Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Screen Preparation and Emulsion Coating interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Screen Preparation and Emulsion Coating Interview

Q 1. What are the different types of emulsion used in screen printing?

Screen printing emulsions are photosensitive liquids that, when exposed to light, harden and become insoluble. The choice of emulsion significantly impacts print quality and durability. There are two main types: Diazo and Photopolymer.

- Diazo Emulsions: These are more traditional, water-based emulsions that are relatively inexpensive and easy to use. They offer good sensitivity to UV light, but are generally less durable than photopolymers and can be more susceptible to pinholes.

- Photopolymer Emulsions: These are typically more expensive but provide superior durability, higher resolution, and better longevity of the screen. They are less prone to pinholes and offer increased resistance to chemicals used in the printing process. They come in both water-based and solvent-based varieties, each with its own advantages and disadvantages.

The choice between diazo and photopolymer depends on factors like budget, desired print quality, the type of ink being used, and the number of prints needed. For high-volume, high-quality work, photopolymer is often preferred. For simpler projects or budget-conscious applications, diazo might suffice.

Q 2. Describe the process of emulsion coating a screen.

Emulsion coating is a crucial step in screen printing, ensuring a uniform, photosensitive layer on the screen mesh. Think of it like applying a very fine, even coat of paint to a finely woven fabric. This process typically involves these steps:

- Prepare the Screen: Thoroughly clean the screen to remove any dust, debris, or previous emulsion. Degreasing is vital for proper adhesion.

- Mix the Emulsion: Carefully follow the manufacturer’s instructions for mixing the emulsion. This often involves gentle stirring to avoid introducing air bubbles.

- Coating the Screen: Using a scoop coater or a trough and squeegee, apply a thin, even layer of emulsion to both sides of the screen. This requires a steady hand and consistent pressure to ensure uniformity. Multiple coats may be necessary, allowing each coat to dry slightly before applying the next.

- Remove Excess Emulsion: After coating, carefully wipe away any excess emulsion from the edges of the screen to prevent build-up.

- Dry the Screen: The emulsion must be dried thoroughly in a controlled environment, away from direct sunlight or dust, to ensure proper curing.

Consistency is key. Practice and attention to detail will lead to a superior, more consistent coating.

Q 3. What factors affect the exposure time during screen printing?

Exposure time during screen printing is critical; it determines how much of the emulsion hardens and, therefore, the quality of the stencil. Several factors influence the required exposure time:

- Emulsion Type: Photopolymer emulsions typically require shorter exposure times than diazo emulsions due to their higher sensitivity to UV light.

- Light Source: The intensity of the light source (e.g., UV lamp) directly impacts exposure time. A more powerful lamp will require less time.

- Distance from Light Source: The closer the screen is to the light source, the shorter the exposure time needed. The inverse square law applies here.

- Screen Mesh: Finer mesh screens may require slightly longer exposure times as the light has to penetrate more tightly woven mesh.

- Film Density: The opacity of the film used in the exposure process affects the amount of light that reaches the emulsion. A denser film will necessitate a longer exposure time.

Proper exposure testing is crucial. Conduct test exposures with varying times to find the optimal setting for your specific setup and materials.

Q 4. How do you ensure even emulsion coating across the screen?

Achieving an even emulsion coating is vital for a consistent print. Here’s how to ensure uniformity:

- Proper Emulsion Mixing: Thoroughly mix the emulsion to achieve consistent viscosity.

- Consistent Coating Technique: Use a consistent back-and-forth motion when applying the emulsion with a scoop coater or squeegee. Maintain even pressure throughout the process.

- Multiple Thin Coats: Applying several thin coats is better than one thick coat. This helps to minimize unevenness and prevent the formation of drips or runs.

- Proper Drying Conditions: A clean, dust-free environment and consistent drying temperature are crucial for preventing inconsistencies during drying.

- Screen Condition: Ensure your screen is clean and free from any imperfections that might affect the even distribution of the emulsion. A slightly bowed screen can also cause uneven coating, so maintaining the proper screen tension is crucial.

Practice makes perfect. Spend time refining your coating technique to achieve consistent results.

Q 5. What are the different methods of screen drying?

Screen drying is a critical step in ensuring the emulsion cures properly and adheres well to the mesh. Several methods exist:

- Air Drying: This is the simplest method, often suitable for smaller screens. It involves allowing the coated screen to dry naturally in a clean, dust-free environment, usually in a dark, well-ventilated area. This can take several hours, depending on the emulsion type and environmental conditions.

- Forced Air Drying: This utilizes fans or specialized drying racks to accelerate the drying process. It helps to maintain a consistent temperature and airflow, leading to more even drying.

- Vacuum Drying: This method is more sophisticated and uses vacuum pressure to remove moisture from the emulsion quickly and evenly. It’s particularly beneficial for larger screens or when time is a factor.

- Oven Drying: Controlled temperature ovens offer precise drying, allowing for consistent curing of the emulsion. The temperature and duration must be carefully controlled to avoid damaging the emulsion or the screen itself.

The choice of drying method depends on the scale of operation, available equipment, and the characteristics of the emulsion.

Q 6. Explain the importance of proper screen tension.

Proper screen tension is crucial for achieving crisp, clean prints and preventing issues during the emulsion coating and printing processes. A screen that’s too loose will sag, leading to uneven coating and potential distortions in the print. A screen that’s too tight can be prone to breaking and may be more difficult to coat evenly.

