Are you ready to stand out in your next interview? Understanding and preparing for Skilled in using various fur cutting, sewing, and finishing tools interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Skilled in using various fur cutting, sewing, and finishing tools Interview

Q 1. What types of fur cutting tools are you proficient with?

Proficiency in fur cutting demands a nuanced understanding of the material. My toolkit includes a variety of specialized shears, each suited for different tasks. I use sharp, fine-bladed shears for intricate detail work, like shaping cuffs or creating precise seam allowances. For heavier cuts and larger pieces, I rely on strong, longer shears that offer better leverage and control. I also utilize electric shears for faster, more consistent cutting, particularly when working with large quantities of pelts. Finally, a good quality rotary cutter with a specialized fur blade is invaluable for cutting patterns on multiple layers efficiently. Regular sharpening and maintenance of all my tools is crucial to maintain clean cuts and prevent damage to the delicate fur.

Q 2. Describe your experience with various fur sewing techniques.

Fur sewing demands a different approach than traditional fabric sewing. I’m experienced with several techniques. Hand sewing with specialized curved needles allows for precise placement and control, especially beneficial for intricate details or repairs. Machine sewing, using a walking foot attachment to prevent slippage and a specialized fur needle, is employed for speed and efficiency on larger areas. The choice depends on the fur type and garment design. For example, I would typically hand-sew delicate mink detailing while machine sewing larger sections of a fox coat. I also frequently utilize invisible stitching techniques to ensure the seams are discreet and visually appealing on the finished garment. The success of any fur sewing project hinges upon careful tension adjustments to avoid puckering or tearing.

Q 3. What are the common finishing techniques used in fur garment making?

Finishing techniques are critical for creating a high-quality fur garment. Seaming, as previously discussed, must be neat and strong. Edge finishing is crucial to prevent fraying and maintain the fur’s integrity. This often involves techniques like binding or overcasting with a thread that closely matches the fur color. Cleaning and grooming after assembly is essential to restore the fur’s natural luster and remove any loose hairs. Finally, lining and interlining add structure and comfort, protecting the delicate fur. The choice of finishing technique depends on factors such as the type of fur, garment style, and desired aesthetic. For instance, a luxurious mink coat might require meticulous hand finishing, while a more casual rabbit-fur garment might be finished using more efficient machine techniques.

Q 4. How do you select appropriate fur for a specific garment?

Selecting appropriate fur is a critical step. I consider several factors: the type of fur (mink for luxury, fox for boldness, rabbit for a softer feel), the quality and density of the fur (lustrous and full is preferred), and the intended garment (a heavy coat versus a lighter vest). For a formal evening coat, I might select premium quality, dark-colored mink. For a casual winter jacket, I might opt for a durable and more affordable rabbit fur. The color and pattern of the fur also play a significant role in the overall aesthetic of the finished garment. Careful examination of the pelt for any imperfections is equally essential.

Q 5. Explain your process for pattern making with fur.

Pattern making for fur differs significantly from traditional fabric pattern making. Unlike fabric which drapes easily, fur has a distinct direction and stiffness. I start with a basic muslin pattern, adjusting it to accommodate the fur’s thickness and nap (the direction of the hair). Grainlines are crucial; cutting against the grain can lead to distortion. I often create multiple pattern pieces to accommodate this, ensuring that the pattern follows the natural direction of the fur. Test fitting on a dress form is essential to make further adjustments before cutting into the precious fur. This iterative process is critical to ensuring a perfect fit and the smooth flow of the fur’s nap.

Q 6. How do you handle different fur types, such as mink, fox, and rabbit?

Each fur type presents unique challenges. Mink is luxurious but delicate; it requires careful handling and precise stitching to avoid damage. Fox is thicker and more durable, allowing for more freedom in design. Rabbit is lighter and softer, often used for linings or less structured garments. Understanding the characteristics of each fur type—its thickness, softness, and drape—guides my choice of tools and techniques. For instance, I’d use a thinner needle for mink and a stronger one for fox. The way I handle each type also changes; fox might tolerate more aggressive stretching during shaping while mink requires a gentler approach.

Q 7. What are the challenges in working with delicate furs?

Delicate furs like mink and sable pose several challenges. They are prone to shedding if mishandled, requiring extra care during cutting and sewing. The fur can easily be damaged by sharp objects or excessive pressure, demanding patience and precision. Maintaining the integrity of the nap is also critical, as improperly handled fur can appear dull or matted. The high cost of these furs necessitates meticulous planning and extra attention to detail throughout the entire process. Experience and a light touch are essential for working with these materials effectively.

Q 8. Describe your experience with fur stretching and blocking techniques.

Fur stretching and blocking are crucial for achieving the desired shape and drape in a garment. Think of it like tailoring a suit – you need to manipulate the fabric to fit perfectly. Stretching involves carefully expanding the fur to remove wrinkles or creases, while blocking involves shaping the fur to a specific pattern or mold. This is often done using specialized stretching frames and steam.

