Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Ship Stability and Structural Integrity interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Ship Stability and Structural Integrity Interview

Q 1. Explain the principles of hydrostatic equilibrium.

Hydrostatic equilibrium is the state where a floating body is at rest, with its weight balanced by the buoyant force acting upon it. Imagine a large wooden block floating in a calm lake. The weight of the block, acting downwards through its center of gravity (G), is exactly counteracted by the upward buoyant force, acting upwards through the center of buoyancy (B). This buoyant force is equal to the weight of the water displaced by the submerged portion of the block. For equilibrium, these two forces – weight and buoyancy – must be equal in magnitude and opposite in direction, and their lines of action must coincide.

In simpler terms, it’s like a seesaw perfectly balanced. The weight of the ship is one side, and the water pushing it up is the other. When these are equal, the ship floats stably.

Q 2. Describe the metacentric height and its significance in ship stability.

The metacentric height (GM) is the distance between the center of gravity (G) of a ship and its metacenter (M). The metacenter is the point of intersection of the lines of action of the buoyant force when the ship is inclined slightly. GM is a crucial indicator of a ship’s initial stability. A larger GM indicates greater initial stability, meaning the ship will readily return to its upright position after a small disturbance, like a wave. A smaller GM suggests reduced initial stability, making the ship prone to larger rolling motions and potentially capsizing.

Think of it like a pendulum. A higher center of gravity (lower GM) is like a longer pendulum – it swings more widely. A lower center of gravity (higher GM) is a shorter pendulum – it swings less dramatically. In ship design, a sufficient GM is essential for safe operation, ensuring the vessel remains upright and responsive to wave action.

Q 3. What are the different types of ship stability? Explain each.

Ship stability is categorized into several types, primarily focusing on different aspects of the vessel’s behavior in response to external forces:

- Initial Stability: This refers to the ship’s tendency to return to its upright position after a small angle of heel (tilt). It’s directly related to the metacentric height (GM).

- Intact Stability: This encompasses the ship’s behavior at larger angles of heel, considering the effects of the shifting weight of cargo and water inside. It’s assessed using the righting arm curve.

- Damage Stability: This addresses the ship’s stability after suffering damage, like flooding of compartments. Regulations stipulate minimum standards for damage stability to ensure the vessel remains afloat and stable even with significant water ingress.

- Longitudinal Stability: This pertains to the ship’s stability along its longitudinal axis (bow to stern), primarily determined by the distribution of weight and buoyancy along the length of the vessel.

Each type is crucial for different stages of a vessel’s operational life and is meticulously evaluated through calculations and simulations during design and operation.

Q 4. How do you calculate the righting moment of a vessel?

The righting moment (RM) is the force that tends to restore a ship to its upright position after an angle of heel. It’s calculated as the product of the ship’s displacement (weight of water displaced) and the righting arm (GZ). The righting arm is the horizontal distance between the center of gravity (G) and the center of buoyancy (B’) when the ship is heeled.

RM = Displacement × GZ

Calculating GZ requires intricate calculations involving geometry and buoyancy considerations, often employing naval architecture software. The process involves determining the new position of the center of buoyancy (B’) when the vessel is inclined. The righting arm curve, a graph of GZ versus the angle of heel, provides a comprehensive picture of the ship’s stability at various heel angles. A positive GZ indicates a righting moment, while a negative GZ suggests a capsizing moment.

Q 5. Explain the concept of freeboard and its importance.

Freeboard is the vertical distance between the waterline and the deck line of a ship. It represents the height of the ship’s side above the waterline. A sufficient freeboard is crucial for preventing seawater from entering the ship during waves or rough seas. It’s a critical safety factor against flooding, protecting the vessel and its crew.

Think of it as the safety margin a ship has above the waterline. Higher freeboard provides greater protection against waves washing over the deck. Freeboard regulations are established by international maritime organizations, based on ship type, size, and operational area, to ensure adequate protection against harsh weather conditions.

Q 6. What are the factors affecting the longitudinal strength of a ship?

The longitudinal strength of a ship, its ability to withstand bending moments along its length, is affected by several crucial factors:

- Ship Length: Longer ships experience greater bending moments.

- Ship Size and Displacement: Larger vessels have larger weights and hence experience greater bending moments.

- Wave Action: Waves exert significant bending forces, particularly in heavy seas, and vary with wave height and length. The hull’s ability to resist the forces associated with different waves needs to be carefully considered.

- Cargo Distribution: Uneven cargo distribution creates significant variations in bending moments. Careful consideration is given to cargo placement during loading operations.

- Hull Form and Structure: The shape of the hull and the structural design, including the location and strength of bulkheads and girders, greatly influence a ship’s ability to resist bending forces.

These factors are carefully considered during the design process to ensure the ship’s hull possesses sufficient strength to withstand expected bending moments throughout its service life.

Q 7. Describe different types of ship structural failures.

Ships can experience various types of structural failures, often catastrophic if not addressed properly:

- Fatigue Failure: Repeated cyclic loading from waves and operational stresses can lead to fatigue cracks and ultimately failure, especially in high-stress areas.

- Brittle Fracture: This can occur in cold conditions or with certain materials, where cracks propagate rapidly, leading to sudden and complete failure. Materials science and appropriate design are vital here.

- Buckling: Excessive compressive loads can cause structural elements, such as plates and stiffeners, to buckle, reducing their load-carrying capacity and potentially leading to collapse.

- Yielding: When the stresses exceed the yield strength of the material, permanent deformation occurs, weakening the structure and potentially leading to failure under subsequent loads.

