Are you ready to stand out in your next interview? Understanding and preparing for Screwing and Bolting interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Screwing and Bolting Interview

Q 1. What are the different types of screw threads and their applications?

Screw threads come in various types, each designed for specific applications. The most common types include:

- Metric Threads: Defined by ISO standards, these are widely used globally. They are identified by their diameter and pitch (distance between thread crests). For example, an M6 x 1 screw has a 6mm diameter and a 1mm pitch. These are robust and versatile, found in automotive, manufacturing, and general engineering.

- Unified National Coarse (UNC) and Fine (UNF) Threads: These are prevalent in the United States and are specified by their diameter and number of threads per inch (TPI). UNC threads have a coarser pitch than UNF threads, making them suitable for applications requiring a faster assembly, but potentially less strength. UNF threads provide greater precision and strength, often used in applications demanding higher clamping forces.

- Whitworth Threads: An older British standard, still found in older machinery. They have a distinctive triangular profile, different from both Metric and Unified threads. They are less common now but require specialist tools.

- Acme Threads: These have a trapezoidal profile, creating less friction than V-threads. They’re ideal for power screws in applications where precise movement is important, such as in lead screws for machine tools or jacks.

- Buttress Threads: These have an asymmetrical profile designed to handle high loads in one direction while minimizing friction during retraction. They’re commonly used in applications like gun mechanisms or clamping devices.

Choosing the right thread depends entirely on the application’s strength requirements, the material being fastened, and the desired level of precision. Using the wrong thread type can lead to failure or damage.

Q 2. Explain the importance of proper torque control in bolting.

Proper torque control in bolting is absolutely crucial for ensuring joint integrity and preventing failures. Over-tightening can lead to bolt fracture, stripped threads, or component damage. Under-tightening results in insufficient clamping force, leading to leaks, loosening, and potential structural collapse. Imagine a car engine: incorrectly torqued cylinder head bolts could lead to catastrophic engine failure.

Torque control ensures that the right amount of clamping force is applied, creating a secure and reliable joint. It’s not about how tight you can turn the bolt, but about applying the correct tension. This is determined by factors such as bolt size, material, and application requirements. Torque specifications are usually provided by the manufacturer or in engineering drawings and should always be followed meticulously.

Q 3. Describe different methods for ensuring proper fastener tightening.

Several methods help ensure proper fastener tightening:

- Torque Wrench: This is the most accurate method, directly controlling the applied torque. Different types exist, such as click-type, beam-type, and digital torque wrenches, each offering varying degrees of precision and cost.

- Angle Tightening: After tightening a bolt to a specific preload, an additional angle of rotation is applied. This is particularly useful for high-strength bolts where exceeding the yield strength is a concern. This ensures consistent tension even if friction varies.

- Tensioning Tools: Hydraulic or pneumatic tensioners apply a precise tension to the bolt, independent of friction. This method is best for large or high-strength bolts where consistent tension is paramount.

- Pre-load Indicators: Some specialized bolts incorporate features like indentations that change colour or markings when the correct tension is achieved, providing visual confirmation.

The chosen method depends on the application and required precision. In many situations, a combination of methods, such as a torque wrench with an angle gauge, offers increased accuracy and safety.

Q 4. What are the safety precautions when using power tools for screwing and bolting?

Safety is paramount when using power tools for screwing and bolting. Always follow these precautions:

- Wear appropriate safety equipment: This includes safety glasses, hearing protection (power tools can be very loud), and work gloves to protect hands from injuries.

- Use the correct tool for the job: Don’t force a tool beyond its capacity or use it for a task it isn’t designed for.

- Ensure proper tool maintenance: Regularly check for wear, damage, and proper functionality. A damaged tool can be dangerous.

- Secure the workpiece: A loose workpiece can easily cause injury. Use clamps or a vise to secure it firmly before starting the operation.

- Never operate power tools while fatigued or under the influence of drugs or alcohol: This significantly increases the risk of accidents.

- Follow the manufacturer’s instructions: Each tool comes with instructions, and they should be followed carefully.

