Are you ready to stand out in your next interview? Understanding and preparing for Shoe Modifications interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Shoe Modifications Interview

Q 1. Describe your experience with different shoe construction methods.

Shoe construction methods significantly impact comfort, durability, and the feasibility of modifications. I have extensive experience with several, including:

- Cement Construction: The most common method, involving the upper being cemented directly to the sole. This is generally easier to modify, particularly for sole replacements. For example, replacing the worn-out sole of a cemented construction sneaker is a straightforward process.

- Stitch-Down Construction: The upper is stitched directly to the welt, which is then stitched to the outsole. This provides excellent durability and makes resoling easier. For instance, I’ve worked on many high-quality boots using this method, extending their lifespan considerably through resoling.

- Goodyear Welt Construction: A sophisticated method involving a welt stitched to both the upper and outsole, allowing for easy replacement of both. This is ideal for premium shoes and allows for extensive customization, such as changing the sole material completely.

- Blake Construction: The upper is stitched directly to the insole, providing a lightweight and flexible shoe. Modifying these shoes can be more challenging due to the lack of a welt, but it’s still possible with careful techniques.

My understanding of these methods allows me to choose the best approach for any modification, considering the shoe’s type, material, and the client’s needs.

Q 2. Explain the process of widening a narrow shoe.

Widening a narrow shoe requires careful consideration to avoid damage. The most common methods include:

- Stretching: Using specialized shoe stretchers, which can gently expand the shoe’s width over time. I often use this for leather shoes. For example, I’ve successfully stretched a pair of dress shoes by a full size using a professional-grade stretcher.

- Heat application: Carefully applying heat (using a hairdryer or heat gun) can soften the material, making it more pliable for stretching. This method must be used with extreme caution to prevent scorching or damaging the materials.

- Insert modification: If stretching isn’t enough, custom insoles or stretching inserts can create more space inside the shoe while maintaining the original shoe shape.

The success of these methods depends heavily on the shoe’s material. Leather responds well to stretching, while synthetic materials are less pliable and might require a different approach, possibly even requiring an insole as the only viable solution.

Q 3. How do you address heel slippage in a shoe?

Heel slippage is a common problem, often caused by a poorly fitting heel cup. Solutions include:

- Heel grips: These adhesive pads are placed inside the heel area of the shoe to increase friction and prevent slippage. They’re a quick, cost-effective solution for minor slippage.

- Heel lifts: Small pads placed under the heel, raising it slightly to improve the fit and reduce slippage. I often customize these to match the arch support and foot shape.

- Custom insoles: Deep heel cups molded into custom insoles can provide the best, most long-term solution by supporting the heel and cradling the foot.

The choice of method depends on the severity of the slippage and the shoe’s construction. For instance, a simple heel grip might suffice for a casual shoe, while a custom insole might be necessary for a more serious problem or dress shoe.

Q 4. What materials are best suited for sole replacement?

The best material for sole replacement depends on the shoe’s intended use and the customer’s preferences. Common choices include:

- Leather: Provides excellent durability, flexibility, and a classic look. Often used for dress shoes and some boots.

- Rubber: Very durable, water-resistant, and offers excellent traction. A popular choice for everyday shoes and athletic shoes.

- PU (Polyurethane): A lightweight and durable synthetic material, often chosen for its cushioning properties and shock absorption.

- TPU (Thermoplastic Polyurethane): A robust material ideal for high-impact activities, offering excellent abrasion resistance.

I carefully consider factors like the climate, the type of activity the shoe is used for, and the client’s budget when recommending a sole material. For example, a customer frequently walking on uneven terrain might benefit from a more rugged rubber sole, while a customer living in a rainy climate might prefer a water-resistant material like polyurethane.

Q 5. Describe your experience with orthopedic shoe modifications.

Orthopedic shoe modifications require specialized knowledge and precision. My experience includes:

- Accommodating orthotics: Modifying shoes to fit custom orthotics, often involving removing existing insoles and making necessary adjustments to the shoe’s internal structure to ensure a proper fit. This could involve deepening the heel cup, widening the toe box or modifying the insole shape itself.

