The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Ship Loading Operations interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Ship Loading Operations Interview

Q 1. Describe the different types of ship loading systems.

Ship loading systems vary greatly depending on the type of cargo and the port’s infrastructure. They can be broadly categorized into:

- Gravitational Loading: This is the simplest method, relying on gravity to move cargo. Think of pouring grain from a silo directly into the ship’s hold. It’s efficient for free-flowing materials but less precise.

- Conveyor Belt Systems: These are widely used for bulk cargo like coal, ores, and grains. Conveyor belts transport cargo from storage areas to the ship’s hold, often incorporating various stages like weighing and sampling. This method offers speed and efficiency.

- Crane Systems: Cranes, including gantry cranes and shipboard cranes, are essential for loading palletized or containerized cargo. They lift and place individual units, allowing for precise placement and stacking. These systems are highly adaptable and suitable for a wide variety of cargoes.

- Pneumatic Systems: Used primarily for powders and granular materials, pneumatic systems utilize pressurized air to transfer cargo through pipes. This method is highly efficient and minimizes dust and spillage, ideal for sensitive materials.

- Specialized Systems: For liquid cargoes like oil and chemicals, specialized systems like pipelines and pumps are employed. The design is dictated by the cargo’s properties and safety requirements, often including rigorous leak prevention measures.

The choice of system depends on factors like cargo type, volume, port facilities, and cost considerations. For example, a container terminal will rely heavily on crane systems, whereas a bulk cargo terminal will likely use conveyor belts and possibly gravitational loading.

Q 2. Explain the process of cargo planning and stowage.

Cargo planning and stowage are critical for safe and efficient loading. It’s a multi-step process aiming to optimize space utilization, maintain vessel stability, and ensure cargo protection. The process involves:

- Cargo Manifest Review: The initial step is meticulously reviewing the cargo manifest, which details each cargo item’s dimensions, weight, type, and handling requirements.

- Stowage Plan Development: A stowage plan, typically created using specialized software, is developed to determine the optimal placement of each cargo item in the ship’s holds. This plan considers factors like weight distribution, stability, cargo segregation (for incompatible items), and accessibility.

- Weight Distribution: Proper weight distribution is crucial for maintaining the vessel’s stability. Heavier cargo is generally placed lower in the holds and closer to the ship’s center of gravity. This minimizes the risk of instability and prevents excessive stress on the ship’s structure.

- Securing Cargo: Once cargo is positioned, it must be adequately secured to prevent shifting during transit. Lashing, dunnage (protective materials), and other securing methods are employed according to the cargo type and voyage conditions.

- Documentation: All aspects of the cargo plan and loading process must be meticulously documented, including the location of each cargo item, securing methods employed, and any exceptions to standard procedures.

Imagine loading a container ship. The stowage plan carefully considers the weight of each container and its location to ensure the ship remains balanced. Heavier containers will be positioned lower, and dangerous goods will be segregated according to regulations.

Q 3. How do you ensure the stability of a vessel during loading?

Ensuring vessel stability during loading is paramount. It’s achieved through careful monitoring and management of several key factors:

- Real-time Weight Monitoring: Sophisticated systems track the weight of cargo being loaded and its location within the vessel. This data feeds into stability calculations.

- Center of Gravity Calculation: The vessel’s center of gravity constantly shifts as cargo is loaded. The loading plan and real-time monitoring ensure this center remains within safe limits. Shifting the center of gravity too high can make the vessel prone to capsizing.

- Trim and List Monitoring: Trim refers to the difference in draft (the depth of the vessel in the water) between the bow and stern, while list is the lateral tilt. Both are closely monitored to identify and correct any imbalances.

- Stability Calculations: Software programs perform complex stability calculations based on the vessel’s characteristics, the cargo’s weight and position, and environmental factors (like waves and wind). This helps predict potential instability and adjust the loading plan accordingly.

- Ballast Water Management: Ballast water is used to maintain stability in empty or partially loaded vessels. Its careful management during loading and unloading is crucial for maintaining optimal stability and preventing excessive stress on the hull.

Think of it like balancing a seesaw. Adding weight to one side requires adjustments to the other side to maintain balance. Similarly, loading a ship requires constant monitoring and adjustments to keep the center of gravity within acceptable limits.

Q 4. What safety procedures are crucial during ship loading operations?

Safety is paramount in ship loading operations. Crucial procedures include:

- Risk Assessment: A thorough risk assessment identifies potential hazards specific to the cargo, vessel, and port environment. This assessment informs the development of specific safety measures.

- Personal Protective Equipment (PPE): All personnel involved must wear appropriate PPE, including hard hats, safety footwear, high-visibility clothing, and safety harnesses where necessary.

- Communication Protocols: Clear communication channels must be established and maintained throughout the loading process. This involves using standardized hand signals, radios, and other communication systems.

- Emergency Procedures: Emergency plans should be well-defined and regularly practiced. This includes procedures for fire, medical emergencies, and cargo spills.

- Safe Loading Practices: Procedures should be in place to prevent falls, crushing injuries, and other accidents related to handling equipment, cargo, and other aspects of the loading process.

- Supervision and Training: Experienced personnel should supervise all loading operations, and all workers must receive adequate training on safe working practices and emergency procedures.

- Permit-to-Work Systems: A permit-to-work system ensures that appropriate safety checks are completed before commencement of high-risk operations.

For example, loading heavy cargo requires clear communication between crane operators and stevedores to avoid accidents. Regular safety drills ensure everyone is prepared to react effectively in an emergency.

Q 5. What are the common challenges in ship loading and how are they addressed?

Common challenges in ship loading include:

- Time Constraints: Port congestion and tight schedules can put pressure on loading operations, potentially compromising safety.

- Weather Conditions: Adverse weather can disrupt loading operations, delaying schedules and increasing risks.

- Cargo Damage: Improper handling or inadequate securing can lead to cargo damage during transit.

- Equipment Malfunctions: Crane failures, conveyor belt breakdowns, or other equipment malfunctions can delay operations.

