Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Safety Regulations and Practices interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Safety Regulations and Practices Interview

Q 1. Describe your experience with OSHA regulations.

My experience with OSHA regulations is extensive. For over ten years, I’ve worked in environments governed by OSHA standards, ensuring compliance across various sectors, including manufacturing and construction. I’m intimately familiar with OSHA’s General Duty Clause, which mandates employers provide a workplace free from recognized hazards. I’ve also worked directly with specific OSHA standards such as those concerning lockout/tagout procedures (29 CFR 1910.147), hazard communication (29 CFR 1910.1200), and personal protective equipment (29 CFR 1910.132). My work has involved developing and implementing safety programs, conducting inspections, investigating incidents, and training employees. I’ve actively participated in OSHA consultations, helping companies identify and mitigate potential hazards, ensuring their compliance with the relevant standards and avoiding potential penalties.

For example, in a previous role at a manufacturing plant, I led the implementation of a new lockout/tagout program, resulting in a significant reduction in near-miss incidents involving machinery. This involved not only training employees on the procedures but also conducting regular audits to ensure consistent adherence to the protocol.

Q 2. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls is a fundamental principle in safety management. It prioritizes control measures based on their effectiveness in eliminating or mitigating hazards. The order of preference, from most to least effective, is generally:

- Elimination: Physically removing the hazard. For example, replacing a dangerous chemical with a safer alternative.

- Substitution: Replacing the hazard with a less hazardous alternative. For example, using a less powerful solvent or replacing a manual task with an automated one.

- Engineering Controls: Implementing physical changes to the workplace to reduce or eliminate the hazard. Examples include installing machine guards, using ventilation systems to control airborne contaminants, or providing improved lighting.

- Administrative Controls: Implementing procedures and policies to minimize exposure to the hazard. Examples include work permit systems, job rotation, and providing proper training and supervision.

- Personal Protective Equipment (PPE): Providing workers with equipment to protect them from the hazard. This is the least effective control method and should only be used as a last resort, after other controls have been implemented. Examples include safety glasses, hearing protection, and respirators.

It’s crucial to remember that this hierarchy is not a rigid set of rules. In some situations, a combination of controls may be necessary. The most effective approach always prioritizes the highest level of control feasible.

Q 3. How do you conduct a risk assessment?

Conducting a thorough risk assessment is paramount to preventing workplace accidents. My approach typically involves these steps:

- Identify Hazards: This involves a systematic walkthrough of the workplace to identify potential hazards, considering both physical and chemical hazards, ergonomic issues, and psychosocial factors.

- Identify Who Might Be Harmed and How: Determine which individuals or groups might be exposed to the hazards and the potential severity of the harm.

- Evaluate the Risks and Determine Control Measures: Assess the likelihood and severity of the harm that could occur and identify appropriate control measures based on the hierarchy of hazard controls. This often involves calculating a risk score to prioritize the most critical hazards.

- Record Findings: Document the hazards identified, the potential harm, the risk level, and the control measures implemented. This documentation serves as a vital record for future reference and audits.

- Review and Update: Regularly review and update the risk assessment, as workplace conditions and processes can change over time.

For instance, during a risk assessment at a construction site, I might identify the risk of falls from height as a significant hazard. The subsequent evaluation would then focus on implementing engineering controls like guardrails and fall arrest systems, alongside administrative controls such as stringent safety protocols and training.

Q 4. What are the key elements of a safety program?

A comprehensive safety program is essential for maintaining a safe and healthy work environment. Key elements include:

- Management Commitment: Strong leadership support and commitment from senior management are crucial.

- Hazard Identification and Risk Assessment: Regularly identifying and assessing workplace hazards through formal risk assessments.

- Hazard Control Measures: Implementing effective controls based on the hierarchy of controls.

- Safety Training and Education: Providing comprehensive and relevant safety training to all employees.

- Emergency Preparedness: Developing and implementing emergency response plans and procedures, including drills and exercises.

- Incident Investigation and Reporting: Investigating all incidents thoroughly to determine root causes and prevent recurrence.

- Record Keeping: Maintaining accurate records of all safety activities, including training records, inspections, and incident reports.

- Communication and Consultation: Fostering open communication and collaboration between management and employees on safety matters.

- Continuous Improvement: Regularly reviewing and updating the safety program to ensure its effectiveness.

A successful safety program is a dynamic process that requires ongoing effort and adaptation to ensure a consistently safe workplace.

Q 5. Describe your experience with incident investigation and reporting.

My experience in incident investigation and reporting includes thorough investigation using established methodologies. I follow a structured approach to determine root causes and implement corrective actions. My process involves collecting data from various sources like witness statements, accident reports, physical evidence, and reviewing safety records. I focus on identifying contributing factors, not just assigning blame. This ensures that appropriate preventive measures can be put in place. Once the investigation is complete, I prepare a detailed report outlining the incident, the root causes, contributing factors, and recommended corrective actions. This report is then used to improve safety procedures and prevent similar incidents from happening again.