- Adding support structures: Incorporating additional support features such as heel counters, arch supports, and metatarsal pads to address specific foot conditions. The added support is often sewn or glued, depending on the stability and the construction of the shoe itself.

- Creating custom shoes: For severe cases, collaborating with orthotic specialists to design and create custom shoes tailored to the individual’s needs. The creation of the perfect shoe for the condition is a collaborative process.

I prioritize comfort and functionality, always working in close consultation with the patient’s physician or podiatrist to ensure the modifications meet their medical needs.

Q 6. How do you determine the appropriate size and shape for a custom insole?

Determining the appropriate size and shape for a custom insole involves a meticulous process. I usually:

- Foot tracing and measurements: Accurately tracing the patient’s foot to determine its length, width, and arch height. This is crucial for proper support.

- Assessing foot type and conditions: Identifying any existing foot problems (e.g., plantar fasciitis, bunions) that may require special modifications to the insole design.

- Pressure mapping (optional): Using pressure mapping technology to identify high-pressure areas that need cushioning or support.

- 3D scanning (optional): Advanced methods like 3D scanning can provide incredibly accurate foot measurements and help create highly customized insoles.

The size and shape aren’t just about the foot outline; they also consider factors like the arch height, heel shape, and the presence of any deformities. Using this information, I can ensure the insole will provide appropriate comfort and support without causing discomfort or impeding the foot’s natural movement.

Q 7. Explain the process of adding support to a shoe for arch problems.

Adding arch support to a shoe helps alleviate pain and improve foot function for individuals with arch problems. Methods include:

- Custom insoles: Providing the most effective support, with specific arch supports molded to fit the individual’s foot. These are usually made from a combination of cushioning and support materials. They’re a comprehensive solution.

- Over-the-counter arch supports: These readily available inserts can provide a degree of arch support, but they may not be as effective for severe arch problems. These are a cost-effective preliminary approach.

- Arch support modifications: Directly modifying the existing insole by adding a suitable material to create additional arch support. This could involve cutting, gluing, and shaping suitable material onto the shoe’s insole.

I always assess the severity of the arch problem and the shoe’s construction before recommending a solution. For example, a flexible insole may be more comfortable in a running shoe than a rigid support that may affect running biomechanics. Conversely, a stiffer, structured support may be preferable for boots to offer stability.

Q 8. What are the common causes of shoe breakdown and how can they be prevented?

Shoe breakdown is a common problem stemming from several factors, primarily wear and tear, improper fit, and material degradation. Let’s break down the causes and prevention strategies:

- Wear and Tear: This is the most frequent cause. High-impact activities, frequent use, and abrasive surfaces gradually damage the sole, upper, and stitching. Prevention: Rotate shoes, use appropriate shoes for different activities (e.g., running shoes for running, hiking boots for hiking), and clean and condition your shoes regularly.

- Improper Fit: Shoes that are too tight or too loose lead to uneven wear and stress on specific areas. This can manifest as creasing, bulging, or even structural damage. Prevention: Get professionally fitted for shoes, consider orthotics for specific foot issues, and break in new shoes gradually.

- Material Degradation: Exposure to water, sunlight, and extreme temperatures can weaken the materials, causing cracking, fading, and loss of flexibility. Poor-quality materials naturally deteriorate faster. Prevention: Store shoes in a cool, dry place, use protective sprays to repel water and UV rays, and choose shoes made from durable, high-quality materials.

- Manufacturing Defects: Occasionally, shoes have inherent flaws that predispose them to premature failure. Prevention: Purchase shoes from reputable brands and inspect them carefully before use.

Addressing these causes proactively extends the lifespan of your shoes significantly, saving you money and reducing waste.

Q 9. How do you assess a customer’s needs for shoe modifications?

Assessing a customer’s needs for shoe modifications is a multi-step process that requires careful observation, questioning, and sometimes, collaboration with other healthcare professionals:

- Initial Consultation: I begin with a thorough discussion to understand the customer’s concerns and lifestyle. This includes their daily activities, footwear preferences, and any pre-existing medical conditions or foot problems.