For example, if a fur pelt is naturally curved, I might use a stretching frame to gently pull it flat. The frame provides even tension, preventing damage. I would carefully monitor the stretching process, ensuring that I don’t overstretch the fur which could cause damage to the hair or the leather. Once stretched, I might use a blocking technique to set the desired shape and create a flawless base for sewing.

Blocking is done differently based on the type of fur, and the final garment shape. For a collar, for instance, I might use a curved form, pinning and steaming the fur to retain its shape. For larger garments, like a coat, a full-sized tailor’s dummy, or custom-built forms might be used, to ensure proper shaping and consistency.

Q 9. How do you ensure the longevity and durability of a fur garment?

Ensuring the longevity and durability of a fur garment requires meticulous care at every stage, from selection of materials to proper storage. Firstly, selecting high-quality pelts with healthy, dense fur is paramount. Secondly, proper sewing techniques are crucial; avoiding stress points by using appropriate seam allowances and reinforcement where needed. For example, I always reinforce seams in high-stress areas such as shoulders and cuffs.

Beyond construction, proper storage plays a vital role. Fur should be stored in a cool, dry, and dark place, ideally in a breathable garment bag. Avoid exposure to direct sunlight, heat, or moisture as these can damage the fur and leather. Regular professional cleaning and conditioning will also help to maintain the fur’s luster and suppleness. Finally, avoiding harsh chemicals and rough handling goes a long way.

Think of it like caring for fine leather – regular care and attention dramatically increase its lifespan. A well-maintained fur garment can last for decades, becoming a treasured heirloom.

Q 10. What are the common problems encountered during fur sewing and how do you resolve them?

Common problems during fur sewing include slippage of the fur, needle breakage, and uneven stitching. Fur slippage happens because of the inherent slipperiness of the pelts. To address this, I use specialized fur needles and sewing techniques, such as using small, even stitches and carefully managing the tension. Sometimes, using a slightly sticky backing (such as a lightweight interfacing) on the wrong side of the fur can provide better control during stitching.

Needle breakage can occur due to using incorrect needles or excessive pressure. I always use needles specifically designed for fur and maintain a gentle touch to avoid breakage. Uneven stitching often results from inconsistent tension or pulling the fur during the sewing process. Slow, controlled stitching is key to achieving uniform and beautiful seams.

Resolving these issues requires experience and attention to detail. Recognizing the signs, for example, a slightly loose stitch indicates tension needs adjusting, helps to prevent bigger problems later on.

Q 11. Explain your understanding of fur grading and sizing.

Fur grading and sizing is a crucial part of pattern making and garment construction. It involves adjusting the size and shape of fur pelts to match the pattern pieces. Because fur pelts are not uniform, unlike woven fabrics, you often need multiple pelts to achieve a desired size and shape for the final garment. Grading involves carefully assessing the pelt’s dimensions and marking cutting lines to accommodate the pattern.

For example, let’s say I’m making a fur coat. I might need to grade several smaller pelts to create a larger sleeve panel. This may involve matching the nap, or the direction of the hair. Proper grading ensures that the final garment will fit correctly and that the fur flows smoothly. Incorrect grading can lead to ill-fitting, awkward-looking garments.

The sizing aspect ensures that the final piece is accurately sized according to the customer’s measurements. This requires a thorough understanding of the fur’s properties and the ability to manipulate it to achieve the desired dimensions.

Q 12. How do you maintain the quality and appearance of finished fur products?

Maintaining the quality and appearance of finished fur products requires careful handling and storage. After sewing, I always inspect the garment for any loose threads or imperfections. Professional cleaning is essential to remove dirt and debris, preserving its luster. Ideally, this should be done by a specialist familiar with fur care. I advise my clients on proper storage, emphasizing the importance of cool, dry conditions, away from direct sunlight and heat.

Regular brushing can help to remove loose fur and maintain the overall texture. For example, a soft brush can be used to gently groom the fur in the direction of the nap. Also, periodic conditioning can help keep the leather supple and prevent dryness or cracking. Think of this as applying moisturizer to skin.

By following these simple maintenance steps, the beauty and longevity of the fur garment can be preserved for years to come.

Q 13. What safety precautions do you take while working with fur cutting tools?

Safety is paramount when working with fur cutting tools. Sharp blades, like those in rotary cutters, shears and knives, demand respect and careful handling. I always use a self-healing cutting mat to protect my work surface and prevent blade damage. Shears are kept sharp, which reduces the force needed to cut, thereby reducing the chance of accidental slips and cuts.

Safety glasses protect my eyes from flying fur or debris, while sharp blades are stored safely when not in use. Always, I cut away from myself and maintain a clear work area. Using the appropriate tool for the task also dramatically reduces the risk of accidents. For example, I would never use a utility knife for trimming fine fur details.

Proper training and a conscientious approach are crucial for maintaining a safe working environment. Safety isn’t just about avoiding injury; it’s about making sure the work is done efficiently and without compromise to quality.

Q 14. Describe your experience with different types of fur sewing machines.