Think of it like stretching a canvas – the right amount of tension ensures a smooth, flat surface. Proper tension allows for a uniform application of emulsion and prevents the mesh from bowing or stretching during the printing process. This directly results in better ink transfer and minimizes unwanted ink bleed or feathering.

Tension is usually achieved using a screen stretching machine, and the ideal tension level varies depending on the mesh count and screen material.

Q 7. What are the common problems encountered during emulsion coating and how do you troubleshoot them?

Several common problems can arise during emulsion coating. Here are some examples and their troubleshooting strategies:

- Uneven Coating: This is often due to inconsistent coating technique, improper emulsion mixing, or a dirty or damaged screen. Solution: Practice a consistent coating technique, remix the emulsion, thoroughly clean the screen, and ensure proper screen tension.

- Pinholes: Small holes in the emulsion layer can cause ink bleed. This can result from dust particles, improper mixing, or the emulsion being too thick. Solution: Work in a clean environment, carefully filter the emulsion, ensure proper mixing, and adjust the viscosity as needed.

- Emulsion Cracking: This happens when the emulsion dries too quickly or is exposed to extreme temperatures. Solution: Slow down the drying process using appropriate techniques, control the drying temperature, and ensure proper ventilation.

- Emulsion Not Adhering: Poor adhesion might be due to a dirty screen or improper degreasing. Solution: Thoroughly clean and degrease the screen before coating.

- Build-up of Emulsion on Edges: This is typically caused by applying too much emulsion or insufficient wiping after coating. Solution: Use a smaller amount of emulsion and carefully wipe away the excess promptly.

Regular maintenance of equipment and attention to detail throughout the entire process can help prevent many of these issues.

Q 8. How do you determine the appropriate mesh count for a particular printing job?

Choosing the right mesh count is crucial for successful screen printing. It directly impacts the detail and ink deposit of your print. A higher mesh count (more threads per inch) results in finer details and thinner ink deposits, ideal for intricate designs and fine lines. Conversely, a lower mesh count allows for thicker ink deposits, better suited for bold graphics or textured effects.

The selection process considers several factors:

- Design complexity: Highly detailed designs require higher mesh counts (e.g., 156-305 threads per inch) to reproduce fine lines and small details accurately. Simpler designs can use lower mesh counts (e.g., 43-86 threads per inch).

- Ink viscosity: Thicker inks necessitate lower mesh counts to allow for proper ink flow through the screen. Thinner inks can tolerate higher mesh counts.

- Substrate material: The material you’re printing on influences mesh count selection. Printing on a thick, textured material might require a lower mesh count than printing on smooth paper.

- Desired ink deposit: Do you need a heavy ink deposit (lower mesh) for opacity or a fine layer (higher mesh) for a subtle effect?

For example, printing a detailed photographic image on a t-shirt might require a 190 mesh, while printing a bold logo on a poster might only need a 60 mesh.

Q 9. Describe the process of reclaiming a screen.

Screen reclaiming is the process of removing the old emulsion from a screen to prepare it for reuse. It’s an essential step in cost-effective screen printing. Improper reclaiming can damage the screen or leave residue that affects future prints.

The process typically involves these steps:

- Remove excess emulsion: Scrape off as much dried emulsion as possible using a squeegee or specialized reclaim tool.

- Emulsion removal: Use a screen cleaning solution designed for emulsion removal. These solutions are often alkaline-based and carefully follow the manufacturer’s instructions. Different types of emulsion require specific cleaning methods.

- Scrubbing: Scrub the screen thoroughly using a sponge or brush to loosen and remove remaining emulsion. Pay attention to areas where emulsion tends to cling.

- Rinse: Rinse the screen thoroughly with water, ensuring all emulsion residue and cleaning solution are gone.

- Drying: Allow the screen to dry completely before storing or recoating.

Remember to always wear appropriate protective gear, like gloves and eye protection, during the reclaiming process. Dispose of the used emulsion and cleaning solutions responsibly according to local regulations.

Q 10. What safety precautions are necessary when working with emulsion?

Emulsion is a photosensitive chemical; therefore, safety precautions are paramount. Working with emulsion without proper safety measures can lead to skin irritation, eye damage, or allergic reactions.

- Protective gear: Always wear gloves (nitrile gloves are recommended), eye protection (safety glasses or goggles), and a dust mask to prevent inhalation of emulsion particles.

- Ventilation: Work in a well-ventilated area to minimize exposure to fumes. Using a respirator is beneficial when working in poorly ventilated spaces or when dealing with large quantities of emulsion.

- Skin contact: Avoid direct skin contact with emulsion. Wash your hands thoroughly with soap and water immediately after handling emulsion, even if you’ve worn gloves.

- Eye contact: If emulsion contacts your eyes, immediately flush them with copious amounts of water for at least 15 minutes and seek medical attention.

- Disposal: Dispose of used emulsion and cleaning solutions properly according to local environmental regulations.

Always refer to the specific safety data sheet (SDS) provided by your emulsion manufacturer for detailed instructions and precautions.

Q 11. How do you handle a screen with emulsion defects?

Emulsion defects can ruin a print. Identifying and addressing these defects promptly is crucial. Common defects include pinholes, scratches, and uneven coatings.

