The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Screen Printing on Glass interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Screen Printing on Glass Interview

Q 1. Describe your experience with different types of glass suitable for screen printing.

Selecting the right glass for screen printing is crucial for a successful outcome. Different glasses have varying properties that affect ink adhesion, durability, and the overall final product. My experience encompasses working with several types:

- Float Glass: This is the most common type, known for its smooth, flat surface, making it ideal for crisp, high-quality prints. It’s readily available and cost-effective.

- Tempered Glass: While offering superior strength and resistance to breakage, tempered glass presents challenges. The tempering process creates internal stresses, which can sometimes affect ink adhesion. Specialized inks and pre-treatments are often necessary.

- Borosilicate Glass: This type of glass is known for its heat resistance and low thermal expansion. It’s excellent for applications requiring durability under temperature fluctuations, but can be more expensive.

- Specialty Glass: This encompasses many types, including textured, colored, or patterned glass. Each type needs to be considered individually because its surface properties directly influence print quality and adhesion. Careful testing with different inks and techniques is usually required.

For example, I once worked on a project using textured glass for a decorative window panel. We had to experiment with several inks to find one that would adequately fill the texture while providing vibrant colors and good adhesion.

Q 2. Explain the process of emulsion coating a screen for glass printing.

Emulsion coating is a critical step, determining the quality of your screen. It involves applying a light-sensitive emulsion to the screen mesh, creating a stencil for your design. Here’s a breakdown:

- Screen Preparation: Thoroughly clean the screen using a degreaser to remove any debris or oils that might interfere with emulsion adhesion. This includes both the mesh and the frame.

- Emulsion Mixing: Follow the manufacturer’s instructions carefully. Most emulsions require a gentle, even mixing to avoid creating air bubbles. Uneven mixing leads to inconsistencies in the stencil.

- Coating: Using a scoop coater or a trough and squeegee, apply a thin, even layer of emulsion to both sides of the screen. A consistent coating is key; too thick, and it might clog the mesh; too thin, and it won’t hold up.

- Drying: Allow the emulsion to dry completely in a dark, dust-free environment. This usually takes a few hours, depending on the emulsion and the environment’s temperature and humidity.

- Exposure: Once dry, the screen is exposed to UV light through a film positive of your design. This hardens the emulsion where it’s exposed to light, creating your stencil.

- Washout: After exposure, the unexposed, softened emulsion is washed away, leaving a stencil of your design on the mesh.

Imagine the emulsion as a photographic film—light hardens it, and the remaining areas are easily washed away. The key to success is careful attention to detail in every step.

Q 3. What are the different types of inks used in screen printing on glass, and when would you choose each?

Choosing the right ink depends heavily on the glass type, intended use, and desired finish. I’ve used a variety of inks, each with its advantages and disadvantages:

- Solvent-Based Inks: These offer vibrant colors and excellent adhesion, especially on difficult surfaces like tempered glass. However, they require proper ventilation due to their strong odor and potentially harmful fumes. They generally are more durable than water based inks.

- Water-Based Inks: Environmentally friendly and low-odor, water-based inks are gaining popularity. Their adhesion can sometimes be less robust than solvent-based inks, particularly on certain glass types. They require a longer curing time for full adhesion.

- UV-Curable Inks: These inks cure instantly upon exposure to ultraviolet light, making them ideal for high-volume production. They offer vibrant, scratch-resistant prints. However, they require specialized curing equipment.

- Ceramic Inks: High-temperature firing is needed for ceramic inks, resulting in extremely durable prints resistant to scratching and chemicals. This is ideal for applications where durability is paramount, but the process is more complex and requires specialized equipment.

For instance, in a project involving outdoor signage, I’d opt for UV-curable inks for their quick curing time and exceptional durability. For a delicate art glass piece, I might choose water-based inks for their less aggressive nature.

Q 4. How do you ensure proper ink viscosity for optimal printing on glass?

Ink viscosity is crucial for achieving a clean, sharp print without clogging the screen or resulting in a blurry image. Too thick, and it won’t flow properly; too thin, and it will seep under the stencil. I use several methods to control viscosity:

- Using a Viscosity Cup: This tool provides an objective measurement of the ink’s flow rate, allowing for consistent viscosity across batches.

- Ink Additives: Retarders slow down the drying time, increasing the working time and making it easier to print large areas. Thickeners increase viscosity to improve print quality and reduce seepage. These must be used cautiously, following manufacturer recommendations.

- Temperature Control: Ink viscosity is affected by temperature. Warmer inks tend to be less viscous. In colder environments, I’ll warm the ink gently to maintain proper consistency.

