Preparation is the key to success in any interview. In this post, we’ll explore crucial Shuttle Pressing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Shuttle Pressing Interview

Q 1. Describe the operation of a shuttle pressing machine.

A shuttle pressing machine, also known as a clamshell press, is a specialized piece of equipment used in the textile industry for pressing and finishing fabrics. It operates by using two heated platens, often called shoes, that clamp down on the fabric with controlled pressure and temperature. A crucial component is the ‘shuttle,’ a moving platform or carriage that carries the fabric between the platens. The shuttle’s movement allows for even heat distribution across the entire fabric piece, preventing wrinkles and ensuring a consistent finish. Imagine it like a giant, heated sandwich maker, but instead of bread, we have fabric, and the ‘filling’ is evenly pressed by the heated plates through the precise movement of the shuttle.

The process typically involves loading the fabric onto the shuttle, setting the desired temperature and pressure, and then activating the machine. The shuttle moves back and forth, passing the fabric between the heated platens, ultimately delivering a smooth, wrinkle-free finish. The cycle completes when the shuttle returns to its original position, allowing for easy fabric removal.

Q 2. Explain the different types of shuttle pressing machines.

Shuttle pressing machines come in various types, categorized primarily by their size, automation level, and specific applications.

- Manual Shuttle Presses: These are smaller, simpler machines where the operator manually loads and unloads the fabric and controls the shuttle’s movement. They’re often used for smaller production runs or in tailoring shops.

- Semi-Automatic Shuttle Presses: These machines offer some automated features, such as automatic timing and pressure control, but still require operator intervention for loading and unloading. They increase efficiency compared to manual presses.

- Automatic Shuttle Presses: These are fully automated machines that handle the entire pressing cycle, from fabric loading and unloading to pressure and temperature control. They are suitable for large-scale production and can handle significant fabric volumes with high consistency.

- Specialized Shuttle Presses: Certain machines are designed for specific fabric types, like delicate silks or heavy-duty denim, with features tailored to their unique pressing requirements. For example, a machine designed for delicate fabrics might have gentler platen surfaces to prevent damage.

The choice of machine depends on production volume, fabric type, budget, and desired level of automation.

Q 3. What are the safety procedures for operating a shuttle pressing machine?

Safety is paramount when operating a shuttle pressing machine. Here’s a summary of essential safety procedures:

- Proper Training: Only trained and authorized personnel should operate the machine.

- Personal Protective Equipment (PPE): Always wear heat-resistant gloves, protective eyewear, and closed-toe shoes to prevent burns and injuries from moving parts.

- Machine Inspection: Before each use, inspect the machine for any damage or loose parts. Check the heating elements, shuttle mechanism, and pressure gauges for proper functioning.

- Lockout/Tagout Procedures: Implement lockout/tagout procedures during maintenance or repairs to prevent accidental activation.

- Clear Working Area: Keep the area around the machine clear of obstructions to prevent accidents. Fabric scraps should be removed promptly.

- Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button.

- Avoid Loose Clothing: Avoid wearing loose clothing or jewelry that could get caught in moving parts.

Following these procedures minimizes the risk of accidents and ensures a safe working environment. Regularly scheduled safety inspections and training reinforce these practices.

Q 4. How do you adjust the pressure and temperature on a shuttle pressing machine?

Adjusting pressure and temperature on a shuttle pressing machine depends on the specific machine model, but the general principles remain consistent. Most machines have control panels with dials or digital displays for setting these parameters.

Pressure Adjustment: The pressure is typically adjusted using a dial or digital interface, often expressed in pounds per square inch (psi) or kilopascals (kPa). The optimal pressure depends on the fabric type; delicate fabrics require lower pressure to avoid damage, while heavier fabrics need higher pressure for effective wrinkle removal. Incorrect pressure can lead to poor results, such as uneven pressing or fabric damage.

