The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Setting up Sewing Machines interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Setting up Sewing Machines Interview

Q 1. What are the key steps involved in setting up a typical industrial sewing machine?

Setting up an industrial sewing machine is a crucial step for efficient and quality production. It involves several key steps, and the specifics can vary slightly depending on the machine’s model and manufacturer, but the general process remains consistent.

- Positioning and Stability: Ensure the machine is placed on a sturdy, level surface. Vibration is the enemy of consistent stitching. I often recommend a dedicated sewing table for better ergonomics and stability.

- Power Connection: Connect the machine to a properly grounded power outlet. This is crucial for safety and to prevent electrical surges from damaging the machine.

- Bobbin Winding and Insertion: Properly wind the bobbin with the correct thread type and tension, then carefully insert it into the bobbin case. This step is often overlooked, but an improperly wound bobbin is a common source of sewing problems. The bobbin should spin freely without resistance.

- Needle Insertion and Threading: Select the appropriate needle for the fabric type and thread, carefully inserting it into the needle clamp. Next, thread the machine according to the manufacturer’s instructions. Always double-check to make sure the thread is correctly positioned through each guide.

- Tension Adjustment: The initial tension setting is critical. Begin with the manufacturer’s recommended setting and adjust as needed based on the fabric and thread. It’s important to understand that upper and lower tensions need to balance each other.

- Stitch Length and Width Adjustment: Set the stitch length and width according to the project requirements. Experimentation with these settings plays a critical role in achieving the desired stitch quality.

- Test Run: Before beginning the actual sewing, perform a test run on a scrap piece of fabric to ensure the machine is correctly threaded, tension is optimal, and stitch quality is satisfactory. Always check your stitch length, width, and consistency.

Following these steps meticulously ensures the machine runs smoothly and produces high-quality results. Remember to always consult the machine’s manual for precise instructions.

Q 2. How do you troubleshoot a sewing machine that is skipping stitches?

Skipped stitches are a common sewing machine problem, but usually easily diagnosed. It points to an imbalance in the machine’s mechanisms.

- Check the Needle: A bent, dull, or incorrectly inserted needle is the most frequent culprit. Replace the needle with a new one of the correct size and type for the fabric. I always keep a variety of needles on hand.

- Inspect the Thread: Ensure the thread is not frayed, damaged, or knotted. Use a consistent thread type and weight recommended for the fabric and needle. Knots or weak points cause inconsistent feed.

- Examine the Tension: Both upper and lower thread tension need to be balanced. Adjust the tension dials slightly, testing between adjustments until the stitches are even and consistent on both sides of the fabric. Too much tension or too little can lead to skipped stitches.

- Verify the Bobbin: A full bobbin is crucial, but also ensure the bobbin case is correctly placed and isn’t damaged. A damaged or improperly placed bobbin case creates friction that causes skips.

- Clean the Machine: Lint, dust, and debris can build up and interfere with the machine’s moving parts, causing skipped stitches. Regular cleaning with a brush is essential for maintaining the machine’s performance.

- Timing Check (Advanced): If the above steps don’t solve the problem, there may be an issue with the machine’s timing. This usually requires professional servicing, as adjusting timing mechanisms is a specialized task.

A systematic approach, starting with the simplest solutions and progressing to more complex adjustments, will help you quickly identify and resolve the cause of skipped stitches.

Q 3. Explain the process of threading a sewing machine, including different types of needles.

Threading a sewing machine might seem daunting, but it becomes second nature with practice. Different machines have slightly different threading paths, so always refer to your machine’s manual. However, the basic principles remain the same.

- Needle Types: Needles come in various types, each suited to specific fabrics. Common types include:

- Universal: A versatile choice for most fabrics.

- Ballpoint: For knits and stretchy fabrics to prevent snagging.

- Sharp: For woven fabrics like cotton and linen.

- Jeans: For heavy-duty fabrics like denim.

- Threading Process (General): The typical process involves inserting the spool of thread onto the spool pin, guiding the thread through the tension discs, then down through the take-up lever, and finally into the needle. Each machine has its specific pathway for this which is generally well illustrated in the manual.

- Bobbin Threading: This usually involves winding thread onto a bobbin, then inserting the bobbin into the bobbin case and then placing it into the machine’s bobbin area.

- Test Stitch: Once threaded, perform a test stitch to ensure proper thread flow and tension.

Remember to always use the appropriate needle for the fabric to prevent damage to both the fabric and the sewing machine.

Q 4. Describe your experience with different types of sewing machine feet and their applications.

Presser feet are essential accessories that dictate the type of stitch and the fabric’s interaction with the needle. Each foot specializes in a particular function. My experience working with various presser feet is extensive.

- General-Purpose Foot: Used for most basic sewing tasks. It’s the workhorse of the presser foot collection.

- Zipper Foot: Allows for precise stitching close to the zipper teeth. It has a groove that guides the foot along the zipper.

- Buttonhole Foot: Creates consistent buttonholes with various stitch patterns. They usually have a small guide to ensure even stitching.