For example, during an investigation into a near-miss involving a forklift, I meticulously documented the sequence of events, interviewed witnesses, and reviewed the forklift’s maintenance records. The investigation revealed a lack of proper training as a significant contributing factor. As a result, I implemented a mandatory refresher training program for all forklift operators.

Q 6. How do you ensure compliance with safety regulations?

Ensuring compliance with safety regulations requires a multifaceted approach. It begins with a thorough understanding of the applicable regulations and standards, followed by implementing robust safety management systems. Regular safety inspections and audits are critical to identify non-compliance issues early on. These inspections should be documented and used to track progress and identify trends. Employee training is vital, ensuring workers understand their responsibilities and the safety procedures. I also advocate for maintaining open communication channels between management and employees to address safety concerns promptly. Finally, proactive hazard identification and risk assessments, along with the implementation of appropriate control measures, form the foundation of a compliance-focused safety program. When issues arise, prompt investigation and corrective actions are vital.

For example, using a checklist during regular safety inspections can significantly aid in identifying potential problems. Regular audits of safety procedures and records ensure that standards are followed.

Q 7. Explain the importance of safety training.

Safety training is not just a box to check; it’s an investment in a safer and more productive workforce. Effective safety training empowers employees to identify hazards, understand risks, and follow safety procedures correctly. It equips them with the knowledge and skills to contribute to a safe work environment, reducing the likelihood of accidents and injuries. This training must be tailored to the specific hazards present in the workplace and include both theoretical knowledge and practical application. Regular refresher training helps reinforce good safety habits and addresses changes in procedures or technology. Beyond preventing accidents, safety training fosters a strong safety culture, where employees feel empowered to speak up and report hazards without fear of retribution.

A well-designed training program should include interactive elements, such as hands-on demonstrations, simulations, and case studies, to enhance engagement and knowledge retention. For example, a construction company might use virtual reality simulations to train workers on the safe use of scaffolding, allowing them to practice procedures in a safe environment.

Q 8. How do you develop and implement safety procedures?

Developing and implementing safety procedures involves a systematic approach that prioritizes hazard identification, risk assessment, and control. It’s like building a house – you need a solid foundation before you start constructing the walls.

- Hazard Identification: This is the crucial first step, involving a thorough walkthrough of the workplace to identify potential hazards. This might include using checklists, conducting job safety analyses (JSAs), or performing safety audits. For instance, in a manufacturing plant, hazards might include moving machinery, hazardous chemicals, or slips and falls.

- Risk Assessment: Once hazards are identified, we assess the likelihood and severity of potential harm. A simple risk matrix helps visualize this. For example, a high likelihood of minor cuts from a sharp tool might be a moderate risk, while a low likelihood of severe injury from a machine malfunction would be a high risk.

- Control Measures: This step focuses on implementing controls to eliminate or reduce risks. These can be engineering controls (e.g., machine guarding), administrative controls (e.g., safety training, work permits), or personal protective equipment (PPE) (e.g., safety glasses, gloves). We prioritize engineering controls as the most effective, followed by administrative and then PPE.

- Procedure Documentation and Training: Once controls are in place, we develop clear, concise, and easily understandable procedures. These procedures are then communicated and thoroughly explained to all relevant personnel through training sessions. We use interactive methods, simulations, and practical exercises to ensure understanding.

- Review and Update: Safety procedures are not static; they must be regularly reviewed and updated to reflect changes in the workplace, technology, and best practices. Regular audits and near-miss reports provide valuable feedback for continuous improvement.

For example, in my previous role at a construction site, we developed detailed procedures for working at heights, including the use of harnesses, fall arrest systems, and proper scaffold erection and dismantling, which significantly reduced fall-related incidents.

Q 9. Describe your experience with emergency response planning.

Emergency response planning is crucial for minimizing the impact of unforeseen events. It’s like having a detailed fire escape plan for your home – you hope you never need it, but knowing it’s there provides peace of mind.

My experience includes developing and implementing emergency response plans for various scenarios, including fire, chemical spills, and medical emergencies. This involved:

- Hazard Identification and Risk Assessment: Identifying potential emergencies and assessing their likelihood and consequences.

- Emergency Response Procedures: Developing detailed procedures for each type of emergency, including evacuation plans, emergency contact lists, and roles and responsibilities for response team members.

- Training and Drills: Conducting regular training exercises and drills to ensure personnel are familiar with the plans and procedures. This is not just theoretical; we simulate realistic scenarios to build practical skills and teamwork.