- Insufficient Resources: Lack of adequate equipment, personnel, or storage space can hinder efficient loading.

- Communication Barriers: Language barriers or poor communication can lead to misunderstandings and accidents.

Addressing these challenges involves detailed planning, robust risk management, contingency planning, and investment in reliable equipment and well-trained personnel. For example, using weather forecasting to plan loading operations around periods of good weather and having backup equipment minimize delays.

Q 6. How do you manage the risks associated with hazardous cargo loading?

Managing risks associated with hazardous cargo loading requires stringent procedures and specialized expertise:

- Strict Segregation: Incompatible hazardous materials must be segregated to prevent reactions or cross-contamination. This often requires careful planning of stowage locations.

- Specialized Handling Equipment: Specific equipment may be required to handle hazardous cargo safely, such as explosion-proof equipment or specialized containers.

- Safety Data Sheets (SDS): SDS must be readily available for all hazardous materials, providing information on handling, storage, and emergency procedures.

- Emergency Response Plan: A detailed emergency response plan must be in place for handling potential spills, leaks, or other incidents involving hazardous cargo.

- Training and Certification: Personnel handling hazardous materials must be adequately trained and certified in their handling, storage, and emergency response procedures.

- Regulatory Compliance: All operations must comply with relevant international and national regulations for the transport of hazardous goods, such as the International Maritime Dangerous Goods (IMDG) Code.

Imagine loading a shipment of flammable chemicals. The entire process needs to be carefully controlled, with specialized equipment and highly trained personnel involved. Each step must strictly adhere to regulations to prevent accidents.

Q 7. Explain the importance of accurate cargo documentation.

Accurate cargo documentation is crucial for several reasons:

- Liability and Insurance: Accurate documentation establishes clear responsibility for cargo during transit, aiding in insurance claims in case of damage or loss.

- Customs and Regulatory Compliance: Accurate documentation is essential for complying with customs regulations and other legal requirements in different jurisdictions.

- Inventory Management: Accurate documentation is critical for tracking cargo throughout its journey, from origin to destination.

- Tracking and Tracing: In case of loss or damage, precise documentation helps in tracking and tracing the cargo, leading to efficient investigations and resolution.

- Safety and Security: Accurate documentation of hazardous materials helps in ensuring their safe handling and transport.

- Financial Settlements: Accurate documentation facilitates efficient financial settlements between the various parties involved in shipping, including shippers, carriers, and receivers.

In essence, accurate documentation is the backbone of the entire shipping process, ensuring everything is correctly accounted for, and disputes can be easily resolved. Think of it as a detailed itinerary for the cargo, guaranteeing its safe and efficient passage.

Q 8. Describe your experience with different types of cargo.

My experience encompasses a wide range of cargo types, from bulk commodities like grain and ore to breakbulk cargo such as steel coils and project cargo including oversized machinery. Each cargo presents unique challenges. For instance, grain requires careful monitoring of moisture content to prevent spoilage and efficient trimming to avoid shifting during transit. Handling steel coils necessitates secure lashing to prevent damage and ensuring proper ventilation to avoid condensation. Project cargo often demands specialized lifting equipment and meticulous planning to account for weight, dimensions, and delicate components. I’ve developed expertise in handling the specific requirements of each, including appropriate stowage plans, securing methods, and documentation to ensure safety and efficient loading.

- Bulk Cargo: Successfully managed the loading of over 50,000 metric tons of iron ore, optimizing the loading rate and minimizing trim variations.

- Breakbulk Cargo: Successfully loaded and secured a shipment of oversized wind turbine blades, requiring careful planning and collaboration with specialized handling equipment operators.

- Containerized Cargo: Supervised the loading of over 1000 TEUs (twenty-foot equivalent units), ensuring efficient space utilization and compliance with weight distribution regulations.

Q 9. How do you handle delays or disruptions during the loading process?

Delays and disruptions are inevitable in ship loading. My approach prioritizes proactive risk management and flexible problem-solving. For example, if a crane malfunctions, I immediately initiate a contingency plan which might involve utilizing a backup crane or re-sequencing loading operations to minimize downtime. We utilize real-time tracking systems to monitor cargo arrival and identify potential holdups. If customs clearance is delayed, I immediately liaise with relevant authorities to expedite the process. Effective communication with all stakeholders – including the vessel’s crew, stevedores, terminal operators, and cargo owners – is crucial in these situations. Documentation of all delays, along with mitigation strategies employed, is essential for post-incident analysis and future process improvement.

For instance, during one operation, a sudden storm threatened to delay the loading schedule. By swiftly coordinating with the meteorological department and the ship’s captain, we adjusted the loading plan, prioritizing critical cargo to minimize the impact of the weather. Post-event analysis helped us refine our weather contingency plan.

Q 10. What are the key performance indicators (KPIs) for ship loading operations?

Key Performance Indicators (KPIs) for ship loading operations are critical for measuring efficiency and effectiveness. These KPIs can be categorized into several key areas:

- Time-Based KPIs: Loading rate (tons/hour), loading time (total time taken), turnaround time (total time in port).

- Cost-Based KPIs: Cost per ton loaded, total loading costs.

- Safety KPIs: Number of accidents, near misses, lost-time injuries.

- Efficiency KPIs: Cargo damage rate, space utilization rate, vessel ballasting efficiency.

- Compliance KPIs: Number of regulatory non-conformances.

Tracking these KPIs allows us to identify areas for improvement, such as optimizing loading procedures, enhancing equipment maintenance, or improving crew training.

Q 11. How do you ensure compliance with international maritime regulations?

Compliance with international maritime regulations is paramount. I ensure adherence to SOLAS (Safety of Life at Sea), MARPOL (International Convention for the Prevention of Pollution from Ships), and other relevant conventions. This involves thorough knowledge of the specific regulations applicable to the type of cargo, vessel, and port. We maintain comprehensive documentation, including cargo manifests, stowage plans, and safety procedures. Regular training programs for the team ensure everyone understands their responsibilities concerning compliance. Pre-loading inspections verify the cargo’s condition and compliance with relevant safety standards. Post-loading checks confirm that all necessary documents are properly completed and that the vessel is seaworthy. We also actively monitor updates and revisions to international regulations to stay ahead of any changes.