- Regular Mixing: Consistent stirring is essential to prevent settling of pigments or additives, maintaining a homogenous viscosity throughout the printing process.

Think of it like painting with watercolors. Too much water, and the colors run; too little, and they don’t spread evenly. Viscosity control in screen printing provides that same level of control over the ink’s flow.

Q 5. Describe your experience with different screen printing techniques (e.g., flood coating, off-contact printing).

My experience involves a range of screen printing techniques, each optimized for specific situations:

- Flood Coating: This technique involves flooding the screen with ink before pulling the squeegee across. It’s efficient for larger areas and solid colors, resulting in a more uniform ink deposit.

- Off-Contact Printing: This is essential for delicate prints and fine details. By maintaining a small gap (off-contact) between the screen and the substrate, the ink is deposited more precisely, reducing smearing and improving print sharpness. It is crucial for achieving fine details.

- Flash Cure: This is a partial curing of the ink between print layers, often used for multi-color jobs. It allows the next layer to adhere properly without disturbing the previous one. It’s especially useful for layering halftones in CMYK printing.

For instance, when printing fine-line artwork on glass, off-contact printing is essential to avoid blurring. On the other hand, flood coating is preferred for large, solid-color backgrounds.

Q 6. How do you troubleshoot issues like pinholes, blurring, or cracking in the printed image on glass?

Troubleshooting is an integral part of screen printing. Here’s how I approach common issues:

- Pinholes: These small holes in the print are often caused by dust, debris, or incompletely hardened emulsion. Solutions include thorough screen cleaning, using a high-quality emulsion, and ensuring proper exposure times.

- Blurring: This usually stems from issues with ink viscosity, squeegee pressure, or off-contact distance. Adjusting ink viscosity, ensuring appropriate squeegee pressure, and optimizing off-contact settings will usually solve this.

- Cracking: Cracking can occur due to improper curing, using incompatible inks, or using an unsuitable substrate. Ensuring correct curing procedures, using compatible inks, and understanding the properties of the glass are crucial.

Systematic troubleshooting is key—eliminate potential causes one by one. For example, if I see pinholes, I’ll first check for dust, then the emulsion, and then the exposure time. This logical approach is essential for finding and correcting any issues.

Q 7. Explain the process of curing inks on glass after screen printing.

Curing is the final and crucial step, ensuring the ink adheres permanently to the glass. The method depends on the type of ink used:

- Solvent-Based Inks: These often require air drying for several hours or even days, depending on the ink and the ambient conditions. Proper ventilation is important during this process.

- Water-Based Inks: Similar to solvent-based inks, they may need several hours of air drying before handling.

- UV-Curable Inks: These require exposure to UV light, instantly hardening the ink. Specialized UV curing equipment is essential for this process.

- Ceramic Inks: These require high-temperature firing in a kiln, creating a very durable and permanent bond with the glass. This is a specialized process requiring specific temperature and time controls.

Imagine baking a cake—curing is the equivalent of baking the print onto the glass, making it permanent and resistant to damage. The type of ‘oven’ (curing method) you use depends entirely on the ‘ingredients’ (inks).

Q 8. How do you manage and maintain screen printing equipment for glass printing?

Maintaining screen printing equipment for glass is crucial for consistent, high-quality prints. It involves a multi-faceted approach focusing on both preventative maintenance and prompt addressing of issues. Think of it like regularly servicing your car – small, consistent effort prevents larger, more costly problems down the line.

- Regular Cleaning: After each printing session, I thoroughly clean the screen printing press, removing excess ink and debris. This prevents ink buildup that can clog the system or lead to inconsistent prints. I use appropriate solvents, always following the manufacturer’s recommendations, and pay close attention to the squeegee, ensuring it’s clean and free from any damage.

- Lubrication: Moving parts, like the press arms and carriage, require regular lubrication with the appropriate grease or oil. This reduces friction, extends the lifespan of the equipment, and ensures smooth operation. Overlooking this can lead to jerky movements and potentially damage the print registration.

- Inspection and Repair: Regular inspections for wear and tear on crucial components, such as the screen clamps, mesh tensioning system, and flash curing unit (if applicable), are vital. Minor repairs should be addressed promptly, preventing small issues from escalating into major problems. For instance, a loose screw on the screen clamp can cause misalignment during printing.

- Storage: When the equipment isn’t in use, I store it in a clean, dry environment, protected from dust and extreme temperatures. This prevents corrosion and degradation of both metal and rubber parts.

Following this regimen ensures my equipment operates efficiently, produces high-quality prints consistently, and extends its useful life.

