Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Safe Handling and Storage of Chemicals interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Safe Handling and Storage of Chemicals Interview

Q 1. Describe the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system designed to ensure consistent classification and communication of chemical hazards worldwide. Think of it as a global language for chemical safety. It standardizes how chemicals are classified based on their health, environmental, and physical hazards, and how this information is presented on labels and Safety Data Sheets (SDS).

The GHS uses hazard classes and categories to group chemicals with similar hazards. For example, flammability is a hazard class, and within that, there are categories indicating different levels of flammability. Each hazard class has specific criteria for classification.

This system ensures that anyone handling a chemical, regardless of their location, can understand the potential hazards and take appropriate precautions. It reduces confusion caused by differing national regulations and improves workplace safety globally.

Q 2. Explain the differences between SDS and labels.

Both SDSs and labels provide crucial safety information about chemicals, but they serve different purposes and contain different levels of detail. Think of the label as a quick warning, like a traffic sign, while the SDS is a detailed instruction manual.

- Labels are affixed directly to the chemical container. They provide a concise summary of the key hazards, pictograms illustrating those hazards (e.g., flame for flammability, skull and crossbones for toxicity), signal words (e.g., Danger, Warning), and precautionary statements. They are designed for quick hazard identification at a glance.

- Safety Data Sheets (SDSs) are comprehensive documents that provide detailed information about a chemical’s properties, hazards, safe handling procedures, emergency response measures, and disposal methods. They are much more extensive than labels and provide the detailed information needed for safe use and handling.

For example, a label might show a flammable symbol and the signal word ‘Warning’, indicating flammability. The SDS, however, would go into detail about the flash point, flammability limits, and the appropriate fire suppression methods.

Q 3. What are the key elements of a comprehensive chemical inventory management system?

A comprehensive chemical inventory management system is crucial for maintaining a safe working environment and complying with regulations. It’s essentially a detailed record-keeping system tracking every chemical in a facility. Key elements include:

- Centralized Database: A database storing all information about each chemical, including its name, CAS number (a unique identifier), quantity on hand, location, SDS, purchase date, and expiration date.

- Regular Inventory Updates: A system for regularly updating the inventory – for example, after chemical receipts, usage, or disposal. This ensures accuracy and prevents outdated information.

- SDS Management: A system for storing and readily accessing SDSs for all chemicals. This might involve a physical file system, a dedicated software program, or online access to SDS databases.

- Location Tracking: Clear labeling and tracking of chemical storage locations to ensure quick retrieval in emergencies and efficient inventory management.

- Access Control: Procedures controlling who has access to chemicals based on training, job roles, and authorization.

- Disposal Tracking: A system for tracking the disposal of chemicals to meet regulatory requirements and ensure environmental protection.

Imagine a hospital: a robust inventory system allows them to quickly locate vital medications, manage expiry dates, and track controlled substances, all while ensuring compliance with stringent regulations.

Q 4. How do you assess the risks associated with handling and storing specific chemicals?

Risk assessment for chemical handling and storage involves identifying hazards and evaluating the likelihood and severity of potential harm. A common approach is the HAZOP (Hazard and Operability) study.

Step 1: Hazard Identification: Identify potential hazards associated with the chemical, such as flammability, toxicity, reactivity, corrosiveness, and carcinogenicity. Consult the SDS for detailed hazard information.

Step 2: Exposure Assessment: Determine the potential for exposure to the chemical. Consider the quantity used, handling procedures, ventilation in the workplace, and potential for spills or leaks.

Step 3: Risk Evaluation: Combine hazard identification and exposure assessment to evaluate the overall risk. This often involves a qualitative or quantitative risk matrix, which considers the likelihood and severity of potential incidents. A high likelihood of a high-severity event would result in a high-risk classification.

Step 4: Risk Control: Implement control measures to reduce or eliminate risks. These measures might include engineering controls (e.g., ventilation systems, enclosed processes), administrative controls (e.g., work permits, training programs), and personal protective equipment (PPE).

Example: Handling concentrated sulfuric acid. The hazards include severe burns and corrosive damage. Risk control measures would include wearing appropriate PPE (acid-resistant gloves, goggles, apron), working in a well-ventilated area, and having a spill kit readily available.

Q 5. What are the different types of personal protective equipment (PPE) used in chemical handling, and when is each appropriate?

Personal Protective Equipment (PPE) is the last line of defense against chemical exposure. The choice of PPE depends on the specific hazards presented by the chemical.

