Unlock your full potential by mastering the most common Skillful in operating and monitoring production equipment interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Skillful in operating and monitoring production equipment Interview

Q 1. Describe your experience operating and monitoring production equipment.

My experience encompasses over eight years of operating and monitoring a diverse range of production equipment, primarily within the manufacturing of high-precision components. This has involved everything from daily operation and routine checks to complex troubleshooting and process optimization. I’ve worked with both automated and manual systems, gaining a strong understanding of their unique needs and potential challenges. For instance, in my previous role at Acme Manufacturing, I was responsible for the daily operation of a CNC milling machine, ensuring consistent production of parts within tight tolerances. I also monitored a robotic welding cell, identifying and resolving minor issues to maintain maximum uptime. This hands-on experience has equipped me with a holistic understanding of the production process and the critical role equipment plays in achieving operational excellence.

Q 2. What are the key performance indicators (KPIs) you monitor in production?

Key Performance Indicators (KPIs) I monitor are crucial for ensuring efficient and effective production. These typically include:

- Overall Equipment Effectiveness (OEE): This metric combines availability, performance, and quality rate to give a holistic view of equipment productivity. A low OEE suggests areas needing improvement, such as reducing downtime or improving product quality.

- Throughput: The number of units produced per unit of time (e.g., parts per hour). Monitoring throughput helps identify bottlenecks and measure the impact of process improvements.

- Defect Rate: The percentage of defective units produced. High defect rates indicate issues requiring immediate attention, such as machine miscalibration or material inconsistencies.

- Downtime: The total time the equipment is not operational. Analyzing downtime helps identify recurring problems and implement preventive measures.

- Cycle Time: The time it takes to complete one production cycle. Reducing cycle time enhances efficiency and increases output.

I regularly track these KPIs using our Manufacturing Execution System (MES), analyzing trends to anticipate potential issues and proactively address them. For example, a consistent increase in cycle time might indicate tool wear on a CNC machine, requiring preventative maintenance or replacement.

Q 3. How do you identify and troubleshoot common equipment malfunctions?

Identifying and troubleshooting malfunctions is a critical part of my role. My approach is systematic and data-driven. I start by observing the equipment for any unusual sounds, vibrations, or behaviors. Then, I review the machine’s error logs and diagnostic codes. These codes often pinpoint the specific problem. I then consult maintenance manuals and schematics to understand the system’s functionality and identify potential causes. If the problem is not immediately apparent, I use a troubleshooting flowchart or decision tree to guide me through a series of tests. For example, if a CNC machine reports a ‘tool sensor error,’ I would first check the tool sensor for damage or misalignment, then examine the wiring and connections. If the problem persists, I would escalate the issue to a senior technician.

A recent example involved a conveyor system experiencing frequent stoppages. By carefully examining the logs and performing visual inspections, I discovered a build-up of debris causing a sensor to malfunction. Cleaning the sensor and implementing a more regular cleaning schedule resolved the issue.

Q 4. Explain your experience with preventative maintenance procedures.

Preventative maintenance is key to maximizing equipment lifespan and minimizing downtime. My experience includes performing routine checks such as lubricating moving parts, cleaning sensors, inspecting belts and chains for wear, and checking fluid levels. I also adhere to a scheduled maintenance program, meticulously documenting all procedures and findings. This involves replacing worn parts before they fail, ensuring the equipment operates at peak performance. I’m proficient in using various diagnostic tools and software to monitor equipment health and predict potential failures. For example, analyzing vibration data from a motor can help identify developing bearing issues, allowing for proactive replacement before a catastrophic failure.

In my previous role, we implemented a predictive maintenance program using vibration sensors on critical equipment. This enabled us to anticipate and prevent numerous potential failures, significantly reducing downtime and maintenance costs.

Q 5. What safety protocols do you follow when operating production machinery?

Safety is paramount. I strictly adhere to all company safety protocols, including wearing appropriate Personal Protective Equipment (PPE) such as safety glasses, hearing protection, and steel-toe boots. Before operating any equipment, I perform a thorough safety check, ensuring all guards are in place, emergency stops are functioning, and the area is clear of obstructions. I understand and follow lockout/tagout procedures to prevent accidental starts during maintenance. I also regularly participate in safety training to stay updated on best practices and new safety regulations. I proactively report any unsafe conditions or potential hazards to my supervisor immediately.