Q 9. What safety precautions do you follow when working with screen printing inks and chemicals?

Safety is paramount in screen printing, especially when handling inks and chemicals. A single lapse in safety can lead to serious consequences. My safety protocols are meticulous and unwavering.

- Personal Protective Equipment (PPE): This is my first line of defense. I always wear gloves (nitrile gloves are preferred for their chemical resistance), eye protection (safety glasses or goggles), and a respirator, especially when working with plastisol inks or cleaning solvents. The type of respirator will depend on the specific chemicals used.

- Ventilation: Working in a well-ventilated area is crucial to minimize exposure to harmful fumes. Ideally, a dedicated screen printing area with an exhaust system is preferred. If this isn’t possible, I ensure adequate airflow using fans.

- Proper Handling of Chemicals: I always read and follow the manufacturer’s safety data sheets (SDS) for all inks and chemicals. This includes understanding the hazards, handling procedures, storage requirements, and emergency response procedures. I use appropriate containers for storage and disposal and clearly label all chemicals.

- Emergency Preparedness: I have a designated emergency eye wash station and readily available spill kits. I also ensure everyone on my team is aware of emergency procedures and knows how to handle potential spills or accidents.

- Waste Disposal: I follow local and national regulations for the proper disposal of used inks and solvents. This prevents environmental pollution and ensures responsible waste management.

Safety is not a checklist; it’s a mindset. By prioritizing safety, I protect myself, my colleagues, and the environment.

Q 10. Describe your experience with different types of squeegees and their impact on print quality.

Squeegees are an essential tool in screen printing, and their choice significantly impacts print quality. The right squeegee, with the right durometer (hardness), blade angle and technique ensures proper ink transfer, sharpness, and overall aesthetic appeal.

- Durometer: The durometer refers to the hardness of the squeegee blade. Softer durometers (e.g., 40-60 Shore A) are generally better for fine detail work on smoother surfaces, while firmer durometers (e.g., 70-90 Shore A) are used for thicker inks or coarser mesh counts. I choose the durometer depending on the ink viscosity, mesh count, and design complexity. A softer squeegee might be better for intricate designs to prevent ink from being pushed under the stencil.

- Blade Angle: The angle at which the squeegee contacts the screen affects the ink deposit. A steeper angle results in a thinner ink layer, better suited for fine details, whereas a shallower angle deposits more ink, suitable for bolder prints or using thicker inks.

- Blade Material: Different materials have unique properties. Rubber squeegees are common and offer good versatility. Polyurethane squeegees offer excellent durability and are preferred for high-volume work. The choice also depends on the cleaning solvent, as some materials may be incompatible with specific chemicals.

- Blade Shape: The shape of the squeegee’s blade can affect the evenness of ink distribution. A straight blade is standard, while curved blades can help with specific printing techniques. For large glass panels, I might even use a longer squeegee to minimize strokes and increase efficiency.

Selecting and maintaining the right squeegee is akin to choosing the right brush for painting – the tool significantly impacts the final outcome. Experience and experimentation help me determine the optimal squeegee for each specific project.

Q 11. How do you prepare the glass surface before screen printing?

Proper glass surface preparation is the foundation of successful screen printing. A clean, properly treated surface ensures optimal ink adhesion and prevents defects like peeling or cracking.

- Cleaning: I start by thoroughly cleaning the glass surface with a high-quality degreaser, followed by a thorough rinse with distilled water to remove any residue. Any remaining dirt or grease will interfere with the adhesion of the ink.

- Deionizing: Removing any lingering water spots is crucial. I use deionized water as a final rinse, which evaporates cleanly, leaving no residue that can affect the ink.

- Pre-treatment (optional): Depending on the ink type and glass surface, I might use a pre-treatment solution, which improves ink adhesion. This is often necessary with low-surface energy materials that don’t readily accept ink.

- Drying: Thorough drying is critical before printing. This ensures that no moisture interferes with the ink transfer. I use lint-free cloths or compressed air for drying, depending on the urgency.

Imagine trying to paint a wall that’s covered in dust and grease – the paint wouldn’t adhere properly. The same principle applies to glass printing. A clean surface is essential for a successful outcome.

Q 12. Explain the process of cleaning and reclaiming screens after use.

Cleaning and reclaiming screens is a vital part of the process and directly affects the longevity of the screens. It requires a systematic approach to ensure thorough cleaning and prevent damage to the mesh.

- Immediate Cleaning: Right after printing, I remove as much excess ink as possible using a soft sponge and appropriate solvent. This prevents the ink from drying and becoming difficult to remove.