- Disconnect the power source before performing maintenance or changing bits: This is a crucial step to prevent accidental start-ups.

A moment of carelessness can lead to serious injuries. Prioritizing safety ensures a safe and productive work environment.

Q 5. How do you identify different types of bolts and screws?

Identifying different types of bolts and screws involves understanding their head styles, thread types, and materials.

- Head Styles: Common head styles include hex heads, Phillips heads, slotted heads, Torx heads, and countersunk heads. The head style dictates the type of driver needed.

- Thread Types: As discussed earlier, thread types vary significantly. Examining the thread profile and measuring the pitch or TPI can help identify the thread type.

- Materials: Bolts and screws can be made from various materials, like steel, stainless steel, brass, or aluminum. Visual inspection and sometimes material testing can determine the material.

- Markings: Many bolts and screws bear markings indicating their grade, material, or manufacturer. These markings can be helpful in identifying them.

A combination of visual inspection, measurements, and knowledge of common fasteners will allow for accurate identification.

Q 6. Explain the difference between a bolt and a screw.

The key difference between a bolt and a screw lies in how they are fastened and their intended application. A bolt is typically used with a nut, creating a fastening system where the bolt threads into a mating hole and is tightened with a nut. Think of a wheel bolt on a car.

A screw, on the other hand, typically creates a fastening by directly screwing into a pre-made hole (threaded or unthreaded), often without the need for a nut. A wood screw is a perfect example; it is directly screwed into the wood. While some screws, like machine screws, can use nuts, the intended function is typically direct engagement with the material.

The distinction isn’t always clear-cut, as some fasteners blur the lines. But the fundamental difference lies in their assembly methods and intended uses.

Q 7. What are the consequences of over-tightening or under-tightening bolts?

The consequences of improper bolt tightening can be severe. Over-tightening can lead to:

- Bolt Fracture: The bolt can snap, rendering the joint completely insecure and potentially causing damage to adjacent components.

- Stripped Threads: The threads on the bolt or the mating part can become damaged, making it impossible to achieve a secure joint.

- Component Damage: Excessive force can deform or damage the parts being fastened.

Under-tightening, conversely, leads to:

- Insufficient Clamping Force: The joint won’t be held securely, leading to loosening over time.

- Leaks: In fluid systems, under-tightening can cause leaks and fluid loss.

- Structural Failure: In critical applications, insufficient clamping force can lead to structural failure and significant safety risks.

In either case, improper tightening can lead to costly repairs, equipment downtime, and potentially serious safety hazards.

Q 8. How do you select the appropriate fastener for a given application?

Selecting the right fastener involves considering several crucial factors. Think of it like choosing the right tool for a job – a screwdriver for a screw, a wrench for a bolt. You wouldn’t use a hammer to drive a screw, right? Similarly, the wrong fastener can lead to failure.

- Material Compatibility: The fastener material must be compatible with the materials being joined to prevent corrosion or galvanic action. For instance, using a stainless steel bolt in an aluminum component might cause corrosion over time.

- Strength Requirements: Determine the required tensile strength, shear strength, and fatigue strength based on the load the joint will experience. A simple shelf might need a small screw, while a bridge support would necessitate a much stronger bolt.

- Environmental Conditions: Consider the operating environment. Will the fastener be exposed to extreme temperatures, chemicals, or moisture? This influences the choice of material and coating.

- Thread Type and Size: Select the appropriate thread type (e.g., coarse, fine) and size to ensure a secure and reliable connection. Fine threads offer better resistance to vibration, while coarse threads are easier to install.

- Head Style and Drive Type: The head style (e.g., countersunk, hex head) and drive type (e.g., Phillips, Torx) depend on accessibility and the torque required.

For example, joining two pieces of mild steel in a low-stress application might involve a simple carbon steel machine screw. However, joining high-strength steel components under significant stress requires a high-strength bolt with a suitable coating for corrosion resistance.

Q 9. What are the common causes of fastener failure?

Fastener failure is often a result of improper selection, installation, or environmental factors. Imagine a poorly tightened bolt on a bicycle wheel – disaster is waiting to happen!

