Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Shoe repair trends interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Shoe repair trends Interview

Q 1. What are the current trends in shoe repair materials?

Current trends in shoe repair materials reflect a growing emphasis on sustainability and durability. We’re seeing a rise in the use of recycled and reclaimed materials, like rubber from recycled tires for soles, and vegetable-tanned leathers for uppers. There’s also a strong focus on high-performance adhesives and stitching threads that offer superior strength and water resistance. For example, I recently started using a new bio-based adhesive that’s incredibly strong yet eco-friendly. It bonds leather and rubber flawlessly and is much better for the environment than traditional solvent-based glues. In addition, manufacturers are producing more durable, long-lasting materials, reducing the frequency of repairs needed. This includes more abrasion-resistant outsoles and stronger stitching techniques. The demand for ethically sourced and sustainable materials is driving innovation in this area, making repair work not just functional but also responsible.

Q 2. Describe different methods for repairing a torn sole.

Repairing a torn sole depends on the extent of the damage and the type of sole material. For smaller tears in leather soles, I often use a leather patch, carefully blending it with the existing leather for a seamless repair. This involves cleaning the area, applying a strong adhesive, positioning the patch, and carefully stitching it in place using specialized thread. For larger tears or damage to rubber soles, a variety of methods are available. One effective technique involves cutting away the damaged section, creating a clean edge, and then applying a rubber patching material or even a new piece of rubber cut to fit. This requires careful shaping and blending to ensure a smooth, durable repair. Finally, for significant sole separation, I might use a combination of adhesive and stitching to reattach the sole to the upper. The choice of method always depends on the shoe itself and the customer’s budget and expectations.

Q 3. Explain the process of resoling a leather shoe.

Resoling a leather shoe is a complex process that requires skill and precision. First, the old sole is carefully removed using a specialized knife and other tools, making sure not to damage the upper. Then, the edges of the remaining insole are prepared for the new sole. The new sole, typically leather or a high-quality rubber, is carefully fitted to the shoe, ensuring a perfect fit and alignment. A strong adhesive is applied to both surfaces, and the sole is firmly pressed into place. It’s then stitched to the upper using a stitching machine or by hand, depending on the style of shoe and the level of detail required. Finally, the edges of the new sole are finished and polished to create a clean, professional look. This process may involve various techniques depending on the type of leather and the shoe’s construction, requiring a keen understanding of shoe anatomy.

Q 4. How do you identify different types of leather?

Identifying different types of leather involves considering its texture, appearance, and feel. Full-grain leather, for example, retains the natural grain and is the most durable. It’s thicker and more resistant to scratches. Top-grain leather is smoother because the grain has been sanded down. Nubuck and suede are also popular, offering a velvety soft texture; these are more delicate than full-grain. I often check for markings on the leather itself, which sometimes indicate the type and origin. I also pay attention to its stiffness and pliability; full-grain leather is generally stiffer than suede. Experience plays a crucial role; over the years, I’ve developed a keen eye for distinguishing different leather types. I also consider the shoe’s overall quality and brand to help inform my assessment of the leather used.

Q 5. What are the common problems encountered when repairing heels?

Common problems encountered when repairing heels include heel lift (separation of the heel from the shoe), heel wear (general wear and tear), and broken heel tips. Heel lift often requires re-attaching the heel using specialized adhesives and stitching. This often necessitates removing the heel completely, preparing the surfaces, and then gluing and stitching them back into place. Heel wear necessitates replacing the worn-out heel piece with a new one. This involves precisely measuring the heel, selecting the appropriate replacement material, and carefully fitting and securing the new piece to the shoe. Broken heel tips require replacing or repairing the tip, often needing to rebuild the tip by molding new material onto the heel and carefully shaping it. Each problem requires a specific and meticulous approach to ensure proper repair and longevity.

Q 6. Describe your experience with repairing damaged zippers on boots.