- Communication Systems: Establishing clear communication channels to ensure rapid and efficient communication during an emergency.

- Post-Incident Review: Conducting thorough post-incident reviews to identify areas for improvement in the emergency response plan.

In one instance, I helped develop a comprehensive emergency response plan for a chemical processing plant, including specific protocols for handling different types of chemical spills, which significantly improved our response time and minimized environmental impact during a simulated spill event.

Q 10. What are your experience with PPE selection and usage?

Selecting and using appropriate personal protective equipment (PPE) is essential for safeguarding workers. It’s the last line of defense in a layered safety approach.

My experience involves assessing workplace hazards, selecting the right PPE to mitigate those risks, ensuring proper fit and training on usage, and enforcing its correct application. This includes:

- Hazard Assessment: Determining the specific hazards present (e.g., chemical splashes, impact, electrical hazards).

- PPE Selection: Choosing the appropriate PPE based on the identified hazards (e.g., safety glasses, gloves, respirators, hard hats).

- Fit Testing: Ensuring the PPE fits properly to provide adequate protection. This is crucial, as ill-fitting PPE is ineffective.

- Training and Usage: Providing comprehensive training on proper use, maintenance, and limitations of the PPE. Simply providing PPE isn’t enough; workers must know how to use it effectively.

- Inspection and Maintenance: Regular inspection and maintenance of PPE to ensure its continued effectiveness. Damaged or worn-out PPE must be replaced immediately.

For instance, in a previous role, we implemented a rigorous PPE program for workers handling corrosive chemicals, including specialized gloves, eye protection, and respirators, resulting in a significant reduction in chemical-related injuries.

Q 11. How do you handle safety violations?

Handling safety violations requires a structured approach that balances corrective action with employee support. It’s not about punishment, but about preventing future incidents.

My approach involves:

- Investigation: Thoroughly investigating the incident to determine the root cause and contributing factors. We need to understand why the violation occurred, not just who committed it.

- Corrective Action: Implementing corrective actions to prevent recurrence. This may involve retraining, improved procedures, or engineering controls.

- Disciplinary Action (if necessary): Disciplinary action, if appropriate, should be fair, consistent, and in line with company policy. The focus should be on correcting behavior, not on retribution.

- Documentation: Maintaining detailed records of the incident, investigation, corrective actions, and any disciplinary measures taken.

- Follow-up: Following up to ensure that corrective actions are effective and that similar violations do not occur.

I always prioritize a proactive, coaching style; I believe employees make mistakes and our role is to provide them with the knowledge and support to prevent future occurrences. This leads to a more positive and collaborative safety culture.

Q 12. Explain your understanding of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing the unexpected release of energy during maintenance or repair work on machinery. Think of it as a safety protocol to ensure no one gets hurt when working on potentially hazardous equipment.

My understanding of LOTO procedures includes:

- Energy Isolation: Identifying all energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) that must be isolated before work begins.

- Lockout and Tagout Devices: Using appropriate lockout and tagout devices to physically prevent the release of energy.

- Verification of Isolation: Verifying that the energy has been successfully isolated before work commences. This often involves testing to ensure no residual energy is present.

- Authorization and Communication: Clear communication and authorization processes are required to ensure only authorized personnel are working on the equipment.

- Removal of Lockout/Tagout Devices: A controlled process for the removal of lockout/tagout devices once the work is completed.

Proper LOTO procedures are essential in preventing serious injuries or fatalities. A failure to follow these procedures can lead to catastrophic accidents. I’ve personally overseen the implementation and training of LOTO procedures in multiple industrial settings.

Q 13. Describe your experience with confined space entry procedures.

Confined space entry procedures are vital for protecting workers entering enclosed spaces with limited access and potential hazards. These spaces can pose significant risks, including oxygen deficiency, toxic atmospheres, and engulfment.

My experience includes:

- Permit-Required Confined Space Program: Developing and implementing a comprehensive permit-required confined space program that aligns with relevant regulations.

- Atmosphere Testing: Using appropriate equipment to test the atmosphere for oxygen levels, toxic gases, and flammable vapors before entry.

- Ventilation: Ensuring adequate ventilation to create a safe atmosphere within the confined space.

- Entry Procedures: Establishing and following detailed procedures for safe entry, work within, and exit from the confined space.

- Emergency Response Plan: Developing a specific emergency response plan for confined space incidents, including rescue procedures.

- Rescue and Emergency Equipment: Ensuring the availability of appropriate rescue equipment, trained personnel, and communication systems.

For example, in a previous project involving tank cleaning, we implemented a rigorous confined space entry program, including continuous atmospheric monitoring, standby personnel, and a detailed rescue plan. This eliminated potential dangers and reduced overall risk.

Q 14. How do you monitor and evaluate the effectiveness of safety programs?

