Preparation is the key to success in any interview. In this post, we’ll explore crucial Sorting and classifying laundry interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Sorting and classifying laundry Interview

Q 1. Explain the process of sorting laundry by color.

Sorting laundry by color is crucial for preventing color bleeding and ensuring vibrant colors remain bright. Think of it like this: you wouldn’t want to mix your bright red shirt with your white socks!

The process typically involves three main categories: Whites, Lights, and Darks. Whites include items that are predominantly white or off-white. Lights encompass pastels, light blues, pinks, and yellows. Darks include navy, black, deep reds, and other deeply saturated colors. Sometimes, a separate category for brightly colored items is helpful to minimize any potential slight bleeding.

For example, a light pink shirt would go with the lights, while a dark blue pair of jeans would be sorted with the darks. If you have a garment with multiple colors, place it with the darkest color present to err on the side of caution.

Q 2. How do you handle delicate items during the sorting process?

Delicate items require special handling to prevent damage during the washing process. These often include lingerie, silk garments, and items with embellishments like lace or sequins. When sorting, I always separate these items from the rest of the laundry. I often hand-wash or use a mesh laundry bag specifically designed for delicate items. This prevents them from getting snagged or stretched during the machine wash cycle.

For instance, I would never put a delicate lace bra in with a load of towels. The rough texture and tumbling action could irreparably damage the lace. Instead, I’d carefully hand-wash it or use a mesh bag for machine washing on a gentle cycle.

Q 3. What are the different methods for sorting laundry by fabric type?

Sorting by fabric type is just as important as color sorting for maintaining the quality and longevity of clothing. Different fabrics react differently to heat and agitation. Consider it like cooking – you wouldn’t cook a delicate fish the same way you’d cook a tough steak!

- Cotton: Durable and can withstand higher temperatures.

- Linen: Similar to cotton, but may require slightly gentler handling.

- Wool: Delicate and often requires hand-washing or a gentle wool cycle.

- Silk: Extremely delicate and almost always requires hand-washing.

- Synthetics (Polyester, Nylon, etc.): Generally durable but can be sensitive to high heat.

For example, I’d never put a wool sweater in with jeans. The wool might shrink or felt in the harsh cycle suitable for denim. Instead, I’d wash the sweater separately in cold water using a gentle cycle.

Q 4. Describe your experience with identifying and separating stained garments.

Identifying and separating stained garments is a critical step to prevent the stain from setting and spreading to other clothes. I always inspect each garment carefully before sorting. Knowing the type of stain is crucial; some stains respond better to pre-treatment than others.

I typically separate stained items and pre-treat them before washing. This could involve applying a stain remover, soaking in cold water, or other methods depending on the stain type. For example, a grease stain might require a pre-wash treatment with dish soap, while a wine stain would benefit from a cold water soak.

I always note the type of stain on a piece of paper and attach it to the garment so that I remember the best approach for removal. Failure to separate and treat stains can result in permanent damage or spread.

Q 5. How do you handle items requiring special washing instructions?

Items with special washing instructions, like those requiring dry cleaning or a specific water temperature, demand extra attention. These instructions are usually found on the garment’s care label. I always carefully review these labels before sorting.

For instance, if a garment requires dry cleaning, it is crucial that it is separated from all other items and sent to a professional dry cleaner. Similarly, items labeled “hand-wash only” should never be placed in a washing machine. Ignoring these instructions can lead to garment damage, shrinkage, or color fading.

Q 6. What is your approach to dealing with mixed loads of laundry?

Mixed loads require careful consideration of fabric type, color, and any special instructions. I would generally avoid mixed loads if possible to ensure optimal cleaning and garment care. However, if a mixed load is necessary, I would prioritize sorting by color and fabric type first, ensuring that all items in the load can tolerate similar water temperatures and wash cycles.

For example, a mixed load might include cotton items of similar colors, ensuring there are no delicate fabrics or colors that might bleed. This approach minimizes the risk of damage or discoloration.

Q 7. Explain the importance of pre-sorting laundry before washing.

Pre-sorting laundry before washing is essential for several reasons. It’s the foundation for successful laundry. It prevents color bleeding, protects delicate items from damage, and ensures that each garment is cleaned effectively.