- Blind Hem Foot: Used for creating almost invisible hems on clothing.

- Walking Foot: Prevents the layers of fabric from shifting during stitching, especially useful for multi-layered fabrics or thick materials. It essentially ‘walks’ both layers along at the same rate

- Quilting Foot: These come in a variety of types, but all assist with quilting tasks.

My experience with these feet spans multiple brands and models of machines. Understanding the correct foot to use significantly improves efficiency and stitch quality. It’s like having the right tool for the right job!

Q 5. How do you maintain the proper tension on a sewing machine?

Maintaining the proper tension is key to achieving professional-looking seams. It’s the balance between the upper and lower threads. An imbalance results in puckered seams, broken stitches, or uneven stitching.

- Understanding Tension Controls: Most sewing machines have dials to adjust both upper (usually on the top of the machine) and lower (in the bobbin case) tension. Upper tension controls the thread coming from the spool, while lower tension controls the thread from the bobbin.

- Adjusting Tension: Start with the manufacturer’s recommended setting. If the stitches are loose, increase the upper tension. If they’re too tight, reduce it. Conversely, adjust lower tension if you see issues stemming from the bobbin thread, adjusting the bobbin case tension dial, if available.

- Test Stitches: Always test the tension on scrap fabric before sewing on your project. Make several stitches and assess their appearance.

- Fabric Considerations: Different fabrics require different tensions. Thicker fabrics generally require higher tension than thinner ones. Experimentation is key.

- Thread Type: The type of thread influences tension. Thicker threads require more tension. Consistent thread type and weight are very important.

Achieving balanced tension takes practice and understanding of your machine and materials. It’s a skill honed over time through experience.

Q 6. What are the common causes of needle breakage and how can they be avoided?

Needle breakage is a frustrating but often preventable problem. It usually arises from a combination of factors.

- Incorrect Needle Size or Type: Using a needle that’s too small or too large for the fabric and thread is a leading cause. The needle must match the thickness of the fabric and the weight of the thread.

- Bent Needles: A bent needle is almost certain to break. Inspect your needle before each use to ensure it’s straight.

- Dull Needles: Dull needles don’t penetrate the fabric smoothly and cause extra stress, leading to breakage. Always replace dull needles.

- Incorrect Threading: Improper threading can cause the needle to bend or break. Always double-check your threading procedure.

- Hitting Pins or Obstacles: Make sure to clear your workspace of any pins, clips, or other obstructions before sewing. They are a very common cause of needle breakage.

- High-Speed Sewing: Sewing at very high speeds puts more stress on the needle, increasing the likelihood of breakage.

- Improper Tension: Extreme tension in the upper or lower thread can cause increased stress and needle breakage.

Preventing needle breakage is about meticulous attention to detail. Regular inspection and proper machine maintenance goes a long way. By using the correct needle for the job, and paying close attention to the details, most needle breakages can be avoided.

Q 7. How do you adjust the stitch length and width on various sewing machine models?

Adjusting stitch length and width varies depending on the sewing machine model, but the basic principles remain similar. Most machines have dials or buttons to control these settings. Some advanced models might even have digital displays.

- Stitch Length: This is usually controlled by a dial or a series of buttons that indicate the stitches per inch (spi). A longer stitch length is suitable for basting or seams that don’t require high durability, while shorter stitch lengths are ideal for areas needing more strength and precision.

- Stitch Width: This determines the width of the zigzag stitch or other decorative stitches. It is typically adjusted using a separate dial or button. Narrower widths are often used for straight stitching, while wider widths are used for decorative stitches or to increase the strength of a seam.

- Machine-Specific Controls: Refer to your machine’s manual for precise instructions. The location and function of these controls vary across different brands and models. Some models may have digital displays that make adjusting settings easier.

- Test Stitches: Always test the stitch length and width settings on scrap fabric before beginning your project. Adjust as needed until you achieve the desired result.

Mastering stitch length and width control is crucial for creating high-quality garments and projects. Understanding how your machine adjusts these parameters will allow you to create a wide range of projects with precision.

Q 8. What safety precautions do you take when setting up and operating industrial sewing machines?

Safety is paramount when working with industrial sewing machines. Before even touching the machine, I always ensure the power is OFF. Then, I inspect the machine for any loose parts, frayed cords, or damaged components. If anything seems amiss, I report it immediately and don’t proceed until it’s fixed. While operating, I never reach under the needle while the machine is running – that’s a major hazard! I always keep my hands and loose clothing away from moving parts. Using safety glasses is essential to protect my eyes from flying debris, and I make sure the area around the machine is clear of clutter to prevent trips and falls. Regular maintenance, including checking belts and tension, is also crucial for preventing accidents.

For example, during a recent project involving high-speed sewing, I noticed a slightly loose belt. Instead of continuing, I immediately stopped and tightened it to avoid potential slippage and machine damage which could also create a safety hazard.