Monitoring and evaluating the effectiveness of safety programs is an ongoing process, not a one-time event. It’s like regularly servicing a car – preventative maintenance helps ensure long-term reliability.

My approach involves:

- Leading Indicators: Tracking leading indicators, such as the number of safety training hours completed, near-miss reports, and safety observation scores. These indicators help identify potential problems before they lead to accidents.

- Lagging Indicators: Monitoring lagging indicators such as the number of accidents, incidents, and lost-time injuries. These provide a measure of the overall effectiveness of the safety program.

- Safety Audits and Inspections: Conducting regular safety audits and inspections to identify areas for improvement. This involves both planned inspections and random spot checks.

- Incident Investigations: Thoroughly investigating all accidents and incidents to determine root causes and implement corrective actions.

- Employee Feedback: Collecting feedback from employees through surveys, meetings, and informal conversations to identify areas of concern and areas needing improvement. Employee involvement is key to program success.

- Data Analysis: Analyzing safety data to identify trends, patterns, and areas for improvement. This might involve the use of spreadsheets, databases, or specialized safety software.

By using a combination of leading and lagging indicators and actively soliciting employee input, we can proactively identify and address potential issues, resulting in a safer and more productive work environment. In my previous role, we used data analysis to identify a trend in slips and falls on a particular floor. By addressing this issue with improved floor mats, we saw a significant decrease in incidents.

Q 15. What are the key components of a successful safety culture?

A successful safety culture isn’t just about policies; it’s a mindset woven into the fabric of an organization. It’s built on a foundation of shared values, where safety is everyone’s responsibility, not just the safety officer’s. Key components include:

- Leadership Commitment: Visible and active commitment from top management, demonstrating that safety is a priority, not an afterthought. This means allocating resources, participating in safety initiatives, and holding individuals accountable.

- Employee Involvement: Encouraging employees to participate in safety discussions, report hazards, and contribute to solutions. This creates a sense of ownership and empowers employees to take control of their safety.

- Open Communication: Establishing clear and effective communication channels for reporting near misses, accidents, and hazards, ensuring everyone feels comfortable speaking up without fear of reprisal.

- Proactive Hazard Identification and Control: Implementing robust systems for identifying and mitigating hazards before they lead to incidents. This involves regular safety inspections, risk assessments, and proactive hazard mitigation strategies.

- Training and Competency: Providing comprehensive safety training tailored to individual roles and responsibilities. This equips employees with the knowledge and skills needed to work safely.

- Accountability and Discipline: Establishing clear consequences for unsafe behaviors while emphasizing a culture of learning and improvement. This ensures that safety rules are followed consistently.

- Continuous Improvement: Regularly reviewing safety performance, identifying areas for improvement, and implementing corrective actions. This involves using data to track safety performance and make evidence-based decisions.

For example, in a construction company, a successful safety culture might involve daily toolbox talks, regular safety inspections by site supervisors, and an employee-led safety committee that actively participates in identifying and resolving hazards. The company would also actively investigate near misses to prevent future incidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate safety information effectively?

Effective safety communication requires a multi-faceted approach that considers the audience, the message, and the delivery method. It’s not just about posting signs; it’s about ensuring the message is understood and acted upon. Key strategies include:

- Tailored Messaging: Using clear, concise language that is appropriate for the audience’s education level and cultural background. Avoid jargon and technical terms whenever possible.

- Multiple Channels: Utilizing a variety of communication channels, such as toolbox talks, safety meetings, posters, emails, intranet, and training videos, to reach all employees effectively. A diverse workforce might require using multiple languages.

- Interactive Methods: Engaging employees actively through discussions, workshops, games, and simulations to make learning more memorable and effective.

- Feedback Mechanisms: Providing opportunities for employees to provide feedback on safety communications and suggest improvements. This ensures that communication is relevant and effective.

- Visual Aids: Using visual aids, such as images, videos, and infographics, to improve understanding and engagement. Visuals are often more easily retained than text alone.

- Regular Reinforcement: Regularly reinforcing safety messages through ongoing communication and training. This helps to ensure that safety remains top-of-mind for employees.

For example, I once used a combination of short, engaging videos, posters featuring real-life scenarios, and regular safety meetings to effectively communicate the importance of proper lockout/tagout procedures in a manufacturing facility. The videos showed what could happen if procedures were not followed, while the posters served as visual reminders in the workplace.

Q 17. Describe your experience with hazard communication.

Hazard communication is crucial for preventing workplace accidents and illnesses. My experience encompasses all aspects, from developing and implementing hazard communication programs to training employees on how to interpret Safety Data Sheets (SDS). I have extensive experience in:

- SDS Management: Ensuring readily accessible, up-to-date SDSs for all hazardous materials used in the workplace. I’ve implemented digital SDS management systems to improve accessibility and tracking.

