Are you ready to stand out in your next interview? Understanding and preparing for Seam Pressing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Seam Pressing Interview

Q 1. What types of pressing equipment are you familiar with?

As a seasoned seamstress, I’m proficient with a range of pressing equipment, from the basics to more specialized tools. This includes:

- Household Irons: While not ideal for large-scale production, understanding how to use a household iron effectively is fundamental. Proper temperature control and the use of pressing cloths are key.

- Professional-Grade Irons: These irons often feature larger soleplates for faster pressing, variable temperature settings for different fabrics, and often steam capabilities for smoother results. I’m comfortable using a variety of brands and models.

- Steam Generators: These produce a consistent and powerful stream of steam, essential for heavier fabrics and for achieving crisp folds. They are particularly useful in commercial settings.

- Pressing Ham: A padded, curved surface used for shaping and pressing curved seams. It’s indispensable for achieving professional-looking results on collars, cuffs, and other curved areas.

- Sleeve Boards: These specialized boards are designed to facilitate the pressing of sleeves and other cylindrical shapes without creating unwanted creases.

- Tailor’s Ham and Point Presser: These specialized tools are crucial for detailed work and precise shaping of curved areas like darts and collars.

My experience spans the spectrum of tools, allowing me to adapt my technique to any situation and achieve optimal results regardless of the equipment available.

Q 2. Explain the difference between pressing and ironing.

Pressing and ironing are often used interchangeably, but there’s a crucial difference. Think of it like this: ironing is like smoothing, while pressing is like shaping.

Ironing involves moving the iron back and forth across the fabric. While this can smooth wrinkles, it can also stretch and distort the fabric, particularly delicate ones. Ironing is primarily used for removing wrinkles from finished garments.

Pressing, on the other hand, involves applying even pressure with the iron to a specific area, without moving it back and forth. This method helps to set seams, create sharp creases, and maintain the structural integrity of the garment. It’s a much more controlled and precise technique.

In short, ironing is for smoothing, pressing is for shaping and setting.

Q 3. How do you identify and correct common seam pressing errors?

Identifying and correcting seam pressing errors requires a keen eye and a methodical approach. Common errors include:

- Seam puckering: This is often caused by insufficient pressing, uneven pressing, or pressing the seam allowance in the wrong direction. The solution is to carefully repress the seam, paying close attention to even pressure distribution. A tailor’s ham or point presser can be invaluable here.

- Shiny marks: These are caused by excessive heat or pressure, particularly on delicate fabrics. The fix involves lowering the heat setting and using a pressing cloth to protect the fabric.

- Uneven seams: This usually results from inconsistent pressing. Repressing the seam with even pressure and using a seam roll can correct the problem.

- Creases in the wrong place: Incorrect placement of the garment on the ironing board can lead to unintended creases. Ensure proper alignment before pressing.

I typically approach error correction by first identifying the root cause – is it temperature, pressure, or technique? Once the cause is understood, the solution usually becomes clear.

Q 4. Describe your experience with different pressing techniques (e.g., blocking, shaping).

My experience with various pressing techniques is extensive.

- Blocking: This technique involves dampening the fabric and then carefully shaping it using a blocking board or ham. It’s ideal for creating crisp, structured shapes in garments, especially those made from heavier fabrics like wool or linen. I have experience blocking everything from tailored jackets to intricate collars.

- Shaping: This involves using the iron and a pressing ham or tailor’s clapper to create curves and three-dimensional shapes in garments. It’s vital for creating the perfect fit and silhouette. Shaping is critical for things like darts and curved seams.

- Seam Pressing Techniques: This encompasses a wide range of techniques. I know how to press open seams, press seams to one side, and use techniques like using a pressing cloth to prevent shine or damage to the fabric. The choice of technique depends on the fabric, the seam type, and the overall garment design.

I adapt my approach based on the specific needs of the garment and fabric. For example, a delicate silk blouse would require a much gentler approach than a heavy wool coat.

Q 5. How do you maintain the quality and consistency of seam pressing throughout a production run?

Maintaining consistent seam pressing quality throughout a production run involves a systematic and meticulous approach. It’s about standardization and attention to detail:

- Consistent Equipment Settings: Using calibrated equipment with consistent heat and steam settings is paramount. Regular maintenance and calibration of equipment are vital.