Q 9. How do you identify and address issues related to bobbin winding?

Bobbin winding issues often stem from a few common problems. First, I check the bobbin itself – it needs to be correctly seated and not damaged. Then I check the tension. Incorrect tension can lead to uneven winding or the thread breaking. Sometimes, the bobbin case might be improperly installed or dirty. A quick clean of lint and debris often solves this.

For instance, I once encountered a situation where the bobbin was winding too loosely. By adjusting the tension dial on the machine—a simple clockwise turn—I immediately resolved the issue. If the problem persists, I would inspect the bobbin winder mechanism for any mechanical problems.

Q 10. Describe your experience with different types of sewing machine lubricants and their uses.

Sewing machine lubrication is critical for longevity and smooth operation. I’ve worked with several types, including general-purpose sewing machine oil, which is perfect for the majority of moving parts. This thin oil penetrates easily and reduces friction. I also use specialized greases for parts that require heavier lubrication, such as the needle bar and hook assembly. Silicone-based lubricants are useful for preventing rust and protecting against moisture. The correct lubricant depends on the machine type and specific part; always consult the machine’s manual.

In my experience, using the wrong lubricant, such as a thick grease where oil is needed, can actually gum up the machine and decrease its lifespan. Once, I mistakenly used a general-purpose grease on the delicate shuttle mechanism, resulting in sluggish movement. After carefully cleaning the parts and using the correct sewing machine oil, the problem was rectified.

Q 11. How do you clean and maintain a sewing machine to ensure optimal performance?

Cleaning and maintenance are essential. Regularly, I brush away lint and dust from all accessible areas, especially around the needle plate, feed dogs, and bobbin case. I remove the needle plate to carefully clean any accumulated lint and debris underneath. I also oil moving parts as needed, following the manufacturer’s guidelines. It’s important to use a lint-free cloth and the appropriate lubricant. For more in-depth cleaning, I might disassemble certain parts (after consulting the manual) to thoroughly clean and re-lubricate them. This keeps the machine running smoothly and extends its lifespan. A well-maintained machine is much less likely to break down unexpectedly, reducing downtime and improving production efficiency.

Q 12. What are the different types of sewing machine motors and their characteristics?

Sewing machine motors come in several types. The most common are direct-drive motors, which offer precise speed control and are quiet. Belt-driven motors are often found in older machines; they are generally more robust but can be louder. Servo motors are increasingly popular in industrial machines due to their precise control, energy efficiency, and ability to precisely adjust the needle’s speed and positioning.

I’ve worked extensively with both belt-driven and servo motors. While belt-driven motors are reliable, I find the precise control offered by servo motors, especially in computerized machines, far superior for intricate designs and high-volume production. The quiet operation of direct-drive motors is also a benefit in quieter work environments.

Q 13. Explain your experience with computerized sewing machines and their programming.

I’m proficient with computerized sewing machines, including their programming and settings. These machines allow for intricate designs, stitch patterns, and automated functions. Programming involves using the machine’s interface to set stitch parameters (length, width, density), speed, needle position, and more. Often, designs are loaded via USB or directly input into the machine’s software. Some advanced systems can even control multiple machines simultaneously.

For example, I recently programmed a computerized machine to automatically sew a complex embroidery pattern onto hundreds of garments. The programmable features eliminated the need for manual adjustments, boosting efficiency and ensuring consistency.

Q 14. How do you diagnose and repair a sewing machine that’s making unusual noises?

Unusual noises from a sewing machine are often signs of problems. A grinding noise could indicate worn bearings or gears needing lubrication. A clicking or tapping noise might point to a loose screw or a component needing tightening. A high-pitched squeal could be a belt problem. The process involves systematically identifying the source of the noise.

My approach is to first listen carefully to pinpoint the location of the noise. Then, I visually inspect the related parts. If the issue isn’t immediately apparent, I might carefully disassemble relevant sections, following the manual, to check for wear, damage, or loose parts. I then clean, lubricate, or replace parts as necessary.

For instance, I once encountered a sewing machine with a loud clicking sound. After careful inspection, I found a loose needle clamp screw. By simply tightening the screw, I eliminated the noise and restored the machine to its proper functionality.

Q 15. What is your experience with different types of sewing machine needles?

Sewing machine needles are far from a one-size-fits-all affair. The right needle is crucial for achieving a beautiful, even stitch and preventing damage to your fabric and machine. My experience encompasses a wide range, from fine needles for delicate silks and chiffons (like a size 60/8) to heavy-duty needles for denim and canvas (size 16/110 or even larger). I’m familiar with various needle types including:

- Universal needles: These are your all-purpose workhorses, suitable for a variety of fabrics.

- Ballpoint needles: Designed for knit fabrics, their rounded tip prevents snagging and skipped stitches.

- Sharp needles: Ideal for woven fabrics like cotton, linen, and silk, they pierce the fabric cleanly.

- Embroidery needles: These needles have a larger eye to accommodate thicker embroidery threads.