Failing to pre-sort can lead to ruined clothing and a frustrating laundry experience. Consider it like organizing your tools before starting a project: proper preparation saves time and prevents unnecessary complications.

Q 8. How do you identify and address potential laundry damage during sorting?

Identifying potential laundry damage during sorting is crucial to prevent further damage and ensure the longevity of garments. It’s a multi-sensory process involving careful visual inspection and even a gentle touch.

Visual Inspection: I look for obvious signs of damage like tears, holes, loose buttons, or broken zippers. I also check for stains that might require special treatment or could set during washing. For example, a fresh red wine stain needs immediate attention; otherwise, it could become permanent.

Fabric Examination: I pay close attention to the fabric type. Delicate fabrics like silk or lace require separate handling and potentially hand-washing. Rough textures or frayed edges indicate potential for snagging during machine washing.

Addressing Potential Damage: If I find a loose button, I’ll secure it before washing to prevent loss. Small tears can be mended with a stitch or temporarily secured with fabric glue before washing. For larger damages, I might make a note for special attention or hand-washing to minimize further damage.

Think of it like a pre-flight check for clothes – a quick inspection before the ‘flight’ through the washing machine can prevent major problems.

Q 9. Describe a time you had to deal with a large volume of laundry quickly and efficiently.

During a large-scale hotel linen turnover, we had to process an enormous amount of laundry in a very short timeframe. We had approximately 500 bedsheets, pillowcases, and towels to sort and wash before the next day’s check-in.

To manage this efficiently, we implemented a streamlined process. We divided the team into smaller groups, each responsible for a specific task: sorting by color and fabric type, pre-treating stains, loading the washing machines, and transferring laundry to the dryers. Clear communication and efficient workflow were key. Using multiple washing machines and dryers in parallel significantly sped up the process. We prioritized quick-drying items and utilized commercial-grade equipment to maximize output. We even employed a color-coded system for different fabric types to minimize errors. The result was a flawless and timely completion of the task.

Q 10. How do you ensure accuracy in sorting and classifying laundry items?

Accuracy in laundry sorting relies on a systematic approach, meticulous attention to detail, and a strong understanding of fabric types and care instructions.

Color Sorting: This is fundamental to prevent color bleeding. I strictly separate whites, lights, and darks. I also pay attention to colors that might bleed, like reds or bright blues.

Fabric Type Sorting: I group items based on fabric type (cotton, linen, silk, wool, synthetics) and weight to ensure proper washing temperatures and cycles. Delicates are always kept separate.

Care Labels: I always check the care labels for specific instructions. These labels provide crucial information about washing temperatures, drying methods, and special treatments.

Visual Inspection: As mentioned earlier, I carefully inspect each item for stains, tears, or other potential problems that might require special attention.

Regularly reviewing and refining my sorting methods ensures consistently accurate classification. I constantly update my understanding of new fabrics and their care requirements.

Q 11. What are the potential consequences of improper laundry sorting?

Improper laundry sorting can lead to a range of undesirable consequences, from minor inconveniences to significant damage.

Color Bleeding: Mixing colors can cause dyes to transfer, ruining lighter-colored clothing.

Fabric Damage: Washing delicate items with heavier fabrics can cause snags, tears, and pilling. Using incorrect washing temperatures can shrink or damage certain fibers.

Stain Setting: Improper sorting can prevent timely stain removal, resulting in permanent stains.

Reduced Lifespan of Clothes: Incorrect handling accelerates wear and tear, shortening the lifespan of clothes.

Ultimately, improper sorting reduces efficiency, wastes resources, and can lead to significant losses.

Q 12. How do you handle items that are damaged or beyond repair?

Items beyond repair are handled with care and according to established procedures. My approach depends on the context – whether I’m in a household setting or a commercial laundry.

Household: For damaged items beyond repair, I’ll usually donate them to charities if they’re still usable as rags. Items with irreparable damage would be disposed of responsibly, often through recycling programs for textiles.

Commercial Laundry: In commercial settings, damaged items would be assessed for repairability. If not repairable, they’re usually discarded according to waste management regulations, often separated for textile recycling.