- Over-tightening: This can lead to stripping threads, yielding of the bolt material, or damage to the joined components. It’s crucial to use the right torque.

- Under-tightening: Insufficient preload allows the joint to loosen under vibration or stress, potentially leading to failure.

- Corrosion: Environmental exposure can weaken the fastener, causing it to fail prematurely. Proper material selection and coatings are vital.

- Fatigue: Repeated cyclic loading, particularly in vibration-prone applications, can lead to fatigue failure. Using a fastener designed for cyclic loading is necessary.

- Improper Threading: Damaged or cross-threaded fasteners cannot transmit loads effectively.

- Galling: This is a severe form of friction welding that can cause fasteners to seize and fail, especially in dissimilar metals.

Preventive measures include careful material selection, proper installation procedures, regular inspections, and the use of appropriate lubricants.

Q 10. Describe the different types of torque wrenches and their use.

Torque wrenches are essential tools for ensuring fasteners are tightened to the correct specification. Just like a baker needs a precise scale, we need a torque wrench for precise fastening. There are several types:

- Beam-type Torque Wrenches: These are simple, economical wrenches with a calibrated beam that indicates when the target torque is reached. They’re suitable for less demanding applications.

- Click-type Torque Wrenches: These wrenches produce an audible ‘click’ when the target torque is reached, providing precise control. They’re common in many applications.

- Electronic Torque Wrenches: These advanced wrenches provide a digital readout of the applied torque, often with additional features like data logging and peak torque recording. They are more expensive but offer higher precision.

- Hydraulic Torque Wrenches: Used for very high torque applications, these wrenches use hydraulic pressure to apply the torque. They’re essential in heavy industrial settings.

The choice of torque wrench depends on the application’s torque requirements, budget, and desired precision. A beam-type wrench might suffice for home repairs, while an electronic wrench would be preferred for critical aerospace applications.

Q 11. How do you calibrate a torque wrench?

Torque wrench calibration is crucial for ensuring accurate and reliable tightening. A miscalibrated wrench can lead to fastener failures. Calibration should be performed by a qualified technician using specialized equipment. The process typically involves:

- Verification of Wrench Type and Range: Confirming the wrench is appropriate for the torque range needed.

- Verification of the Calibration Procedure: Utilizing a calibrated torque measuring device to assess the accuracy of the wrench.

- Testing at Multiple Points: Performing tests at several points within the wrench’s range to identify any deviations.

- Documentation: Maintaining detailed records of the calibration procedure and results.

- Frequency: Calibrating the wrench at recommended intervals, typically annually or according to manufacturer’s guidelines or specific industry requirements.

Ignoring calibration can lead to costly repairs or even catastrophic failures, so regular calibration is non-negotiable.

Q 12. How do you handle stripped threads?

Stripped threads are a common problem, but there are ways to fix them. Imagine trying to screw a screw into soft wood – if you’re not careful, you can easily strip the wood. Similar things happen with metal threads.

- Thread Repair Inserts (Helicoils): These are small, coiled inserts that are installed into the stripped threads to restore their integrity.

- Time-Sert Inserts: These are similar to helicoils, but offer a different installation process and potentially stronger repair.

- Thread Chasing: Using a thread chaser tool to clean up damaged threads, but this might not work if the damage is extensive.

- Oversized Fastener: If the damage is minor, using a slightly larger diameter fastener (requiring a larger hole) can sometimes work, but it weakens the joint.

- Welding: In some cases, welding a new nut or thread onto the damaged component might be an option.

The best approach depends on the severity of the damage, the material of the component, and the accessibility of the damaged area.

Q 13. What is the importance of lubrication in bolting?

Lubrication plays a vital role in bolting, much like oil in an engine. It reduces friction, improves torque transmission, and prevents galling and corrosion. Consider this: a dry bolt is harder to turn and more likely to be damaged.

- Reduced Friction: Lubricant reduces friction between the bolt threads and the mating surfaces, allowing for easier installation and more accurate torque control.