- Corrosion: Environmental exposure can degrade materials, reducing their strength and increasing the risk of failure. This can range from general corrosion to localized pitting.

Regular inspections, maintenance, and non-destructive testing (NDT) are crucial for detecting structural defects and preventing catastrophic failures.

Q 8. How do you assess the structural integrity of a vessel?

Assessing a vessel’s structural integrity involves a multi-faceted approach combining theoretical calculations, experimental data, and practical inspections. Think of it like a thorough medical checkup for a ship. We need to understand its overall health and identify potential weaknesses before they become critical.

- Plan Approval and Design Review: Starting with the design phase, we scrutinize the plans to ensure they meet all relevant classification society rules and regulations (like those from DNV, ABS, or Lloyd’s Register). This involves checking calculations related to strength, stability, and fatigue life.

- Material Testing: Samples of the materials used in construction are tested to verify their properties meet specifications. This is crucial because variations in material strength can significantly impact the vessel’s structural performance.

- Non-Destructive Testing (NDT): Throughout the vessel’s life, NDT methods like ultrasonic testing, radiography, and magnetic particle inspection are used to detect internal flaws or defects without damaging the structure. Imagine it as an X-ray for the ship’s hull, revealing hidden problems.

- Finite Element Analysis (FEA): Sophisticated computer simulations (FEA) model the vessel’s behavior under various loading conditions (waves, cargo, etc.) to predict stress and strain distributions. This helps to identify potential weak points and optimize the design.

- In-Service Inspections: Regular surveys and inspections are vital to detect signs of corrosion, damage, or wear. These inspections involve visual checks, thickness measurements, and other relevant tests.

By combining these methods, we obtain a comprehensive picture of the vessel’s structural health, enabling us to predict its remaining life and identify any necessary maintenance or repairs.

Q 9. Explain the role of finite element analysis (FEA) in ship structural design.

Finite Element Analysis (FEA) is an indispensable tool in ship structural design. It’s like having a digital twin of the ship, allowing us to simulate its behavior under real-world conditions without physically building it. Instead of using simplified mathematical models, FEA divides the ship’s structure into numerous small elements, each with its own properties. This allows for a highly detailed and accurate analysis.

FEA helps us to:

- Optimize Design: By simulating various loading scenarios, we can identify areas of high stress and refine the design to minimize weight and maximize strength. This leads to more fuel-efficient and cost-effective vessels.

- Predict Structural Behavior: FEA predicts how the ship will respond to different forces, such as wave impacts, cargo loads, and ice pressure. This ensures the design can withstand these stresses without failure.

- Assess Fatigue Life: FEA allows us to evaluate the vessel’s fatigue life, which is crucial for predicting its lifespan. It helps us understand how repeated loading cycles will affect the structure over time.

- Analyze Damage Tolerance: We can use FEA to investigate the consequences of potential damage scenarios, like collisions or grounding, to determine the extent of structural weakening and the need for repairs.

For example, FEA can help identify optimal locations for strengthening members to improve the resistance of a container ship’s hull against the significant stresses experienced during heavy seas.

Q 10. What are the common methods for determining the stress distribution in a ship’s hull?

Determining the stress distribution in a ship’s hull is crucial for ensuring its structural integrity. Several methods exist, ranging from simplified analytical approaches to sophisticated numerical techniques.

- Simplified Analytical Methods: These methods use simplified assumptions and formulas to estimate stress in specific sections of the hull. They are useful for quick preliminary assessments but may lack the accuracy of more advanced techniques.

- Finite Element Analysis (FEA): As discussed previously, FEA provides a highly detailed and accurate representation of stress distribution throughout the entire hull. It considers complex geometries and material properties, yielding a much more precise result than simplified methods.

- Experimental Stress Analysis: This involves using strain gauges or photoelasticity to measure actual stresses on a physical model or section of the hull. This provides valuable experimental data that can be used to validate FEA results or to investigate areas where FEA might be less accurate.

The choice of method depends on the complexity of the problem, the required accuracy, and the available resources. For simple components, analytical methods may suffice, while complex hull structures usually require the precision of FEA.

Q 11. Describe the importance of material selection in ship structural design.

Material selection is paramount in ship structural design. The choice of material significantly impacts the vessel’s weight, strength, durability, cost, and maintainability. Imagine choosing the right building blocks for a house—you wouldn’t use cardboard for the foundation!

Key considerations include:

- Strength: The material must be strong enough to withstand the stresses encountered during operation.

- Corrosion Resistance: The marine environment is highly corrosive, so materials with excellent corrosion resistance are essential to extend the vessel’s lifespan.

- Weldability: Many ship structures are built using welded joints, requiring materials that weld easily and produce strong joints.

- Cost: Balancing cost and performance is vital. High-strength steel is often preferred for its strength-to-weight ratio, despite potentially higher initial costs.

- Formability: The material must be easily formed and shaped into the complex geometries required for ship construction.

Common materials used in ship construction include various grades of steel, aluminum alloys, and composites. The choice depends on the vessel type, size, and intended operational conditions.

Q 12. What are the effects of corrosion on ship structural integrity?

Corrosion is a significant threat to ship structural integrity. It’s a gradual process that weakens the material, reducing its strength and ultimately leading to failure. Think of rust eating away at a car body—the same principle applies to ships.

The effects of corrosion include:

- Reduced Strength: Corrosion weakens the material, making it more susceptible to failure under stress.

- Increased Weight: Corrosion products can add significant weight, affecting the vessel’s performance and fuel efficiency.