The approach depends on the severity and type of defect:

- Minor defects (pinholes, small scratches): If the defects are minor and localized, you might be able to touch up the emulsion using a fine-tipped brush and a small amount of fresh, unsensitized emulsion. Allow it to dry completely before exposure.

- Major defects (large scratches, uneven coating): If the damage is extensive, it’s often best to reclaim the screen and start over. Trying to repair significant defects often results in uneven prints or further complications.

- Prevention is key: Careful handling during the coating and drying process significantly reduces the risk of defects. Maintaining a clean workspace and using appropriate techniques are essential.

If a screen has consistent defects across multiple attempts, it is worth assessing the factors like emulsion age, coating technique, and screen quality.

Q 12. Explain the process of degreasing a screen before coating.

Degreasing is a critical preliminary step before emulsion coating. It ensures proper adhesion of the emulsion to the screen, preventing peeling or lifting during the printing process. Oils, dirt, and other residues on the screen can repel the emulsion, creating areas where it doesn’t adhere effectively.

The degreasing process typically involves:

- Screen cleaning: Use a screen degreaser, which is usually a solvent-based cleaner, to remove any dirt, dust, or debris from the screen. Follow the manufacturer’s instructions for dilution and application.

- Scrubbing: Use a soft sponge or brush to scrub the screen thoroughly, ensuring the degreaser reaches all areas.

- Rinsing: Thoroughly rinse the screen with clean water, removing all traces of the degreaser. Any remaining degreaser can interfere with emulsion adhesion.

- Drying: Allow the screen to air dry completely before applying the emulsion. A damp screen will prevent proper emulsion adhesion.

After degreasing, the screen should be clean, dry, and free from any residue, creating an optimal surface for the emulsion to bond with.

Q 13. What are the different types of screens used in screen printing?

Several types of screens are used in screen printing, each suited for different applications and printing requirements. The choice depends on factors like mesh count, material, and the desired print quality.

- Polyester mesh: The most common type, offering a good balance of strength, durability, and image quality. Available in various mesh counts to accommodate different printing needs.

- Nylon mesh: Generally less durable than polyester but can be more suitable for printing on certain sensitive substrates.

- Stainless steel mesh: Extremely durable and resistant to chemicals, ideal for high-volume printing and specialized applications. Often used for industrial screen printing.

- Monofilament mesh: Features individual threads that are not interwoven; these screens provide excellent resolution and are suitable for very fine detail work but can be less durable.

The choice of screen material impacts factors such as tension, durability, and its compatibility with different printing processes and inks.

Q 14. How do you prevent pinholes in the emulsion layer?

Pinholes are tiny holes that appear in the emulsion layer after coating and drying, leading to unwanted ink leakage during printing. They can significantly affect the quality of your print. Preventing pinholes requires careful attention to detail throughout the screen preparation process.

- Proper degreasing: Ensure the screen is thoroughly degreased, removing any particles that could create pinholes during coating.

- Even emulsion coating: Apply the emulsion evenly using a consistent technique to avoid areas of thin emulsion. This ensures there are no weak points likely to develop pinholes.

- Proper emulsion mixing: Mix the emulsion according to manufacturer’s instructions to ensure proper viscosity. Unevenly mixed emulsion may contain lumps or inconsistencies leading to pinhole formation.

- Controlled drying conditions: Avoid rapid drying which can cause the emulsion to shrink and create pinholes. Slow and even drying in a controlled environment is preferable. Avoid drafts and dust.

- Screen quality: Check for any damage or defects in the screen itself before coating. These imperfections can compromise the emulsion layer and lead to pinholes.

By following these guidelines and paying attention to detail, you can minimize the occurrence of pinholes and improve the quality and consistency of your screen prints.

Q 15. What is the significance of using a scoop coater versus a trough coater?

The choice between a scoop coater and a trough coater for emulsion application hinges on the desired coating thickness consistency and the scale of the operation. A scoop coater offers greater control and consistency for thinner, more even coatings, especially crucial for fine-detail screen printing. Think of it like using a precise spatula to spread icing – you have fine-tuned control over the amount applied. It’s ideal for smaller jobs or when precision is paramount. In contrast, a trough coater is faster and more suited for larger screens and higher-volume production. It’s less precise, leading to a slightly less uniform coating but significantly speeding up the process. Imagine using a wider, flatter tool to spread the icing – quicker, but potentially less precise.

For instance, a fine art print shop producing limited edition prints might prefer a scoop coater for its precision, while a t-shirt printing business with high daily volumes would likely opt for a trough coater for its efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does the emulsion viscosity affect the coating process?

Emulsion viscosity, or thickness, is paramount in screen coating. Too thick, and the emulsion will be difficult to spread evenly, leading to uneven coating thickness, pinholes, and potential clogging. The squeegee will struggle to move it smoothly, resulting in streaks and inconsistencies. Too thin, and the emulsion might be too runny, resulting in a thin, weak coating prone to scratching and poor image reproduction. It won’t have the necessary depth to hold the ink effectively during printing.

Finding the ‘Goldilocks’ viscosity is key. The manufacturer’s recommendations serve as a starting point, but adjustments might be needed depending on factors like temperature, humidity, and the type of screen mesh used. A higher mesh count (finer screen) will often require a slightly thinner emulsion to avoid clogging, while a lower mesh count can handle a thicker emulsion.

Think of it like painting a wall; too thick a paint, and it will drip and run; too thin, and you’ll need multiple coats for adequate coverage. The ideal viscosity provides the right balance for even application and durable results.

