Preparation is the key to success in any interview. In this post, we’ll explore crucial Sensor Operation and Interpretation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Sensor Operation and Interpretation Interview

Q 1. Explain the different types of sensor noise and how to mitigate them.

Sensor noise is the unwanted signal that interferes with the actual measurement. Think of it like static on a radio – it obscures the desired signal (the actual measurement). Several types exist:

- Thermal Noise (Johnson-Nyquist Noise): Caused by the random thermal motion of electrons within the sensor and its circuitry. It’s always present and increases with temperature. Mitigation involves using low-noise amplifiers and cooling the sensor.

- Shot Noise: Arises from the discrete nature of charge carriers (electrons or holes). It’s proportional to the square root of the current flowing through the sensor. Mitigation involves using high-quality components and signal processing techniques.

- Flicker Noise (1/f Noise): A low-frequency noise with a power spectral density inversely proportional to frequency. Its source is complex and not fully understood. Mitigation often involves high-pass filtering.

- Environmental Noise: External factors like electromagnetic interference (EMI), vibrations, or temperature fluctuations can corrupt sensor readings. Shielding, grounding, and signal filtering are essential mitigation strategies. Imagine trying to measure the temperature of a liquid in a noisy factory – the ambient noise needs to be addressed.

Effective noise mitigation often involves a combination of hardware and software techniques. For example, averaging multiple readings can reduce the impact of random noise, while sophisticated signal processing algorithms can filter out specific noise patterns.

Q 2. Describe your experience with sensor calibration techniques.

Sensor calibration is crucial for ensuring accurate measurements. It involves establishing a known relationship between the sensor’s output and the actual physical quantity being measured. I’ve extensive experience with various techniques, including:

- Two-point calibration: This simple method involves calibrating the sensor at two known points (e.g., minimum and maximum values). It’s suitable for sensors with linear responses. For instance, I calibrated a pressure sensor using a known pressure source at 0 and 100 psi.

- Multi-point calibration: More precise than two-point, this involves calibrating at multiple known points across the sensor’s range. This is beneficial for sensors with non-linear responses and produces a more accurate calibration curve. I used this method for a temperature sensor, calibrating it at several points across its operational temperature range.

- In-situ calibration: This calibration occurs while the sensor is in its operating environment, providing a more accurate representation of its performance under real-world conditions. This is particularly relevant for sensors deployed in challenging environments.

Calibration often involves generating a calibration curve (a mathematical relationship between the sensor’s output and the true value) that is used to correct subsequent measurements. This may involve linear regression or other curve-fitting techniques. Accurate documentation of calibration procedures and results is essential for maintaining traceability and ensuring data integrity.

Q 3. How do you troubleshoot a malfunctioning sensor system?

Troubleshooting a malfunctioning sensor system is systematic. My approach typically involves:

- Inspect the sensor and its connections: Check for any physical damage, loose connections, or corrosion. Sometimes, a simple visual inspection can pinpoint the problem.

- Verify power supply: Ensure the sensor receives the correct voltage and current. A faulty power supply can easily lead to incorrect readings or system failure.

- Check the sensor’s output signal: Use a multimeter or oscilloscope to measure the sensor’s output and compare it to expected values. This helps determine whether the problem lies with the sensor itself or with the signal processing circuitry.

- Review the sensor’s data logs: Examine any available data logs to look for trends or anomalies that may indicate a failing sensor or other system issues. Unexpected spikes or drifts in the data often point towards problems.

- Isolate the problem: Use a methodical approach to isolate the malfunction to specific components – sensor, wiring, power supply, signal conditioning, or data acquisition.

- Calibration and recalibration: If the problem is not readily apparent, recalibrating the sensor is a key step in verifying proper operation. Comparison of pre- and post-calibration data can help determine if calibration is the root cause of the problem.

- Replace components: If the problem persists, replacing suspected faulty components, such as the sensor itself, might be necessary.

Proper documentation at every step is critical for traceability and future reference.

Q 4. What are the key performance indicators (KPIs) for evaluating sensor performance?

Key Performance Indicators (KPIs) for evaluating sensor performance vary depending on the application but generally include:

- Accuracy: How close the measured value is to the true value.

- Precision: How repeatable the measurements are. A highly precise sensor produces consistently similar readings, even if those readings are consistently off from the actual value.

- Sensitivity: The sensor’s response to a change in the measured quantity.

- Resolution: The smallest change in the measured quantity that the sensor can detect.

- Linearity: How well the sensor’s output follows a straight line across its measurement range.

- Stability: How consistent the sensor’s output is over time and under varying environmental conditions.

- Range: The range of values the sensor can accurately measure.

- Noise level: The amount of unwanted signal interfering with the measurement.

- Response time: The time it takes for the sensor to respond to a change in the measured quantity.