- Emulsion Removal: For reusable screens, I use a screen degreaser to remove the old emulsion. This is done carefully to avoid damaging the mesh. Some processes use enzymatic cleaners that are gentler than chemical degreasers.

- Mesh Cleaning: I then thoroughly clean the mesh itself, removing any residual ink or emulsion. This can involve using a specialized screen-cleaning brush and a combination of water and solvent. Depending on the ink type, special cleaning solutions are often necessary.

- Drying: I allow the screens to completely air dry before storage. This prevents the growth of mildew or mold and ensures they are ready for reuse.

- Screen Storage: Clean and dry screens are stored carefully, preventing damage and making them available for future prints. I sometimes store them flat, or depending on their size and design, I might use screen storage racks.

Just as a painter cleans their brushes after use, screen cleaning is essential for maintaining the quality of both the screen and the prints.

Q 13. How do you align and register multiple colors in multi-color screen printing on glass?

Aligning and registering multiple colors in multi-color screen printing on glass requires precision and a methodical approach. Inaccurate registration results in misaligned colors, significantly impacting the overall aesthetic appeal of the print.

- Accurate Screen Preparation: Each screen needs to be meticulously prepared with the correct design and color. The screens themselves need to be prepared with proper tensioning to prevent distortions. Any distortion would lead to misalignment.

- Registration Marks: I use registration marks (small, easily identifiable marks printed on each screen) to ensure accurate alignment. These marks serve as guides for precise positioning of each screen during printing. The more complex the design, the more crucial these marks become.

- Registration System: My printing press usually has a built-in registration system, which helps align the screens accurately. This system aids in fine-tuning alignment and prevents human error.

- Test Prints: I conduct test prints with each color to check for registration accuracy before proceeding with full production. This allows for any necessary adjustments before printing the final piece.

- Micrometer Adjustment: Fine adjustments to screen placement might be needed and can often be achieved using micrometer adjustments on the printing press.

Imagine trying to create a layered cake where each layer isn’t properly aligned. Precise registration is paramount for a successful multi-color print, just as layering cakes needs precision.

Q 14. What experience do you have with different mesh counts and their effects on print quality?

Mesh count (the number of threads per inch in the screen) directly affects the print quality. Choosing the right mesh count depends on the design detail and the ink being used.

- Fine Detail: For designs with fine details, a higher mesh count (e.g., 156-230 threads per inch) is necessary. This allows for finer lines and sharper images, preventing ink bleed.

- Bold Designs: For bolder designs or designs with large areas of solid color, a lower mesh count (e.g., 86-110 threads per inch) is typically used. This allows for greater ink deposit, resulting in vibrant and opaque colors.

- Ink Viscosity: The viscosity of the ink also influences mesh count selection. Thicker inks often require a lower mesh count, as higher mesh counts might restrict ink flow and lead to incomplete prints.

- Print Technique: The printing technique itself also plays a role. Certain techniques, such as halftone printing, require specific mesh counts to achieve the desired results.

Think of it like using different fabrics for sewing – a finer fabric for intricate details and a coarser fabric for larger pieces. Mesh count selection is crucial for achieving the desired print quality.

Q 15. How do you handle large-format glass screen printing projects?

Handling large-format glass screen printing projects requires meticulous planning and specialized equipment. We typically use a combination of strategies to ensure efficiency and quality. First, we utilize large-format screen printing presses capable of accommodating the dimensions of the glass panels. These presses often incorporate automated features like conveyor systems for smooth and even movement of the glass.

Second, we pre-register the screens with extreme accuracy using sophisticated alignment systems to guarantee precise registration of multiple colors. Think of it like a giant jigsaw puzzle where each piece (color) needs to fit perfectly. Any misalignment becomes hugely magnified on a large scale. Third, we employ a modular approach to the printing process, breaking down complex designs into manageable sections that can be printed individually and then seamlessly assembled.

For instance, on a recent project involving a 10-foot-tall glass wall, we divided the design into six manageable sections, printed each section individually, and then carefully joined them to create a cohesive final image. This approach minimized the risk of errors and allowed for better quality control.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software do you use for designing screen printing artwork for glass?

We primarily use Adobe Illustrator and Photoshop for designing screen printing artwork for glass. Illustrator is crucial for creating vector-based artwork, which is essential for crisp, clean lines and scalable designs. Its precision is paramount for accurate screen separations. Photoshop is then used for image manipulation, color correction, and adding subtle effects. We avoid using raster-based images directly for screen printing as they can lead to pixelation and loss of detail when scaled up. Instead, we vectorize images or ensure a high enough resolution for crisp printing.

