Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Screen Printing on Plastic interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Screen Printing on Plastic Interview

Q 1. What types of plastics are best suited for screen printing?

Choosing the right plastic for screen printing is crucial for successful results. Not all plastics are created equal when it comes to ink adhesion and the printing process itself. Generally, plastics with a smooth, non-porous surface are best. Here are some top choices:

- ABS (Acrylonitrile Butadiene Styrene): A very common choice due to its strength, durability, and good ink adhesion. It’s often used for housings, signs, and promotional items.

- Polypropylene (PP): A less expensive option, but requires proper surface treatment (like corona treatment) to ensure good ink adhesion. Frequently used for containers and some toys.

- Polycarbonate (PC): Known for its impact resistance and clarity, making it suitable for lenses and durable applications. It can be printed but requires careful consideration of inks and pre-treatment.

- High-Density Polyethylene (HDPE): Often used in bottles and containers. It’s more challenging to print on directly and often requires specialized inks and surface treatments.

- Polyethylene Terephthalate (PET): Another common plastic, but its surface properties can make ink adhesion tricky, often needing a primer or special ink.

The key is to consider the plastic’s surface energy – higher surface energy means better ink adhesion. If you’re unsure, always test print on a sample piece of the plastic before committing to a large run.

Q 2. Explain the process of emulsion coating a screen.

Emulsion coating is the process of applying a photosensitive emulsion to your screen, creating the stencil that will define your design. Think of it as creating a temporary mask on the screen. Here’s a step-by-step breakdown:

- Screen Preparation: The screen (typically made of polyester mesh) needs to be thoroughly cleaned to remove any debris or oils. Degreasing solvents are commonly used.

- Emulsion Mixing: The photosensitive emulsion is carefully mixed according to the manufacturer’s instructions. This ensures proper sensitivity and consistency. Improper mixing can lead to printing failures.

- Coating: Using a scoop coater or a trough and squeegee, the emulsion is evenly applied to both sides of the screen, creating a thin, consistent layer. The thickness is crucial for detail and print quality.

- Drying: The coated screen is then carefully dried in a dark, dust-free environment. This process allows the emulsion to harden and become light-sensitive.

- Exposure: The dried screen is exposed to a high-intensity ultraviolet (UV) light source through a film positive of your design. The exposed areas harden, while unexposed areas remain soft and can be washed away.

- Washout: Using a gentle spray of water, the unexposed emulsion is carefully removed, revealing the open areas of the screen that will allow ink to pass through during printing.

This process requires precision and cleanliness. Even small particles of dust can clog the screen and ruin the print. Proper emulsion coating is the foundation of a successful screen print.

Q 3. Describe different screen printing techniques used for plastics.

Several screen printing techniques are employed when working with plastics, each with its own advantages and disadvantages:

- Manual Screen Printing: A classic approach where the screen is held and ink is pushed across the screen with a squeegee. This offers maximum control for smaller runs or complex designs but can be more time-consuming.

- Automatic Screen Printing: Machines handle the entire process, greatly increasing speed and consistency for large-volume production. These machines automate the screen movement, ink application, and substrate handling.

- Carousel Screen Printing: Efficient for printing multiple colors on a single item by using a rotating carousel that moves the substrate between different screens, each with a different color.

- Flash-Off Drying: This involves a quick dry between color applications using heat or UV lamps to ensure that the next color prints over a dry surface. It is crucial for multi-color designs.

- Tack Printing/Overprinting: If the ink isn’t perfectly dry after each pass, the previous print may slightly shift position. Tack printing uses a slightly tacky ink to aid in registration.

The selection of a technique depends on factors such as the volume of prints, the complexity of the design, the size of the substrate, and budget constraints.

Q 4. How do you ensure proper ink adhesion to plastic substrates?

Ensuring proper ink adhesion to plastic is paramount. Poor adhesion leads to peeling, cracking, and an overall unsatisfactory print. Several strategies can improve ink adhesion:

- Surface Treatment: Methods like corona treatment, plasma treatment, or flame treatment increase the surface energy of the plastic, making it more receptive to ink. This creates a microscopic roughness allowing the ink to better grip.

- Primer Application: A specialized primer can act as a bonding agent between the plastic and the ink, improving adhesion, especially on low-surface-energy plastics.

- Ink Selection: Choosing the correct ink for the specific type of plastic is vital. Certain inks are formulated to adhere better to specific plastics. For example, UV-curable inks often offer superior adhesion.

- Proper Curing: Adequate curing of the ink is essential. This is done with UV curing for UV inks and thermal curing for other types of inks. The time and temperature must be optimized for complete polymerization.

- Pre-cleaning: Cleaning the plastic substrates to remove dirt, oil, or other contaminants ensures optimal ink adhesion.

A simple test to assess adhesion involves applying pressure to the printed area with tape after curing. If the print is intact, then the adhesion is likely acceptable. This is called a tape test.

Q 5. What are the common challenges in screen printing on plastic?

Screen printing on plastics presents unique challenges:

- Ink Adhesion Issues: As mentioned earlier, achieving good adhesion on certain plastics can be difficult and requires surface treatment or specialized inks.

- Static Electricity: Plastics can build up static charge, causing the substrate to move during printing and affecting registration.

- Substrate Distortion: Heat from the curing process can distort the substrate, particularly with thinner plastics.

- Ink Bleeding: Certain inks may bleed into the plastic, especially porous ones.

- Pinholes: Small holes in the print are a common defect, often caused by emulsion issues or debris in the screen.

- Registration Problems: Aligning multiple colors accurately can be tricky, especially with substrates that move during printing.

Careful planning, precise execution, and selection of appropriate materials and techniques help minimize these challenges.

Q 6. How do you troubleshoot issues like pinholes or ink bleeding?

Troubleshooting pinholes and ink bleeding requires a systematic approach:

Pinholes:

- Check the Emulsion: Ensure the emulsion is properly mixed and applied, avoiding air bubbles. An uneven coating can lead to pinholes.

