Are you ready to stand out in your next interview? Understanding and preparing for Safe loading and unloading interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Safe loading and unloading Interview

Q 1. Describe your experience with different types of loading equipment.

My experience encompasses a wide range of loading equipment, from forklifts and pallet jacks to overhead cranes and conveyor systems. I’m proficient in operating and maintaining these machines, understanding their limitations and safety protocols. For instance, I’ve extensively used counterbalance forklifts for stacking pallets in warehouses, and I’ve also supervised the safe operation of reach stackers for loading containers onto ships. My experience also includes working with specialized equipment like side loaders for handling long and bulky items, ensuring efficient and safe handling for diverse cargo.

I understand the nuances of each type of equipment, including their weight capacities, maneuvering capabilities, and potential hazards. This knowledge allows me to select the most appropriate equipment for each job, ensuring optimal efficiency and safety. For example, when loading fragile goods, I would prioritize a forklift with cushioned forks and slower operation speeds over a higher-capacity machine that might risk damaging the cargo.

Q 2. Explain the importance of proper weight distribution during loading.

Proper weight distribution is paramount for safe and efficient loading. An unevenly distributed load can lead to instability, increasing the risk of tipping, structural damage to the vehicle or equipment, and accidents. Think of it like balancing a seesaw: if all the weight is on one side, it will tip over. Similarly, if the weight in a truck is concentrated on one side, it could cause instability during turns and braking.

Proper weight distribution ensures the vehicle’s center of gravity remains within safe limits. This is achieved through careful planning and loading techniques. We often use load distribution charts or specialized software to determine the optimal placement of items. For heavy goods, we strategically position them lower and closer to the vehicle’s center of gravity. Lighter goods are usually placed higher, but always within the weight limits of the upper structure. Regular checks during loading with specialized equipment such as load sensors also play a crucial role in maintaining safe weight distribution.

Q 3. How do you ensure the safety of personnel during loading and unloading operations?

Ensuring personnel safety is my top priority. This begins with a thorough pre-job briefing covering all potential hazards, emergency procedures, and the use of Personal Protective Equipment (PPE). PPE, such as high-visibility vests, safety helmets, and safety footwear, is mandatory. Clear communication is vital – a designated signaler directs the equipment operator, ensuring everyone understands the procedures. We establish designated walkways and safe zones, keeping personnel away from moving equipment and potential hazards.

Regular safety checks of equipment and the loading area are crucial. Before starting operations, I inspect forklifts, cranes, and other equipment for any mechanical issues. We also check the surrounding area for obstacles, ensuring a clear and safe working environment. Furthermore, I conduct regular training sessions to update personnel on safety procedures and best practices. By adhering to these stringent measures, we minimize the risk of workplace accidents.

Q 4. What are the common hazards associated with loading and unloading?

Loading and unloading operations present various hazards. Common risks include:

- Crushing injuries: From falling objects, being struck by equipment, or being caught between equipment and cargo.

- Struck-by hazards: Being hit by moving equipment like forklifts or cranes.

- Caught-in/between hazards: Getting trapped between equipment and cargo.

- Slips, trips, and falls: Due to uneven surfaces, spills, or inadequate lighting.

- Musculoskeletal injuries: From manual handling of heavy loads.

- Exposure to hazardous materials: If handling dangerous goods.

These hazards demand proactive risk mitigation strategies. For example, using proper lifting techniques and providing adequate training can dramatically reduce the occurrence of musculoskeletal injuries. Similarly, well-lit areas and maintained walkways can minimize slips, trips and falls.

Q 5. How do you identify and address potential hazards before starting the process?

Identifying and addressing potential hazards is a systematic process. It starts with a thorough site survey, identifying potential risks like uneven terrain, overhead obstructions, and the presence of hazardous materials. We review the load manifest to understand the cargo’s weight, dimensions, and any special handling requirements. We conduct equipment inspections to ensure everything is functioning correctly and safely.

This risk assessment guides the development of a safe work plan, defining roles, responsibilities, and safety procedures. We might implement additional safety measures, such as installing barriers or using spotters, depending on the identified risks. For example, if we’re loading a tall, unstable item, we might use additional securing straps and have a spotter guide the crane operator. This proactive approach ensures the safety of personnel and the integrity of the cargo throughout the operation.

Q 6. What are your methods for securing loads to prevent shifting or damage?

Securing loads is crucial to prevent shifting and damage during transit. The methods used depend on the cargo’s characteristics and the mode of transport. We use various securing devices, such as:

- Straps: Providing tension to hold down cargo.

- Chains: For heavier and more secure attachment.

- Ratchet straps: Offering adjustable tension for secure fastening.

- Dunnage: Wooden blocks or other materials to fill gaps and prevent shifting.

- Blocking and bracing: To immobilize cargo, especially during transit.

