The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Sensors and Electronics Systems interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Sensors and Electronics Systems Interview

Q 1. Explain the difference between active and passive sensors.

The core difference between active and passive sensors lies in how they acquire data. Active sensors emit a form of energy (light, sound, radio waves, etc.) and then measure the response from the target. Think of radar: it sends out radio waves and analyzes the returning echoes to determine the distance and speed of objects. This emission requires an internal power source. In contrast, passive sensors simply measure the energy already present in their environment. A thermometer measuring ambient temperature is a great example; it doesn’t emit anything, but rather responds to the existing heat. Passive sensors generally consume less power than active ones but might be less sensitive or have a more limited range.

Here’s a table summarizing the key differences:

| Feature | Active Sensor | Passive Sensor |

|---|---|---|

| Energy Source | Internal | External |

| Sensitivity | Generally higher | Generally lower |

| Range | Can be longer | Often shorter |

| Power Consumption | Higher | Lower |

| Examples | Radar, Sonar, Lidar | Thermometer, Photoresistor, Microphone |

Q 2. Describe various types of sensor noise and their mitigation techniques.

Sensor noise is the unwanted signal that interferes with the actual measurement. Several types exist:

- Thermal Noise (Johnson-Nyquist Noise): This is inherent to all resistive components at temperatures above absolute zero and is caused by the random thermal motion of electrons. It’s proportional to temperature and bandwidth.

- Shot Noise: Occurs in devices with current flow across a potential barrier, such as diodes or transistors. It’s due to the discrete nature of charge carriers.

- Flicker Noise (1/f Noise): This low-frequency noise has an intensity inversely proportional to frequency. Its origin is complex and often related to imperfections in materials.

- Environmental Noise: External sources such as electromagnetic interference (EMI), vibrations, or temperature fluctuations can introduce noise.

Mitigation techniques include:

- Shielding: Protecting sensors from external electromagnetic interference.

- Filtering: Using analog or digital filters to remove unwanted frequency components.

- Averaging: Taking multiple readings and averaging to reduce random noise.

- Signal Conditioning: Amplifying the desired signal relative to the noise.

- Careful Sensor Placement: Minimizing exposure to sources of environmental noise.

For instance, in a medical sensor application, using shielded cables and implementing a low-pass filter to reduce high-frequency interference ensures reliable signal acquisition.

Q 3. What are the key considerations for selecting a sensor for a specific application?

Choosing the right sensor hinges on several critical factors:

- Accuracy and Precision: How close the measurements are to the true value and how repeatable the measurements are.

- Range and Sensitivity: The minimum and maximum values the sensor can measure and its ability to detect small changes.

- Resolution: The smallest increment of measurement.

- Linearity: How well the sensor’s output is proportional to the input.

- Bandwidth: The range of frequencies the sensor can accurately measure.

- Operating Temperature Range: The temperature range within which the sensor functions correctly.

- Size and Weight: Particularly important in portable or embedded applications.

- Cost and Power Consumption: A balance between performance and budget constraints.

- Environmental Factors: Considering aspects like humidity, pressure, and light.

Suppose you’re designing a system to monitor heart rate. You would prioritize accuracy, a suitable measurement range, and a high sampling rate. Factors like size and power consumption might also be important depending on whether it’s a wristband or a hospital-grade monitor.

Q 4. Explain the concept of sensor calibration and its importance.

Sensor calibration is the process of adjusting the sensor’s output to match a known standard. This ensures accurate and reliable measurements. It involves comparing the sensor’s readings against a reference standard, often traceable to national or international standards. Without calibration, sensors will drift over time or due to environmental changes, leading to inaccurate readings.

Importance:

- Accuracy: Eliminates systematic errors and ensures measurements are close to the true value.

- Reliability: Reduces inconsistencies and improves the overall confidence in the data.

- Traceability: Allows for comparison and validation of results across different measurements and systems.

For example, a pressure sensor used in industrial automation needs regular calibration to maintain precision and prevent costly errors. Calibration procedures vary based on the sensor type; some involve simple offset and gain adjustments, while others require complex mathematical models.

Q 5. How do you handle sensor data acquisition and processing in real-time systems?

Real-time sensor data acquisition and processing require efficient and timely handling of data streams. This involves:

- Data Acquisition Hardware: Selecting appropriate analog-to-digital converters (ADCs) for signal conversion and interfaces for communication with sensors.

- Real-Time Operating System (RTOS): Using an RTOS to manage tasks and ensure deterministic timing.

- Efficient Data Processing Algorithms: Implementing optimized algorithms for data filtering, noise reduction, and feature extraction.

- Buffering: Using circular buffers to temporarily store data before processing to handle data bursts or temporary interruptions.

- Data Transfer Protocols: Utilizing efficient communication protocols like SPI, I2C, or UART for low latency data transfer.

Imagine a robotic arm controlled by multiple sensors. An RTOS schedules tasks for data acquisition from each sensor, processing the data, and sending commands to the actuators. Efficient buffering is critical to avoid data loss, ensuring smooth, responsive arm movements.

// Example code snippet (Conceptual):while(1){ // Read data from sensors sensorData = readSensors(); // Process data (filter, etc.) processedData = processData(sensorData); // Send commands to actuators sendCommands(processedData);}

Q 6. Describe different signal conditioning techniques for sensors.

Signal conditioning prepares raw sensor signals for accurate and reliable use. Common techniques include:

- Amplification: Increasing the signal amplitude to improve signal-to-noise ratio.