- Clean the Screen: Thoroughly clean the screen to remove any debris that might block the mesh.

- Review Exposure Time: Insufficient exposure may result in incomplete hardening of the emulsion, leading to pinholes.

- Inspect the Mesh: The mesh itself may have defects. Examine it closely.

Ink Bleeding:

- Choose the Right Ink: Select an ink that is specifically designed for the plastic and minimizes bleeding. This is the most significant step.

- Surface Treatment: If bleeding persists, a surface treatment on the substrate is necessary.

- Reduce Ink Viscosity: If the ink is too thick, it might bleed. Adjust the viscosity by adding thinner, if recommended by the ink manufacturer.

- Avoid Over-Squeegee Pressure: Excessive pressure forces ink into areas where it shouldn’t go.

In both cases, starting with a test print is invaluable for identifying the root cause and making adjustments before committing to a large production run. Keep detailed notes during each test to aid problem-solving.

Q 7. Explain the importance of pre-press preparation for plastics.

Pre-press preparation is the cornerstone of successful screen printing on plastics. It lays the groundwork for a clean, accurate, and consistent print. Here’s what it entails:

- Artwork Creation: Creating high-resolution artwork optimized for screen printing, ensuring proper color separation for multi-color prints.

- Film Positive Generation: Converting the artwork into a film positive, which is used to expose the screen emulsion. The film must have accurate dimensions and sharp details.

- Screen Preparation: This involves properly cleaning the screen to remove any contaminants and preparing it for emulsion coating. Degreasing is crucial.

- Substrate Preparation: Thoroughly cleaning the plastic substrate to remove oils, dust, or any other contaminants that might affect ink adhesion. This might involve wiping, washing, or specialized cleaning agents.

- Testing: Performing test prints using a sample piece of the plastic and ink to check for proper adhesion, color consistency, and alignment. This allows you to identify and fix problems *before* running the actual print.

Thorough pre-press prep prevents costly mistakes and ensures a smooth and efficient printing process. Think of it as planning a complex project—a well-thought-out plan greatly improves the chances of a successful outcome.

Q 8. What are the different types of inks used for screen printing on plastic?

The choice of ink for screen printing on plastic depends heavily on the type of plastic, the desired finish, and the application. We have several categories:

- Plastisol Inks: These are the workhorses of the industry, known for their vibrant colors, excellent opacity, and durability. They’re thick and require a higher mesh count. They are ideal for applications needing a strong, raised print, but require curing with heat.

- Water-Based Inks: Environmentally friendly and softer on the skin, water-based inks offer a wider range of color and are popular for printing on certain plastics like softer PVC. They require less heat to cure and have less of a raised print compared to plastisol.

- UV-Curable Inks: These inks cure instantly upon exposure to ultraviolet light. This makes them incredibly fast and efficient, perfect for high-volume jobs. They offer exceptional durability and are suitable for various plastics. However, they often need specialized curing equipment.

- Solvent-Based Inks: These are less common now due to environmental concerns but still used for specific applications. They offer good adhesion to certain plastics and have excellent durability but have strong odors and often require extensive ventilation.

Choosing the right ink is crucial. For instance, a thin, flexible plastic might require a water-based or UV-curable ink to prevent cracking, while a rigid plastic might tolerate a more durable plastisol ink.

Q 9. How do you choose the appropriate mesh count for a specific job?

Mesh count refers to the number of threads per inch (TPI) in the screen. A higher mesh count means finer threads, allowing for more detailed prints with finer lines and halftones. A lower mesh count allows for larger areas of solid color and thicker ink deposits. The choice depends on the design’s complexity and the ink being used.

- Fine Detail: For intricate designs with fine lines and halftones, a higher mesh count (156-230 TPI) is necessary. This allows the ink to pass through more precisely, resulting in sharper images.

- Solid Colors & Large Areas: For designs with large areas of solid color, a lower mesh count (86-110 TPI) is usually sufficient. This allows more ink to pass through, providing better opacity and coverage.

- Ink Type Consideration: Plastisol inks, being thicker, necessitate a lower mesh count than thinner water-based or UV-curable inks, which are suitable for higher mesh counts.

Imagine trying to paint a tiny detail with a thick brush versus a thin one. The thin brush (high mesh) gives you finer control.

Q 10. Describe the process of exposing and developing a screen.

Screen exposure and development is the process of transferring the design onto the screen. Here’s the breakdown:

- Preparing the Screen: The screen is coated with a photosensitive emulsion, a light-sensitive coating that hardens when exposed to UV light.

- Creating a Film Positive: A reverse image of the design is created on a transparent film, typically using specialized software. This positive will be placed on top of the screen.

- Exposure: The film positive is placed on top of the coated screen, and the entire assembly is exposed to a strong UV light source. This hardens the emulsion where the light penetrates (non-image areas). The areas covered by the film remain soft.

- Washing Out: The screen is then washed using water under pressure to remove the unexposed, soft emulsion. This leaves the hardened emulsion in the shape of the desired design, effectively creating a stencil.

Think of it like a photographic negative; the light-hardened emulsion is like the developed image creating a stencil blocking ink where we want blank areas.

Q 11. How do you maintain and clean your screen printing equipment?

Maintaining and cleaning screen printing equipment is critical for longevity and consistent print quality. This includes:

- Screens: After each use, screens should be thoroughly cleaned with appropriate solvents (depending on the ink used) to remove all ink residue. Screens should be stored properly, ideally in a dry, clean place to prevent emulsion degradation.

- Squeegees: Squeegees should be cleaned after each use and the blade should be properly stored to avoid damage.

- Printing Press (if applicable): Regularly inspect and lubricate moving parts. Clean the platen and other surfaces to prevent ink build-up and ensure proper functionality. Any malfunctioning parts should be addressed immediately.

- Ink Storage: Inks need to be kept in their original containers, tightly sealed to prevent drying or contamination.

Regular maintenance prevents clogs, ensures consistent ink flow, and extends the life of your equipment. A well-maintained press is a highly productive press.