My experience encompasses various types of fur sewing machines, ranging from industrial walking foot machines to specialized fur sewing machines with adjustable stitch length and tension. Industrial walking foot machines are excellent for heavier fabrics and larger fur pieces. The walking foot feeds the material evenly, preventing slippage. Specialized fur machines, often equipped with micro-adjustable settings, provide greater control and precision for intricate work.

Each machine type has its strengths and weaknesses. For example, a specialized fur machine may be better suited for delicate fur types or when creating intricate seams, offering fine control over stitch length and tension. Industrial walking foot machines are robust and excel in handling thicker pelts, however, might lack the finesse for more delicate fabrics. The choice often depends on the project and type of fur.

Understanding the capabilities of different machines and choosing the most appropriate tool for the task is essential for efficiency and high-quality results. I can easily adapt to various machines and tailor my sewing techniques accordingly. Having a grasp on the nuances of different machines is a critical skill for a furrier.

Q 15. How do you repair common damages in fur garments (e.g., tears, worn areas)?

Repairing fur garments requires precision and a deep understanding of the fur’s structure. Tears, for instance, need careful stitching to match the nap (the direction of the fur). I start by assessing the damage, determining the best method for repair based on the size and location of the tear. For small tears, I use a fine needle and thread that closely matches the fur’s color, meticulously stitching the edges together, ensuring the stitches are almost invisible. For larger tears, I might use a fur patch, carefully blending it into the surrounding fur to create a seamless repair. Worn areas usually require patching, too, but might also be addressed by using a specialized fur filling material to restore the loft and thickness. Consider, for example, repairing a small tear on a fox fur collar – I’d use a near-invisible stitch, ensuring the nap direction flows consistently across the repair. A larger tear on a mink coat might require a small patch taken from an inconspicuous area, carefully blended for an imperceptible fix.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different fur dyeing techniques?

My experience encompasses a range of fur dyeing techniques, from traditional methods to modern innovations. I’m proficient in both dip dyeing, where the entire garment is submerged in dye, and spray dyeing, which allows for more nuanced color application. I also have experience with techniques like tipping (dyeing the tips of the fur), which can create highlights and depth. Each technique requires careful consideration of the fur type; for example, delicate furs like chinchilla require gentler methods than more robust furs like mink. Choosing the right dye is crucial; I always ensure compatibility with the specific fur to prevent damage or discoloration. One interesting project involved creating a unique ombre effect on a fox stole using a combination of spray dyeing and hand painting. This required meticulous layering and blending to achieve the desired gradient.

Q 17. How do you ensure consistent quality throughout the fur production process?

Maintaining consistent quality is paramount. It begins with the selection of high-quality pelts, carefully inspected for imperfections. Throughout the manufacturing process, I meticulously check every step – from pattern cutting (precise cutting to minimize waste and ensure consistent sizing) to sewing (using appropriate stitch types for each fur type and area of garment) and finishing (paying careful attention to details like evenness of nap, seam integrity, and overall aesthetic). Regular quality checks at different stages, along with detailed documentation, prevent errors and ensure every garment meets our high standards. This structured approach leads to consistent quality and helps identify and address potential issues promptly. For example, during the sewing phase, consistent stitch tension is checked to avoid pulling or damaging the delicate fur.

Q 18. Explain your knowledge of different fur types and their characteristics.

My knowledge of fur types is extensive. I’m familiar with various species like mink, fox, sable, chinchilla, and many more. Each fur has unique characteristics: Mink is known for its luxurious sheen and dense underfur, while fox possesses a longer, more voluminous guard hair. Sable is highly prized for its deep, lustrous color and exceptional softness, whereas chinchilla is valued for its incredibly dense and fine underfur. Understanding these differences is essential when choosing patterns, cutting techniques, and sewing methods. For example, a pattern suitable for a heavier fur like fox wouldn’t work well for a more delicate fur like chinchilla. The knowledge also extends to understanding fur grades and assessing the quality of raw materials.

Q 19. How do you handle customer requests or special orders for fur garments?

Handling customer requests and special orders requires close collaboration and a thorough understanding of their needs. I begin by consulting with the client, discussing their preferences regarding fur type, style, and design. This consultation involves reviewing sketches, measurements, and fabric samples, if applicable. Detailed notes are kept to ensure all specifications are met. Throughout the design and creation process, I maintain open communication with the client, providing updates and seeking feedback. I strive to exceed their expectations, delivering a custom garment that reflects their personal style and fits perfectly. A recent project involved creating a bespoke mink coat with intricate hand-stitched detailing, a design that required multiple consultations to ensure it met the client’s vision.

Q 20. What is your experience with working with different types of leather and other materials alongside fur?

Working with leather and other materials alongside fur enhances the design possibilities. I have experience incorporating leather accents, such as trim or detailing, into fur garments. This often requires precise cutting and stitching techniques to ensure a seamless blend between the materials. Other materials, such as silk or cashmere, can also be used to create lining or decorative elements. Understanding the properties of each material is crucial to ensure proper construction and longevity. The combination of leather and fur, for instance, offers a beautiful textural contrast; the smooth leather complements the plush fur, resulting in a sophisticated and unique design. In one project, I incorporated supple suede panels into a shearling coat, enhancing both the aesthetic and the garment’s warmth.