- Filtering: Removing unwanted noise or frequencies using low-pass, high-pass, band-pass, or notch filters.

- Linearization: Compensating for non-linear sensor characteristics to improve accuracy.

- Offset Adjustment: Removing a DC offset to center the signal around zero.

- Analog-to-Digital Conversion (ADC): Converting analog sensor signals to digital values for processing.

For instance, a thermocouple used for temperature measurement might require amplification to boost its weak millivolt signal and filtering to eliminate high-frequency noise from the environment.

Q 7. Explain the working principle of a microcontroller and its role in sensor systems.

A microcontroller (MCU) is a small, programmable computer on a single integrated circuit (IC). It’s the brain of many sensor systems. It integrates processing capabilities, memory, and input/output (I/O) peripherals on a single chip. In a sensor system, the MCU’s role is multifaceted:

- Data Acquisition: Reading data from sensors using various interfaces (ADC, SPI, I2C).

- Signal Processing: Filtering, amplifying, and processing raw sensor data.

- Decision Making: Implementing algorithms to interpret data and make decisions based on sensor inputs.

- Control: Actuating devices based on processed sensor data (e.g., controlling motors or valves).

- Communication: Sending data to other systems (computers, networks) via various communication protocols.

In a smart thermostat, for example, the MCU reads temperature data from a sensor, processes it, and adjusts the heating/cooling system accordingly. The MCU acts as the central hub, coordinating all aspects of the system’s operation based on sensor feedback.

Q 8. What are different communication protocols used in sensor networks?

Sensor networks rely on various communication protocols to exchange data. The choice depends on factors like range, bandwidth, power consumption, and network topology. Common protocols include:

- Wireless protocols:

- Zigbee: A low-power, low-data-rate protocol ideal for short-range, mesh networks. Think of it as a whisper network perfect for home automation sensors.

- Bluetooth Low Energy (BLE): Excellent for mobile applications and short-range communication, offering a good balance between power and data rate. Imagine your fitness tracker communicating with your smartphone.

- Wi-Fi: Provides high bandwidth and longer range, but consumes significantly more power. Suitable for applications requiring large data transmission, like industrial sensor networks monitoring large machinery.

- LoRaWAN: A long-range, low-power wide-area network (LPWAN) technology, perfect for applications needing wide coverage with minimal power usage, like smart city sensors.

- Sigfox/NB-IoT: Other LPWAN technologies focusing on ultra-low power and long range, often used in smart metering or asset tracking.

- Wired protocols:

- RS-485: A robust and reliable protocol for industrial applications, offering multi-point communication and noise immunity. Think of it as a sturdy, long-distance messenger service.

- CAN bus: Common in automotive applications, providing high speed and deterministic communication. Its real-time capabilities are crucial in safety-critical systems.

Selecting the appropriate protocol is crucial for optimizing network performance and meeting application-specific requirements. For instance, a smart agriculture network might leverage LoRaWAN for long-range soil moisture sensor data transmission, while a robotics system might rely on CAN bus for precise real-time motor control.

Q 9. How do you design for EMC/EMI compliance in sensor systems?

Designing for Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) compliance in sensor systems is crucial for reliable operation and preventing malfunctions. It involves minimizing emissions and ensuring immunity to external interference. Key strategies include:

- Shielding: Enclosing sensitive circuitry within conductive enclosures to prevent EMI ingress and egress. Think of it as a Faraday cage protecting the sensor from electromagnetic storms.

- Filtering: Using filters (e.g., LC filters) to attenuate unwanted frequencies on power lines and signal paths. It’s like a gatekeeper, letting only the desired signals through.

- Grounding: Establishing a robust ground plane to minimize loop currents and reduce common-mode noise. A proper ground is the foundation for a stable system.

- Layout optimization: Strategically positioning components on a PCB to minimize coupling between sensitive and noisy circuits. Spatial separation helps prevent interference like preventing two loudspeakers from drowning each other out.

- Component selection: Choosing components with inherently low EMI emission and high EMI immunity. Some components are more robust and less susceptible to noise than others.

- Cable management: Using shielded cables and proper routing to minimize electromagnetic radiation and susceptibility. Properly managed cables act like insulated pathways.

Compliance testing, according to standards like CISPR and FCC regulations, is critical to ensure the system meets legal requirements and operates reliably in its intended environment. Failing to account for EMC/EMI can lead to data corruption, malfunctions, or even safety hazards.

Q 10. Explain the concept of sensor fusion and its benefits.

Sensor fusion involves combining data from multiple sensors to obtain a more accurate, complete, and reliable understanding of the environment than any single sensor could provide. Think of it like getting a richer picture by combining different perspectives (e.g., sight, sound, touch).

Benefits:

- Increased accuracy: Combining sensor readings helps compensate for individual sensor inaccuracies and limitations.

- Improved robustness: If one sensor fails, the system can still function using data from other sensors.

- Enhanced perception: Sensor fusion can provide a more comprehensive understanding of the environment than using individual sensors alone. For example, combining camera (visual) and lidar (distance) data provides a detailed 3D map.

- Reduced uncertainty: By integrating data, the overall uncertainty in the system’s understanding of the environment is reduced.

Example: In autonomous driving, sensor fusion combines data from cameras, lidar, radar, and GPS to create a detailed and robust perception of the vehicle’s surroundings. This allows for safe and reliable navigation.

Q 11. Discuss different types of analog-to-digital converters (ADCs) and their applications.