- Drift: Gradual changes in the sensor’s output over time.

The choice of KPIs depends on the application’s requirements. For example, a high-precision sensor might be needed for scientific measurements, while a highly sensitive sensor might be crucial for detecting small changes in a process variable.

Q 5. Explain the difference between accuracy and precision in sensor measurements.

Accuracy and precision are distinct but related aspects of sensor performance. Imagine shooting arrows at a target:

- Accuracy refers to how close the arrows land to the bullseye. A high-accuracy sensor consistently provides measurements close to the true value.

- Precision refers to how closely clustered the arrows are. A high-precision sensor consistently provides measurements very close to one another, even if they aren’t close to the true value.

A sensor can be precise but not accurate (all arrows clustered but far from the bullseye), accurate but not precise (arrows scattered around the bullseye), or both accurate and precise (arrows tightly clustered around the bullseye). Ideally, a sensor should be both accurate and precise.

Q 6. How do you handle data outliers in sensor readings?

Data outliers in sensor readings, those values significantly different from others, can indicate sensor malfunctions, external interference, or genuine anomalies. Handling them requires careful consideration:

- Visual inspection: Plot the data and visually identify outliers. A simple scatter plot can quickly reveal unusual data points.

- Statistical methods: Employ techniques like the Z-score or the Interquartile Range (IQR) method to identify outliers based on their deviation from the data’s central tendency and spread. Data points outside a defined threshold are flagged as potential outliers.

- Contextual analysis: Consider if the outlier aligns with any known events (e.g., equipment maintenance, environmental changes). Understanding the context can help determine if the outlier is truly an error or a legitimate phenomenon.

- Data smoothing: Methods like moving averages or median filtering can smooth the data and reduce the influence of outliers. However, this should be used cautiously as it can mask genuine signals.

- Rejection or replacement: Based on the analysis, outliers might be rejected (removed) from the dataset or replaced with a more reasonable value (e.g., using interpolation). Thorough documentation of outlier handling procedures is vital for data integrity.

The best approach depends on the application and data characteristics. Removing outliers without careful consideration could lead to loss of valuable information; however, leaving them unaddressed can skew analyses and produce misleading results.

Q 7. Describe your experience with different sensor communication protocols (e.g., I2C, SPI, Modbus).

I have experience with several sensor communication protocols, each with its strengths and weaknesses:

- I2C (Inter-Integrated Circuit): A simple, two-wire serial communication protocol widely used for low-speed data transfer between microcontrollers and sensors. It’s relatively easy to implement and requires minimal wiring. I’ve utilized I2C with numerous sensors, including temperature and humidity sensors.

- SPI (Serial Peripheral Interface): A full-duplex, multi-wire serial protocol offering higher speed and more robust data transfer compared to I2C. It’s often preferred for applications requiring higher bandwidth. I’ve used SPI with high-speed ADCs and other peripherals.

- Modbus: A widely adopted industrial communication protocol used for connecting sensors and actuators to programmable logic controllers (PLCs). It’s known for its robustness and reliability in industrial environments. My experience with Modbus includes integrating sensors in industrial automation systems.

The choice of protocol depends on factors like data rate requirements, distance between sensors and controllers, and the complexity of the system. For instance, I2C is well-suited for simple sensor networks with short distances, while Modbus is better for large, complex industrial systems. Understanding the nuances of each protocol is critical for successful sensor integration.

Q 8. Explain your understanding of signal conditioning techniques.

Signal conditioning is the process of modifying a sensor’s raw output signal to make it suitable for further processing and analysis. Think of it as preparing the ingredients before you cook a meal – raw sensor data is often noisy, weak, or in an inconvenient format. Signal conditioning ‘cleans’ and transforms this data to make it usable.

- Amplification: Weak signals, such as those from thermocouples, need amplification to be measurable. Operational amplifiers (op-amps) are commonly used for this purpose.

- Filtering: Sensors often pick up unwanted noise (e.g., electromagnetic interference). Filters remove these unwanted frequencies, leaving only the desired signal. Low-pass, high-pass, and band-pass filters are common types.

- Linearization: Many sensors have a non-linear relationship between the input stimulus and output signal. Linearization techniques, often involving look-up tables or mathematical transformations, convert this non-linear relationship into a more manageable linear one.

- Conversion: The sensor output might not be in the desired format. For instance, a sensor might produce a current, while the system requires a voltage. Signal conditioning circuits are used to perform necessary conversions (current-to-voltage, voltage-to-frequency, etc.).

Example: Imagine a pressure sensor used in a weather station. Its output might be a weak, noisy voltage signal. Signal conditioning would involve amplifying the signal to a suitable level, filtering out noise from nearby electrical equipment, and potentially linearizing the output to create a direct relationship between pressure and voltage.