Q 17. Describe the proper way to store screens before and after coating.

Proper screen storage is crucial for maintaining emulsion quality and preventing issues before and after coating. Before coating, screens should be stored in a clean, dry, and dark environment. Direct sunlight or extreme temperature fluctuations can damage the emulsion before it’s even applied. Ideally, store them flat, supported to avoid warping.

After coating, the coated screens are even more sensitive. They should be stored in a dark, cool, and dry location away from direct sunlight and dust. Avoid stacking them directly on top of each other to prevent the emulsion from being compressed or damaged. Properly drying the emulsion, typically in a dark, controlled environment, is a critical step before storage. You could think of it as similar to the way a painter carefully protects a freshly painted canvas; any premature exposure can ruin the work.

Q 18. What is the role of a squeegee in screen printing?

The squeegee is the heart of the screen printing process. It’s a rubber blade, typically made of polyurethane or silicone, that pushes the ink across the screen. The angle, pressure, and speed at which the squeegee is moved across the screen directly impact the amount of ink deposited and the overall quality of the print. A sharp, precise angle and consistent pressure will produce clean, sharp prints, while a dull or uneven squeegee can result in blurry or inconsistent images.

The squeegee’s flexibility and hardness also affect the print quality. A harder squeegee will produce a crisper, more defined print; a softer squeegee will deposit more ink and create a softer, less defined image. Think of the squeegee as a painter’s brush; different brushes, handled in different ways, achieve different effects on the canvas.

Q 19. What are the different types of inks used in screen printing?

Screen printing inks are diverse, each suited for different substrates and printing effects. Common types include:

- Plastisol inks: These are the workhorses of the industry, known for their vibrant colors, durability, and wide application range. They require a curing process with heat to set the ink.

- Water-based inks: Environmentally friendly and less harsh, these inks are easily cleaned with water but might require more coats to achieve the same opacity as plastisol inks. They are often used for textiles.

- UV-curable inks: These inks cure quickly upon exposure to ultraviolet light, making them ideal for fast production. They have high color density and are great for applications that demand rapid turnaround.

- Discharge inks: These inks remove the color from the fabric, creating a faded or washed effect.

The choice of ink depends heavily on the substrate (e.g., fabric, paper, plastic), desired print quality, and production requirements.

Q 20. How do you determine the correct ink viscosity for a specific job?

Determining the correct ink viscosity is vital for achieving optimal print quality. Too thick, and the ink will not flow smoothly across the screen; too thin, and it will bleed under the stencil, resulting in a blurry or inaccurate print. The manufacturer’s guidelines for each ink are a good starting point. However, several factors influence the final viscosity, including temperature, humidity, and the type of ink itself. Testing small batches and fine-tuning are vital.

A simple test is using a Zahn cup, a device which measures flow rates to assess viscosity, or through visual inspection (checking how fast the ink drips from a spoon/stick). Using a viscometer provides a more precise measurement and will be necessary for more complex printing jobs. Adjusting viscosity might involve adding ink reducers or thickeners (depending on what is needed) in small amounts until the desired consistency is achieved. Consistent viscosity is key to consistent print quality. This is why quality control involves regularly testing the viscosity through the printing run to ensure that the quality of print does not fluctuate.

Q 21. Explain the process of cleaning screens after printing.

Cleaning screens is a critical post-printing step to ensure the longevity of the screens and prevent cross-contamination of inks. The process usually involves several stages:

- Initial Cleaning: Immediately after printing, remove excess ink from the screen using a suitable cleaning solvent, and a soft cloth or sponge. For water-based inks, soap and water may be sufficient. Plastisol inks require solvent-based cleaners.

- Emulsion Removal: This is often the most challenging part. Commercial emulsion removers are commonly used to break down and remove the emulsion, and various methods like scrubbing and pressure washing can be employed.

- Thorough Rinsing: Rinse the screen thoroughly with water (or solvent, as necessary) to remove all traces of ink and emulsion.

- Drying: Allow the screen to air dry completely before storage. Ensure it is completely free of any residue.

The specific cleaning method will depend on the type of ink used. Failing to clean the screens thoroughly will lead to ink build-up and contaminate subsequent printing runs.

Q 22. What are the advantages and disadvantages of different emulsion types?

Choosing the right emulsion is crucial for successful screen printing. Different emulsions offer varying properties impacting print quality and longevity. Let’s explore some common types:

- Diazo Emulsion: This is a workhorse in the industry, known for its sensitivity to UV light, relatively easy application, and good durability. It’s a great all-around choice for many applications. However, it can be more prone to pinholes if not handled carefully during the coating process.

- Photopolymer Emulsion: This emulsion offers higher resolution and sharper image details than diazo emulsion because of its higher sensitivity. It’s ideal for fine-detail work and intricate designs. The downside? It’s typically more expensive and requires more precise handling due to its higher sensitivity to light.

- Direct Emulsion: This emulsion type is exposed directly onto the screen without a stencil, making it suitable for very simple designs or stencil-free techniques. It simplifies the process but is less versatile than other types.

- Capillary Film Emulsion: This option pre-coats the screen for you, eliminating the need for manual coating. It’s quick and convenient but typically less forgiving for achieving a perfectly even coating than direct application.