Analog-to-digital converters (ADCs) transform continuous analog signals into discrete digital representations. Different types exist, each with specific characteristics and applications:

- Successive Approximation ADC (SAR ADC): A common type that uses a successive approximation register to compare the analog input voltage to a series of internally generated reference voltages. It’s relatively fast and accurate, commonly used in data acquisition systems.

- Delta-Sigma ADC: A high-resolution ADC that uses oversampling and noise shaping to achieve high accuracy at lower sampling rates. It’s excellent for applications requiring high precision, like audio processing or weighing scales.

- Flash ADC: The fastest ADC type, using a parallel architecture to convert the analog signal directly to digital. However, it’s expensive and only suitable for applications where high speed is paramount, like high-speed signal processing.

- Sigma-Delta ADC: Similar to Delta-Sigma but with a slightly different architecture, it also prioritizes high resolution and is suited for similar applications.

- Pipeline ADC: A high-speed ADC that breaks down the conversion process into multiple stages for increased speed and precision.

The selection of the appropriate ADC depends on factors like required resolution, speed, power consumption, and cost. For instance, a low-power sensor node might use a SAR ADC, whereas a high-speed data acquisition system might require a Flash ADC.

Q 12. What are the advantages and disadvantages of different sensor technologies (e.g., capacitive, resistive, optical)?

Different sensor technologies offer unique advantages and disadvantages:

- Capacitive sensors: Detect changes in capacitance between two conductive plates.

- Advantages: High sensitivity, contactless operation, long lifespan.

- Disadvantages: Susceptible to environmental factors (temperature, humidity), limited range.

- Example: Touchscreens, proximity sensors.

- Resistive sensors: Measure changes in resistance due to physical deformation.

- Advantages: Simple, inexpensive, widely available.

- Disadvantages: Relatively low accuracy, susceptible to wear and tear.

- Example: Potentiometers, force sensors, strain gauges.

- Optical sensors: Based on the interaction of light with the measured object.

- Advantages: High accuracy, non-contact measurement, fast response time.

- Disadvantages: Can be affected by ambient light, expensive, potentially complex.

- Example: Photodiodes, phototransistors, optical fiber sensors.

The optimal choice depends on the specific application requirements. For instance, a high-precision displacement measurement might benefit from an optical sensor, while a simple button might use a resistive sensor.

Q 13. How do you troubleshoot sensor system failures?

Troubleshooting sensor system failures is a systematic process involving several steps:

- Gather information: Observe the symptoms of the failure, noting any error messages, unusual behavior, or environmental factors. What are the specific symptoms?

- Check for obvious issues: Inspect the sensor, wiring, and connections for any physical damage, loose connections, or broken components. Are there any visible problems?

- Test sensor functionality: Use a multimeter or other test equipment to check sensor output signals and compare them to expected values. Does the sensor give a realistic reading? Is there continuity in the wiring?

- Analyze signal path: Trace the signal path from the sensor to the data acquisition system, checking for signal degradation or noise. Are there any signal attenuation or distortions?

- Verify power supply: Ensure the sensor and associated circuitry receive adequate and stable power. Does the sensor get the required voltage?

- Check software and firmware: Verify that the data acquisition software and sensor firmware are functioning correctly. Is the code performing as expected? Are there any log files that show errors?

- Calibration and adjustment: If possible, calibrate or adjust the sensor to ensure it provides accurate readings. Has the sensor drifted from its calibrated value?

- Replace components: If the fault is isolated to a specific component (sensor, cable, or circuit board), replacement is necessary. Has the sensor reached the end of its lifespan?

This systematic approach helps efficiently identify and resolve sensor system failures. The troubleshooting process may involve using specialized tools, technical documentation, and collaborating with other engineers.

Q 14. Describe your experience with different embedded operating systems.

My experience with embedded operating systems (OS) encompasses various platforms, each tailored for specific application requirements. I have worked extensively with:

- FreeRTOS: A widely used real-time operating system known for its lightweight nature and suitability for resource-constrained microcontrollers. I’ve leveraged its task scheduling and inter-process communication capabilities in numerous projects, including sensor data acquisition and control systems.

- Zephyr RTOS: A modern, scalable real-time operating system designed for resource-constrained devices, suitable for IoT applications and sensor networks. Its modularity and support for various architectures made it a perfect fit for a recent project involving a distributed network of environmental sensors.

- RT-Thread: Another real-time operating system offering features like memory management, file systems, and networking protocols, making it suitable for more complex embedded applications. I utilized its rich functionality in a project involving a sophisticated industrial control system.

- Linux (embedded versions): I have worked with embedded versions of Linux (e.g., Yocto Project) when a more powerful OS with advanced features like networking and extensive software libraries were necessary. This was crucial in a project developing a system that needed complex data processing and communication features.

My experience extends beyond simply using these OSes to designing and integrating software components that interact efficiently within the chosen OS environment, including drivers, middleware, and application logic. I am adept at optimizing performance and resource utilization in embedded systems, ensuring reliable and efficient operation.

Q 15. Explain the role of firmware in a sensor system.

Firmware is the soul of a sensor system, the low-level software that acts as the bridge between the physical sensor hardware and the higher-level application software. Think of it as the operating system specifically tailored for your sensor. It manages the sensor’s internal workings, data acquisition, pre-processing, and communication with external systems. For instance, in a temperature sensor, the firmware would handle tasks such as calibrating the sensor readings based on its internal characteristics, converting raw sensor output into meaningful temperature units (Celsius or Fahrenheit), and transmitting this data through a chosen communication protocol (e.g., I2C, SPI, UART).

A well-designed firmware is crucial for optimizing the sensor’s performance and reliability. It handles crucial functions like:

- Data Acquisition: Regularly sampling data from the sensor.