Q 21. Describe your approach to quality control in fur garment manufacturing.

My approach to quality control is multi-faceted. It begins with meticulous material selection and extends throughout the entire production process. Regular inspections are conducted at each stage: after pattern cutting to ensure accuracy, during the sewing process to check seam integrity and stitch quality, and finally, after finishing, to examine the overall aesthetic and functionality. I employ a detailed checklist for each garment, ensuring adherence to established standards. Defects are documented, and corrective actions are implemented immediately. This commitment to quality control guarantees every garment meets the highest standards of craftsmanship and durability. A final quality check, often including a thorough inspection by a second pair of eyes, ensures that the finished product is free from flaws before delivery to the customer.

Q 22. How do you stay up-to-date with the latest trends and techniques in fur work?

Staying current in the dynamic world of fur work requires a multi-pronged approach. It’s not enough to rely solely on past experience; continuous learning is key.

- Trade Publications and Journals: I regularly subscribe to and read industry publications such as Fur & Fashion and other specialized magazines that feature the latest trends, techniques, and innovations in fur design and manufacturing.

- Industry Events and Workshops: Attending international fur trade shows, like those held in Copenhagen or Hong Kong, provides invaluable opportunities to network with fellow furriers, see the latest collections, and learn about new technologies firsthand. I actively participate in workshops led by master furriers, focusing on advanced techniques like intricate pattern making or innovative fur-dyeing processes.

- Online Resources and Communities: I actively engage with online forums, social media groups, and educational platforms dedicated to fur work. These communities facilitate the exchange of knowledge, insights, and creative solutions to challenges. I’m a member of several online groups where furriers share their expertise and discuss current projects.

- Mentorship and Collaboration: I believe in the power of mentorship and regularly seek opportunities to learn from experienced furriers. I actively participate in collaborative projects, often exchanging ideas and learning from the approaches of others.

This combination of formal and informal learning keeps me at the forefront of the industry, ensuring my skills remain relevant and competitive.

Q 23. What software or technologies are you familiar with in the context of fur design or production?

While CAD software isn’t as prevalent in fur work as in other textile industries due to the unique nature of fur, I’m proficient in several software tools that enhance my design and production processes.

- Adobe Illustrator: I use Illustrator for creating and refining intricate patterns for fur garments. Its vector-based capabilities are essential for precise pattern design and scaling.

- Photoshop: Photoshop is invaluable for digital manipulation of fur images, allowing me to visualize different color palettes, textures, and designs before implementation. It aids in creating detailed renderings for client presentations.

- Specialized Pattern-Making Software: Although not widely used, I am familiar with some niche pattern-making software specifically designed for garment construction. This software often streamlines the process of creating and modifying patterns, especially for complex 3D fur designs.

- Spreadsheet Software (Excel, Google Sheets): I use spreadsheets extensively for organizing material inventory, tracking project timelines, and managing client orders.

I am always open to learning new software relevant to the industry; the ability to adapt to technological advancements is crucial for staying competitive.

Q 24. Explain your experience with working in a team environment within a fur atelier or workshop.

I thrive in collaborative team environments. My experience at [Previous Atelier Name] involved working closely with pattern makers, cutters, sewers, and finishers on various high-end fur garments.

- Clear Communication: Effective communication is paramount. I always ensure clear understanding of tasks, deadlines, and expectations through regular team meetings and individual check-ins.

- Problem-Solving: When challenges arise, I actively participate in brainstorming solutions with my colleagues. My experience allows me to quickly identify potential problems and offer practical solutions.

- Respectful Collaboration: I value each team member’s contributions and expertise, creating a collaborative and respectful atmosphere conducive to successful project completion. For example, during a particularly challenging project involving a complex mink coat, I worked closely with the pattern maker to refine the pattern, ensuring a seamless fit and minimizing waste.

- Mentoring: I’ve mentored junior furriers, sharing my knowledge and providing guidance to ensure team members grow professionally.

My ability to work seamlessly within a team contributes significantly to efficient and high-quality output.

Q 25. How do you manage your time effectively when working on multiple fur garment projects?

Managing multiple projects requires a structured and organized approach. I use a combination of strategies to ensure efficient time management.

- Prioritization: I prioritize projects based on deadlines, complexity, and client urgency. This ensures that the most time-sensitive projects receive the attention they require.

- Detailed Project Planning: Before starting each project, I create a detailed plan outlining all tasks, timelines, and resource requirements. This breakdown aids in identifying potential bottlenecks and allows for better allocation of time.

- Time Blocking: I allocate specific time blocks for individual tasks, minimizing distractions and maximizing productivity. For instance, I might dedicate mornings to intricate cutting work and afternoons to sewing.

- Regular Check-ins: I conduct regular check-ins on project progress, adjusting the schedule as needed to account for unforeseen challenges.