- Foot Examination: I carefully examine the customer’s feet, paying attention to their gait, alignment, and any abnormalities. This helps identify the root cause of their footwear issues and informs the modification strategy. I may use measuring tools to get precise dimensions.

- Shoe Evaluation: I assess the existing shoes, analyzing their condition, construction, and suitability for modification. Certain shoes are better candidates for modification than others.

- Modification Planning: Based on the assessment, I design a modification plan that addresses the customer’s specific needs. This may involve adding supports, widening the shoe, altering the heel height, or replacing worn components.

- Trial and Feedback: Whenever possible, I offer a trial period after the modification to gather feedback from the customer and make necessary adjustments. Comfort and functionality are paramount.

For example, a customer with plantar fasciitis might need heel lifts and arch supports, whereas someone with bunions may require a wider toe box. A personalized approach ensures the modifications effectively address the problem while maintaining shoe aesthetics and comfort.

Q 10. What are the ethical considerations when modifying shoes for customers with disabilities?

Ethical considerations when modifying shoes for customers with disabilities are paramount. The core principles revolve around:

- Autonomy and Informed Consent: Customers must fully understand the modifications being made, their potential benefits and limitations, and any associated risks. They need to give informed consent for all procedures.

- Confidentiality: Customer information, including their medical history and the nature of their disability, must be kept confidential and handled according to professional standards and relevant data protection laws.

- Accessibility and Affordability: Modifications should be accessible to people with disabilities regardless of their financial situation. Transparent pricing and exploring options for financial assistance are important.

- Quality and Safety: Modifications must be of high quality, durable, and safe. Using appropriate materials and techniques to ensure the shoes are functional and do not pose risks to the customer is crucial.

- Non-Discrimination: All customers, regardless of their disability, should be treated with respect and dignity. Avoid stereotypes or assumptions about their needs or abilities.

In short, ethical shoe modification prioritizes the well-being, dignity, and autonomy of the customer above all else.

Q 11. Describe your experience with different types of shoe leather and their properties.

My experience encompasses a wide range of shoe leathers, each with unique properties impacting both the modification process and the final product’s durability and comfort. Here are some examples:

- Full-Grain Leather: The highest quality, featuring the top layer of the hide. It’s durable, breathable, and develops a beautiful patina over time. However, it’s more prone to scratching and requires more careful treatment during modification.

- Top-Grain Leather: The top layer of the hide, but with the imperfections sanded off. This makes it more uniform and less expensive than full-grain but somewhat less breathable and durable.

- Corrected-Grain Leather: The most processed type, with imperfections heavily sanded and a synthetic layer applied. It’s cheap, consistent, and easy to work with, but it lacks the breathability and character of full-grain leather.

- Suede and Nubuck: These are softer, more delicate leathers with a napped finish. They are harder to modify without damaging the nap. Special techniques are necessary to ensure the modifications blend seamlessly.

- Synthetic Leathers: Offer a wide range of properties, from durable and water-resistant to lightweight and breathable. They are easier to work with in some aspects but may not age as well or provide the same level of comfort as natural leathers.

Understanding these properties allows me to choose the appropriate tools and techniques for each modification, ensuring both quality and longevity.

Q 12. What tools and equipment are essential for shoe modification?

Essential tools and equipment for shoe modification are diverse and depend on the specific task. However, some staples include:

- Sewing Machines: Various types, from heavy-duty machines for stitching soles to lighter ones for delicate upper repairs.

- Hand Sewing Tools: Needles, thread (various strengths and colors), awls, and stitching groovers.

- Knives and Cutters: Sharp blades for precise cutting of leather, soles, and other materials.

- Mallets and Hammers: For shaping and attaching components.

- Lasts: Forms that hold the shoe in place during repairs and modifications.

- Adhesives: Specialized shoe glues, contact cement, and other bonding agents.

- Measuring Tools: Rulers, calipers, and templates for precise measurements.

- Sandpaper and Files: For smoothing surfaces and refining edges.

- Heat Guns and Irons: For shaping and adhering certain materials.

- Orthotic Inserts and Components: Arch supports, heel cups, and other materials used to provide custom support.