- Signal Conditioning: Filtering noise and applying calibration algorithms.

- Data Processing: Performing calculations or transformations on the raw data (e.g., averaging, smoothing).

- Communication: Sending data to a microcontroller, computer, or cloud platform.

- Power Management: Optimizing power consumption, crucial for battery-powered applications.

Without effective firmware, your sensor is just a collection of hardware components—unable to process or communicate its data effectively. In a smart home application, for example, faulty firmware might lead to inaccurate temperature readings, preventing your smart thermostat from functioning correctly.

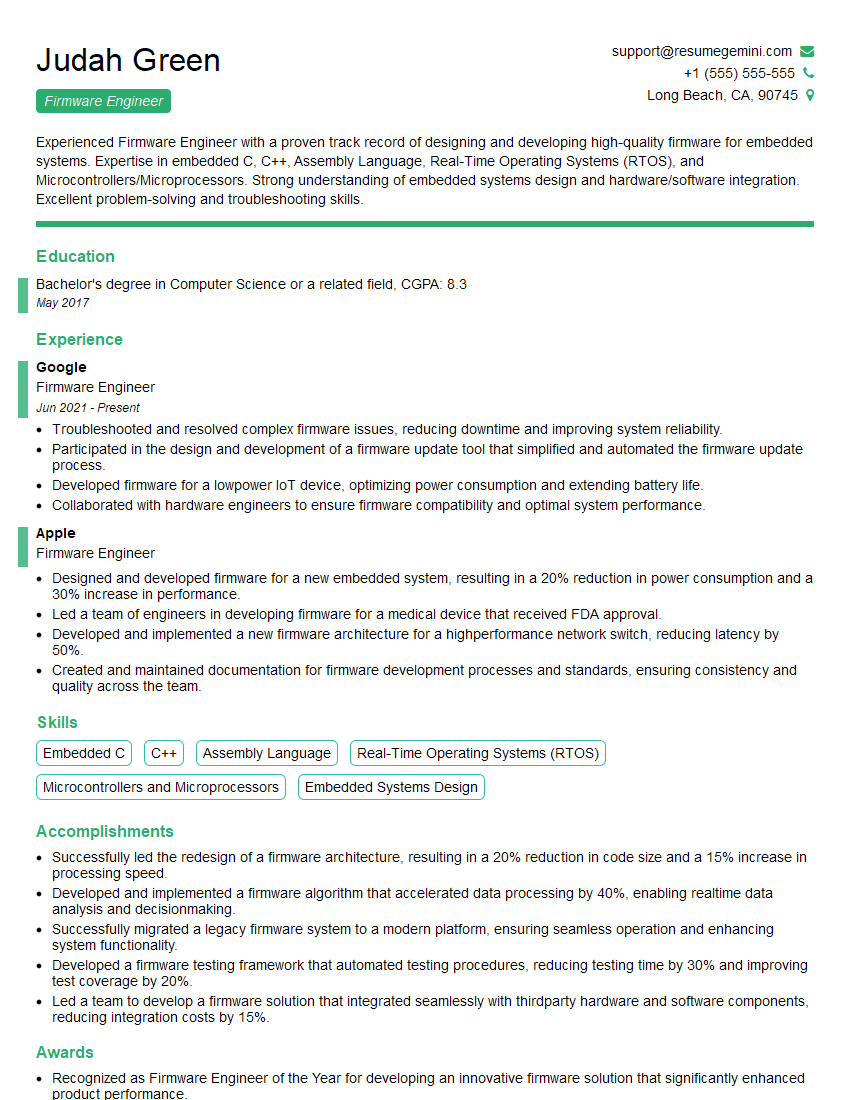

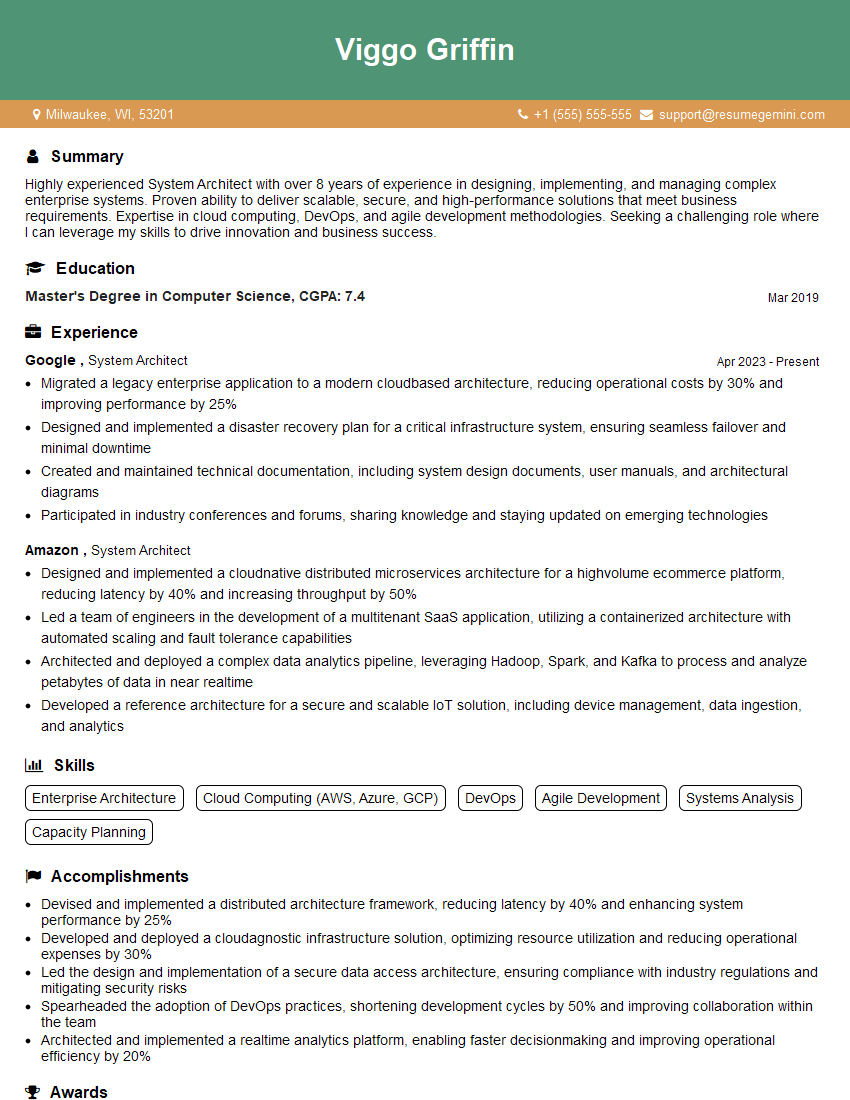

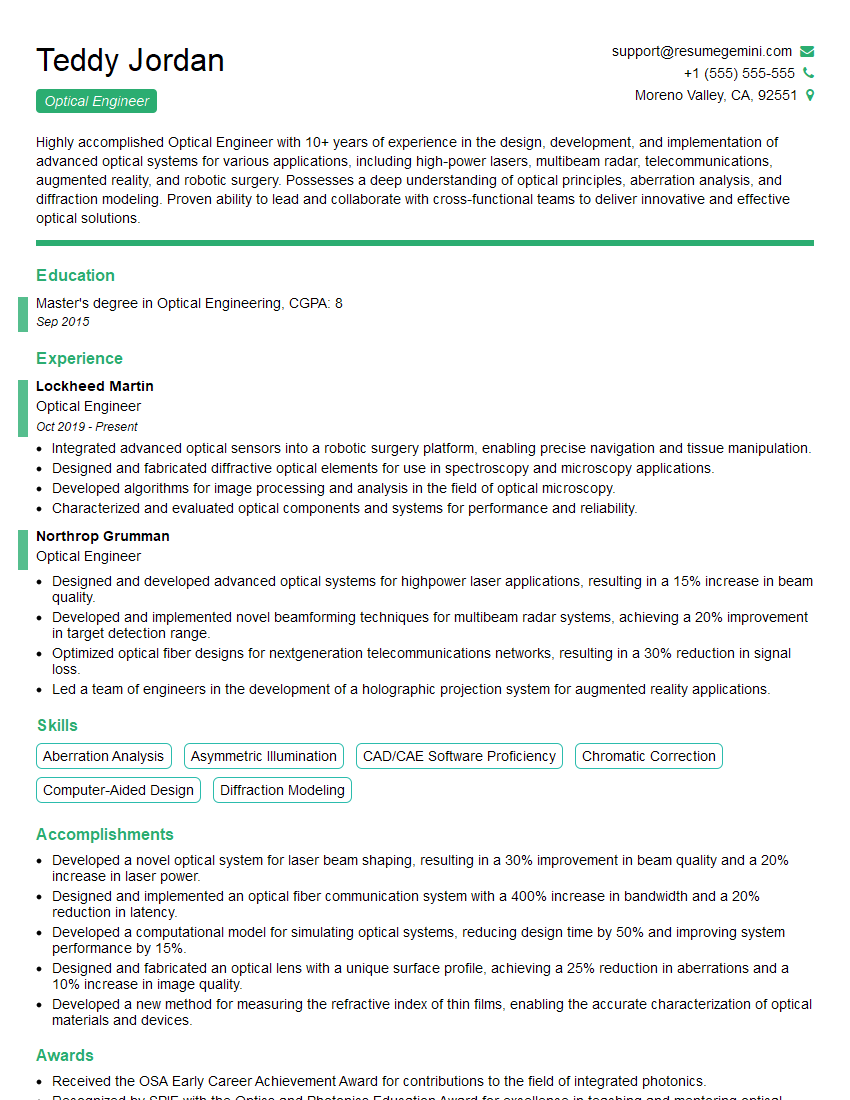

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) for sensor systems?

Key Performance Indicators (KPIs) for sensor systems are metrics used to evaluate their effectiveness and efficiency. These are crucial for both design and post-deployment analysis. Key KPIs typically include:

- Accuracy: How close the sensor’s readings are to the true value. This often includes characterizing the systematic error (bias) and random error (precision).

- Precision: The consistency or repeatability of the sensor’s measurements. A high-precision sensor will provide similar readings under identical conditions.

- Sensitivity: How much the sensor’s output changes in response to a change in the measured quantity. A highly sensitive sensor will detect even small changes.

- Resolution: The smallest measurable change that the sensor can detect. A higher resolution means more precise measurements.

- Range: The span of values that the sensor can accurately measure.

- Linearity: How well the sensor’s output is a linear function of the measured quantity. Non-linearity can complicate data interpretation.

- Response Time: The time it takes for the sensor to respond to a change in the measured quantity.

- Power Consumption: Crucial for battery-powered applications, this measures the energy used by the sensor.

- Reliability: The probability that the sensor will function correctly over its specified lifetime. This is often expressed as Mean Time Between Failures (MTBF).