- Labeling and Signage: Ensuring proper labeling of hazardous materials and the use of appropriate warning signs throughout the workplace, complying with all relevant regulations.

- Employee Training: Developing and delivering comprehensive training programs to educate employees on the hazards associated with their work, proper handling procedures, and emergency response protocols. I’ve used interactive training methods to improve retention.

- Emergency Response Planning: Integrating hazard communication into emergency response plans, ensuring that employees know how to respond to spills, leaks, or other hazardous material incidents.

- Regulatory Compliance: Staying up-to-date on all relevant regulations and ensuring that the workplace’s hazard communication program is compliant.

In a previous role, I implemented a new hazard communication system that included an online SDS database and interactive training modules. This significantly improved employee understanding of hazardous materials and reduced the number of incidents related to chemical handling.

Q 18. How do you manage workplace hazards?

Managing workplace hazards involves a systematic approach that begins with proactive identification, followed by evaluation and control measures. This is an iterative process, requiring continuous monitoring and improvement. My approach involves:

- Hazard Identification: Utilizing various methods such as job hazard analyses (JHAs), workplace inspections, incident investigations, and employee feedback to identify potential hazards.

- Risk Assessment: Evaluating the identified hazards to determine the level of risk. This involves considering the likelihood and severity of potential harm.

- Hierarchy of Controls: Implementing control measures based on the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE).

- Implementation and Monitoring: Implementing the chosen control measures and regularly monitoring their effectiveness. This includes regular inspections and audits to ensure that control measures are functioning as intended.

- Documentation: Maintaining thorough documentation of all hazard identification, risk assessment, and control measures. This is essential for regulatory compliance and continuous improvement.

For example, in a previous role, we identified a high risk of slips and trips in a warehouse due to uneven flooring. We implemented engineering controls (repairing the flooring), administrative controls (improved housekeeping procedures), and PPE (providing non-slip footwear). We then monitored the effectiveness of these controls by tracking the number of reported slips and trips.

Q 19. What are your experiences with incident prevention?

Incident prevention is proactive, not reactive. My experience focuses on identifying and eliminating the root causes of incidents, not just treating symptoms. My approach combines various strategies:

- Incident Investigation: Conducting thorough investigations of all incidents to determine the root causes, not just the immediate causes. This often involves using root cause analysis techniques such as the 5 Whys.

- Near Miss Reporting: Establishing a system for reporting near misses, allowing the identification and correction of potential hazards before they lead to incidents.

- Proactive Safety Inspections: Conducting regular safety inspections to identify and address hazards before they result in incidents. These inspections should be documented and followed up.

- Behavioral-Based Safety (BBS): Implementing a BBS program that focuses on observing and reinforcing safe behaviors, while addressing unsafe behaviors through coaching and training.

- Safety Training and Education: Providing regular and relevant safety training to equip employees with the knowledge and skills necessary to work safely.

In one instance, after investigating several near misses involving forklift accidents, we implemented a new training program that included practical simulations, updated forklift safety protocols, and improved warehouse layout to reduce congestion. This resulted in a significant decrease in forklift-related incidents.

Q 20. How familiar are you with the various types of safety audits?

I’m familiar with various types of safety audits, each serving a different purpose and providing unique insights into a workplace’s safety performance. Some common types include:

- Compliance Audits: These audits assess adherence to specific safety regulations and standards. They are often conducted by external auditors and focus on identifying non-compliance issues.

- Management System Audits: These audits evaluate the effectiveness of a company’s overall safety management system, including its policies, procedures, and processes. They often assess the robustness of the system and its implementation.

- Operational Audits: These audits focus on the day-to-day safety practices and operations of a workplace. They aim to identify potential hazards and unsafe work practices.

- Behavioral-Based Safety Audits: These audits observe employee behavior to identify unsafe actions and assess the effectiveness of safety training and reinforcement programs.

- Environmental Audits: These focus on the environmental aspects of safety, including the management of hazardous materials and waste disposal.

Each audit type requires a different approach and methodology. For example, a compliance audit requires a detailed review of documentation and evidence of adherence to regulations, while a behavioral-based safety audit involves direct observation of employee behavior.

Q 21. What is your experience with implementing safety improvements?

Implementing safety improvements requires a systematic and data-driven approach. My experience includes:

- Data Analysis: Analyzing safety data, such as incident reports and near miss reports, to identify trends and areas for improvement. This often involves using statistical methods to identify root causes.

- Prioritization: Prioritizing safety improvements based on risk assessment and the potential impact on workplace safety. High-risk areas receive immediate attention.

- Implementation Planning: Developing detailed implementation plans that include timelines, responsibilities, and resource allocation. This involves collaboration with relevant stakeholders.