- Eye Protection: Safety glasses, goggles, or face shields protect against splashes and fumes. Goggles offer better protection than safety glasses.

- Respiratory Protection: Respirators protect against inhalation hazards. The type of respirator (e.g., particulate respirator, acid gas respirator) depends on the specific chemical and its hazards.

- Hand Protection: Gloves protect against skin contact. The material of the gloves (e.g., nitrile, neoprene, butyl rubber) must be compatible with the chemical. Never use the same gloves for handling multiple chemicals.

- Skin Protection: Aprons, coveralls, or other protective clothing protect against skin contact and splashes. The material of the clothing must be compatible with the chemical.

- Foot Protection: Safety shoes protect against chemical spills on the feet.

Example: When working with concentrated acids, acid-resistant gloves, goggles, and a lab coat are essential. If there is a risk of airborne fumes, a respirator might be necessary. Always refer to the SDS for guidance on appropriate PPE.

Q 6. Explain the procedures for handling chemical spills and leaks.

Handling chemical spills and leaks requires a rapid and controlled response to minimize risks. The steps involved include:

- Evacuation: Evacuate the immediate area and restrict access to prevent further exposure.

- Emergency Response: Call for emergency services (if necessary) and follow the facility’s emergency response plan.

- PPE: Don appropriate PPE to protect yourself from the spilled chemical. This might include respirators, gloves, and protective clothing, as needed.

- Containment: Contain the spill using absorbent materials (e.g., spill pads, vermiculite), dikes, or other appropriate methods to prevent further spread.

- Neutralization (if applicable): Some spills may require neutralization using a compatible neutralizing agent. This is not always safe and should only be done by trained personnel. Refer to the SDS for guidance on the proper procedures.

- Cleanup: Carefully collect the spilled chemical and absorbent materials. Dispose of them following proper waste disposal protocols.

- Decontamination: Decontaminate the affected area, according to the SDS.

Remember, prevention is better than cure! Proper storage, training, and regular safety checks significantly reduce the risk of spills.

Q 7. Describe the proper procedures for the disposal of chemical waste.

Chemical waste disposal must comply with all applicable local, state, and federal regulations. The process usually involves:

- Segregation: Separate chemical waste into compatible streams to prevent dangerous reactions or contamination. Incompatible chemicals should never be mixed.

- Containerization: Store waste in properly labeled containers designed to prevent leaks and spills. These should be compatible with the chemical being disposed of.

- Documentation: Maintain detailed records of chemical waste generated and disposed of. This documentation is essential for regulatory compliance.

- Waste Characterization: Determine the chemical composition of the waste to ensure proper disposal. This is often required by waste disposal facilities.

- Disposal: Contact a licensed hazardous waste disposal facility to arrange for pickup and disposal. Never dispose of hazardous waste in regular trash or down the drain.

Ignoring proper waste disposal procedures can lead to severe environmental damage and legal penalties. Always prioritize safe and responsible disposal practices.

Q 8. How do you ensure the compatibility of chemicals stored together?

Ensuring chemical compatibility in storage is paramount to prevent dangerous reactions. Incompatible chemicals can react violently, creating fire, explosions, or releasing toxic gases. The key is to understand the chemical properties of each substance and their potential interactions.

- Consult Safety Data Sheets (SDS): Every chemical should have an SDS. These sheets provide crucial information, including reactivity data, incompatibility lists, and storage recommendations. Always check the SDS before storing any chemical.

- Segregation: Store incompatible chemicals in separate areas, ideally in separate cabinets or storage rooms. For example, strong acids should never be stored near strong bases. Oxidizers should be kept away from flammable materials. Think of it like separating oil and water – they don’t mix, and neither should many chemicals.

- Use of Inert Materials: For some chemicals, storing them in inert containers (e.g., certain plastics for specific acids) can prevent unwanted reactions.

- Visual Cues: Employ clear labeling and color-coding systems to instantly identify incompatible chemicals. A well-organized storage area makes it easier to maintain compatibility.

Example: Storing sodium metal (highly reactive with water) in a tightly sealed container, away from any sources of moisture or acids is critical. Failure to do so can lead to a fire.

Q 9. What are the legal requirements for the storage and handling of hazardous chemicals?

Legal requirements for hazardous chemical storage and handling vary by jurisdiction, but generally align with overarching principles of safety and environmental protection. These regulations typically cover aspects like labeling, SDS provision, employee training, spill response plans, and emergency procedures. Key legislation often includes:

- OSHA (Occupational Safety and Health Administration): In the US, OSHA sets standards for workplace safety, including the handling of hazardous chemicals. This includes regulations on hazard communication, personal protective equipment (PPE), and emergency response planning.