Record-keeping is crucial for tracking damaged or lost items to improve processes and prevent future incidents.

Q 13. What safety procedures do you follow when handling laundry?

Safety is paramount when handling laundry. This involves awareness of potential hazards and following established safety protocols.

Handling Chemicals: When using detergents, bleaches, or stain removers, I always wear appropriate protective gear like gloves and eye protection. I follow the product instructions carefully.

Machine Safety: I ensure that washing machines and dryers are properly loaded and operated according to manufacturer’s instructions. I avoid overloading machines, and I never reach into a running machine.

Ergonomics: I employ proper lifting techniques to avoid injuries. Heavy laundry baskets are lifted correctly, and I avoid prolonged periods of bending or reaching.

Hot Surfaces: I use caution when handling hot surfaces such as dryers or irons. I let hot items cool down before handling.

Regular equipment checks and maintenance are crucial for preventing accidents.

Q 14. How do you maintain a clean and organized laundry workspace?

Maintaining a clean and organized laundry workspace is essential for both efficiency and safety. This involves regular cleaning and strategic organization.

Regular Cleaning: I regularly wipe down surfaces, sweep or vacuum the floor, and empty lint traps in dryers. Any spills are cleaned immediately.

Organized Storage: Detergents, stain removers, and other cleaning supplies are stored properly, out of reach of children and away from moisture.

Designated Areas: I have designated areas for clean laundry, dirty laundry, and items needing repair. This helps maintain a clear workflow.

Equipment Maintenance: Regularly checking and cleaning laundry equipment such as washing machines, dryers, and ironing boards helps prevent malfunctions and maintain efficiency.

A clean and organized workspace prevents accidents, improves efficiency, and contributes to overall quality of work.

Q 15. How do you manage different laundry priorities (e.g., urgent vs. non-urgent)?

Managing laundry priorities involves a system that prioritizes urgency. Think of it like a hospital triage system – the most critical items get immediate attention. I typically use a color-coded system. Urgent items, like a stained work shirt needed for tomorrow’s presentation, are marked with a red tag and processed immediately. Non-urgent items, such as bedsheets, receive a green tag and can wait for a larger load. This ensures that time-sensitive items are handled promptly without impacting the overall laundry flow.

For example, if I’m facing a deadline and have several urgent items, I’ll put aside the non-urgent items and focus exclusively on the red-tagged ones, ensuring they are washed, dried, and folded efficiently. I may even use an express wash cycle on the washing machine to speed up the process. Once the urgent tasks are completed, I’ll then proceed to the non-urgent tasks, thereby maintaining an optimal balance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What experience do you have with different types of washing machines?

My experience encompasses various washing machine types, from top-loading agitator machines to high-efficiency (HE) front-loaders and even commercial-grade industrial washers. Each type has its own nuances. Top-loading agitators are great for heavily soiled items but can be rougher on clothes. HE front-loaders are more gentle on fabrics, use less water and energy, but require different detergent formulations. With industrial washers, I’m familiar with different water temperatures, cycle durations, and the importance of proper chemical dispensing.

For instance, when using an HE washer, I always ensure to use HE-compatible detergent to avoid excessive foaming and potential damage to the machine. With industrial washers, I follow the manufacturer’s instructions precisely concerning chemical dosage and cycle selection, depending on the fabric type and soil level. Understanding the specifics of each machine allows me to optimize the cleaning process and extend its lifespan.

Q 17. How do you troubleshoot issues related to laundry sorting or washing?

Troubleshooting laundry issues involves a systematic approach. First, I identify the problem: Is it related to sorting (e.g., color bleeding), washing (e.g., clothes not clean), or drying (e.g., clothes not dry)? Then, I investigate the possible causes. For example, if clothes are stained after washing, I check if I followed proper sorting guidelines (separating colors) or if the detergent was suitable for the fabric type. If clothes are not clean, I evaluate water temperature, detergent quantity, and the washing machine’s function.

