Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Sheetfed Press Operations interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Sheetfed Press Operations Interview

Q 1. Explain the difference between perfecting and two-sided printing.

While both perfecting and two-sided printing result in double-sided prints, they differ significantly in their process. Perfecting refers to printing both sides of a sheet in a single pass through the press. This typically involves a perfecting unit which flips the sheet after the first side is printed. Think of it like a sheet going through a sophisticated flipping mechanism. Two-sided printing, on the other hand, might involve printing one side, stacking the sheets, and then running them through the press again for the second side. This is a simpler, less efficient approach than perfecting, often used on smaller or simpler presses. The key difference boils down to efficiency: perfecting is faster and more economical for large print runs.

Imagine printing a booklet. Perfecting would be like printing all the even pages on one pass and all the odd pages on the other, while two-sided printing would require running the sheets through twice, once for the even pages and again for the odd pages.

Q 2. Describe the process of makeready on a sheetfed press.

Makeready, the process of setting up a sheetfed press for a printing job, is crucial for quality and efficiency. It’s like preparing a complex machine for a specific task, ensuring everything is perfectly aligned and calibrated. The process typically involves several key steps:

- Plate mounting: Installing the printing plates onto the press cylinders. This requires precision to ensure proper registration (alignment of colors).

- Ink and roller setup: Adjusting the ink fountains and rollers to deliver the correct amount of ink to the plates. This involves careful consideration of ink viscosity and the desired ink density.

- Blanket washing and cleaning: Cleaning the blankets, which transfer the ink from the plates to the paper, ensuring a clean start and avoiding smudging.

- Paper feed adjustments: Configuring the paper feed system to handle the specific paper stock’s size, weight, and characteristics. This minimizes jams and ensures smooth paper flow.

- Registration adjustments: Fine-tuning the alignment of the printing units to ensure that colors and images are perfectly registered. This might involve minor adjustments to the plate cylinders.

- Impression adjustment: Setting the correct pressure between the printing cylinders and blankets to ensure a crisp, well-defined print. Too much pressure can damage the blankets or paper; too little can result in light or blurry printing.

- Test run and adjustments: Printing test sheets to check color balance, registration, and ink density, making further adjustments as needed before starting the full run.

A well-executed makeready minimizes waste, ensures consistent print quality, and speeds up the overall printing process.

Q 3. What are the common causes of paper jams in a sheetfed press?

Paper jams are a common headache in sheetfed printing. They can stem from various causes, often related to the interaction between the paper and the press’s mechanics.

- Improper paper feed: Problems with the paper feed rollers, sensors, or the paper stack itself can lead to misaligned sheets or multiple sheets feeding at once (double feeding).

- Static electricity: Static cling can cause sheets to stick together, hindering smooth movement through the press.

- Paper moisture content: Too much or too little moisture can affect the paper’s stiffness and ability to feed correctly.

- Paper defects: Damaged, torn, or wrinkled sheets are prone to jamming.

- Improper sheet size or weight setting: Incorrectly set parameters can cause misfeeds.

- Poor registration: If the sheets aren’t precisely aligned, they can snag on components.

- Dust or debris: Foreign objects can obstruct the paper path.

Regular maintenance, proper paper handling, and attention to press settings are vital in preventing jams. Addressing the root cause is key to resolving the issue permanently.

Q 4. How do you identify and resolve common printing defects like ghosting or slurring?

Identifying and resolving printing defects requires a systematic approach. Ghosting, a faint, shadowy impression of an image on the opposite side of a sheet, often results from insufficient drying time of the ink or excessive ink transfer. Slurring, blurred or fuzzy text or images, typically points to problems with ink viscosity, roller settings, or impression pressure.

Troubleshooting Steps:

- Ghosting: Check ink drying time, reduce ink density, potentially use a faster-drying ink, or increase air circulation around the sheets.

- Slurring: Adjust ink viscosity to the manufacturer’s recommendations, check roller settings for even ink distribution, and ensure proper impression pressure. Sometimes, worn rollers or blankets can contribute to slurring.

Careful observation of the print and a systematic investigation of possible causes, using the elimination method, is crucial to resolve these defects effectively.

Q 5. What are the different types of inks used in sheetfed printing?

Sheetfed printing utilizes a variety of inks, each with specific properties and applications:

- Conventional Offset Inks: Oil-based inks, known for their vibrant colors and gloss, but require longer drying times.

- UV (Ultraviolet) Curing Inks: These inks cure instantly upon exposure to UV light, allowing for immediate further processing. They offer exceptional durability and scratch resistance.

- Vegetable-Based Inks: Environmentally friendly inks derived from vegetable oils, becoming increasingly popular due to their sustainability.

- Water-Based Inks: These inks use water as the base, providing a more environmentally friendly option. They are often used in specific applications requiring quick drying.

The choice of ink depends on factors such as the application (packaging, brochures, etc.), budget constraints, environmental concerns, and the drying capabilities of the press.

Q 6. Explain the importance of maintaining proper ink viscosity.