Temperature Adjustment: Temperature is adjusted similarly, using a dial or digital interface, typically in degrees Celsius or Fahrenheit. The appropriate temperature also varies based on the fabric type. Synthetics might require lower temperatures to prevent melting or scorching, while natural fibers may tolerate higher temperatures. Incorrect temperature can lead to scorching, discoloration, or inadequate wrinkle removal.

Many modern machines allow for pre-programmed settings for different fabric types, making the process easier and more consistent. Always consult the machine’s operating manual for detailed instructions on adjusting pressure and temperature. Trial runs with fabric swatches are recommended to find the perfect settings for each type of material.

Q 5. What are the common causes of malfunctions in shuttle pressing machines?

Malfunctions in shuttle pressing machines can stem from several sources:

- Heating Element Failure: Burnout or malfunction of heating elements can lead to inconsistent heating and poor pressing results. This is often indicated by uneven heating or failure to reach the set temperature.

- Shuttle Mechanism Problems: Issues with the shuttle’s movement, such as sticking, binding, or inconsistent travel, can cause uneven pressing or damage to the fabric. This might be due to mechanical wear or lubrication issues.

- Pressure Gauge Malfunction: An inaccurate pressure gauge can lead to inconsistent pressure and poor pressing results. Regular calibration is crucial.

- Electrical Problems: Faulty wiring, blown fuses, or other electrical issues can prevent the machine from functioning correctly. This can manifest as complete failure or inconsistent operation.

- Mechanical Wear and Tear: Over time, normal wear and tear on moving parts can lead to various malfunctions. Regular maintenance and lubrication are essential to prolong the machine’s lifespan.

Regular maintenance and preventative measures can minimize these issues and increase the machine’s operational lifespan.

Q 6. How do you troubleshoot common problems with shuttle pressing machines?

Troubleshooting shuttle pressing machine problems requires a systematic approach:

- Safety First: Always disconnect the power before attempting any repairs or inspections.

- Identify the Problem: Determine the specific problem; is it uneven heating, inconsistent pressure, or complete machine failure?

- Check Basic Things First: Ensure that the machine is properly plugged in, the power switch is on, and the appropriate settings are selected. This simple check often resolves minor issues.

- Visual Inspection: Carefully inspect the machine for any visible damage, loose connections, or obstructions. Look for signs of wear and tear in moving parts.

- Consult the Manual: Refer to the machine’s operating manual for troubleshooting guidance and diagrams. It often contains a section for diagnosing and fixing common issues.

- Check Heating Elements: Test the heating elements for continuity using a multimeter (if you have the appropriate skills and knowledge). This can help determine if a heating element has failed.

- Lubrication: Lubricate moving parts as needed according to the machine’s manual. Insufficient lubrication is a common cause of mechanical problems.

- Call for Service: If the problem persists, contact a qualified technician for professional assistance. Attempting complex repairs without proper training can be dangerous and may cause further damage.

A methodical approach to troubleshooting minimizes downtime and ensures the machine’s continued safe and efficient operation.

Q 7. Describe your experience with different fabrics and their pressing requirements.

My experience with various fabrics and their pressing requirements is extensive. I’ve worked with a wide range of materials, each demanding a specific approach to ensure a high-quality finish without causing damage.

Delicate Fabrics (Silk, Lace, Rayon): These require low temperature and pressure settings. Using a press cloth is crucial to prevent scorching or shine. I often use a low-pressure, steam-based pressing method for these delicate fabrics.

Natural Fibers (Cotton, Linen, Wool): These fabrics generally tolerate higher temperatures and pressures, but the specifics depend on the weave and weight of the fabric. For example, heavy linen might require higher pressure to remove creases, while a finer cotton might need less. I adjust temperatures to accommodate the moisture content of the material to prevent shrinkage.

Synthetic Fabrics (Polyester, Nylon): Synthetic fabrics often require lower temperatures than natural fibers to prevent melting or scorching. I usually use a lower temperature setting with moderate pressure and a press cloth. I pay close attention to not applying too much pressure for prolonged periods.