The best emulsion for a project depends on factors like design complexity, budget, and the substrate being printed on. For example, a fine-art print needing crisp details might benefit from photopolymer, while a simple t-shirt print might be perfectly suited to a diazo emulsion.

Q 23. How do you maintain proper screen storage conditions?

Proper screen storage is essential to prevent emulsion degradation and maintain screen quality. Think of it like keeping your paints in a cool, dark place to prevent them from drying out. For screens, this means:

- Cool, Dry Environment: Store screens in a climate-controlled area away from direct sunlight, excessive heat, and moisture. Temperature fluctuations can cause emulsion to crack or separate.

- Darkness: Exposure to light, especially UV light, can prematurely harden the emulsion. Cover screens with a dark cloth or store them in a dark closet.

- Vertical Storage: Store screens vertically to prevent sagging, which can distort the mesh and potentially damage the emulsion.

- Protection from Dust and Debris: Keep the screens clean and protect them from dust, dirt, and other particles that can contaminate the emulsion and affect print quality. Consider using screen racks or protective covers.

- Properly Cured Emulsion: Ensure the emulsion is fully cured before storage. This minimizes the risk of the emulsion softening or degrading during storage.

Remember, neglecting proper storage can lead to unusable screens and wasted materials. Paying attention to these details pays dividends in the long run.

Q 24. Describe your experience with different screen printing techniques.

My experience spans several screen printing techniques, each with its own advantages and challenges:

- Manual Screen Printing: This is the most basic method, perfect for small runs and learning the fundamentals. The hands-on approach gives you precise control but can be labor-intensive for large projects. I’ve used this method extensively for artistic projects and small-batch apparel printing.

- Automatic Screen Printing Presses: For high-volume production, automatic presses are invaluable. These presses automate much of the process, increasing efficiency and consistency. My experience with these machines includes the use of various models for mass-producing items such as promotional products and large-scale apparel designs.

- Carousel Presses: These allow for the printing of multiple colors with high efficiency. The efficiency is incredible when you need several colors on a large batch. My experience with these has mostly revolved around multi-color projects in the apparel industry.

- Wash-out Booths: These are vital for efficient and safe emulsion removal. Working with wash-out booths has been crucial in ensuring our designs stay crisp and clear. I understand how to utilize different pressures and chemicals to maximize the clean-out and reduce errors.

I’m comfortable adapting my techniques based on the project’s needs and the equipment available.

Q 25. How do you troubleshoot a screen with poor image registration?

Poor image registration is a frustrating but common problem in screen printing. It happens when the printed images don’t align correctly. Troubleshooting involves a methodical approach:

- Check Screen Alignment: Ensure the screens are properly aligned on the press. This includes confirming that the screen clamps are tight and properly positioned, and that the screen is square to the platen. Inaccurate alignment is often the root cause.

- Examine the Registration Marks: Look for misalignment in the registration marks on your screens. These marks are essential for accurate placement. Any discrepancy needs immediate correction.

- Inspect the Substrate Positioning: The substrate needs to be consistently and accurately placed under the screens. Inconsistent placement will result in misalignment. Consider using guides or jigs to ensure accurate positioning.

- Review the Press Mechanics: Examine the press for any mechanical issues. Worn parts, loose screws, or incorrect adjustments can all contribute to registration problems. Proper maintenance is essential to prevent this.

- Consider the Emulsion: In rare cases, emulsion inconsistencies (such as uneven thickness) could affect registration. If everything else looks good, this might be worth re-evaluating.

Addressing these points systematically will usually pinpoint the cause. A combination of factors could also be at play; a thorough assessment is crucial. Sometimes, small adjustments can make a big difference.

Q 26. How do you address issues with emulsion cracking or peeling?

Emulsion cracking and peeling are common issues, often stemming from improper handling or storage. Let’s look at some solutions:

- Improper Curing: Insufficient curing of the emulsion can lead to weakness and peeling. Ensure you follow the manufacturer’s recommended curing times and conditions. Using a UV curing system speeds this up and gives consistent results.

- Poor Emulsion Application: Uneven coating thickness can cause weak points where cracking is more likely. Consistent coating is paramount and it is a skill developed with practice.

- Aggressive Cleaning: Harsh chemicals or excessive scrubbing during screen cleaning can damage the emulsion. Use appropriate cleaning solutions and gentle cleaning techniques.

- Incorrect Emulsion Choice: The type of emulsion can affect its durability. Select the proper emulsion for the application and substrate.

- Storage Issues: Improper storage conditions (humidity, temperature fluctuations, light exposure) can degrade the emulsion over time. Always follow the storage recommendations.

Prevention is key! Careful attention to detail throughout the process, from emulsion selection to storage, can go a long way in avoiding these issues. If they do occur, addressing the underlying cause is vital to prevent future occurrences.

Q 27. What is your experience with different types of screen printing presses?

My experience includes working with a variety of screen printing presses, each tailored to different needs:

- Manual Presses: Ideal for smaller projects, prototypes, and learning the basics. They offer a great deal of control and are cost-effective for small-scale operations.

- Automatic Presses: These are essential for high-volume production runs. The automation increases speed and consistency, essential for meeting large orders. My experience involves using these to handle large orders of t-shirts and other promotional materials. Different presses have various functionalities like multiple color stations or advanced registration systems.

- Carousel Presses: These are specialized for multi-color prints. The carousel design allows for efficient printing of numerous colors with precise registration, maximizing output for complex designs.