Q 12. What safety precautions are crucial during screen printing on plastic?

Safety is paramount in screen printing. Here are some crucial precautions:

- Proper Ventilation: Always work in a well-ventilated area, especially when using solvent-based inks. This prevents inhalation of harmful fumes.

- Personal Protective Equipment (PPE): Use gloves, eye protection, and a respirator when handling inks and solvents. Different inks require specific PPE, depending on the ink chemistry.

- Handling Chemicals: Always follow the manufacturer’s instructions when using chemicals. Store them properly and keep them away from ignition sources. Understand the safety data sheets of each chemical used.

- Heat Safety: When using heat presses, be cautious of burns. Always allow sufficient time for the substrate to cool and use appropriate heat-resistant gloves.

- Emergency Procedures: Know where the nearest eye wash stations and fire extinguishers are located.

Safety isn’t just a suggestion; it’s a non-negotiable requirement for a healthy and productive workspace.

Q 13. Explain the importance of proper ink viscosity.

Ink viscosity is the thickness or thinness of the ink. Maintaining the correct viscosity is crucial for consistent and high-quality prints.

Too thick: The ink will not flow smoothly, leading to uneven coverage, incomplete images, and difficulty in achieving fine details. It can also clog the mesh.

Too thin: The ink will be too runny, resulting in blurry prints and bleeding into adjacent areas, especially if you’re using high mesh count screens. Ink will penetrate the screen leaving behind messy prints.

Proper viscosity ensures a smooth, even ink flow, resulting in clean, crisp prints. Viscosity can be adjusted using ink reducers or thickeners, following the ink manufacturer’s instructions. Consistency is key—using a viscosity cup or a Zahn cup helps to maintain a standardized viscosity throughout the printing process. A simple example is making sure your paint is not too watery so it goes where you want it.

Q 14. How do you achieve precise registration in multi-color screen printing?

Precise registration in multi-color screen printing ensures that each color aligns perfectly with the others. This is crucial for creating sharp, well-defined images and avoiding misaligned prints.

Achieving precise registration involves:

- Accurate Screen Setup: Use accurate alignment tools and a stable printing press to minimize shifts between colors.

- Registration Marks: Incorporate registration marks on your film positives and screens. These marks act as guides for aligning each color accurately.

- Micron adjustments: Adjust the screen positioning through careful incremental movements on the print bed to finely tune the registration.

- Test Prints: Run test prints after setting up the initial alignment to evaluate the precision and correct any misalignments before proceeding.

- Use of Registration Pins: These can offer even better precision compared to just registration marks.

Imagine trying to create a colorful image with misaligned paint; the result would not be appealing at all. Registration is similar – it is an essential step to make sure your printed image is clear and high quality.

Q 15. Describe different curing methods for screen-printed plastics.

Curing in screen printing on plastic refers to the process of hardening the ink, making it durable and resistant to scratching or fading. The method chosen depends heavily on the type of ink used (plastisol, water-based, UV, etc.) and the substrate material.

- Convection Oven Curing: This is the most common method for plastisol inks. The printed plastic parts are placed in a large oven with circulating hot air. The temperature and time are carefully controlled to fully cure the ink without damaging the plastic. Think of it like baking a cake – you need the right temperature and time for perfect results. For example, a typical cure might be 320°F (160°C) for 3-5 minutes.

- Infrared (IR) Curing: IR curing uses infrared lamps to directly heat the ink. This method is faster than convection curing because it focuses the heat directly onto the ink, curing it more quickly and efficiently. It’s often used for high-volume production due to speed but requires careful monitoring to prevent scorching or uneven curing.

- UV Curing: UV curable inks are cured using ultraviolet light. This is a rapid and clean process, ideal for inks that require immediate handling post-printing. However, UV curing requires specialized equipment and is often more expensive than thermal curing.

The choice of curing method is a crucial part of the screen printing process, directly impacting the final product’s quality and longevity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the quality control checks you perform during and after printing?

Quality control is paramount in screen printing. We perform checks throughout the process:

- Pre-Press: We meticulously check the film positives for accuracy, ensuring the design is sharp and free of defects. This prevents costly reprints later.

- Screen Preparation: We inspect screens for proper emulsion coating and stencil burning to ensure consistent ink deposit. A poorly prepared screen will result in blurry prints or missed areas.

- Printing Process: Continuous monitoring during printing identifies issues like ink consistency, registration (alignment), and screen clogging, allowing for immediate adjustments. We regularly check test prints to maintain quality.

- Post-Printing Inspection: After curing, we conduct a 100% inspection of every piece for defects such as smudges, pinholes, or incomplete prints. This might involve visual inspection, sometimes aided by magnification.

- Packaging & Shipping: Before packaging, final checks ensure that all pieces meet the quality standards, are clean and properly protected for shipping.

Employing these steps minimizes waste, ensures customer satisfaction, and maintains our reputation for high-quality screen printing.

Q 17. How do you handle different plastic thicknesses and shapes?

Handling various plastic thicknesses and shapes requires adaptability in the screen printing process. Here’s how we handle it:

- Screen Tension: Thicker plastics require higher screen tension to maintain consistent contact with the surface and avoid blurring. Thinner plastics require lower tension to prevent them from being damaged.

- Squeegee Pressure and Angle: Adjusting the squeegee pressure and angle is vital. More pressure might be needed for thicker materials to ensure proper ink deposition, while less pressure might be needed for thinner plastics to prevent distortion.

- Printing Fixtures: We utilize different jigs, vacuum tables, or other fixtures to hold the plastic parts securely during printing, regardless of their shape. This ensures accurate and consistent print placement, preventing shifting or misalignment.

- Ink Viscosity: Ink viscosity (thickness) might need adjustments based on the material’s surface. More viscous ink may be needed for rougher surfaces.

- Curing Considerations: Curing times and temperatures might also be adjusted to prevent warping or damage to the plastics. Thinner materials can cure faster than thicker ones.

For example, printing on a thin, flexible sheet necessitates a gentle approach with lower pressure and appropriate fixturing to prevent the plastic from stretching or tearing during the printing process.