Repairing damaged zippers on boots is a common task. My approach depends on the nature of the damage. If the slider is broken, I replace it with a new one of the correct size. For a zipper that’s separated, I carefully realign the teeth and stitch the separated portions back together. For teeth that are bent or broken, I may need to replace the affected section of the zipper. I always use high-quality zipper replacement parts and employ precise hand-stitching to ensure a smooth, durable repair. It’s important to work carefully to avoid damaging the surrounding leather and ensure that the repaired zipper functions correctly. I’ve repaired dozens of zippers over the years, and I’m confident in my ability to handle most issues that may arise.

Q 7. How do you handle customer requests for custom shoe modifications?

Handling custom shoe modifications requires creativity and skilled craftsmanship. I begin by having a thorough discussion with the customer to understand their vision and needs. This might involve altering the height of a heel, adding custom stitching, changing the color of the shoe, or other modifications. I always assess the feasibility of the request, discussing any potential challenges or limitations, and providing realistic expectations regarding the timeline and cost. Once we agree on the design, I carefully plan and execute the modification, always prioritizing the shoe’s structural integrity and aesthetic appeal. Each modification is a unique project, requiring adaptation and flexibility. I believe that collaboration with the customer throughout the process is crucial to ensuring a successful and satisfactory outcome. It’s particularly fulfilling to see a customer’s smile when they see their customized shoes.

Q 8. What are sustainable practices in shoe repair?

Sustainable shoe repair prioritizes minimizing environmental impact throughout the repair process. This involves several key practices.

- Using recycled and reclaimed materials: Instead of always buying new materials, I prioritize using recycled leather scraps, rubber soles from discarded shoes, and reclaimed threads whenever possible. This reduces waste and lowers the demand for new resources.

- Choosing eco-friendly adhesives and chemicals: Many conventional glues and cleaning agents contain volatile organic compounds (VOCs) that are harmful to the environment. I opt for water-based, non-toxic alternatives whenever feasible, ensuring a healthier workspace and reducing air pollution.

- Reducing energy consumption: Efficient use of tools and machinery minimizes energy usage. For instance, I regularly maintain my equipment to optimize its performance and avoid unnecessary power consumption. I also favor natural light whenever possible instead of relying solely on artificial lighting.

- Proper waste management: I diligently sort and recycle all waste materials, including leather scraps, rubber, metal, and packaging. This minimizes landfill waste and promotes a circular economy.

- Extending the lifespan of shoes: Ultimately, the most sustainable practice is repairing shoes to extend their life, reducing the need for frequent replacements. This is the core philosophy of my business.

For example, recently I repaired a customer’s favorite boots using recycled leather patches and a water-based adhesive. The boots looked as good as new, and the customer was thrilled to avoid buying a new pair.

Q 9. How do you determine the appropriate glue for different materials?

Choosing the right glue depends heavily on the materials being bonded. There’s no one-size-fits-all solution; understanding the properties of the materials is crucial.

- Leather to Leather: A high-quality contact cement specifically designed for leather is ideal. These cements are strong, flexible, and provide a durable bond. I typically use a rubber-based cement, ensuring a strong, long-lasting repair.

- Rubber to Rubber: A flexible rubber cement or adhesive is crucial for bonding rubber soles and heels. Rigid glues can crack with the flexing of the shoe.

- Leather to Rubber: A specialized adhesive designed for bonding leather and rubber is necessary. These adhesives usually have a strong initial tack and good flexibility. I often choose a polyurethane-based adhesive for this combination.

- Plastic to Plastic: This requires a strong, solvent-based adhesive, though careful ventilation is crucial as these adhesives often have strong fumes.

- Fabric to Fabric: Shoemaker’s glue or a strong fabric glue designed for textiles will work well for canvas and other fabric components. These should be flexible to avoid cracking with movement.

I always test a small, inconspicuous area before applying the glue to the whole area to ensure compatibility and avoid damaging the shoe material. It’s always better to be cautious than to ruin a repair.

Q 10. What are the different stitching techniques used in shoe repair?

Different stitching techniques are employed depending on the area of the shoe and the type of material. Here are some common techniques:

- Blind Stitch: This is ideal for repairing seams where the stitching shouldn’t be visible from the outside. It’s commonly used for leather and finer fabrics.