- Leather needles: With their strong, sharp points, these are perfect for penetrating thick leather and upholstery fabrics.

Understanding needle sizes and types is fundamental. For instance, using a sharp needle on a knit fabric will result in runs, while a ballpoint on denim will lead to weak stitches. I always carefully match the needle to the fabric type and weight to ensure optimal sewing performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting sewing machine timing issues.

Timing issues, where the needle and bobbin don’t coordinate perfectly, are among the most frustrating sewing machine problems. My troubleshooting approach is systematic. First, I visually inspect the machine’s timing mechanism, checking the hook and feed dogs for any misalignment or damage. This often involves opening the machine’s front cover (after unplugging it, of course!).

I then check the tension settings and ensure the bobbin is correctly wound and seated. Sometimes, a slightly loose screw or a bit of lint can disrupt the timing. A common problem I address is incorrect bobbin insertion – a simple error that can create major timing problems. I’ll carefully re-insert the bobbin, following the machine’s instructions precisely. If the issue persists, it might require a more in-depth adjustment which may necessitate calling in a qualified technician for more complex internal adjustments.

I’ve also encountered cases where the timing belt needs replacement – a clear indication of wear and tear. In such cases, I replace the belt following manufacturer instructions. Remember, attempting advanced internal repairs without experience can cause more damage. Accurate diagnosis is key before proceeding with any repairs.

Q 17. How do you determine the correct type of needle for different fabrics?

Selecting the correct needle for different fabrics is paramount to prevent skipped stitches, broken needles, and damaged fabric. I always consult a needle size chart provided by the sewing machine manufacturer or needle supplier. The chart usually lists fabric types alongside recommended needle sizes. However, experience plays a vital role.

For example, delicate fabrics like silk or chiffon require a fine needle (size 60/8 or smaller), while heavier fabrics like denim or canvas need a much sturdier needle (size 16/110 or larger). Knit fabrics, like jersey, require ballpoint needles to prevent snagging. The fabric weight, weave type (loose weave, tight weave) and its composition dictate the choice of needle size and type. I often test on a scrap of fabric first to avoid irreversible damage to the project.

Consider this analogy: think of trying to sew with a blunt needle on a thick canvas – frustrating and likely to break the needle. Just as you’d choose a different hammer for a small nail compared to a large bolt, the choice of needle directly influences sewing efficiency and result. Fabric type and needle compatibility is vital to a successful sewing operation.

Q 18. Explain the importance of proper lubrication for sewing machine longevity.

Regular lubrication is the unsung hero of sewing machine longevity. Without proper lubrication, the internal parts experience increased friction, leading to wear and tear, overheating, and ultimately, machine failure. It’s like oiling the hinges on a door – it keeps things running smoothly and prevents squeaking and seizing.

I use a high-quality sewing machine oil, applying a few drops to the designated lubrication points as recommended in the machine’s manual. These points usually include the bobbin hook mechanism, the shuttle race, and the feed dog area. Over-lubrication can be as detrimental as under-lubrication, leading to the accumulation of excess oil and attracting lint or dust, which can hinder the mechanism. Applying only a few drops at a time is key.

I advise customers to lubricate their machines regularly, perhaps every 6-12 months or more frequently for heavy use. Preventive maintenance through proper lubrication is far cheaper and less time consuming than replacing worn-out parts or the whole machine, thus substantially extending its lifespan.

Q 19. How do you identify and resolve problems related to fabric feed?

Fabric feed problems often manifest as uneven feeding, skipped stitches, puckering, or bunching of fabric. My approach to troubleshooting these issues is methodical. I start by checking the condition of the feed dogs, ensuring they’re clean and free from any obstructions such as lint, threads, or broken needle fragments.

Next, I inspect the presser foot pressure. If the pressure is too light, the fabric won’t feed properly; if it’s too tight, the fabric might be stretched or wrinkled. I adjust the pressure dial until the fabric moves smoothly. Sometimes, the problem is with the fabric itself. Using slippery or stretchy fabrics can also cause feed issues; in such cases, using a walking foot or a special Teflon foot can solve the problem.

Another factor is the proper alignment of the needle plate and the feed dogs. Any misalignment can create inconsistent fabric feed. I’ve had cases where the needle plate was slightly bent, requiring minor adjustment or even replacement. Persistent issues may suggest a problem with the feed dog mechanism itself, requiring professional attention.

Q 20. What are the common causes of inconsistent stitch formation?

Inconsistent stitch formation, where stitches are uneven in length or width, or where some stitches are skipped, has several common causes. First, I examine the upper and lower thread tension. Incorrect tension is a frequent culprit. Too much tension pulls the fabric, leading to puckering; too little tension can result in skipped stitches or loose stitching. I adjust both the upper and lower tension dials, testing regularly until the stitch is even and consistent.