Q 18. Explain the concept of halftone screens in screen printing.

In screen printing, a halftone screen is a technique used to reproduce continuous-tone images (like photographs) using only dots of ink. Since screen printing is a process that deposits ink in discrete areas, it can’t reproduce smooth gradations of color directly. The halftone screen simulates these gradations by varying the size and density of dots.

Think of a newspaper photo – it appears continuous-tone from a distance, but up close, you see it’s made of tiny dots. That’s the halftone effect. The screen’s lines per inch (LPI) determine the dot size and the resulting image resolution. Higher LPI results in smoother gradations but requires finer screens and more precise registration.

In practice, the image is digitally converted into a halftone pattern using specialized software. This pattern is then burned onto the screen, and the dots are printed, creating the illusion of continuous tone.

Q 19. What are the advantages and disadvantages of using plastisol inks?

Plastisol inks are a popular choice for screen printing on plastics, especially for apparel. They offer several advantages but also have some drawbacks:

- Advantages:

- Vibrant Colors: Plastisol inks produce exceptionally bright and opaque colors, essential for many applications.

- Durability: They offer excellent washability, scratch resistance, and durability, crucial for items that experience regular wear and tear.

- Wide Range of Applications: Suitable for various substrates, including plastics, fabrics, and other materials.

- Thick Film Deposits: Plastisol inks can lay down a thick film, creating a raised, tactile print.

- Disadvantages:

- High Curing Temperature: Require high temperatures for curing, potentially limiting the substrate choices.

- Less Environmentally Friendly: Some plastisol inks contain PVC, which is not environmentally friendly.

- Longer Curing Time: Curing times can be longer compared to some other inks.

- Requires Specialized Equipment: Curing often requires specialized ovens or other equipment.

The choice of plastisol ink versus other ink types requires careful consideration of the specific project’s requirements, including budget and environmental impact.

Q 20. How do you calculate the amount of ink needed for a particular job?

Calculating ink requirements involves several steps:

- Determine the print area: Calculate the total area to be printed on each piece (length x width). Consider the number of colors and how they overlap.

- Ink Coverage: Estimate the ink coverage percentage needed. For example, a solid color is 100%, a half-tone might be 50%, and a light screen print may be less.

- Ink layer thickness: This varies depending on the ink type and desired effect. Plastisol inks typically have a thicker layer than water-based inks.

- Total ink volume: Multiply the print area, coverage percentage, and ink layer thickness to find the total ink volume per piece.

- Total Job Quantity: Multiply the ink volume per piece by the total number of pieces in the job.

- Add Waste Factor: Always add a waste factor (typically 10-20%) to account for ink loss during setup, cleaning, and potential errors.

Example: Let’s say we’re printing 100 pieces, each with a 10cm x 10cm print area (100cm²), at 100% coverage, with an ink layer thickness of 0.2mm. The total ink volume would be 100cm² * 0.02cm = 2cm³. Adding a 15% waste factor gives us a total ink requirement of 2.3cm³. We need to convert this volume to the standard unit of your ink supplier.

Q 21. What is the process for reclaiming and cleaning screens?

Screen reclaiming and cleaning are crucial for maintaining screen quality and extending their lifespan. Here’s a typical process:

- Remove Excess Ink: Immediately after printing, remove as much ink as possible from the screen using a screen-cleaning squeegee. This prevents the ink from drying and hardening.

- Initial Cleaning: Flush the screen with a suitable solvent or emulsion remover. The choice of cleaner depends on the type of ink used. For plastisol, you would use a plastisol remover. Always follow the manufacturer’s instructions.

- De-emulsification (if necessary): If the emulsion is damaged or needs to be removed, apply an emulsion remover according to the manufacturer’s guidelines. Let it dwell as instructed.

- Scrubbing: Use a specialized screen-cleaning brush to remove stubborn ink or emulsion. Be gentle to prevent damage to the screen mesh.

- Rinsing: Thoroughly rinse the screen with clean water to remove all traces of cleaner and ink. This is an important step for ensuring quality and longevity.

- Drying: Allow the screen to air dry completely before storage or reuse. This prevents mold or mildew growth.

- Storage: Properly store screens to protect them from damage and maintain their condition. This may involve storing them flat or in a protective sleeve.

Proper reclaiming and cleaning significantly extend the life of expensive screens, reducing the overall costs associated with screen printing.

Q 22. How do you handle variations in substrate material?

Handling variations in substrate material is crucial for successful screen printing on plastic. Different plastics have varying properties like surface tension, porosity, and flexibility, which directly impact ink adhesion and the final print quality. My approach involves a multi-step process:

- Material Identification: First, I meticulously identify the type of plastic – ABS, PETG, Polycarbonate, etc. – as each requires a tailored approach. For instance, a highly porous plastic might require a pre-treatment to improve ink adhesion.

- Pre-Treatment Testing: I conduct thorough pre-treatment tests, experimenting with different techniques like corona treatment (for non-porous plastics) or flame treatment (for some porous plastics). These treatments increase surface energy, allowing for better ink grip. This testing ensures I achieve optimal adhesion without damaging the substrate.

- Ink Selection: Choosing the right ink is paramount. I select inks specifically formulated for the target plastic. For example, plastisol inks are widely used but require careful consideration of the plastic’s heat resistance during the curing process. UV-curable inks offer faster curing times but might require specialized equipment.

- Print Pressure and Squeegee Technique: The pressure applied during printing and the squeegee technique need adjusting based on the substrate’s flexibility. A softer plastic might require less pressure to avoid distortion.

- Curing Optimization: Curing parameters are adjusted depending on the plastic’s heat tolerance. Overheating can warp or melt the plastic, while insufficient curing leads to poor adhesion and durability.

For example, I once worked on a project involving a uniquely flexible and slightly porous bioplastic. Through rigorous testing, I determined that a combination of flame treatment and a low-tack, UV-curable ink provided the best results, maintaining the substrate’s flexibility while ensuring a crisp, durable print.