Beyond these, specialized tools are often required for advanced modifications or working with specific materials. Safety equipment, such as protective eyewear and gloves, is also crucial.

Q 13. How do you maintain the quality and integrity of modified shoes?

Maintaining the quality and integrity of modified shoes requires meticulous attention to detail and appropriate aftercare. My methods include:

- Quality Materials: Using high-quality threads, glues, and other materials that are durable and compatible with the shoe’s existing components.

- Precise Workmanship: Employing techniques that ensure the modifications are structurally sound and aesthetically pleasing, blending seamlessly with the original shoe design.

- Proper Finishing: Smoothing out rough edges, cleaning up any adhesive residue, and applying protective sprays or conditioners as needed.

- Post-Modification Advice: Providing customers with clear instructions on caring for their modified shoes, including cleaning, conditioning, and storage.

- Quality Control Checks: Thorough inspection of the finished product to ensure the modification meets both quality and safety standards. This might include walking tests or simulations of typical activities.

For example, using a strong, UV-resistant thread for stitching ensures longevity. Similarly, careful application of a durable adhesive provides robust bonding.

Q 14. What are the common challenges in shoe modification work?

Challenges in shoe modification work are varied and can be quite demanding. Here are some common issues:

- Material Compatibility: Finding materials that are compatible with the existing shoe materials, ensuring they adhere properly and don’t cause discoloration or deterioration.

- Structural Integrity: Ensuring the modifications don’t compromise the shoe’s structural integrity, which can be challenging, particularly with older or damaged shoes.

- Aesthetics: Making modifications that are both functional and aesthetically pleasing, blending seamlessly with the original shoe design.

- Customer Expectations: Meeting customer expectations while maintaining professional standards and providing honest assessments of what’s achievable.

- Time Constraints: Balancing the need for thorough work with the desire to complete projects efficiently and meet deadlines.

- Specialized Tools and Skills: Access to the right tools and having the expertise to use them effectively.

For example, repairing a vintage leather shoe requires specialized knowledge of the leather type and appropriate adhesives to maintain the patina and avoid damage. Addressing these challenges proactively minimizes errors and maximizes the chances of a successful outcome.

Q 15. How do you handle difficult or unusual requests?

Handling unusual requests is a cornerstone of my expertise. I approach them systematically. First, I listen carefully to the customer, clarifying their needs and the desired outcome. Then, I assess the feasibility, considering the materials, techniques, and the structural integrity of the shoe. For instance, a request to add significant height to a delicate heel would require a different approach than adding a simple patch. If the request is feasible, I present options, outlining potential challenges and associated costs. If it’s not feasible, I explain why, offering alternative solutions that meet their needs as closely as possible. Open communication and transparency are key to managing expectations and maintaining a positive customer experience. For example, a customer once asked for a completely custom-made sole design. After discussing the design, the materials needed, and the significant time investment, we collaborated to slightly alter the design for easier fabrication, resulting in a happy customer and a unique final product.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with various stitching methods used in shoe repair.

My experience encompasses a wide array of stitching methods vital for shoe repair and modification. I’m proficient in both hand-stitching and machine stitching, adapting my technique based on the shoe’s material, the repair’s complexity, and the desired aesthetic. Hand-stitching, for example, using a blind stitch or saddle stitch, is ideal for delicate repairs and creating invisible seams on leather shoes. Machine stitching offers speed and precision for tasks like attaching new soles or replacing linings. I use different types of needles and threads, selecting them based on the material’s thickness and strength. For instance, heavier-gauge needles and durable nylon thread are better suited for canvas shoes while finer needles and silk thread are preferred for finer leather. Understanding the properties of different threads—their strength, colorfastness, and durability—is crucial for achieving a lasting repair.

Q 17. What are some common issues related to shoe lasts?