The technique involves strategically positioning these devices to create multiple points of contact, distributing the load’s weight evenly. We follow strict guidelines and regulations regarding the correct tension and placement of securing devices. Regular inspections throughout the journey are necessary to ensure the load remains secure, preventing costly damage and safety incidents.

Q 7. Describe your experience with different types of packaging and their impact on loading.

My experience encompasses various packaging types, from simple cardboard boxes to specialized crates and containers. The packaging significantly influences loading procedures and safety. Strong, well-designed packaging protects the goods from damage and simplifies handling. For instance, pallets wrapped in shrink wrap offer stability and prevent shifting of individual items.

Conversely, inadequate packaging can create significant challenges. Damaged or poorly designed packaging can lead to spills, breakage, and even injuries. This necessitates extra care during handling and potentially requires additional securing measures. We also consider the packaging’s material compatibility with the goods and the environmental conditions. For example, goods susceptible to moisture damage need to be packaged and loaded accordingly, considering protection from rain, humidity and condensation.

Q 8. Explain your understanding of load capacity and weight limits.

Load capacity and weight limits are crucial for safe loading and unloading. Load capacity refers to the maximum weight a vehicle, container, or structure can safely carry without compromising its structural integrity or stability. Weight limits are specific restrictions on the amount of weight allowed for different parts of the loading process. For example, a forklift might have a weight limit for its forks and a separate weight limit for its overall carrying capacity. Ignoring these limits significantly increases the risk of accidents like vehicle rollovers, structural failures, or equipment malfunctions.

Think of it like this: a shopping cart has a weight limit. If you overload it, it might tip over. Similarly, exceeding a truck’s load capacity can lead to dangerous situations. We always consult the manufacturer’s specifications and relevant regulations to determine the exact load capacity and weight limits for each load and vehicle involved.

Q 9. How do you ensure compliance with relevant safety regulations and standards?

Compliance with safety regulations is paramount. This involves thorough familiarity with OSHA (Occupational Safety and Health Administration) regulations, Department of Transportation (DOT) guidelines, and any other industry-specific standards. We meticulously follow these rules, ensuring proper training for all personnel, regular equipment inspections, and adherence to safe loading and unloading procedures. This includes using appropriate safety equipment like harnesses, securing loads properly with straps and chains, and implementing robust pre-trip inspections to identify and address potential hazards before loading begins. Documentation of all safety checks is rigorously maintained.

For instance, we always ensure that all loads are properly balanced to prevent shifting during transit. We also implement detailed risk assessments for each loading scenario, identifying potential hazards and implementing control measures to mitigate them. Regular audits and safety meetings keep everyone updated on best practices and identify areas for improvement.

Q 10. What is your process for documenting loading and unloading procedures?

Documentation is a cornerstone of our process. We use a standardized system, often involving checklists and digital logs, to document every step of the loading and unloading process. This includes recording the type and quantity of goods, weight of the load, the equipment used, the personnel involved, the time of loading and unloading, and any safety incidents or near misses. Each load is assigned a unique identifier for easy traceability. Photos and videos of secured loads are often included to provide additional verification. This detailed record-keeping aids in efficient inventory management, provides evidence of compliance, and helps in analyzing patterns and identifying potential improvements in our procedures. It’s essentially a detailed story of the entire process.

Q 11. Describe your experience with inventory management related to loading and unloading.

Inventory management is integral to efficient loading and unloading. We use inventory management software to track goods, monitor stock levels, and optimize the loading sequence. This ensures that the most urgently needed items are loaded and unloaded first. We also use barcodes or RFID tags to accurately track items throughout the process, minimizing errors and reducing the time spent searching for items. Real-time tracking provides us with up-to-the-minute visibility on inventory movement, facilitating better decision-making in handling unexpected situations or delays.

For example, we might prioritize loading perishable goods to ensure they reach their destination quickly and prevent spoilage. Efficient inventory management minimizes delays, reduces waste, and optimizes space utilization within the vehicle.

Q 12. How do you handle unexpected issues or delays during the loading and unloading process?

Unexpected issues, such as equipment malfunctions or weather delays, are handled with pre-planned contingency strategies. For equipment malfunctions, we have backup equipment and procedures in place. We prioritize safety, stopping the process if a serious issue arises. In case of weather delays, we have designated shelter areas and procedures to secure equipment and personnel. Effective communication with all involved parties ensures everyone is aware of the situation and the plan of action. We also use real-time data to quickly assess the impact of delays on other operations and adjust schedules accordingly, prioritizing the safety and integrity of the load above all else.

Think of it as having a backup plan for a road trip – you wouldn’t just drive without checking your tires or mapping out an alternate route. It’s the same with loading and unloading; proactive planning and contingency measures are crucial.

Q 13. Explain your approach to communicating with drivers and other personnel involved in the process.