For example, we meticulously follow MARPOL Annex V guidelines for waste management, ensuring proper disposal of garbage and other waste to protect the marine environment.

Q 12. Explain your experience with using loading and unloading equipment.

My experience includes extensive use of various loading and unloading equipment, such as cranes (both shipboard and shore-based), gantry cranes, forklifts, conveyors, and specialized lifting gear. I’m proficient in operating and supervising these machines, ensuring safe and efficient operations. Understanding the limitations and capabilities of each piece of equipment is critical for planning and execution. This includes regular maintenance schedules, operator training, and risk assessments to prevent accidents and equipment malfunctions. For instance, I’m familiar with the different types of crane hooks and slings and their appropriate use for different cargo types. I also understand the importance of load charts and weight limitations for ensuring safety.

In one instance, a critical piece of project cargo required the use of a specialized heavy-lift crane. By working closely with the crane operator and the engineering team, we successfully loaded the item without any incidents.

Q 13. Describe your experience with different types of ships and their loading requirements.

My experience includes working with various ship types, including bulk carriers, container vessels, general cargo ships, and tankers. Each type has its own unique loading requirements. Bulk carriers require careful planning of cargo distribution to maintain stability and prevent shifting during transit. Container vessels necessitate efficient space utilization and adherence to weight restrictions for each bay. General cargo ships demand flexible stowage plans to accommodate diverse cargo types, including proper segregation of incompatible goods. Tankers necessitate rigorous procedures to ensure safe handling of liquids, including gas freeing and inerting when necessary. I have developed expertise in understanding the specific design features, stability characteristics, and loading limitations of each vessel type, ensuring safe and efficient loading operations.

For example, loading a tanker requires a thorough understanding of the cargo’s properties, such as its density, viscosity, and flammability, to ensure safe and efficient transfer.

Q 14. How do you manage communication between the ship’s crew and the shore team?

Effective communication between the ship’s crew and the shore team is paramount. I use a multi-pronged approach to ensure seamless information exchange. This involves regular pre-loading meetings to discuss the loading plan, safety procedures, and potential challenges. During loading, we use a combination of communication channels, including VHF radio, dedicated loading control systems, and digital communication platforms to relay information in real-time. Clear, concise communication is emphasized to avoid misunderstandings. We maintain a logbook documenting all communications, decisions, and events that occur throughout the loading process. A designated communication officer ensures smooth coordination between the shore and ship crews. Regular feedback sessions with all stakeholders are also conducted for continuous improvement.

In one instance, using a dedicated digital platform proved crucial in resolving a last-minute change in the cargo manifest. The instant update allowed for swift adjustments on the vessel and prevented significant delays.

Q 15. How do you resolve conflicts between different stakeholders involved in ship loading?

Resolving conflicts during ship loading requires a proactive, collaborative approach centered on clear communication and established protocols. Stakeholders often include shippers, receivers, port authorities, stevedores, and the vessel’s crew. Conflicts can arise from scheduling discrepancies, cargo damage claims, or differing interpretations of contractual obligations. My approach involves:

- Facilitated meetings: Bringing all parties together to openly discuss concerns, fostering mutual understanding.

- Prioritized issue identification: Defining the root cause of the conflict, separating emotional aspects from factual ones.

- Neutral mediation: Offering an objective perspective and guiding parties toward mutually agreeable solutions. This often involves reviewing contracts, relevant regulations, and industry best practices.

- Documentation: Meticulously recording all discussions, agreements, and actions taken. This safeguards against future misunderstandings.

- Escalation procedures: Establishing a clear pathway for escalating unresolved issues to higher management if necessary.

For example, I once mediated a dispute between a shipper and the port authority concerning late arrival of cargo. By reviewing the port’s scheduling system and the shipper’s delivery schedule alongside the relevant contract clauses, we identified a miscommunication about required documentation, which we then resolved through immediate corrective action and clear procedural updates.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of pre-loading inspections.

Pre-loading inspections are crucial for ensuring the safe and efficient loading of cargo. They help prevent delays, damage, and potential safety hazards. These inspections cover various aspects, including:

- Cargo condition: Assessing the packaging integrity, ensuring no damage or spoilage, and verifying quantity against shipping documents.

- Stowage plan review: Checking the feasibility and safety of the planned cargo arrangement considering weight distribution, stability, and center of gravity.

- Hold cleanliness and structural integrity: Inspecting the ship’s cargo holds for cleanliness, structural soundness, and the presence of any potential hazards.

- Equipment functionality: Checking the functionality of loading and securing equipment, like cranes, forklifts, and lashing gear.

A thorough pre-loading inspection can prevent costly delays such as a discovered structural damage to the hold necessitating repairs or identifying damaged goods that will need replacement, ultimately impacting the vessel’s schedule and operational costs. Imagine discovering a damaged container during the loading process; this pre-inspection will prevent the risk of the collapse of the entire stack.

Q 17. What are the best practices for securing cargo during transit?

Securing cargo during transit is paramount to prevent shifting, damage, and potential safety incidents. Best practices encompass:

- Proper stowage planning: Utilizing specialized software to create a detailed stowage plan that considers weight distribution, cargo type, and stability.

- Effective lashing: Employing appropriate lashing materials and techniques to secure cargo against movement. This includes using high-tensile steel wire ropes, chains, and lashing bars.

- Dunnage use: Utilizing dunnage (wood, plywood, etc.) to fill voids, prevent shifting, and protect cargo from damage.

- Blocking and bracing: Preventing movement by placing blocks and braces to secure cargo against shifting.

- Regular inspections during transit: Carrying out routine checks to ensure lashings remain secure and the cargo hasn’t shifted.

For example, securing heavy machinery requires careful planning and the use of robust lashing systems and multiple securing points. Failure to properly secure such cargo could lead to significant damage to the vessel and the cargo itself.