For example, for a client who needed intricate floral designs printed on their glass doors, we used Illustrator to create vector versions of the floral motifs. This allowed us to scale the designs without any loss in quality, ensuring that the final print looked just as stunning on the glass as it did on our computer screen. We then carefully separate the colours into individual files for separate screens.

Q 17. How do you measure and control the thickness of the ink layer on the glass?

Controlling ink thickness is critical for achieving optimal opacity, color vibrancy, and preventing ink runs or drips. We use a combination of methods to manage this. First, we carefully select the appropriate mesh count for our screens. A finer mesh allows for more precise ink deposition, leading to thinner ink layers. Conversely, a coarser mesh deposits thicker layers.

Second, we meticulously control the squeegee pressure and speed during the printing process. More pressure and slower squeegee speed leads to thicker ink deposits. Third, we use ink reducers or additives to modify the viscosity of the ink, allowing us to achieve the desired thickness. Finally, we often utilize a specialized ink-measuring tool, a simple yet accurate tool akin to a gauge which ensures the consistency of ink application across different projects and areas of a single project. Think of it as ensuring each printed area receives the correct ‘dose’ of ink.

We consistently monitor the ink layer thickness by visual inspection after printing and, in some cases, utilizing a micrometer to measure the dried ink film.

Q 18. Explain your experience with different drying methods for screen-printed glass.

Our experience encompasses several drying methods for screen-printed glass, each suited for specific situations. For smaller projects, air drying is often sufficient. Larger projects often require more efficient techniques. We utilize convection ovens to facilitate more rapid and even drying at controlled temperatures, preventing uneven drying and cracking. This is especially crucial for thicker ink layers.

UV curing is another preferred technique, particularly for projects needing immediate handling and quicker turnaround times. UV curing instantly hardens the ink, using ultraviolet light, significantly speeding up the production process. We also have explored infrared drying as an effective alternative. This method uses infrared radiation to heat the glass and cure the ink effectively, combining efficiency with the benefits of avoiding harsh chemicals or high temperatures.

The selection of drying method depends on several factors, including ink type, project size, turnaround time, and budget considerations. We always perform thorough tests beforehand to determine the optimal drying method for each project.

Q 19. Describe your experience with quality control processes in screen printing on glass.

Quality control is paramount in our screen printing process. It begins even before printing with careful design review and screen preparation. We meticulously inspect each screen for imperfections such as pinholes or damaged mesh that could negatively impact print quality. During the printing process, we continuously monitor ink consistency, squeegee pressure, and registration. After printing, each piece undergoes rigorous quality checks.

We examine each printed glass piece for defects such as pinholes, smudges, uneven ink coverage, and color inconsistencies. We utilize specialized lighting and magnification tools to detect even minor flaws. We keep detailed records of each project, including ink formulations, drying times, and quality control findings. This documentation is essential for troubleshooting and continuous improvement. A defective piece is immediately set aside and marked to prevent it from continuing down the line.

Our quality control process ensures consistency and high standards in every project, from small decorative items to large architectural installations.

Q 20. How do you address inconsistencies in the color of printed images on glass?

Color inconsistencies in screen-printed glass can stem from several sources, including variations in ink viscosity, mesh consistency, printing pressure, and even ambient temperature and humidity. Addressing these inconsistencies requires a systematic approach.

First, we meticulously calibrate our printing equipment before each job to ensure consistent ink deposit and pressure. Second, we perform regular color checks of our inks to ensure consistent batches. We use color management software and spectrophotometers for accurate color matching and correction. Third, we maintain a controlled printing environment with consistent temperature and humidity to minimize variables that could impact color consistency. Fourth, if inconsistencies persist, we might repeat the entire printing process from that batch or section, ensuring consistency.

For example, if we notice a slight color shift in one section of a large project, we’ll re-examine all parameters – ink batch, mesh, print pressure – to identify the root cause and take corrective action. Re-printing the affected section ensures visual uniformity and client satisfaction.

Q 21. What is your experience with different types of glass cleaning agents?

The choice of glass cleaning agent is crucial, as residue can significantly affect ink adhesion and print quality. We use a range of cleaning agents, tailored to the type of glass and the level of soiling. For lightly soiled glass, isopropyl alcohol (IPA) is a common and effective choice. It’s volatile and evaporates quickly, leaving minimal residue. For more stubborn dirt or grease, we might use a mild detergent solution specifically formulated for glass cleaning. It is crucial to completely rinse off any residue to avoid interfering with the ink adhesion.