Specialty Fabrics (Leather, Suede): These require specialized techniques and may not be suitable for all shuttle pressing machines. Leather, for instance, might require a specific low-heat, soft-press approach to avoid cracking or discoloration. Suede should never be directly pressed with heat.

Throughout my career, I’ve learned the importance of understanding fabric composition and weave to select the appropriate pressing parameters. This knowledge, coupled with experience, helps me achieve consistent, high-quality results without damaging the fabric.

Q 8. Explain the importance of proper fabric handling in shuttle pressing.

Proper fabric handling is paramount in shuttle pressing because it directly impacts the final product’s quality and appearance. Different fabrics react differently to heat and pressure. Handling them incorrectly can lead to scorching, uneven pressing, or even damage to the fabric itself. Think of it like baking a cake – you wouldn’t use the same technique for a delicate sponge cake as you would for a sturdy fruitcake.

- Delicate Fabrics: Silks, satins, and other delicate materials require a gentler touch. They should be pressed with lower temperatures and potentially using a pressing cloth to prevent direct heat contact. I always prioritize a test press on a hidden seam before pressing the entire garment.

- Heavy Fabrics: Denim, wool, and other heavy fabrics can withstand higher temperatures and pressures. However, even with these fabrics, paying attention to the grain and avoiding harsh pulling is essential to prevent distortion.

- Fabric Composition: Understanding the fiber content of the fabric (e.g., cotton, linen, polyester blends) is key to selecting the appropriate pressing temperature and pressure. Synthetic materials can melt under excessive heat, whereas natural fabrics might wrinkle or scorch.

For example, I once had a client who provided a beautiful silk blouse. Using the wrong temperature and pressure would have resulted in irreversible damage. Instead, I carefully selected a low temperature, used a pressing cloth, and pressed the fabric in small sections, paying attention to its drape.

Q 9. How do you identify and correct pressing defects?

Identifying and correcting pressing defects requires a keen eye for detail and a methodical approach. The most common defects include wrinkles, creases, shine marks, scorching, and uneven pressing. It’s like being a detective for fabric!

- Wrinkles and Creases: These usually indicate insufficient heat or pressure. The solution is to increase the temperature or pressure accordingly, using a damp pressing cloth if needed.

- Shine Marks (Press Marks): These glossy areas appear due to excessive heat and pressure. To correct this, use a lower temperature, a pressing cloth, or a different pressing technique, such as pressing from the wrong side of the fabric.

- Scorching: This is caused by excessively high temperatures. It’s irreversible and indicates a need to adjust the machine settings. Always test on a hidden seam first!

- Uneven Pressing: This often results from inconsistent pressure application or poor fabric handling. Carefully check the machine’s pressure settings and ensure even pressure across the fabric surface.

For instance, if I see shine marks on a wool garment after pressing, I immediately lower the temperature and switch to using a press cloth, re-pressing the affected areas until the shine is gone. It is important to identify the root cause to prevent the same mistake from happening again.

Q 10. What are the quality control checks you perform during shuttle pressing?

Quality control in shuttle pressing is a multi-step process that aims to ensure the final product meets the highest standards. It starts before the pressing even begins and continues throughout the process.

- Pre-Pressing Inspection: I meticulously examine the garment for any pre-existing defects or imperfections. This helps determine the appropriate pressing technique.

- During Pressing: I constantly monitor the machine’s settings (temperature, pressure, time) and ensure that the fabric is handled correctly.

- Post-Pressing Inspection: After pressing, I carefully inspect the garment for any defects, ensuring it’s wrinkle-free, properly shaped, and free from shine marks or scorching. I pay particular attention to sensitive areas like collars, cuffs, and seams.

- Documentation: I maintain detailed records of the pressing parameters for each job, including fabric type, temperature, pressure, and any special instructions.