- Improved Torque Transmission: The lubricant ensures that the applied torque is effectively transferred to the joint, leading to a more secure connection.

- Corrosion Prevention: Many lubricants offer corrosion protection, extending the life of the fastener and preventing premature failure.

- Galling Prevention: Lubricants act as a barrier between mating surfaces, preventing galling (a type of welding) which can damage threads.

Appropriate lubricants should be selected based on the materials being joined and the operating environment. Some common choices include anti-seize compounds, molybdenum disulfide-based lubricants, and specialized high-temperature greases.

Q 14. What are some common problems encountered during screwing and bolting?

Screwing and bolting, while seemingly simple, can present several challenges:

- Stripped Threads: As discussed earlier, this occurs when excessive force is applied during installation.

- Incorrect Torque: Over-tightening or under-tightening can compromise the integrity of the joint.

- Galling: This is a particularly nasty problem, which can make fasteners incredibly difficult to remove.

- Corrosion: Moisture, chemicals, and other environmental factors can cause corrosion, leading to fastener failure.

- Premature Loosening: Vibration or cyclical loading can cause fasteners to loosen over time.

- Difficulty of Access: In some applications, limited space makes it difficult to use standard tools.

- Material Compatibility Issues: Using incompatible materials can lead to corrosion or other problems.

Careful planning, appropriate tool selection, and a thorough understanding of materials and environmental factors are crucial to prevent these problems. A well-planned approach significantly reduces problems and helps ensure the safety and reliability of the bolted joint.

Q 15. How do you troubleshoot problems with fastener installation?

Troubleshooting fastener installation problems involves a systematic approach. First, identify the issue: Is the fastener stripping, is it not tightening sufficiently, is it cross-threading, or is there a material incompatibility?

- Stripping: This usually means the fastener is too small for the hole, the material is too soft, or excessive torque was applied. Solution: Use a larger diameter fastener, switch to a harder material, or use a torque wrench to control applied force.

- Insufficient Tightening: This could be due to a dull driver bit, incorrect torque application, or a damaged fastener. Solution: Replace the bit, use a calibrated torque wrench, and inspect the fastener for damage.

- Cross-threading: This occurs when the threads of the fastener don’t align correctly with the threads in the hole. Solution: Carefully align the threads before tightening; in severe cases, you might need to re-tap the hole.

- Material Incompatibility: Using the wrong fastener type for a specific material can lead to failure. For example, using a standard steel screw in an aluminum part might lead to stripping. Solution: Consult fastener selection charts and use appropriate materials and coatings.

Often, a visual inspection followed by methodical investigation of the above points will reveal the root cause. Remember to always prioritize safety and use appropriate personal protective equipment (PPE).

Career Expert Tips:

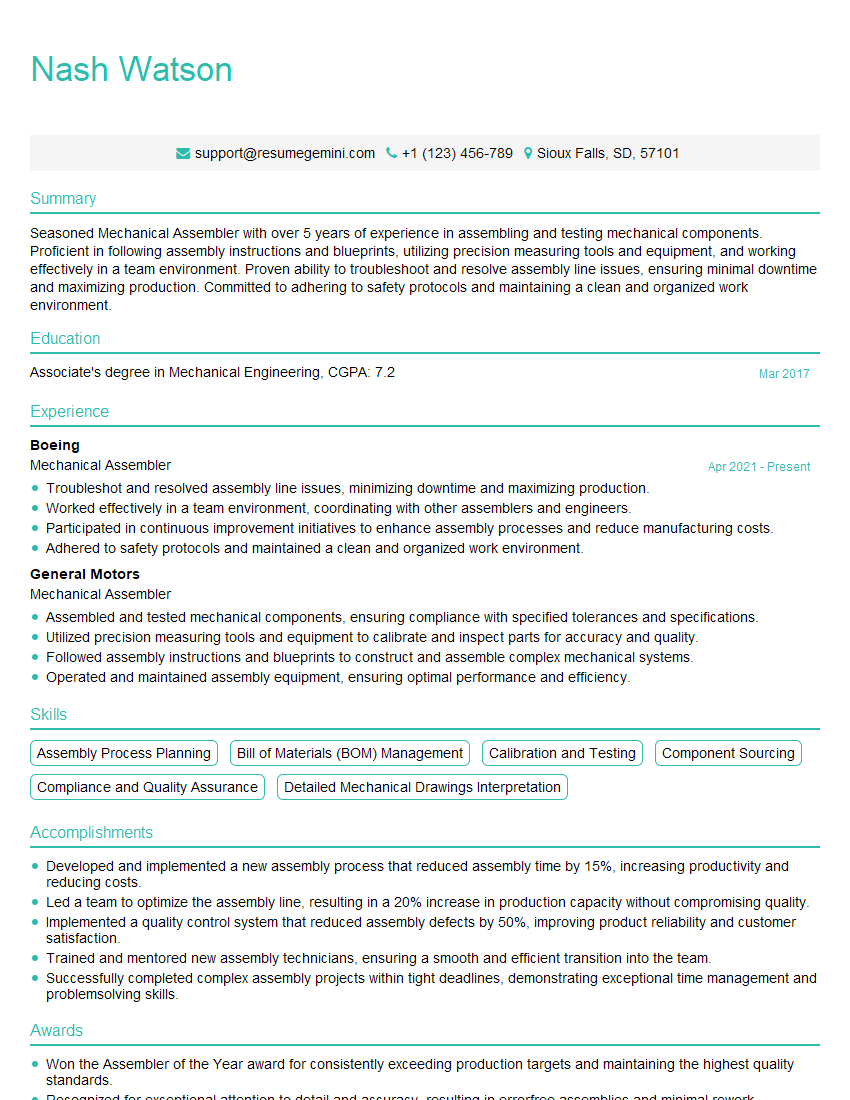

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of power tools used for screwing and bolting.

My experience encompasses a wide range of power tools used for screwing and bolting, including impact drivers, impact wrenches, and cordless drills.

- Impact Drivers: Excellent for driving screws into hard materials, minimizing cam-out (driver slipping off the screw head). They provide high torque in a compact size.

- Impact Wrenches: Ideal for bolting applications requiring high torque and speed, particularly in repetitive tasks. They can significantly reduce the time required for tightening numerous bolts.

- Cordless Drills: Versatile and useful for less demanding screwing applications, but lack the power of impact drivers and wrenches for heavy-duty tasks. The variable speed settings allow for precise control.

I’m proficient in selecting the appropriate tool based on the job’s requirements. For instance, a small impact driver is perfect for assembling furniture, while a powerful impact wrench is necessary for connecting heavy machinery components. Regular maintenance of these tools is vital to ensure their accuracy and longevity, including cleaning, lubrication, and regular calibration checks for torque tools.

Q 17. Explain the concept of preload in bolting.

Preload in bolting refers to the initial tension applied to a bolt before it is subjected to external loads. Imagine it like pre-stretching a rubber band before using it – it gives it more strength and resilience. This tension is crucial because it clamps the joined parts together, creating friction that resists external forces.

Adequate preload ensures that the joint remains secure even under stress, preventing loosening, leakage, or failure. Insufficient preload can lead to joint separation, while excessive preload may damage the bolt or the joined materials. The proper preload depends on factors like the bolt size, material, and the applied loads.

Q 18. How do you determine the correct bolt tension?

Determining the correct bolt tension is paramount for joint integrity. There are several methods:

- Torque Wrench Method: This is the most common method, employing a calibrated torque wrench to apply the specified torque to the fastener. Torque values are typically found in engineering drawings or fastener manufacturer’s specifications. The torque value must be correctly selected to achieve the desired clamp load.

- Turn-of-Nut Method: This involves tightening the bolt to a specific number of turns after it makes initial contact. This method is less precise than the torque wrench method but can be helpful in situations where a torque wrench isn’t readily available.

- Strain Gage Method: This method uses strain gauges attached to the bolt to measure the bolt’s elongation, which is directly related to tension. This is a very precise method often used in critical applications.