Q 6. How do you interpret and react to production equipment alarms and alerts?

Production equipment alarms and alerts require prompt and accurate responses. My approach is to:

- Identify the alarm source: The alarm’s description or code usually indicates the problem’s location and nature.

- Assess the severity: Determine whether the alarm requires immediate action or if it can wait until a scheduled maintenance period.

- Investigate the cause: Consult the equipment manuals, diagnostic tools, and error logs to understand the root cause.

- Take corrective action: This might involve simple fixes like resetting a tripped circuit breaker, replacing a worn component, or making a minor adjustment. If the problem is beyond my expertise, I will escalate it to the appropriate maintenance personnel.

- Document the incident: Record the alarm details, actions taken, and the resolution in the maintenance log.

For example, a high-temperature alarm on a CNC machine would trigger a prompt investigation, possibly revealing a coolant leak. This would require immediate action to prevent damage to the machine and ensure operator safety.

Q 7. Describe your experience with different types of production equipment (e.g., CNC machines, conveyors).

My experience encompasses a variety of production equipment. I’m proficient in operating and maintaining CNC milling machines, lathes, and routers for precision machining. I’m also experienced with robotic welding cells, automated assembly lines, and conveyor systems for material handling. I’ve worked with both PLC (Programmable Logic Controller) controlled systems and manual machines, gaining a comprehensive understanding of their functionalities and limitations. I understand the programming aspects of some CNC machines and can modify simple programs to accommodate changes in production requirements. Furthermore, I’m familiar with hydraulic and pneumatic systems commonly used in industrial machinery and can troubleshoot basic issues within these systems.

For instance, I have extensive experience programming and operating a Fanuc CNC milling machine, capable of producing complex parts with tight tolerances. I’m equally comfortable troubleshooting issues on a simpler manual lathe or diagnosing problems in a conveyor belt system.

Q 8. How do you ensure the accuracy and consistency of production output?

Ensuring accurate and consistent production output is paramount. It’s a multifaceted process that starts with precise calibration and maintenance of equipment and extends to rigorous monitoring and quality checks throughout the production cycle. Think of it like baking a cake – you need the right ingredients (inputs), the right recipe (process), and the right oven temperature (equipment settings) to get a consistent, high-quality result every time.

- Precise Calibration and Maintenance: Regularly scheduled preventative maintenance minimizes equipment malfunctions and ensures consistent performance. For instance, in a bottling plant, regular calibration of filling machines ensures each bottle receives the correct volume of liquid. Any deviation is documented and addressed promptly.

- Process Monitoring and Control: Real-time monitoring of key process parameters – like temperature, pressure, or flow rate – using sensors and control systems is crucial. Deviations from set points trigger alerts, allowing for immediate corrective action. Imagine a manufacturing process where temperature is critical; a sudden spike could ruin the batch. Our systems provide real-time monitoring and automated adjustments.

- Quality Control Checks: Regular sampling and testing at various stages of production identify and rectify errors early. This can range from simple visual inspections to complex laboratory analysis depending on the product. In food manufacturing, random sampling is essential to ensure adherence to safety and quality standards.

Q 9. What software or systems do you use to monitor and manage production data?

I’ve worked extensively with various software and systems for monitoring and managing production data. My experience includes using Supervisory Control and Data Acquisition (SCADA) systems, Manufacturing Execution Systems (MES), and Enterprise Resource Planning (ERP) systems. These systems provide a comprehensive view of the production process, from raw material tracking to finished goods shipment.

- SCADA: Provides real-time monitoring of equipment parameters and allows for remote control and adjustments. I’ve used SCADA systems to monitor and control automated assembly lines, identifying bottlenecks and optimizing production flow.

- MES: Integrates shop floor data with higher-level planning and execution systems. This helps in scheduling, tracking production progress, and managing quality control. I’ve used MES to track the progress of specific orders and identify delays proactively.

- ERP: Provides an integrated view of the entire business, including production, inventory, and sales. I’ve leveraged ERP data to analyze production efficiency, identify areas for improvement, and optimize resource allocation.

