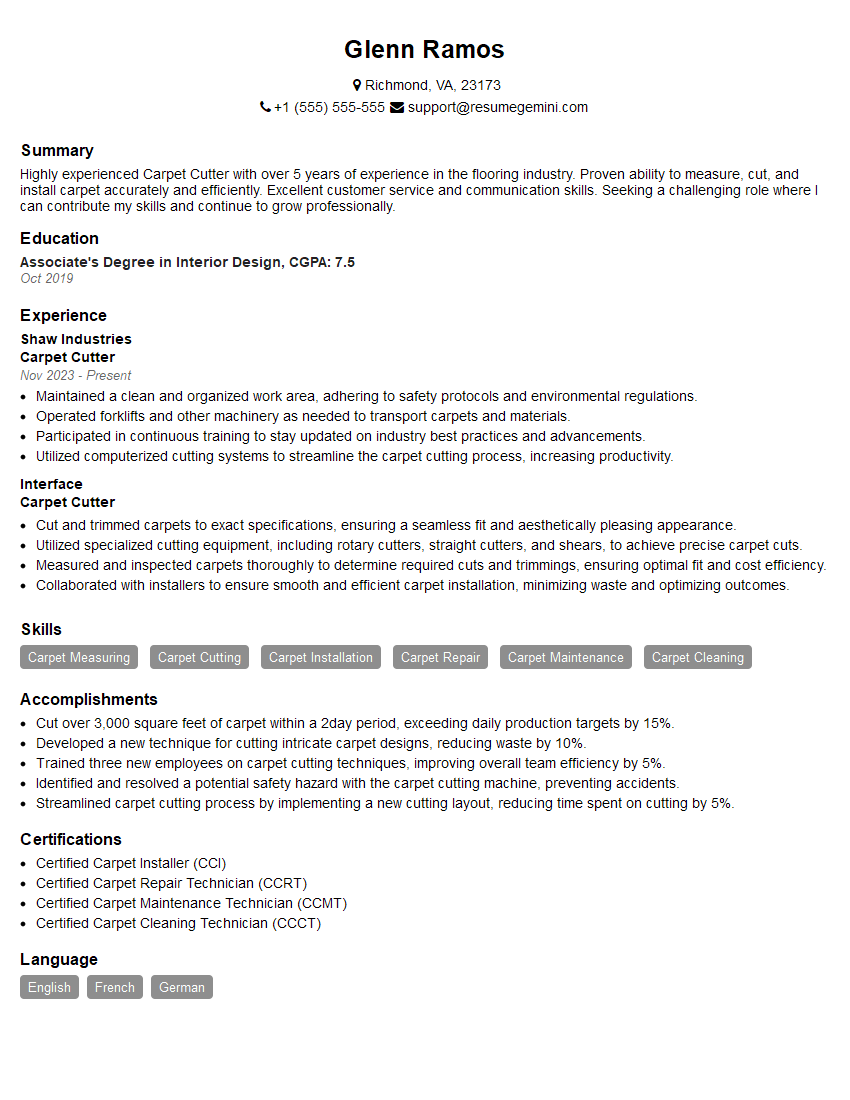

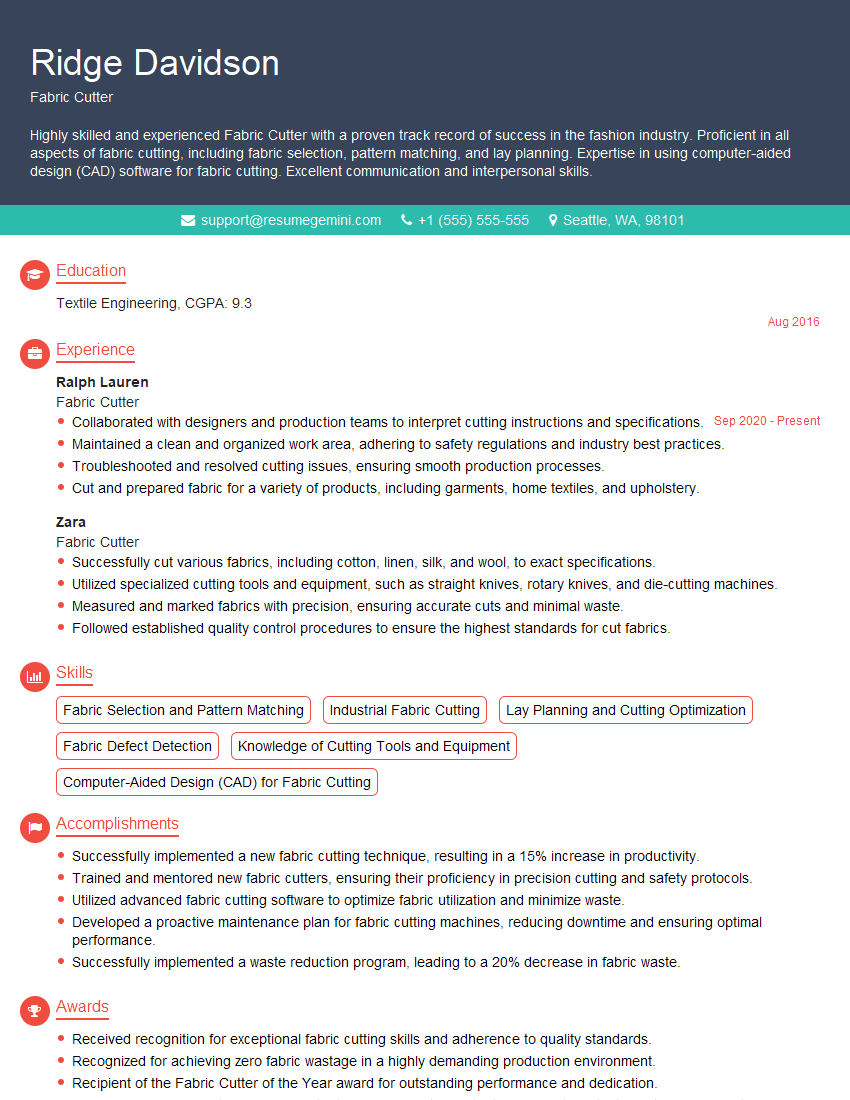

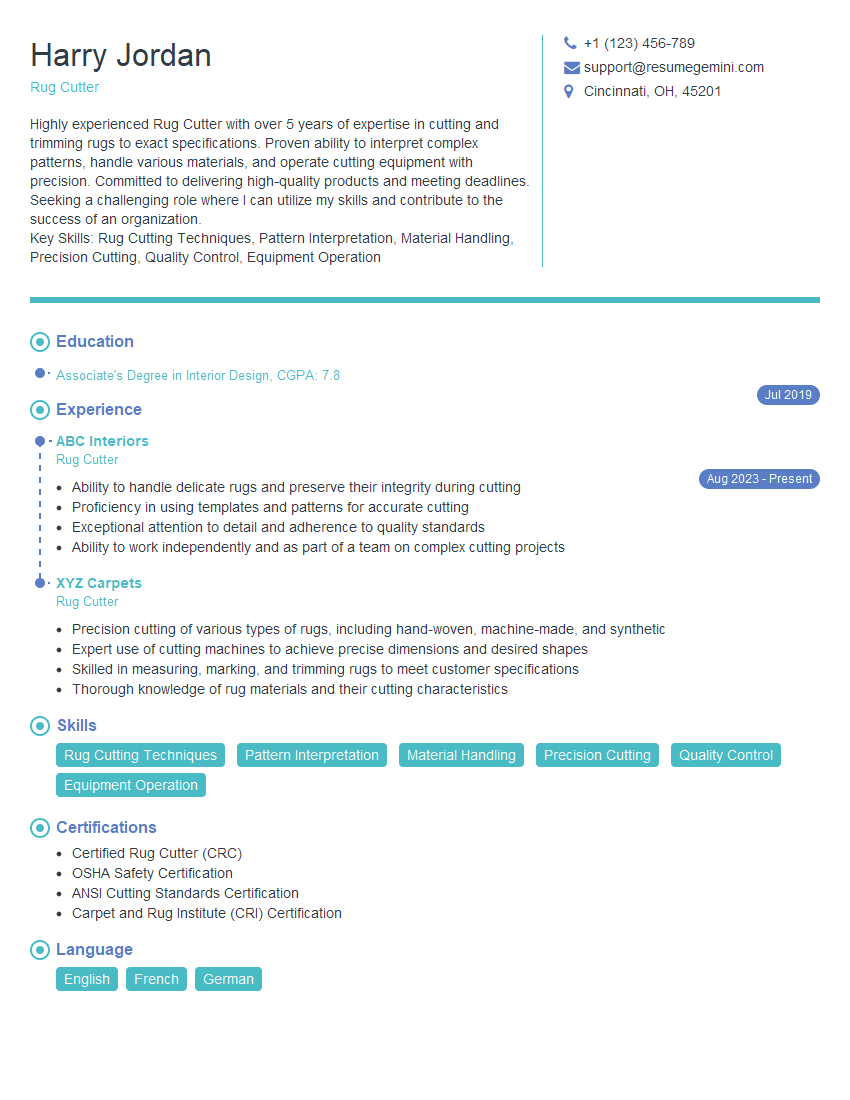

Mastering rug cutting opens doors to exciting career opportunities in the textile industry, offering growth potential and specialization in a highly skilled trade. To maximize your job prospects, it’s crucial to have a resume that effectively highlights your skills and experience to Applicant Tracking Systems (ATS). Create a strong, ATS-friendly resume to ensure your application gets noticed. We highly recommend using ResumeGemini, a trusted resource for building professional resumes. Examples of resumes tailored to Rug Cutting are available below to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good