Q 23. Describe your experience with different types of screen printing presses.

My experience spans a range of screen printing presses, from manual to automated systems. I’ve worked extensively with:

- Manual Presses: These are excellent for smaller runs and detailed work, allowing for precise control over the printing process. I’m proficient in adjusting pressure, speed, and squeegee angle for optimal results.

- Semi-automatic Presses: These offer a balance between manual control and efficiency. They often incorporate features like automatic pallet indexing and micro-registration adjustments, which improve speed and consistency.

- Automatic Presses: These high-volume presses are suitable for mass production. I’m familiar with programming and maintaining these systems, including troubleshooting malfunctions and optimizing print parameters for maximum throughput and consistent quality. I’ve worked with presses featuring conveyor systems, automated ink dispensing, and advanced registration systems.

Each press type presents its own challenges and benefits. Understanding their mechanics and capabilities is essential for selecting the appropriate equipment for a given project and optimizing production efficiency.

Q 24. Explain how you would troubleshoot a registration problem.

Registration problems, where the printed image isn’t aligned correctly, are common in screen printing. Troubleshooting involves a systematic approach:

- Visual Inspection: Begin by carefully inspecting the printed output to identify the nature and extent of the misalignment. Is it consistent across all prints, or does it vary?

- Screen Alignment: Check the alignment of the screens themselves. Ensure they are properly positioned and clamped on the press. Loose clamps or incorrect positioning can be major culprits.

- Pallet/Substrate Positioning: Verify that the substrate is consistently placed on the pallet. Inconsistent placement will directly lead to registration problems. Are there any issues with the pallet itself?

- Press Mechanics: Examine the press’s mechanical components. Worn parts or misaligned guides can lead to inconsistent registration. Check for any play or looseness in the press’s moving parts.

- Micrometer Adjustments: Many presses offer fine-tuning adjustments using micrometers. Carefully and incrementally adjust these to fine-tune registration. Make small adjustments and re-check the alignment after each step.

- Film Accuracy: Review the accuracy of the film positives used to create the screens. Errors in the film can directly translate to registration errors in the final print.

For example, a recent registration problem I solved involved a worn bearing in the press’s indexing mechanism. Replacing the bearing promptly resolved the issue.

Q 25. How do you address issues related to ink drying time?

Ink drying time is a critical factor in screen printing. Several factors affect drying time, and addressing issues requires a multifaceted approach:

- Ink Selection: Choosing the right ink for the substrate and environmental conditions is paramount. Low-viscosity inks dry faster than high-viscosity inks. UV-curable inks offer the fastest drying times.

- Environmental Conditions: High humidity and low temperatures slow down drying. Improving air circulation and increasing temperature can significantly reduce drying time. Consider using a drying cabinet or conveyor dryer.

- Ink Additives: Specific additives, such as catalysts or retarders, can be added to the ink to adjust the drying rate. This requires precise measurement and testing to avoid negatively impacting ink quality.

- Substrate Porosity: Porous substrates will absorb ink more quickly and result in faster drying. Non-porous substrates might require techniques like enhanced airflow or additional heat to speed up drying.

- Print Thickness: Thicker print layers require longer drying times. Optimizing the print thickness can reduce drying time without compromising print quality.

For instance, I once encountered slow drying times during a hot, humid summer. By adjusting the air circulation in our print shop and incorporating a forced-air drying system, we substantially reduced drying times and improved production efficiency.

Q 26. What is your experience with automated screen printing processes?

My experience with automated screen printing processes is substantial. I’ve worked with fully automated systems that encompass various stages, from screen preparation and ink dispensing to printing and curing. This involves:

- Programming and Setup: I’m proficient in programming automated presses, setting parameters like print speed, pressure, squeegee angle, and ink flow. I understand the interplay between different variables to optimize print quality and speed.

- Troubleshooting and Maintenance: Automated systems require regular maintenance and troubleshooting. I’m experienced in identifying and resolving malfunctions, optimizing system performance, and performing preventative maintenance.

- Data Analysis and Optimization: Automated presses generate significant data about production parameters. I’m skilled in analyzing this data to identify areas for improvement, optimizing the printing process for efficiency, consistency, and reduced waste.

- Integration with other Systems: Many automated systems are integrated with other manufacturing technologies like automated feeding systems, conveyor belts, and curing ovens. Understanding these integrations is essential for smooth operation.

For example, I helped optimize an automated screen printing line by analyzing production data and identifying inconsistencies in ink dispensing. Fine-tuning the automated ink delivery system significantly reduced ink waste and improved print consistency.

Q 27. What are the common causes of screen damage and how do you prevent them?

Screen damage is a major concern in screen printing. Common causes include:

- Improper Cleaning: Aggressive cleaning or the use of harsh chemicals can damage the screen mesh. Always use appropriate cleaning solutions and gentle techniques.

- Incorrect Emulsion Application: Uneven emulsion application or inadequate drying can weaken the screen, making it more susceptible to damage.

- Excessive Pressure During Printing: Applying too much pressure during printing can stretch or tear the mesh.

- Sharp Objects: Carelessness can lead to punctures from sharp objects.

- Improper Storage: Incorrect storage can cause screens to warp or become damaged.

Prevention involves careful handling, proper cleaning techniques, and appropriate storage. I emphasize training and preventative measures to reduce screen damage, thereby minimizing costs and downtime. For example, we implemented a strict screen handling protocol, including designated storage areas and regular inspections, that significantly reduced the incidence of screen damage in our operations.

Q 28. How do you stay updated with the latest advancements in screen printing techniques?

Staying updated on advancements in screen printing is crucial for maintaining competitiveness. My strategies include:

- Industry Publications and Trade Shows: I regularly read industry publications, attend trade shows (like SGIA), and participate in webinars. This provides insight into new equipment, inks, and techniques.

- Networking with Professionals: I actively network with other screen printers and industry experts to share knowledge and learn about best practices.

- Online Resources and Forums: I utilize online resources and forums to engage with the wider screen printing community and stay informed about the latest developments.