In addition to these systems, I’m proficient in using data analysis tools like Microsoft Excel, and SQL to extract and interpret relevant production data. For example, I might use SQL queries to pull historical data on production output and identify trends or anomalies.

Q 10. How do you handle unexpected downtime or production disruptions?

Unexpected downtime is inevitable in any production environment. My approach to handling these disruptions is systematic and proactive. It involves a rapid response to minimize disruption and a thorough root cause analysis to prevent recurrence.

- Immediate Response: The first step is to assess the situation, ensure safety, and implement immediate contingency plans. This might involve switching to backup systems, re-routing production, or temporarily halting operations depending on the nature of the disruption. In one instance, a sudden power outage led to an immediate shift to backup generators, minimizing downtime.

- Root Cause Analysis: Once the immediate situation is under control, a thorough investigation is launched to identify the root cause of the disruption. This often involves reviewing logs, interviewing personnel, and inspecting equipment. For example, a recurring equipment failure led to a detailed analysis revealing a faulty component that required replacement.

- Corrective Action and Prevention: Based on the root cause analysis, corrective actions are implemented to prevent future occurrences. This could involve equipment upgrades, process improvements, or enhanced training for personnel. Implementing preventive maintenance schedules and improved training significantly reduced downtime.

Q 11. Explain your experience with quality control procedures.

Quality control is integral to my work. I have extensive experience implementing and managing quality control procedures, focusing on both process control and final product inspection. My experience spans various quality control methodologies, including statistical process control (SPC) and Six Sigma.

- Process Control: This involves monitoring and controlling the production process to ensure consistency and prevent defects. I’ve used control charts to track key process variables and identify potential problems before they escalate. This proactive approach minimizes scrap and rework.

- Final Product Inspection: This involves inspecting the finished product to ensure it meets quality standards. This could involve visual inspection, dimensional measurements, or functional testing depending on the product. We use a combination of manual and automated inspection techniques to ensure accuracy and efficiency.

- Continuous Improvement: Quality control isn’t a one-time event; it’s an ongoing process. I actively participate in continuous improvement initiatives, using data to identify areas for improvement and implement corrective actions.

Q 12. Describe your experience with data analysis related to production performance.

Data analysis is essential for optimizing production performance. I routinely analyze production data to identify trends, pinpoint bottlenecks, and improve efficiency. My skills encompass descriptive, diagnostic, predictive, and prescriptive analytics.

- Descriptive Analytics: This involves summarizing and visualizing production data to understand past performance. For instance, I might create charts and graphs showing production output over time or identify the most frequent types of defects.

- Diagnostic Analytics: This involves identifying the root causes of performance problems. For example, I might analyze production data to determine why a particular machine is experiencing frequent breakdowns.

- Predictive Analytics: This involves using statistical models to forecast future performance. I might use predictive models to estimate future demand or predict when equipment is likely to fail.

- Prescriptive Analytics: This involves recommending actions to improve future performance. Based on my analysis, I might recommend changes to the production process or suggest investments in new equipment.

I use statistical software packages and data visualization tools to perform these analyses. For example, I’ve used R to build predictive models for equipment maintenance and to identify factors that affect production yield.

Q 13. How familiar are you with different types of production processes?

My experience encompasses a variety of production processes, including batch processing, continuous flow processing, and just-in-time (JIT) manufacturing. Understanding the nuances of each is crucial for effective operation and optimization.

- Batch Processing: This involves producing goods in batches, often used in industries like pharmaceuticals and food processing. I’ve worked in environments where careful batch tracking and quality control are crucial.

- Continuous Flow Processing: This involves a continuous flow of materials through the production process, commonly used in industries like oil refining and chemical manufacturing. I’m familiar with the monitoring and control systems required for these processes.

- Just-in-Time (JIT) Manufacturing: This involves producing goods only when they are needed, minimizing inventory and waste. I’ve worked in environments where efficient scheduling and coordination are essential for successful JIT implementation.

My adaptability allows me to quickly grasp the specifics of any new production process and contribute effectively to its optimization.

Q 14. What is your experience with Lean Manufacturing principles?