- Saddle Stitch: This is a very strong stitch often used for leather work, especially in areas subjected to significant stress, like the welt stitching of a Goodyear welted shoe. It involves piercing the material from both sides.

- Backstitch: This simple technique is suitable for reinforcing seams or patching holes in fabric. It provides a strong, durable repair.

- Running Stitch: A quick stitch used for basting or temporary repairs. Not as strong as other techniques, it is useful for holding pieces together before applying a more permanent stitch.

- Whip Stitch: Used for edging or joining two pieces of leather or fabric, often used on the edges of a sole or leather patch.

The choice of stitch depends on factors like the material’s thickness, required strength, and the visibility of the stitch. I often adapt my techniques based on the unique needs of the repair. For instance, when repairing a vintage leather bag, I would carefully choose a blind stitch to preserve the original aesthetic.

Q 11. How do you deal with a shoe with significant water damage?

Dealing with water-damaged shoes requires a careful and methodical approach to prevent further damage and mold growth.

- Immediate Action: The first step is to remove the insoles and allow the shoes to air dry naturally. Avoid direct heat sources like ovens or hair dryers, which can warp the materials.

- Cleaning: Once dry, gently clean the shoes using a soft brush and mild detergent to remove dirt and debris. Focus on removing any salt stains which can damage the leather over time.

- Conditioning: Apply a leather conditioner specifically designed for the type of leather to rehydrate and restore suppleness. This is crucial to prevent cracking.

- Mold Prevention: In cases of significant water damage and lingering moisture, an anti-fungal treatment might be necessary to prevent mold growth. This is especially important for shoes made from natural materials.

- Structural Repair: If the water damage has caused structural damage, such as separation of layers or weakened seams, additional repair work may be needed.

I once worked on a pair of suede boots that had been submerged in floodwater. Following this process, I was able to restore them to a wearable condition, albeit with some minor discoloration. Prevention is always better than cure, however, so proper waterproofing is strongly recommended.

Q 12. Explain the process of replacing a broken buckle.

Replacing a broken buckle is a straightforward process, though the specifics depend on the type of buckle and the shoe’s construction.

- Remove the Old Buckle: Carefully detach the old buckle from the strap. This may involve unscrewing, unclipping, or removing rivets, depending on the buckle’s design.

- Prepare the New Buckle: Ensure the new buckle is the correct size and style to match the existing hardware.

- Attach the New Buckle: Re-attach the new buckle using the appropriate method. This may involve screwing, clipping, or riveting. I often use small rivets or screws for a secure and professional finish.

- Inspect and Secure: After re-attaching the buckle, carefully inspect the strap to ensure the buckle is securely fastened and the strap isn’t damaged.

It’s important to have the right tools for this job. For example, rivets require a special rivet setter, and screws will need a small screwdriver. Choosing the correct tools ensures a clean and durable repair.

Q 13. Describe your experience with repairing orthopedic shoes.

Repairing orthopedic shoes requires a high degree of precision and attention to detail to ensure the shoe maintains its therapeutic function. The key is to preserve the shoe’s original structural integrity while addressing the damage.

My experience involves repairs ranging from replacing worn-out soles and heels to mending damaged straps and supports. I pay particular attention to the specific design elements and materials used in the orthopedic shoe, always ensuring that any modifications don’t compromise the shoe’s therapeutic properties. I often collaborate with orthotists or podiatrists to maintain the integrity of the customized support provided by the shoe.

For example, I recently repaired a custom-made diabetic shoe with a damaged sole. Using a specialized adhesive and careful stitching techniques, I was able to restore the shoe’s functionality and the patient’s comfort. It’s critical to prioritize both the aesthetic and functional aspects of the shoe in these repairs.

Q 14. What are the safety precautions you take during shoe repair?

Safety is paramount in shoe repair. I adhere to strict safety protocols to prevent injuries and protect both myself and the environment.