Q 18. Describe your experience with inventory management during ship loading.

Inventory management during ship loading is critical to ensure that all cargo is accounted for, loaded correctly, and corresponds to the shipping documentation. My experience involves:

- Real-time tracking: Utilizing barcode or RFID scanning systems to track cargo as it moves from the warehouse or storage area to the ship.

- Cross-referencing documents: Continuously verifying the physical cargo against packing lists, commercial invoices, and bills of lading. Ensuring everything aligns perfectly.

- Discrepancy reporting: Documenting any discrepancies in quantities, conditions, or packaging immediately, and escalating as needed.

- Inventory reconciliation: Performing a final reconciliation check against documentation once the loading is complete.

During one project involving a large shipment of perishable goods, we implemented a real-time inventory system. This system tracked the temperature and location of each pallet throughout the loading process, minimizing the chance of spoilage and ensuring swift response to any issues discovered.

Q 19. How do you maintain accurate records and reports of loading activities?

Maintaining accurate records and reports is vital for accountability, compliance, and efficient operations. My approach involves:

- Digital record-keeping: Utilizing specialized ship loading management software to record all relevant data, including cargo details, stowage plans, loading times, and personnel involved.

- Automated reporting: Generating automated reports detailing loading progress, discrepancies, and completed tasks. This allows for real-time monitoring and quicker issue resolution.

- Data backup and security: Implementing robust data backup and security measures to prevent data loss or unauthorized access.

- Compliance adherence: Ensuring that all records adhere to relevant international regulations and standards (e.g., SOLAS).

Using this system, we can instantly generate reports on loading times for various types of cargo, which helps us identify areas for improvement and optimize future operations. These reports are crucial for demonstrating compliance to relevant regulatory bodies.

Q 20. What is your experience with different loading techniques (e.g., grab, conveyor belt)?

I’m experienced with various loading techniques, including grab loading, conveyor belt loading, and conventional crane operations. Each has its strengths and weaknesses, making the choice dependent on the cargo type, vessel design, and port infrastructure.

- Grab loading: Efficient for bulk cargoes (e.g., grains, ores), using a crane-mounted grab to scoop and transfer cargo. Requires suitable infrastructure and is susceptible to cargo damage if not handled carefully. I’ve supervised operations using grabs in many bulk commodity loading projects.

- Conveyor belt loading: Ideal for high-volume, continuous loading of bulk or packaged goods. Requires specialized equipment and is most effective with level access and direct transfer from storage to ship. Efficient, and minimizes manual handling.

- Crane operations: Versatile for handling various cargo types and sizes, using cranes to lift and move cargo. Requires skilled crane operators and careful planning to prevent accidents.

Choosing the right technique is a critical aspect of efficient and safe ship loading. It involves a thorough assessment of the cargo, the vessel, and available resources.

Q 21. Explain how you ensure the efficient use of resources during ship loading.

Efficient resource utilization during ship loading is key to minimizing costs and maximizing productivity. This involves:

- Optimized scheduling: Creating realistic schedules that account for potential delays and uncertainties. Effective communication with all stakeholders is paramount.

- Proper equipment utilization: Maintaining and servicing loading equipment regularly to minimize downtime. Using the correct equipment for the task reduces labor costs.

- Skilled workforce: Employing well-trained and experienced personnel to operate equipment safely and efficiently. This will minimize errors and delays.

- Waste reduction: Implementing measures to minimize cargo damage and waste. Effective planning, and efficient use of dunnage are critical.

- Continuous improvement: Regularly analyzing loading operations to identify areas for improvement in resource allocation and overall efficiency. Data-driven decision making is essential.

By implementing these strategies, I’ve consistently reduced loading times, minimized costs, and improved overall efficiency across several projects. For example, through careful scheduling and optimized crane operations, we reduced loading time for a project by 15%, saving both time and money.

Q 22. Describe your experience with using loading software or systems.

Throughout my career, I’ve extensively used various loading software and systems, ranging from simple spreadsheet-based programs to sophisticated, integrated systems like CargoSmart and Macgregor’s loading calculators. My experience encompasses data input, stowage planning, ballast calculations, and report generation. For instance, in a recent project involving the loading of a bulk carrier with iron ore, I utilized CargoSmart to optimize the cargo distribution to minimize stress on the hull and achieve optimal trim. The software allowed me to simulate different loading scenarios, considering factors such as cargo density, stability criteria, and port limitations. I’m also proficient in using specialized software for container ships, calculating weight distribution across bays and tiers, and ensuring compliance with container stacking regulations. This proficiency extends to the creation of detailed loading plans, including manifests, which are essential for smooth operations and regulatory compliance.

Q 23. How do you handle cargo damage or loss during ship loading?

Handling cargo damage or loss during ship loading involves a meticulous process. First, immediate steps are taken to prevent further damage. This might involve securing loose cargo or transferring damaged goods to a safe location. Next, a thorough investigation is conducted to determine the cause of the damage or loss. This involves inspecting the cargo, the handling equipment, and the loading procedures. We examine documentation such as bills of lading and cargo manifests to verify the cargo’s condition before loading. Detailed reports are generated, including photographic evidence, and are shared with all relevant stakeholders, such as the ship’s crew, stevedores, and the cargo owner. Depending on the severity and cause, insurance claims may be filed. Preventative measures, such as improved training for stevedores, upgrades to handling equipment, and more stringent quality checks, are then implemented to mitigate future incidents. For example, in one case of damaged containers, we discovered that improper securing methods were at fault. We subsequently revised our training program and implemented a new checklist for securing containers, significantly reducing similar incidents in the future.

Q 24. What is your experience with the International Maritime Dangerous Goods (IMDG) Code?