- Direct Tension Measurement: This involves measuring the tension directly using specialized tools. This is typically used for high-strength bolts in critical applications.

It’s crucial to use the appropriate method and tool for the job. Calibration of torque wrenches is also critically important, as inaccuracies can compromise joint integrity.

Q 19. Describe your experience with various types of fasteners (e.g., hex bolts, cap screws, self-tapping screws).

I have extensive experience with various fastener types, each with unique characteristics and applications:

- Hex Bolts: Common general-purpose fasteners with a hexagonal head, ideal for applications requiring high clamping force and ease of tightening with a wrench.

- Cap Screws: Similar to hex bolts but with a shorter head and often used in applications where head appearance is important. Various head types are available, such as socket head cap screws which can be tightened with an Allen key or socket.

- Self-tapping Screws: Designed to create their own threads when driven into a material, eliminating the need for pre-drilled holes. These are widely used in applications requiring quicker assembly, particularly in softer materials like wood or plastic.

- Machine Screws: Typically smaller than hex bolts and cap screws and are used where a smaller head profile is required.

Selecting the right fastener is crucial, considering factors like material strength, thread type, and head style. For example, using stainless steel fasteners in corrosive environments prevents rust and ensures long-term reliability. I always carefully examine the application before choosing a fastener to ensure compatibility and safety.

Q 20. What are the safety procedures for working at heights involving bolting tasks?

Safety is paramount when performing bolting tasks at heights. This involves adhering to strict safety protocols:

- Fall Protection: Employing appropriate fall protection systems such as harnesses, lifelines, and anchor points is mandatory. Regular inspection of safety equipment is crucial.

- Scaffolding and Access: Using stable and properly constructed scaffolding or other access equipment provides a secure working platform. All scaffolding must be erected and inspected by a competent person.

- Tool Tethering: Attaching tools to prevent accidental drops is essential. Dropped tools pose a significant risk to those below.

- Communication: Clear communication with ground personnel is vital, particularly when working in teams.

- Weather Conditions: Work at heights should be avoided during adverse weather conditions (high winds, rain, snow).

Following these procedures ensures the safety of both the worker and those around them. Thorough planning and risk assessment before commencement of the work is extremely important.

Q 21. How do you handle damaged or worn fasteners?

Damaged or worn fasteners should never be reused. This is a critical safety consideration. Indicators of damage include:

- Stripped Threads: Threads that are damaged or deformed, making it difficult or impossible to obtain proper tightening.

- Bent or Broken Fasteners: Fasteners that have been bent or broken, compromising their structural integrity.

- Corrosion: Significant corrosion weakens the fastener and can cause unpredictable failure.

Replacing damaged fasteners is always the safest and most effective solution. Using damaged fasteners risks structural failure and potential injuries. In critical applications, damaged fasteners may require a complete system inspection to verify the extent of the damage.

Q 22. What is your experience with automated bolting systems?

My experience with automated bolting systems spans several years and various applications. I’ve worked extensively with hydraulic and pneumatic bolt tensioning systems, including those used in large-scale industrial projects like wind turbine assembly and bridge construction. These systems significantly improve efficiency and consistency compared to manual methods. For instance, on a recent wind turbine project, the automated system allowed us to tighten over 100 bolts per turbine with precise torque control, guaranteeing uniform tension and reducing assembly time by approximately 40%. I’m familiar with programming and troubleshooting these systems, ensuring proper calibration and maintenance for optimal performance. This includes understanding the nuances of different control systems and integrating them with other automated processes on the assembly line.

Beyond the large-scale applications, I’ve also worked with smaller, more specialized automated systems, such as those found in automotive manufacturing. These often utilize robotic arms for precise bolt placement and tightening, maximizing efficiency and minimizing human error. My experience encompasses both the practical operation and the theoretical understanding of the engineering principles behind these systems.

Q 23. Describe your experience with different types of bolt materials (e.g., steel, stainless steel, aluminum).