Next, I check the needle for any damage or bending. A bent or dull needle will create uneven stitches. Replacing the needle often resolves this issue. I also verify that the correct needle type and size are being used for the chosen fabric. Incorrect needle choice is another significant source of stitching problems. Lint or debris buildup in the bobbin case or under the needle plate can also cause irregular stitches, requiring thorough cleaning. Finally, I examine the condition of the timing mechanism as explained in Question 2. Irregular stitches can also be indicative of a more serious timing issue.

Q 21. Describe your experience with different types of presser feet and their uses.

Presser feet are specialized attachments that perform a multitude of functions beyond the basic straight stitch foot. My experience includes using various presser feet including:

- Zipper foot: Allows for close-to-the-zipper sewing.

- Buttonhole foot: Guides the fabric accurately for making buttonholes.

- Walking foot: Helps feed thick or slippery fabrics evenly.

- Overlock foot: Used with an overlock stitch for clean, finished seams.

- Blind hem foot: Creates a nearly invisible hem.

- Quilting foot: Facilitates precise quilting with varying stitch densities.

- Cording foot: Creates decorative cords within seams.

Each foot has a specific function and requires proper usage. For example, a walking foot is essential for sewing multiple layers of fabric or slippery materials, while a zipper foot prevents stitches from catching on the zipper teeth. Knowing which presser foot to use enhances precision, efficiency, and the overall aesthetic quality of the project. The correct presser foot for the right job makes all the difference between a frustrating experience and a successful sewing project.

Q 22. How do you maintain and troubleshoot a sewing machine’s feed dogs?

Maintaining and troubleshooting a sewing machine’s feed dogs is crucial for consistent stitching. Feed dogs are the toothed mechanisms that move fabric under the needle. Problems with them often manifest as uneven feeding or skipped stitches.

Maintenance: Regular cleaning is key. Use a soft brush or compressed air to remove lint, dust, and thread buildup from around and between the feed dogs. A small screwdriver can help remove stubborn debris. Lubricating the feed dogs with a high-quality sewing machine oil, as per the manufacturer’s instructions, ensures smooth movement and prevents wear.

Troubleshooting: If the feed dogs are bent or damaged, they need to be replaced or carefully straightened (if possible, depending on the machine). If the feed dogs aren’t engaging properly, check the mechanism controlling their raising and lowering. This often involves adjusting a lever or screw (refer to your machine’s manual). If stitches are still uneven after cleaning and lubrication, the problem might lie with the machine’s timing or other internal components requiring professional attention.

Example: Once, I had a machine where the feed dogs were jammed with thread. After a thorough cleaning and lubrication, the machine sewed perfectly again, showcasing the impact of simple maintenance.

Q 23. What is your experience with different types of sewing machine drive mechanisms?

I have extensive experience with various sewing machine drive mechanisms, ranging from the simple hand-crank models to sophisticated computerized systems. Understanding the nuances of each mechanism is vital for effective setup, maintenance, and troubleshooting.

- Hand-crank: These are the most basic, offering direct control over the sewing speed. They’re great for fine detail work but are less efficient for large-scale production.

- Belt-driven: Common in older machines, these use a belt to transfer power from a motor to the sewing mechanism. Maintaining belt tension is important for optimal performance. A slipping belt is a common issue that needs prompt attention.

- Direct-drive: In these machines, the motor is directly connected to the sewing mechanism. This offers greater precision and speed control, reducing the wear and tear associated with belts. They are very common in modern industrial machines.

- Computerized: These use sophisticated electronics to control various sewing functions. They offer programmable stitch patterns, speed control, and often automatic needle threading. Troubleshooting these systems requires specialized knowledge of electronics.

My experience working with these different drive mechanisms has allowed me to quickly diagnose and solve problems, saving time and ensuring efficient production.

Q 24. How would you handle a situation where a sewing machine malfunctions during production?

A malfunction during production is a serious issue that requires a calm and systematic approach. My first step is to ensure the safety of everyone involved by immediately stopping the machine and assessing the situation.

- Safety First: Turn off the power and disconnect the machine to prevent further incidents.

- Identify the Problem: Carefully examine the machine to determine the nature of the malfunction. Is it a simple thread jam, a broken needle, or something more complex? Listen to any unusual sounds.

- Basic Troubleshooting: Attempt basic troubleshooting steps, like clearing a thread jam or replacing a broken needle. If these resolve the issue, restart the machine to verify.

- Escalation: If the problem persists or is beyond my basic troubleshooting skills, I would consult the machine’s manual or contact a qualified technician. In a production setting, having a backup machine or a service contract is essential to minimize downtime.

- Documentation: Document all steps taken, including the initial problem, troubleshooting steps, and the resolution. This helps identify recurring issues and prevent future malfunctions.

Example: In one instance, a machine’s motor suddenly stopped working during peak production. After initial checks, I found a blown fuse. Replacing it quickly resumed production, preventing significant delays.

Q 25. How do you prioritize repairs and maintenance tasks on multiple sewing machines?

Prioritizing repairs and maintenance on multiple sewing machines requires a well-defined strategy. I usually use a combination of factors to create a prioritization matrix:

- Urgency: Machines that are critical to ongoing production and are causing significant downtime get immediate attention. A completely non-functional machine takes precedence over one with minor issues.