Q 9. How do you select the appropriate sensor for a specific application?

Selecting the right sensor depends heavily on the application’s specific requirements. It’s a multi-faceted decision involving careful consideration of several factors.

- Measurand: What physical quantity needs to be measured (temperature, pressure, acceleration, etc.)?

- Range and Resolution: What is the expected range of values and the required level of precision?

- Accuracy and Precision: How accurate and precise does the measurement need to be? This impacts the sensor’s cost and complexity.

- Operating Conditions: What are the environmental conditions (temperature, humidity, pressure, vibration) the sensor will experience?

- Size and Weight: Are there constraints on the sensor’s physical dimensions and weight?

- Cost: What’s the budget for the sensor and associated equipment?

- Interface: How will the sensor interface with the data acquisition system (analog, digital, etc.)?

Example: If you are designing a system to monitor the temperature of a furnace, you’d need a high-temperature sensor with a wide range and good accuracy. A thermocouple or a RTD (Resistance Temperature Detector) would likely be suitable, but a standard thermistor might not withstand the high temperatures. Conversely, measuring the subtle temperature changes in a human body requires a much more sensitive and precise sensor like a thermistor.

Q 10. Describe your experience with sensor data acquisition and logging systems.

My experience with sensor data acquisition and logging systems is extensive. I’ve worked with various systems, from simple microcontroller-based setups to sophisticated industrial-grade data loggers. I am proficient in selecting appropriate hardware (A/D converters, multiplexers, etc.) and software (LabVIEW, Python with libraries like PyVISA, etc.) for different applications.

I understand the importance of proper system timing, synchronization, and data integrity checks during acquisition. I have experience designing systems that handle real-time data acquisition with high sampling rates, as well as systems for long-term data logging, often involving data storage and retrieval strategies. I’m familiar with various communication protocols such as RS-232, RS-485, I2C, SPI, and Ethernet for connecting sensors to the acquisition systems.

Example: In a previous project involving environmental monitoring, I designed a system using an Arduino microcontroller to acquire data from multiple sensors (temperature, humidity, pressure, light) and logged the data to an SD card. The system also included a GSM modem for remote data access and alerts.

Q 11. How do you ensure data integrity in sensor measurements?

Ensuring data integrity is critical in sensor measurements. It’s about making sure the data accurately reflects the actual physical phenomenon being measured, without errors or corruption.

- Calibration: Regular calibration using traceable standards is essential to compensate for sensor drift and bias.

- Error Detection and Correction: Implementing techniques like parity checks, checksums, and cyclic redundancy checks (CRC) can detect and correct errors introduced during data transmission or storage.

- Data Validation: Implement range checks and plausibility checks to identify values outside the expected range or inconsistent with other sensor data. For example, a sudden drastic change in temperature reading without a corresponding change in other sensors might indicate a malfunction.

- Redundancy: Using multiple sensors to measure the same quantity provides redundancy and allows for cross-checking and error detection. Data fusion techniques can then combine the readings from multiple sensors.

- Environmental Considerations: Proper shielding, grounding, and temperature control are vital to minimize external interference and maintain data accuracy.

Example: In a precision manufacturing environment, multiple pressure sensors might be used to measure the same pressure point. Discrepancies between readings can trigger an alert, prompting investigation into potential sensor errors or equipment malfunctions.

Q 12. What is your experience with sensor data analysis and interpretation techniques?

My experience in sensor data analysis and interpretation involves a range of techniques, depending on the type of data and the desired outcome.

- Signal Processing: Techniques like Fourier transforms, wavelet transforms, and filtering are used to extract relevant information from noisy signals, identify patterns, and detect anomalies.

- Statistical Analysis: Descriptive statistics (mean, standard deviation, etc.) and inferential statistics (hypothesis testing, regression analysis, etc.) provide insights into the data’s characteristics and relationships.

- Machine Learning: Algorithms like classification, regression, and clustering can be applied for pattern recognition, predictive modeling, and anomaly detection. For instance, I have used Support Vector Machines (SVMs) for classifying different types of sensor faults.

- Data Visualization: Effective data visualization is crucial for understanding trends, patterns, and anomalies. Tools like MATLAB, Python (Matplotlib, Seaborn), and specialized data analysis software are used to create informative graphs and charts.

Example: In a project monitoring structural health, I analyzed vibration sensor data using wavelet transforms to detect subtle changes indicating potential structural damage before it became visible.

Q 13. Explain your understanding of sensor fusion techniques.

Sensor fusion combines data from multiple sensors to produce a more accurate, reliable, and comprehensive understanding than any single sensor could provide on its own. Imagine having multiple witnesses to an event – each provides a slightly different perspective, but combining their accounts gives a clearer picture.