- Cost: The overall cost of the sensor system, including hardware, software, and manufacturing.

For example, in a medical sensor application, accuracy and reliability are paramount, whereas in a simple environmental monitoring system, cost might be a more significant factor.

Q 17. Describe your experience with sensor data logging and analysis.

My experience with sensor data logging and analysis is extensive. I’ve worked on projects ranging from environmental monitoring using multiple sensors to advanced industrial process control applications. My typical workflow involves:

- Data Acquisition: Using appropriate hardware and software interfaces to collect sensor data at desired sampling rates. This often includes implementing data buffering and error handling.

- Data Storage: Selecting a suitable storage method, from simple SD cards to cloud-based databases, depending on the project’s requirements. Data formatting and organization are critical for efficient retrieval and analysis.

- Data Cleaning and Preprocessing: Handling missing data, outliers, and noise. This may involve applying filtering techniques (e.g., moving average, Kalman filter) and calibration algorithms.

- Data Analysis: Using statistical methods and data visualization tools (e.g., MATLAB, Python with libraries like Pandas and Scikit-learn) to identify trends, patterns, and anomalies in the sensor data.

- Report Generation: Creating clear and concise reports summarizing the analysis results and findings, often with accompanying graphs and charts.

For instance, I once worked on a project monitoring bridge structural health using strain gauges. We collected terabytes of data over several months, and rigorous data preprocessing and analysis were essential to accurately detect subtle changes indicating potential structural issues.

Q 18. How do you ensure the reliability and accuracy of sensor data?

Ensuring the reliability and accuracy of sensor data is a multi-faceted process. It begins with careful sensor selection and continues throughout the design, implementation, and deployment phases. Here’s my approach:

- Sensor Selection: Choosing the right sensor for the application, considering factors such as accuracy, precision, range, and environmental conditions. Understanding the sensor’s specifications and limitations is critical.

- Calibration: Accurately calibrating the sensor to compensate for systematic errors and biases. This usually involves comparing the sensor’s readings to known standards or reference values.

- Signal Conditioning: Implementing appropriate circuitry to filter noise, amplify weak signals, and protect the sensor from external interference.

- Data Validation: Implementing checks and algorithms to detect and flag potentially erroneous data points. This may involve using range checks, consistency checks, and statistical outlier detection.

- Redundancy: Employing multiple sensors to measure the same quantity, allowing for cross-checking and error detection. This is particularly valuable in critical applications.

- Environmental Considerations: Carefully considering the effects of temperature, humidity, pressure, and other environmental factors on sensor performance.

- Regular Maintenance: Implementing a schedule for regular sensor calibration and maintenance, including cleaning and replacing sensors as needed.

For example, in a high-precision industrial process, we might use multiple sensors with independent data acquisition systems and compare their results to ensure reliability and detect potential malfunctions.

Q 19. Explain your experience with different PCB design software and tools.

My experience with PCB design software encompasses several industry-standard tools. I’m proficient in Altium Designer, Eagle, and KiCad. My choice of software depends on project requirements and team preferences. Altium Designer is well-suited for complex projects needing advanced features such as library management, version control, and collaboration tools. Eagle offers a simpler, more streamlined interface suitable for smaller projects. KiCad, being open-source, provides a cost-effective alternative with robust capabilities. My skills extend beyond simple schematic capture and PCB layout to include:

- Component Selection and Placement: Optimizing component placement for signal integrity, thermal management, and manufacturability.

- Routing: Creating efficient and reliable signal traces, adhering to impedance matching and EMI/EMC guidelines.

- Design Rule Checking (DRC): Thoroughly verifying the design against predefined rules to prevent manufacturing errors.

- Gerber File Generation: Creating the necessary Gerber files for manufacturing the PCB.

I’m also familiar with simulation tools such as LTSpice and Altium’s built-in simulator for analyzing circuit performance before manufacturing. This helps prevent costly design iterations and improves reliability.

Q 20. Describe the process of designing and testing a sensor circuit.

Designing and testing a sensor circuit is an iterative process requiring careful planning and execution. It typically involves the following steps:

- Requirements Definition: Clearly defining the sensor’s specifications, including accuracy, precision, range, power consumption, and communication interface.

- Schematic Design: Designing the circuit schematic, including the sensor, signal conditioning circuitry (e.g., amplifiers, filters, ADCs), microcontroller, and communication interface.

- PCB Layout: Designing the PCB layout, carefully placing components and routing traces to optimize signal integrity and manufacturability.

- Simulation: Simulating the circuit using appropriate software to verify its performance before manufacturing. This helps identify potential issues early in the design process.

- Prototyping and Testing: Building a prototype PCB and testing its performance in various conditions. This often involves collecting and analyzing sensor data to evaluate its accuracy, precision, and reliability.

- Iteration and Refinement: Iteratively refining the design based on testing results. This may involve modifying the circuit schematic, PCB layout, or firmware.

- Documentation: Creating thorough documentation, including schematics, PCB layouts, bill of materials (BOM), and test reports.

For example, I recently designed a circuit for a pressure sensor used in a medical device. Rigorous testing, including temperature cycling and shock testing, was critical to ensure its reliability in a demanding environment.

Q 21. What are your preferred debugging techniques for embedded systems?

Debugging embedded systems requires a systematic and methodical approach. My preferred techniques include:

- Print Statements/Logging: Strategically placing print statements in the code to monitor variable values and program flow. This is a fundamental debugging technique.

- Logic Analyzers: Using logic analyzers to capture and analyze digital signals, which can be extremely helpful in tracking data transfers and identifying timing issues.

