The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Seaming and finishing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Seaming and finishing Interview

Q 1. Describe your experience with various seaming techniques (e.g., flatlock, overlock, French seams).

Seaming techniques are the foundation of garment construction, each offering unique properties. My experience encompasses a wide range, including flatlock, overlock, and French seams.

- Flatlock seams are a stylish and durable choice, often used in sportswear. They’re created by stitching two fabric layers together with a specialized flatlock stitch, leaving a clean, flat seam on both sides. Think of athletic socks or high-end yoga wear; this seam type is a key player there. The stitch itself offers a slight give which prevents seam bursting under stress.

- Overlock seams (serged seams) are known for their speed and durability. An overlock machine simultaneously cuts, stitches, and overedges raw fabric, preventing fraying and offering a professional finish. This is a workhorse in the industry, used for everything from basic t-shirts to intricate dresses. I often use overlocking for initial seams before finishing techniques, providing a stable base for the next step.

- French seams are the epitome of elegance and durability, particularly suitable for fine fabrics. This method encloses all raw edges within the seam, creating a clean, beautifully finished edge, visible only on the right side of the garment. It’s perfect for sheer fabrics like silk or fine linens where raw edges would be unacceptable. Imagine a high-end blouse—a French seam makes all the difference.

My expertise extends to selecting the appropriate seam based on fabric type, garment style, and desired aesthetic. For instance, I wouldn’t use a French seam on a heavy denim jacket (too time-consuming!), but it’s ideal for a delicate silk camisole.

Q 2. What types of sewing machines are you proficient with?

My proficiency spans a variety of sewing machines, from industrial models to specialized machines. I’m adept at using industrial straight stitch machines for production, overlock/serger machines for edge finishing and speed, coverstitch machines for professional-looking hems, and even specialized flatlock machines for contemporary styles.

Beyond the specific machine types, I’m equally comfortable working with computerized machines offering programmable stitch settings and older mechanical machines demanding a nuanced hand and understanding of tension and stitch length.

My familiarity extends to troubleshooting common machine issues, performing routine maintenance, and adapting to varying machine setups to optimize performance.

Q 3. How do you identify and correct common seaming defects?

Identifying and correcting seaming defects requires a keen eye and systematic approach. Common defects include puckering, skipped stitches, uneven seam allowances, and broken threads.

- Puckering: Often caused by inconsistent tension or improper fabric handling. Correction involves adjusting tension, using a walking foot, or grading seam allowances.

- Skipped stitches: Can be due to a bent needle, improper threading, or low machine speed. Check the needle, re-thread, and adjust speed. A poorly lubricated machine can also cause this.

- Uneven seam allowances: Caused by inconsistent cutting or inaccurate sewing. Precise cutting and careful attention to seam allowance markings are essential. Accurate pattern making is also a crucial factor here.

- Broken threads: Usually from using damaged needles or incorrect thread tension. Replace the needle immediately and ensure tension is correctly adjusted, and the correct type of needle and thread is used for the fabric.

I troubleshoot by carefully examining the seam, identifying the root cause, and implementing the appropriate correction. Often, a simple adjustment is all it takes, but sometimes more complex intervention is required such as adjusting the machine’s feed dogs.

Q 4. Explain your process for quality control during seaming and finishing.

My quality control process is a multi-stage system, starting from fabric inspection and extending through every step of the seaming and finishing process. I believe in building quality in, not inspecting it in.

- Pre-Seaming Inspection: I carefully inspect fabric for flaws, paying close attention to grainlines, and any potential issues that could affect the seams.

- Seaming Process: I maintain consistent stitch length, tension, and seam allowance throughout the process, employing quality control checks at each stage. It’s about building habits and training to minimize defects in the first place.

- Post-Seaming Inspection: After each seam is completed, I check for skipped stitches, unevenness, or fabric distortion. I also perform a “press check” to identify any issues that become apparent after pressing.