- EPA (Environmental Protection Agency): The EPA focuses on environmental regulations, including the proper disposal and management of hazardous waste generated from chemical use.

- WHMIS (Workplace Hazardous Materials Information System): In Canada, WHMIS is a system that mandates the labeling of hazardous materials, the provision of SDSs, and worker training.

- Local and State/Provincial Regulations: In addition to federal regulations, there may be specific local or state/provincial laws that govern the handling and storage of certain chemicals.

Non-compliance can result in hefty fines, legal action, and, most importantly, severe workplace accidents and environmental damage.

Q 10. Explain the importance of ventilation in chemical storage areas.

Adequate ventilation in chemical storage areas is critical for preventing the buildup of hazardous vapors and gases. Many chemicals release volatile compounds that can be toxic, flammable, or even explosive at certain concentrations. Good ventilation reduces these risks.

- Removal of Vapors: Ventilation systems exhaust dangerous fumes, ensuring that air quality remains safe for personnel and preventing the accumulation of potentially explosive mixtures.

- Temperature Control: Proper ventilation helps regulate temperature, minimizing the risk of chemical degradation or spontaneous ignition, which can occur with certain temperature-sensitive materials.

- Prevention of Fire and Explosion: By diluting flammable vapors, ventilation reduces the risk of fire or explosion, particularly if ignition sources are present.

- Types of Ventilation: Systems can range from simple exhaust fans to complex HVAC systems with specialized filtration.

Example: Storing highly volatile solvents like acetone requires a well-ventilated area with exhaust fans to remove the vapors and prevent their build-up.

Q 11. What are the fire safety precautions related to chemical storage?

Fire safety is a top priority in chemical storage. Many chemicals are flammable or can contribute to a fire’s intensity. Precautions include:

- Fire Suppression Systems: Appropriate fire suppression systems, such as sprinklers, fire extinguishers (of the correct type for the specific chemicals), and fire alarm systems are essential.

- Ignition Source Control: Eliminating all potential ignition sources, such as open flames, sparks, and static electricity, is critical. This might involve using explosion-proof electrical equipment.

- Storage of Flammables: Flammable chemicals must be stored in designated flammable materials storage cabinets or rooms, away from ignition sources and incompatible substances.

- Fire Drills and Training: Regular fire drills and comprehensive fire safety training for all personnel are necessary to ensure a coordinated response in case of a fire.

- Spill Control: Having appropriate spill kits readily available and knowing how to use them is critical to mitigate a fire that may be caused by a spill.

Example: Storing sodium metal requires specific fire suppression methods, as it reacts violently with water, making standard water-based fire extinguishers unsuitable.

Q 12. How do you conduct a risk assessment for a new chemical?

Conducting a risk assessment for a new chemical is a systematic process to identify potential hazards and develop control measures. It involves:

- Gather Information: Obtain the SDS, review literature, and consult with experts to understand the chemical’s properties (toxicity, flammability, reactivity).

- Identify Hazards: Determine the potential hazards associated with handling, storage, and use of the chemical (e.g., fire, explosion, toxicity, burns).

- Identify Exposure Pathways: Analyze how workers or the environment might be exposed (e.g., inhalation, skin contact, ingestion).

- Assess Risks: Evaluate the likelihood and severity of each hazard. This might involve using quantitative methods or qualitative judgments (e.g., using a risk matrix).

- Develop Control Measures: Implement control measures to reduce or eliminate identified risks. This includes engineering controls (e.g., ventilation, enclosed systems), administrative controls (e.g., work practices, training), and PPE (e.g., gloves, respirators).

- Monitor and Review: Regularly monitor the effectiveness of implemented controls and review the risk assessment as needed.

Example: A new solvent might require the implementation of local exhaust ventilation to reduce inhalation risks and the use of specialized gloves to prevent skin absorption.

Q 13. What are the signs and symptoms of common chemical exposures?

Signs and symptoms of chemical exposure vary greatly depending on the specific chemical, the route of exposure (inhalation, skin contact, ingestion), and the concentration and duration of exposure. Some common symptoms include:

- Respiratory Issues: Coughing, shortness of breath, wheezing, burning in the throat or lungs (often from inhaling vapors or gases).

- Skin Irritation: Redness, itching, burning, blisters, rashes, or other skin reactions (from skin contact).

- Eye Irritation: Burning, stinging, redness, watering, or blurred vision (from eye contact).