Clear and concise communication is essential. We use a multi-pronged approach that includes pre-loading briefings to ensure everyone understands the plan, detailed instructions regarding load placement and securing, and regular updates during the process. We utilize two-way radios and other communication technologies for quick and effective information sharing. We encourage questions and feedback to create a collaborative environment and maintain a culture of safety. Clear communication prevents miscommunications, reduces errors, and fosters a safe working environment. It’s not just about giving instructions; it’s about building a shared understanding of the process.

Q 14. How do you ensure the safe operation of forklifts or other material handling equipment?

Safe operation of forklifts and other material handling equipment is ensured through rigorous training, regular inspections, and adherence to strict operational procedures. Operators must be certified and receive refresher training regularly. Equipment undergoes routine maintenance checks to identify potential issues before they lead to accidents. We enforce the use of Personal Protective Equipment (PPE) and designated operating areas to prevent collisions and accidents. Proper load-handling techniques, such as ensuring stability and avoiding overloading, are emphasized during training. Regular safety audits help to identify and correct any unsafe practices or equipment deficiencies before they lead to incidents.

Imagine a pilot needing to undergo regular check-ups and training to maintain flight proficiency – the same principle applies to forklift operators to ensure safe and efficient operations.

Q 15. Describe your experience with pallet stacking and racking procedures.

My experience with pallet stacking and racking procedures is extensive, encompassing various warehouse environments and industry best practices. Safe and efficient pallet stacking is crucial for maximizing space, preventing damage, and ensuring worker safety. I’m proficient in understanding weight capacity limits for both pallets and racking systems, following the principles of FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) inventory management as needed.

For example, I’ve worked in facilities utilizing both selective racking (individual pallet access) and drive-in racking (block stacking) systems. In each case, my approach involves a careful assessment of the load’s weight and dimensions, ensuring proper pallet placement to avoid overloading or instability. I’m also experienced in using specialized equipment like forklifts and pallet jacks, adhering strictly to safety regulations for operation and maintenance.

Furthermore, I’m meticulous about maintaining clear aisle space for safe maneuverability of equipment and ensuring that all stacked pallets are properly secured, using appropriate bracing or strapping where necessary, particularly for taller stacks. Regular inspections of the racking system for damage and proper functionality are a key part of my routine. A visual inspection before beginning work is standard practice to prevent accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your methods for preventing damage to goods during loading and unloading?

Preventing damage to goods during loading and unloading is paramount. My methods focus on a multi-faceted approach encompassing careful handling, proper securing, and environmental considerations. This begins with a pre-loading inspection of the goods and packaging to identify any potential vulnerabilities. Fragile items are clearly labeled and handled with extra care.

Proper securing techniques are crucial. This includes using appropriate bracing, dunnage (protective materials), and strapping to prevent shifting or damage during transit. I’m skilled in using various types of securing equipment, from simple cardboard separators to specialized high-strength straps and corner boards, depending on the nature of the goods being handled. For example, I’ve successfully prevented damage to glass containers by using inflatable dunnage bags that conform to the shape of the product.

Environmental factors also play a significant role. Extreme temperatures, moisture, and direct sunlight can all damage goods. I ensure that all goods are protected from the elements during loading and unloading. This might involve using tarps, weatherproof covers, or selecting appropriate storage areas within the vehicle or warehouse.

Q 17. How do you handle damaged goods during loading or unloading operations?

Handling damaged goods requires a systematic approach to minimize further loss and maintain accountability. First, I thoroughly document the damage, including photographs and detailed descriptions. This documentation is crucial for insurance claims and traceability. The type and extent of damage are noted, along with the suspected cause if it’s apparent.

Next, damaged goods are segregated from undamaged goods to prevent further contamination or damage. Depending on the severity of the damage and the nature of the goods, the damage may be repairable, or the goods may need to be disposed of according to company policies and environmental regulations. For example, slight damage to packaging may be repaired on-site. However, severely damaged or contaminated goods may need to be properly disposed of. I’m also familiar with protocols for handling hazardous materials if they are involved.

Finally, all steps involved in the handling of damaged goods are meticulously documented, including disposal methods and any relevant communication with relevant parties. Transparency and accurate record-keeping are crucial in these situations.

Q 18. Explain your experience with different loading techniques (e.g., roll-on/roll-off, container loading).

My experience with various loading techniques is broad, including roll-on/roll-off (RoRo), container loading, and conventional truck loading. Each method requires different skills and considerations.

Roll-on/roll-off (RoRo) operations involve driving vehicles directly onto and off of a vessel or transport. This requires careful maneuvering, awareness of weight limits, and understanding of the vessel’s securement system. I’ve worked in ports ensuring safe and efficient loading and unloading of vehicles and heavy machinery.

Container loading involves loading goods into standardized shipping containers. This necessitates efficient space utilization and securement of goods within the container to prevent shifting during transit. I’m experienced in optimizing space for maximum load capacity while maintaining stability. Proper bracing and securing of goods is critical here to avoid damage and ensure compliance with shipping regulations.