- Reduced Fatigue Life: Corrosion can create stress concentrations, accelerating fatigue damage and reducing the lifespan of the structure.

- Leaks: Corrosion can cause holes or cracks in the hull, leading to leaks and potential flooding.

- Structural Instability: Severe corrosion can compromise the structural integrity of the vessel, making it unsafe to operate.

Corrosion control measures, including protective coatings, cathodic protection, and regular inspections, are crucial for mitigating these risks.

Q 13. Explain the role of non-destructive testing (NDT) in ship maintenance.

Non-destructive testing (NDT) plays a vital role in ship maintenance. It allows us to inspect the structure for defects without causing damage, preventing catastrophic failures and ensuring the safety of the vessel and its crew. Imagine it as a doctor using an ultrasound to examine a patient’s internal organs without surgery.

Common NDT methods used in ship maintenance include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws like cracks or voids.

- Radiographic Testing (RT): Uses X-rays or gamma rays to create images of internal structures, revealing defects.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface cracks in ferromagnetic materials.

- Liquid Penetrant Inspection (LPI): Reveals surface cracks by allowing a colored dye to penetrate the cracks and then be drawn out by a developer.

NDT helps to identify corrosion, fatigue cracks, welding defects, and other damage before they escalate into major problems. This allows for timely repairs, preventing expensive and potentially hazardous failures.

Q 14. How do you handle damage stability calculations?

Damage stability calculations are essential for assessing a vessel’s ability to remain afloat and stable after sustaining damage, such as flooding or hull breaches. It’s a critical aspect of ship safety, ensuring the vessel can survive an accident and allow for safe evacuation.

The process typically involves:

- Defining Damage Scenarios: We consider various damage scenarios, based on the vessel type and operating conditions. This includes the location, size, and extent of damage.

- Calculating Water Ingress: We determine the amount of water entering the vessel due to the damage.

- Calculating the Vessel’s Residual Stability: We calculate the vessel’s stability characteristics after water ingress, considering factors like the ship’s intact buoyancy, the center of gravity, and the metacentric height.

- Assessing Residual Stability Criteria: We compare the calculated residual stability against regulatory requirements to determine if the vessel meets the required safety standards.

- Evaluating Escape and Rescue Time: Ensuring there’s sufficient time to safely evacuate passengers and crew post-damage is crucial.

Software packages and established calculation methods are used to perform these calculations, ensuring accurate and reliable assessments of the vessel’s damage stability. These calculations are critical in designing and certifying seaworthy vessels.

Q 15. What are the international regulations concerning ship stability and structural integrity (e.g., SOLAS)?

International regulations governing ship stability and structural integrity are primarily established by the International Maritime Organization (IMO) and codified in the Safety of Life at Sea (SOLAS) Convention. SOLAS Chapter I, Regulation 12, mandates that ships must be designed and constructed to ensure sufficient stability and structural strength to withstand the stresses of normal operation and foreseeable severe conditions. Specific requirements are detailed in other SOLAS chapters and related IMO codes, such as the International Code for the Intact Stability of Cargo Ships (IS Code) and the International Code on Load Lines (LL Code). These regulations cover aspects like:

- Intact stability criteria: Defining minimum stability standards for various loading conditions and ship types.

- Damage stability: Ensuring sufficient buoyancy and stability even after damage, such as flooding of a compartment.

- Structural design standards: Setting minimum requirements for material strength, scantlings (dimensions of structural members), and overall structural design to withstand stresses from waves, cargo loads, and other environmental factors.

- Surveys and inspections: Regular inspections and surveys to ensure compliance with regulations and good condition of the ship’s structure.

- Cargo securing: Regulations on proper securing of cargo to prevent shifting and loss of stability.

Non-compliance can lead to serious consequences, including detention of the vessel, fines, and potentially catastrophic accidents. The regulations are constantly evolving to incorporate new knowledge and address identified weaknesses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of conducting a stability assessment for a cargo ship.

Conducting a stability assessment for a cargo ship is a systematic process involving several stages. It begins with gathering all relevant information about the vessel, including its hydrostatic data (relationships between draft and displacement), hull geometry, and structural details. Next, the cargo plan is developed, specifying the type, quantity, and location of each cargo item. This is crucial because the weight and distribution of cargo significantly influence stability.

The assessment then involves calculations using established methods, often with the aid of specialized software. These calculations determine key stability parameters like:

- GM (Metacentric Height): A measure of initial static stability. A larger GM generally indicates greater initial stability.

- KG (Height of the center of gravity): The vertical distance from the keel to the center of gravity of the ship and its cargo. A lower KG leads to improved stability.

- Righting lever (GZ): The moment arm that tends to restore the ship to its upright position after an inclination.

- Angle of loll: A static equilibrium angle at which the ship heels to one side.

Using these parameters, stability curves are generated. These curves graphically represent the ship’s stability characteristics for various angles of heel. The curves are analyzed to ensure compliance with the relevant stability criteria defined in the IS Code. The final stage is the issuance of a stability booklet or report, containing all relevant calculations, diagrams, and conclusions. The booklet serves as a guide for safe operation of the vessel.

For example, a stability assessment might reveal a potential for loss of stability if certain cargo is loaded in a particular area. The assessment would then guide the crew on how to distribute cargo effectively to enhance stability and prevent dangerous situations.

Q 17. Explain the influence of cargo loading on ship stability.