- Proper ventilation: I use a well-ventilated workspace, especially when working with solvents and adhesives that release harmful fumes. This prevents inhalation of toxic chemicals.

- Protective gear: I always wear appropriate safety glasses to protect my eyes from flying debris and particles. When working with sharp tools or chemicals, I also wear gloves to prevent cuts, burns, or skin irritation.

- Sharp tool handling: I handle all sharp tools with care and store them safely when not in use. This minimizes the risk of accidental cuts and injuries.

- Proper disposal of waste: I properly dispose of all waste materials, including adhesives, solvents, and sharp objects, in accordance with local regulations. This protects the environment and prevents accidental exposure.

- Ergonomic workspace: I maintain an ergonomically designed workspace to minimize strain and fatigue during prolonged periods of work. This reduces the risk of repetitive strain injuries.

Safety isn’t just a checklist; it’s an integral part of my daily routine. A safe and healthy workspace leads to better quality repairs and a more satisfying experience for both myself and my clients.

Q 15. How do you estimate the cost of a shoe repair job?

Estimating the cost of a shoe repair involves a multi-step process. First, I assess the damage, identifying the type of repair needed (e.g., sole replacement, heel repair, stitching). Next, I consider the materials required. Different materials – like leather, rubber, or specialized adhesives – have varying costs. The complexity of the repair is also a major factor. A simple heel replacement is quicker and less expensive than a complex resoling job involving stitching and multiple materials. Finally, I factor in my labor costs, which depend on my hourly rate and the estimated time needed. I usually explain this breakdown transparently to the customer, so they understand the pricing justification. For example, a simple heel tap might cost $15-$25, while a full sole replacement could range from $50 to $150+ depending on the shoe’s material and the type of sole used.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle difficult or demanding customers?

Handling difficult customers requires patience, empathy, and clear communication. I start by actively listening to their concerns, even if expressed angrily. I validate their feelings by acknowledging their frustration before offering solutions. For example, if a customer is upset about a delay, I apologize and explain the reasons, offering a realistic timeframe. Transparency is key – if a repair is beyond my capabilities, I’ll say so honestly, and offer recommendations for other professionals. I always strive to find a win-win solution, and focusing on the quality of my work helps to ease most concerns. Ultimately, the goal is to address the issue professionally and preserve the customer relationship, even if things don’t go perfectly.

Q 17. What are the common causes of heel wear and tear?

Heel wear and tear stem from several factors. The most common is simply repeated impact from walking. The type of surface walked on plays a significant role; uneven or hard surfaces accelerate wear. The shoe’s material also contributes; softer materials wear down more quickly than durable ones. Walking style affects heel wear; people with a pronounced heel strike often experience accelerated wear. Body weight is another factor; heavier individuals tend to see more heel wear. Finally, neglecting regular maintenance allows minor problems to escalate into major issues. Regular inspections and minor repairs can prevent premature heel deterioration.

Q 18. What tools are essential for effective shoe repair?

Essential tools for effective shoe repair vary based on the type of repair, but some are fundamental. These include various types of pliers (for removing and attaching parts), hammers (for setting nails or applying components), awls (for making holes), different sized needles and thread (for stitching), knives and blades (for cutting and trimming), clamps (for holding parts together during repairs), and a variety of adhesives appropriate for different materials. Specialized tools such as a stitching machine or heel-building tools are also valuable but not always essential for a smaller operation. Regular maintenance and sharpening of these tools are crucial to ensure precision and efficiency.

Q 19. What are some common issues with athletic shoe repairs?

Athletic shoe repairs present unique challenges. The materials are often synthetic and can be difficult to work with, requiring specialized adhesives. The intricate designs and construction of athletic shoes make repairs more complex. Common issues include sole separation, midsole breakdown, and damage to the upper material. Repairing the cushioning systems in running shoes is particularly demanding and might require specialized knowledge. Because of the technical nature, some repairs might not be economically feasible; a replacement might be the better option in such cases.

Q 20. Describe your experience with working with different types of soles (e.g., rubber, leather).