- Standardized Procedures: Creating and following detailed pressing instructions helps ensure every seam is pressed uniformly, and consistently.

- Regular Quality Checks: Frequent checks of the finished product help identify any deviations from the standard early on. This allows for immediate adjustments and prevents large-scale errors.

- Training and Skill Development: Ensuring that all team members are properly trained in the same pressing techniques and quality standards is crucial.

- Pressing Cloths: Using clean pressing cloths regularly prevents the transfer of dirt or residue onto the fabrics, maintaining the quality of the garment.

By implementing these steps, I help to ensure that each garment meets the highest standards of quality and consistency.

Q 6. What fabrics require special pressing techniques?

Certain fabrics demand specialized pressing techniques due to their unique properties:

- Silk: Requires low heat and a pressing cloth to prevent scorching or shine. Often requires a press and lift method to avoid stretching.

- Linen: Benefits from steam pressing to remove wrinkles but should be pressed while slightly damp to avoid creating creases.

- Velvet: Needs to be pressed from the wrong side using a light touch and a pressing cloth to preserve the pile.

- Wool: Can handle higher heat, but it’s vital to press in the direction of the nap to avoid disturbing the fabric’s texture.

- Leather: Requires specialized equipment and techniques, often involving a damp cloth and a low temperature to avoid scorching.

Understanding a fabric’s composition and drape is crucial for choosing the right pressing method. Each fabric is unique, and treating them with the appropriate care is essential for achieving professional results.

Q 7. How do you handle delicate or easily damaged fabrics during pressing?

Handling delicate fabrics during pressing requires a gentle touch and specific techniques:

- Low Heat: Always use the lowest possible heat setting. Test on an inconspicuous area first.

- Pressing Cloths: Always use a pressing cloth between the iron and the fabric to protect it from direct heat and prevent shine.

- Steam Control: Avoid excessive steam; lightly mist the fabric if needed.

- Lift and Press Method: Instead of sliding the iron, lift and press the iron onto the fabric to avoid stretching or distorting the material.

- Blocking: For very delicate materials, blocking can be a more effective method than direct pressing.

My approach is always cautious and precise. I prioritize preserving the fabric’s integrity while achieving the desired shape and smoothness. Patience and precision are key.

Q 8. What safety precautions do you observe while operating pressing equipment?

Safety is paramount when working with pressing equipment. Before even turning on the iron or press, I always ensure the area is clear of obstructions, preventing trips and falls. I inspect the equipment for any damage, loose wires, or malfunctions. If anything seems amiss, I immediately report it and do not use the equipment. While pressing, I never leave the iron unattended, especially with the power on. I use heat-resistant gloves to protect my hands from burns, and I’m mindful of steam escaping; it can cause burns or scalding. Finally, I always unplug the equipment after use and allow it to cool completely before storing. Think of it like this: treating your pressing equipment with the same care you’d give a finely tuned instrument ensures its longevity and your safety.

Q 9. How do you determine the appropriate temperature and pressure for various fabrics?

Determining the correct temperature and pressure is crucial for achieving professional results and avoiding fabric damage. I always consult the fabric content label as a starting point. Natural fibers like cotton and linen generally require higher temperatures than synthetics like polyester or rayon. Delicate fabrics such as silk or wool need lower temperatures and less pressure. For example, a heavy cotton might need a high temperature and firm pressure for crisp creases, whereas silk would need a low temperature and gentle pressure to avoid scorching. I often do test presses on a scrap piece of the fabric to ensure the settings are correct before proceeding with the garment. Over time, experience allows for intuitive adjustments based on fabric weight and weave. It’s a delicate balance, but with practice, you develop a feel for the right combination.

Q 10. Explain your experience with different types of interfacing and their impact on pressing.

My experience with interfacing is extensive. Different interfacings significantly affect how a garment presses and holds its shape. Fusible interfacing, which adheres with heat, is incredibly useful for collars, cuffs, and other structured areas. However, the type of fusible interfacing matters – a lightweight woven interfacing is suitable for delicate fabrics, while a heavier knit interfacing works well for heavier fabrics. Non-fusible interfacing, which is basted to the fabric, offers more flexibility and allows for shaping. I’ve also worked with sew-in interfacings, providing support without adding bulk. Each type responds differently to heat and pressure, and selecting the correct one greatly influences the final press. For instance, using a heavy fusible interfacing on a lightweight fabric can lead to distortion; the careful selection is paramount for a flawless finish.