Conventional truck loading involves loading goods onto standard trucks. This calls for attention to weight distribution and securement to prevent imbalances and damage. I’m familiar with various loading techniques for different types of goods, using straps, pallets, and other methods to ensure secure and efficient loading.

Q 19. What are your procedures for dealing with spills or leaks during loading?

Dealing with spills or leaks during loading requires immediate and decisive action to prevent further contamination and ensure safety. My procedure begins with assessing the nature of the spill, identifying any hazardous materials involved.

Safety is paramount; I ensure that the area is secured to prevent access, and appropriate personal protective equipment (PPE), such as gloves, eye protection, and possibly respirators, are worn. Next, I take steps to contain the spill, using absorbent materials like spill pads or booms to prevent its spread. The type of absorbent material used depends on the nature of the spilled substance; for instance, absorbent materials specifically designed for oils or chemical spills will be used instead of regular rags.

After containment, the spilled material is cleaned up according to safety protocols and environmental regulations. This might involve using specialized cleaning agents. Thorough documentation of the spill, including the type of substance, quantity, and cleanup methods used, is crucial. Finally, a thorough inspection of the surrounding area is performed to ensure no further issues exist.

Q 20. How do you ensure the cleanliness and organization of the loading dock area?

Maintaining a clean and organized loading dock is essential for safety and efficiency. My procedures involve a multi-pronged approach. Firstly, regular cleaning is scheduled, including sweeping, mopping, and removal of debris. This reduces the risk of accidents caused by slips, trips, or falls.

Secondly, a designated area for different materials is implemented. Pallets, empty containers, and other equipment are stored in specified locations, minimizing congestion and improving efficiency. Clear signage is used to indicate designated areas for various purposes. Clear markings on the ground improve traffic flow and reduces confusion.

Thirdly, preventative measures are implemented to minimize future mess. This includes implementing leakproof containers and regular checks of equipment to prevent spills or leaks. Regular inspections of the loading dock area help identify any potential hazards before they become a problem. Finally, all personnel are encouraged to maintain a clean and orderly workspace, making it everyone’s responsibility to contribute to maintaining cleanliness.

Q 21. What is your experience with using loading documentation such as bills of lading?

I have extensive experience using loading documentation, primarily bills of lading. I understand that the bill of lading serves as a contract between the shipper, carrier, and receiver, outlining the terms of the shipment. My use of bills of lading involves several key steps.

Before loading, I carefully verify the information on the bill of lading against the actual goods being loaded. This includes checking the quantity, description, and condition of the goods to ensure accuracy. Discrepancies are immediately reported to the relevant parties.

During loading, I meticulously track the loading process, noting any significant events or issues that may affect the shipment, such as damages or delays. The bill of lading is signed by the relevant parties to confirm the goods were loaded and received in good condition.

After loading, I ensure that a copy of the signed bill of lading is retained for record-keeping purposes. This documentation is crucial for tracking shipments, resolving discrepancies, and handling insurance claims in case of any damage or loss.

Q 22. Describe your understanding of hazardous materials handling procedures during loading.

Hazardous materials handling during loading demands meticulous adherence to safety protocols. It begins with proper identification and classification of the hazardous materials using the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) or similar systems. This involves checking the Safety Data Sheet (SDS) for each material to understand its hazards, required handling procedures, and appropriate PPE.

- Segregation: Incompatible materials must be segregated to prevent dangerous reactions. For instance, oxidizers should never be stored near flammable materials.

- Packaging and Containment: Materials must be properly packaged and secured to prevent leaks or spills. This includes using appropriate containers, ensuring seals are intact, and employing secondary containment where necessary.

- Labeling and Documentation: All containers must be clearly labeled with the correct hazard warnings, and detailed loading manifests must be maintained, recording the type and quantity of hazardous materials loaded.

- Emergency Response Planning: Before loading, emergency response plans should be in place, identifying potential hazards and outlining procedures for spills, leaks, or other incidents. This should include communication protocols and access to emergency equipment.

For example, during the loading of corrosive chemicals, we’d ensure the use of specialized, leak-proof containers, and the loading personnel would wear appropriate PPE including chemical-resistant gloves, eye protection, and aprons. Furthermore, spill kits would be readily available in case of an accident.

Q 23. What steps do you take to ensure the security of the loading dock area?

Securing the loading dock is crucial for preventing theft, accidents, and unauthorized access. My approach involves a multi-layered security system:

- Access Control: Restricting access to authorized personnel only, typically through keycard systems or designated personnel. Visitors should be escorted and monitored.

- Surveillance: Installing CCTV cameras with clear visibility of the entire loading dock area, both internally and externally, to monitor activities and deter theft.

- Lighting: Adequate lighting is vital for preventing accidents and enhancing visibility, especially during night operations. Motion-sensor lights can increase security further.

- Regular Inspections: Conducting regular inspections of the loading dock area to identify and address potential safety hazards, such as damaged flooring, obstructions, or faulty equipment.