Shoe lasts, the forms around which shoes are constructed, can present several issues. One common problem is wear and tear, leading to warping or cracking. This can affect the shoe’s shape and fit, potentially causing discomfort or even damage to the shoe’s upper. Another issue is incorrect sizing or shape. If the last doesn’t properly match the shoe’s design or the intended foot shape, it can result in ill-fitting shoes with structural problems. Sometimes, the materials used for lasts are not durable enough, causing them to deform over time, affecting the consistency of shoe production. Finally, improper storage or handling of lasts can cause damage and impact the quality of the shoes produced. Identifying and addressing these issues through proper maintenance, selection, and storage is key for preventing significant problems down the line.

Q 18. How do you repair a damaged shoe sole?

Repairing a damaged shoe sole depends heavily on the type and extent of the damage. For minor scuffs or superficial damage, a simple cleaning and application of a protective sealant might suffice. More significant damage, such as cracks, holes, or significant wear, requires a more involved process. This could include cleaning the damaged area, removing loose or damaged materials, and applying a durable adhesive to bond a new piece of sole material. For example, I might use a high-quality rubber cement to attach a new leather or rubber patch or, for more extensive damage, a complete sole replacement might be necessary, involving removing the old sole entirely and carefully attaching a new one. The choice of material for the replacement sole should match the original material and the customer’s needs for durability and aesthetic. Proper preparation is essential for a successful and long-lasting repair, as is the correct selection of adhesive.

Q 19. Describe your experience working with different types of adhesives.

My experience encompasses a broad range of adhesives, each chosen according to the specific materials being bonded and the intended use. I frequently use contact cements for attaching soles and heels, these are strong and provide a firm bond between rubber and leather. For delicate repairs, I often opt for water-based adhesives, which offer flexibility and are less likely to damage the surrounding material. Epoxy resins are invaluable for stronger repairs and for filling gaps or cracks, providing added structural support. Each type of adhesive has its strengths and weaknesses. Understanding their curing times, adhesion strength, flexibility, and resistance to wear is critical to ensuring a long-lasting and successful repair. For example, in repairing a vintage leather boot with a split welt, I might utilize a specialized leather adhesive and then reinforce the repair with stitching for added strength and longevity.

Q 20. How do you deal with customers who have unrealistic expectations?

Managing unrealistic customer expectations is a critical skill. I approach this by first actively listening to understand their vision. Then, I use my expertise to explain the limitations, realistically outlining what is achievable given the shoe’s condition, the available materials, and current techniques. For instance, restoring a severely damaged, decades-old shoe to ‘like-new’ condition might not be entirely feasible, but I can offer a repair that significantly improves its appearance and functionality. I present options, showing pictures of similar successful repairs. This transparent approach allows for a shared understanding of the possibilities and limitations, and often helps the customer adjust their expectations to a realistic level. Empathy and open dialogue are crucial—building a relationship based on trust and mutual understanding leads to positive outcomes, even if the final product isn’t exactly what they initially envisioned.

Q 21. What are the safety precautions you take while using shoe modification tools?

Safety is paramount in my work. When using sharp tools like knives, awls, or stitching needles, I always use them with care, ensuring the blade or needle is sharp and in good working condition—a dull tool is more dangerous than a sharp one. I wear protective eyewear to guard against flying debris and sharp objects. When working with adhesives, I ensure proper ventilation and avoid prolonged contact with my skin. I adhere to all relevant safety data sheets (SDS) for chemicals and materials. Additionally, I maintain a clean, organized workspace to prevent accidents. I regularly inspect and maintain my equipment to ensure that it’s in proper working order. By prioritizing safety and employing appropriate precautions, I protect myself and ensure that I can continue to provide quality service for many years to come.

Q 22. How do you manage your workload efficiently?

Efficient workload management is crucial in shoe modification. I utilize a project management system that combines a digital calendar with a prioritized task list. Each client’s project, from initial consultation to final delivery, is meticulously documented, including materials needed, estimated time, and deadlines. This allows me to accurately estimate project timelines and allocate my time effectively. For instance, I might schedule all leather repairs on Mondays and focus on athletic shoe modifications on Wednesdays, grouping similar tasks together to optimize workflow. I also actively manage client communication, ensuring clear expectations and prompt responses to avoid delays.

- Prioritization: I prioritize urgent projects and those with shorter deadlines first, employing techniques like the Eisenhower Matrix (urgent/important) to manage time efficiently.