This detailed approach ensures consistent quality and helps identify areas needing improvement in the overall process.

Q 11. How do you maintain the cleanliness and hygiene of the shuttle pressing machine?

Maintaining cleanliness and hygiene in the shuttle pressing machine is crucial for preventing fabric damage and ensuring the longevity of the equipment. Just as a chef keeps their kitchen spotless, a shuttle press operator must maintain a clean workspace.

- Regular Cleaning: I regularly clean the pressing surface with a soft cloth and a specialized cleaning solution designed for the machine’s material. This removes any residue from fabrics, preventing staining and discoloration.

- Preventative Maintenance: I regularly check the machine for any signs of wear or tear and report any issues promptly. This ensures the smooth and safe operation of the machine.

- Proper Disposal: I ensure all cleaning solutions are disposed of properly according to safety regulations.

Neglecting machine hygiene can lead to issues like fabric staining, reduced machine efficiency, and even equipment damage, so I treat it as a high priority.

Q 12. What is your experience with different pressing techniques?

My experience encompasses a wide range of pressing techniques tailored to different fabric types and garment styles. I’m proficient in various methods, including:

- Blocking: Used for shaping structured garments like jackets and coats.

- Pleating: Requires precision to create crisp and even pleats.

- Seam Pressing: Essential for creating smooth, flat seams.

- Tailor’s Clapper: A tool I use to set and shape seams and darts.

I constantly adapt my technique based on the fabric’s requirements. For example, I use a pressing cloth for delicate silks to prevent scorching. For heavier fabrics, I use a more aggressive approach to ensure sharp creases.

Q 13. Describe your experience with high-speed shuttle pressing machines.

I have extensive experience operating high-speed shuttle pressing machines. These machines offer significant advantages in terms of productivity, but they also demand a higher level of skill and precision. The increased speed requires careful monitoring to avoid pressing defects and potential safety hazards.

- Safety Precautions: Operating high-speed machines mandates strict adherence to safety protocols. Before operating, I thoroughly inspect the machine’s functionality. I always use appropriate safety gear.

- Precision and Control: High-speed machines require precise control over temperature, pressure, and time. To get consistent results, I need to maintain close monitoring and make minute adjustments.

- Maintenance: High-speed machines demand more frequent maintenance to ensure their optimal performance and longevity. I follow the manufacturer’s recommendations and conduct regular cleaning.

One particular project involved pressing hundreds of shirts for a major retailer. Using a high-speed machine allowed me to complete the task swiftly and efficiently, while maintaining the highest standards of quality.

Q 14. How do you ensure consistent pressing results?

Consistency in shuttle pressing is achieved through a combination of factors, including precise machine settings, proper fabric handling, and a thorough understanding of different fabrics and their behaviors.

- Consistent Machine Settings: I carefully calibrate the machine’s temperature and pressure settings based on the fabric type, ensuring that these settings remain consistent throughout the pressing process. I frequently check and readjust these parameters to maintain consistency.

- Standardized Procedures: I adhere to established pressing procedures to maintain uniformity in the handling and pressing techniques. This prevents inconsistencies.

- Regular Calibration and Maintenance: Regular maintenance ensures the machine operates efficiently, reducing variations in the pressing process. Calibration keeps the parameters stable.

- Operator Skill: Experience and expertise play a vital role in achieving consistent results. My years of experience provide me with the knowledge and skill to recognize and resolve any inconsistencies.

By maintaining these standards, I ensure that every garment receives the same level of quality pressing, leading to a consistent and high-quality final product. This contributes to customer satisfaction and reduces waste from rework.

Q 15. Explain your understanding of pressing parameters and their impact on fabric.