Several methods exist for sensor fusion, including:

- Weighted Averaging: A simple method where each sensor’s reading is weighted based on its accuracy and reliability.

- Kalman Filtering: A powerful technique used to estimate the state of a system based on noisy sensor measurements. It’s particularly effective in situations where there’s uncertainty in the sensor readings and the system dynamics.

- Bayesian Networks: A probabilistic approach that models the relationships between sensors and their uncertainties.

Example: In autonomous driving, sensor fusion combines data from cameras, LiDAR, radar, and GPS to create a detailed map of the environment, allowing the vehicle to navigate safely and effectively. Each sensor has its strengths and weaknesses – cameras excel at identifying objects, LiDAR provides accurate distance measurements, and radar is good for detecting moving objects even in low visibility. Fusion combines these data sources to provide a robust and complete understanding.

Q 14. How do you handle sensor drift and bias?

Sensor drift and bias are common sources of error. Drift refers to a gradual change in the sensor’s output over time, while bias refers to a consistent offset between the measured value and the true value.

Several techniques can be used to handle these:

- Calibration: Regular calibration against a known standard helps correct for bias and partially compensate for drift.

- Compensation Algorithms: Algorithms can be implemented to model and correct for drift and bias based on the sensor’s characteristics and environmental conditions. This often involves using additional sensors to monitor relevant environmental factors.

- Data Filtering: Techniques like moving averages can smooth out short-term fluctuations and reduce the impact of drift.

- Sensor Selection: Choosing sensors with low drift and bias characteristics in the first place minimizes the need for extensive correction.

Example: In a high-precision weighing scale, temperature changes can lead to drift in the sensor readings. An additional temperature sensor can be used to compensate for the drift by applying a correction factor based on the temperature measurement.

Q 15. Describe your experience with sensor maintenance and repair procedures.

Sensor maintenance and repair are crucial for ensuring accurate and reliable data acquisition. My experience encompasses a wide range of procedures, from routine checks to complex repairs. Routine maintenance includes cleaning sensors, checking for physical damage, verifying cable connections, and calibrating against known standards. This is similar to regularly servicing a car – preventative maintenance prevents bigger problems later. For example, I’ve routinely cleaned optical sensors from dust accumulation using compressed air and specialized cleaning solutions, significantly improving signal quality. More complex repairs involve troubleshooting malfunctioning components, replacing faulty sensors or parts, and performing recalibration procedures using specialized equipment. I’ve successfully diagnosed and repaired faulty pressure sensors by identifying a short circuit in the wiring harness and replacing the damaged section, restoring system functionality. My experience also covers implementing preventative maintenance schedules to minimize downtime and extend sensor lifespan, including predictive maintenance strategies using data analytics to anticipate potential failures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of sensor linearity and its importance.

Sensor linearity refers to the consistency of a sensor’s output in relation to its input. Ideally, a linear sensor produces a perfectly proportional output for a given input range. For example, if a sensor measures temperature, a perfectly linear sensor would show a consistent 1-degree increase in output for every 1-degree increase in temperature. The importance of linearity lies in the accuracy and predictability of the sensor data. A non-linear sensor can introduce significant errors in measurements, particularly when performing precise calculations or control actions. Imagine a pressure sensor in a critical industrial setting. If the sensor exhibits non-linearity, it might incorrectly trigger a safety shutdown or lead to inaccurate process control, resulting in production losses or safety hazards. Assessing linearity often involves plotting the sensor’s output against the input and evaluating the deviation from a straight line. This can be quantified using metrics like linearity error, which indicates how much the sensor deviates from ideal linear behavior within a specific operating range.

Q 17. What is your experience with different sensor technologies (e.g., optical, ultrasonic, capacitive)?

My experience with sensor technologies spans a variety of domains, encompassing optical, ultrasonic, and capacitive sensors, among others. Optical sensors, which leverage light for measurement, have been extensively used in projects involving optical fiber sensors for strain measurement in structural health monitoring. I have considerable experience interpreting the resulting data and using it to model structural behavior. Ultrasonic sensors, using sound waves, have been critical in my work with non-destructive testing, such as detecting internal flaws in materials. Here, understanding the principles of wave propagation and signal processing is key to interpreting the results correctly. Capacitive sensors, which measure changes in capacitance, were central in a project developing a proximity sensor for robotic applications. Understanding how changes in the dielectric material affect the capacitance is crucial to designing such systems. I am also familiar with other technologies like resistive sensors, infrared sensors, and accelerometers. My expertise lies not just in operating these sensors but also in critically evaluating their limitations, selecting the right technology for specific applications and integrating them into larger systems.

Q 18. How do you ensure the safety and reliability of sensor systems?