- Batching: I group similar tasks together. For example, I might complete all the sole replacements before moving to heel repairs.

- Time Blocking: I allocate specific time slots for different tasks to avoid interruptions and improve focus.

Q 23. How do you stay updated on new techniques and materials in shoe modification?

Staying current in shoe modification requires a multi-pronged approach. I regularly subscribe to industry journals like Shoe Repair and Maintenance and attend workshops and seminars offered by organizations such as the National Shoe Repair Association (fictional name – replace with actual organization if applicable). Online platforms like YouTube channels focused on shoemaking and repair are invaluable resources for learning new techniques, particularly specialized stitching methods or the application of novel materials. I also actively participate in online forums and communities dedicated to shoe modification, where professionals share their experiences and expertise, enabling a constant exchange of knowledge. Furthermore, attending shoe trade shows and collaborating with material suppliers keeps me informed about the latest advancements in both materials and tools. For example, I recently learned about a new adhesive specifically designed for repairing high-performance athletic shoes, drastically improving the longevity of my repairs.

Q 24. Describe your experience with repairing different types of footwear (e.g., boots, sandals, athletic shoes).

My experience spans a wide range of footwear, encompassing boots, sandals, athletic shoes, and even delicate high-fashion pieces. Working with boots, for instance, often involves stitching repairs, replacing worn-out soles, and conditioning the leather. Sandals require a different approach, focused on repairing straps, replacing buckles, and addressing issues with the sole’s integrity. Athletic shoes often present unique challenges, such as repairing tears in mesh uppers, replacing worn-out midsoles, and applying specialized cushioning materials. Each type of footwear necessitates a unique understanding of its construction and the materials used in its creation. For example, a delicate Italian leather sandal needs a different approach compared to a heavy-duty hiking boot. My expertise lies in adapting my techniques to the specific needs of each footwear type.

Q 25. How do you ensure the longevity of your shoe modifications?

Ensuring the longevity of my modifications hinges on several key factors. First and foremost is the quality of materials I use. I source high-quality leather, adhesives, threads, and soles from reputable suppliers. Second, I meticulously follow proper repair techniques, ensuring that the repairs are structurally sound and aesthetically pleasing. For instance, when replacing a sole, I pay close attention to the alignment and adhesion to ensure the new sole integrates seamlessly with the upper part of the shoe. Third, I always provide clients with aftercare instructions, advising them on proper cleaning and storage techniques. Fourth, for particular repairs, I might apply protective coatings or sealants to enhance water resistance and prevent future damage. For example, for a repaired leather boot, a protective water-resistant spray will add extra years of life. By combining quality materials with precise techniques and thorough client education, I strive to maximize the lifespan of my modifications.

Q 26. What are your strengths and weaknesses as a shoe modification specialist?

My strengths lie in my meticulous attention to detail, my adaptability to different footwear types, and my commitment to client satisfaction. I’m a problem-solver, always seeking the most effective and durable solution for each repair. I am also proficient in a wide range of repair techniques and comfortable working with various materials. One weakness I’m actively addressing is time management, particularly when juggling multiple complex projects simultaneously. I am implementing project management techniques to improve my efficiency and meet deadlines consistently.

Q 27. What is your hourly rate or your pricing structure for shoe modifications?

My pricing structure is based on an hourly rate of [insert your hourly rate here], which varies depending on the complexity and time required for the repair. However, I also offer fixed pricing for common repairs, such as simple sole replacements or heel repairs. For more complex modifications, such as extensive leather restoration or custom alterations, I provide a detailed estimate after a thorough assessment of the footwear. Transparency in pricing is crucial, so I always communicate the cost upfront, providing a breakdown of labor and materials involved. For example, a simple heel replacement might have a fixed price, while a full sole rebuild would be quoted hourly based on the assessment of the condition of the shoe.

Q 28. What are your career goals in the field of shoe modifications?