Cargo loading significantly impacts ship stability. The primary factors are the weight and location (distribution) of the cargo. Heavy cargo loaded high up in the vessel raises the center of gravity (KG), reducing stability. Imagine stacking heavy boxes on the roof of a car – it becomes less stable. Conversely, loading heavy cargo low down lowers the center of gravity, thus enhancing stability.

The distribution of cargo is also critical. Uneven distribution can lead to list (a permanent heel to one side) or trim (a difference in draft between the bow and stern). For example, if all the cargo is concentrated on one side of the ship, it will heel over to that side. A proper cargo plan must ensure that cargo is distributed evenly across the ship’s breadth to minimize transverse (side-to-side) list and uniformly along the length to minimize longitudinal trim.

Different types of cargo have different effects. Loose bulk cargo like grains can shift during voyage, posing a significant stability risk. This risk is countered by proper segregation of cargo, filling of void spaces, and use of effective methods for securing the cargo. Liquid cargo introduces another layer of complexity that needs specialized treatment (discussed in the next answer).

Q 18. How do you address potential stability issues related to liquid cargo?

Liquid cargo presents unique stability challenges due to its free-surface effect. When a tank is partially filled with liquid, the liquid’s surface can slosh around as the ship rolls, causing a dynamic shift in the center of gravity. This reduces the effective metacentric height (GM) and can lead to instability, particularly in roll. Think of shaking a partially filled bottle of water – the movement of the water changes how the bottle behaves.

Addressing these stability issues involves:

- Proper tank filling and arrangements: Loading liquid cargo to maintain a relatively low center of gravity and minimize free surface effects. This can include using smaller tanks and maintaining consistent levels in interconnected tanks.

- Cross-flooding: The intentional filling or emptying of adjacent tanks on opposite sides to counter the shifting of the liquid’s center of gravity.

- Use of baffles: Internal structural features in tanks that break up the liquid’s surface and reduce the free surface effect.

- Stability calculations incorporating free surface effects: Accurate stability assessment requires specialized calculations considering the effects of sloshing liquid.

- Loadicator systems: Monitoring systems that accurately measure the levels in cargo tanks in real-time and provide information about the vessel’s stability.

Accurate calculation and consideration of free surface effects are critical for preventing accidents with liquid cargo.

Q 19. Discuss the impact of environmental factors (waves, currents) on ship stability.

Environmental factors like waves and currents significantly impact ship stability. Waves introduce dynamic forces and moments on the hull, causing rolling, pitching, and heaving motions. The severity of these motions depends on the wave’s height, period, and direction relative to the ship’s heading.

High waves can induce large heeling angles, potentially exceeding the ship’s stability limits. The ship’s response is influenced by its size, shape, and loading condition. A ship with a low metacentric height (GM) is generally more susceptible to large rolling motions, while a ship with a high GM might experience more abrupt, potentially dangerous movements. Similarly, strong currents can exert lateral forces on the hull, causing a lateral drift or list, impacting stability.

In extreme conditions, the combined effects of waves and currents can lead to significant reductions in ship stability, increasing the risk of capsizing. Consider a small boat in a storm – the waves can easily capsize it due to its small size and limited stability.

Understanding the effects of these environmental factors is crucial in route planning, speed adjustment, and ship handling, especially in adverse weather conditions.

Q 20. How do you interpret a stability curve?

A stability curve (often called a GZ curve) is a graphical representation of a ship’s righting lever (GZ) against the angle of heel. The righting lever is the horizontal distance between the center of buoyancy (B) and the center of gravity (G) projected onto a vertical plane through the center of buoyancy.

Interpreting a stability curve involves analyzing several key features:

- Maximum GZ: The maximum value of GZ indicates the ship’s maximum righting moment. A higher maximum GZ generally indicates better stability.

- Range of positive stability: The angle of heel at which the GZ becomes zero represents the point of vanishing stability. Angles beyond this point indicate negative stability, a dangerous condition where the ship will continue to heel over.

- Area under the curve: The area under the curve represents the total energy required to capsize the ship. A larger area means more energy is needed to capsize, indicating improved stability.

- Initial stability: The slope of the curve at small angles of heel reflects initial stability. A steeper slope near zero heel indicates better initial stability.

By carefully examining these features, naval architects and marine engineers can assess the ship’s stability characteristics and identify potential vulnerabilities. A stability curve that shows a small or quickly diminishing righting arm indicates a dangerous situation.

Q 21. Explain the concept of trim and how it affects stability.

Trim refers to the difference in draft between the bow (forward end) and the stern (after end) of a ship. A ship is said to be trimmed by the head if the draft at the bow is greater than the draft at the stern, and trimmed by the stern if the opposite is true. Ideally, a vessel is designed to operate with a minimal trim.

Trim affects stability primarily by changing the position of the center of gravity (KG) and consequently the metacentric height (GM). While a small trim doesn’t usually drastically affect stability, excessive trim can significantly impact it. A large trim by the stern might increase the likelihood of the ship becoming more vulnerable to large pitching motions. Similarly, excessive trim by the head can cause issues in some operational situations. In extreme cases, large trim values may affect the vessel’s ability to correct for sea motions, reducing overall stability.

Proper cargo loading and ballasting procedures are crucial for controlling trim. If a ship has an uneven cargo distribution or imbalance in weight, this can affect the vessel’s trim. A skilled crew would need to consider the impact of adding weights, removing weights, or shifting weights to maintain a safe and appropriate trim, and maintain good stability.

Q 22. Describe different types of structural members used in ship construction.

Ship construction utilizes a variety of structural members, each designed to withstand specific loads and stresses. These members can be broadly categorized into plates, beams, and stiffeners.