- Cylinder Presses: These are powerful machines best suited for high-volume printing of cylindrical items, such as mugs and bottles. The use of these has required specialized setup and maintenance knowledge.

My understanding extends to press setup, maintenance, troubleshooting, and operation across these different types.

Q 28. How do you handle different substrates in screen printing?

Handling various substrates requires careful consideration of the ink, emulsion, and printing process. Here are some examples:

- Textiles (Cotton, Polyester, Blends): These require inks formulated for fabric, often plastisol inks for their durability and vibrant colors. The mesh count and emulsion type should be appropriate for the fabric’s weave. Pre-treatment of the fabric is often needed to enhance ink adhesion. I’ve worked with everything from fine cotton t-shirts to heavy-duty canvas tote bags.

- Paper and Cardstock: Water-based inks are often preferred for paper, while plastisol inks can be used with appropriate underbases to enhance adhesion. Proper mesh count selection is crucial to avoid ink bleeding. I have experience printing on a range of paper weights, from delicate stationery to thick, textured board.

- Plastics (PVC, Acrylic): Plastics require specialized inks that adhere to non-porous surfaces. Careful attention to the curing process is vital to ensure durability. The pretreatment of plastics is equally important, depending on the type of plastic and its properties.

- Metal (Aluminum, Steel): Metal requires specific inks designed to adhere to metal surfaces and withstand potential scratching. Pretreatment like cleaning and degreasing are crucial to prevent adhesion failures. I’ve completed projects on metals for signage and promotional items.

Substrate selection significantly affects the print process, and understanding these nuances is vital to achieving high-quality results. Proper ink selection, surface preparation, and printing techniques are key to successfully printing on various substrates.

Key Topics to Learn for Screen Preparation and Emulsion Coating Interview

- Screen Mesh Selection and Preparation: Understanding different mesh counts, materials (e.g., polyester, nylon), and their impact on print quality. Practical application: Choosing the appropriate mesh for various printing jobs based on image detail and ink viscosity.

- Emulsion Types and Properties: Knowing the characteristics of diazo, photopolymer, and other emulsion types; understanding their sensitivity to light, resolution capabilities, and shelf life. Practical application: Troubleshooting emulsion coating issues such as pinholes or uneven coating thickness.

- Coating Techniques and Equipment: Familiarizing yourself with different coating methods (e.g., scoop coater, trough coater), their advantages and limitations. Practical application: Optimizing coating parameters (e.g., emulsion viscosity, coating speed, squeegee pressure) to achieve consistent and even emulsion layers.

- Exposure and Development Processes: Understanding the principles of light exposure (UV or visible light), developing techniques (washout), and the impact of exposure time and intensity on stencil quality. Practical application: Diagnosing and resolving exposure issues such as under-exposure or over-exposure leading to poor stencil quality.

- Stencil Quality Control and Troubleshooting: Identifying and addressing common stencil defects (pinholes, scumming, bridging). Practical application: Implementing quality control measures during each step of the process to minimize defects and maximize print quality.

- Safety Procedures and Regulations: Understanding and adhering to safety protocols related to chemicals used in the emulsion coating process. Practical application: Demonstrating knowledge of safe handling procedures for chemicals and proper disposal methods.

- Understanding the relationship between screen preparation and final print quality: Connecting the dots between meticulous screen preparation and the resulting print quality, highlighting the impact of each stage on the final outcome.