I have extensive experience working with various soles. Rubber soles are durable and widely used but require specific adhesives. Leather soles offer a classic look but need careful attention to prevent cracking and wear. The repair techniques differ significantly – leather soles often require stitching and careful application of edge paint, while rubber soles are better suited for gluing and minimal stitching. The choice of materials is critical; I always select soles matching the original quality and color to maintain the shoe’s aesthetic appeal. Over the years I’ve repaired everything from delicate dress shoes with leather soles to sturdy work boots with thick rubber soles, each requiring a unique approach and material selection.

Q 21. How do you maintain your tools and equipment?

Maintaining tools and equipment is essential for longevity and consistent quality. I regularly clean my tools after each use, removing any debris or adhesive residue. I sharpen blades and needles frequently to maintain precision. I store tools in an organized manner to prevent damage and to make them easily accessible. For specialized equipment like sewing machines, I follow manufacturer’s guidelines for maintenance and lubrication. Regular inspection for damage or wear is crucial; promptly addressing these issues helps extend the lifespan of my tools, resulting in higher efficiency and lower replacement costs.

Q 22. What are your strategies for marketing and attracting new clients to a shoe repair shop?

Marketing a shoe repair shop requires a multi-pronged approach focusing on both online and offline strategies. Think of it like crafting a bespoke shoe – each element needs careful consideration.

Local SEO Optimization: Ensure your Google My Business profile is complete and accurate, including high-quality photos of your work. Positive online reviews are crucial. Consider running targeted Google Ads campaigns focusing on keywords like ‘shoe repair near me’ or ‘cobbler [your city/town].’

Social Media Engagement: Platforms like Instagram and Facebook allow you to showcase your craftsmanship through visually appealing before-and-after photos and videos. Run contests and offer special promotions to boost engagement.

Community Partnerships: Collaborate with local dry cleaners, tailors, or even shoe stores. Offer discounts to their customers or participate in local events to increase brand visibility.

Loyalty Programs: Reward repeat customers with discounts or exclusive services. This cultivates customer loyalty and encourages word-of-mouth referrals.

Traditional Marketing: Flyers, local newspaper ads, and even a simple, well-placed signboard can still be highly effective in reaching potential customers.

For example, I once partnered with a local running store to offer a discount on repairs for their customers. This resulted in a significant increase in new clients and built a strong referral network.

Q 23. Describe your experience with shoe repair software or management systems.

My experience with shoe repair software is extensive. I’ve used several systems, ranging from simple inventory management programs to more sophisticated point-of-sale (POS) systems that integrate customer relationship management (CRM) features. A good system is essential for efficient operations.

I find that a system with features like:

- Inventory tracking: Managing materials (leather, soles, heels, etc.) and keeping track of stock levels.

- Customer order management: Tracking repair jobs, deadlines, and customer contact information.

- Appointment scheduling: Facilitating easy appointment booking and minimizing wait times.

- Reporting and analytics: Generating reports on sales, popular services, and inventory turnover.

is invaluable. For instance, I previously used a system that allowed me to generate a comprehensive report detailing my most profitable repair types, which helped me optimize my marketing efforts. Although I’m proficient in using various systems, I’m always open to exploring new technology that can improve efficiency and customer service.

Q 24. Explain your understanding of shoe construction techniques.

Understanding shoe construction is fundamental to successful shoe repair. It’s akin to knowing the anatomy of a human body before performing surgery. Different shoes have different constructions; understanding this is key to successful repair.

My expertise encompasses various techniques including:

Goodyear Welt Construction: This robust method features a welt stitch that joins the upper, insole, and outsole, allowing for resoling and other repairs. It’s a classic and durable construction.

Blake Stitch Construction: This construction involves stitching the upper directly to the insole, creating a lighter and more flexible shoe, but making resoling more challenging.

Cement Construction: This method uses adhesives to attach the upper to the outsole, a common construction in many modern shoes. Repairs can be more complex due to the reliance on adhesives.

Knowing the specific construction allows me to determine the best repair methods and materials, ensuring longevity and maintaining the shoe’s integrity.