- Impact: The impact of a malfunction on production volume is crucial. A machine producing a high-demand item needs quicker repair than one producing a less crucial item.

- Severity: The severity of the problem dictates the priority. A simple thread jam is less urgent than a major mechanical failure.

- Preventative Maintenance Schedule: I always adhere to a preventive maintenance schedule for each machine, performing routine cleaning and lubrication to minimize the risk of major breakdowns.

I utilize a visual aid like a whiteboard or spreadsheet to track the status of each machine, allowing me to easily identify and manage priorities.

Q 26. What safety measures do you implement to prevent workplace accidents during machine setup?

Safety is paramount when setting up sewing machines. I implement various measures to prevent accidents:

- Proper Training: All operators must receive comprehensive training on the safe operation and maintenance of sewing machines, including emergency procedures.

- Machine Guards: Ensure all safety guards, such as needle guards and presser foot guards, are properly installed and functioning correctly.

- Power Switches: Always use the power switch to turn off the machine, rather than unplugging it directly.

- Proper Lighting: Adequate lighting ensures clear visibility, preventing accidental injuries from needles or moving parts.

- Clear Work Area: Maintain a clean and organized workspace free from obstructions. Avoid clutter around the machine.

- Regular Inspections: Perform regular safety inspections of the machines, paying close attention to worn parts and potential hazards.

- Personal Protective Equipment (PPE): Operators should always wear appropriate safety gear such as safety glasses and finger guards.

Example: I always stress the importance of using the proper needle for the fabric type, as using the wrong needle can lead to breakage and potential injury.

Q 27. Describe your experience with preventative maintenance on industrial sewing machines.

Preventative maintenance is the cornerstone of keeping industrial sewing machines running smoothly. My approach is proactive and systematic:

- Regular Cleaning: Daily cleaning of lint, dust, and thread buildup from the machine’s components is essential to avoid jams and malfunctions.

- Lubrication: Regular lubrication with high-quality sewing machine oil, according to the manufacturer’s recommendations, is crucial for preventing wear and tear on moving parts.

- Timing Checks: Periodically check the machine’s timing to ensure proper synchronization of the needle and feed dogs. Improper timing can lead to skipped stitches or broken needles.

- Tension Adjustments: Regularly check and adjust thread tension to maintain consistent stitch quality.

- Needle and Bobbin Checks: Inspect needles and bobbins for damage and replace them as needed. Bent or damaged needles can cause skipped stitches or fabric damage.

- Belt Adjustments (if applicable): For belt-driven machines, maintain proper belt tension to prevent slippage and ensure efficient power transfer.

By consistently following a preventive maintenance schedule, I’ve significantly reduced breakdowns and extended the lifespan of industrial sewing machines.

Q 28. How do you stay updated on the latest technologies and advancements in sewing machine technology?

Staying updated on the latest sewing machine technologies is crucial in this ever-evolving field. I employ a multi-pronged approach:

- Industry Publications: I subscribe to industry magazines and journals that feature articles on the latest advancements in sewing machine technology.

- Trade Shows and Conferences: Attending industry trade shows and conferences allows me to see demonstrations of new machines and technologies and network with other professionals.

- Manufacturer Websites: I regularly check the websites of major sewing machine manufacturers for updates on new models and technologies.

- Online Courses and Webinars: Many online platforms offer courses and webinars on advanced sewing machine techniques and maintenance.

- Networking with Peers: Engaging with other sewing machine professionals through online forums and networking events allows me to learn about the latest trends and best practices.

This multi-faceted approach ensures I remain at the forefront of technological developments, allowing me to optimize the maintenance and utilization of sewing machines in any setting.

Key Topics to Learn for Setting Up Sewing Machines Interview

- Machine Selection & Types: Understanding different sewing machine types (mechanical, electronic, computerized), their capabilities, and suitability for various tasks. Knowing when to recommend a specific machine type based on project needs.

- Thread & Needle Selection: Matching thread and needle types to fabric weight and project requirements. Troubleshooting issues related to incorrect thread/needle combinations (e.g., skipped stitches, broken needles).

- Bobbin Winding & Insertion: Proper techniques for winding bobbins, correctly inserting them into the machine, and identifying common bobbin-related problems (e.g., tangled thread, uneven stitch length).

- Tension Adjustment: Understanding the role of upper and lower tension, diagnosing tension problems (e.g., loops on the top or bottom), and making adjustments to achieve balanced stitching.

- Stitch Selection & Adjustment: Familiarity with different stitch types and their applications. Adjusting stitch length, width, and other parameters to suit various fabrics and projects.

- Troubleshooting Common Issues: Identifying and resolving common sewing machine problems, such as skipped stitches, jammed needles, broken needles, and inconsistent stitch quality. A practical understanding of preventative maintenance is key.