- Final Inspection: A thorough final inspection is conducted after all seaming and finishing is complete. This includes checking for overall fit, stitch quality, and the presence of any defects. This is often done at a later stage after the garment has rested.

This multi-layered approach ensures that any defects are identified and corrected early, preventing costly rework and ensuring a high-quality finished product. It’s always faster and cheaper to get it right the first time.

Q 5. How do you maintain sewing machines to ensure optimal performance?

Maintaining sewing machines is crucial for optimal performance and longevity. My routine includes regular cleaning, lubrication, and inspections.

- Daily Cleaning: Removing lint and thread scraps from the bobbin area, feed dogs, and stitch plate is essential. A small brush or compressed air can be highly effective here.

- Weekly Maintenance: I lubricate moving parts according to the manufacturer’s instructions, ensuring smooth operation and preventing wear and tear. Using the correct oil is critical—never use WD40 on a sewing machine.

- Monthly Inspection: I thoroughly inspect the needle for damage, replace it as needed, and check the timing and tension of the machine. Sometimes, a small adjustment is all that is needed.

- Annual Servicing: I schedule annual professional servicing for a more thorough cleaning, lubrication, and potential adjustments or repairs.

By adhering to a consistent maintenance schedule, I maximize machine lifespan, minimize downtime due to repairs, and ensure consistent, high-quality stitching.

Q 6. What are your preferred methods for hemming different fabric types?

Hemming techniques vary greatly depending on the fabric type. My approach is always tailored to the specific characteristics of the material.

- Lightweight Fabrics (silk, chiffon): I prefer a rolled hem, either by hand or using a specialized rolled-hem foot on my sewing machine. This creates a delicate, almost invisible hem.

- Medium-Weight Fabrics (cotton, linen): A simple double-turned hem is often sufficient. This method creates a clean, durable finish.

- Heavyweight Fabrics (denim, canvas): A double-stitched hem or even a bound hem offers superior durability. The added stitching prevents fraying and wear, particularly important for heavier materials.

- Knit Fabrics: A blind hem stitch is excellent for knit fabrics as it avoids visible stitching on the right side. This stitch is designed to stitch between the rows on a knit material.

Choosing the right hemming technique is essential for achieving a professional and durable finish. The wrong technique can ruin a garment’s aesthetic and functionality.

Q 7. Describe your experience with different types of finishing, such as topstitching, binding, and edge finishing.

Finishing techniques elevate a garment from basic to professional. My experience encompasses a wide range of techniques, including topstitching, binding, and edge finishing.

- Topstitching: I use topstitching to add decorative accents and reinforce seams. The stitch type, spacing, and thread choice are carefully considered for aesthetic appeal and durability. Think of a well-placed topstitch on a denim jacket—it adds a design element and strength.

- Binding: Bias binding is a versatile technique I use to finish raw edges neatly and professionally. I choose the binding fabric based on its color and weight, ensuring it complements the garment. This is ideal for necklines, armholes, and curved seams.

- Edge Finishing: Techniques such as pinking, overlocking, and zigzag stitching are employed to prevent fraying. The choice depends on the fabric type and the desired aesthetic. Pinking shears are great for lightweight fabrics while overlocking is ideal for most others.

The selection of finishing techniques is crucial in determining the overall quality and appearance of a garment. It’s the final touch that transforms a functional piece of clothing into a well-crafted item.

Q 8. How do you handle challenging fabrics that are difficult to seam or finish?

Challenging fabrics, like silk charmeuse or heavy denim, require specialized techniques. The key is understanding the fabric’s properties. For example, silk’s delicate nature necessitates using a fine needle and a slow stitch speed to prevent snagging. With heavy denim, a heavier needle and stronger thread are needed, potentially combined with techniques like using a walking foot to feed the fabric evenly and prevent puckering.