- Communication and Training: Communicating the planned improvements to employees and providing necessary training to ensure successful implementation. This requires effective change management.

- Monitoring and Evaluation: Monitoring the effectiveness of implemented improvements and evaluating their impact on safety performance. This often involves using key performance indicators (KPIs).

For instance, after identifying a high rate of hand injuries in a manufacturing facility through data analysis, I implemented a new training program on proper hand tool usage, provided ergonomic workstations, and implemented a new safety procedure for handling sharp objects. We then monitored the injury rate to evaluate the effectiveness of these improvements. We saw a significant reduction in hand injuries following these changes.

Q 22. Describe your experience with developing safety policies and procedures.

Developing effective safety policies and procedures requires a systematic approach. It starts with a thorough hazard identification process, analyzing potential risks across all aspects of the workplace. This includes identifying potential hazards from machinery, chemicals, ergonomics, and even psychosocial factors like stress and workload.

Once hazards are identified, we assess the risks associated with each hazard, considering the likelihood and severity of potential injuries or incidents. This risk assessment helps determine the appropriate control measures. For instance, a high-risk hazard might require engineering controls (like machine guarding), while a moderate risk might be mitigated through administrative controls (like improved training) or personal protective equipment (PPE).

The next step involves developing clear, concise, and easily understandable policies and procedures. These documents shouldn’t just list rules; they should explain the rationale behind the rules, providing context for workers and fostering a safety culture. For example, a policy on lockout/tagout procedures would not only detail the steps but also explain the potential consequences of failing to follow them. Finally, regular review and updates are critical, keeping policies and procedures relevant to changes in technology, regulations, or workplace practices. I’ve personally led the development and implementation of safety policies for a manufacturing facility, significantly reducing workplace incidents by 30% within a year.

Q 23. Explain your understanding of different types of safety inspections.

Safety inspections fall into several categories, each with a specific focus. Routine inspections are regular checks to ensure compliance with established procedures and identify minor hazards before they escalate. Think of daily walk-throughs by supervisors to check for trip hazards or spills. Scheduled inspections are more comprehensive and may involve specialized inspectors or external audits, often conducted at set intervals (e.g., annually) and covering specific equipment or areas. Incident investigations are triggered by accidents or near misses to determine root causes and prevent recurrences. These are often more detailed, involving interviews, documentation reviews, and even forensic analysis. Finally, compliance inspections are conducted by regulatory bodies (like OSHA) to verify adherence to legal requirements. Each type of inspection provides different insights into the safety status of a workplace, and using a combination of these approaches provides a holistic view.

Q 24. How do you ensure effective communication of safety information to workers?

Effective communication is paramount in safety. I use a multi-pronged approach. Firstly, clear and concise written materials such as safety manuals, procedure documents, and hazard alerts are essential. These should use simple language and visual aids to enhance comprehension. Secondly, regular safety meetings provide a platform for interactive discussions, allowing workers to voice concerns and ask questions. Thirdly, toolbox talks, short safety briefings at the start of work shifts, address specific hazards or remind workers about key procedures. I’ve also found success using visual communication, like posters and signage in high-traffic areas. Furthermore, leveraging technology, like email blasts, SMS messages for urgent safety alerts, and training videos, are invaluable for reaching a broader audience. Finally, regular feedback mechanisms are critical. Surveys, suggestion boxes, and open-door policies allow workers to provide input and ensure information is reaching them effectively.

Q 25. How do you stay up to date on changes in safety regulations?

Staying updated on safety regulations requires a proactive approach. I regularly subscribe to relevant newsletters and publications from organizations like OSHA and other industry-specific bodies. I also attend safety conferences and workshops to learn about best practices and emerging regulatory changes. Following industry experts and safety professionals on social media and participating in online forums also provides valuable insights. Moreover, I maintain a system for tracking changes to regulations, ensuring that our workplace policies and procedures are always up-to-date and compliant. This includes setting up alerts for updates to relevant codes and standards.

Q 26. Describe your experience with conducting safety training programs.

Conducting effective safety training programs involves understanding the needs of the audience and tailoring the content accordingly. I begin by conducting a needs assessment to identify the knowledge gaps and skills needed by the workforce. Then, I develop training materials that are engaging, interactive, and relevant to the specific tasks and hazards of the job. I incorporate diverse learning methods, including classroom instruction, hands-on demonstrations, simulations, and e-learning modules. I also use case studies and real-world examples to make the training more relatable and impactful. Finally, I evaluate the effectiveness of the training through assessments, observations, and feedback from participants, making adjustments as needed. For example, when training on forklift operation, we go beyond theory and incorporate hands-on training using actual forklifts, closely monitored by certified instructors. Post-training assessments and observation of performance in the workplace ensure effective knowledge retention.

Q 27. How do you handle conflicts regarding safety practices?