My experience encompasses a wide range of bolt materials, each with its own unique properties and applications. Steel bolts are the most common, offering a good balance of strength and cost-effectiveness. I frequently work with various grades of carbon steel, choosing the appropriate grade based on the specific load requirements and environmental conditions. For example, higher-strength steel bolts are crucial in applications with significant stress, such as structural steel connections. Stainless steel bolts provide excellent corrosion resistance, making them ideal for marine or chemical processing environments. Their higher cost is justified by their extended lifespan and reduced maintenance needs. I’ve also used aluminum bolts in situations where weight reduction is paramount, such as in aerospace applications. However, aluminum’s lower strength must be considered carefully during design and selection.

Understanding the material properties is key to selecting the right bolt. This goes beyond simply knowing the material – it involves understanding its yield strength, tensile strength, and fatigue characteristics. The choice also depends on the working temperature range and the expected corrosive environment. Mismatched bolt material can lead to premature failure and catastrophic consequences. For example, using a low-grade steel bolt in a high-stress application could result in a fracture, potentially leading to structural collapse.

Q 24. How do you ensure the quality and integrity of bolted joints?

Ensuring the quality and integrity of bolted joints is paramount. My approach is multifaceted and starts with proper design. This includes selecting appropriate bolt sizes and materials based on the expected loads, considering factors like shear, tension, and fatigue. I always adhere to relevant codes and standards like ASME, ISO, and industry-specific guidelines. After the bolts are installed, the joint’s integrity is verified through various methods.

- Torque Measurement: Precise torque wrenching ensures each bolt is tightened to the specified tension, preventing over-tightening (which can lead to bolt failure) or under-tightening (which compromises joint strength).

- Turn-of-Nut Method: This method uses a calibrated wrench to measure the number of turns after the initial tightening, ensuring consistent tension across multiple bolts.

- Ultrasonic Testing: This non-destructive testing method identifies potential flaws within the joint, such as incomplete tightening or micro-cracks.

- Visual Inspection: A thorough visual inspection checks for damage to the bolts or mating surfaces.

Documentation is crucial; maintaining detailed records of torque values, bolt materials, inspection results, and any deviations from specifications ensures traceability and aids in troubleshooting potential issues. A well-documented process minimizes the risk of failures and allows for quick diagnosis of any problems.

Q 25. Explain your experience using torque multipliers.

Torque multipliers are invaluable tools for tightening high-torque bolts, offering a significant mechanical advantage. I have extensive experience using both hydraulic and pneumatic torque multipliers in various applications, from heavy machinery assembly to bridge construction. These tools allow us to achieve high torque values with relatively less effort, reducing fatigue and the risk of injury to technicians.

The selection of a torque multiplier depends on the required torque, the accessibility of the bolt, and the overall safety requirements. For example, in confined spaces, a compact pneumatic multiplier might be preferred. For extremely high torque values, a hydraulic multiplier is typically necessary. I understand the importance of regular calibration and maintenance of these tools. Calibration ensures accuracy, and proper maintenance prevents damage to the tool or the bolts being tightened. Incorrect calibration or maintenance can lead to faulty torque values, affecting the overall integrity of the bolted joint.

In practice, I always use a torque multiplier in conjunction with a torque wrench or other accurate measuring device to ensure the desired torque is achieved. This layered approach offers a crucial safety net.

Q 26. Describe your experience with different locking mechanisms for fasteners.

Various locking mechanisms ensure the integrity of bolted joints over time, preventing loosening due to vibration or environmental factors. My experience includes using several locking methods, each suitable for different applications and levels of required security.

- Locknuts: These include nylon insert locknuts, all-metal locknuts, and prevailing torque nuts. The choice depends on the required clamping force and the operating environment.

- Washers: Various types of washers, like spring washers, tooth lock washers, and Belleville washers, are used to increase friction and prevent loosening.

- Thread Lockers: Anaerobic thread locking adhesives provide a strong chemical bond, preventing loosening. The choice of adhesive strength varies based on the application requirements.

- Pins and Cotter Pins: These provide a mechanical lock, offering a robust and reliable solution in critical applications.