Pressing parameters are the settings on a shuttle pressing machine that control the amount of pressure, temperature, and time applied to the fabric. These parameters significantly impact the final look and feel of the garment. For instance, insufficient pressure might leave wrinkles, while excessive pressure could damage delicate fabrics. High temperatures are needed for certain fabrics to remove creases effectively, but excessive heat can scorch or discolor them. The duration of pressing also plays a critical role; too little time won’t fully remove wrinkles, and too much can lead to over-pressing.

- Pressure: Measured in PSI (pounds per square inch), pressure needs to be adjusted depending on the fabric weight and type. Heavier fabrics like denim require higher pressure than lightweight silks.

- Temperature: Measured in degrees Fahrenheit or Celsius, temperature settings should align with fabric composition. Synthetics typically require lower temperatures to prevent melting, while natural fibers like cotton may need higher heat for optimal results.

- Time: The duration of pressing needs to be optimized to allow for crease removal without causing damage. This is often determined through experience and understanding of different fabric types.

For example, pressing a crisp cotton shirt requires a higher pressure and temperature than a delicate silk blouse. If I were pressing a silk blouse, I would use lower pressure, a moderate temperature, and a shorter pressing time to avoid shine or damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of pressing accessories?

My experience encompasses a wide range of pressing accessories, all crucial for achieving professional results on various garments. These accessories are carefully chosen based on the fabric type and the desired finishing effect.

- Pressing Cloths: I’m proficient in using various pressing cloths, such as cotton, linen, and Teflon-coated cloths. Cotton cloths are versatile for most fabrics, while linen helps to reduce shine on certain materials. Teflon-coated cloths are perfect for preventing shine and sticking on delicate or synthetic fabrics.

- Pressing Hammers and Blocks: I’m adept at using pressing hammers for sharp creases on trousers and sleeves, and various-shaped pressing blocks for more delicate areas. These tools provide even pressure distribution and help achieve precise finishing.

- Sleeve Boards and Tailoring Ham: I’m experienced in using these specialized tools for shaping and pressing sleeves and curved garment sections. These prevent unwanted creases and help to achieve a smooth, professional finish.

For instance, I would use a tailor’s ham for pressing darts and curves on a jacket, ensuring a smooth, three-dimensional shape. Using a pressing cloth is essential to avoid direct heat contact on most fabrics, protecting them from scorching.

Q 17. How do you handle different types of garments during shuttle pressing?

Handling different garment types during shuttle pressing involves understanding the specific needs of each fabric and garment construction. The process requires careful consideration to avoid damaging delicate materials or causing unwanted creases.

- Delicate Fabrics: For delicate materials such as silk, lace, or chiffon, I use low pressure, moderate temperatures, and a pressing cloth. I may also use a pressing ham or tailor’s cushion to support curved areas.

- Heavy Fabrics: For heavy fabrics such as denim or wool, I use higher pressure and temperature, ensuring the pressing time is adequate to remove wrinkles thoroughly. I often pre-steam these fabrics before pressing to relax the fibers and achieve a better finishing result.

- Structured Garments: Garments with interfacings or structured components require careful manipulation to avoid warping or distorting their shape. I use specialized pressing tools such as pressing blocks and tailor’s ham to support and shape these areas.

For example, when pressing a suit jacket, I would use a tailor’s ham to support the curves of the shoulders and lapels, while using pressing blocks to precisely press the collars and pockets, ensuring crisp edges.

Q 18. Describe your experience with automated shuttle pressing systems.

My experience with automated shuttle pressing systems includes operating and maintaining several high-tech machines. These systems offer significant advantages in terms of speed, consistency, and efficiency.

- Increased Productivity: Automated systems allow for significantly higher throughput compared to manual pressing, resulting in increased production output.

- Consistent Quality: Automated systems apply consistent pressure, temperature, and time to each garment, leading to more uniform results compared to manual pressing.

- Reduced Operator Fatigue: Automation minimizes physical strain on the operator, reducing the risk of repetitive strain injuries.

However, understanding the limitations of automated systems is equally vital. While efficient for large-scale production, automated systems may not be as adaptable to intricate or highly customized garments. Troubleshooting technical issues requires specialized knowledge.