We never use abrasive cleaners or scouring pads, which can scratch the glass surface. After cleaning, we thoroughly rinse and dry the glass before printing. The cleanliness of the glass is verified by a visual inspection under controlled lighting. Choosing the right cleaning agent and technique is paramount for creating a durable and visually appealing print.

Selecting the right glass cleaner depends upon the type of dirt and the type of glass. We have specific procedures for different types of glass to ensure that the cleaning process is appropriate and doesn’t damage the glass.

Q 22. What is your experience in troubleshooting problems with screen mesh clogging?

Mesh clogging is a common frustration in screen printing, especially on glass, where the ink’s viscosity and the surface tension can exacerbate the issue. Troubleshooting starts with identifying the cause. Is it due to ink build-up, emulsion degradation, incorrect screen tension, or perhaps the wrong type of mesh for the ink being used?

- Ink Build-up: This is often caused by insufficient cleaning after each print run. I’ve found that a thorough cleaning with the appropriate solvent, followed by a final rinse with water and a complete drying process is crucial. Ignoring this step leads to progressive clogging.

- Emulsion Degradation: Old or improperly stored emulsion can break down, causing clogs. Regular emulsion maintenance and proper storage conditions are critical. I often recommend using a fresh batch of emulsion to mitigate this.

- Screen Tension: A poorly tensioned screen can cause the mesh to sag, trapping ink and causing clogs. Regular checks on screen tension and making adjustments as needed is part of my daily routine.

- Mesh Selection: Using a mesh with too small a thread count for the ink being used can lead to clogs. For example, using a high thread count mesh with a very thick ink would make clogging more likely. Choosing the right mesh for the job is paramount.

My approach involves systematically checking each potential issue. I start with the simplest solutions – cleaning and rinsing – before moving to more complex issues like checking screen tension or evaluating the emulsion quality. A detailed record-keeping system helps me track the source of past clogging issues to prevent recurrence.

Q 23. How do you handle customer feedback regarding screen printed glass?

Customer feedback is paramount. I always view it as an opportunity for improvement. My process involves actively soliciting feedback through surveys, direct communication, and post-project reviews.

- Understanding the Issue: I carefully listen to and document every detail of the customer’s concern, whether it’s a color discrepancy, a print defect, or a durability problem. A clear understanding is the first step to a solution.

- Investigating the Root Cause: I then investigate the reported issue. This could involve inspecting the printed glass, reviewing the production process details, and even recreating the printing process to identify any inconsistencies.

- Providing Solutions: Once the root cause is determined, I present the customer with viable solutions. These could range from re-printing the affected pieces to offering a partial refund, or explaining what steps to take to resolve the issue. Transparency is key.

- Building Relationships: Even if the issue is beyond our direct control, maintaining a professional and courteous approach strengthens customer relations. A positive resolution can turn a negative experience into an opportunity to demonstrate my commitment to excellence.

For example, one time a customer complained about slight color variations. We investigated and found a minor calibration issue with the printing press. We addressed the issue, corrected the prints, and even provided complimentary additional items as a gesture of goodwill. This built trust and strengthened the relationship.

Q 24. Describe your experience with environmental regulations related to screen printing inks.

Environmental regulations regarding screen printing inks are increasingly stringent. My experience includes understanding and adhering to local, state, and federal regulations related to VOC (Volatile Organic Compound) emissions and the proper disposal of hazardous waste inks.

- VOC Compliance: I ensure that all inks used comply with local VOC emission limits. This often involves using low-VOC or water-based inks whenever feasible. We regularly monitor and document our VOC emissions.

- Waste Management: Proper disposal of spent inks and cleaning solvents is crucial. We maintain detailed records of ink usage and waste disposal, complying strictly with all relevant regulations. We utilize licensed waste disposal companies specializing in hazardous materials.

- Regulatory Updates: I regularly stay informed about changes in environmental regulations and ensure that our practices align with the latest standards. Professional development courses and industry newsletters are vital tools.

- Sustainable Practices: Beyond legal compliance, we actively seek out sustainable practices, such as reducing ink consumption through process optimization and exploring environmentally friendly ink alternatives.

I’ve found that proactive compliance not only avoids penalties but also enhances our reputation for responsible environmental stewardship. It’s a significant factor for many clients who are increasingly concerned about environmental impact.

Q 25. Explain the concept of halftone screening in relation to glass printing.

Halftone screening is a crucial technique in screen printing on glass, allowing us to reproduce images with various shades of gray or color using only dots of ink. It’s impossible to print continuous tones directly onto glass using screen printing; halftone screening bridges this gap.