- Plates: These form the outer shell and inner bulkheads of the vessel, providing the primary structural skin. They are typically made of steel, though aluminum and other materials are used in specific applications. Their size and thickness are crucial for strength and weight considerations.

- Beams: These are longitudinal or transverse members that run the length or width of the ship, providing significant strength and stiffness. They transfer loads from the deck and hull to the ship’s main structural frame. Common examples include deck girders, longitudinal bulkheads, and keel structures.

- Stiffeners: These are smaller members, often shaped as T-bars or angles, welded to plates to increase their resistance to buckling and local deformation. They significantly enhance the overall strength of the plating.

- Columns and Pillars: These vertical members provide support for decks and other structural components. Their design needs to consider the vertical and lateral loads they’ll experience.

The specific type and arrangement of these members vary depending on the ship’s size, type, and intended operational conditions. For instance, a tanker will have different structural requirements compared to a container ship due to the different types of cargo and stresses involved.

Q 23. How do you analyze the buckling of a ship’s structural component?

Analyzing the buckling of a ship’s structural component involves understanding the interplay of compressive loads and the component’s geometry and material properties. The process typically involves these steps:

- Determining the critical load: This is the load at which the component will begin to buckle. This is often calculated using Euler’s formula for slender columns, or more complex methods for other geometries, accounting for factors like boundary conditions (fixed, hinged, etc.).

- Finite Element Analysis (FEA): For complex geometries and load cases, FEA is essential. This numerical method divides the component into smaller elements and solves for the stresses and deformations within each element. Software like ANSYS or ABAQUS is commonly used.

- Material properties: The elastic modulus (Young’s modulus) and yield strength of the material are crucial inputs in the analysis. These determine the component’s resistance to deformation and failure.

- Geometric imperfections: Real-world components have imperfections that can significantly reduce their buckling strength. These imperfections should be incorporated into the analysis, often through statistical models.

- Safety factors: The calculated critical load is typically multiplied by a safety factor to account for uncertainties in the analysis and potential overloads. This ensures a sufficient margin of safety.

The results of the buckling analysis will show the critical load and the buckling mode (how the component will deform). This information is crucial for ensuring the structural integrity of the ship and preventing catastrophic failure.

Q 24. What are the common methods used to improve ship structural strength?

Improving ship structural strength involves a combination of design enhancements and material selection. Common methods include:

- Increased plate thickness: Thicker plates offer greater resistance to bending and buckling, but this increases weight and cost.

- Optimized stiffener arrangements: Strategic placement and design of stiffeners can significantly enhance the strength-to-weight ratio of the plating.

- Higher-strength steels: Utilizing advanced steels with higher yield strength allows for thinner plates while maintaining the required strength, reducing overall weight.

- Improved welding techniques: High-quality welding is essential for ensuring the integrity of the joints, which are often the weakest points in a structure.

- Use of composite materials: In specific applications, composite materials like fiber-reinforced polymers can offer high strength-to-weight ratios, but their use is often limited by cost and manufacturing challenges.

- Structural optimization techniques: Advanced computational techniques, such as topology optimization, can help design structures that are lighter and stronger.

The choice of method depends on factors like the ship’s type, intended operating conditions, and cost considerations. Often, a combination of these approaches is used to achieve the optimal balance between strength, weight, and cost.

Q 25. Explain the concept of fatigue in ship structures and its prevention.

Fatigue in ship structures refers to the progressive damage caused by repeated cyclic loading. Imagine repeatedly bending a paper clip back and forth – eventually, it will break, even though the individual loads are far below the material’s ultimate strength. This is fatigue.

In ships, fatigue is caused by waves, vibrations, and operational loads. These cyclic stresses can lead to crack initiation and propagation, eventually resulting in structural failure. Prevention strategies include:

- Detailed fatigue analysis: This involves identifying areas of high stress concentration and predicting fatigue life using sophisticated analytical methods and software.

- Improved design details: Reducing stress concentrations through careful design of structural details, such as welded joints and cutouts, is crucial.

- Regular inspections and maintenance: Visual inspections and non-destructive testing (NDT) methods, such as ultrasonic testing, are used to detect cracks and other defects early.

- Corrosion protection: Corrosion significantly reduces material strength and accelerates fatigue crack growth. Effective corrosion protection systems are essential.

- Fatigue-resistant materials: Using materials with inherently better fatigue resistance can also enhance longevity.

Addressing fatigue is vital for ensuring the long-term safety and reliability of ship structures. Ignoring it can lead to unexpected and potentially catastrophic failures.

Q 26. Discuss the significance of risk assessment in ship stability and structural integrity.

Risk assessment in ship stability and structural integrity is crucial for ensuring safe operation. It’s a systematic process of identifying hazards, analyzing their potential consequences, and implementing measures to mitigate risks. This involves considering various factors:

- Loading conditions: Determining the potential for overloading, improper cargo distribution, and free surface effects on stability.

- Environmental conditions: Assessing the impact of waves, currents, and wind on both stability and structural integrity.

- Structural condition: Evaluating the condition of the hull, decks, and other structural components, considering age, corrosion, and previous damage.

- Operational procedures: Reviewing operational procedures to identify potential sources of risk, such as improper loading practices or inadequate crew training.

A thorough risk assessment helps in prioritizing safety measures, optimizing designs, and developing robust operational protocols. The goal is to minimize the probability and severity of incidents that could compromise stability or structural integrity.

Techniques like Failure Modes and Effects Analysis (FMEA) and HAZOP (Hazard and Operability Study) are commonly used to systematically identify and assess risks.