My approach involves testing different needle types, thread weights, and stitch settings on a scrap piece of the fabric before starting the actual seam. This allows me to identify the ideal combination for that specific fabric’s weight, drape, and texture. For fabrics prone to fraying, like jersey knits, I’ll use a serger or overlock stitch to prevent unraveling before constructing the garment. For difficult-to-handle fabrics like leather or suede, specialized needles and techniques, such as using a roller foot to prevent slippage, are essential.

Q 9. What safety precautions do you follow when operating sewing machines?

Safety is paramount. Before operating any sewing machine, I always ensure my workspace is clean and clutter-free to prevent accidents. Loose clothing and jewelry are removed to avoid entanglement. I never reach across the moving needle and always use the machine’s safety features, such as the needle guard.

Regular machine maintenance is crucial. I inspect needles for damage or bending before every sewing session, replacing them if necessary. I also keep the machine clean and lubricated according to the manufacturer’s instructions. Finally, I always unplug the machine before cleaning or making any adjustments. This is a crucial habit to prevent electrical shocks.

Q 10. How do you ensure consistent seam allowances?

Consistent seam allowances are vital for a professional finish and consistent sizing. I use a combination of techniques to ensure accuracy. Firstly, I always use a seam guide on my machine, setting it to the required seam allowance (e.g., 5/8 inch). Secondly, I regularly check my work with a ruler and measuring tape, adjusting as needed to maintain consistency throughout the garment construction.

For complex projects, using a template or pattern markings is very helpful in maintaining accurate seam allowances. In mass production, a consistent seam allowance is ensured by using specialized equipment such as automated cutting systems that incorporate the seam allowance into the cut pattern pieces. Careful planning and attention to detail are key to ensure consistent quality.

Q 11. What experience do you have with different types of needles and threads?

My experience encompasses a wide range of needles and threads. I’m proficient in selecting the appropriate needle size and type (e.g., universal, ballpoint, stretch, leather) based on the fabric’s weight and type. For delicate fabrics like silk, I use fine needles with a sharp point to avoid damage. Heavier fabrics like canvas require heavier needles, potentially with a blunt point to prevent holes.

Thread selection is equally crucial. I understand the differences between cotton, polyester, silk, and other thread types and select accordingly. For example, polyester thread is more durable and less prone to breaking than cotton thread. The correct thread weight and strength must also be matched to the needle and fabric.

Q 12. How familiar are you with different types of seam finishes?

I’m familiar with a variety of seam finishes, each serving a distinct purpose. These include serging/overlocking (for preventing fraying), zigzag stitching (for added durability and preventing raveling), pinking (for a decorative and fray-resistant finish), French seams (for a high-end, clean finish, ideal for sheer fabrics), and bound seams (for a professional finish and durability).

The choice of finish depends on the fabric type, garment style, and desired level of quality. For example, a serged seam is suitable for knit fabrics, while a French seam might be preferred for luxury garments. My selection ensures the seam is both functional and aesthetically pleasing, considering the factors discussed.

Q 13. Describe your experience with industrial sewing machines.

I have extensive experience with industrial sewing machines, including high-speed models and specialized machines like button-attaching and buttonhole machines. I’m comfortable operating various makes and models, understanding their unique features and maintenance requirements. I know how to adjust stitch length, tension, and pressure settings to optimize performance for different fabrics and tasks.

Working with industrial machines has enhanced my efficiency and precision significantly. I’m proficient in troubleshooting common issues and performing basic machine maintenance. My experience extends to managing multiple machines and working in high-volume production environments.

Q 14. How do you handle large production volumes while maintaining quality?

Maintaining quality during high-volume production demands meticulous planning and execution. This starts with efficient workflow management and clear communication with my team. I utilize lean manufacturing principles and prioritize organization and error prevention.

Regular quality checks at different stages of production are crucial. This helps to identify and address potential issues early on. Using standardized operating procedures and training for team members ensures consistency in quality. For example, the team regularly checks seam allowances, stitch quality, and overall garment construction using specific checklists. This approach ensures that even with large production volumes, the quality remains consistently high.