The choice of locking mechanism depends heavily on the application. In high-vibration environments, for instance, a combination of a prevailing-torque nut and a thread locker might be necessary. Conversely, in a less demanding application, a simple lockwasher might suffice. In selecting the appropriate locking mechanism, I carefully assess all potential environmental factors and anticipated loads, ensuring a reliable and secure fastening solution.

Q 27. What is your experience with preventative maintenance of bolting equipment?

Preventative maintenance is critical for ensuring the longevity and reliability of bolting equipment, both manual and automated. My preventative maintenance strategy includes regular inspections, lubrication, and calibration. For torque wrenches, this means regular calibration according to a defined schedule using certified equipment. For torque multipliers, I follow the manufacturer’s recommendations for lubrication and inspection, ensuring that all moving parts are functioning correctly and free from damage. I also check for any leaks in hydraulic systems and inspect hoses and fittings for wear. For automated systems, preventative maintenance is more involved and may include software updates, sensor checks, and regular cleaning to prevent malfunctions.

A comprehensive maintenance log is essential, documenting all inspections, maintenance activities, and calibration results. This allows for tracking potential issues, anticipating failures, and planning repairs efficiently. Neglecting preventative maintenance leads to increased downtime, potential safety hazards, and ultimately, more expensive repairs.

Q 28. How do you ensure compliance with relevant safety standards and regulations?

Compliance with relevant safety standards and regulations is a non-negotiable aspect of my work. I meticulously follow guidelines from organizations such as OSHA (Occupational Safety and Health Administration), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization) which are crucial for the safety of personnel and the integrity of the bolted joints. This encompasses the proper use of personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. All equipment used must be correctly calibrated and maintained to ensure accurate operation and avoid accidents. The selection of appropriate bolts and locking mechanisms must always adhere to the relevant standards for the specific application.

I regularly review updates to these standards to maintain my knowledge and ensure that my practices are always current. Thorough documentation of all procedures and compliance activities forms an auditable trail that proves adherence to regulations and best practices. I view compliance not just as a set of rules, but as a fundamental element of ensuring safety and project success.

Key Topics to Learn for Screwing and Bolting Interview

- Fastener Types and Selection: Understanding various screw and bolt types (machine screws, self-tapping screws, bolts, studs), their materials (steel, stainless steel, etc.), and selecting the appropriate fastener for specific applications based on strength, material compatibility, and environmental conditions.

- Torque Specifications and Control: Mastering the importance of proper torque application to ensure secure fastening and avoid damage. Understanding different torque measurement methods and tools (torque wrenches, torque multipliers).

- Thread Engagement and Failure Modes: Identifying potential failure points in screwed joints, such as stripped threads, galling, and improper torque. Knowing preventative measures and troubleshooting techniques.

- Joint Design and Analysis: Understanding the principles of joint design considering factors like load distribution, clamping force, and fatigue resistance. This includes knowledge of different joint configurations and their strengths and weaknesses.

- Safety Procedures and Regulations: Familiarity with relevant safety standards and regulations concerning the handling and use of fastening tools and equipment. This includes understanding personal protective equipment (PPE) requirements.

- Practical Applications and Case Studies: Being able to discuss real-world examples where screwing and bolting techniques are crucial, such as in automotive, aerospace, construction, or manufacturing industries. Analyzing successful and unsuccessful case studies.

- Troubleshooting and Problem-Solving: Demonstrating the ability to diagnose and solve problems related to fastening, such as loose connections, stripped threads, or incorrect torque settings. This includes understanding root cause analysis techniques.

Next Steps

Mastering the art of screwing and bolting is crucial for a successful career in many manufacturing and engineering fields. A strong understanding of these principles demonstrates technical expertise and problem-solving abilities highly valued by employers. To further enhance your job prospects, crafting an ATS-friendly resume is key. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application gets noticed. Examples of resumes tailored specifically to the Screwing and Bolting field are available within ResumeGemini, providing you with a strong template to build from. Take the next step and create a resume that showcases your skills and experience effectively!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good