- Safety Procedures: Understanding and adhering to safety protocols when operating and maintaining sewing machines, including proper handling of needles and other sharp objects.

- Setting up for Specific Projects: Demonstrating the ability to adapt the machine setup (needle, thread, stitch type, tension) to the needs of specific projects, like quilting, garment construction, or upholstery.

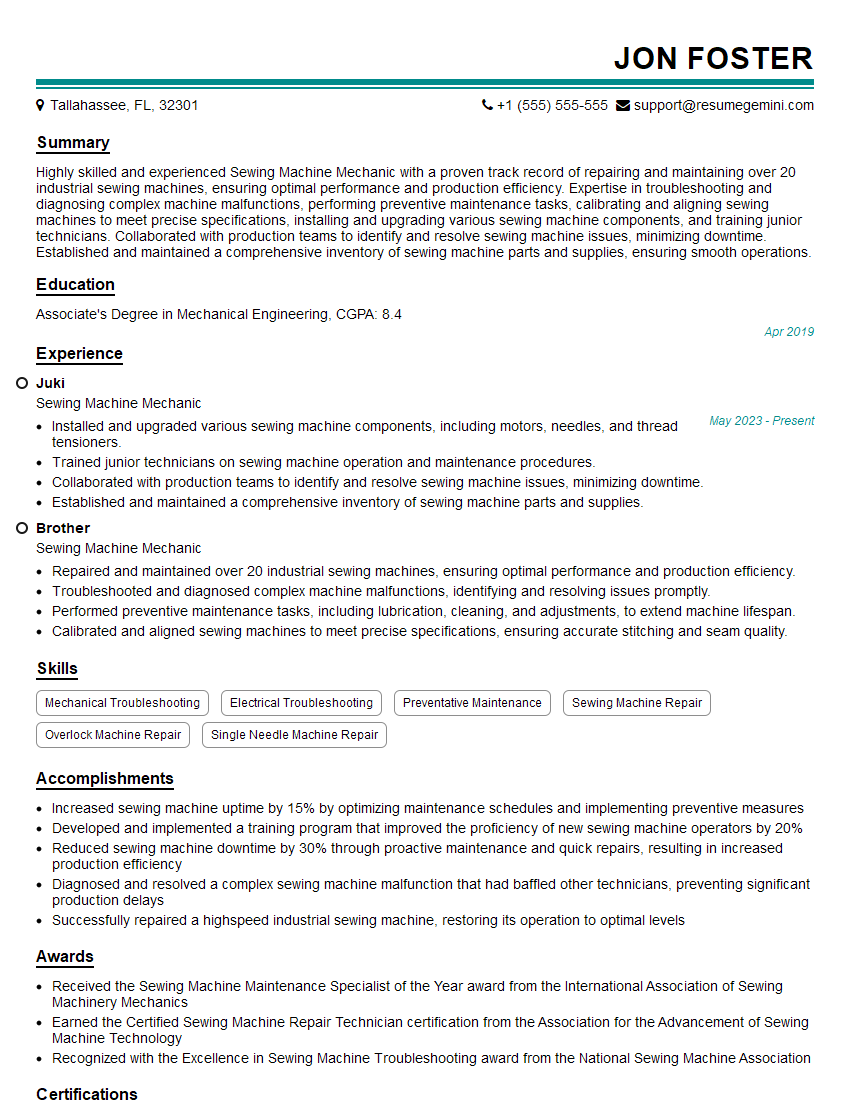

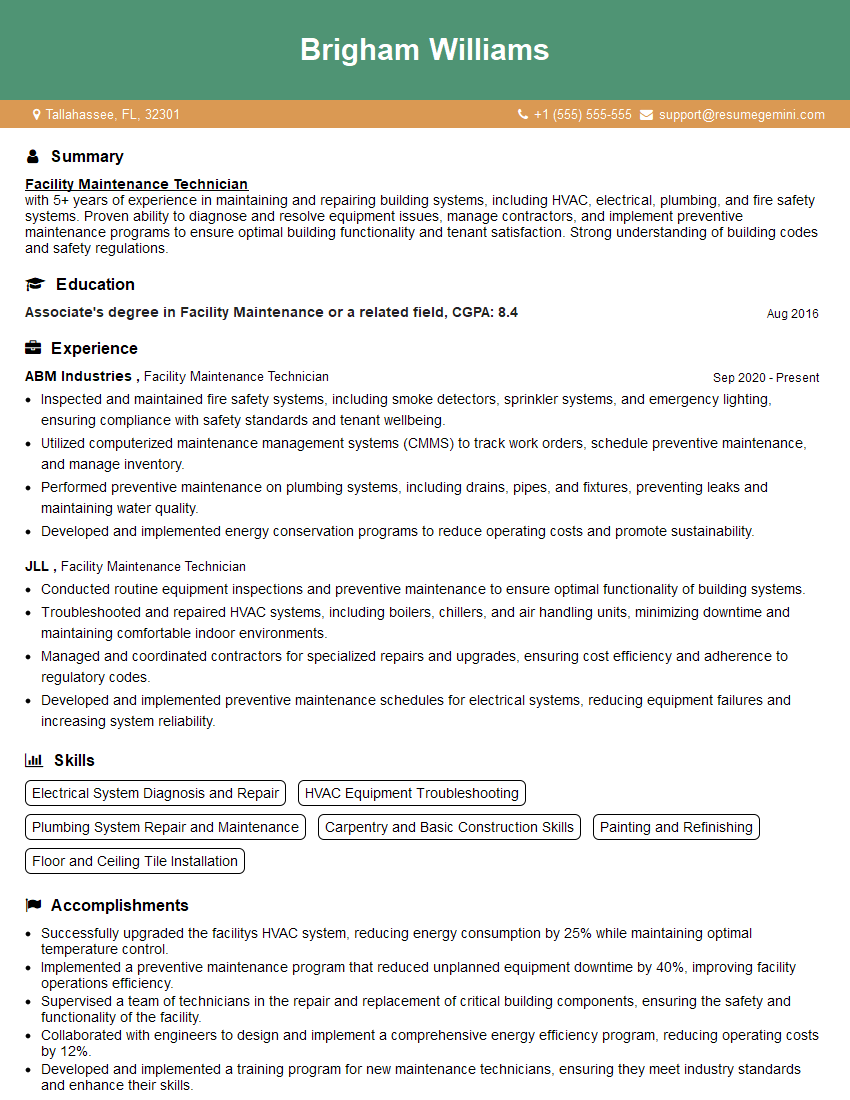