A practical example: If a customer reports color bleeding, I’d first verify that items were sorted correctly. If the error was in sorting, the corrective action is clear; otherwise, I’d look at the water temperature—perhaps it was too hot, causing dye migration. By systematically examining each step, I pinpoint the root cause and implement the appropriate solution, ensuring the quality of the laundry service.

Q 18. Describe your understanding of different laundry detergents and their uses.

My understanding of laundry detergents extends beyond simply knowing the brand names. I comprehend their chemical compositions and how they interact with different fabrics and stains. I’m familiar with various types: powder detergents, liquid detergents, pods, and specialized detergents for delicates, colors, or stain removal. Powder detergents are generally more cost-effective, but can leave residue. Liquid detergents are more versatile, and pods offer convenience. Specialized detergents target specific issues, like removing grease or brightening whites.

For instance, I use a delicate detergent for items like silk or lace to prevent damage. For heavily soiled items, I might pre-treat stains with a stain remover before washing. Understanding the properties of each detergent allows me to select the best option for each load, guaranteeing optimal cleaning and fabric care.

Q 19. How do you deal with missing or misplaced laundry items?

Dealing with missing or misplaced laundry items requires a methodical approach. I start by retracing the laundry’s journey – from collection to sorting, washing, drying, and folding. I check all areas involved in the process: hampers, washing machines, dryers, folding areas, and even lost and found bins. If the item is still missing, I review the laundry logs to verify if it was even received. I then communicate with the owner about the situation and proceed with the steps agreed upon, like rescheduling a laundry service.

For example, if a sock is missing from a pair, I’ll thoroughly check the dryer lint trap, as socks can sometimes get lodged inside. If that doesn’t yield results, I might advise the owner to recheck their own belongings; sometimes an item is inadvertently taken away without notice. Good communication is key throughout this process.

Q 20. What are the key performance indicators (KPIs) for efficient laundry sorting?

Key Performance Indicators (KPIs) for efficient laundry sorting focus on speed, accuracy, and minimizing errors. These include:

- Sorting Time per Load: This measures the efficiency of the sorting process. A lower time indicates greater efficiency.

- Error Rate (Mis-sorted items): Tracks the number of incorrectly sorted items. A lower error rate signifies greater accuracy.

- Throughput: This represents the total number of loads sorted per unit of time. Higher throughput suggests better productivity.

- Damage Rate: Measures items damaged during sorting (e.g., snags). Lower rates point to improved handling techniques.

By monitoring these KPIs, I can identify areas for improvement, such as implementing better sorting strategies or providing additional training to ensure high efficiency and accuracy.

Q 21. What are your strategies for minimizing laundry loss or damage?

Minimizing laundry loss or damage necessitates careful handling at every stage. This includes:

- Proper Sorting: Separating items by color, fabric type, and soil level prevents color bleeding and damage to delicate items.

- Appropriate Detergents and Water Temperatures: Using suitable detergents and water temperatures protects fabrics from damage or fading.

- Careful Handling: Gentle handling of clothing during sorting, loading, and unloading minimizes snags and tears.

- Regular Machine Maintenance: Regular cleaning of washing machines and dryers prevents damage caused by lint buildup or other blockages.

- Repairing Damaged Items Promptly: Addressing small tears or snags quickly prevents them from worsening.

For instance, always checking pockets before washing prevents damage from items inside; using mesh laundry bags for delicates prevents them from getting caught in the machine. A proactive approach, paying attention to detail at each step, is vital in preserving the quality of the laundry.

Q 22. How do you adapt your sorting techniques to different laundry types (e.g., hospital, hotel)?

Adapting sorting techniques to different laundry types hinges on understanding the specific needs and potential biohazards associated with each environment. Hospital laundry, for example, requires stringent protocols to prevent the spread of infection. This involves meticulous sorting based on contamination levels – soiled linens are separated from clean ones, and further segregated into categories like surgical gowns, patient bedding, and staff uniforms. Each category may require different washing parameters to ensure effective decontamination.

In contrast, hotel laundry focuses on efficiency and maintaining high-quality finishes. Sorting might prioritize linen type (sheets, towels, pillowcases) and color, with less emphasis on stringent infection control. We may use color-coded bags or sorting racks to streamline the process and avoid mixing colors that could bleed.