Maintaining proper ink viscosity is critical for consistent print quality. Viscosity refers to the ink’s thickness or resistance to flow. Too thick, and the ink won’t transfer evenly, resulting in poor coverage or printing defects. Too thin, and the ink will be prone to drying out quickly or running, again leading to unsatisfactory results.

Consequences of Improper Viscosity:

- Uneven ink distribution: Causes mottled or streaky print.

- Poor print quality: Leads to dull colors, blotches, or fuzzy images.

- Drying issues: Ink can dry too quickly on the rollers or too slowly on the paper.

- Increased waste: Requires more makeready time, and potentially more sheets ruined during the print run.

Regularly checking and adjusting ink viscosity using a viscometer or by observing the ink’s flow is essential for a smooth and efficient printing process.

Q 7. How do you adjust the impression on a sheetfed press?

Impression refers to the pressure between the printing plates and the paper. Adjusting the impression on a sheetfed press is crucial to ensure optimal print quality. The goal is to achieve a balance—enough pressure for crisp, sharp images without causing damage to the paper or blankets.

Adjustment Methods: Most sheetfed presses have a mechanism for adjusting impression pressure. This often involves adjusting screws or levers that control the gap between the impression cylinder and the blanket cylinder. The specific method varies based on the press model. Fine adjustments are usually made to address specific areas of the sheet experiencing light or heavy impression.

Troubleshooting and Indicators:

- Light Impression: Faint or light images, lacking detail.

- Heavy Impression: Paper damage (indentation or crushing), ink smearing, or excessively thick ink transfer.

Adjusting the impression is an iterative process; it requires carefully observing the results of each adjustment and making fine-tuning changes until the desired outcome is achieved.

Q 8. What safety procedures are crucial when operating a sheetfed press?

Safety is paramount in sheetfed press operation. Think of it like this: we’re dealing with heavy machinery, fast-moving parts, and potentially hazardous materials. Every procedure must prioritize preventing accidents.

- Lockout/Tagout (LOTO): Before any maintenance or repair, the press must be completely shut down and locked out using LOTO procedures to prevent accidental start-up. This is non-negotiable.

- Personal Protective Equipment (PPE): Appropriate PPE, including safety glasses, hearing protection, and cut-resistant gloves, is mandatory at all times. We never compromise on this. For example, during plate changes, cut-resistant gloves protect against sharp edges.

- Paper Handling Safety: Proper lifting techniques are essential to prevent back injuries when handling large paper stacks. Furthermore, we always ensure the paper is properly aligned and fed to avoid jams, which can cause unexpected movement of press components.

- Regular Inspections: Daily inspections of the press and its components are vital to identify potential hazards before they cause an incident. Things like checking for loose parts, oil leaks, and worn belts are part of our routine.

- Emergency Procedures: Every operator must be thoroughly trained on emergency procedures, including fire safety, first aid, and the location of emergency shut-off switches. We conduct regular drills to ensure everyone is prepared.

Ignoring these procedures can lead to severe injuries or even fatalities. A culture of safety is not just a policy; it’s a mindset.

Q 9. Describe your experience with different types of sheetfed presses (e.g., Heidelberg, Komori).

My experience encompasses a wide range of sheetfed presses, primarily Heidelberg and Komori models. I’ve worked extensively on Heidelberg Speedmaster presses, from the older SM 52 to the more advanced XL series. I’m proficient in their operation, maintenance, and troubleshooting. With Komori, I’ve worked extensively with Lithrone presses, appreciating their advanced automation features and precise registration capabilities. Each manufacturer has its own nuances. For instance, Heidelberg’s control systems are known for their robust design, while Komori systems often prioritize ease of use and automation.

The differences are not just in the control systems. Heidelberg presses are often lauded for their durability and reliability, while Komori presses are sometimes preferred for their speed and efficiency, particularly in high-volume printing environments. I’ve adapted my skills readily between the two. It’s more about understanding the core principles of sheetfed printing than being tied to a specific brand.

In short, my expertise isn’t limited to one manufacturer; it’s about understanding the underlying mechanisms of sheetfed technology and applying that knowledge effectively across different platforms.

Q 10. How do you troubleshoot a problem with incorrect color registration?

Incorrect color registration is a common issue, but systematically troubleshooting it allows for efficient resolution. Imagine color registration as perfectly aligning puzzle pieces. If they are misaligned, the image is flawed.

- Identify the Problem: Is it a consistent misregistration across the sheet, or only in specific areas? Does it affect all colors, or just a few?

- Check the Paper Path: Examine the paper path for any obstructions, misaligned guides, or worn rollers. A misaligned guide is a common culprit. Small discrepancies build up.

- Inspect the Plate Cylinders: Ensure the plates are securely mounted and correctly positioned on the cylinders. Even a slight misalignment can impact registration.

- Examine the Impression Cylinders: Check for any wear, damage, or misalignment of the impression cylinders. They influence the paper’s final positioning.

- Check Gripper Bars: Verify the gripper bars are clean and properly adjusted. Gripper marks are a classic sign of issues here.

- Review the Print Specifications: Double-check the job specifications and ensure the correct settings are entered into the press controls.

- Adjustments and Testing: After addressing potential causes, conduct test prints to assess improvements. Make small, incremental adjustments, documenting each change.