Q 15. Explain your experience with troubleshooting malfunctioning sewing equipment.

Troubleshooting malfunctioning sewing equipment requires a systematic approach. My experience involves identifying the problem, isolating the cause, and implementing the solution. This often begins with a visual inspection – checking for obvious issues like broken needles, tangled thread, or clogged bobbins.

For instance, if a machine is skipping stitches, I’d first check the needle for damage or incorrect size for the fabric. Then I’d move to the tension settings, ensuring they are correctly adjusted for the thread type and fabric weight. If the problem persists, I systematically check the bobbin case, hook timing, and feed dogs. I’m proficient in using both mechanical and electronic troubleshooting guides, and I’m comfortable disassembling and reassembling various machine parts to find and resolve more complex issues, always following safety procedures. In one instance, a consistent thread breakage issue was solved by simply replacing a worn-out pressure foot. Documenting these troubleshooting processes is crucial for preventing future issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks in a fast-paced production environment?

In a fast-paced production environment, prioritization is key. I use a combination of techniques to manage tasks effectively. I begin by identifying deadlines and urgency levels – using a Kanban-style system, visually representing tasks on a board. This provides a clear overview of what needs to be done and when. I prioritize urgent and high-impact tasks first, ensuring those that significantly impact the production timeline are completed promptly. Tasks are further prioritized based on their dependencies – completing tasks that unlock subsequent stages in the production flow. Communication is vital; actively communicating potential delays or bottlenecks helps prevent major disruptions.

For example, in a scenario with an urgent rush order and several ongoing projects, I would focus on the rush order first, allocating the necessary resources (machines, materials, and personnel) to meet the deadline. Once that is complete, I would return to the other projects, maintaining a steady workflow.

Q 17. Describe your experience with pattern interpretation and marking.

Pattern interpretation and marking are fundamental to accurate garment construction. My experience involves carefully studying the pattern pieces, understanding grainlines, notches, and markings, and accurately transferring these to the fabric. This includes understanding different pattern symbols and their significance; for instance, knowing the difference between a dart, a pleat, and a seam allowance is crucial for creating a well-fitting garment. I am adept at using various marking tools, such as chalk, tailor’s tacks, or disappearing ink markers, selecting the most appropriate tool for different fabric types.

I’ve worked with both commercially produced and custom-designed patterns. A specific example involved working with a complex pattern requiring intricate shaping. Accurately marking and transferring the pattern pieces onto the fabric, paying close attention to the grainlines and ensuring proper alignment of notches was key to the successful creation of the garment.

Q 18. What is your understanding of different stitch types and their applications?

My understanding of stitch types is extensive and includes a range of applications. Different stitches are chosen based on the fabric type, garment construction detail, and desired aesthetic. Basic stitches like straight stitch, zig-zag stitch, and overlock stitch are foundational. Straight stitch is used for seams and topstitching, while the zig-zag stitch prevents fraying and is ideal for stretchy fabrics. Overlock stitch is excellent for finishing seams and preventing unraveling. Beyond these basics, I’m proficient with decorative stitches, blind hemstitches, and more specialized stitches depending on the specific needs of the garment.

- Straight Stitch: Strong and versatile, ideal for seams.

- Zig-zag Stitch: Prevents fraying, good for stretchy fabrics.

- Overlock Stitch (Serger): Finishes seams, prevents unraveling.

- Blind Hem Stitch: Creates an invisible hem.

For example, a delicate silk garment would require a fine straight stitch to avoid damaging the fabric, while a durable denim garment might use a heavier straight stitch for strength.

Q 19. How do you manage your time effectively to meet deadlines?