Q 25. How do you ensure the longevity of your shoe repair work?

Ensuring longevity in my shoe repair work involves a combination of meticulous craftsmanship and material selection. It’s about building a repair that’s as durable, if not more so, than the original construction.

High-Quality Materials: I only use premium leather, soles, and adhesives to guarantee durability and prevent premature wear.

Precise Stitching: Careful and consistent stitching is crucial for strength and a professional finish. Think of it as the foundation of a sturdy house; a strong stitch is vital for longevity.

Proper Preparation: Thorough cleaning and preparation of the shoe before repair are essential to ensure proper adhesion and a lasting result.

Understanding the Customer’s Needs: Knowing how the customer uses their shoes informs repair decisions. A repair for a hiking boot will differ from a dress shoe repair.

For example, I always advise customers on proper shoe care to maximize the lifespan of their shoes, both before and after repair.

Q 26. What are the latest advancements in shoe repair technology?

The shoe repair industry, while traditional, is embracing modern technology in exciting ways.

3D Printing: Used to create custom replacement parts or even entire soles for specialized repairs.

Advanced Adhesives: New adhesives offer stronger bonds and faster curing times, improving repair efficiency.

Specialized Tools: Electric stitching machines, automated buffing systems, and precision measuring tools improve both speed and accuracy.

Digital Design & Scanning: Allows for precise replication of original parts or customization for intricate repairs.

While traditional hand skills remain essential, these advancements allow for greater precision, efficiency, and customization, ultimately benefiting both the repairer and the customer.

Q 27. How do you handle repairs that require specialized skills?

Handling repairs requiring specialized skills involves a multi-step approach.

Accurate Assessment: First, a thorough assessment of the damage is crucial to determine the required skills and materials.

Skill-Matching: If a repair is beyond my expertise, I have a network of skilled cobblers I can consult or refer the client to. Honesty and transparency are key here.

Continuing Education: I constantly update my skills through workshops, online courses, and attending industry events to stay current with the latest techniques.

Documentation and Research: For unfamiliar repairs, research and detailed documentation of the process are vital for achieving a successful outcome.

For instance, I once encountered a particularly complex repair involving antique shoe construction. I contacted a specialist cobbler who had expertise in that area, ensuring the client received the highest quality service.

Q 28. What are your strategies for managing a shoe repair shop’s workflow?

Efficient workflow management is the backbone of a successful shoe repair shop. It’s all about optimizing processes for maximum efficiency and customer satisfaction.

Organized System: A clear system for receiving, processing, and delivering repairs. This might include a ticketing system, a dedicated workspace for each stage of the repair process, and clear labeling.

Prioritization: Prioritizing urgent repairs and managing customer expectations effectively. Clear communication about turnaround times is essential.

Inventory Control: Efficient inventory management ensures that necessary materials are readily available. This minimizes delays and prevents lost time.

Teamwork (If Applicable): If you have a team, clear roles and responsibilities, and effective communication are crucial for smooth workflow.

I use a combination of a digital system for tracking orders and a physical workflow system in my shop. This ensures that repairs progress smoothly and deadlines are met efficiently.

Key Topics to Learn for Shoe Repair Trends Interview

- Sustainable Shoe Repair Practices: Understanding environmentally friendly materials and methods, including the use of recycled and biodegradable components. Practical application: Discussing your experience with eco-friendly repair techniques and their impact on the business.

- Technological Advancements in Shoe Repair: Familiarity with new tools, machinery, and repair techniques that improve efficiency and quality. Practical application: Explaining how you’ve adapted to or incorporated new technologies into your workflow.

- Specialized Shoe Repair Techniques: Mastery of repairing various shoe types (e.g., athletic shoes, leather boots, high heels) and materials (e.g., leather, suede, synthetics). Practical application: Detailing your expertise in specific repair methods and troubleshooting difficult repairs.

- Customer Service and Communication in Shoe Repair: Understanding the importance of effective communication with clients, handling complaints, and building rapport. Practical application: Describing a scenario where you successfully addressed a customer’s concern or provided exceptional service.