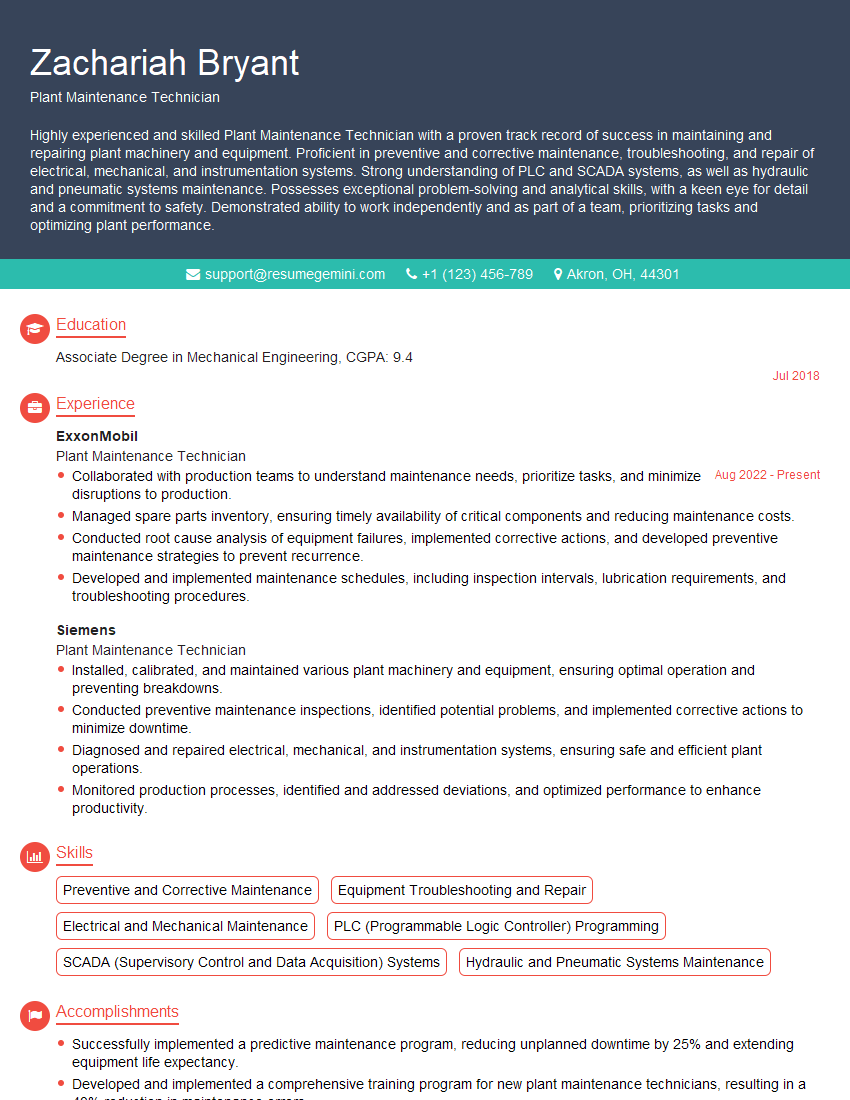

Next Steps

Mastering the setup and operation of sewing machines is crucial for success in many textile-related roles, opening doors to exciting career opportunities and advancement. To enhance your job prospects, it’s essential to create a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to Setting up Sewing Machines are available to guide you. Investing time in crafting a compelling resume will significantly increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good