Ensuring the safety and reliability of sensor systems is paramount. This involves a multi-faceted approach. First, proper sensor selection is crucial; choosing sensors rated for the specific operating environment (temperature, pressure, etc.) prevents malfunctions and potential hazards. Second, robust design incorporating redundancy and fail-safes is essential. For example, using multiple sensors to measure the same parameter and employing a voting mechanism ensures system functionality even if one sensor fails. This is like having a backup system in place. Third, regular calibration and maintenance are indispensable for maintaining accuracy and preventing errors that could have safety implications. For example, in a chemical processing plant, an improperly calibrated level sensor could lead to an overflow and a potentially hazardous situation. Fourth, rigorous testing and validation of sensor data are performed to catch inconsistencies early. This could involve simulations, lab testing, and on-site trials. Finally, adhering to relevant safety standards and regulations is critical, particularly in applications with high safety risks.

Q 19. Describe your experience with sensor network design and deployment.

My experience with sensor network design and deployment includes several projects where I have been responsible for all phases of design, from requirements gathering to implementation and testing. This begins with careful consideration of the application’s specific needs, including the type of sensors, communication protocols, power requirements, and environmental factors. For example, in a project deploying a network of soil moisture sensors, we carefully selected low-power wireless sensors, used a mesh network architecture for robust communication, and implemented energy-harvesting techniques to minimize maintenance. Deployment involves careful planning of sensor placement to optimize coverage and minimize interference, followed by rigorous testing to ensure all sensors are functioning correctly and communicating effectively. Data processing and visualization are integral parts of the deployment, enabling real-time monitoring and analysis of the collected data.

Q 20. Explain the challenges of working with wireless sensor networks.

Wireless sensor networks (WSNs) present several unique challenges. Power limitations are a major concern, as many sensors are battery-powered, requiring careful power management and energy-efficient communication protocols. Communication range and reliability are also important factors; obstacles, interference, and signal attenuation can disrupt communication. Data security and privacy can be significant concerns. Data needs to be secured to prevent unauthorized access or tampering. Finally, dealing with large amounts of data generated by the sensor network requires effective data processing, storage, and analysis techniques. For example, techniques like data aggregation, compression, and filtering are vital to reducing the amount of data that needs to be transmitted and processed. Robust error detection and correction mechanisms are essential to ensure data integrity given the inherent unreliability of wireless communication.

Q 21. How do you validate sensor data?

Validating sensor data involves a multi-step process to ensure accuracy and reliability. This starts with checking sensor calibration and ensuring that the sensors are operating within their specified ranges. Next, comparing sensor readings with independent measurements from other sources, like manual measurements or readings from different sensor types (cross-validation), provides a reality check. This is crucial to identifying any systematic errors. Statistical methods, such as calculating mean, standard deviation, and identifying outliers, help to detect random errors and inconsistencies. Data visualization through plotting and creating charts can highlight potential problems. Finally, understanding the sensor’s limitations and error sources is essential to interpreting the data correctly. This could involve analyzing sensor drift, noise levels, and other potential error sources. Inaccurate or invalid data points might be discarded or corrected depending on the situation and potential biases. A thorough validation process is absolutely necessary to ensure that the collected data can be trusted and used for reliable decision-making.

Q 22. How do you address sensor redundancy and fault tolerance?

Sensor redundancy and fault tolerance are critical for reliable sensor systems. Redundancy involves using multiple sensors to measure the same parameter. If one sensor fails, the others continue to provide data, ensuring system operation. Fault tolerance goes a step further by incorporating mechanisms to detect and handle sensor failures gracefully. This might involve voting algorithms (majority rules), where the output is based on the consensus of multiple sensors, or using data fusion techniques to combine data from multiple sensors, weighting them based on their reliability. For example, in a robotic arm, multiple encoders measuring joint angles could ensure that the robot continues to function even if one encoder malfunctions. The system would compare the readings and detect the outlier, potentially ignoring it or using sophisticated algorithms to estimate the correct angle.

Strategies for achieving this include:

- Hardware redundancy: Using multiple identical sensors.

- Software redundancy: Implementing data validation and error-correction algorithms.

- Data fusion: Combining data from multiple sensors using weighted averages or Kalman filters (a powerful algorithm for estimating states in dynamic systems).

The choice of method depends on factors like cost, complexity, and the criticality of the application. A simple system might only require hardware redundancy, while a safety-critical system might necessitate a combination of hardware and software redundancy with sophisticated data fusion.

Q 23. What are the limitations of your preferred sensor technologies?

