Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Sorting and Classifying Linen interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Sorting and Classifying Linen Interview

Q 1. Describe your experience with different linen types (e.g., sheets, towels, uniforms).

My experience encompasses a wide range of linen types, from the everyday – like bed sheets (various thread counts, materials like cotton, linen, or blends), bath towels (different weights and absorbencies), and pillowcases – to more specialized items such as uniform textiles (hospital scrubs, hotel linens, restaurant napkins, etc.). I’m familiar with the unique handling requirements of each. For instance, high-thread-count sheets require gentler handling to prevent damage, while heavier towels can withstand more rigorous processes. Understanding the material composition – cotton, polyester blends, microfiber – is crucial because it dictates appropriate washing and drying temperatures and methods.

- Sheets: I’ve worked with various sizes, from twin to California king, and different materials, impacting their handling and sorting.

- Towels: Experience includes sorting bath towels, hand towels, washcloths, and even specialized towels like those used in spas or gyms, each with different sizes and weights.

- Uniforms: My expertise extends to handling delicate fabrics like those found in surgical scrubs, requiring careful sorting to avoid contamination and damage.

Q 2. How do you identify and separate soiled linen from clean linen?

Identifying soiled linen is paramount for hygiene and infection control. It’s a visual process, combined with a keen sense of smell. Soiled linen is often visibly dirty, stained, or marked with bodily fluids. A strong odor is another clear indicator. We use clearly marked containers or designated areas – often color-coded – to separate soiled from clean linen. Clean linen is stored in sealed bags or containers to prevent recontamination. Imagine it like separating your whites from your colors in laundry – but with higher stakes concerning hygiene and safety.

The separation process begins at the point of collection. Soiled linen is bagged or placed in designated hampers immediately to prevent spreading contamination. The bags are then transported directly to the laundry area, without any contact with clean linen.

Q 3. Explain your process for sorting linen by size, type, and condition.

Sorting linen involves a multi-step process that ensures efficient laundering and minimizes damage. First, we categorize by type (sheets, towels, uniforms). Then, we sort by size (e.g., twin, full, queen sheets; bath towels, hand towels). Finally, we assess the condition, separating out damaged or stained items for special handling. Think of it like organizing a filing cabinet: you wouldn’t file a tax return alongside a grocery list! Similarly, you don’t want to mix delicate uniforms with heavy towels.

- Type: This step separates sheets, towels, uniforms, etc., ensuring correct washing procedures for each material.

- Size: This prevents smaller items from getting lost or damaged with larger items during the washing process.

- Condition: Items with significant stains or tears are set aside for special handling, potential repair, or disposal.

Q 4. What methods do you use to count and track linen inventory?

Accurate linen inventory tracking is vital for efficient operations and cost control. We typically utilize a combination of methods: physical counts, barcode scanning, and dedicated linen management software. Physical counts are performed regularly, particularly at the beginning and end of shifts. Barcode scanning offers a faster, more accurate count, especially in high-volume settings. The software integrates these counts, tracking linen usage, loss, and the overall inventory levels. It’s like managing a stockroom inventory – you need to know what you have and how much you’re using.

The system allows us to generate reports on linen usage, identify potential loss areas, and predict future needs. This data-driven approach ensures we have the right amount of linen on hand to meet demand, while minimizing waste.

Q 5. How do you handle damaged or stained linen items?

Damaged or stained linen requires careful handling. Minor stains are pre-treated before laundering. For heavily stained items or those with significant damage, we assess the extent of the problem. Items beyond repair are discarded following proper disposal protocols. Repair is considered for items with minor tears or damage – we might mend a small tear in a sheet, for instance, rather than discarding it immediately. Think of it like a triage system – assess, treat, or dispose of as appropriate.

Documentation is crucial; we log the disposal or repair of each item, linking it to the inventory management system to maintain an accurate record. This process ensures adherence to hygiene standards and helps minimize linen loss and waste.

Q 6. Describe your experience with linen tagging and labeling systems.

Linen tagging and labeling systems are essential for efficient tracking. We typically use barcode labels that are attached to each item during its initial processing. These labels contain information such as linen type, size, and potentially a unique ID number. This helps in accurate inventory management, tracking the item’s life cycle from cleaning to potential disposal. Imagine it like a unique serial number for each piece of linen.

This system enhances efficiency in sorting, counting, and managing inventory. It also allows for quick identification of specific items, which is particularly useful if there’s an issue with a particular item or batch.

Q 7. What safety precautions do you follow when handling linen?

Safety is a top priority when handling linen. We adhere to strict guidelines to prevent injuries and infections. This includes wearing appropriate personal protective equipment (PPE), such as gloves, especially when handling soiled linen. Proper lifting techniques are essential to prevent back injuries, especially when dealing with heavier items like blankets or towels. We maintain a clean and organized workspace to minimize the risk of slips, trips, and falls.

Regular training on safety protocols, including proper handling and disposal of contaminated linen, is crucial for all staff. The goal is to ensure a safe and healthy environment for everyone involved in linen handling and processing.

Q 8. How do you prioritize tasks when faced with a large volume of linen?

Prioritizing linen tasks with high volume involves a structured approach. I use a system combining urgency and importance. Think of it like a hospital’s triage system – the most critical needs get immediate attention.