Q 11. Describe your process for pressing seams in different garment constructions (e.g., set-in sleeves, princess seams).

Pressing seams depends on the garment construction. For set-in sleeves, I press the seam allowances open, paying close attention to avoid pressing the seam allowance towards the sleeve cap to maintain the smooth curve. I use a tailor’s ham to support the curve during pressing. With princess seams, I typically press the seam allowances towards the back, providing a smoother finish and helping to maintain the structured lines of the bodice. Before pressing any seam, I make sure the seam is carefully stitched and any puckers are smoothed out. I often use a pressing cloth to protect the fabric’s surface from scorching, especially with delicate fabrics. The specific technique depends on the fabric and the desired look – a sharp crease or a softer, more relaxed line. Understanding the structure of the garment is critical to ensuring the pressing enhances the garment’s design rather than detracting from it.

Q 12. How do you handle wrinkles or creases that appear after pressing?

Wrinkles or creases appearing after pressing are often caused by improper initial pressing or by the fabric’s tendency to wrinkle. My approach involves carefully re-pressing the affected area using the appropriate temperature and pressure, often with a pressing cloth. If the wrinkle persists, I might use a slightly damp pressing cloth and a lower temperature to gently steam out the crease. In some cases, particularly with stubborn creases, I might use a spray bottle with distilled water to lightly mist the area before re-pressing. The key is patience and a light touch to avoid making the situation worse. Sometimes, a careful re-pressing is all that is needed; in other cases, a more careful manipulation of the damp pressing cloth is required to release the crease without marking the fabric. It’s a bit like coaxing the fabric back into shape.

Q 13. What are your methods for achieving a crisp and professional finish?

Achieving a crisp, professional finish requires attention to detail throughout the entire process. This begins with choosing the right interfacing and correctly pressing seams as they are sewn. Consistent, even pressure is crucial to preventing wrinkles and creases. A pressing cloth is essential for protecting fabric surfaces, and careful manipulation of the garment during pressing helps maintain proper shape and line. Knowing how to use specialty tools like a tailor’s ham and sleeve board helps to maintain three-dimensional curves and shapes. Lastly, a final overall press, often with a lighter touch, helps to unify the garment and ensure a clean, polished appearance. This final press is the finishing touch – akin to the final brushstroke on a painting, tying everything together seamlessly.

Q 14. How do you troubleshoot malfunctioning pressing equipment?

Troubleshooting malfunctioning equipment starts with safety. I disconnect the power source before attempting any repair or inspection. A common issue is a faulty heating element, often indicated by inconsistent heat or no heat at all. This requires professional repair. If the iron or press isn’t steaming properly, the water reservoir might be empty or clogged; I clean it thoroughly. Sometimes, the problem is as simple as a loose wire connection. If I can’t identify the issue, I immediately call for professional maintenance to prevent further damage or injury. The equipment is an investment, and regular maintenance is vital to ensure it functions safely and effectively. A well-maintained press can last for years – it’s a fundamental tool that needs care to ensure quality output.

Q 15. What is your experience with industrial steam presses?

My experience with industrial steam presses spans over 10 years, encompassing various models from leading manufacturers like Juki and Dürkopp Adler. I’m proficient in operating both computerized and manual models, understanding the nuances of pressure, temperature, and steam regulation crucial for different fabrics. For instance, I’ve mastered the art of using high-pressure steam for crisp pleats on linen suits while employing gentler settings for delicate silks. I’m also adept at troubleshooting common issues like boiler malfunctions and pressure inconsistencies, ensuring minimal downtime. I’m familiar with regular maintenance procedures, including cleaning and descaling, to prolong the life of the equipment and maintain optimal performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with manual pressing tools.

My expertise extends to a wide range of manual pressing tools, including tailor’s ham, sleeve board, point presser, clapper, and various irons. I understand how each tool contributes uniquely to the pressing process. For example, I use the tailor’s ham to shape curved seams like armholes and collars, while the sleeve board helps in pressing sleeves without creating unwanted creases. The clapper is essential for setting seams and pressing crisp edges. Proficiency with these tools allows me to achieve impeccable results even without an industrial press, especially for smaller projects or delicate areas where a press might be too forceful.