Lean Manufacturing principles are central to my approach to production. I’ve implemented various Lean tools and techniques to eliminate waste, improve efficiency, and enhance quality. These principles focus on maximizing value for the customer while minimizing waste in all forms.

- Value Stream Mapping: I’ve used value stream mapping to visually represent the flow of materials and information in a production process, identifying bottlenecks and areas for improvement. This technique highlights non-value-added steps allowing for targeted improvements.

- 5S Methodology: I’ve implemented the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to create a more organized and efficient work environment. This reduces waste and improves safety.

- Kaizen Events: I’ve participated in Kaizen events (continuous improvement workshops) to identify and implement quick and efficient process improvements.

- Kanban: I’m familiar with Kanban systems for managing workflow and inventory, ensuring a smooth and efficient flow of production.

My experience shows a consistent application of Lean principles to optimize production processes and achieve significant improvements in efficiency and quality.

Q 15. How do you maintain accurate records of equipment operation and maintenance?

Maintaining accurate equipment records is crucial for optimizing performance and preventing costly downtime. My approach involves a multi-faceted system leveraging both digital and physical methods.

Computerized Maintenance Management System (CMMS): I utilize a CMMS, such as Fiix or UpKeep, to meticulously document all aspects of equipment operation and maintenance. This includes scheduled maintenance activities, unplanned repairs, parts used, labor hours, and any associated costs. The CMMS allows for easy data retrieval and analysis, providing valuable insights into equipment performance trends and potential issues.

Physical Logbooks: While digital systems are primary, I also maintain physical logbooks for critical equipment. These serve as a backup and provide a readily available record even in case of system failures. Detailed entries include date, time, operator, maintenance performed, and any relevant observations.

Data Synchronization: Regular synchronization between the CMMS and physical logs is essential to ensure data integrity. Any information recorded in one system is immediately reflected in the other, minimizing discrepancies and potential errors.

This combined approach ensures comprehensive, accurate, and readily accessible records, facilitating proactive maintenance and informed decision-making.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with safety and environmental regulations?

Safety and environmental compliance are paramount in any production setting. My approach involves a proactive and multi-layered strategy:

Regular Safety Training and Audits: I actively participate in and promote regular safety training, ensuring all personnel are aware of and adhere to safety protocols. I also participate in and contribute to safety audits to identify and mitigate potential hazards.

Lockout/Tagout Procedures: I strictly adhere to lockout/tagout procedures before performing any maintenance or repairs, ensuring the equipment is completely de-energized to prevent accidents. This includes verifying the lockout and confirming with other personnel before beginning work.

Environmental Regulations: I am familiar with relevant environmental regulations concerning waste disposal, emissions, and resource conservation. I ensure that all operations are compliant, following established procedures for handling hazardous materials and disposing of waste responsibly.

Documentation and Reporting: All safety and environmental-related incidents, near misses, and maintenance activities are meticulously documented and reported according to company procedures. This proactive approach helps identify trends, implement corrective actions, and improve overall safety performance.

Compliance isn’t just a checklist; it’s a continuous process of vigilance and improvement.

Q 17. Describe a time you had to solve a complex problem related to production equipment.

During a critical production run, our main conveyor system experienced a sudden shutdown. The initial diagnosis pointed towards a motor failure, but replacing the motor didn’t solve the problem. The system continued to trip its overload protection.

Problem-Solving Steps:

Systematic Investigation: Instead of immediately replacing parts, I systematically checked each component of the system: motor, belts, pulleys, sensors, and control circuitry.

Sensor Analysis: I discovered that an amperage sensor was providing inaccurate readings. While the motor itself wasn’t faulty, the sensor was signaling an overload, causing the system to shut down. I verified the sensor’s reading with a multimeter and confirmed the discrepancy.

Temporary Fix: As a temporary fix, I bypassed the faulty sensor, allowing the production line to resume operation. This was done cautiously, ensuring the system was still monitored closely for any signs of overload.

Permanent Solution: I then ordered a replacement sensor and, after its installation, conducted thorough tests to verify the system’s stability. This ensured that the conveyor system would work correctly and avoid future shutdowns.