A crucial difference lies in the documentation. Hospital laundry necessitates detailed tracking of each batch, including its origin, processing, and disposal to maintain comprehensive infection control records. Hotel laundry documentation focuses more on inventory management and ensuring timely service.

Q 23. Explain your understanding of different fabric composition and its impact on washing.

Understanding fabric composition is paramount for effective laundry processing. Different fibers react differently to heat, water, and detergents. For example, cotton is durable and can withstand high temperatures, while delicate fabrics like silk or wool require gentler handling and lower temperatures to prevent shrinkage or damage. Synthetic fibers, such as polyester or nylon, may be more resistant to wrinkling but could melt at high temperatures.

Consider a blend like cotton-polyester: the cotton component might shrink if washed too hot, while the polyester could melt under excessive heat. Therefore, understanding the percentage of each fiber in a fabric blend allows us to choose the appropriate washing parameters (temperature, spin speed, detergent type) to optimize cleaning and protect the garment. We use fabric composition guides and information labels diligently to inform our sorting and processing decisions.

Q 24. Describe your experience with industrial laundry equipment.

My experience with industrial laundry equipment is extensive, encompassing various types of washers, dryers, and finishing equipment. I’m proficient in operating high-capacity washers and extractors, understanding their cycles, water and energy efficiency parameters and troubleshooting malfunctions. I have hands-on experience with industrial dryers, including those with advanced features like heat recovery systems to optimize energy consumption.

I’m familiar with different types of ironing and folding equipment, including automated systems for higher throughput. Safety protocols surrounding heavy machinery are second nature to me; I’m trained in lock-out/tag-out procedures, regular safety inspections, and reporting any mechanical issues promptly. Experience with automated systems allows me to monitor and optimize the efficiency of the entire laundry workflow, identifying bottlenecks and suggesting improvements.

Q 25. How do you ensure compliance with health and safety regulations in a laundry environment?

Health and safety is my top priority. Compliance involves adhering to all relevant OSHA (Occupational Safety and Health Administration) regulations and maintaining a clean and organized workspace. This includes proper handling of chemicals, wearing appropriate Personal Protective Equipment (PPE) such as gloves and eye protection when handling detergents and disinfectants, and following strict hygiene protocols, particularly in handling potentially contaminated laundry.

Regular safety training is crucial, covering hazard identification, emergency procedures (fire safety, chemical spills), and the safe operation of machinery. Proper disposal of hazardous waste, including chemical containers and contaminated items, is crucial for environmental and health compliance. We meticulously maintain records of training, inspections, and incident reports to demonstrate our commitment to a safe working environment.

Q 26. How do you handle customer complaints regarding laundry services?

Handling customer complaints is a crucial aspect of providing excellent service. I approach each complaint with empathy and a commitment to finding a resolution. My first step involves actively listening to the customer, understanding their concerns without interruption. I then ask clarifying questions to fully grasp the issue, documenting all details carefully.

Depending on the nature of the complaint (damage to garments, unsatisfactory cleaning, delays), I determine the appropriate course of action, which might include re-washing the items, offering a discount on future services, or providing a replacement. Transparency is key; I clearly communicate the steps I’m taking to address the issue and keep the customer informed of the progress. Following up after the resolution is important to ensure customer satisfaction and gather feedback for continuous improvement.

Q 27. What are your strategies for continuous improvement in laundry sorting and classification?

Continuous improvement in laundry sorting and classification is achieved through a multi-pronged approach. Regularly reviewing our sorting procedures and identifying bottlenecks are crucial. This includes analyzing workflow, identifying areas where time is wasted or errors occur, and implementing changes to improve efficiency. Data analysis plays a key role; tracking the volume of different laundry types, processing times, and error rates helps to pinpoint areas needing attention.

Implementing new technologies, such as automated sorting systems using image recognition or RFID tags can significantly enhance efficiency and accuracy. Staff training and development is ongoing. Regular training sessions cover new techniques, best practices, and updated safety protocols. Feedback from staff is invaluable for identifying areas of improvement and for fostering a culture of continuous improvement. Finally, actively seeking industry best practices and benchmarks allows us to stay abreast of the latest advancements and apply them in our operations.