My preferred sensor technologies often involve a mix of optical and inertial measurement units (IMUs). While powerful, these technologies have limitations. Optical sensors, like cameras or laser rangefinders, can be sensitive to lighting conditions; poor lighting can significantly reduce accuracy or even make the data unusable. They can also be susceptible to occlusion (objects blocking the line of sight). IMUs, although very robust and compact, are prone to drift over time due to integration of noise in accelerometer and gyroscope data. This means their measurements accumulate errors, resulting in inaccurate position estimation after a period of time. Calibration procedures are essential to mitigate this, however, perfect calibration is not always achievable. Furthermore, both optical sensors and IMUs can be susceptible to electromagnetic interference, which requires careful shielding and proper grounding techniques. For instance, in a high-vibration environment, IMU readings can be significantly corrupted, thus calling for specialized ruggedized IMUs. Finally, the cost and computational requirements for processing sensor data from sophisticated sensors like lidar can be substantial.

Q 24. Explain your understanding of sensor data visualization and reporting.

Sensor data visualization and reporting are crucial for understanding and interpreting sensor data. Effective visualization transforms raw data into meaningful insights. The goal is to present data in a way that is both clear and easily interpretable. This can involve various techniques, including:

- Time-series plots: Showing sensor readings over time.

- Scatter plots: Showing relationships between different sensor readings.

- Heatmaps: Representing spatial data, such as temperature distributions.

- 3D visualizations: Visualizing data in three dimensions.

The choice of visualization technique depends on the type of data and the questions being asked. Reporting typically involves summarizing key findings from the data analysis. This might include statistical summaries (mean, standard deviation, etc.), identification of trends, anomalies, or correlations. Reports should be well-structured, easy to understand, and include clear conclusions and recommendations. For example, in environmental monitoring, a report might include a map visualizing temperature and humidity across a region, with summarized statistics and an analysis of trends over time.

Q 25. Describe your experience with programming languages relevant to sensor data acquisition and analysis.

I have extensive experience with several programming languages relevant to sensor data acquisition and analysis. Python is a go-to language due to its rich ecosystem of libraries like NumPy (for numerical computation), SciPy (for scientific computing), Pandas (for data manipulation), and Matplotlib/Seaborn (for data visualization). I frequently use these libraries to process sensor data, perform statistical analysis, build machine learning models, and generate reports. I’m also proficient in C++ for situations that require high performance and low-level hardware interaction, particularly when dealing with real-time embedded systems. My experience also extends to using MATLAB for advanced signal processing and control system design. Finally, I’ve worked with languages like LabVIEW for graphical programming in data acquisition systems.

For example, a common task involves reading sensor data from a serial port in Python, cleaning the data, performing some signal processing and then plotting the results using Matplotlib. A code snippet illustrating basic serial communication in Python could look like this:

import serial

ser = serial.Serial('/dev/ttyACM0', 9600)

while True:

line = ser.readline().decode('utf-8').rstrip()

print(line)Q 26. How do you ensure compatibility between different sensors in a system?

Ensuring compatibility between different sensors in a system requires careful planning and execution. The primary considerations are:

- Data formats: Sensors may output data in different formats (e.g., analog voltage, digital signals, various communication protocols like I2C, SPI, or USB). A central data acquisition system needs to handle these diverse formats. This often involves using appropriate hardware interfaces (e.g., ADC, DAC) and writing custom software drivers.

- Data rates: Sensors may operate at different speeds. The system needs to manage the different data rates and ensure that no data is lost or delayed. Techniques like buffering and synchronization are crucial.

- Power requirements: Sensors have varying power needs. The system needs to supply appropriate power to each sensor, potentially using voltage regulators or power distribution circuits.

- Communication protocols: Choosing a suitable communication protocol (e.g., CAN bus, Ethernet) is important for efficient and reliable data transfer. The protocol should handle data from all sensors while maintaining timing requirements and error detection/correction.

In practice, this often involves using a central microcontroller or a computer to act as an intermediary, handling data conversion and communication for all the sensors. This allows for easier management of the entire system and makes integration of new sensors simpler.

Q 27. Describe a time you had to troubleshoot a complex sensor issue, and how you resolved it.

During a project involving a network of environmental sensors deployed across a large area, we experienced a situation where one sensor consistently reported abnormally high humidity readings. Initial checks of the sensor itself showed no obvious faults. The problem was intermittent and didn’t show any clear pattern. We systematically investigated the possibilities:

- Sensor Calibration: We recalibrated the sensor, but the issue persisted.

- Environmental Factors: We considered local environmental conditions, but other sensors in the vicinity showed normal readings.

- Communication Issues: We examined the communication link, suspecting data corruption during transmission. After carefully reviewing the communication protocol and rechecking the cabling, we discovered the issue was not the sensor itself, but rather a faulty connection near the sensor’s power supply. A loose wire was causing intermittent power surges, which interfered with the sensor’s electronics and led to the erroneous humidity readings.

- Power Supply: Replacing the power supply and ensuring a stable power source immediately resolved the problem. The sensor readings returned to normal, aligning with those of other sensors in the network.