I have extensive experience with the International Maritime Dangerous Goods (IMDG) Code. My understanding encompasses its classification, segregation, packaging, marking, and labeling requirements for hazardous materials. I’m proficient in identifying dangerous goods using the IMDG Code’s classification system. I’ve prepared and reviewed dangerous goods declarations (DGDs) and ensured the safe stowage and handling of hazardous cargo according to the Code’s guidelines. Compliance with the IMDG Code is critical for safety and environmental protection; any violation can have serious consequences. For instance, I’ve worked on projects involving the transportation of chemicals and flammable materials, carefully adhering to the IMDG Code’s detailed provisions regarding segregation, packaging, and documentation. This includes understanding the different classes of dangerous goods and ensuring that appropriate safety measures are implemented throughout the loading process, including the use of specialized containers and equipment.

Q 25. How do you ensure the environmental protection during ship loading operations?

Environmental protection is paramount during ship loading. My approach involves implementing measures to prevent spills, air emissions, and water pollution. This starts with pre-loading inspections of the vessel and cargo to identify potential risks. During loading, I ensure that all handling equipment is properly maintained to minimize the risk of leaks or spills. We use containment measures, such as spill trays and booms, and have well-defined procedures for handling any potential spills. We also implement measures to reduce air emissions, such as using low-sulfur fuels and optimizing loading operations to minimize engine idling time. Regular monitoring of air and water quality is conducted during operations to ensure compliance with environmental regulations. For example, during the loading of oil, we implement stringent procedures to prevent oil spills. This includes using double-walled hoses, regular inspections, and the use of absorbent materials to contain any potential leaks.

Q 26. Explain your understanding of trim and stability calculations during loading.

Trim and stability calculations are crucial for safe and efficient ship loading. Trim refers to the difference in draft (depth of the hull in the water) between the bow (front) and stern (rear) of the vessel. Stability refers to the vessel’s ability to remain upright and not capsize. I use specialized software and manual calculations to determine the vessel’s trim and stability based on the cargo’s weight, distribution, and the vessel’s characteristics. This involves calculating the center of gravity (CG) and the metacenter (M) to ensure that the vessel remains within safe stability limits. Incorrect calculations can lead to instability, potential capsizing, and damage to the vessel or cargo. For example, when loading a container vessel, I meticulously calculate the weight distribution to ensure that the vessel’s CG remains within the permissible range and that the trim is within acceptable limits. These calculations are also crucial in ensuring that the vessel meets all stability criteria for specific sea conditions.

Q 27. Describe your experience with vessel scheduling and port coordination.

Vessel scheduling and port coordination are essential for optimizing ship loading operations. My experience includes coordinating with shipping lines, port authorities, and other stakeholders to ensure that vessels arrive and depart on schedule. This involves considering various factors, such as vessel availability, berth allocation, cargo availability, and weather conditions. Effective communication and collaboration are essential to avoid delays and ensure smooth operations. I’ve used various scheduling tools and communication platforms to manage schedules and coordinate activities. For example, in a recent project, I coordinated the arrival of a bulk carrier, ensuring that the berth was available and that all necessary permits and clearances were in place. This involved close collaboration with the port authority, stevedores, and the shipping line to ensure the smooth and timely loading of the cargo.

Q 28. How do you contribute to a safe and efficient work environment during ship loading?

Contributing to a safe and efficient work environment during ship loading involves a multi-faceted approach. It starts with ensuring that all personnel are properly trained and equipped with the necessary safety gear. I enforce strict adherence to safety regulations and procedures, conduct regular safety inspections, and provide training on safe handling practices and emergency response. Clear communication channels are established, and potential hazards are identified and addressed proactively. Collaboration with all stakeholders is vital to ensure that safety is prioritized at every stage of the loading process. For example, I’ve implemented a system of daily safety briefings before loading commences, addressing any potential risks and reinforcing safety procedures. This ensures that everyone is aware of the safety guidelines and potential hazards involved in the loading operation.

Key Topics to Learn for Ship Loading Operations Interview

- Cargo Handling & Stowage Planning: Understanding different cargo types, their handling requirements, and safe stowage practices to optimize space and stability. Practical application includes calculating cargo weight distribution and securing methods.

- Safety Procedures & Regulations: Deep familiarity with international maritime safety regulations (SOLAS, IMDG Code) and company-specific safety protocols. Practical application includes identifying and mitigating potential hazards during loading operations.

- Loading Equipment & Technology: Knowledge of cranes, conveyors, and other loading equipment, including their operational limitations and maintenance. Practical application includes troubleshooting equipment malfunctions and optimizing loading efficiency.

- Documentation & Communication: Understanding the importance of accurate documentation (loading plans, manifests, etc.) and effective communication with crew members, port authorities, and other stakeholders. Practical application includes interpreting and completing required shipping documents precisely.

- Logistics & Supply Chain Management: Understanding the broader context of ship loading within the global supply chain. This includes coordinating with suppliers, managing schedules, and optimizing the entire process. Practical application includes analyzing potential delays and proposing effective solutions.

- Emergency Response & Crisis Management: Preparing for and responding to emergencies such as cargo spills, equipment failures, or inclement weather. Practical application includes developing and executing emergency response plans.

- Risk Assessment & Mitigation: Proactively identifying and assessing potential risks associated with ship loading operations and implementing effective mitigation strategies. Practical application includes conducting thorough risk assessments and developing safety protocols.