This experience highlighted the importance of systematic troubleshooting and not jumping to conclusions based on initial assumptions. A thorough investigation, combined with a combination of practical knowledge and problem-solving skills, was crucial in resolving the issue efficiently and minimizing production downtime.

Q 18. What are your strategies for improving efficiency in a production environment?

Improving production efficiency requires a holistic approach focusing on several key areas:

Preventive Maintenance: A well-structured preventive maintenance program is crucial for minimizing unplanned downtime. Regular inspections, lubrication, and part replacements prevent minor issues from escalating into major problems.

Process Optimization: Analyzing production processes to identify bottlenecks and inefficiencies is key. This might involve streamlining workflows, optimizing material handling, or implementing lean manufacturing principles.

Data Analysis: Utilizing data from CMMS and production monitoring systems allows us to identify trends, predict potential issues, and proactively address inefficiencies. This data-driven approach allows for continuous improvement.

Employee Training and Empowerment: Well-trained employees are more efficient and safer. Providing them with the skills and authority to identify and resolve minor issues quickly reduces downtime and improves overall productivity.

Automation where applicable: Exploring automation opportunities, such as robotic systems or automated guided vehicles (AGVs), can significantly enhance efficiency and reduce reliance on manual labor for repetitive tasks.

Continuous improvement is an ongoing process. Regularly reviewing and adjusting strategies based on performance data ensures sustained efficiency gains.

Q 19. How do you communicate effectively with colleagues and supervisors regarding production issues?

Effective communication is the backbone of a smoothly running production environment. I utilize various methods depending on the situation and urgency:

Clear and Concise Reporting: When reporting issues, I provide concise summaries that include the problem, its impact on production, and any initial observations. I avoid technical jargon unless necessary and explain it in plain language.

Visual Aids: For complex issues, I use visual aids such as diagrams, photos, or short videos to clearly communicate the problem and potential solutions.

Formal Communication Channels: For critical issues, I follow established communication channels to ensure timely notification of supervisors and relevant personnel. This might involve email, instant messaging systems, or direct meetings.

Active Listening: I am an active listener, ensuring that I understand the concerns of colleagues and supervisors, and offering solutions collaboratively.

Regular Team Meetings: Regular team meetings provide a platform to discuss ongoing challenges, share best practices, and foster a collaborative environment.

Open communication builds trust and fosters a culture of problem-solving and continuous improvement.

Q 20. What is your experience with different types of industrial sensors and instrumentation?

My experience encompasses a wide range of industrial sensors and instrumentation, including:

Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors for measuring temperature in various processes.

Pressure Sensors: Various types of pressure transducers and switches for monitoring pressure in pneumatic and hydraulic systems.

Flow Sensors: Mass flow meters, ultrasonic flow meters, and differential pressure flow meters for monitoring fluid flow rates.

Level Sensors: Ultrasonic, capacitive, and float-type level sensors for monitoring liquid levels in tanks and reservoirs.

Proximity Sensors: Inductive, capacitive, and photoelectric sensors for detecting the presence of objects in automated systems.

I am proficient in understanding sensor specifications, calibration procedures, and troubleshooting techniques for these and other sensor types. I can interpret sensor data and use it to diagnose equipment performance and identify potential issues.

Q 21. How familiar are you with Programmable Logic Controllers (PLCs)?

I have extensive experience with Programmable Logic Controllers (PLCs). My skills include:

PLC Programming: I am proficient in programming PLCs using various languages such as ladder logic, function block diagrams, and structured text. I can develop and modify PLC programs to control and monitor industrial processes.

Troubleshooting PLC Systems: I can effectively troubleshoot PLC systems, diagnosing problems using diagnostic tools and my understanding of PLC programming and industrial control systems. I have experience using various troubleshooting techniques, including reviewing PLC program logic, checking I/O signals, and using diagnostic software.

HMI Interaction: I am comfortable working with Human-Machine Interfaces (HMIs) to configure screens, set parameters, and monitor PLC operation. I understand the role of HMIs in providing operators with a user-friendly interface for interacting with the PLC.

Specific PLC Platforms: I have hands-on experience with various PLC platforms, including Allen-Bradley, Siemens, and Omron, demonstrating versatility and adaptability.