- Gastrointestinal Distress: Nausea, vomiting, diarrhea, abdominal pain (from ingestion).

- Neurological Symptoms: Dizziness, headache, confusion, loss of coordination, seizures (from exposure to neurotoxic chemicals).

- Systemic Effects: More serious systemic effects can include organ damage (e.g., liver or kidney damage) and even death.

Important Note: If you suspect chemical exposure, seek immediate medical attention. Provide the medical professional with information about the specific chemical involved, the nature of the exposure, and any symptoms experienced.

Q 14. Explain the emergency response procedures for chemical incidents.

Emergency response procedures for chemical incidents must be well-defined, practiced, and readily accessible. They should be based on a thorough risk assessment and include:

- Evacuation Plan: A clear evacuation plan, including designated assembly points and escape routes, should be in place for different scenarios.

- Spill Response Procedures: Detailed procedures for containing, cleaning up, and disposing of chemical spills, including specific materials and equipment.

- Emergency Contact Information: Easy access to emergency contact numbers for fire departments, medical services, and the relevant authorities.

- PPE for Responders: Appropriate PPE (e.g., respirators, protective suits, gloves, eye protection) must be readily available and responders must be trained in their use.

- First Aid Procedures: Personnel should be trained in providing basic first aid for chemical exposures, while ensuring their own safety.

- Post-Incident Procedures: Procedures for investigating the incident, determining the cause, and implementing corrective actions to prevent future occurrences.

Example: A spill response plan for a corrosive acid would specify the use of specific neutralizing agents, absorbent materials, and appropriate PPE before attempting cleanup.

Q 15. How do you train employees on safe chemical handling and storage practices?

Employee training on safe chemical handling and storage is paramount. It’s not a one-time event but a continuous process involving several key steps. We begin with a comprehensive initial training program covering hazard communication, SDS (Safety Data Sheet) interpretation, proper PPE (Personal Protective Equipment) selection and use, spill response procedures, and the specific hazards of the chemicals used in our workplace. This initial training is typically delivered through a combination of classroom instruction, interactive modules, and hands-on demonstrations.

Beyond initial training, we implement regular refresher courses to reinforce learned behaviors and address any updates to regulations or procedures. We also conduct regular audits to assess employee competency and provide additional training or coaching as needed. For example, if we introduce a new chemical, we immediately provide targeted training to those employees who will handle it. We also emphasize a culture of safety where employees feel comfortable reporting near misses or unsafe practices without fear of reprisal, as this allows us to address potential issues proactively.

- Classroom Instruction: Lectures, presentations, and discussions about chemical hazards and safe practices.

- Interactive Modules: Online or software-based training to engage employees and test their understanding.

- Hands-on Demonstrations: Practical exercises and simulations to reinforce theoretical knowledge.

- Regular Refresher Courses: Keep employees up-to-date on best practices and address changes in regulations.

- Audits and Assessments: Ensure employees understand and follow safe chemical handling practices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate chemical inventory records?

Maintaining accurate chemical inventory records is crucial for safety and regulatory compliance. We utilize a computerized inventory management system that tracks every chemical’s receipt, storage location, quantity, date of purchase, and expiration date. This system generates alerts when quantities fall below a certain threshold, helping us to proactively manage our stock levels and prevent shortages. We conduct regular physical inventory checks to verify the accuracy of our records and reconcile any discrepancies. This two-pronged approach—combining a digital system with manual verification—minimizes errors and enhances the reliability of our inventory data.

For instance, if a spill occurs, we can quickly identify the affected chemical, its location, and the quantity lost, enabling an efficient cleanup and minimizing environmental impact. Similarly, during regulatory inspections, we can easily provide documentation demonstrating compliance with all applicable regulations.

Q 17. What is your experience with different types of chemical storage containers?

My experience encompasses a wide range of chemical storage containers, chosen based on the specific properties of the chemicals being stored. For example, we use:

- High-density polyethylene (HDPE) containers: Ideal for storing many common chemicals due to their durability and resistance to many chemicals.

- Glass containers: Used for certain chemicals, but require careful handling due to their fragility. We typically use them only when absolutely necessary and take extra precautions for storage and transport.

- Steel drums: Suitable for larger quantities of less reactive chemicals. They offer excellent protection but are heavier and require appropriate handling equipment.

- Flammable Safety Cabinets: These are specifically designed for storing flammable and combustible materials, featuring features like ventilation and fire-resistant construction.