My career goals include establishing a reputable and highly sought-after shoe modification business. I envision expanding my services to include custom shoe design and bespoke modifications, catering to a clientele that values high-quality craftsmanship and unique footwear. I am also keen on mentoring aspiring shoe modification specialists, sharing my knowledge and experience to cultivate the next generation of skilled artisans in the field. Long-term, I aim to contribute to the preservation of traditional shoemaking techniques while incorporating modern materials and technology to meet evolving customer needs.

Key Topics to Learn for Shoe Modifications Interview

- Anatomy of Footwear: Understanding the construction of different shoe types (e.g., boots, sneakers, heels) and their components (outsoles, midsoles, uppers, etc.) is fundamental. This includes knowledge of materials used and their properties.

- Modification Techniques: Mastering various techniques such as resoling, heeling, stretching, widening, and adding orthotics. Practical application involves understanding the tools and processes involved in each technique.

- Material Selection and Repair: Knowing which materials are suitable for specific repairs and modifications, considering durability, aesthetics, and customer requirements. This includes understanding the properties of leather, synthetics, and other materials used in shoemaking.

- Customer Consultation and Needs Assessment: Successfully modifying shoes requires understanding the customer’s needs and preferences. This involves effective communication, problem-solving, and finding solutions that meet both functional and aesthetic requirements.

- Troubleshooting and Problem-Solving: Being able to identify and resolve common issues during the modification process, such as fitting problems, material damage, and unexpected challenges. This includes creative problem-solving to overcome unexpected difficulties.

- Health and Safety: Familiarity with relevant health and safety regulations and procedures related to working with tools, materials, and chemicals common in shoe modification.

- Pricing and Estimation: Accurately estimating the cost of materials and labor for different modification projects. This includes understanding pricing models and competitive market rates.