My PLC skills are critical for maintaining, upgrading and optimizing automated industrial processes.

Q 22. What is your experience with SCADA systems?

My experience with SCADA (Supervisory Control and Data Acquisition) systems spans several years and encompasses various applications. I’m proficient in using SCADA systems to monitor and control industrial processes, including data acquisition, alarm management, and historical trending. For example, in my previous role at Acme Manufacturing, I used a Siemens WinCC SCADA system to monitor the entire production line, from raw material input to finished product output. This involved configuring screens to display real-time data such as temperature, pressure, and flow rates. I was also responsible for troubleshooting alarms, identifying root causes of production issues, and implementing corrective actions based on the data presented by the SCADA system. I’m familiar with various SCADA protocols, including Modbus and Profibus, and have experience integrating SCADA systems with other enterprise systems like ERP and MES. I also have experience with data analysis from SCADA systems, generating reports to improve process efficiency and reduce downtime.

Q 23. How do you contribute to a safe and productive work environment?

Contributing to a safe and productive work environment is paramount. My approach is multi-faceted. Firstly, I strictly adhere to all safety regulations and protocols, acting as a role model for my colleagues. I regularly inspect equipment for any potential hazards, promptly reporting any issues to the appropriate personnel. For instance, during my time at Beta Industries, I noticed a loose wire near a high-voltage component, immediately halting the operation and reporting it to the maintenance team, preventing a potentially hazardous situation. Secondly, I actively participate in safety training and encourage others to do the same. I believe in proactive safety measures, not just reactive ones. Finally, I strive to create a collaborative and supportive team environment where everyone feels comfortable reporting safety concerns without fear of reprisal. Open communication and mutual respect are key to a safe and productive workplace.

Q 24. Describe your experience working in a team setting within a production environment.

I thrive in team settings within production environments. In my previous role at Gamma Processing, I was part of a team responsible for the 24/7 operation of a critical processing unit. We regularly held shift handover meetings to ensure seamless transitions and effective communication. I collaborated closely with maintenance technicians, engineers, and supervisors to troubleshoot issues, implement improvements, and optimize production processes. One specific example involved a production bottleneck we resolved collaboratively. By analyzing the SCADA data and combining our individual expertise – a maintenance technician’s understanding of the equipment and my knowledge of the process flow – we identified a minor mechanical issue that was causing significant delays. We solved it efficiently, minimizing downtime and exceeding production targets. This collaboration highlighted the importance of effective teamwork and open communication in high-pressure situations.

Q 25. How do you prioritize tasks and manage your workload effectively in a fast-paced production setting?

Prioritizing tasks and managing workload in a fast-paced production setting requires a structured approach. I utilize techniques such as prioritization matrices (like Eisenhower Matrix) to categorize tasks based on urgency and importance. I break down large tasks into smaller, manageable sub-tasks to make them less daunting and easier to track. I also use tools like Kanban boards or digital task management software to visualize my workflow and stay organized. For example, during periods of high demand, I utilize the Eisenhower Matrix to ensure critical tasks like preventative maintenance are completed while other tasks are delegated or postponed as needed. Proactive communication with supervisors and teammates is also essential to ensure everyone is aligned and resources are allocated efficiently. Regularly reviewing and adjusting my schedule allows for flexibility and adaptability in response to unexpected events or changes in priority.

Q 26. What are your strengths and weaknesses in operating and monitoring production equipment?

My strengths lie in my quick problem-solving abilities and my detailed understanding of equipment operation and maintenance. I am adept at identifying the root cause of equipment malfunctions and quickly implementing effective solutions, minimizing downtime. For example, I successfully diagnosed and resolved a recurring fault on a critical piece of equipment that had plagued the production line for weeks. My weakness is occasionally getting overly focused on meticulous detail, potentially impacting the speed of less critical tasks. However, I actively work on balancing attention to detail with efficient task completion through time management techniques and prioritizing tasks based on importance and urgency. I also actively seek feedback from supervisors and colleagues to help me manage this aspect of my work more effectively.

Q 27. What are your salary expectations?