Key Topics to Learn for Sorting and Classifying Laundry Interview

- Understanding Fabric Types and Care Instructions: Learn to identify common fabrics (cotton, linen, silk, wool, synthetics) and their specific washing requirements (temperature, cycle, drying method). This includes recognizing symbols on clothing labels.

- Color Sorting and Stain Pre-Treatment: Master the art of separating whites, lights, and darks to prevent color bleeding. Understand basic stain removal techniques and appropriate pre-treatment methods for various stains (grass, grease, blood, etc.).

- Efficient Sorting Processes: Develop strategies for quickly and accurately sorting large volumes of laundry, minimizing handling time and maximizing efficiency. Consider techniques like pre-sorting by garment type or color before further classification.

- Handling Delicate Items: Learn proper handling procedures for delicate items like lingerie, sweaters, and other garments requiring special care. This includes understanding when hand-washing is necessary and appropriate drying methods.

- Safety and Hygiene Protocols: Familiarize yourself with laundry safety procedures, including the proper use of machinery, handling of chemicals (detergents, bleach), and maintaining a clean and organized work environment.

- Problem-Solving and Troubleshooting: Be prepared to discuss how you would handle common laundry problems, such as accidental color bleeding, shrinkage, or damage to garments. Demonstrate your ability to think critically and find solutions.

- Understanding Laundry Equipment: Become familiar with the operation and maintenance of various laundry equipment, including washing machines, dryers, and folding machines. Knowing the different settings and their applications will be beneficial.