- Cryogenic containers: For the storage of extremely low-temperature materials, utilizing vacuum insulation and specialized materials to maintain the temperature.

The selection of a container is driven by factors like chemical compatibility, container strength, size requirements, and the need for secondary containment in case of leaks or spills.

Q 18. Describe your experience with using different types of chemical labeling systems.

We employ a comprehensive chemical labeling system fully compliant with OSHA’s Hazard Communication Standard. Each container is clearly labeled with:

- Chemical name: The common and chemical name of the substance.

- Hazard warnings: Using pictograms to quickly communicate potential hazards (e.g., flammability, toxicity, corrosion).

- Precautionary statements: Instructions on how to handle the chemical safely.

- Supplier information: Contact details of the chemical’s manufacturer or supplier.

- Date of receipt: To help with inventory management and shelf-life tracking.

We utilize a standardized format for labels to ensure consistency and avoid confusion. We also regularly inspect labels to ensure they are legible and undamaged. For example, if a label becomes damaged, it is immediately replaced with a new one to prevent accidents. We use barcodes and QR codes integrated into our labeling system for efficient inventory management and easier access to SDS information.

Q 19. Explain the importance of regular inspections of chemical storage areas.

Regular inspections of chemical storage areas are critical for preventing accidents and ensuring compliance. Inspections are typically carried out weekly, and more frequently if needed, such as after a spill or a change in storage practices. We look for several things:

- Proper labeling and identification of all chemicals: Ensuring accuracy and legibility.

- Correct storage practices: Checking for incompatibilities, proper ventilation, and adherence to segregation guidelines.

- Condition of containers: Looking for leaks, corrosion, or damage.

- Adequate aisle space: To ensure easy access and movement.

- Emergency equipment availability: Checking the functionality of spill kits, eyewash stations, and safety showers.

- Proper ventilation and temperature control: Maintaining appropriate conditions for stored chemicals.

Any deficiencies identified during inspections are immediately addressed through corrective actions, which are documented and followed up. Think of it like a regular medical checkup; it proactively identifies problems before they escalate into serious issues.

Q 20. How do you ensure compliance with OSHA regulations for chemical handling and storage?

Ensuring OSHA compliance is an ongoing process that requires diligent attention to detail. We achieve this through several methods:

- Developing and implementing a comprehensive Chemical Hygiene Plan (CHP): This document outlines our procedures for handling, storing, and managing chemicals in our workplace.

- Providing comprehensive employee training: As discussed previously, regular training is critical for ensuring that employees understand and follow OSHA’s regulations.

- Maintaining accurate records: Keeping meticulous records of chemical inventory, training records, and inspections demonstrates our commitment to compliance.

- Regularly reviewing and updating our safety procedures: Staying abreast of changes in OSHA regulations and best practices is essential.

- Conducting regular safety audits and inspections: To identify and correct any potential hazards before they lead to incidents.

We also actively participate in OSHA outreach programs and workshops to stay informed about the latest changes and best practices in chemical safety.

Q 21. Describe your experience with chemical spill kits and their use.

Chemical spill kits are essential emergency response equipment, and our facility is equipped with several strategically located kits appropriate for the types of chemicals handled in each area. These kits contain absorbent materials (like spill pads and pillows), neutralizers specific to the types of chemicals we use, protective equipment (gloves, eye protection, respirators), and cleanup tools (shovels, brooms). We conduct regular inspections of these kits to ensure that they are complete, well-stocked, and all materials are within their expiration dates.

In the event of a spill, we follow a strict procedure. First, we evacuate the area and secure the scene. Then, trained personnel, wearing appropriate PPE, use the spill kit to contain, neutralize, and clean up the spill following the guidance provided on the SDS for that specific chemical. We also properly dispose of the contaminated materials according to our waste management procedures. Following the cleanup, we conduct a thorough post-incident review to identify areas for improvement in our procedures or training. This ensures we learn from every event and improve our response capabilities.

Q 22. What is your experience with various types of chemical monitoring equipment?

My experience with chemical monitoring equipment spans a wide range of technologies. I’m proficient in using fixed and portable gas detectors, capable of detecting various hazardous gases like hydrogen sulfide, carbon monoxide, and ammonia. These devices often employ electrochemical, infrared, or photoionization sensors. I’ve also extensively used photoionization detectors (PIDs) for detecting volatile organic compounds (VOCs), which are frequently encountered in many industrial settings. Beyond gas detection, I’m familiar with using continuous monitoring systems that provide real-time data on airborne contaminants. These systems often include data logging and alarm functions, crucial for maintaining a safe working environment. Finally, I’m experienced in using personal sampling pumps to collect air samples for later laboratory analysis, providing a more comprehensive picture of potential exposures.