This experience highlighted the importance of thorough investigation and systematic troubleshooting. Rushing to conclusions about the sensor itself without examining the entire system, including its power and communication components, could have wasted considerable time and resources.

Q 28. What are your experience with different signal filtering methods?

Signal filtering is essential for removing noise and unwanted artifacts from sensor data. Several methods exist, each with its strengths and weaknesses. Common techniques include:

- Moving Average Filter: A simple technique where the output is the average of a window of data points. It’s effective at smoothing out high-frequency noise but can blur sharp transitions and introduce lag.

- Median Filter: Replaces each data point with the median of the neighboring data points. It’s robust to outliers but can also blur sharp transitions.

- Kalman Filter: A powerful algorithm that uses a model of the system dynamics to predict future states and update the estimate based on new sensor readings. It’s effective at removing noise and estimating hidden states in dynamic systems.

- Butterworth Filter: A type of digital filter known for its flat passband and good roll-off characteristics. It can be designed to remove specific frequency ranges, making it suitable for removing noise at particular frequencies.

- Fourier Transform based filtering: Used to analyze the frequency spectrum of a signal. This allows for the identification of noise components which can then be attenuated before an inverse Fourier Transform is applied to return the signal to the time domain. This is particularly useful if noise is concentrated at specific frequencies.

The choice of filter depends on the type of noise, the desired level of smoothing, and the nature of the signal. For example, a moving average filter might be sufficient for removing random noise from a slowly varying signal, while a Kalman filter might be more appropriate for tracking a moving object with noisy sensor readings. Designing an effective filter often involves experimentation and careful analysis of the signal characteristics.

Key Topics to Learn for Sensor Operation and Interpretation Interview

- Sensor Fundamentals: Understanding sensor types (e.g., optical, acoustic, thermal), their operating principles, and limitations. Explore signal-to-noise ratios and calibration techniques.

- Data Acquisition and Processing: Learn about analog-to-digital conversion, data filtering techniques (e.g., smoothing, noise reduction), and signal conditioning methods. Consider the practical application of these techniques in different sensor systems.

- Signal Interpretation and Analysis: Master techniques for interpreting sensor data, including pattern recognition, anomaly detection, and statistical analysis. Practice identifying trends and drawing meaningful conclusions from complex datasets.

- Sensor Integration and System Design: Understand how sensors are integrated into larger systems, including considerations for power management, data communication protocols, and system reliability. Explore case studies of successful sensor system implementations.

- Troubleshooting and Maintenance: Develop your ability to diagnose sensor malfunctions, perform routine maintenance, and implement corrective actions. Be prepared to discuss strategies for ensuring sensor accuracy and longevity.

- Specific Sensor Technologies: Depending on your target role, focus on mastering the operation and interpretation of specific sensor types relevant to the job description (e.g., lidar, radar, accelerometers, pressure sensors).

- Data Visualization and Reporting: Practice presenting sensor data effectively through charts, graphs, and reports. Be ready to discuss your ability to communicate technical information clearly and concisely.