Effective time management is paramount in meeting deadlines. I utilize several strategies, including detailed planning, task breakdown, and time-blocking. I break down large projects into smaller, manageable tasks, creating a checklist to track my progress. This allows for better organization and prevents feeling overwhelmed. Time-blocking involves scheduling specific time slots for particular tasks, allocating sufficient time and preventing multitasking. I also prioritize self-care and breaks to maintain focus and avoid burnout. This ensures I can consistently maintain productivity throughout the day.

For example, if I have a week to complete a large order, I would allocate specific days to cutting, sewing, pressing, and finishing, setting realistic timelines for each step. Regular check-ins with my progress enable me to make adjustments if needed.

Q 20. Explain your experience working with different fabric weights and types.

Experience working with diverse fabric weights and types is crucial in seaming and finishing. Different fabrics require different needle sizes, stitch lengths, and pressing techniques. Lightweight fabrics like silk or chiffon need delicate handling and fine needles to avoid damage, while heavier fabrics such as denim or canvas require stronger needles and stitches for durability. Understanding fabric drape, stretch, and shrinkage properties is also vital for creating well-fitting and durable garments.

For instance, sewing a sheer fabric like silk needs a very fine needle and a slow stitching speed to avoid pulling the fabric. Conversely, sewing thick denim requires a heavier needle and potentially a stronger stitch to penetrate the fabric efficiently. Understanding the unique properties of each fabric type, from its weave to its inherent stretch or drape, allows for appropriate seam selection and finishing techniques to create a professional result.

Q 21. How familiar are you with using different pressing equipment (e.g., iron, steam press)?

I am highly proficient in using various pressing equipment, including irons and steam presses. Proper pressing is essential for achieving professional-looking seams and garment construction. Different fabrics require different pressing techniques to prevent scorching or damage. I understand the importance of using the correct temperature settings for various fabric types. I can use different pressing tools like clappers, seam rolls, and tailor’s ham to create crisp seams and precise shaping. Using a steam press is essential for smoothing out wrinkles and creating sharp creases, particularly helpful in areas like collars and cuffs.

For example, I would use a lower heat setting and a pressing cloth when pressing delicate fabrics like silk to avoid scorching or shine. Conversely, heavier fabrics, like linen, often need a higher heat setting and firm pressure for crisp results.

Q 22. Describe your process for creating clean, professional-looking seams.

Creating clean, professional-looking seams involves precision and attention to detail throughout the entire process. It starts with proper fabric preparation – ensuring the fabric is pre-washed to prevent shrinkage and that all pattern pieces are accurately cut. Then, the choice of seam allowance is crucial; a consistent seam allowance (typically 5/8” or ½”) ensures a uniform finish.

Next, I prioritize accurate pinning before stitching. This prevents shifting and ensures straight, even seams. I use a quality sewing machine, well-maintained and with the correct needle and stitch type for the fabric. I always test stitch on a scrap piece of fabric first to adjust tension and stitch length as needed.

After stitching, I trim excess seam allowances, grading them (reducing the width of one side for bulk reduction) whenever possible. Finally, I press the seam open or to one side depending on the garment’s design, using a tailor’s ham or pressing cloth to prevent impressions. This pressing step is key to achieving a professional, flat finish. For more delicate fabrics, I may use a steam iron with a low setting. Think of it like baking a cake – careful preparation and precise execution are essential for the best results.

Q 23. How do you ensure accurate measurements and consistent finishing across multiple garments?

Consistency in measurements and finishing across multiple garments relies on a robust system of checks and balances. First, I always meticulously follow the pattern instructions and marking guidelines, carefully transferring all markings from the pattern to the fabric. I use a variety of measuring tools – rulers, measuring tapes, and pattern weights – to ensure accuracy.

Secondly, I create and maintain a detailed reference chart of my measurement and finishing specifications for each garment. This ensures I’m consistent in stitch length, seam allowance, and finishing techniques for different components throughout the production process. Regularly checking my work against this chart prevents errors and ensures uniform results across multiple garments.