For example, during a recent project involving the handling of solvents, I implemented a network of fixed gas detectors in the work area to provide continuous monitoring. This ensured immediate alerts in case of a leak, enabling prompt response and preventing potential harm to personnel. In contrast, for a project involving spot-checking of various work stations for VOCs, I used portable PIDs to efficiently assess the levels of these contaminants.

Q 23. Explain your experience with investigating chemical incidents.

Investigating chemical incidents requires a systematic and thorough approach. My experience includes conducting root cause analyses, interviewing witnesses, and reviewing safety documentation, including Standard Operating Procedures (SOPs) and Safety Data Sheets (SDSs). I meticulously document all findings, using photographic evidence and samples when necessary. This documentation is critical for identifying contributing factors and preventing future occurrences.

For example, I once investigated an incident involving a minor chemical spill. By carefully examining the scene, interviewing the involved personnel, and reviewing their work practices, I determined that the spill was due to improper handling of the container during transfer. The investigation resulted in the implementation of new procedures, including improved training for employees on proper handling techniques and improved labeling of containers.

Data analysis plays a significant role. Reviewing historical safety data, maintenance records of equipment and even weather conditions can help reveal patterns and underlying issues leading to incidents. It is crucial to establish timelines of events using interviews and reviewing data logs.

Q 24. How do you stay up-to-date on changes in chemical safety regulations?

Staying current on chemical safety regulations is paramount. I regularly review publications from OSHA (Occupational Safety and Health Administration), EPA (Environmental Protection Agency), and other relevant agencies. I also actively participate in professional organizations such as the AIHA (American Industrial Hygiene Association), attending conferences, webinars, and workshops to learn about the latest updates. Subscription to industry-specific journals and newsletters, keeps me informed about emerging issues and best practices. Furthermore, I often attend training courses and maintain certifications that ensure I’m up-to-date on regulations and safe practices.

For instance, the recent updates to Globally Harmonized System of Classification and Labelling of Chemicals (GHS) required significant changes in our SDS handling and employee training. I ensured our company was compliant with these new requirements in a timely manner.

Q 25. Describe your experience with different types of chemical handling equipment.

My experience encompasses various chemical handling equipment, including safety showers, eyewash stations, spill kits, and fume hoods. I am adept at selecting appropriate Personal Protective Equipment (PPE) such as gloves, respirators, and safety glasses, based on the specific chemical hazards. I’m also proficient in operating different types of pumps, transfer systems, and specialized containers used for handling various chemicals with different physical properties (viscosity, volatility, reactivity).

For example, when working with highly corrosive acids, I ensure that appropriate safety measures such as acid-resistant gloves and eye protection are used, and the transfer is done under a fume hood to prevent exposure to harmful fumes. Proper neutralising agents and spill kits are always readily available.

Q 26. What is your familiarity with different types of chemical storage racking systems?

My familiarity with chemical storage racking systems includes various designs catered to different chemical properties and safety requirements. I understand the importance of selecting appropriate racking systems based on factors such as chemical compatibility, weight capacity, and fire safety. This includes understanding the differences between bulk storage solutions, flammable chemical storage cabinets, and secondary containment systems.

For instance, when storing flammable liquids, I ensure that the racking system is designed to prevent the spread of fire and provides adequate spacing between containers to allow for ventilation. I also ensure compatibility with the chemicals stored – avoiding materials that could react negatively.

Q 27. How do you communicate chemical safety information to workers?

Communicating chemical safety information to workers is crucial for a safe workplace. I use various methods, including training sessions, on-the-job demonstrations, and readily accessible safety data sheets (SDS). I ensure the training is tailored to the worker’s specific tasks and the hazards they might encounter. I use plain language, visual aids, and interactive sessions to improve understanding and retention.

For example, when training workers on handling a new chemical, I begin by explaining its hazards using clear and concise language. I then demonstrate proper handling procedures, highlighting the importance of wearing appropriate PPE and using the correct equipment. I conduct quizzes to ensure comprehension and provide refresher training as needed.

Regular safety meetings, signage at the point of work, and utilizing digital platforms like intranets for disseminating up-to-date information are other effective communication channels. Regular audits ensure that these communications are having the desired impact.

Q 28. Describe your experience with developing and implementing chemical safety programs.