- Delegation (when applicable): In a team environment, I effectively delegate tasks to team members, ensuring optimal use of everyone’s skills and time.

This systematic approach helps me manage multiple projects simultaneously without compromising quality or exceeding deadlines. Think of it like conducting a symphony – each instrument (task) plays its part at the right time, resulting in a harmonious whole.

Q 26. Describe a situation where you had to troubleshoot a problem during fur garment construction.

During the construction of a sable coat, I encountered a significant challenge related to the alignment of a complex panel. The fur had a pronounced nap, which caused inconsistencies in the appearance when the panels were joined.

Troubleshooting Steps:

- Problem Identification: I carefully examined the affected area, pinpointing the exact points of misalignment and identifying the root cause: inconsistent nap direction.

- Solution Exploration: I considered several solutions: re-cutting the panels (time-consuming and wasteful), using a different joining method, or altering the placement of the panels.

- Implementation: I opted to carefully re-align the nap of the fur within the panels before joining them. This involved meticulous manipulation to achieve consistent direction and minimized visible seams. I then employed a specialized stitching technique to secure the join, ensuring both strength and an aesthetically pleasing result.

- Verification: After the repair, I carefully inspected the coat to ensure the problem was resolved and the overall aesthetic integrity was maintained.

This experience reinforced the importance of careful planning, meticulous attention to detail, and the ability to adapt to unexpected challenges in fur garment construction.

Q 27. What are your salary expectations for this furrier position?

My salary expectations for this furrier position are commensurate with my experience and skills, and are in line with industry standards for a professional with my level of expertise. Considering my extensive experience in high-end fur garment construction and my proficiency in various techniques, I am seeking a salary in the range of $[Salary Range] annually.

Q 28. What are your long-term career goals within the fur industry?

My long-term career goals involve continued growth and leadership within the fur industry. I aspire to:

- Master Furrier Status: I aim to achieve recognition as a master furrier, demonstrating mastery of advanced techniques and contributing to the advancement of the craft.

- Design and Innovation: I plan to expand my skills in fur design, creating innovative and sustainable fur garments that push the boundaries of the industry.

- Mentorship and Training: I would like to contribute to the future of the fur industry by mentoring and training aspiring furriers, passing on my knowledge and expertise to the next generation.

- Entrepreneurship (Potential): Eventually, I might pursue opportunities for entrepreneurship, establishing my own atelier or design house to create and sell unique and high-quality fur garments.

My dedication to excellence and my commitment to continuous learning will help me achieve these goals.

Key Topics to Learn for Skilled in using various fur cutting, sewing, and finishing tools Interview

- Fur Cutting Techniques: Understanding different cutting methods (e.g., pattern cutting, freehand cutting) for various fur types and their impact on the final product’s quality and aesthetics. Consider the importance of precision and minimizing waste.

- Sewing Techniques for Fur: Mastering specialized sewing techniques for fur, including different stitch types (e.g., saddle stitch, blind stitch) and their suitability for different fur textures and thicknesses. Discuss challenges specific to sewing fur and how to overcome them.

- Fur Finishing Techniques: Exploring various finishing techniques like shearing, blocking, and cleaning to enhance the appearance and durability of fur garments. Understand the impact of different finishing methods on the final product’s look and feel.

- Tool Knowledge and Maintenance: Demonstrating proficiency with various tools, including shears, sewing machines (specialized for fur if applicable), needles, and other finishing tools. Discuss proper maintenance and safety procedures for these tools.

- Pattern Making and Alterations: Understanding how to adapt and create patterns specifically designed for fur garments. Explain your ability to make alterations and adjustments based on fit and design needs.

- Material Selection and Knowledge: Demonstrate knowledge of different fur types, their characteristics (e.g., density, thickness, durability), and how to select appropriate materials for various projects. Explain how these choices affect the final outcome.

- Problem-Solving and Troubleshooting: Discuss your approach to troubleshooting common issues encountered during fur cutting, sewing, and finishing, such as dealing with difficult fur types or repairing damaged sections.