Finally, I utilize a consistent workflow. A systematic approach to each step – from cutting to final pressing – reduces the likelihood of errors and allows for efficient, quality production. It’s like following a recipe – measuring ingredients carefully and sticking to the recipe’s steps leads to the expected results.

Q 24. What experience do you have with specialized finishing techniques (e.g., embroidery, buttonholes)?

I have extensive experience with specialized finishing techniques, including embroidery and buttonholes. My embroidery skills encompass various types, from free-motion embroidery for decorative elements to using embroidery machines for complex designs or logos. I understand the importance of thread selection and tension for optimal results and can adjust settings depending on the fabric type.

Similarly, I’m proficient in creating both hand-sewn and machine-made buttonholes. I can adapt techniques based on button type and fabric weight. For example, I use a blanket stitch for hand-sewn buttonholes on heavier fabrics, while for more delicate materials, I might opt for a machine-made buttonhole with a reinforcing stitch. I’m familiar with the various types of buttonhole feet used on sewing machines and how to adjust their settings based on fabric type and button size. This detailed knowledge lets me offer a varied range of finishing techniques.

Q 25. How do you adapt to changes in production requirements or deadlines?

Adapting to changes in production requirements or deadlines is a crucial skill in this field. My approach involves careful listening and clarification to fully understand the new requirements. I then prioritize tasks based on urgency and feasibility, using project management techniques like time blocking or creating a revised production schedule.

Open communication with my supervisor and team members is vital. If needed, I’m willing to work extra hours to meet tighter deadlines while maintaining the quality of my work. I focus on flexibility, problem-solving, and collaborative teamwork to handle unexpected changes efficiently and effectively. It’s like navigating an unexpected detour – I adapt my route to reach my destination on time.

Q 26. Describe a time you had to resolve a significant seaming or finishing problem.

Once, I encountered a significant problem with a batch of silk garments. The seams were consistently puckering after pressing, ruining the clean finish. After investigating, I discovered that the initial pressing temperature was too high for the delicate silk, causing it to shrink and pucker.

To resolve this, I implemented a systematic troubleshooting approach. I started by testing different pressing temperatures and techniques on scrap pieces of silk. I then adjusted the pressing method, opting for steam pressing instead of dry pressing and using a pressing cloth. Finally, I adjusted my seam allowance slightly, reducing the bulk around the seams. This multi-pronged approach effectively resolved the puckering issue, resulting in perfectly finished garments.

Q 27. How do you maintain a clean and organized work station?

Maintaining a clean and organized workstation is paramount for efficiency and preventing errors. I begin each day by organizing my workspace, ensuring all tools, threads, and fabrics are readily accessible. I utilize various storage solutions – drawers, containers, and labeled bins – to keep my supplies neat and sorted.

During the day, I consistently tidy up my workspace, removing scraps, and putting away tools as I finish using them. I regularly clean my sewing machine, ensuring that the bobbin area, feed dogs, and needle plate are free of lint and debris. This disciplined approach to maintaining my workspace optimizes my efficiency, reduces stress, and improves the quality of my work. A tidy workstation is the foundation of quality output.

Q 28. What are your strengths and weaknesses regarding seaming and finishing?

My strengths in seaming and finishing lie in my meticulous attention to detail, my mastery of various techniques, and my ability to consistently produce high-quality work. I’m adept at troubleshooting problems and adapting to different fabrics and designs. I’m also a highly efficient and organized worker.

A potential weakness is that my perfectionism can sometimes lead to slower production speeds. However, I’m working on improving my time management skills to balance quality with efficiency. It’s a constant learning process of refining my skillset and workflow while never compromising on excellence.

Key Topics to Learn for Seaming and Finishing Interviews

- Seam Types and Selection: Understanding various seam types (e.g., French seams, flat felled seams, overlock seams) and their appropriate applications based on fabric type, garment style, and desired durability. Consider the pros and cons of each.

- Finishing Techniques: Mastering different finishing methods like edge stitching, binding, hemming (various types), and facing. Focus on achieving professional, clean finishes that enhance garment aesthetics and longevity.