- Continuing Education Courses: I seek out continuing education courses and workshops offered by industry organizations to enhance my expertise in specific areas.

- Manufacturer Websites and Technical Documentation: I consult manufacturer websites and technical documentation to learn more about the capabilities and features of new equipment and supplies.

Staying current ensures I remain at the forefront of the industry, enabling me to provide innovative solutions and deliver high-quality results for my clients. For example, recently I learned about a new type of low-migration ink through a trade show, which I successfully implemented to meet stricter regulations for food packaging applications.

Key Topics to Learn for Screen Printing on Plastic Interview

- Screen Preparation & Design: Understanding film positives, emulsion application, exposure techniques, and screen reclaiming processes. Consider the impact of different mesh counts on print quality.

- Ink Selection & Properties: Knowledge of various plastisol inks, their curing methods, and the importance of choosing the right ink for the substrate and application (e.g., flexibility, durability). Discuss viscosity and its role in the printing process.

- Printing Techniques & Press Operation: Familiarity with manual and automatic screen printing presses, including setup, registration, squeegee pressure and angle, and troubleshooting common printing issues (e.g., pinholes, smearing).

- Substrate Preparation & Handling: Understanding the specific requirements for preparing plastic substrates for screen printing, including cleaning, pre-treatments, and surface preparation techniques to ensure proper ink adhesion.

- Curing & Post-Printing Processes: Knowledge of different curing methods (convection, UV, infrared) and their impact on ink adhesion, durability, and the overall quality of the printed product. Discuss quality control and inspection procedures.

- Safety and Environmental Considerations: Understanding safety protocols related to ink handling, cleaning solvents, and proper waste disposal. Discuss environmentally friendly printing practices.

- Troubleshooting & Problem-Solving: Ability to diagnose and resolve common screen printing problems, such as ink issues, registration errors, and substrate imperfections. Showcase your analytical and problem-solving skills.

- Industry Standards & Best Practices: Familiarity with industry standards and best practices related to color matching, quality control, and efficient production processes.