My salary expectations are in line with the market rate for a skilled production equipment operator and monitor with my level of experience and qualifications. Considering my expertise, my consistent record of exceeding expectations, and the value I bring to a production team, I am seeking a salary range of [Insert Salary Range Here]. I am open to discussing this further based on the specifics of the role and the company’s compensation structure.

Q 28. Do you have any questions for me?

Yes, I do. I would appreciate learning more about the specific technologies and equipment used in this role. I’m also keen to understand the company’s safety culture and training programs in more detail, as well as the opportunities for professional development and career growth within the organization.

Key Topics to Learn for Skillful in operating and monitoring production equipment Interview

- Understanding Production Processes: Gain a thorough grasp of the specific production processes relevant to the role. This includes understanding the flow of materials, the stages of production, and the overall goals of the process.

- Equipment Operation and Maintenance: Demonstrate knowledge of safe and efficient operation of relevant equipment. Be prepared to discuss preventative maintenance procedures, troubleshooting common issues, and adhering to safety regulations.

- Data Analysis and Monitoring: Explain your ability to interpret data from production equipment, identify trends, and react to anomalies. This includes understanding key performance indicators (KPIs) and using data to optimize production efficiency.

- Troubleshooting and Problem-Solving: Showcase your ability to identify and resolve equipment malfunctions efficiently and effectively. Describe your approach to diagnosing problems, implementing solutions, and documenting the process.

- Safety Procedures and Regulations: Highlight your commitment to safety by demonstrating knowledge of relevant safety protocols, emergency procedures, and compliance regulations within a production environment.

- Quality Control and Assurance: Discuss your experience with ensuring that production meets quality standards. Explain how you monitor quality metrics and identify areas for improvement.

- Teamwork and Communication: Emphasize your ability to collaborate effectively with team members, communicate effectively regarding equipment status, and contribute to a positive work environment.