- Fabric Handling and Preparation: Proper pre-treatment of fabrics (e.g., pre-washing, pressing) to prevent shrinkage and ensure optimal seam performance. Understanding fabric properties and how they impact seam construction.

- Equipment and Tools: Familiarity with various sewing machines (industrial and domestic), pressing equipment (irons, pressing ham, tailor’s clapper), and other tools used in seaming and finishing operations. Know how to maintain and troubleshoot these tools.

- Quality Control and Inspection: Developing a keen eye for detail to identify imperfections in seams and finishes. Understanding quality standards and procedures for identifying and rectifying defects.

- Problem-Solving and Troubleshooting: Ability to diagnose and resolve common issues encountered during seaming and finishing, such as skipped stitches, uneven seams, or fabric puckering. Demonstrate practical solutions and preventative measures.

- Efficiency and Productivity: Understanding techniques for optimizing workflow and maximizing efficiency in a production setting. This includes time management and effective use of equipment.

- Safety Procedures: Adherence to safety protocols related to operating machinery and handling sharp objects. Understanding safe work practices in a manufacturing environment.

Next Steps

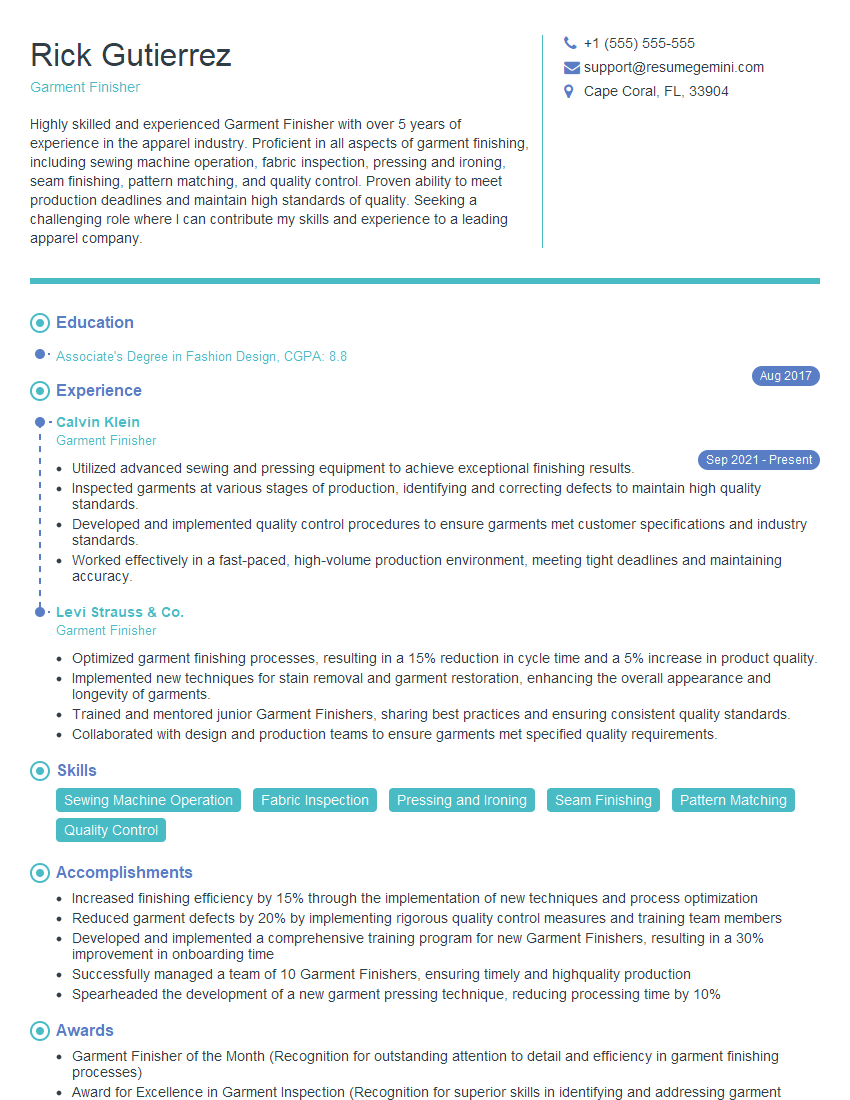

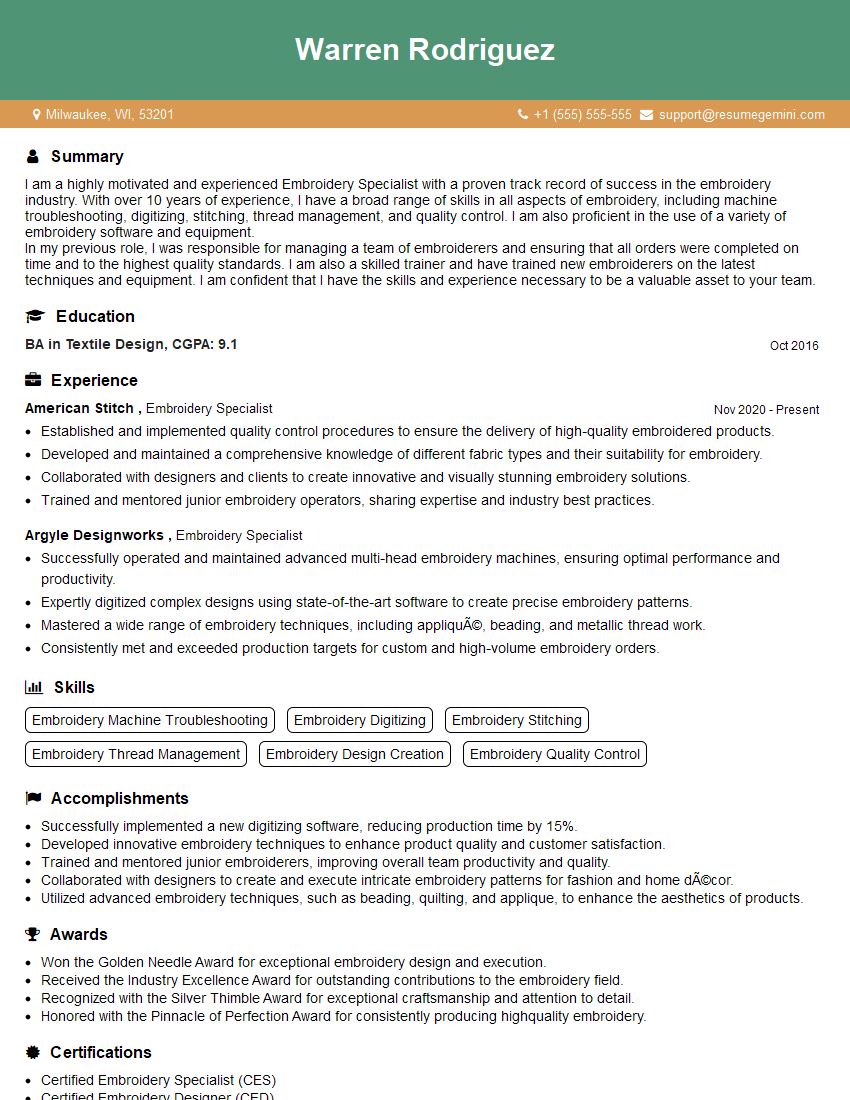

Mastering seaming and finishing is crucial for career advancement in the apparel industry. Strong skills in this area are highly sought after, opening doors to diverse roles and greater earning potential. To maximize your job prospects, invest time in creating a professional and ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource to help you build a standout resume that highlights your accomplishments and skills. Examples of resumes tailored to Seaming and Finishing positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good