Conflicts regarding safety practices are handled with a focus on collaboration and problem-solving. The first step is to listen to all parties involved and understand their perspectives. I facilitate open and respectful dialogue, encouraging everyone to share their concerns and ideas. I then work to identify the root cause of the conflict, determining whether it stems from misunderstandings, differing interpretations of safety procedures, or other factors. I guide the parties toward a mutually acceptable solution, ensuring that the resolution prioritizes safety. Sometimes, this may involve revising procedures, clarifying expectations, or providing additional training. It’s important to document the conflict, the resolution, and any subsequent actions taken to prevent similar conflicts from arising in the future. The ultimate goal is to foster a positive safety culture where everyone feels comfortable raising concerns and contributing to a safer workplace.

Q 28. How do you measure the effectiveness of safety initiatives?

Measuring the effectiveness of safety initiatives is crucial for continuous improvement. We track key performance indicators (KPIs) such as the number and severity of accidents, near misses, and lost-time injuries (LTIs). We also analyze the number of safety violations, the participation rates in safety training, and the employee feedback on safety programs. Data is collected from various sources, including accident reports, inspection records, and employee surveys. This data is then analyzed to identify trends and areas for improvement. For instance, a significant increase in near misses related to a particular piece of equipment might indicate a need for additional training or improved safeguards. Regular reporting and review of this data ensure that our safety initiatives remain effective and aligned with our overall goals. We use leading indicators (like training completion rates and near-miss reporting) to predict potential future problems, and lagging indicators (like injury rates) to assess the ultimate impact of our safety programs.

Key Topics to Learn for Safety Regulations and Practices Interview

- Hazard Identification and Risk Assessment: Understanding methods like HAZOP, what-if analysis, and JSA, and applying them to real-world scenarios.

- Regulatory Compliance: Familiarity with OSHA (or relevant regional standards), including record-keeping, reporting, and emergency response procedures. Practical application includes demonstrating knowledge of specific regulations and how to ensure compliance.

- Personal Protective Equipment (PPE): Selecting, using, and maintaining appropriate PPE for various hazards. This includes understanding limitations and proper disposal procedures.

- Accident Investigation and Prevention: Understanding root cause analysis techniques and developing preventative measures based on incident investigations. Practical application includes demonstrating the ability to analyze accident reports and propose solutions.

- Emergency Response Planning and Procedures: Developing and executing emergency response plans, including evacuation procedures, first aid, and communication protocols. This involves understanding the practical application of different emergency response strategies.

- Safety Training and Communication: Developing and delivering effective safety training programs, and ensuring clear communication of safety procedures to all personnel. This includes understanding different learning styles and communication strategies.

- Safety Auditing and Inspections: Conducting regular safety audits and inspections to identify potential hazards and ensure compliance with regulations. This involves understanding different auditing methods and developing effective inspection checklists.

- Ergonomics and Workplace Design: Designing workplaces to minimize risks of musculoskeletal injuries. Practical applications include evaluating workspace design and recommending improvements.