Q 27. How do you ensure compliance with relevant regulations and standards during design and construction?

Compliance with regulations and standards is paramount in ship design and construction. This involves adhering to rules and guidelines established by international organizations such as the International Maritime Organization (IMO) and national classification societies like ABS, DNV, and Lloyd’s Register. The process includes:

- Design approval: Submitting detailed design plans to the classification society for review and approval, ensuring compliance with relevant standards and regulations.

- Material certification: Using certified materials that meet the required strength and quality standards.

- Construction supervision: Having classification society surveyors oversee the construction process to ensure adherence to the approved plans and quality control procedures.

- Testing and inspection: Conducting various tests and inspections throughout the construction and commissioning phases to verify structural integrity and stability.

- Documentation: Maintaining detailed documentation of all design, construction, and testing processes for future reference and audits.

Non-compliance can lead to serious consequences, including delays, fines, and even operational restrictions or prohibitions. A robust quality management system is essential for ensuring consistent compliance throughout the project lifecycle.

Q 28. Describe a situation where you had to troubleshoot a stability or structural problem on a vessel.

During the dry-docking of a bulk carrier, a significant amount of corrosion was discovered on a transverse bulkhead near the double-bottom. Initial assessments suggested the corrosion had weakened the bulkhead significantly, raising concerns about its load-carrying capacity. The problem was further compounded by the fact that this bulkhead was situated in a high-stress region of the vessel.

To troubleshoot the issue, we first conducted a thorough visual inspection and used ultrasonic testing to precisely determine the extent of the corrosion and the remaining thickness of the bulkhead. Finite element analysis was then employed to model the structural behavior of the bulkhead, incorporating the detected corrosion damage. This analysis helped to determine the bulkhead’s reduced load-carrying capacity and identify potential failure modes.

Based on these findings, we developed several repair options, evaluating their feasibility, cost, and time impact. The chosen solution involved reinforcement of the corroded section using high-strength steel plates and advanced welding techniques. This approach ensured the bulkhead could safely withstand the operational loads while minimizing downtime. Post-repair inspections verified the success of the intervention, restoring the vessel’s structural integrity and ensuring continued safe operation. Detailed documentation of the entire process was maintained, including the findings of the investigations and the implementation of the repair solution.

Key Topics to Learn for Ship Stability and Structural Integrity Interview

- Hydrostatics and Buoyancy: Understanding Archimedes’ principle, calculating displacement, and determining the center of buoyancy. Practical application: Analyzing the effect of loading and unloading on vessel stability.

- Stability Criteria and Calculations: Mastering the concepts of metacentric height (GM), righting moment, and angle of heel. Practical application: Assessing the stability of a vessel in various loading conditions and sea states.

- Intact and Damaged Stability: Analyzing the effects of flooding on stability and understanding damage control procedures. Practical application: Evaluating the survivability of a vessel after damage.

- Structural Analysis Techniques: Applying finite element analysis (FEA) and other methods to assess structural strength and integrity. Practical application: Designing and analyzing ship structures for various loads and stresses.

- Material Science and Selection: Understanding the properties of different materials used in shipbuilding and their suitability for specific applications. Practical application: Choosing appropriate materials to optimize strength, weight, and cost.

- Fatigue and Fracture Mechanics: Analyzing the effects of cyclic loading on ship structures and predicting potential failure points. Practical application: Designing structures to resist fatigue and ensure long-term service life.

- Regulations and Standards: Familiarity with relevant classification society rules and international maritime regulations related to ship stability and structural integrity. Practical application: Ensuring compliance with regulatory requirements throughout the design and operation of a vessel.

- Experimental and Numerical Modeling: Understanding the use of model testing and computational fluid dynamics (CFD) in ship stability and structural analysis. Practical application: Validating design calculations and investigating complex phenomena.