Next Steps

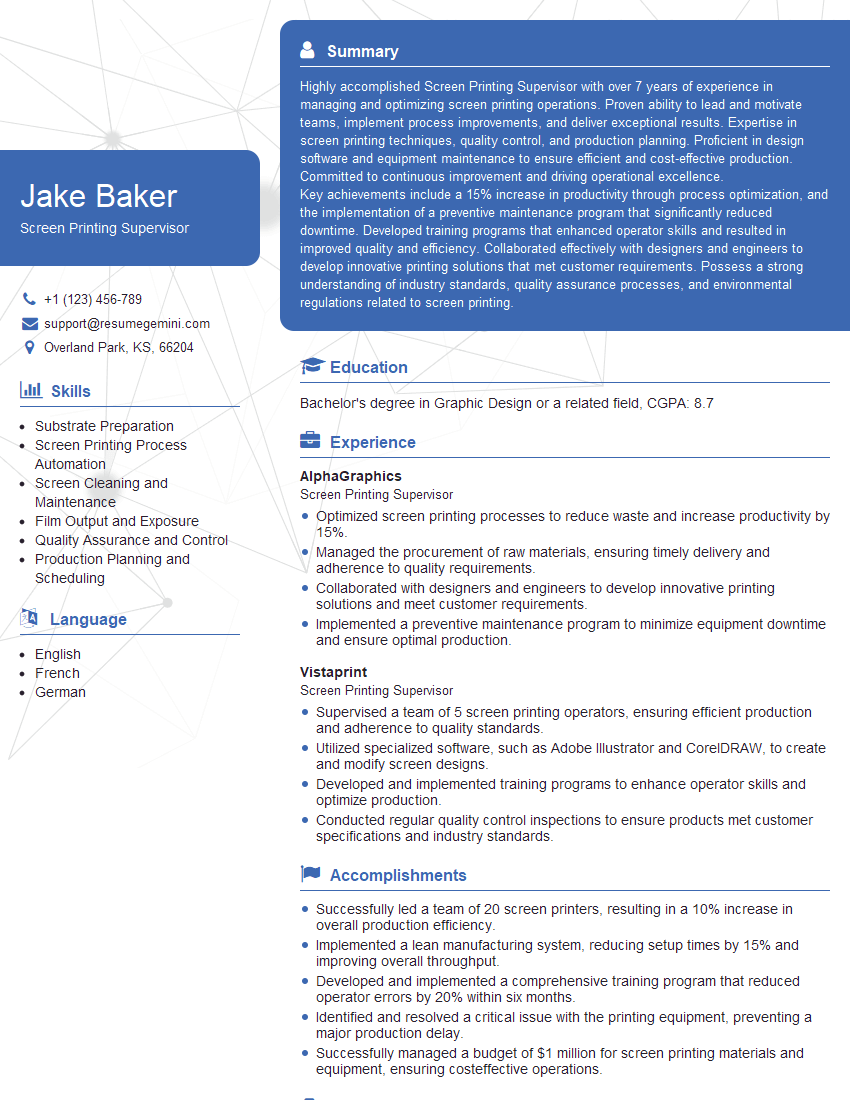

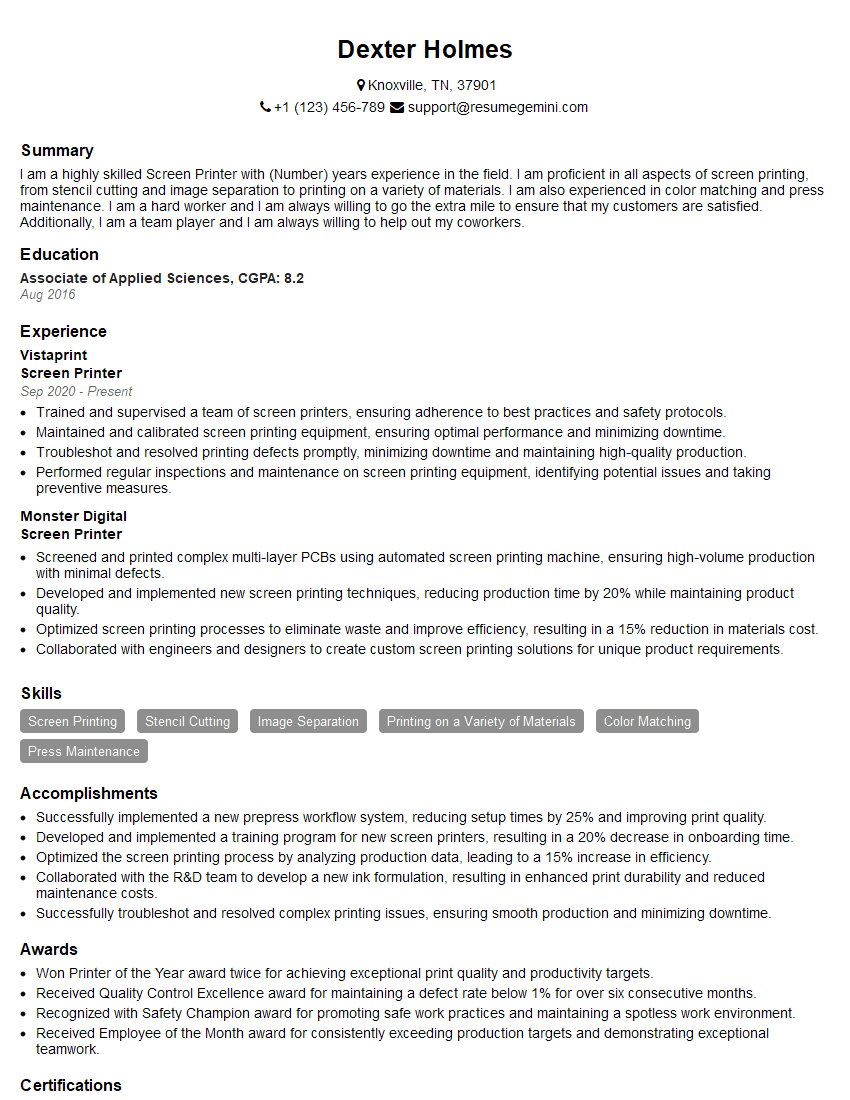

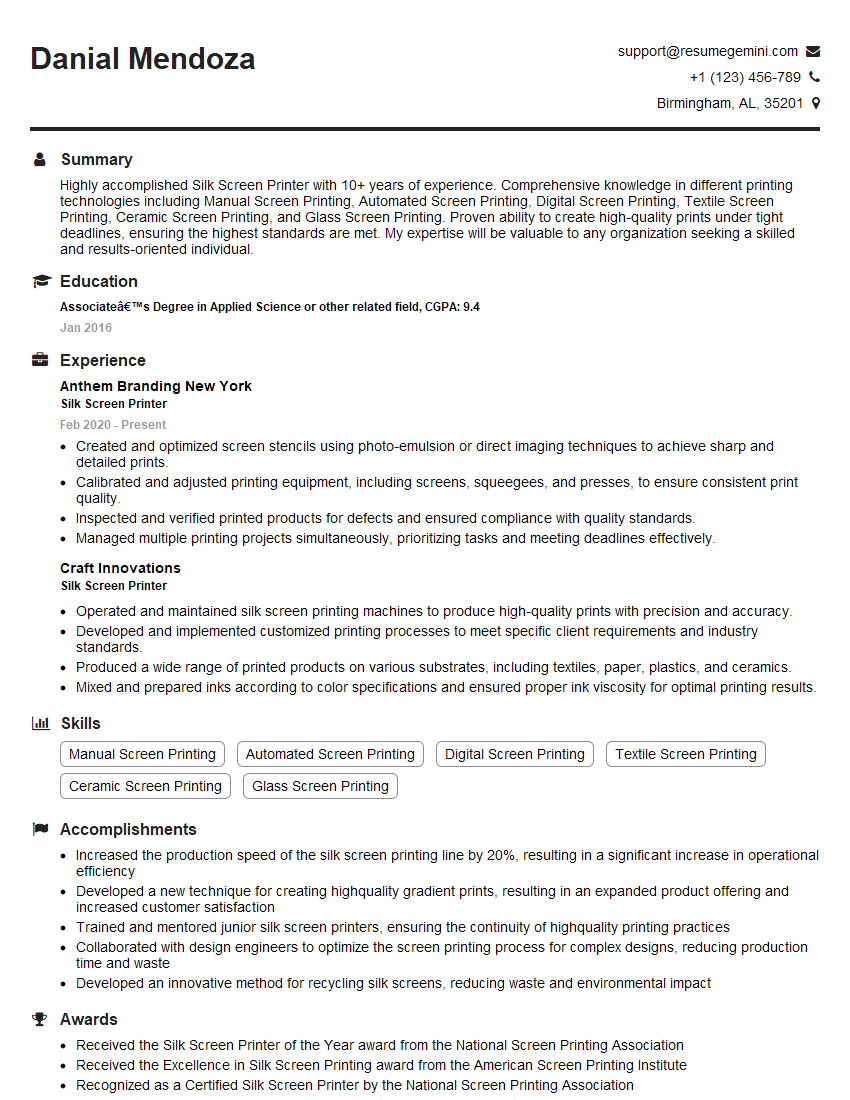

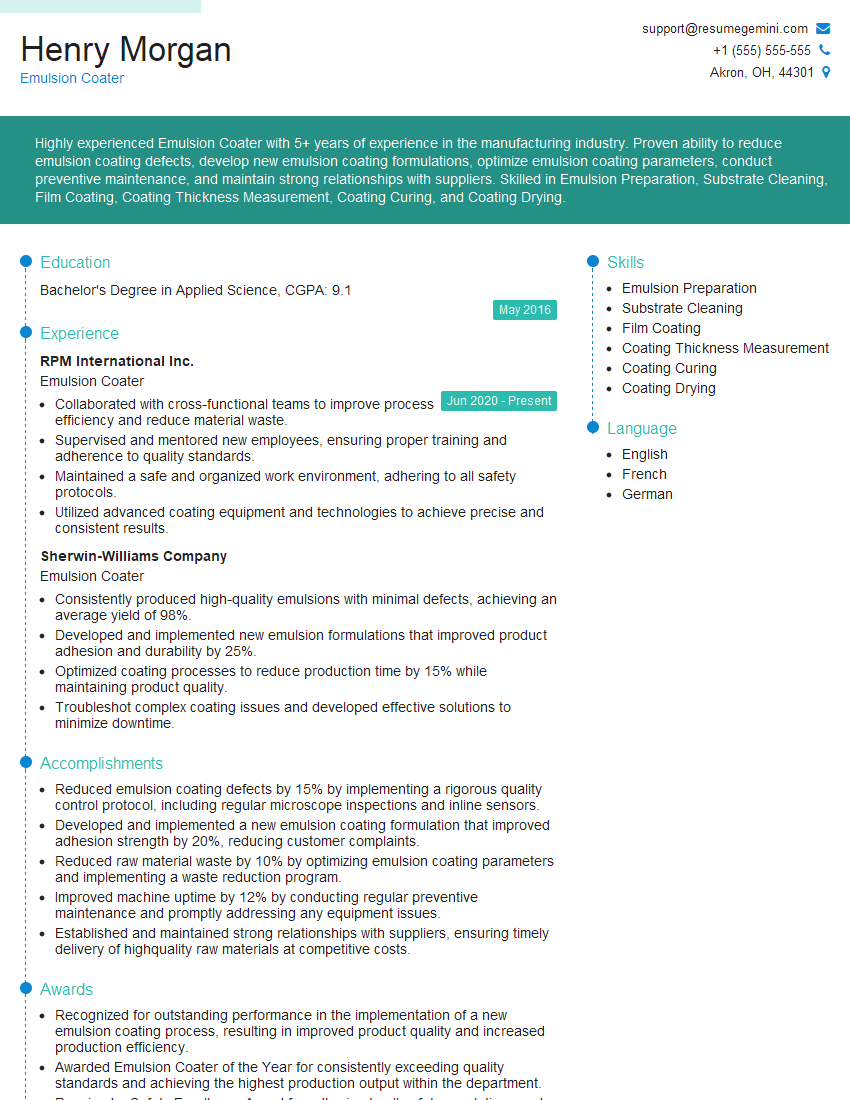

Mastering Screen Preparation and Emulsion Coating is crucial for career advancement in the printing industry, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume that highlights your skills and experience is essential for getting noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to Screen Preparation and Emulsion Coating are available to guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good