Q 19. What is your experience with maintaining production targets in shuttle pressing?

Maintaining production targets in shuttle pressing necessitates a combination of efficient work practices, effective time management, and proactive problem-solving.

- Efficient Workflow: I optimize my workflow by pre-sorting garments according to fabric type, allowing for efficient parameter adjustments. Minimizing downtime through proactive maintenance is also critical.

- Time Management: I monitor production progress regularly, identifying potential bottlenecks early. If I fall behind schedule, I prioritize urgent orders and identify areas where I can improve my efficiency.

- Proactive Problem-Solving: I anticipate potential issues, such as machine malfunctions or fabric-related challenges, and promptly address them to minimize downtime and maintain production flow.

For example, if a machine malfunction causes a delay, I quickly notify the maintenance team and prioritize completing easier tasks while waiting for repairs. Careful planning of breaks also helps maintain a consistent pace throughout the day.

Q 20. Explain your understanding of productivity and efficiency in shuttle pressing.

Productivity and efficiency in shuttle pressing are interconnected. Productivity refers to the output, measured in the number of garments pressed per hour or day. Efficiency, on the other hand, focuses on optimizing resources to maximize output while minimizing waste (e.g., time, energy, and materials). Both are crucial for successful operation.

- Optimizing Parameters: Selecting appropriate pressing parameters (pressure, temperature, time) for each fabric type ensures quick and effective crease removal, maximizing productivity without compromising quality.

- Efficient Machine Utilization: Minimizing downtime through regular maintenance and prompt troubleshooting ensures that the equipment is consistently operational, maximizing efficiency.

- Ergonomic Practices: Maintaining proper posture and using appropriate tools prevents fatigue and improves efficiency, ensuring consistent and high-quality work throughout the day.

For example, using an automated system improves productivity by increasing the number of garments pressed per hour. However, ensuring the system is properly maintained and operated efficiently is vital to maximizing its effectiveness.

Q 21. How do you prioritize tasks when working with a shuttle pressing machine?

Prioritizing tasks in shuttle pressing involves a structured approach that combines urgency, complexity, and fabric type. This ensures efficient workflow and avoids compromising the quality of the final product.

- Urgency: Orders with tight deadlines are prioritized first. This requires effective communication with the production team to understand deadlines and potential bottlenecks.

- Complexity: Garments requiring more intricate pressing techniques (e.g., structured jackets, delicate fabrics) may require more time and are often prioritized based on their complexity and potential for damage if rushed.

- Fabric Type: Certain fabrics require specific parameters and processes. Grouping similar fabrics can streamline the process, making the workflow more efficient.

I typically use a combination of Kanban boards (visual representation of work progress) and prioritized task lists. This helps me keep track of the urgent orders while ensuring that all tasks are completed with the necessary care and attention.

Q 22. What are your strategies for handling urgent pressing requirements?

Handling urgent pressing requirements in shuttle pressing involves prioritizing tasks effectively and optimizing the machine’s capabilities. My strategy focuses on a three-pronged approach: Prioritization, Efficiency, and Communication.

Prioritization: I assess the urgency of each order, identifying those with the tightest deadlines. This allows me to strategically sequence jobs to maximize throughput and meet critical deadlines. For instance, if I receive an urgent rush order for a high-profile client, I’ll immediately adjust the production schedule, potentially temporarily delaying less critical orders, while keeping all stakeholders informed.

Efficiency: I ensure the machine is optimally set up for each job, minimizing changeover times between different fabric types and pressing requirements. This involves pre-planning, ensuring all necessary materials and settings are ready before starting the job. I also meticulously maintain the machine to prevent downtime.

Communication: Open and constant communication with supervisors and colleagues is crucial. I’ll promptly inform them of any potential delays or unexpected issues, allowing for proactive problem-solving and adjustments to the schedule. This proactive approach prevents minor issues from escalating into major production bottlenecks.