Using a methodical approach ensures you don’t chase shadows and get to the root cause of registration problems quickly. This prevents waste and delays in production.

Q 11. Explain your understanding of color management in sheetfed printing.

Color management in sheetfed printing is about ensuring the colors you see on screen match the printed output. It’s a delicate dance between your design software, the press, and the printing materials.

- Color Profiles: Accurate color profiles (ICC profiles) are essential. These profiles describe how a device (monitor, printer) renders color. Mismatched or outdated profiles are a major source of color discrepancies.

- Proofing: Soft proofing on screen is a first step, but hard proofing (using a high-quality proof printer) is crucial for simulating final output. This lets you catch errors early.

- Calibration: Regular calibration of monitors, colorimeters, and spectrophotometers is necessary to maintain consistent color accuracy. Think of it like tuning a musical instrument for a perfect performance.

- Press Calibration: Press calibration involves fine-tuning the ink density, dot gain, and other factors to achieve the desired color output on the specific press and paper being used. This is where expertise and experience shine.

- Ink Management: Maintaining consistent ink viscosity and density is essential for accurate color reproduction. Regular ink changes or adjustments may be needed to ensure consistent color throughout a long print run.

Good color management eliminates guesswork, reduces waste from color mismatches, and helps in maintaining brand consistency. It’s all about precision and control.

Q 12. What is your experience with pre-press procedures and their impact on press operation?

Pre-press procedures are foundational to successful press operation. They are like laying the groundwork for a building. If the foundation is weak, the building won’t stand.

- File Preparation: Correct file setup in terms of resolution, color mode (CMYK), and bleeds is crucial. Incorrect file preparation results in delays and costly reprints.

- Imposition: The way pages are arranged on the sheet (imposition) directly impacts efficiency and waste. An experienced pre-press operator optimizes imposition to minimize waste and maximize sheet usage.

- Proofing: As mentioned before, digital and hard proofs allow for detection of errors and color inconsistencies before printing, saving both time and materials. It’s better to fix an issue on a screen than on a stack of printed sheets.

- Plate Making: High-quality plates are essential for sharp images and consistent color reproduction. Plate defects can lead to problems during printing, even if other steps were perfect.

Effective communication between pre-press and press operators is vital. Any issues spotted in pre-press should be addressed before starting the press run. My experience shows that a well-prepared job reduces downtime and ensures a smoother printing process.

Q 13. Describe your experience with different paper stocks and their characteristics.

Understanding paper stocks is crucial. Each type has its own characteristics that affect the printing process. Different papers offer different experiences.

- Coated Papers: These offer smooth surfaces, sharp details, and vibrant colors, ideal for high-quality brochures or magazines. However, they can be more expensive.

- Uncoated Papers: These have a more natural texture, providing a different feel and aesthetic, ideal for stationery or invitations. Ink absorption varies widely.

- Recycled Papers: Environmentally friendly, but they can have inconsistencies in texture and absorbency, impacting print quality. This is where expertise is crucial in setup.

- Specialty Papers: These include textured papers, metallic papers, and other options that add unique effects. Each requires specific press adjustments and considerations.

My experience allows me to quickly assess the suitability of different paper stocks for particular jobs and adjust press settings accordingly. Knowing the paper’s weight, grain direction, and absorbency is crucial for consistent, high-quality results.

Q 14. How do you manage waste and reduce spoilage during printing?

Waste management and spoilage reduction are vital for efficient printing. This impacts both profitability and environmental responsibility. It’s not just about throwing things away; it’s about mindful operations.

- Makeready Waste: Minimize makeready waste (waste from setting up the press) through careful planning and precise adjustments. Fewer test runs mean less waste.

- Optimized Imposition: Efficient imposition, as discussed earlier, directly reduces paper waste. Skilled imposition minimizes the amount of paper used.

- Careful Setup: Precise color and registration adjustments minimize waste from imperfect prints. This prevents the need to reprint full sheets.

- Regular Maintenance: A well-maintained press runs more smoothly, reducing the chance of jams and spoilage. Consistent machine upkeep prevents unexpected downtime.

- Quality Control: Strict quality control procedures ensure early identification of errors, preventing large batches of spoiled prints.

- Waste Recycling: Implement a system for recycling waste paper, ink cartridges, and other materials, minimizing environmental impact. This is responsible practice.

Continuous improvement in these areas not only improves profitability but also demonstrates environmental stewardship. It’s about optimizing every step in the process.

Q 15. Explain your process for maintaining press cleanliness and hygiene.

Maintaining a clean and hygienic press is paramount for consistent print quality and the longevity of the equipment. My process involves a multi-stage approach, beginning with daily cleaning and extending to more thorough, scheduled maintenance.

- Daily Cleaning: This includes removing debris and ink from the press components such as rollers, blankets, and impression cylinders using appropriate cleaning solutions. I pay particular attention to areas prone to ink buildup, ensuring all surfaces are free of smudges or smears.

- Weekly Maintenance: A more in-depth cleaning process that involves a more thorough examination of all components, including the feeder and delivery systems. This step often involves the use of specialized cleaning agents to remove stubborn ink and paper dust.