Next Steps

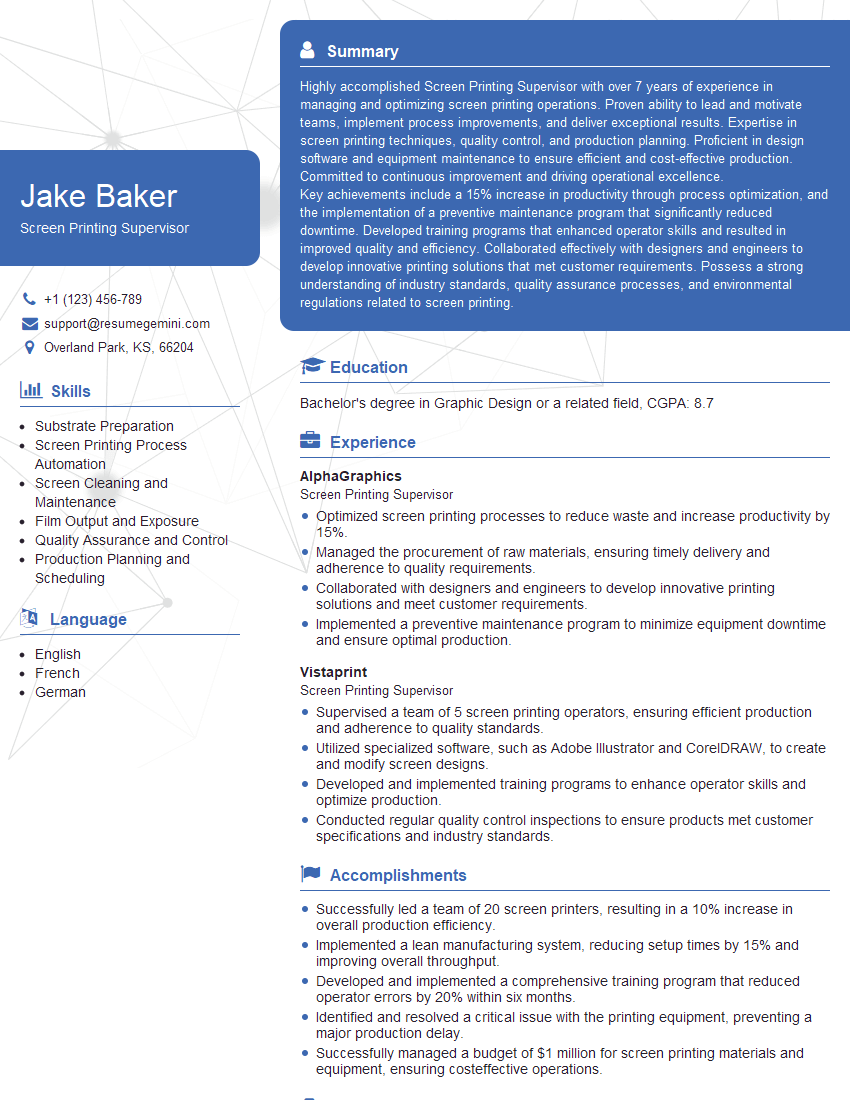

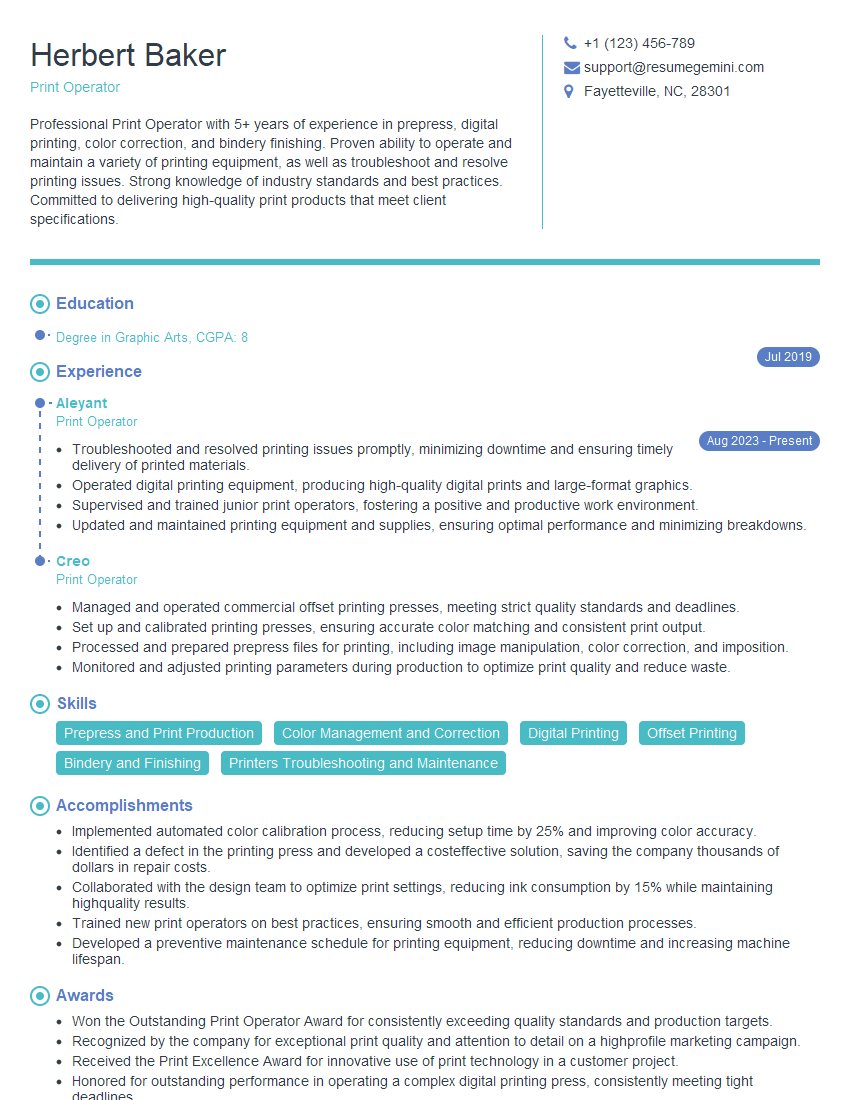

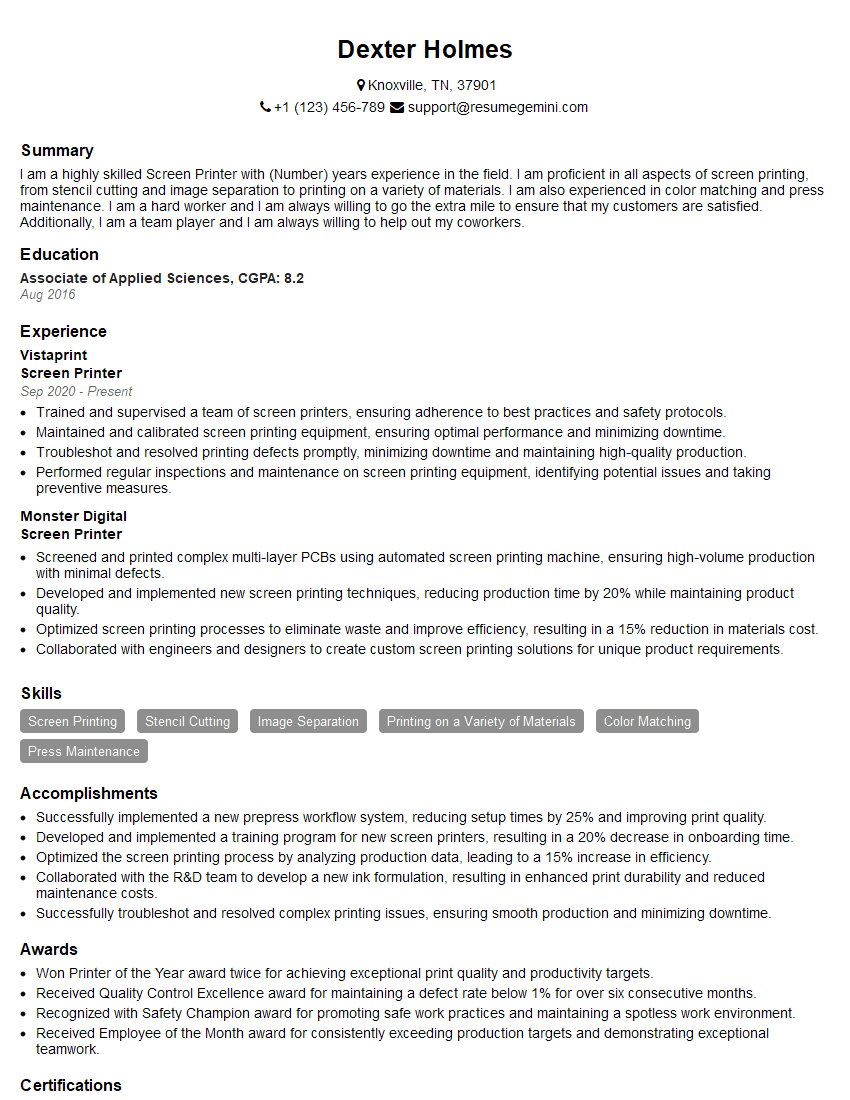

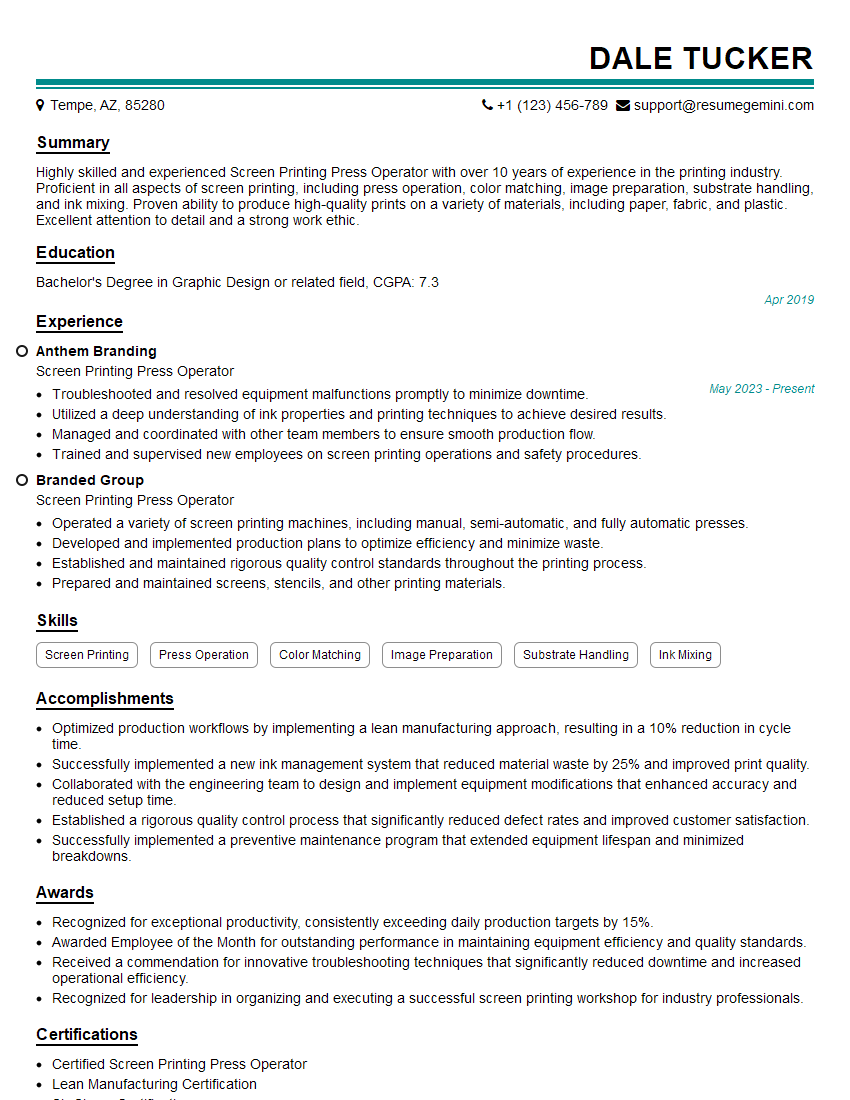

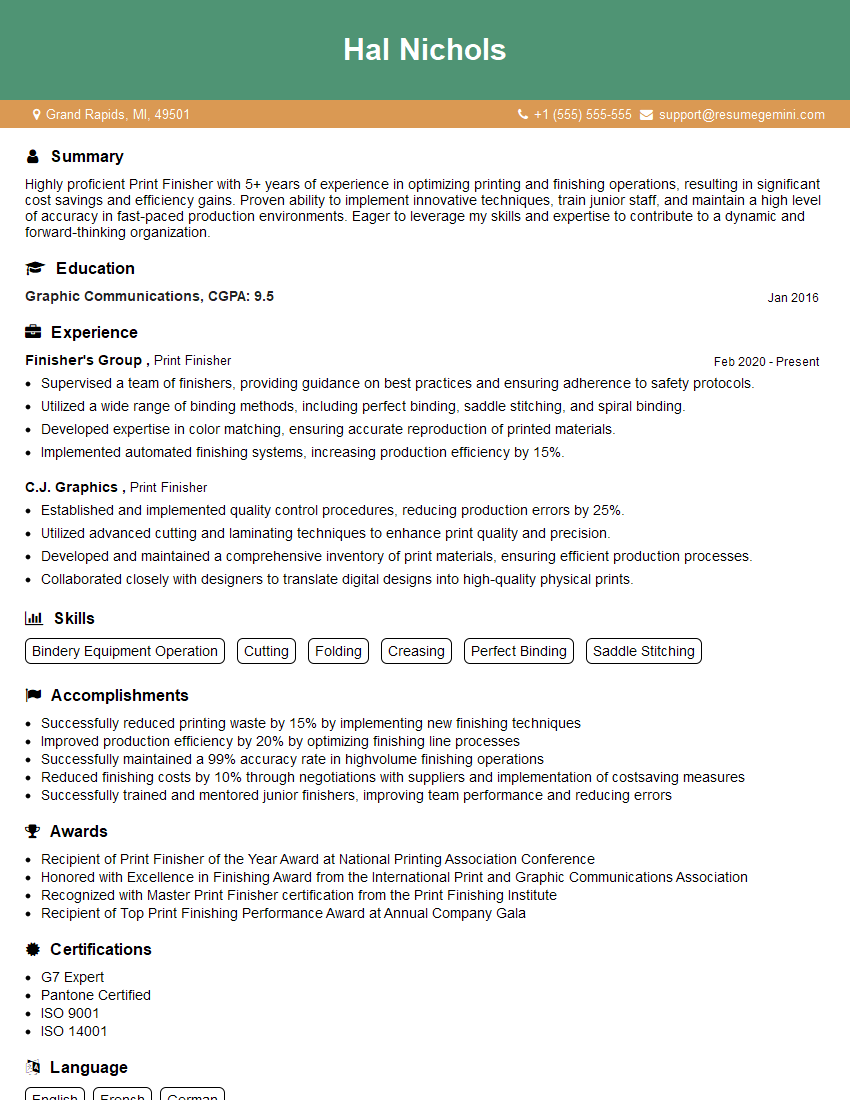

Mastering screen printing on plastic opens doors to exciting career opportunities in diverse industries, from packaging and signage to promotional products and apparel. A strong understanding of this specialized skillset significantly increases your marketability and earning potential. To stand out from the competition, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource for building professional, impactful resumes that get noticed. They provide examples of resumes tailored to Screen Printing on Plastic to help you create a document that effectively showcases your skills and experience. Invest the time to build a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good