Next Steps

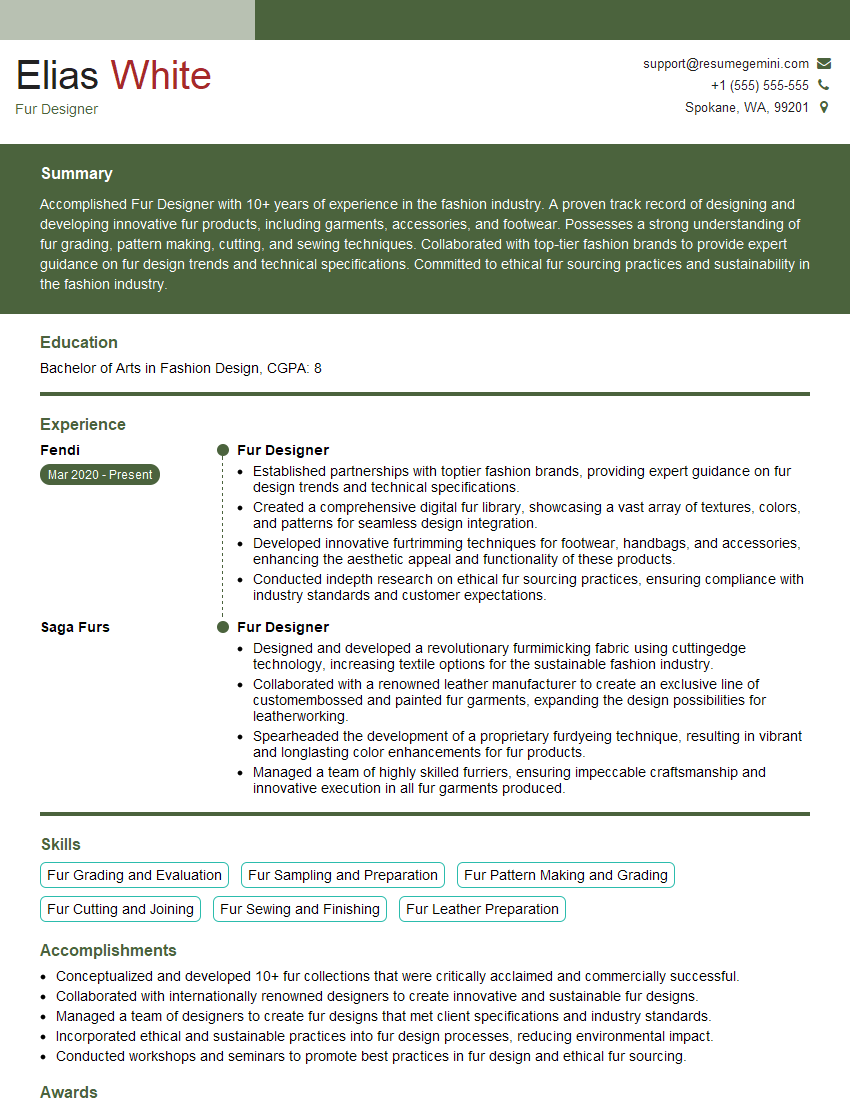

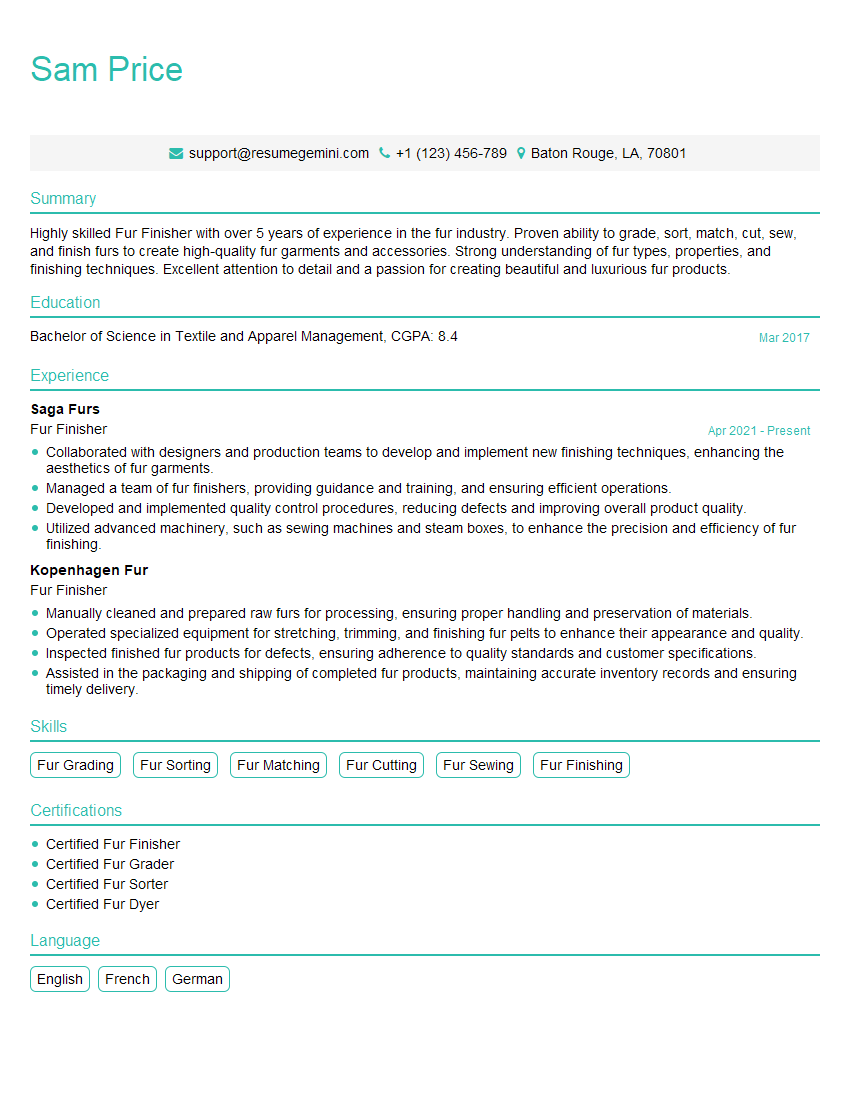

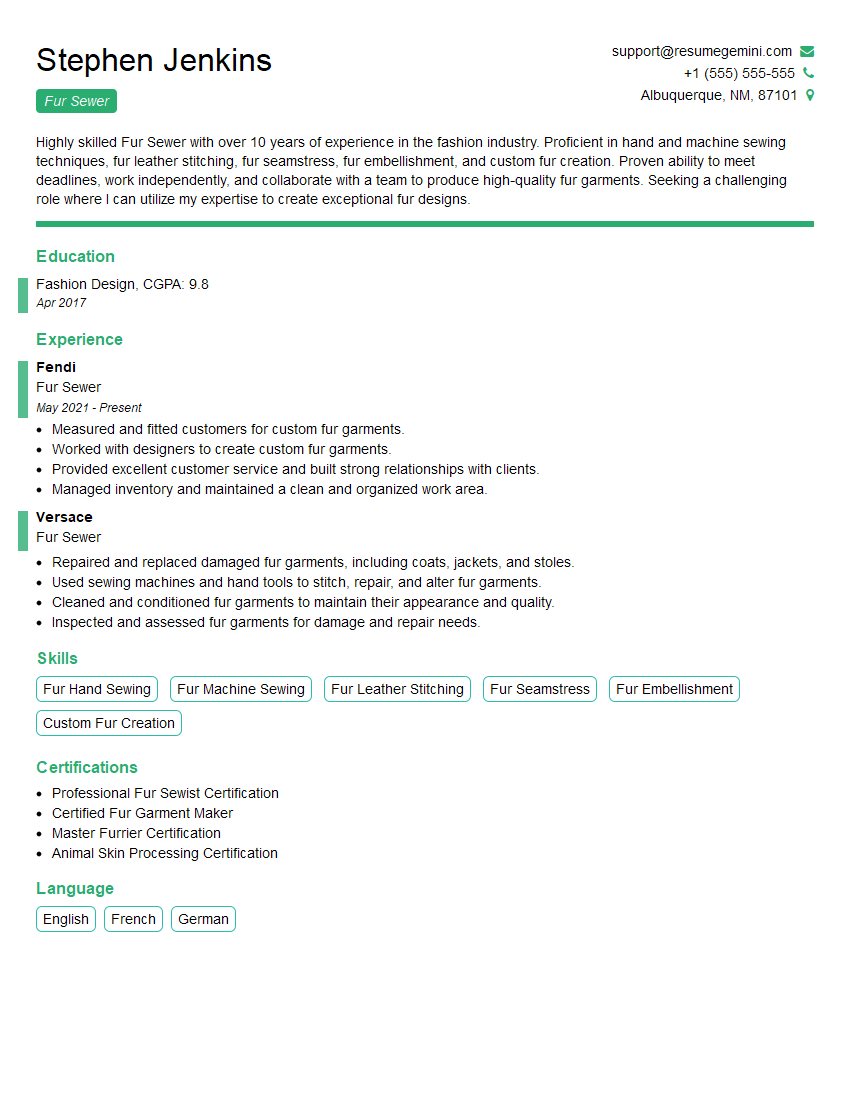

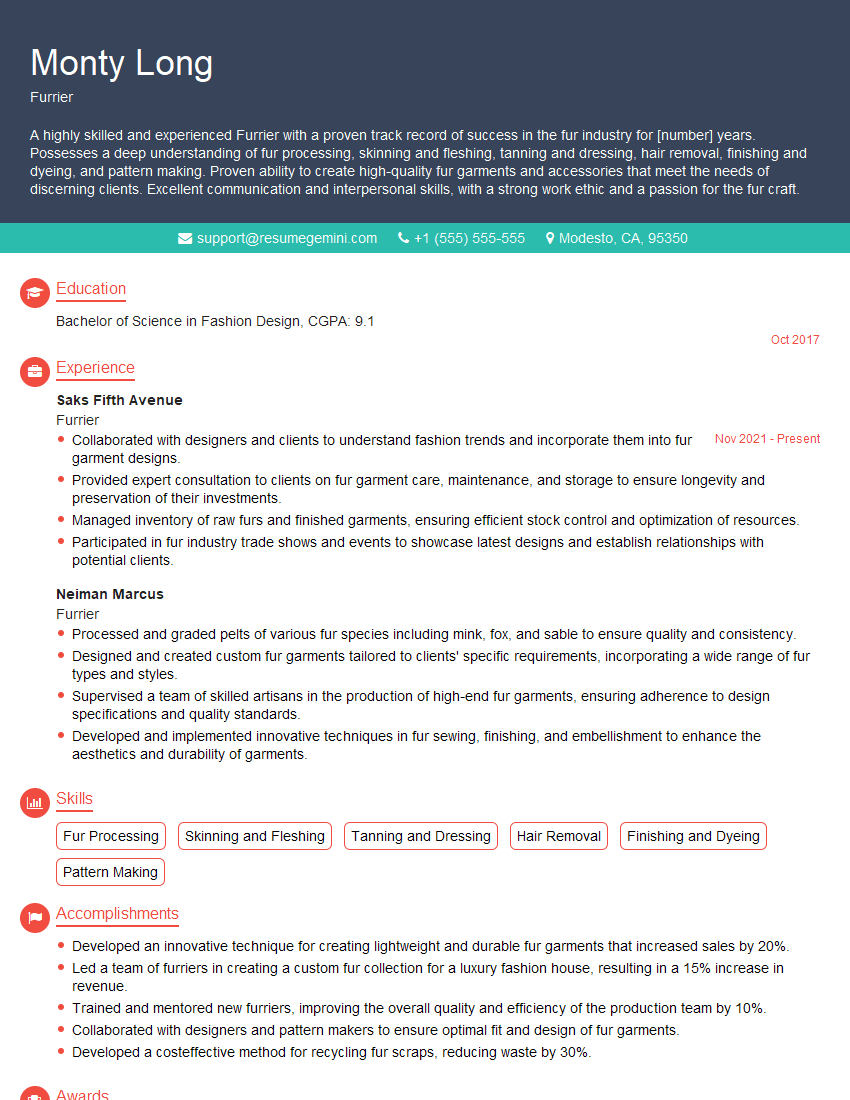

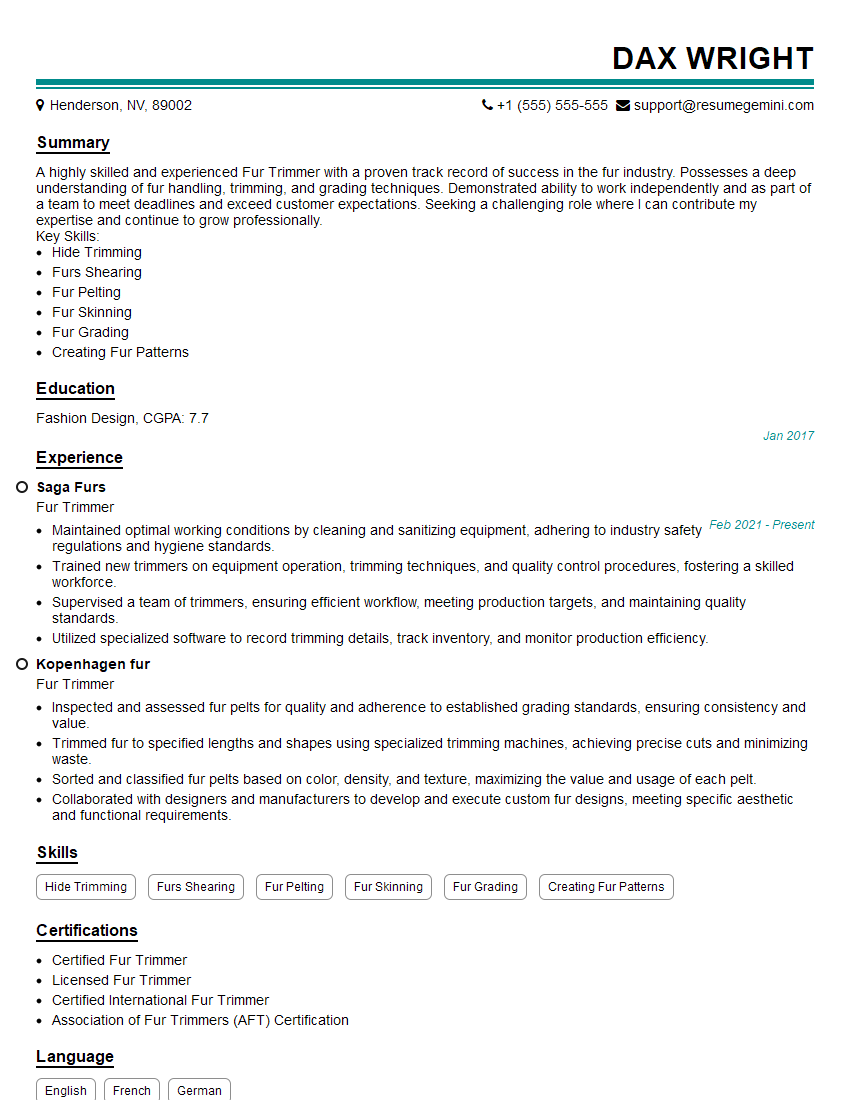

Mastering the skills of fur cutting, sewing, and finishing is crucial for career advancement in this specialized field. Proficiency in these areas demonstrates a high level of craftsmanship and attention to detail, qualities highly valued by employers. To increase your chances of landing your dream job, it’s essential to create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to showcasing expertise in fur cutting, sewing, and finishing tools are available, providing you with valuable templates and guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good