- Preventative Maintenance: Scheduled preventative maintenance, often conducted by specialized technicians, goes beyond cleaning. This includes lubrication of moving parts, replacing worn components, and calibration of the press to optimize performance and prevent breakdowns. We maintain detailed records for all scheduled maintenance tasks.

- Hygiene Practices: Cleanliness extends beyond just the press. This includes proper disposal of waste materials, maintaining a tidy workspace, and following strict hygiene guidelines to prevent contamination of printed materials. For instance, we always use clean gloves when handling plates and inks.

Think of it like maintaining a finely tuned engine; regular cleaning and lubrication ensures smooth and efficient operation. A neglected press will inevitably lead to malfunctions, poor print quality, and increased downtime. My experience shows that consistent attention to cleanliness translates directly into fewer problems and higher productivity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks and manage your workload during peak production periods?

Prioritizing tasks during peak production is crucial. My approach involves a combination of planning, efficient workflow management, and effective communication.

- Job Prioritization: I start by analyzing the production schedule, identifying jobs with the tightest deadlines or those requiring specialized setup. Urgency and importance dictate the order.

- Workflow Optimization: I break down complex jobs into smaller, manageable tasks. This allows for better resource allocation and clearer progress tracking. For instance, pre-flighting files and preparing plates ahead of time can significantly reduce press setup time.

- Team Communication: Open and constant communication is vital. I keep the team informed of priorities, potential bottlenecks, and any changes to the schedule. This ensures everyone works cohesively and efficiently towards shared goals.

- Efficient Resource Allocation: We make sure to have sufficient paper, inks, and other consumables readily available. This prevents downtime caused by material shortages. Also, we strategically utilize all available press time, perhaps grouping similar jobs together to minimize setup changes.

During peak periods, flexibility and adaptability are key. A well-defined plan, combined with effective team communication, allows us to navigate the pressures of high-volume production smoothly.

Q 17. How do you work with a team to ensure efficient press operations?

Efficient press operations depend heavily on teamwork. I foster a collaborative environment where each member feels valued and empowered.

- Clear Roles and Responsibilities: Defining clear roles and responsibilities prevents confusion and overlap. We have a well-defined hierarchy ensuring smooth workflow. Each person understands their contribution to the overall process.

- Open Communication: I encourage open dialogue and information sharing within the team. This includes regular team meetings to discuss progress, identify potential problems, and brainstorm solutions.

- Mutual Support and Training: We support each other, sharing expertise and offering training to enhance skills. A strong team thrives on collaboration and mutual respect. For instance, more experienced operators might train newer members on specific press functions.

- Problem-Solving as a Team: When faced with challenges, we tackle them collectively, leveraging everyone’s knowledge and experience. Brainstorming sessions can often unearth creative solutions that an individual might miss.

Building a strong team isn’t just about assigning tasks; it’s about fostering trust, respect, and open communication. A well-functioning team leads to improved productivity, higher quality output, and a more positive work environment.

Q 18. What is your experience with quality control checks and ensuring print accuracy?

Quality control is an integral part of my work. It’s not just about ensuring print accuracy; it’s about delivering a product that meets the client’s expectations and our own high standards.

- Pre-Press Checks: I thoroughly review the supplied artwork and printing specifications before initiating any printing. This often includes checking color profiles, resolution, and file integrity.

- Plate Inspection: A meticulous inspection of printing plates is crucial before mounting them on the press. This helps to identify any defects that could impact print quality.

- Press Checks (Proofing): We run test prints (proofs) before the main run to check color accuracy, registration, and overall print quality. Adjustments can be made before proceeding with the complete job.

- In-Process Monitoring: Constant monitoring throughout the printing process helps to catch any inconsistencies early. This might involve checking color density, ink distribution, and paper feed.

- Post-Press Inspection: Following the print run, I conduct a final inspection to ensure that the printed output meets the specifications, checking for any defects such as color variations, misregistration, or blemishes.

Our commitment to quality control minimizes waste, ensures client satisfaction, and enhances our reputation. It’s a continuous process—a cycle of checks and adjustments—that strives for perfection in every print.

Q 19. Describe your problem-solving approach when encountering a complex press issue.

My problem-solving approach when dealing with complex press issues is systematic and data-driven.

- Identify the Problem: First, I clearly define the problem. What exactly is going wrong? Is it a color issue, registration problem, or a mechanical malfunction? Gathering information such as error messages, visual observations, and operator feedback helps to refine this.

- Gather Data: I collect as much relevant data as possible. This might include press logs, production records, and any other pertinent information. Detailed records are vital for troubleshooting and root cause analysis.

- Analyze the Data: I analyze the collected data, looking for patterns or trends that might indicate the cause of the problem. Sometimes, simple observation is enough, other times, more complex analysis might be necessary.

- Develop and Test Solutions: Based on the analysis, I develop potential solutions and test them systematically. This might involve adjusting press settings, replacing parts, or consulting with technical support. Each test needs proper documentation.

- Implement the Solution: Once an effective solution is found, I implement it, ensuring thorough documentation of the repair process. This is crucial for future reference and helps avoid similar issues.