Next Steps

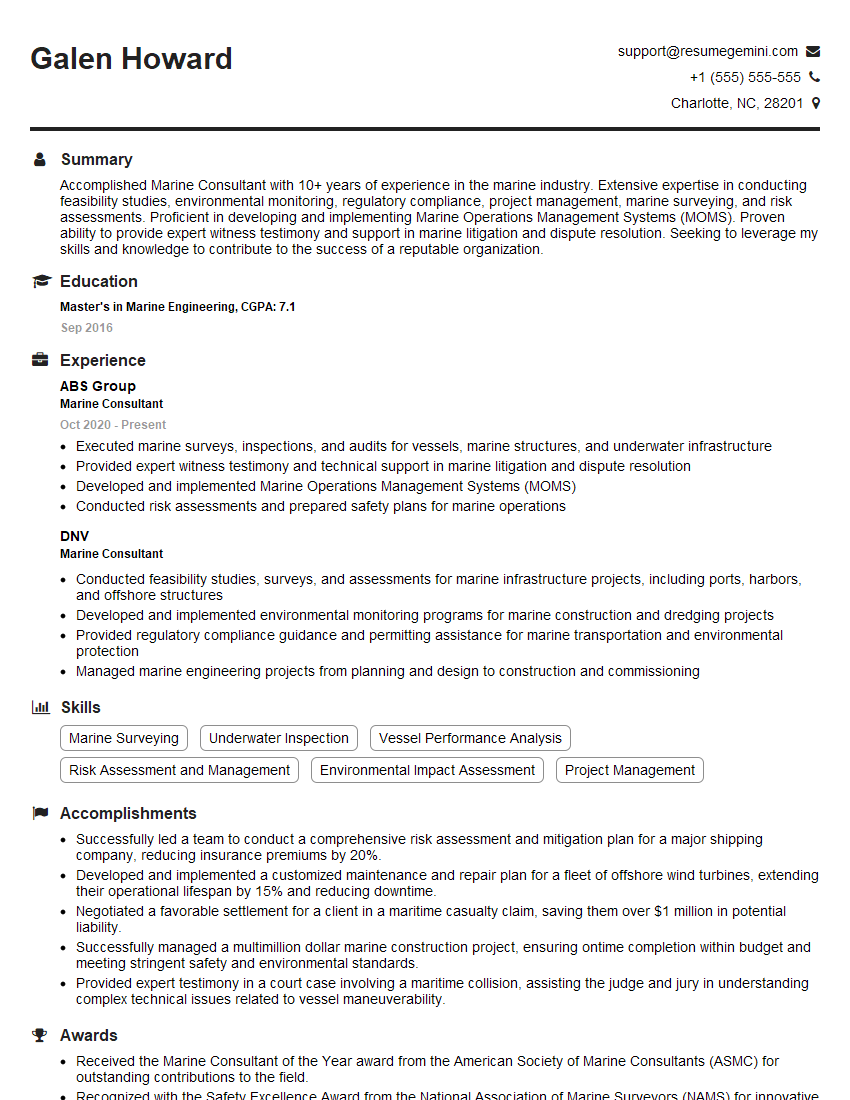

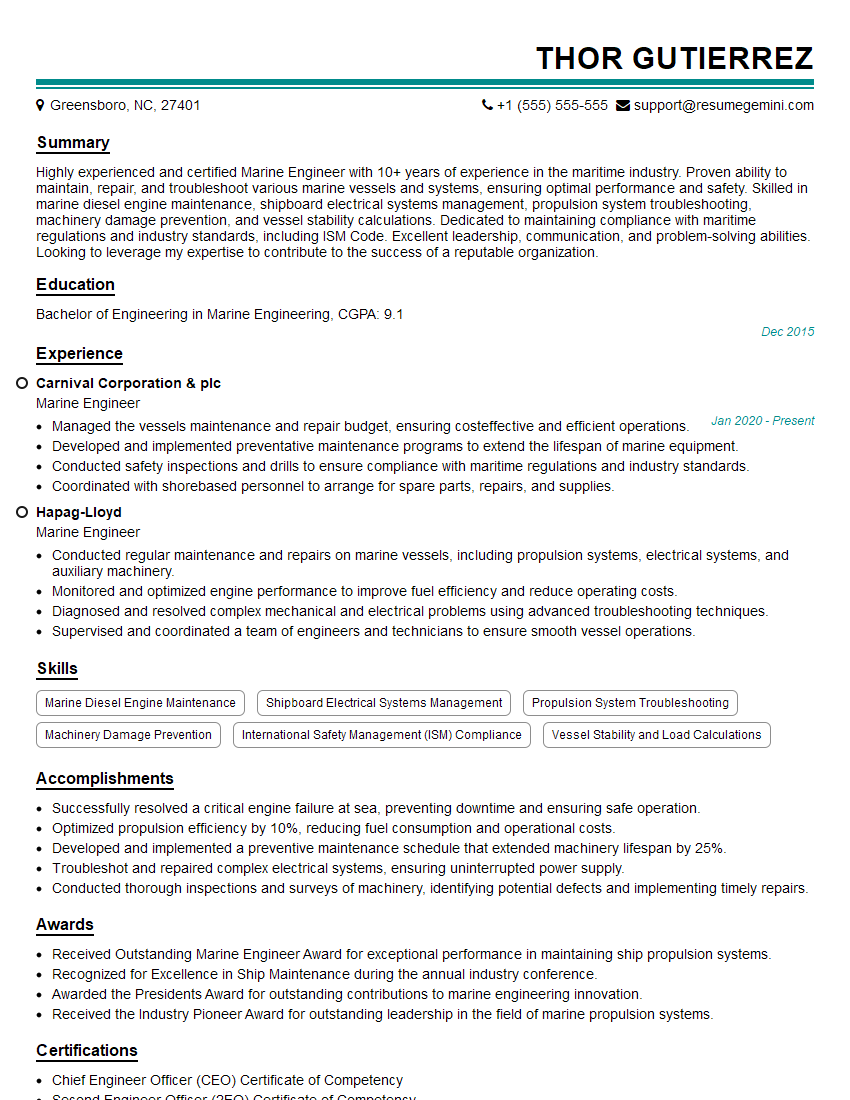

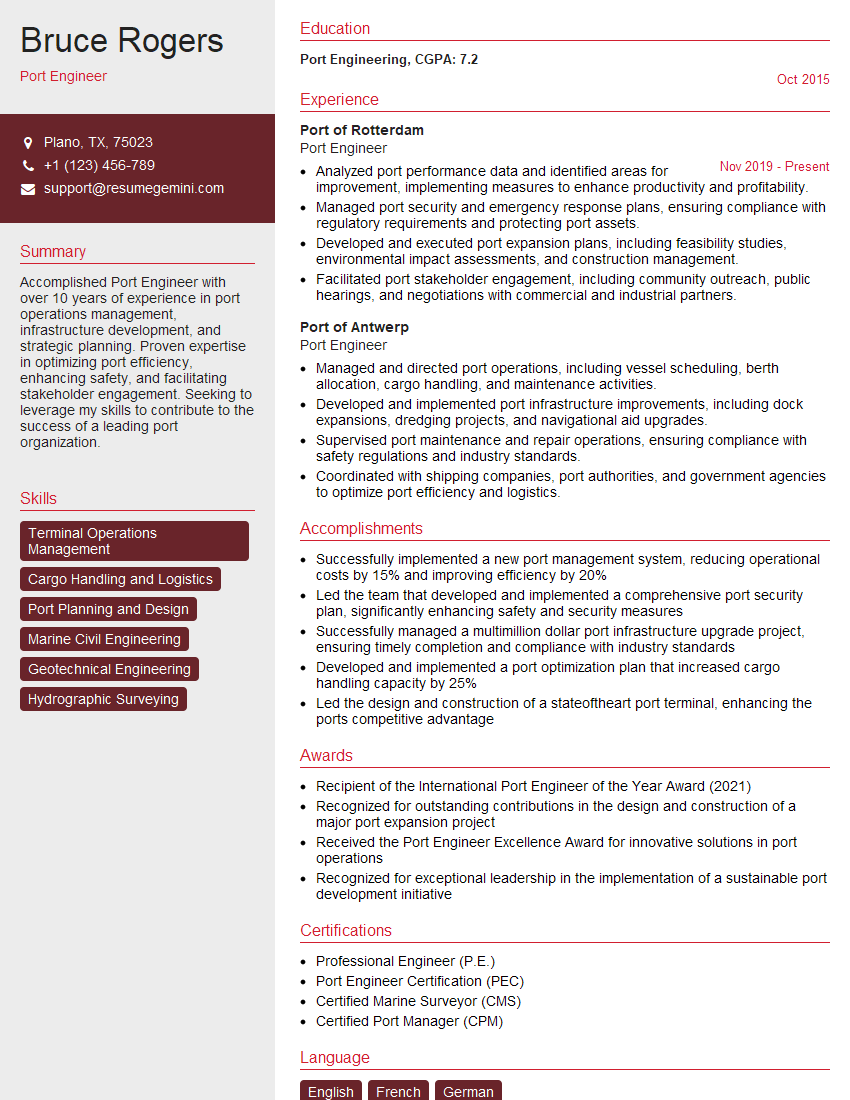

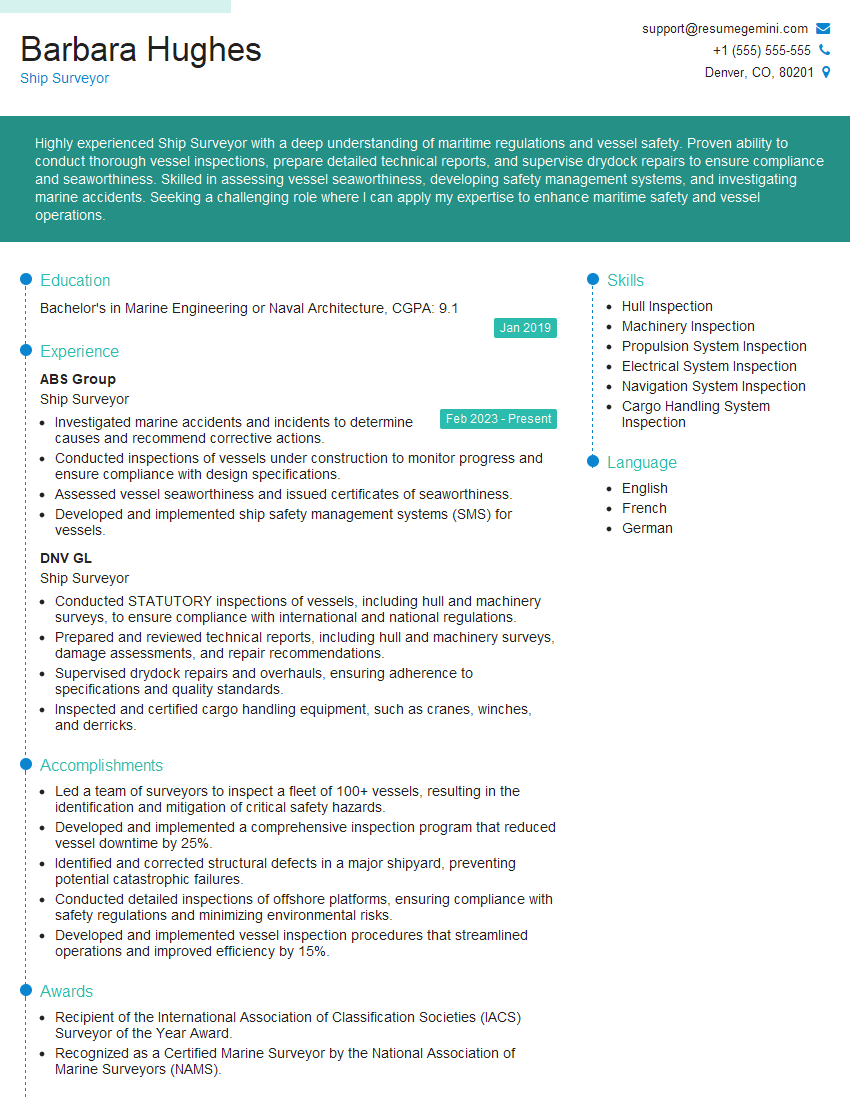

Mastering Ship Stability and Structural Integrity is crucial for a successful and rewarding career in the maritime industry. A strong understanding of these principles opens doors to exciting opportunities in design, construction, operation, and regulatory oversight. To significantly enhance your job prospects, it’s vital to create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of this field. Examples of resumes tailored to Ship Stability and Structural Integrity are available to guide you through this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good