Next Steps

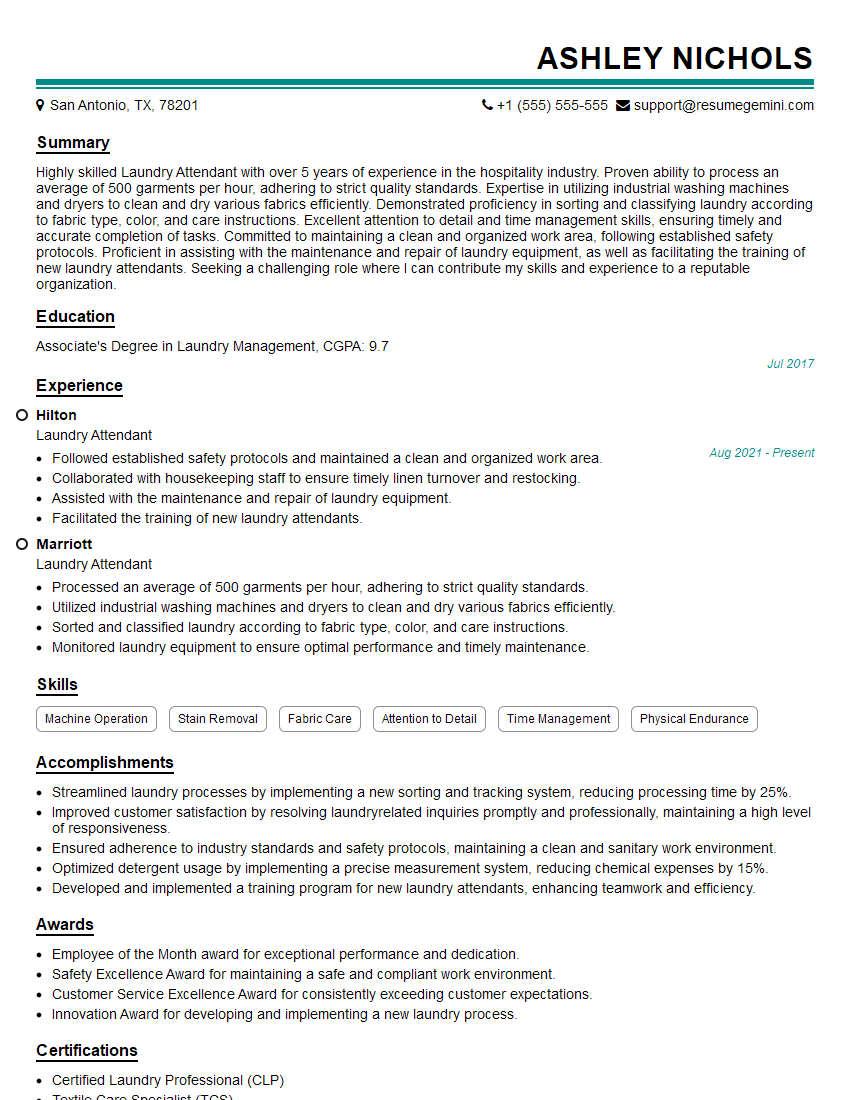

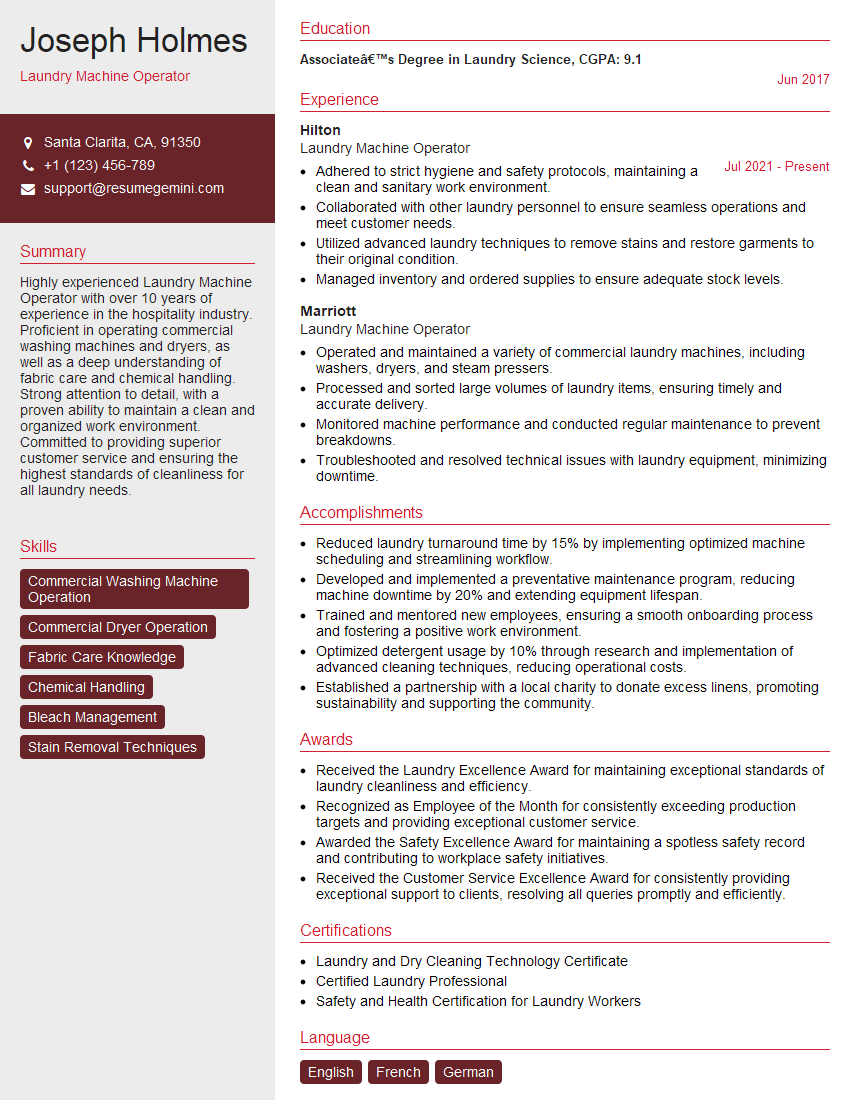

Mastering the art of sorting and classifying laundry is crucial for success in various roles, demonstrating attention to detail, efficiency, and problem-solving skills highly valued by employers. To significantly improve your job prospects, create a strong, ATS-friendly resume that highlights these skills. ResumeGemini is a trusted resource to help you build a professional resume that showcases your abilities effectively. Examples of resumes tailored to sorting and classifying laundry are available, helping you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good