- Preventative Measures: Finally, I analyze what happened to prevent recurrence. This might include adjustments to press maintenance schedules, operator training, or improvements to the workflow.

A methodical approach, combined with a willingness to learn from mistakes, ensures that problems are resolved efficiently and that preventative measures are implemented to minimize future occurrences.

Q 20. How do you stay updated on the latest technologies and trends in sheetfed printing?

Staying updated on the latest technologies and trends in sheetfed printing is crucial for remaining competitive. My approach is multifaceted:

- Industry Publications and Websites: I regularly read industry publications such as magazines and online journals, keeping abreast of new developments in print technology, software, and materials.

- Trade Shows and Conferences: Attending industry trade shows and conferences provides firsthand exposure to the latest advancements and networking opportunities with other professionals.

- Manufacturer Websites and Training: Staying updated on the latest offerings and enhancements from press manufacturers is vital. I regularly check their websites and participate in their training programs.

- Online Courses and Webinars: Online courses and webinars provide in-depth training on specialized topics, keeping me current on the evolving technology landscape.

- Networking with Colleagues: Regular interaction and collaboration with other print professionals provides insights into best practices and new trends in the industry.

Continuously learning and adapting is vital for success in this dynamic field. The print industry is constantly evolving, and staying ahead of the curve is crucial for delivering high-quality results and utilizing the most efficient technologies available.

Q 21. What are your experience with different types of printing plates and their preparation?

My experience encompasses various types of printing plates, including conventional plates (such as aluminum plates), and newer technologies like computer-to-plate (CTP) systems. Plate preparation is a critical aspect of achieving high-quality prints.

- Conventional Plates: These plates typically involve a photographic process. My experience includes preparing these plates through careful exposure, processing, and proofing, ensuring accurate image reproduction.

- CTP Plates: Computer-to-plate (CTP) technology has revolutionized the process. I’m proficient in using different CTP systems, creating plates directly from digital files, eliminating the need for film. Understanding the nuances of different CTP workflows (e.g., thermal, violet, UV) is essential for optimal plate quality. This includes understanding the impact of resolution, screening, and color profiles on the final print.

- Plate Mounting: Proper plate mounting on the press is essential for accurate registration and print quality. I’m skilled in this process, ensuring the plate is securely fastened and properly aligned on the cylinder.

- Plate Cleaning and Storage: Proper cleaning and storage of printing plates is necessary to extend their lifespan and prevent degradation of image quality. I follow best practices for cleaning and storing plates, optimizing their reusability.

Choosing the right plate type depends on factors such as print volume, required image quality, and available resources. My experience allows me to select and prepare the optimal plates to meet the specific demands of any project.

Q 22. Explain the impact of different paper moisture levels on printing quality.

Paper moisture content significantly impacts print quality. Think of it like baking a cake – the right amount of moisture is crucial for a perfect result. Too much moisture, and the paper can stretch, leading to misregistration (colors not lining up properly), and potentially causing the ink to feather or bleed. Too little moisture, and the paper becomes brittle, prone to cracking, especially during folding or other finishing processes. This can result in sheets jamming in the press or tearing during post-print operations. The ideal moisture content varies depending on the paper type and the printing process, but generally, manufacturers provide guidelines for optimal performance. For example, a sheet fed offset press might require paper within a range of 5-7% moisture content for optimal printing.

In practice, I routinely monitor paper moisture levels using a calibrated moisture meter before and during long print runs. If levels are outside the acceptable range, we adjust the press settings (like impression strength) or, in more extreme cases, allow the paper to acclimatize to the pressroom environment to reach the desired moisture balance.

Q 23. How do you perform routine press maintenance to prevent breakdowns?

Routine press maintenance is essential for preventing costly breakdowns and ensuring consistent print quality. My approach involves a combination of preventative measures and regular inspections. This includes daily checks of critical components like rollers, dampening system, and ink delivery units, alongside more in-depth weekly and monthly maintenance schedules.

- Daily: Cleaning rollers, checking ink levels, inspecting the paper path for any obstructions, and verifying the functionality of all automated systems.

- Weekly: More thorough cleaning of rollers and blankets, lubricating moving parts, and checking the condition of the grippers and feed system.

- Monthly: A more comprehensive inspection of all press components, including checking the dampening system for leaks or irregularities, inspecting the vacuum system, and performing a full cleaning of the entire press.

- Quarterly/Semi-Annually: Scheduling preventative maintenance sessions with qualified technicians to perform tasks that demand specialized expertise, such as replacing worn parts or performing more intensive cleaning.

I also meticulously keep detailed maintenance logs, recording all inspections, cleaning, and repairs performed. This helps in tracking the press’s overall health, predicting potential issues, and optimizing our maintenance strategy. Think of it like regular car maintenance – small preventative actions save huge repairs later.

Q 24. Describe your experience with CIP4 (or other relevant workflow automation) systems.

I have extensive experience with CIP4 JDF (Job Definition Format) workflow automation systems. These systems streamline the entire print production process, from prepress to finishing. Using JDF, we can automate tasks like job submission, press settings adjustments, and even integrate with finishing equipment. This minimizes manual intervention, reducing errors and improving overall efficiency. For example, using JDF, information about a job’s specifications—such as paper type, ink, and finishing requirements—is digitally transmitted to the press. This allows for automated press setup, reducing setup time and minimizing the risk of human error. We use this to optimize our workflow. We are able to track jobs, costs, and material usage in real-time, which enables better resource allocation and improved project management.