Q 17. How do you maintain cleanliness and organization in your pressing area?

Maintaining a clean and organized pressing area is paramount for efficiency and quality control. I follow a strict protocol: At the beginning of each day, I thoroughly clean the pressing surface, removing any lint or residue from previous projects. Tools are organized in a designated area, within easy reach. I use separate receptacles for different types of pressing cloths (linen, cotton, silk) and ensure they are clean and ready to use. This organized approach prevents delays, minimizes the risk of cross-contamination, and ensures I always have the right tools readily available.

Q 18. How do you ensure consistent seam pressing across multiple garments?

Ensuring consistent seam pressing across multiple garments requires a systematic approach. I begin by carefully examining the garment’s fabric content and construction before selecting the appropriate pressing tools and settings. For instance, I use a lower temperature for delicate fabrics and higher temperatures for heavier materials. I establish a standard pressing sequence – first pressing open seams, then pressing edges – to ensure consistency. I also regularly check my work throughout the pressing process to identify and correct any inconsistencies. Moreover, I employ standardized pressing cloths to maintain uniform pressure and temperature across different garments. Regular calibration of my tools is also crucial to achieve consistent results.

Q 19. What methods do you use to prevent fabric shine or scorching during pressing?

Preventing fabric shine or scorching requires careful attention to temperature and pressure. I always start with a lower temperature and gradually increase it as needed, constantly monitoring the fabric for any signs of shine or scorching. Using a pressing cloth is crucial—it acts as a buffer between the hot iron or press and the fabric, distributing heat evenly and protecting delicate materials. For very delicate fabrics, I might use a steam setting that produces a gentle mist rather than a strong jet of steam. The type of pressing cloth is also important; a coarser cloth may be suitable for heavier fabrics while a finer one is necessary for delicates. Finally, minimizing the length of contact with the iron or press is important, quickly lifting and re-positioning to ensure even heat distribution.

Q 20. How do you handle different types of seam finishes (e.g., serged, pinked)?

Different seam finishes require tailored pressing techniques. For serged seams, the pressing technique focuses on opening the seam allowance and gently pressing it flat to avoid disturbing the serged edge. I use a pressing cloth to protect the delicate serged stitches. With pinked seams, the emphasis is on preventing the pinked edges from curling or fraying, often requiring more precise work and perhaps a lighter press. Overlocking seams (a form of serging) may require the use of a tailor’s ham to press curves for a smooth finish. Each finish demands a technique that preserves its integrity and enhances the garment’s overall look. Knowing the specific characteristics of each finish is essential for achieving a professional result.

Q 21. How do you adapt your pressing techniques to different garment styles?

Adapting pressing techniques to different garment styles requires a thorough understanding of construction and design elements. For example, pressing a tailored suit requires precision and attention to detail, ensuring sharp creases and crisp edges. Pressing a flowing gown demands a gentler approach, focused on shaping the fabric without creating hard creases. The fabric type greatly influences the technique; structured fabrics require more pressure, while delicate materials need a lighter touch. Understanding the drape and silhouette of the garment directs the pressing methods employed, as each piece has unique requirements to achieve its intended form.

Q 22. What is your understanding of pressing as it relates to overall garment quality?

Pressing is far more than just ironing; it’s a crucial step that significantly impacts the overall quality and professional finish of a garment. Think of it as the final ‘polish’ that elevates a good garment to a great one. Proper pressing sets the seams, removes wrinkles, and creates a smooth, professional look. Poor pressing, on the other hand, can result in a garment that looks sloppy, unprofessional, and ultimately, diminishes its value.

It affects both the aesthetic appeal and the structural integrity. A well-pressed garment holds its shape better, drapes correctly, and looks more expensive. Neglecting pressing can lead to puckered seams, distorted shapes, and an overall lack of definition – all impacting the wearer’s experience and the perceived quality of the garment.

Q 23. How do you use pressing to enhance the shape and drape of a garment?

Pressing is key to achieving the desired shape and drape. For example, pressing open a seam on a skirt will create a flatter, more tailored look, while pressing it to one side can add volume and shaping. Similarly, pressing the interfacing in a collar will create a crisp, structured look, while improper pressing could result in a limp, undefined collar.