Next Steps

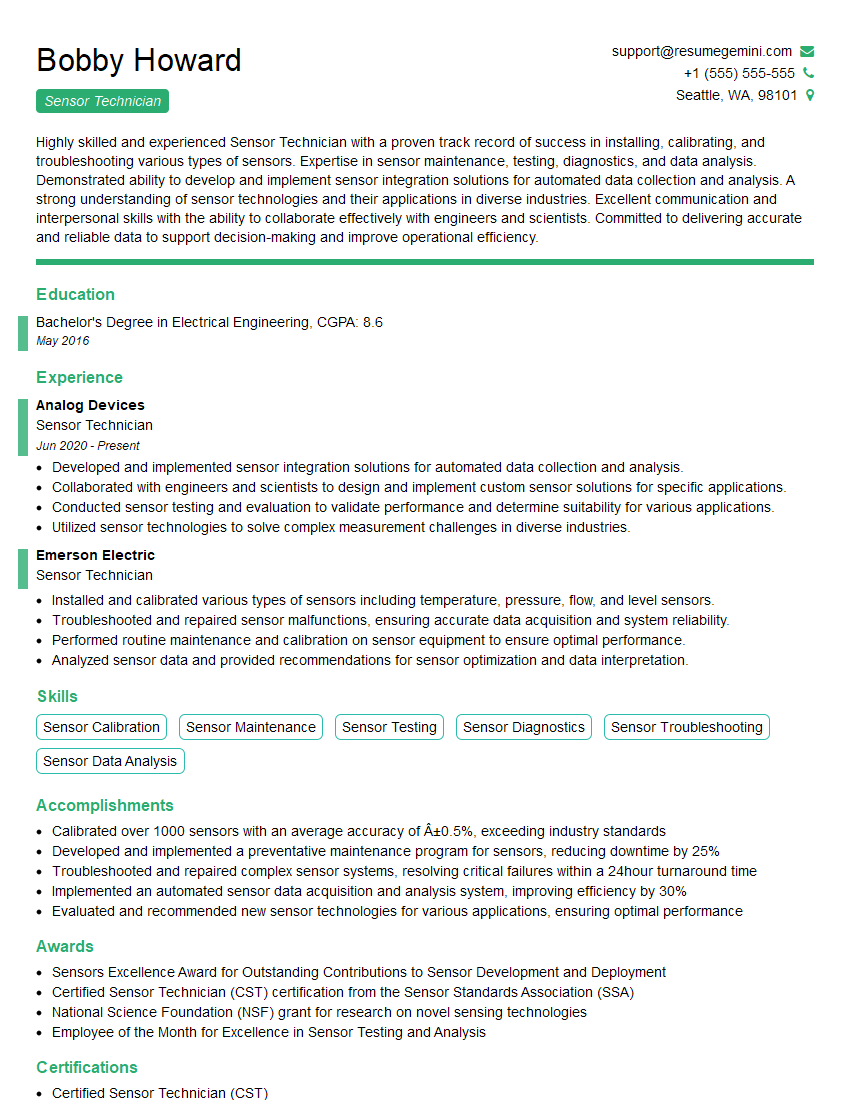

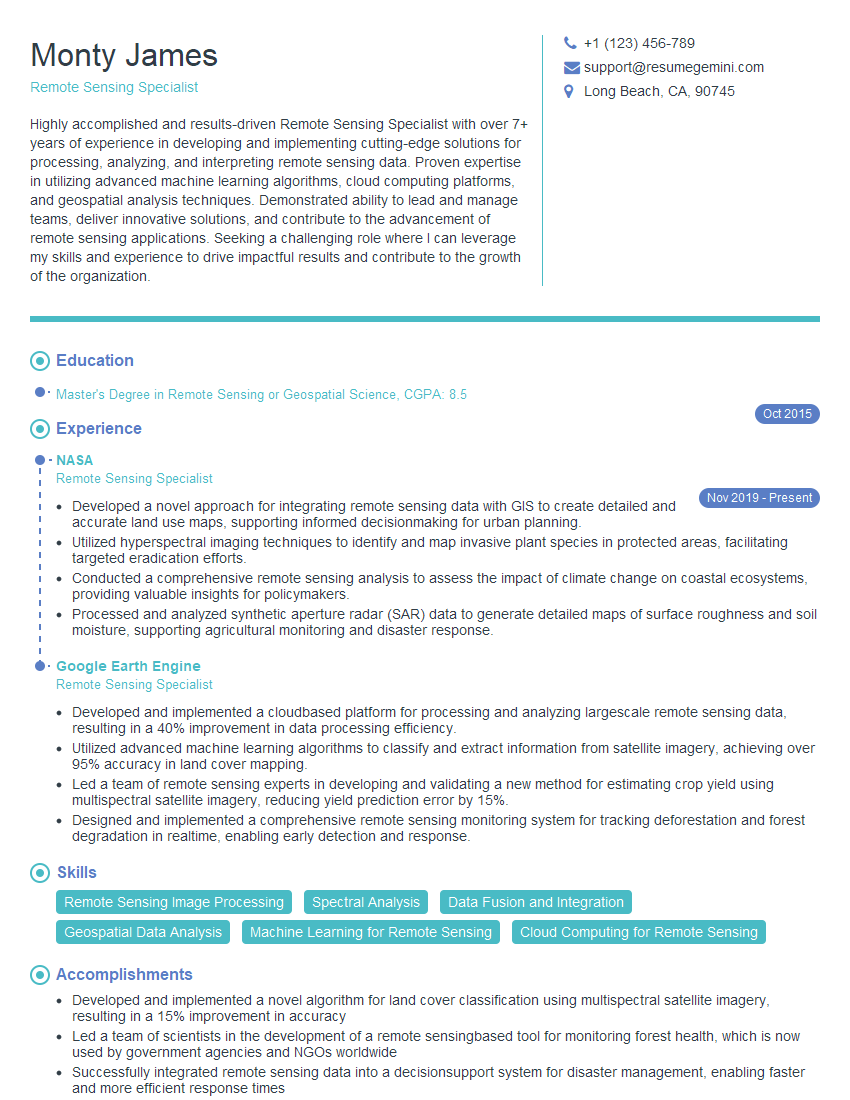

Mastering Sensor Operation and Interpretation is crucial for career advancement in numerous high-growth fields. A strong understanding of these concepts opens doors to exciting opportunities and positions you for technical leadership. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of your target roles. Examples of resumes tailored to Sensor Operation and Interpretation are available to guide you in crafting your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good