- Emergency Procedures: Clearly defined emergency procedures, including contact information for emergency services, should be posted prominently.

Think of it like securing your home – multiple layers of protection offer the best defense. In the event of a suspected security breach, I’d immediately contact security personnel and follow established protocols.

Q 24. How do you maintain a safe working environment during loading and unloading?

Maintaining a safe working environment during loading and unloading involves proactive measures and consistent vigilance. It starts with proper training and communication:

- Training: Ensuring all personnel receive thorough training on safe loading and unloading procedures, including hazard identification, proper lifting techniques, and emergency protocols.

- Communication: Establishing clear communication channels between loaders, drivers, and warehouse staff to coordinate activities and avoid misunderstandings. This includes using hand signals or radios.

- Housekeeping: Maintaining a clean and organized loading dock area free from debris, spills, and obstructions to prevent accidents. This includes proper waste disposal procedures.

- Equipment Maintenance: Regularly inspecting and maintaining loading equipment, such as forklifts and pallet jacks, to ensure they are in good working order and functioning safely.

- Ergonomics: Implementing ergonomic principles to minimize strain and injuries. This includes using proper lifting techniques and providing ergonomic tools.

For instance, we might use a system of colored cones to delineate safe walkways and loading zones, providing clear visual cues to everyone on the dock.

Q 25. Describe your experience with using personal protective equipment (PPE).

My experience with PPE is extensive. I understand that the correct PPE varies depending on the task and potential hazards. I ensure that all personnel use the appropriate PPE before commencing any loading or unloading activity.

- Safety Helmets: Protecting against falling objects.

- Safety Glasses/Goggles: Protecting against flying debris or chemical splashes.

- High-Visibility Clothing: Improving visibility in low-light conditions.

- Gloves: Protecting hands from cuts, abrasions, and chemical exposure (specific glove type depends on the material being handled).

- Steel-Toe Boots: Protecting feet from crushing hazards.

- Hearing Protection: Protecting against noise from machinery.

- Respiratory Protection: Protecting against dust, fumes, or gases.

Regular inspections of PPE and prompt replacement of damaged items are crucial. I emphasize the importance of proper PPE use through training and regular reminders, considering it a fundamental aspect of safety.

Q 26. How do you handle conflicts or disagreements regarding loading procedures?

Conflicts regarding loading procedures are addressed through open communication and a collaborative approach. I believe in fostering a respectful and safe work environment.

- Active Listening: I listen carefully to all sides of the disagreement, ensuring everyone feels heard.

- Facilitation: I facilitate a discussion where everyone can express their concerns and perspectives.

- Objective Assessment: I objectively evaluate the situation, considering all relevant safety regulations and procedures.

- Finding Common Ground: I work with all parties to find a mutually agreeable solution that prioritizes safety.

- Documentation: Any agreements or changes to procedures are documented and communicated to all relevant personnel.

For example, if there was a disagreement about the best method for securing a particular load, I’d involve all stakeholders – the loading crew, the driver, and possibly supervisors – to discuss the options, review safety guidelines, and arrive at a consensus that prioritizes safety and efficiency.

Q 27. What are your methods for continuous improvement of safety procedures in loading and unloading?

Continuous improvement of safety procedures is a priority. I use a multi-pronged approach:

- Regular Safety Meetings: Conducting regular safety meetings to discuss potential hazards, near misses, and incidents, to identify areas for improvement.

- Data Analysis: Analyzing accident data and near-miss reports to pinpoint trends and implement corrective actions.

- Employee Feedback: Actively soliciting feedback from employees to identify areas of concern and implement improvements based on their suggestions.

- Staying Updated: Keeping abreast of the latest safety regulations, best practices, and industry standards.

- Safety Audits: Conducting regular safety audits to evaluate the effectiveness of existing safety procedures and identify areas needing attention.

For example, if we noticed an increase in minor injuries related to lifting, we might invest in new equipment like lifting aids or provide additional training on proper lifting techniques. The key is a culture of continuous learning and adaptation.

Q 28. Describe a time you had to solve a safety problem related to loading or unloading.

During the loading of a particularly large and heavy piece of equipment, the securing straps proved insufficient, leading to a near-miss incident where the equipment shifted during transit. The problem was the improper assessment of the equipment’s weight and center of gravity, combined with the use of standard straps instead of specialized heavy-duty ones.

To solve this, I first stopped the loading process immediately, ensuring the safety of everyone involved. Then:

- Re-assessment: We accurately re-weighed the equipment and determined its center of gravity to ensure appropriate weight distribution.

- Proper Strapping: We replaced the standard straps with heavy-duty, ratchet-straps designed for the specific weight and size of the equipment. These straps were strategically positioned to distribute the weight effectively.

- Additional Support: We added additional support using wooden blocks to prevent any movement during transit.