By carefully manipulating the fabric with the iron and the pressing surface, we can enhance the garment’s three-dimensional form. We achieve this through techniques like pressing darts, pleats, and seams in specific directions to either flatten or emphasize certain areas. For instance, sharp creases on trousers are achieved by using a tailor’s ham to support the fabric while pressing. Conversely, soft draping on a dress is often the result of carefully easing curves into the fabric during pressing, thereby avoiding sharp creases.

Q 24. How do you prioritize speed and accuracy in a high-volume production environment?

In a high-volume environment, efficiency without compromising quality is paramount. This means streamlining processes and employing techniques that maximize speed while maintaining precision. This requires a strong understanding of the garment construction and the appropriate pressing methods for each component.

I accomplish this through careful planning and organization. This includes having all pressing equipment readily available, setting up a well-organized workstation, and mastering quick, efficient pressing techniques. We use specialized equipment like industrial steam presses and sleeve boards to speed up the process. For instance, using a tailor’s clapper to rapidly set seams reduces ironing time considerably. A team approach, where each person focuses on specific pressing tasks based on their expertise, also ensures fast turnaround times without sacrificing quality.

Q 25. Describe your experience with different types of pressing boards and their applications.

I have extensive experience using various pressing boards, each suited for specific applications. A basic sleeve board is indispensable for pressing sleeves and other curved areas, ensuring even heat distribution and preventing creases. A tailor’s ham, a padded form, is critical for creating smooth curves on collars, lapels, and darts, providing support to prevent unwanted impressions.

The point press is essential for precise pressing of small areas, such as buttonholes or pleats, ensuring sharp definition. And, finally, an ironing board serves as a multi-purpose surface for general pressing. The choice of pressing board depends on the garment’s design and the areas needing pressing. Selecting the incorrect board can lead to uneven pressing and undesirable wrinkles, hence precise board selection is essential for quality.

Q 26. How do you prevent seam puckering during pressing?

Seam puckering is a common problem that can significantly affect garment quality. It’s often caused by uneven pressure, insufficient steam, or improper seam finishing. To prevent puckering, I ensure the seam allowance is properly pressed open or to one side before pressing the seam itself. I use a pressing cloth to protect the fabric and to distribute the heat and pressure evenly. Another crucial step is to press with the grain of the fabric to maintain its integrity and structure.

Using the correct amount of steam is also essential – too little won’t relax the fibers sufficiently, and too much can cause unwanted shrinkage or water marks. Additionally, properly clipping curves and grading seam allowances before pressing greatly reduce the risk of puckering.

Q 27. What are the common causes of seam distortion and how do you avoid them?

Seam distortion often results from incorrect pressing techniques, improper seam allowances, or using excessive pressure. For example, stretching the fabric while pressing can cause distortion, leading to uneven seams and misshapen garments. Another common cause is pressing across a seam, rather than pressing along the seam line. Improper grading of seam allowances can also create bulk which leads to distortion after pressing.

To avoid these issues, I carefully manage fabric tension during pressing. I always use the appropriate amount of pressure and steam, and ensure all seams are correctly finished before pressing. Applying the pressing tool at a 90-degree angle to the seam line minimizes distortion.

Q 28. How would you train a new employee on proper seam pressing techniques?

Training new employees involves a structured approach, starting with the basics of pressing equipment and safety. I demonstrate proper techniques, emphasizing the importance of consistent pressure, correct steam application, and appropriate tools for different fabrics. Hands-on practice is crucial; I would supervise them as they work on sample garments, providing feedback and guidance. We’d focus on various pressing techniques like pressing open seams, pressing seams to one side, and using different pressing tools.

I also highlight the importance of understanding fabric types and their different pressing requirements. The training includes troubleshooting common issues like puckering and distortion. Finally, regular feedback sessions ensure that the new employee develops the necessary skills and confidence to achieve consistently high-quality results. This approach allows for a comprehensive understanding of seam pressing, translating knowledge into proficient execution.

Key Topics to Learn for Seam Pressing Interview

- Understanding Fabric Types and Their Pressing Needs: Knowing how different fabrics (e.g., linen, silk, cotton) react to heat and pressure is crucial for achieving professional results. This includes understanding the potential for shrinkage or damage.

- Mastering Pressing Equipment: Become familiar with various pressing tools, including irons, steam generators, pressing ham, tailor’s clapper, and sleeve boards. Understand their proper use and maintenance for optimal performance.