Q 23. How do you ensure smooth operation of the shuttle pressing machine?

Ensuring smooth operation of a shuttle pressing machine requires a proactive approach focusing on preventative maintenance, diligent operation, and consistent monitoring. I follow a comprehensive checklist that includes:

Daily Checks: Before each shift, I meticulously inspect the machine for any loose parts, oil leaks, or signs of wear and tear. This includes checking the steam pressure, temperature settings, and the overall condition of the pressing surface.

Regular Maintenance: I follow the manufacturer’s recommended maintenance schedule, including regular cleaning, lubrication, and replacement of worn parts. I maintain detailed records of all maintenance activities.

Troubleshooting: I’m proficient in identifying and resolving common machine malfunctions. My experience allows me to quickly diagnose problems and implement effective solutions, minimizing downtime. For example, I know how to identify the cause of uneven pressing by checking the pressure plates and adjusting the steam settings accordingly.

Operator Skill: I am adept at adjusting the machine settings to accommodate different fabric types and thicknesses, ensuring consistent and high-quality results. This includes understanding the impact of temperature, pressure, and steam settings on the final product.

Q 24. Describe your experience working in a team environment.

I thrive in team environments. In my previous role, I was part of a team responsible for meeting demanding production quotas. We collaborated closely, sharing best practices and supporting each other during peak periods. For instance, when one team member faced a machine malfunction, the rest of the team pitched in to assist, ensuring minimal disruption to the overall workflow. My communication skills and collaborative spirit are assets to any team.

Q 25. How do you handle workplace pressure in a fast-paced environment?

Fast-paced environments are where I excel. My ability to remain calm under pressure, prioritize tasks effectively, and maintain focus allows me to consistently deliver high-quality results, even during peak periods. I find that a structured approach, combined with breaks for mental rejuvenation, helps me manage stress effectively. When I feel the pressure mounting, I take short breaks to refocus and strategize, ensuring I approach each task with clarity and precision.

Q 26. What are your strengths and weaknesses as a shuttle pressing operator?

My strengths as a shuttle pressing operator include my proficiency in machine operation, my attention to detail, and my ability to consistently produce high-quality results. I am also a quick learner and adept at adapting to new technologies and processes. A weakness I am actively working on is delegating tasks more effectively in team settings. While I enjoy taking ownership, I recognize the value of teamwork and am actively developing my skills in this area.

Q 27. What are your salary expectations for this role?

Based on my experience and the requirements of this role, my salary expectation is in the range of [Insert Salary Range] annually. I am open to discussing this further based on the complete compensation package and benefits offered.

Q 28. Why are you interested in this shuttle pressing position?

I am highly interested in this shuttle pressing position because it offers an opportunity to leverage my expertise and experience in a challenging and rewarding environment. I am particularly drawn to [Mention specific aspects of the company or role that appeal to you, e.g., the company’s reputation for quality, the opportunity to work with advanced equipment, the potential for professional development]. I believe my skills and work ethic align perfectly with your company’s values and the demands of this role, and I am confident I can make a significant contribution to your team.

Key Topics to Learn for Shuttle Pressing Interview

- Shuttle Pressing Machine Operation: Understanding the mechanical components, control systems, and safety protocols of various shuttle pressing machines.

- Fabric Handling and Preparation: Mastering techniques for efficient fabric feeding, alignment, and tension control to optimize pressing results.

- Pressing Techniques and Parameters: Learning to adjust pressure, temperature, and time settings according to fabric type and desired finish. This includes understanding the impact of these parameters on fabric quality.

- Quality Control and Troubleshooting: Identifying and resolving common pressing defects, such as wrinkles, creases, and scorching. Implementing quality checks throughout the pressing process.

- Maintenance and Cleaning: Understanding routine maintenance procedures, including cleaning, lubrication, and minor repairs, to ensure optimal machine performance and longevity.