- Training Reinforcement: We reinforced training for the loading crew emphasizing the importance of accurate weight estimation, proper strap selection, and load securing techniques.

This incident highlighted the importance of thorough pre-loading checks and the necessity of using the right equipment for the job. We amended our procedures to include a mandatory double-check on weight and equipment assessment before commencing any heavy-load operation.

Key Topics to Learn for Safe Loading and Unloading Interviews

- Understanding Weight Distribution and Center of Gravity: Learn how to calculate and manage weight distribution to prevent tipping and ensure stability during loading and unloading operations. Consider different load types and vehicle capacities.

- Proper Securing Techniques: Explore various methods for securing loads, including the use of straps, chains, and other equipment. Understand the importance of appropriate tension and placement to prevent shifting during transit.

- Hazard Identification and Risk Assessment: Practice identifying potential hazards associated with loading and unloading, such as uneven surfaces, unstable loads, and equipment malfunctions. Develop strategies for mitigating these risks.

- Equipment Operation and Maintenance: Gain a solid understanding of the operation and maintenance of relevant equipment, including forklifts, cranes, and pallet jacks. This includes pre-operation checks, safe operating procedures, and recognizing signs of malfunction.

- Regulations and Compliance: Familiarize yourself with relevant safety regulations and industry best practices related to loading and unloading. Understand the importance of documentation and compliance procedures.

- Communication and Teamwork: Practice effective communication with team members and supervisors to coordinate loading and unloading operations safely and efficiently. Understand the importance of clear instructions and signal communication.

- Emergency Procedures: Learn about established emergency procedures in case of accidents or incidents during loading and unloading. Know how to react appropriately and prioritize safety.

- Practical Problem-Solving: Develop your ability to assess and solve problems related to load stability, equipment malfunctions, and unexpected challenges that might arise during loading and unloading.