Next Steps

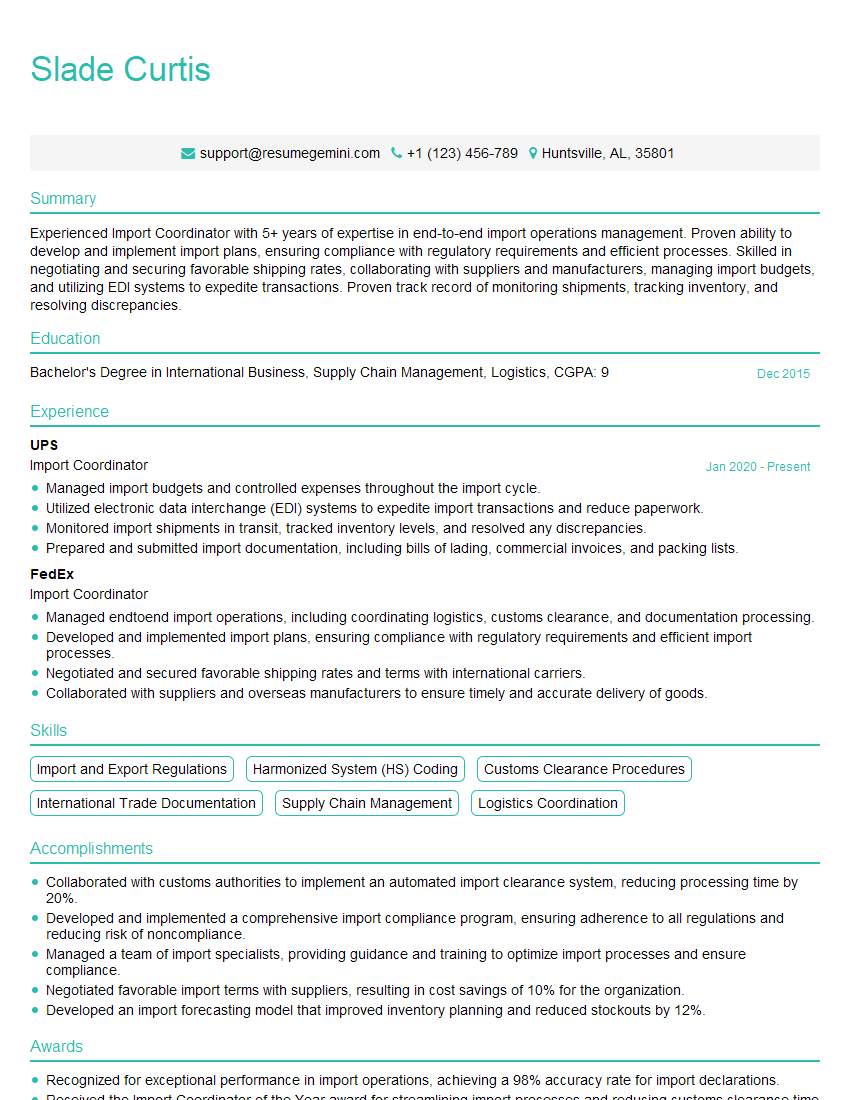

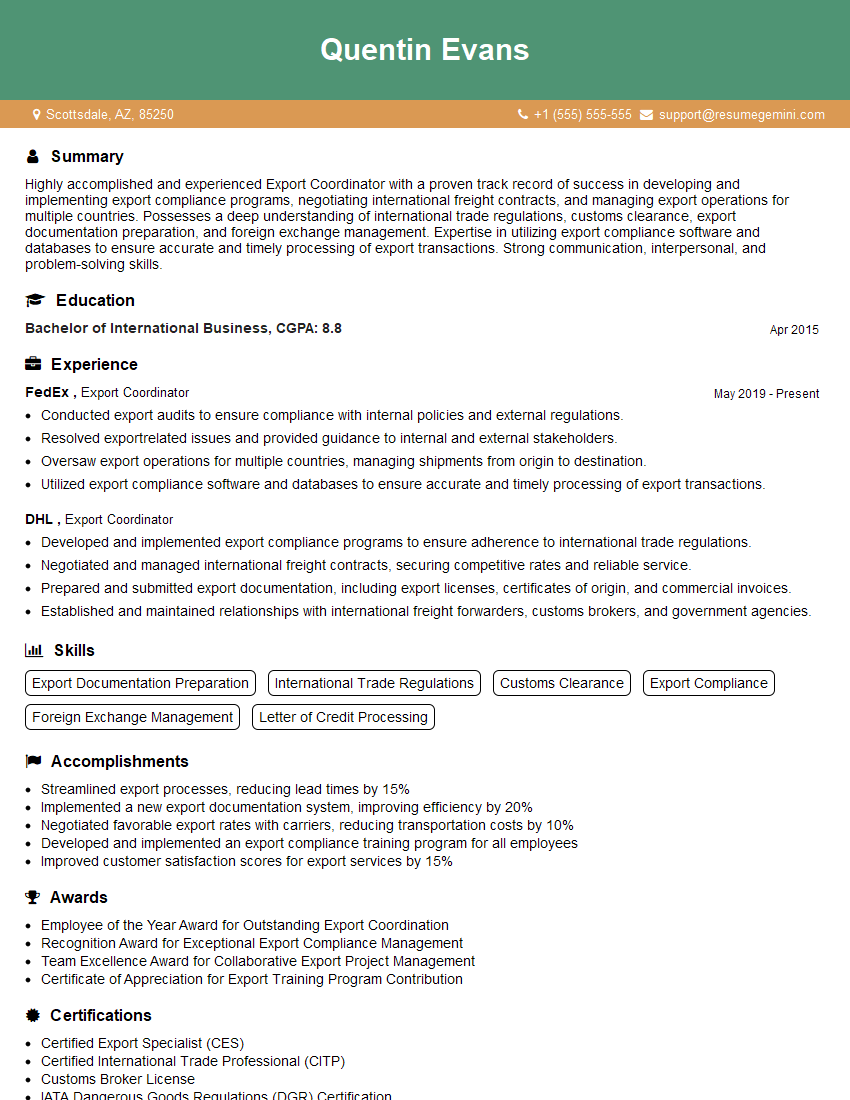

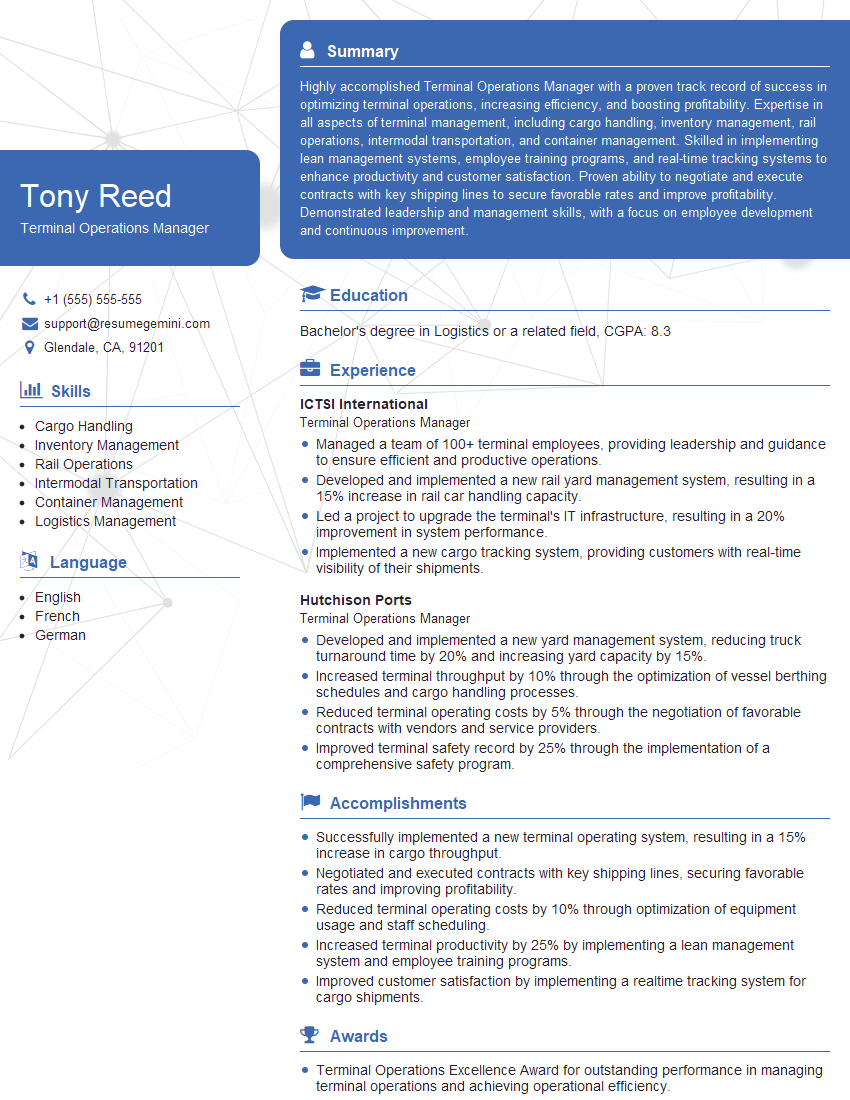

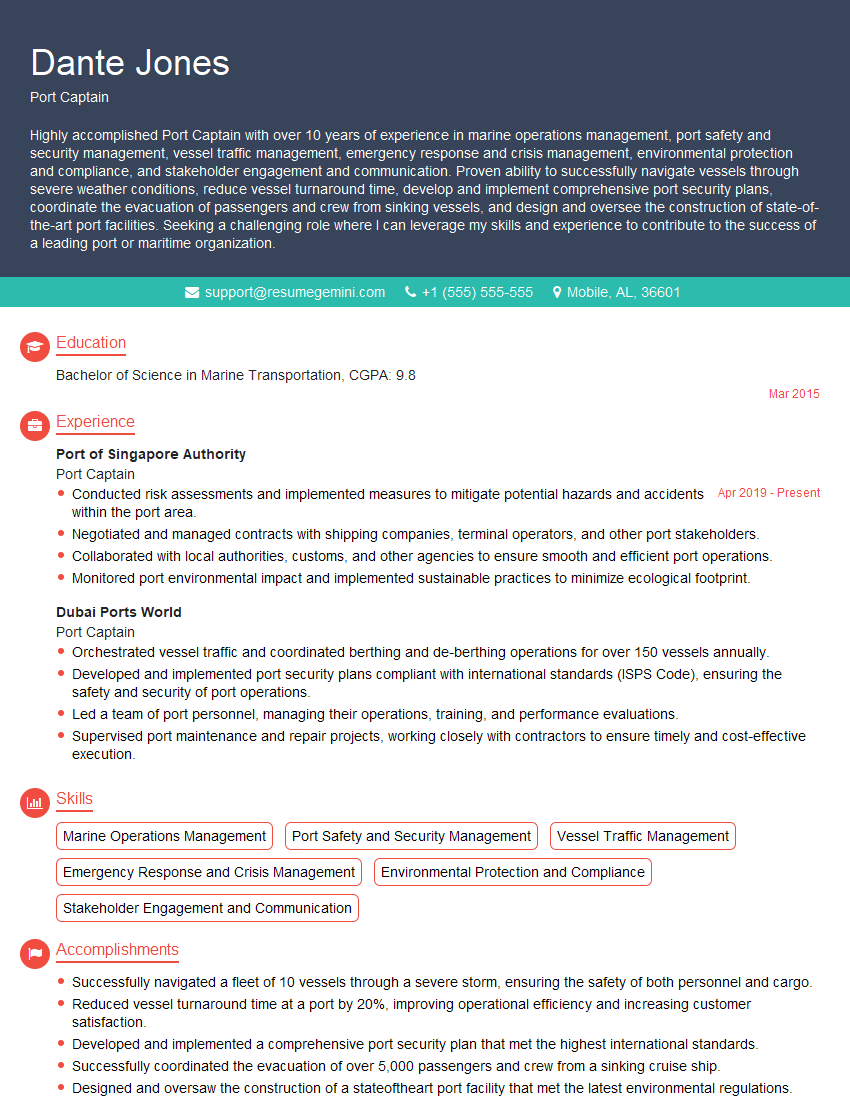

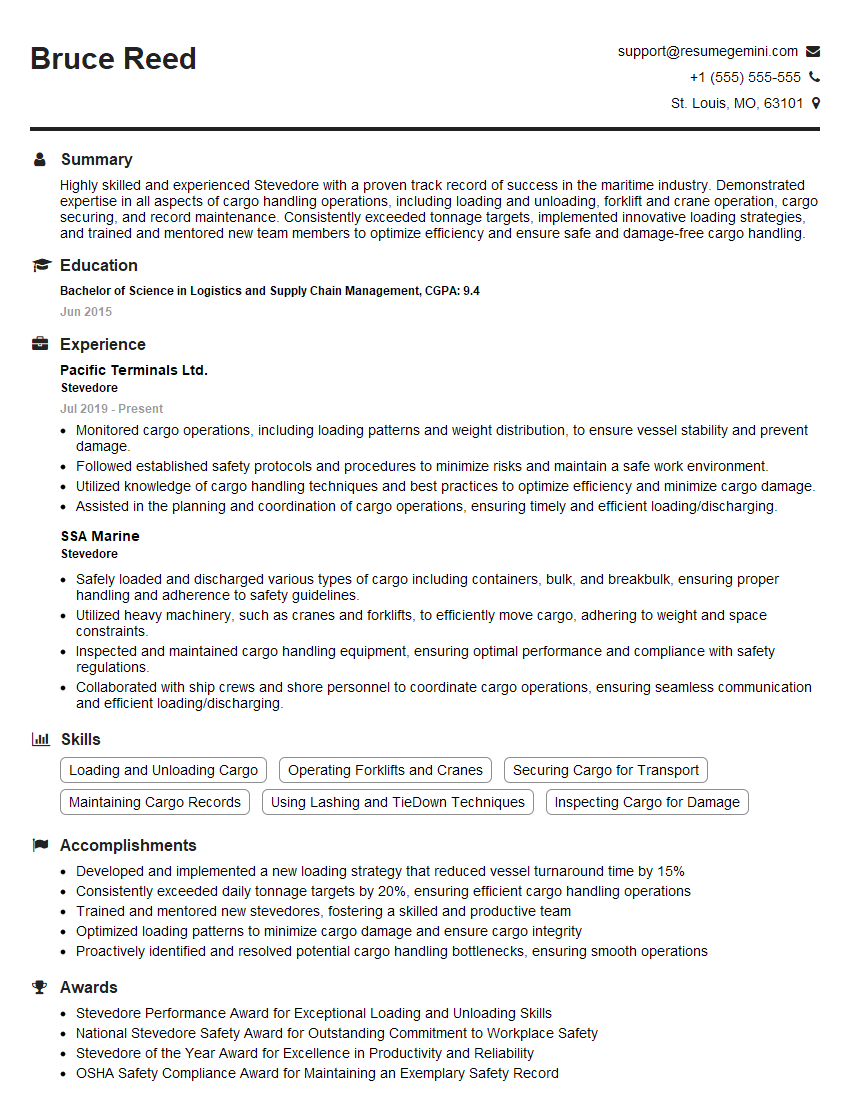