- Business Management Aspects of Shoe Repair: Knowledge of inventory management, pricing strategies, marketing techniques, and financial planning within a shoe repair business. Practical application: Discussing your experience with inventory control, pricing decisions, or marketing strategies.

- Health and Safety in Shoe Repair: Understanding and adhering to safety protocols and regulations related to using tools, chemicals, and handling materials. Practical application: Describing your experience with maintaining a safe and organized workspace.

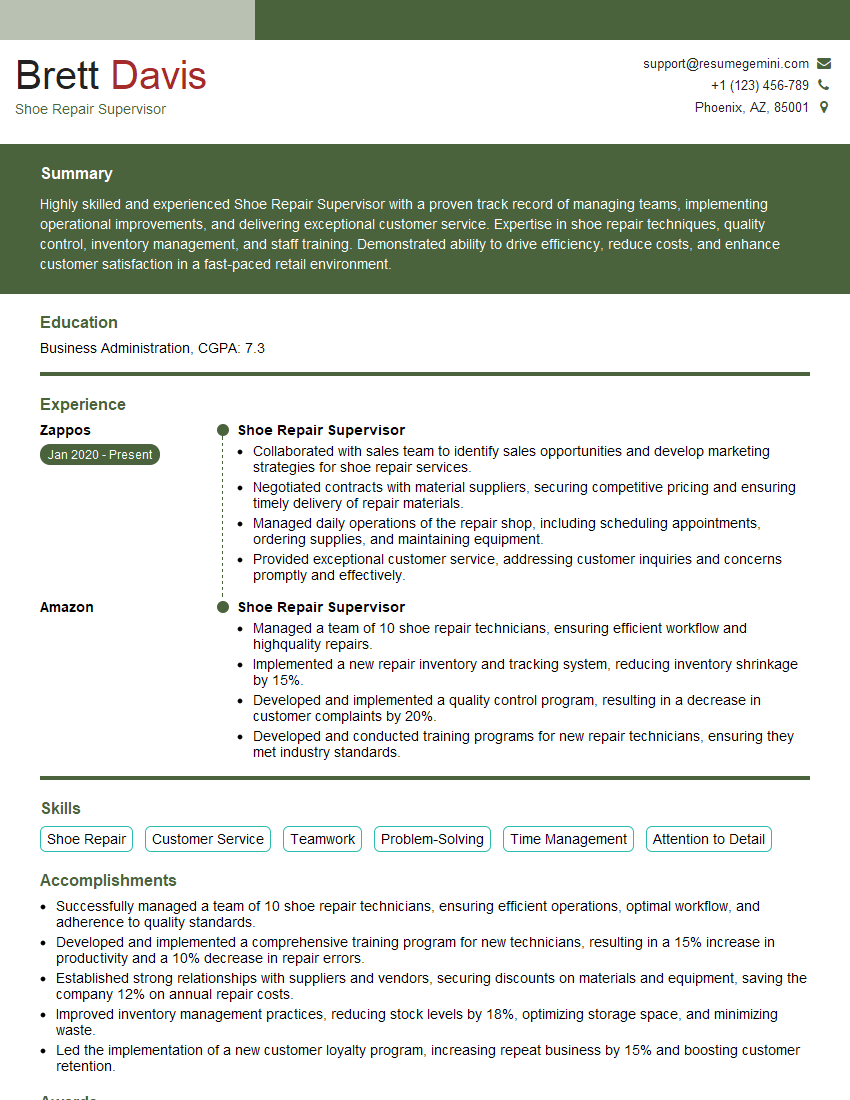

Next Steps

Mastering shoe repair trends is crucial for career advancement in this evolving industry. Demonstrating your knowledge of sustainable practices, new technologies, and effective business management will significantly improve your job prospects. To increase your chances of landing your dream role, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource for building professional resumes that highlight your skills and experience effectively. We provide examples of resumes tailored to the shoe repair industry to help you showcase your qualifications. Take advantage of these resources to craft a winning resume that grabs the attention of potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good