- Oscilloscope: Observing analog signals using an oscilloscope to check voltage levels, signal integrity and identify noise.

- Debuggers (e.g., JTAG): Employing debuggers to step through the code, inspect variables, and set breakpoints. This is essential for understanding program execution and identifying errors.

- Emulators: Using emulators to simulate the target hardware, allowing for debugging without needing the actual hardware. This is particularly helpful for complex or expensive systems.

- Software Version Control (e.g., Git): Using version control systems to track changes in the code and easily revert to previous working versions.

- Static Analysis Tools: Employing static code analysis tools to automatically detect potential errors and coding style violations.

A recent challenge involved a communication error between a sensor and microcontroller. Using a logic analyzer, I pinpointed a timing issue in the communication protocol that was causing data corruption. Through a combination of careful code review and hardware analysis, the problem was resolved quickly and efficiently.

Q 22. How familiar are you with different power management techniques for embedded systems?

Power management in embedded systems is crucial for extending battery life and optimizing performance. It involves a range of techniques targeting different aspects of energy consumption. These techniques can be broadly classified into:

- Hardware-based techniques: These involve using low-power components, such as low-power microcontrollers, efficient power converters (DC-DC converters), and power switches. For example, choosing a microcontroller with multiple power modes (active, sleep, deep sleep) allows significant power savings when the system is idle.

- Software-based techniques: These involve optimizing the software to minimize energy consumption. This includes techniques like clock gating (disabling clock signals to unused modules), power gating (completely powering down unused modules), and using low-power peripherals. For instance, I’ve implemented a system where sensor data acquisition was only triggered periodically, significantly reducing the active time of the microcontroller.

- System-level techniques: These encompass strategies that optimize the overall system architecture. This might involve employing energy harvesting techniques to supplement the battery, or implementing sophisticated power management ICs (PMICs) to handle various power rails and voltage levels efficiently. One project I worked on involved designing a system that used solar cells to recharge the battery and a PMIC to dynamically allocate power among different sensors and communication modules based on usage patterns.

The choice of technique depends on factors like the application’s power budget, the available hardware, and the performance requirements. Often, a combination of these techniques is employed for optimal results.

Q 23. Explain the concept of signal-to-noise ratio (SNR) and its significance in sensor systems.

The signal-to-noise ratio (SNR) quantifies the level of a desired signal relative to the background noise. A higher SNR indicates a clearer signal with less interference. In sensor systems, SNR is paramount because it directly impacts the accuracy and reliability of measurements. A low SNR means the sensor data is heavily contaminated by noise, leading to inaccurate readings and potentially flawed conclusions.

The SNR is typically expressed in decibels (dB) and calculated as: SNR (dB) = 10 * log10(Signal Power / Noise Power)

Imagine trying to hear a quiet conversation in a noisy room. The conversation is your signal, and the room’s noise is, well, the noise. A high SNR (like a quiet room) makes it easy to understand the conversation, while a low SNR (loud room) makes it almost impossible. Similarly, in a sensor system, high SNR is crucial for extracting meaningful data from the sensor readings. For example, in a temperature sensor, noise might come from electronic interference or fluctuations in the environment. A high SNR ensures that the temperature readings accurately reflect the actual temperature and aren’t obscured by noise.

Improving SNR in sensor systems involves techniques like signal averaging, filtering (both analog and digital), and using higher-quality sensors with lower inherent noise levels. Careful shielding to minimize electromagnetic interference is also important.

Q 24. Describe your experience with different microcontroller architectures.

My experience spans a range of microcontroller architectures, including:

- ARM Cortex-M: I’ve extensively worked with various Cortex-M series microcontrollers, such as the STM32 family from STMicroelectronics and the NXP Kinetis family. These are known for their low power consumption, extensive peripheral sets, and strong development tool support. I’ve used them in projects involving wireless sensor networks, motor control, and data acquisition systems.

- AVR: I have experience with Atmel AVR microcontrollers, particularly in smaller, simpler embedded systems where their ease of use and low cost are advantageous. These are great for projects requiring simple processing and limited resources.

- MSP430: I’ve worked with Texas Instruments’ MSP430 ultra-low power microcontrollers, focusing on applications where energy efficiency is paramount, such as long-life battery-powered devices.

My expertise includes not just using these architectures but also understanding their internal workings, including memory management, interrupt handling, and peripherals. I’m comfortable choosing the most suitable architecture for a specific application based on power requirements, processing needs, and budget constraints.

Q 25. What are your experiences with designing for low power consumption in sensor systems?

Designing for low power consumption in sensor systems is a core competency of mine. It usually involves a multi-pronged approach:

- Component Selection: Choosing low-power components, such as microcontrollers with various sleep modes, low-power sensors, and efficient power supply components, is the first step. I carefully evaluate datasheets to choose components with minimal power draw in active and sleep modes.

- Software Optimization: Implementing power-saving software techniques, such as clock gating, power gating, and optimizing code for speed and efficiency, is essential. I’ve often used techniques like putting peripherals to sleep when not actively used.

- Hardware Optimization: Designing efficient hardware architectures, such as minimizing the number of components and using power efficient circuitry, can significantly reduce power consumption. This involves understanding trade-offs between power, performance, and cost.

- Duty Cycling: Implementing duty cycling strategies where sensors and other components only operate for short periods, then enter a low-power mode, can significantly reduce power consumption without sacrificing functionality. I have designed several applications where sensors take readings only periodically, only waking up for the measurement process.