Next Steps

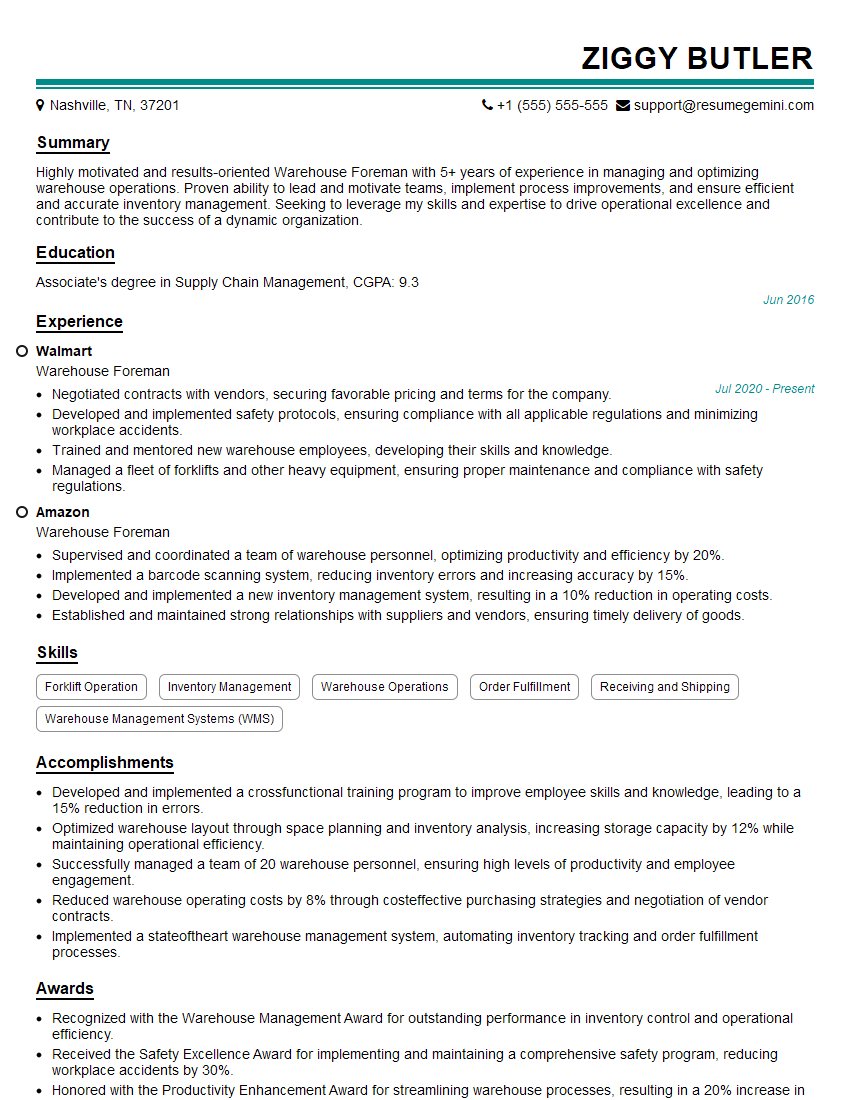

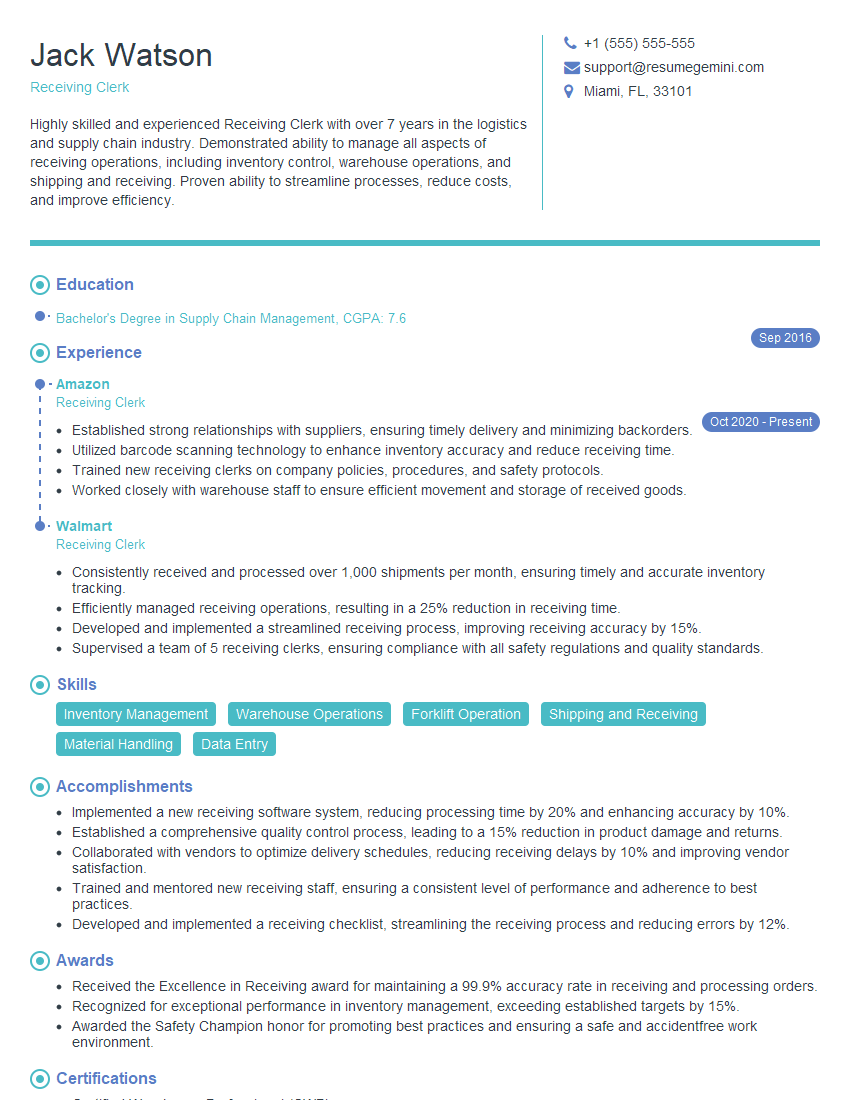

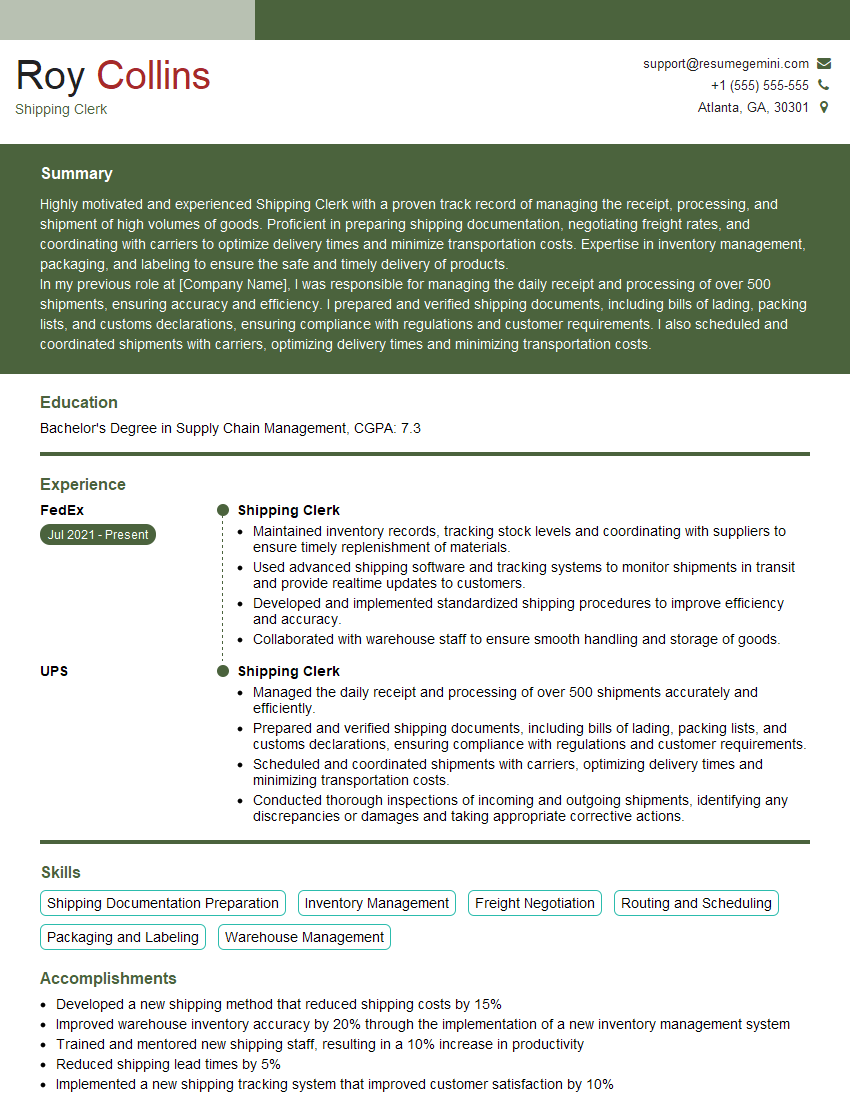

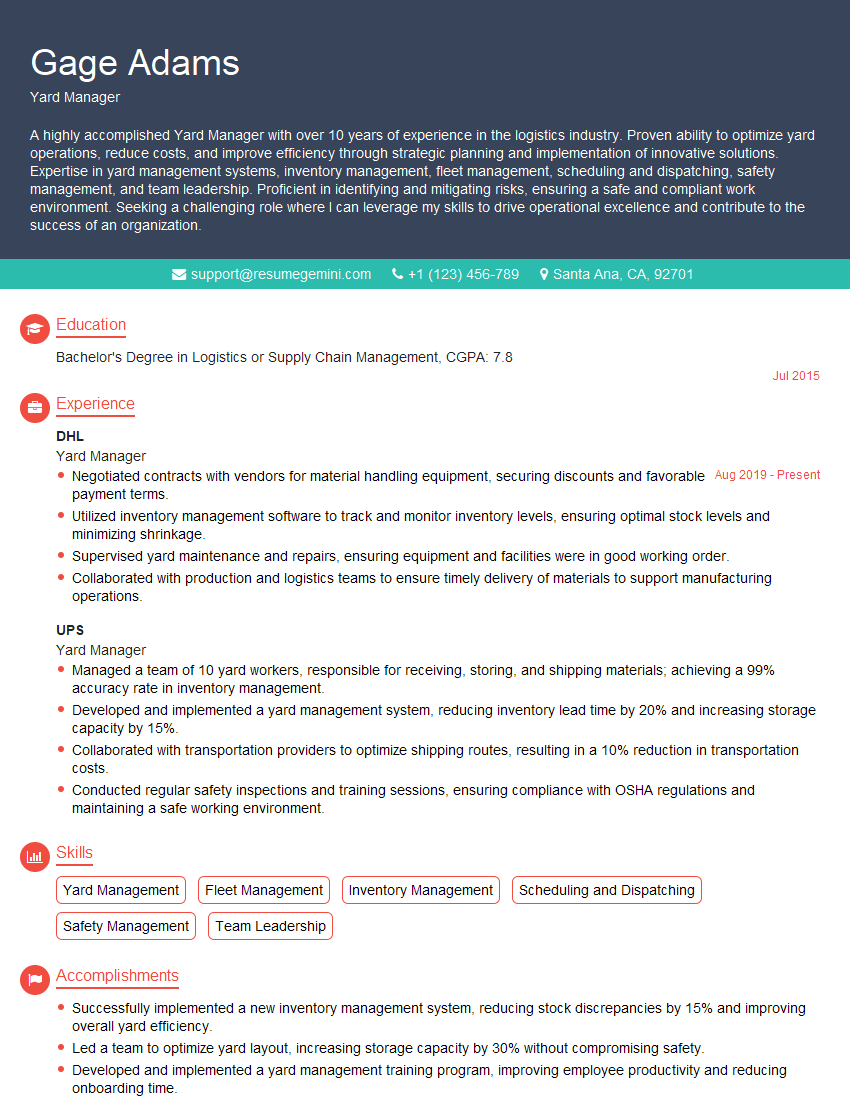

Mastering safe loading and unloading techniques is crucial for career advancement in logistics, warehousing, and transportation. Demonstrating a strong understanding of safety protocols and best practices will significantly enhance your job prospects and make you a valuable asset to any employer. To increase your chances of securing your dream role, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to the Safe loading and unloading field to help guide you. Take this opportunity to craft a compelling resume that showcases your qualifications and sets you apart from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good