- Production Efficiency and Optimization: Strategies for maximizing output while maintaining high quality standards, including workflow optimization and time management.

- Safety Regulations and Procedures: Adhering to all relevant safety regulations and best practices to prevent accidents and injuries.

- Understanding Different Fabric Types and their Pressing Requirements: Knowledge of various fabrics (e.g., cotton, silk, linen) and their unique pressing needs.

Next Steps

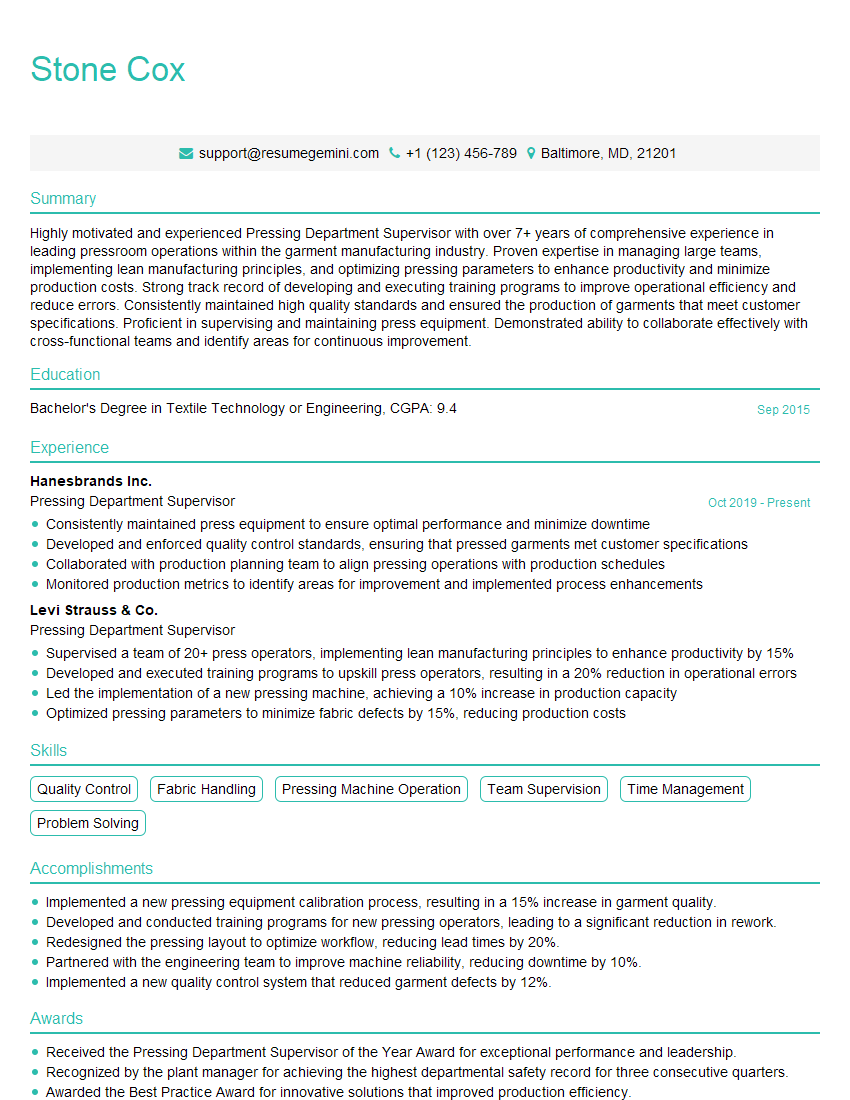

Mastering shuttle pressing opens doors to rewarding careers in the textile and garment industries, offering opportunities for advancement and specialization. To significantly boost your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to highlight your shuttle pressing skills and experience. Examples of resumes tailored to the Shuttle Pressing field are available to guide you. Take advantage of these resources to present your qualifications in the best possible light and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good