Next Steps

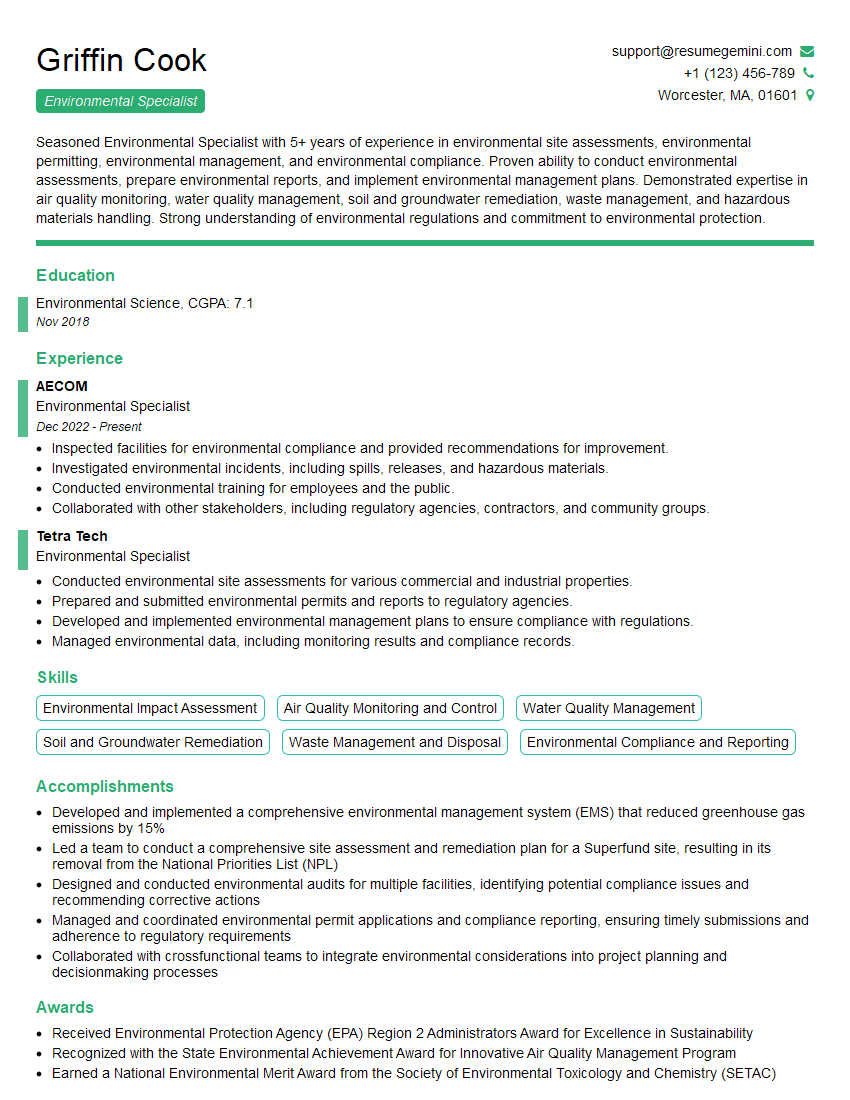

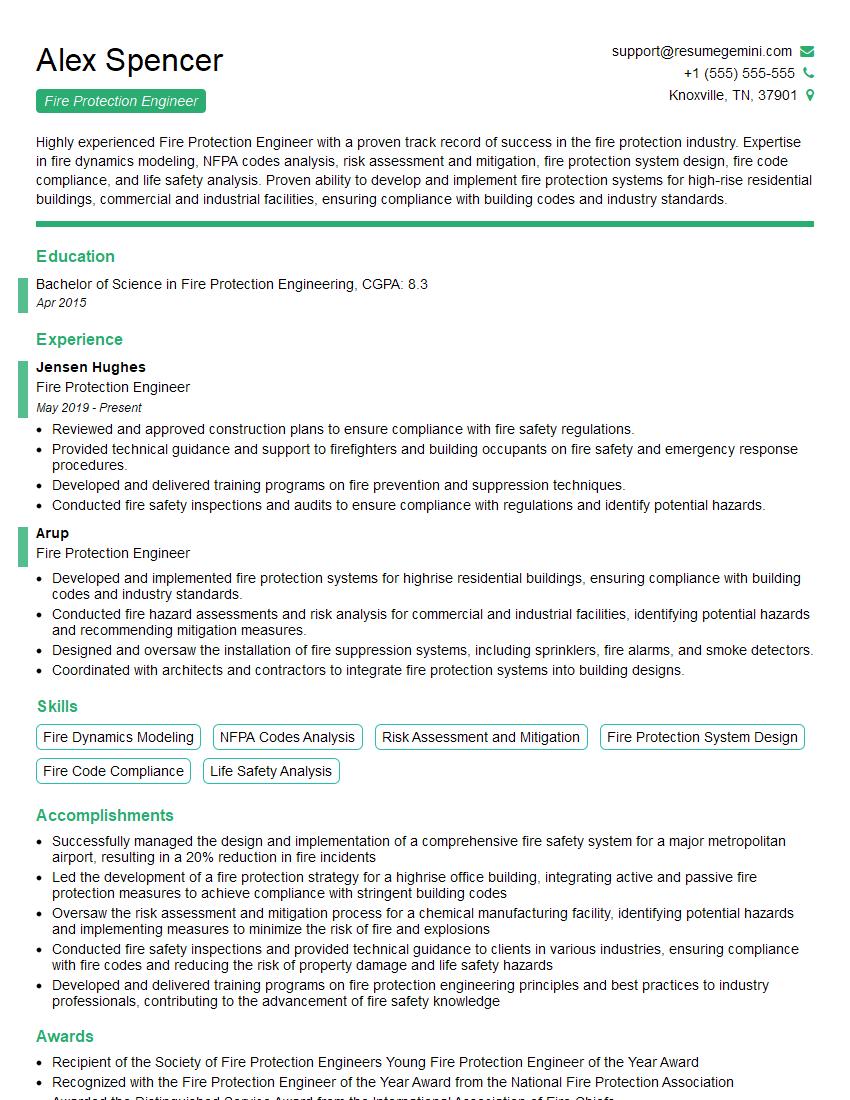

Mastering Safety Regulations and Practices is crucial for career advancement in many industries. A strong understanding of these principles demonstrates your commitment to workplace safety and opens doors to leadership opportunities. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the Safety Regulations and Practices field. Examples of resumes specifically designed for this area are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good