In essence, a digital image is converted into a pattern of dots of varying sizes. Larger dots represent darker areas, while smaller dots represent lighter areas. When viewed from a distance, the human eye blends these dots, creating the illusion of continuous tone. The Line Screen Ruling (LSR), measured in lines per inch (lpi), determines the dot density; a higher LSR creates a finer, more detailed image.

The choice of LSR depends on the complexity of the image and the viewing distance. A higher LSR is suitable for detailed images viewed up close, while a lower LSR might be sufficient for images viewed from a distance. For glass printing, I generally use a LSR ranging from 150 to 200 lpi to balance detail and smooth tonal transitions. Incorrect LSR selection can result in a grainy or muddy appearance.

Software plays a vital role in halftone screening. It enables controlling the dot shape, size, and angle, which further influences the final printed image’s quality. Common dot shapes are round, elliptical, and square. Precise control over these parameters ensures optimal results.

Q 26. What is your experience with different types of screen printing frames?

Different screen printing frames offer advantages depending on the application and the print job’s requirements. My experience includes using various types, each with its pros and cons.

- Wooden Frames: Traditional and cost-effective, but they are susceptible to warping and can be less durable than other options. Suitable for smaller, less demanding print jobs.

- Aluminum Frames: More durable and resistant to warping than wooden frames. They provide better screen tension and are ideal for larger format prints and repeated use. This is my most frequently used type of frame.

- Steel Frames: Extremely durable and robust, best suited for heavy-duty applications and high-volume production. However, they are also more expensive.

Frame size is another crucial factor. Larger frames are suitable for printing large designs, while smaller frames are better for detail-oriented work or smaller projects. The choice of frame material and size impacts the print’s quality, durability, and efficiency of the process.

For instance, I often use aluminum frames for most projects due to their balance of cost-effectiveness and durability. For high-volume production runs involving very large glass panels, steel frames are preferable due to their strength and resistance to distortion under pressure.

Q 27. How do you ensure the durability and longevity of screen-printed images on glass?

Ensuring the longevity of screen-printed images on glass requires careful consideration of several factors throughout the entire process.

- Ink Selection: Utilizing high-quality, UV-resistant inks is crucial. These inks are specifically formulated to withstand prolonged exposure to sunlight and prevent fading. Choosing the correct ink chemistry for the specific glass type is also vital.

- Pre-treatment: Properly cleaning and preparing the glass surface is essential. This ensures optimal ink adhesion, minimizing the chances of peeling or chipping over time.

- Curing Process: The curing process is critical for durability. This may involve UV curing or heat curing to properly harden the ink and ensure its long-term adhesion to the glass.

- Post-treatment: Applying a protective coating, such as a clear varnish or UV-resistant sealant, can further enhance the durability and longevity of the printed image by protecting the ink from scratches and environmental factors. This step is often crucial for outdoor applications.

For example, a recent project involving outdoor signage required using a specialized UV-resistant ink and a protective UV sealant to ensure the image’s vibrant colors would remain for many years. A thorough curing process ensured the ink bonded strongly with the glass.

Q 28. Describe your experience with automated screen printing equipment for glass.

My experience with automated screen printing equipment for glass involves operating and maintaining high-speed, automated carousel presses. These machines offer significant advantages in terms of speed, precision, and consistency compared to manual screen printing.

- Increased Efficiency: Automated presses significantly increase production speed, allowing for a much higher output compared to manual methods.

- Improved Consistency: Automated systems ensure consistent print quality and minimize variations that can occur during manual printing.

- Precision and Accuracy: The automated systems’ precise registration mechanisms guarantee accurate placement of the images, critical for multi-color prints and complex designs.

- Reduced Labor Costs: While the initial investment is higher, the reduced labor costs over time make automated presses cost-effective for high-volume production.

However, operating and maintaining these complex machines requires specialized training and technical expertise. Understanding the intricacies of the automated systems’ mechanical and electronic components is crucial for preventing downtime and ensuring optimal performance. Regular maintenance, including cleaning and calibration, is essential for maintaining the machine’s precision and longevity. Furthermore, troubleshooting mechanical or software-related issues requires a strong understanding of the system’s architecture.

Key Topics to Learn for Screen Printing on Glass Interview

- Substrate Preparation: Understanding different types of glass (float, tempered, etc.) and appropriate cleaning and pre-treatment techniques for optimal ink adhesion.

- Screen Preparation & Mesh Selection: Choosing the right mesh count and tension for various designs and ink viscosities; proper emulsion coating and exposure techniques.