- Seam Construction and Pressing Techniques: Explore different seam types (e.g., French seams, flat felled seams) and the appropriate pressing techniques for each. This includes understanding pressing sequences to create crisp, professional finishes.

- Problem-Solving and Troubleshooting: Learn to identify and resolve common pressing issues, such as uneven pressing, scorching, or unwanted creases. This demonstrates practical skills and attention to detail.

- Quality Control and Inspection: Understand the importance of inspecting finished garments for pressing imperfections. This shows a commitment to delivering high-quality work.

- Safety Procedures and Ergonomics: Demonstrate knowledge of safe handling of pressing equipment and the importance of maintaining proper posture and work practices to prevent injury.

- Understanding Pressing as a Finishing Technique: Articulate how effective pressing elevates the overall quality and presentation of a garment, contributing significantly to the final product.

Next Steps

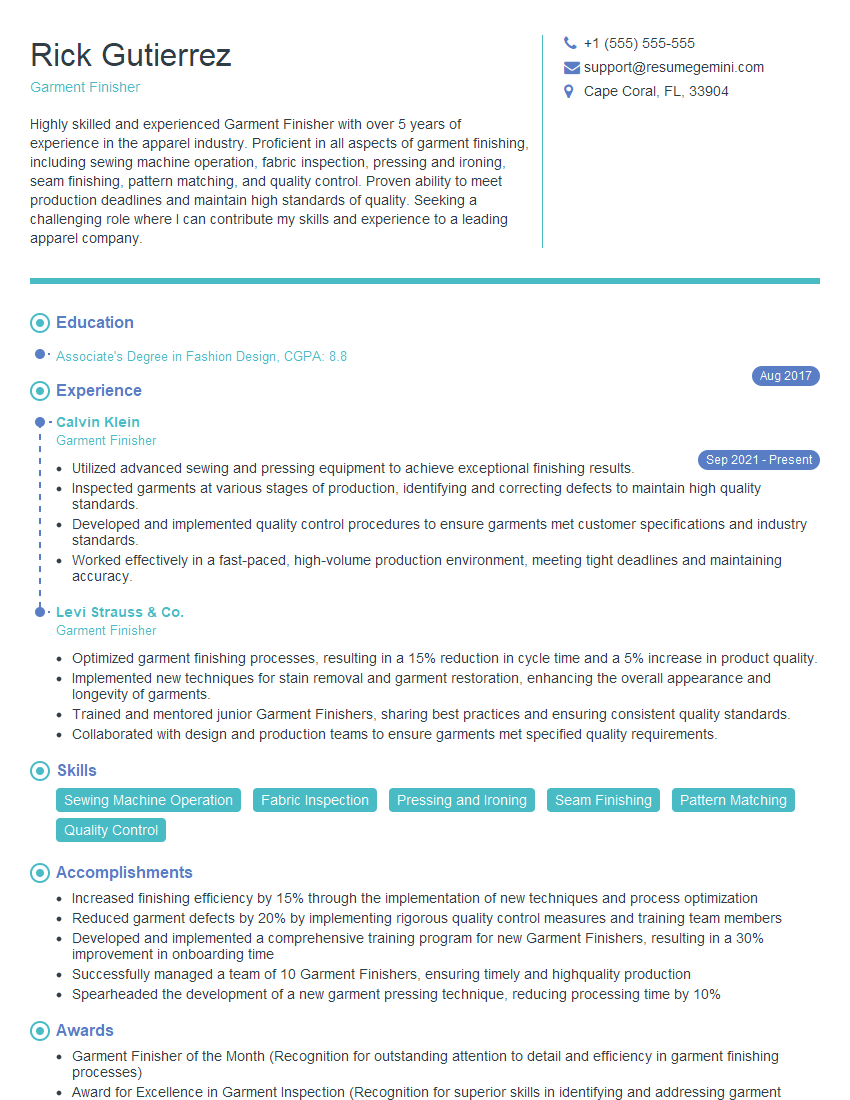

Mastering seam pressing is essential for career advancement in the garment industry, opening doors to more skilled roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. Building an ATS-friendly resume is crucial for getting noticed by potential employers. ResumeGemini is a valuable tool to help you create a professional and effective resume that highlights your seam pressing expertise. We provide examples of resumes tailored to Seam Pressing to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good