In a previous role, we implemented a fully automated JDF-based workflow, resulting in a 15% reduction in makeready time and a 10% increase in overall productivity. The system provided real-time production data, allowing for proactive adjustments and optimization, leading to improved scheduling and reduced waste.

Q 25. What metrics do you use to evaluate press performance and efficiency?

Evaluating press performance and efficiency requires a multifaceted approach, utilizing key metrics. I primarily focus on:

- Makeready time: The time it takes to set up the press for a new job. Shorter makeready times indicate better efficiency.

- Press speed/Output: Measured in impressions per hour (IPH) or sheets per hour (SPH), reflecting the press’s productivity.

- Waste percentage: The ratio of wasted sheets to total printed sheets. Minimizing waste is critical for cost control.

- Uptime percentage: The percentage of time the press is actively running versus being down for maintenance or repairs. High uptime signifies reliability.

- Cost per sheet/impression: A crucial indicator of overall economic efficiency, considering ink, paper, labor, and maintenance costs.

- Quality metrics: This involves measuring aspects like color accuracy, registration, and print density, using colorimeters and densitometers.

By tracking these metrics, we identify bottlenecks, areas for improvement, and ultimately optimize the press’s overall performance and contribution to profitability.

Q 26. How do you handle difficult customers or challenging print requests?

Handling difficult customers or challenging print requests requires a combination of clear communication, problem-solving skills, and a proactive approach. I always start by actively listening to the customer’s needs and concerns, clarifying their expectations. Then, I analyze the print request, identifying potential challenges or constraints.

For example, if a customer requests a specific color that’s difficult to reproduce, I’d discuss alternatives, providing samples and explaining the limitations of achieving the exact desired shade. If the request presents technical challenges, I work with the prepress team to develop a viable solution, possibly involving adjusting the artwork or choosing a different printing method. Transparency is key; I always keep the customer informed of progress, potential issues, and any adjustments made. A proactive approach, highlighting potential issues early, often prevents costly mistakes and unhappy customers. In some cases, this might involve suggesting an alternative approach that delivers the same results more efficiently and cost-effectively. I view challenges as opportunities for collaboration and creativity.

Q 27. Describe your experience with different types of finishing processes.

My experience encompasses a wide range of finishing processes, including:

- Cutting and Trimming: Using guillotines and other cutting devices to precisely cut printed sheets to the required size and shape.

- Folding: Employing different folding techniques (e.g., letter fold, gate fold, parallel fold) to create brochures, leaflets, and other folded materials.

- Binding: Various binding methods, such as saddle-stitch, perfect binding, wire-o binding, and case binding, are used depending on the document’s size and required durability.

- Laminating: Applying a protective film to enhance the durability and water resistance of printed materials.

- Die-cutting and Embossing: Using specialized dies to create custom shapes and add textural effects to enhance the aesthetic appeal.

Understanding the nuances of each process is vital to ensure the final product meets the customer’s expectations and is of the highest quality. I’m experienced in selecting the most appropriate finishing methods for different applications, considering factors like budget, desired aesthetics, and the volume of work.

Q 28. What is your experience working with MIS (Management Information Systems) in a print shop?

Management Information Systems (MIS) are crucial for efficient print shop operations. I’ve worked extensively with various MIS software solutions, using them for:

- Job tracking and scheduling: Managing the workflow from job submission to completion, tracking progress and identifying potential delays.

- Estimating and costing: Calculating job costs accurately, including materials, labor, and machine time.

- Inventory management: Tracking paper, ink, and other consumables, optimizing stock levels and minimizing waste.

- Client relationship management (CRM): Maintaining client records, tracking orders, and managing communication.

- Financial reporting: Generating reports on profitability, costs, and productivity, providing critical data for business decision-making.

In my previous role, we implemented a new MIS system that integrated all aspects of the print shop’s operations. This resulted in improved accuracy in cost estimations, streamlined scheduling, reduced inventory costs, and provided management with more comprehensive insights into the business’s overall performance. Proficient use of an MIS is vital for effective management, increased efficiency, and profitable operation of any print shop.

Key Topics to Learn for Sheetfed Press Operations Interview

- Press Operation Fundamentals: Understanding the mechanics of sheetfed presses, including the paper path, feeder, impression cylinder, delivery system, and various control panels. This includes knowing the differences between different press types (e.g., Heidelberg, Komori).

- Color Management and Calibration: Practical application of color theory and its importance in achieving accurate color reproduction. This involves understanding color profiles, ink density, and the process of press calibration and adjustments to match proofs.

- Makeready and Setup: Detailed knowledge of the makeready process, including plate mounting, ink and water settings, and achieving register. Troubleshooting common makeready challenges is crucial.

- Quality Control and Troubleshooting: Identifying and resolving common printing defects (e.g., hickeys, slur, mottle). Implementing quality control checks throughout the printing process to ensure consistent output.