- Ink Selection & Mixing: Knowledge of different ink types (UV-curable, ceramic, etc.), their properties, and how to mix them to achieve desired opacity and color accuracy. Understanding color matching and achieving consistent results.

- Squeegee Techniques & Pressure Control: Mastering the art of consistent ink deposition; understanding the impact of squeegee angle, pressure, and speed on print quality. Troubleshooting issues like pinholes and uneven coverage.

- Drying & Curing Processes: Understanding the importance of proper drying and curing methods for different ink types to ensure durability and prevent cracking or smearing. Familiarity with UV curing systems.

- Troubleshooting & Quality Control: Identifying and resolving common printing defects such as pinholes, smearing, registration errors, and color inconsistencies. Implementing quality control measures to maintain consistent print quality.

- Safety Procedures & Regulations: Familiarity with relevant health and safety regulations related to ink handling, cleaning solvents, and equipment operation.

- Production Processes & Workflow: Understanding the overall workflow from design to finished product, including job scheduling, setup, and production efficiency.

- Design Considerations for Glass Printing: Understanding design limitations and best practices specific to glass, considering factors such as transparency, light transmission, and potential distortion.

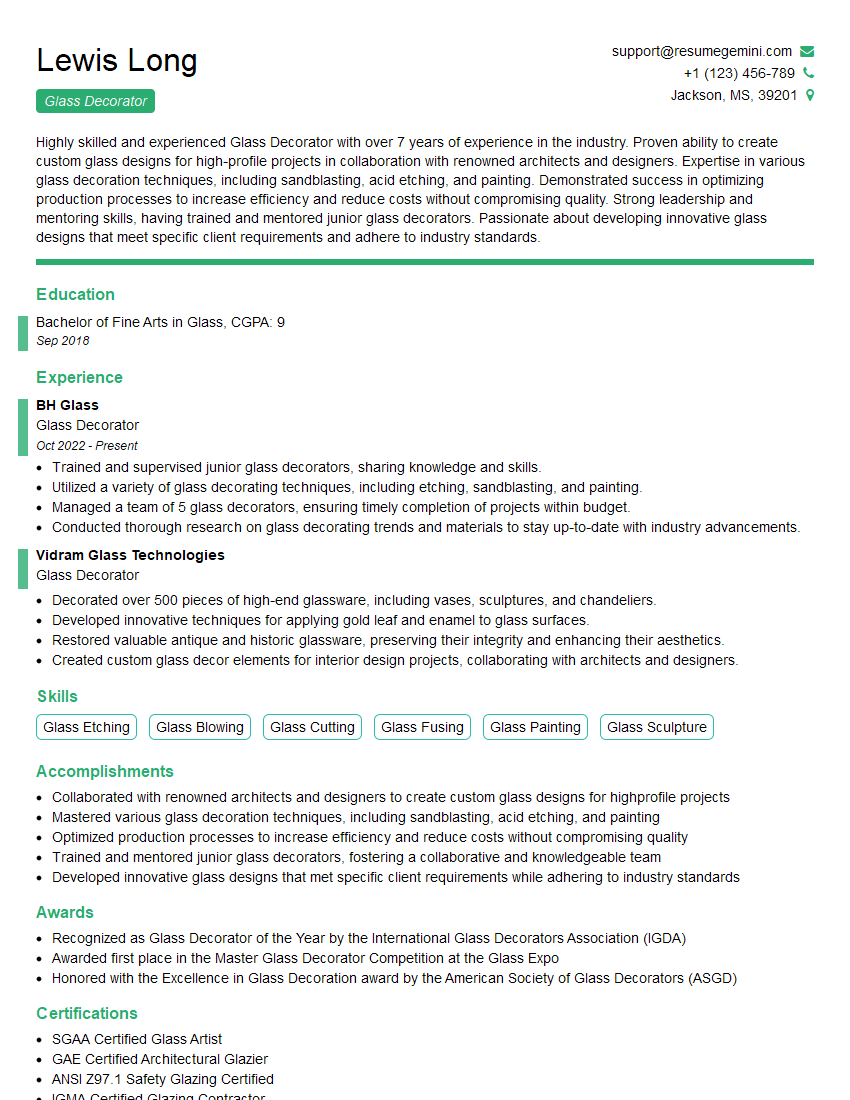

Next Steps

Mastering screen printing on glass opens doors to exciting career opportunities in diverse industries, from architectural glass to custom artwork. A strong understanding of this specialized skill will significantly enhance your job prospects and earning potential. To maximize your chances of landing your dream job, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is key to getting past applicant tracking systems and into the hands of hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to highlight your unique skills and experience in screen printing on glass. Examples of resumes specifically tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good