Developing and implementing chemical safety programs involves a multi-faceted approach. I begin by conducting a thorough hazard assessment to identify potential chemical hazards in the workplace. This includes reviewing existing processes, evaluating the properties of chemicals used, and analyzing potential exposure pathways.

Based on the hazard assessment, I develop a comprehensive chemical safety program which includes standard operating procedures (SOPs) for handling, storage, and disposal of chemicals. The program also incorporates emergency response plans, worker training protocols, and a system for tracking and reviewing incidents. Regular audits and inspections are scheduled to monitor effectiveness and compliance. I also ensure the program aligns with relevant regulations and best practices.

For example, I recently developed a new chemical safety program for a manufacturing facility. This involved a complete overhaul of their existing procedures and training, incorporating new technologies for leak detection and enhanced emergency response measures. The improved program resulted in a significant reduction in incidents and an improvement in worker safety.

Key Topics to Learn for Safe Handling and Storage of Chemicals Interview

- Chemical Hazard Identification and Classification: Understanding GHS (Globally Harmonized System) pictograms, labels, and Safety Data Sheets (SDS) – knowing how to interpret this information is crucial for safe handling.

- Personal Protective Equipment (PPE): Selecting and properly using appropriate PPE (gloves, respirators, eye protection, etc.) based on chemical hazards. Practical application: Knowing the limitations of different PPE types and when to escalate safety concerns.

- Storage and Containment: Safe storage practices including compatibility of chemicals, proper labeling, ventilation requirements, and emergency spill response procedures. Practical application: Designing a safe storage area for a given set of chemicals.

- Spill Response and Emergency Procedures: Developing and implementing effective spill response plans, including containment, cleanup, and disposal methods. Problem-solving approach: Thinking critically about the immediate and long-term risks associated with different spills.

- Waste Disposal and Regulatory Compliance: Understanding relevant regulations and procedures for the safe disposal of chemical waste, including proper documentation and record-keeping. Practical application: Knowing where to find and how to interpret local and national regulations.

- Risk Assessment and Mitigation: Conducting thorough risk assessments to identify potential hazards and implement control measures to minimize risks. Problem-solving approach: Analyzing scenarios and proposing effective preventive measures.

- Transportation of Chemicals: Safe transportation procedures, including proper packaging, labeling, and handling during transit. Practical application: Understanding the implications of different modes of transportation and relevant regulations.