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols within a pressroom environment. This includes proper handling of chemicals and machinery.

- Press Maintenance and Cleaning: Knowledge of routine press maintenance procedures, including cleaning and lubrication, to ensure optimal performance and longevity of the equipment. Understanding preventative maintenance schedules.

- Job Ticketing and Production Scheduling: Understanding the workflow from job order to completion, including efficient job setup and tracking to meet deadlines.

- Waste Management and Sustainability: Understanding environmentally friendly printing practices and minimizing waste throughout the printing process.

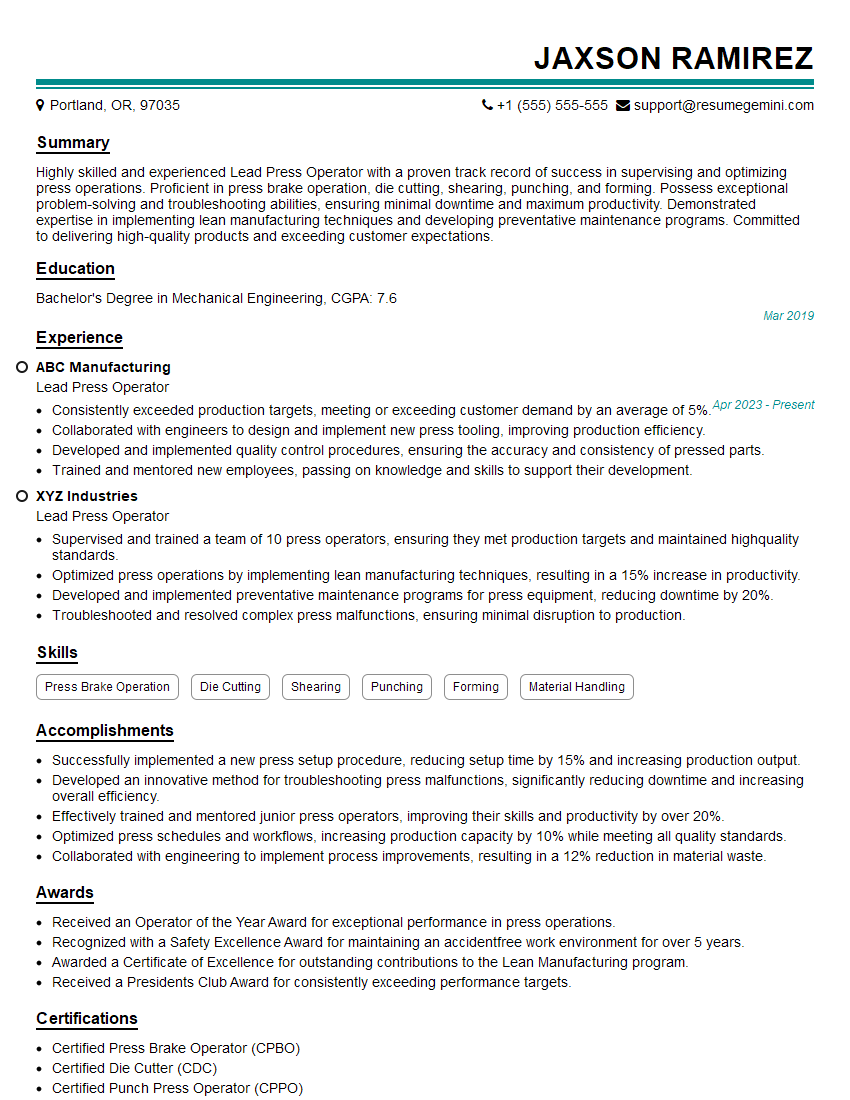

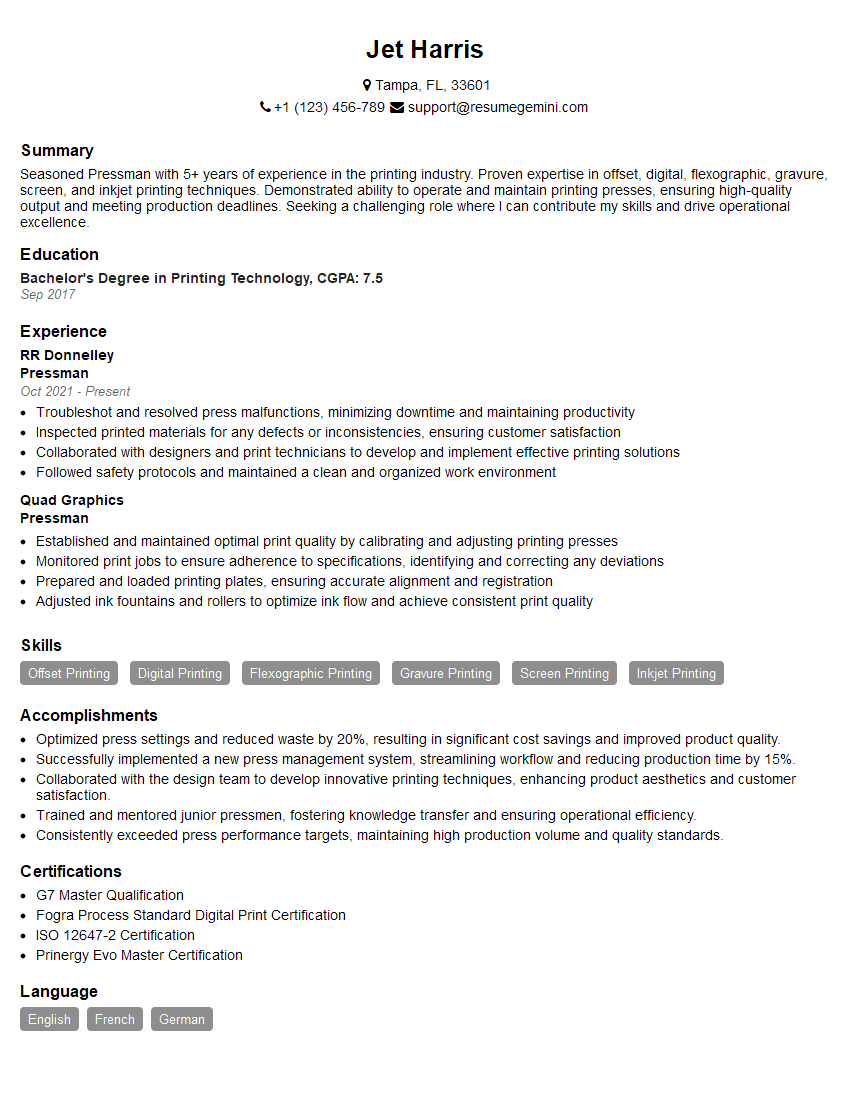

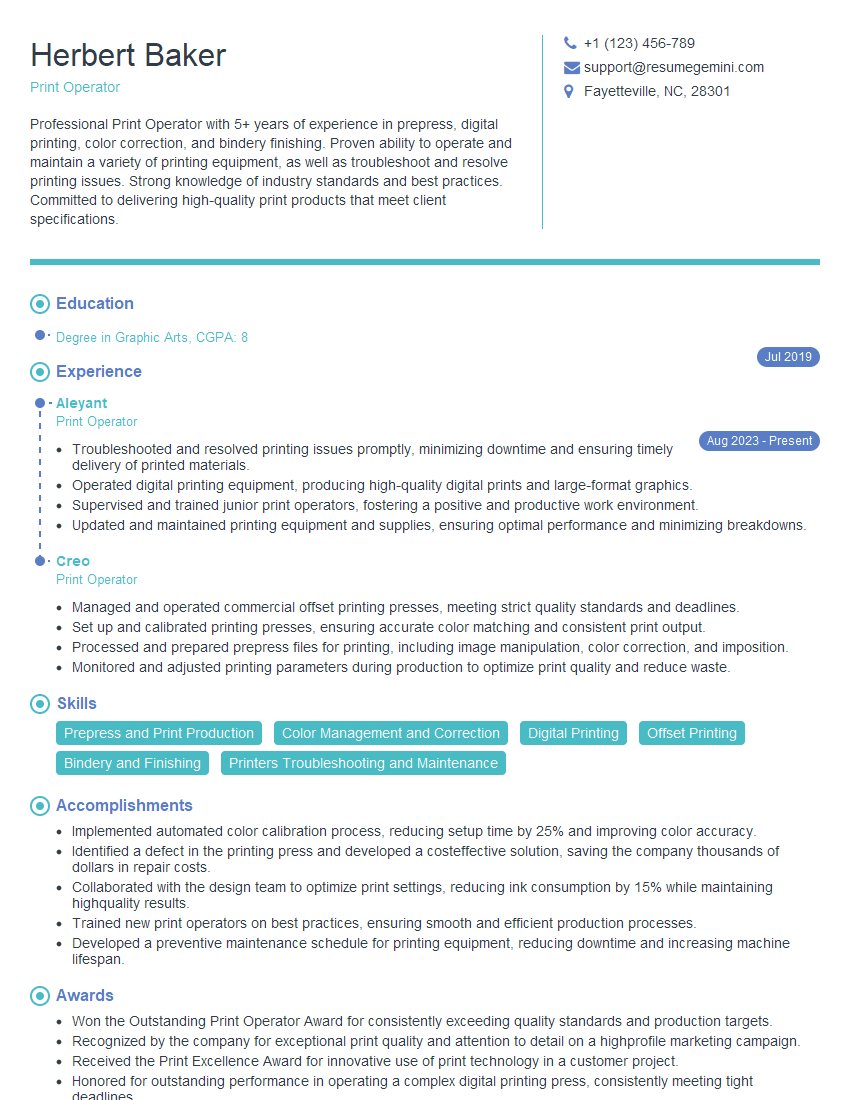

Next Steps

Mastering Sheetfed Press Operations opens doors to exciting career opportunities, from skilled press operator to lead technician and beyond. Your expertise will be highly sought after in a competitive market. To significantly boost your job prospects, it’s vital to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that catches the eye of recruiters. They provide examples of resumes tailored to Sheetfed Press Operations to help guide you in building your own compelling application. Take the next step in your career journey—build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good