Next Steps

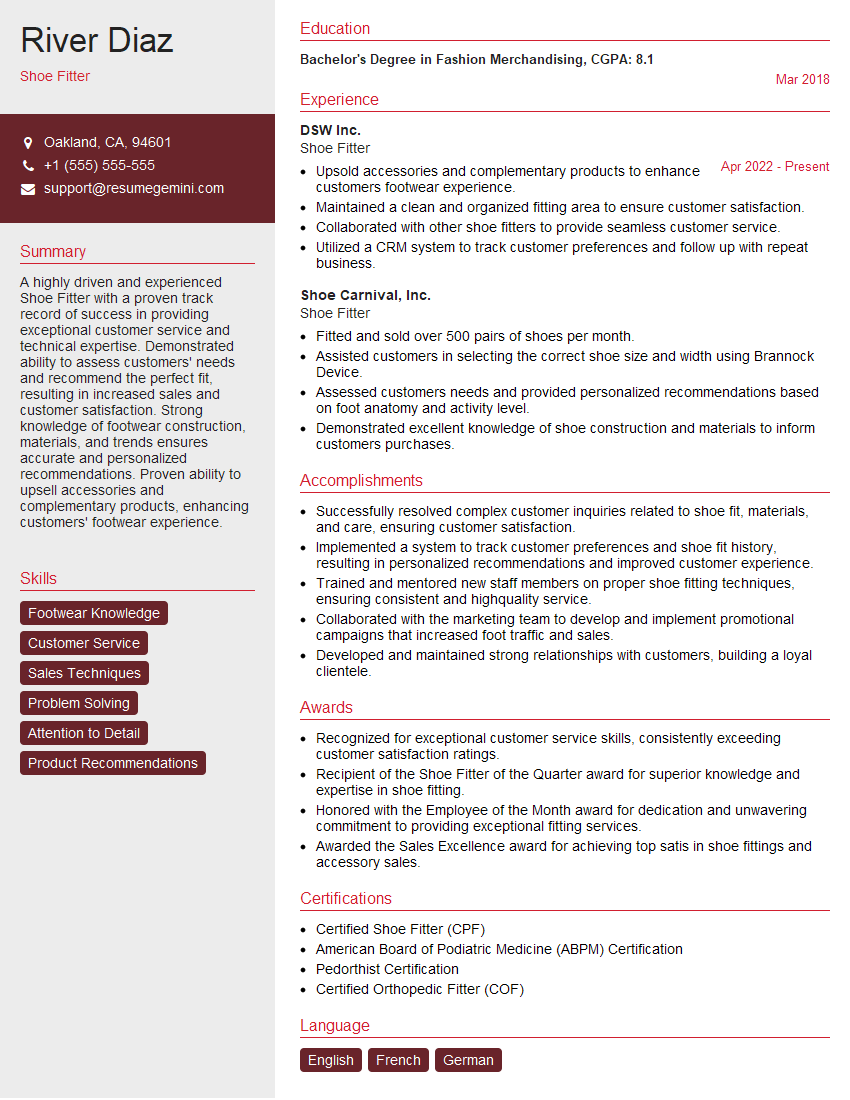

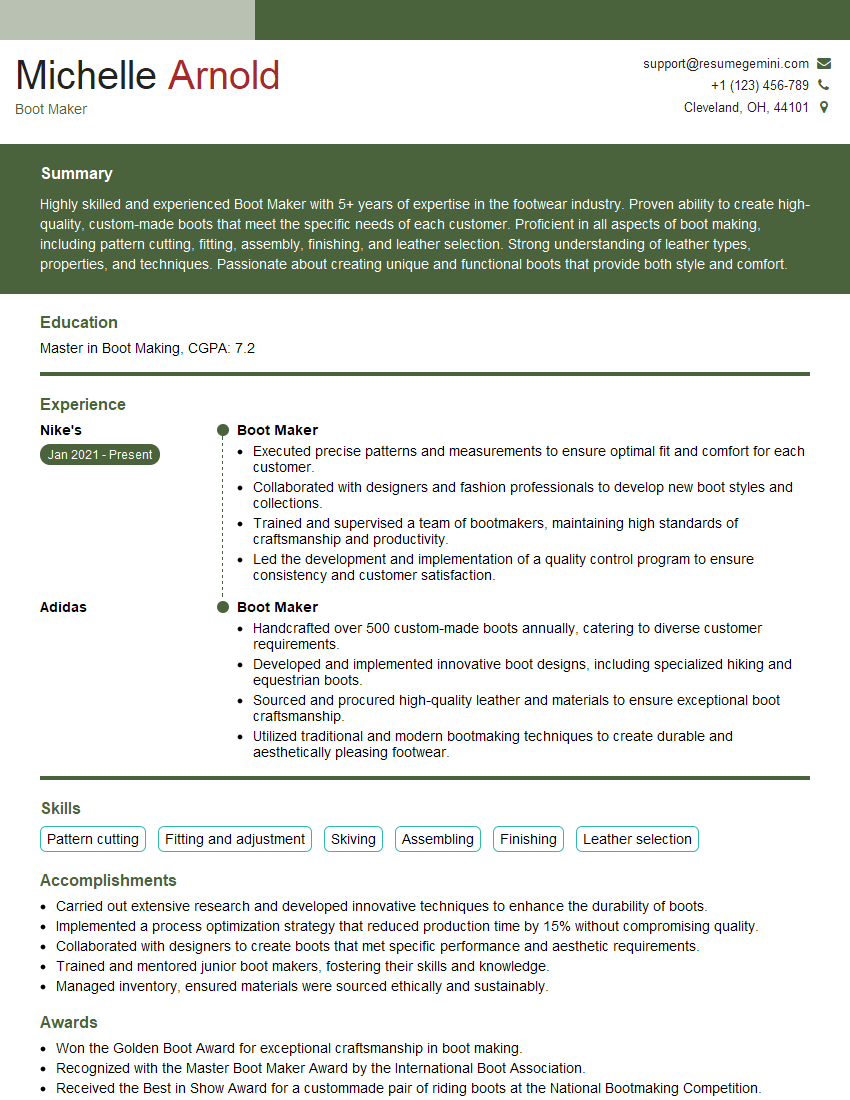

Mastering shoe modifications opens doors to exciting career opportunities in the footwear industry, offering a blend of creative problem-solving and technical skills. To significantly increase your chances of landing your dream job, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored specifically to the Shoe Modifications field are available to guide you, ensuring your application stands out from the competition. Invest time in creating a strong resume – it’s your first impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good