Next Steps

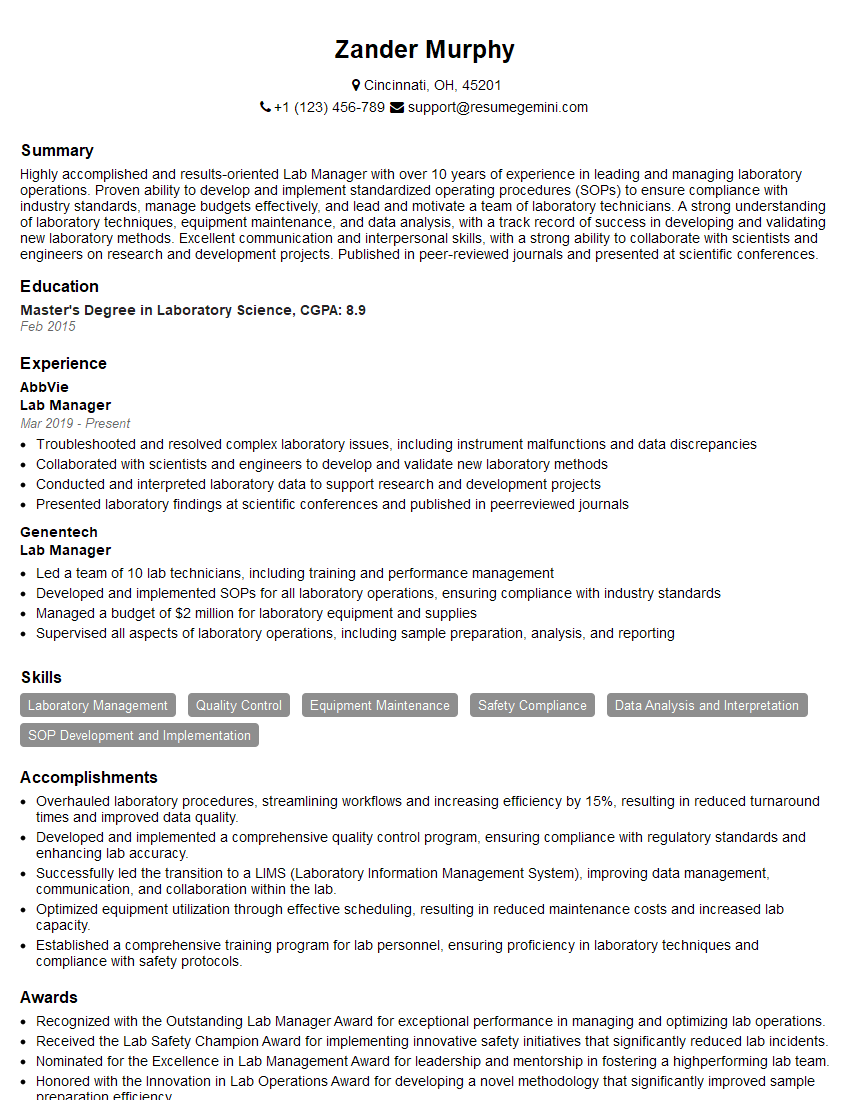

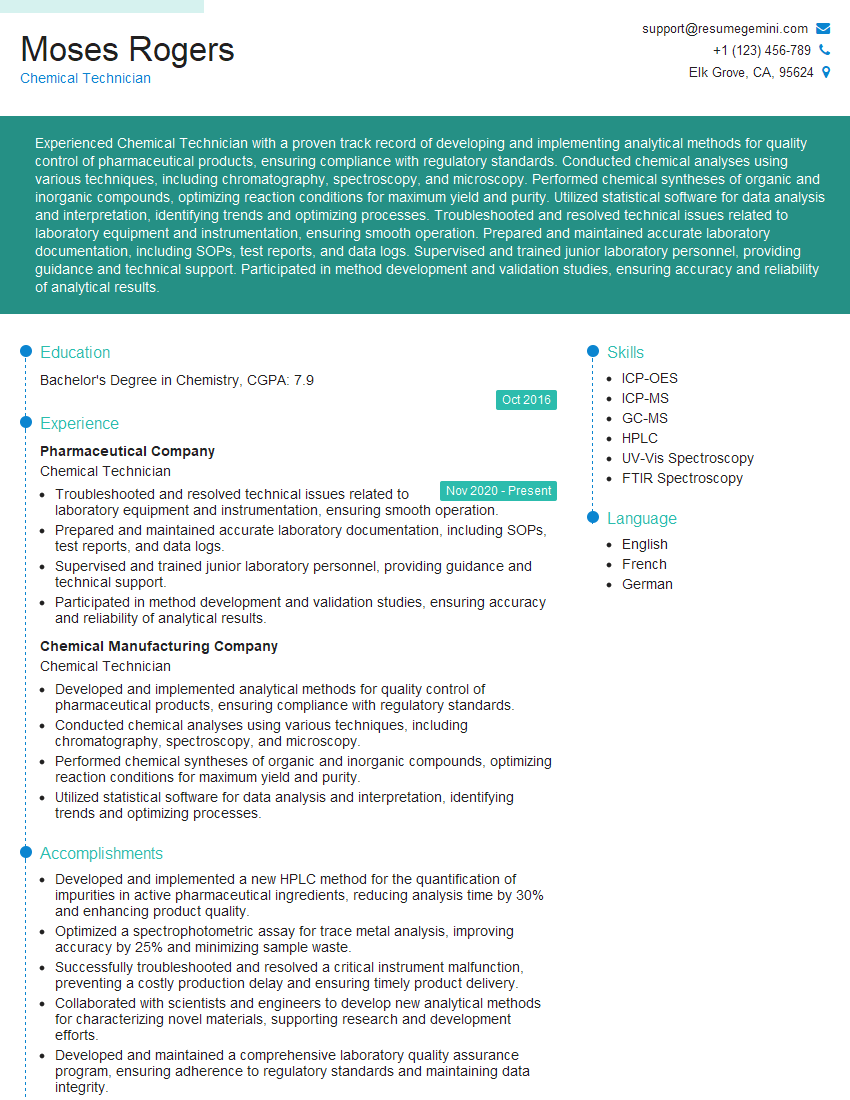

Mastering safe handling and storage of chemicals is vital for a successful and safe career in many industries. A strong understanding of these principles demonstrates your commitment to safety and professionalism, significantly enhancing your job prospects. To stand out, create an ATS-friendly resume that effectively highlights your skills and experience. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and examples of resumes tailored to the Safe Handling and Storage of Chemicals field, helping you present your qualifications in the best possible light. Invest time in creating a strong resume; it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good