One project involved designing a wireless sensor node for environmental monitoring that needed to run on a single battery for over a year. Through a combination of these techniques, we achieved an average current consumption of less than 10µA, which easily met the longevity requirements.

Q 26. How do you choose appropriate filters for sensor signal processing?

Selecting appropriate filters for sensor signal processing is crucial for removing noise and improving the accuracy of measurements. The choice depends on the type of noise and the characteristics of the signal. The process involves:

- Analyzing the noise: First, I characterize the noise present in the sensor signal. Is it high-frequency noise, low-frequency drift, or impulsive noise? This helps to determine the appropriate filter type.

- Choosing a filter type: Different filter types are suitable for different types of noise. Common filter types include:

- Low-pass filters: Remove high-frequency noise.

- High-pass filters: Remove low-frequency noise (DC offsets, drift).

- Band-pass filters: Allow only a specific range of frequencies to pass.

- Band-stop filters (notch filters): Remove a specific frequency range.

- Implementing the filter: Filters can be implemented using analog circuits or digitally using algorithms like Finite Impulse Response (FIR) or Infinite Impulse Response (IIR) filters. Digital filters are often preferred in embedded systems because they are flexible and less susceptible to component variations.

For example, if a sensor signal is contaminated with high-frequency noise, a low-pass filter with a carefully chosen cutoff frequency can effectively remove the noise while preserving the relevant signal components. The choice between FIR and IIR filters usually involves a trade-off between computational complexity and performance.

Q 27. Describe your experience working with different sensor interfaces (e.g., I2C, SPI, UART).

I have extensive experience working with various sensor interfaces, including I2C, SPI, and UART. Each has its strengths and weaknesses:

- I2C: I’ve used I2C extensively for communication with numerous sensors and peripherals. Its simplicity, use of only two wires, and built-in error checking make it suitable for many applications. However, its lower speed compared to SPI can be a limitation in high-speed systems.

- SPI: SPI is frequently used for high-speed data transfer, particularly with devices requiring fast communication, such as flash memory and high-resolution ADCs. Its full-duplex nature allows simultaneous sending and receiving of data. However, it requires more wires than I2C.

- UART: UART is a ubiquitous interface for asynchronous serial communication. Its simplicity makes it suitable for various tasks. While slower than I2C or SPI, its simplicity and prevalence make it ideal when dealing with other systems or modules that use standard serial communication.

My experience includes designing, implementing and debugging communication protocols on these interfaces. I understand the timing considerations, error handling mechanisms, and the importance of proper termination in these communication protocols.

Q 28. How do you ensure the security of data transmitted from sensors?

Ensuring the security of data transmitted from sensors is crucial, especially in applications where data integrity and confidentiality are paramount. Security measures depend on the specific application and the level of risk, but some common strategies include:

- Data Encryption: Encrypting sensor data before transmission using encryption algorithms like AES (Advanced Encryption Standard) protects the data from unauthorized access. This requires careful selection of key management strategies.

- Authentication: Verifying the authenticity of the sensor and the receiver helps to prevent unauthorized devices from accessing or manipulating the data. This can involve using digital signatures or challenge-response protocols.

- Data Integrity Checks: Employing checksums, cyclic redundancy checks (CRCs), or other error detection mechanisms helps to detect data corruption during transmission or storage. This ensures the integrity of the received data.

- Secure Communication Protocols: Using secure communication protocols, such as TLS (Transport Layer Security) or DTLS (Datagram Transport Layer Security), provides secure communication channels for sensor data transmission.

- Firmware Security: Secure coding practices and secure boot mechanisms protect the sensor’s firmware from malicious attacks or unauthorized modification. This is particularly important to prevent compromised sensors from sending false data.

The choice of security measures depends on the sensitivity of the data and the risk profile of the deployment environment. A layered approach, using a combination of these techniques, provides robust security for sensor data transmission.

Key Topics to Learn for Sensors and Electronics Systems Interview

- Sensor Fundamentals: Understand different sensor types (e.g., capacitive, resistive, optical, piezoelectric), their operating principles, and limitations. Consider signal conditioning techniques and noise reduction strategies.

- Signal Processing: Master analog and digital signal processing techniques relevant to sensor data. Explore filtering, amplification, A/D conversion, and data acquisition methods. Practice analyzing sensor data and identifying artifacts.

- Microcontroller Systems: Gain a strong understanding of microcontroller architectures, programming (e.g., C, C++), and interfacing with sensors. Familiarize yourself with common communication protocols (e.g., I2C, SPI, UART).

- Embedded Systems Design: Learn about designing and implementing embedded systems involving sensors and actuators. This includes power management, real-time operating systems (RTOS), and debugging techniques.

- Data Acquisition and Analysis: Develop skills in collecting, processing, and interpreting large datasets from sensor networks. Understand statistical analysis methods and data visualization techniques.

- System Integration and Testing: Practice integrating various sensors and electronics components into a complete system. Master testing and validation methodologies to ensure system performance and reliability.

- Specific Sensor Applications: Explore applications relevant to your target roles, such as IoT devices, industrial automation, automotive systems, or biomedical engineering.

Next Steps

Mastering Sensors and Electronics Systems opens doors to exciting and high-demand careers in various innovative fields. A strong foundation in these areas significantly enhances your job prospects and allows you to contribute meaningfully to cutting-edge projects. To maximize your chances of landing your dream job, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of each position you apply for. Examples of resumes tailored to Sensors and Electronics Systems roles are available to guide you. Take advantage of this resource to present yourself as the ideal candidate!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good