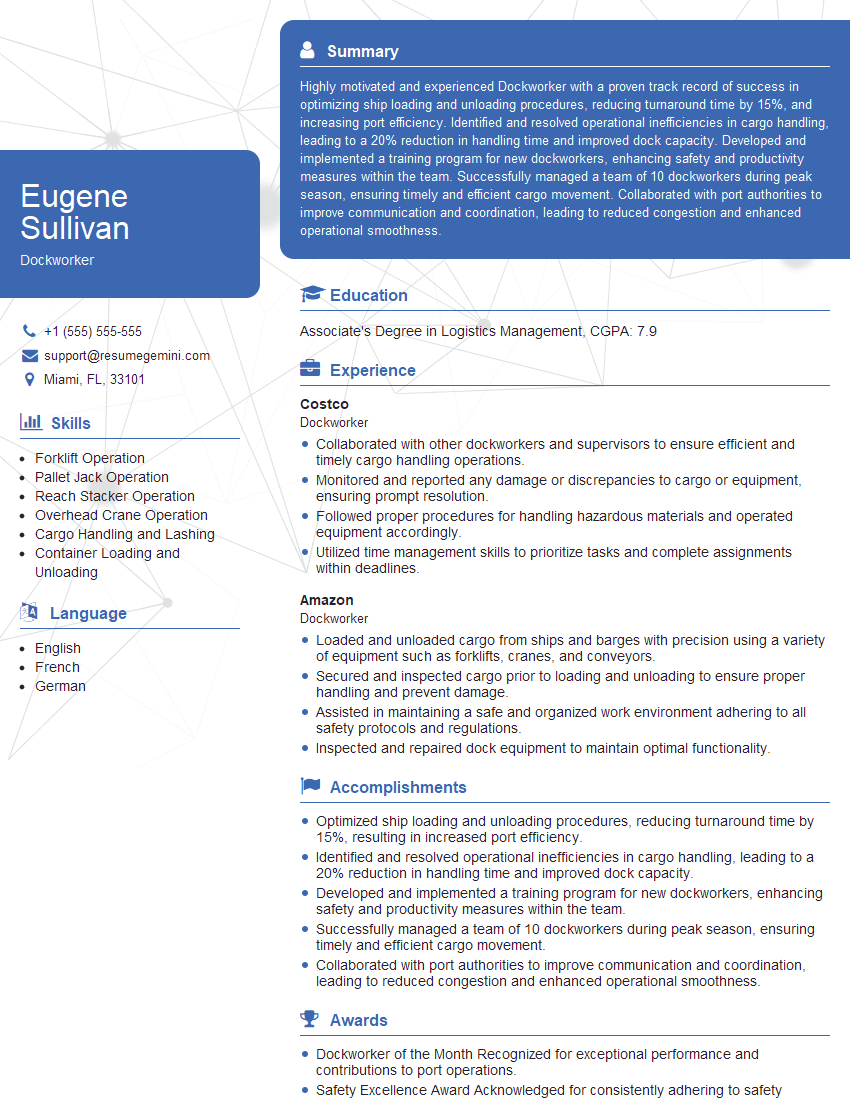

Mastering Ship Loading Operations opens doors to exciting career advancements, offering opportunities for increased responsibility and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to ensure it gets noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Ship Loading Operations are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good