Next Steps

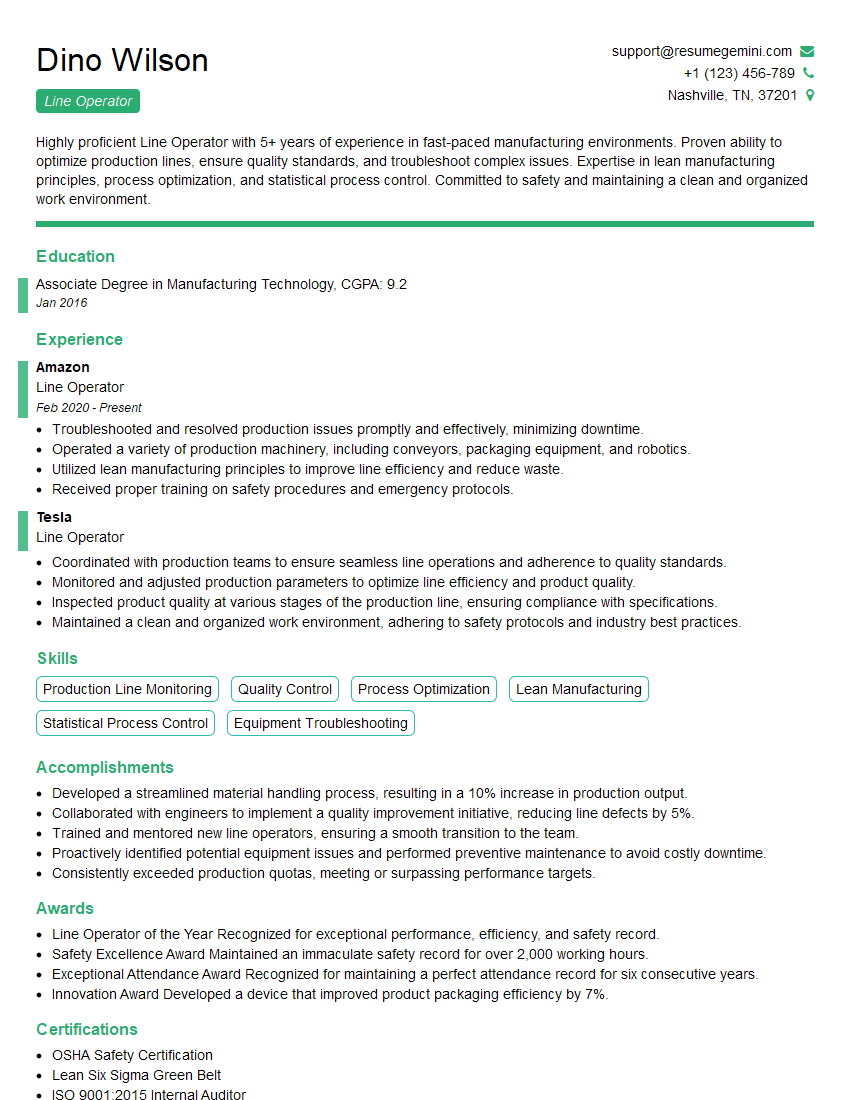

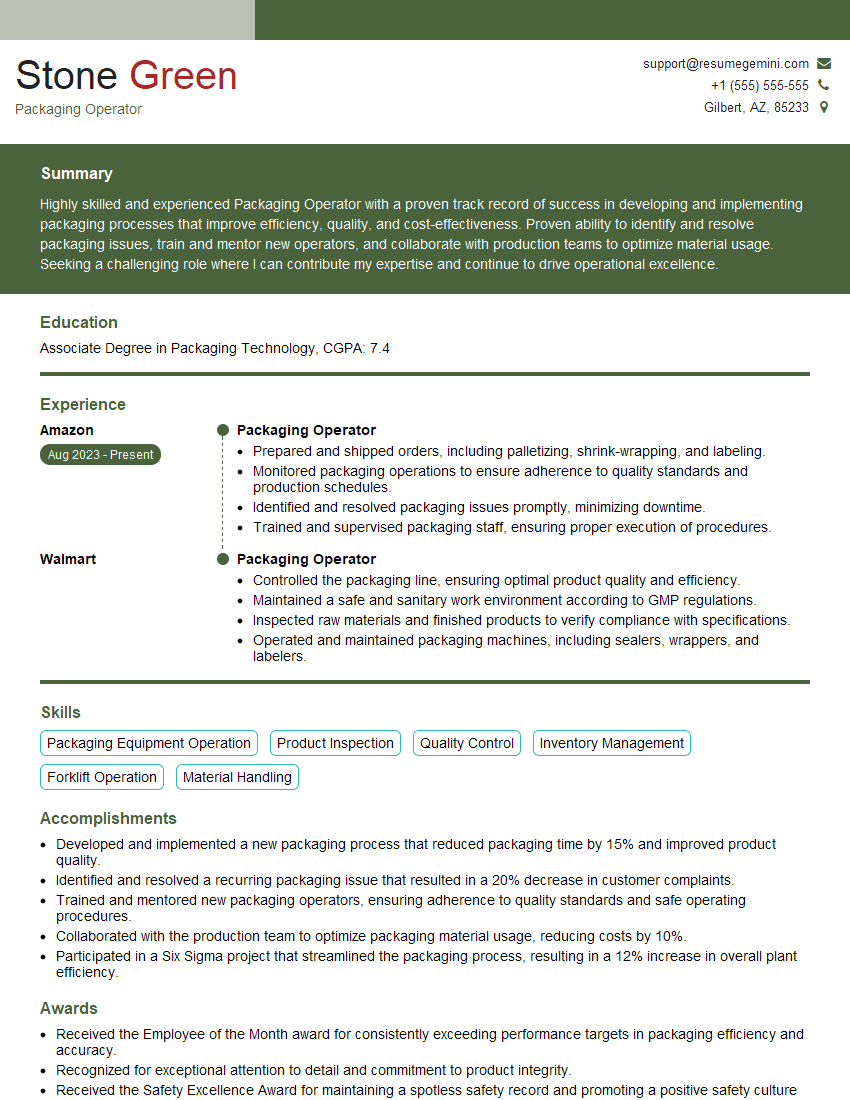

Mastering the skillful operation and monitoring of production equipment is crucial for career advancement in many manufacturing and industrial sectors. It demonstrates your technical abilities, problem-solving skills, and commitment to efficiency and safety. To significantly boost your job prospects, creating an ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a powerful, professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Skillful in operating and monitoring production equipment, giving you a head start in crafting your application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good