- Urgent & Important: This category includes tasks like soiled linen from operating rooms or emergency departments. These require immediate processing to maintain hygiene and patient safety.

- Important but Not Urgent: This might encompass clean linen stock replenishment for less critical areas. While important for consistent service, it can be scheduled for later in the day or next shift.

- Urgent but Not Important: This could include a sudden influx of linen from a specific department due to an unexpected event. While it demands quick action, the overall impact on the system isn’t as critical as the first category.

- Neither Urgent Nor Important: Tasks like minor inventory adjustments or equipment cleaning fall here. These are important for overall efficiency, but can be slotted when there’s downtime.

This approach ensures timely processing of critical items, while preventing bottlenecks and optimizing workflow. I frequently adapt this based on the daily volume and unexpected situations.

Q 9. Explain your experience with using linen chutes or carts.

I have extensive experience with both linen chutes and carts, each suited to different settings and needs. Linen chutes are excellent for high-volume, continuous flow situations, like in a large hospital. They provide a streamlined way to move soiled linen from various points to a central processing area, minimizing handling and improving hygiene. However, they require regular maintenance to prevent jams and ensure smooth operation.

Linen carts, on the other hand, offer more flexibility and control. They’re ideal for smaller facilities or situations needing specific routing and segregation of linen types. For example, we might have separate carts for highly contaminated items, requiring specific handling protocols. Efficient use involves proper labeling, regular cleaning, and a planned route to optimize collection and delivery times.

My experience involves optimizing both systems by implementing procedures for prompt emptying of chutes and efficient cart routing to maximize productivity and minimize handling of soiled linen.

Q 10. How do you ensure the efficient flow of linen through a processing system?

Efficient linen flow through the processing system relies on a carefully designed workflow, from collection to storage. Think of it as an assembly line, each stage meticulously planned for smooth operation.

- Collection & Sorting: Designated areas for soiled linen collection, using appropriate containers, and initial sorting based on linen type (e.g., towels, sheets, gowns) are crucial.

- Transportation: Efficient use of chutes or carts, depending on the setup. Regular maintenance of these systems is key.

- Washing & Drying: Optimized use of washing machines and dryers, with proper loading and scheduling to maximize throughput and minimize energy consumption.

- Folding & Finishing: Efficient folding and stacking techniques, potentially using automated machinery for high-volume processing, to improve speed and consistency.

- Storage & Distribution: Clearly labeled shelves or racks to facilitate easy retrieval and distribution, and regularly updated inventory systems to avoid shortages.

Regular monitoring of each stage and adjusting workflow as needed, based on real-time data, is essential for maintaining optimal flow. I often use visual management tools, such as Kanban boards, to track progress and identify bottlenecks.

Q 11. What are your strategies for maintaining cleanliness and order in a linen room?

Maintaining cleanliness and order in a linen room is paramount for hygiene and efficiency. It involves a multi-pronged approach.

- Regular Cleaning Schedule: Daily cleaning of floors, surfaces, and equipment is essential. This involves using appropriate disinfectants and following safety protocols.

- Organized Storage: Clearly labeled shelves and storage areas for different linen types, ensuring easy access and preventing mix-ups. Proper shelving and stacking methods maximize space and prevent items from getting crushed or damaged.

- Pest Control: Regular pest checks and preventative measures to avoid infestation, which can contaminate linen and create a hygiene risk.

- Inventory Management: A well-organized inventory system helps prevent clutter and improves workflow efficiency by knowing what’s available and when replenishment is needed.

- Staff Training: Training staff on proper hygiene practices and procedures is vital to maintain cleanliness. This includes handling soiled linens safely and following appropriate cleaning protocols.

By implementing a comprehensive cleaning and organization plan, we can ensure a safe and efficient linen room. Visual cues, like color-coded containers, can be very helpful in improving staff compliance and reducing errors.

Q 12. Describe your experience with linen inventory management software.

My experience with linen inventory management software has been overwhelmingly positive. It significantly improves accuracy, reduces manual errors, and streamlines the entire process. Specifically, I’ve used systems that track linen usage, predict demand based on historical data, and generate reports on linen consumption. This aids in strategic purchasing, minimizing waste, and reducing costs.

Features such as barcode scanning for accurate tracking, real-time inventory updates, and automated ordering have proven invaluable. For example, one software I used alerted us to a potential shortage of surgical gowns a week in advance, allowing us to place an order and avoid a critical supply issue. Data analysis from these systems helps in identifying trends, optimizing stock levels, and making informed decisions about linen purchasing and management.

Q 13. How do you identify and report discrepancies in linen counts?

Identifying and reporting linen count discrepancies involves a systematic approach. It starts with accurate tracking at every stage of the linen cycle.

- Regular Counts: Conducting regular physical counts of linen in storage, comparing them against the inventory system.

- Variance Analysis: Investigating any discrepancies between physical and recorded counts. This might involve checking for errors in data entry, losses due to damage, or theft.

- Documentation: Meticulously documenting all discrepancies, including the date, type of linen affected, quantity, and possible causes.

- Reporting: Communicating findings to relevant personnel, such as the purchasing department or management, to initiate corrective actions.

The use of barcode scanning and robust inventory management software significantly reduces discrepancies, but thorough audits and attention to detail are essential for maintaining accurate linen counts. A root cause analysis of recurring discrepancies helps in implementing preventive measures.

Q 14. What are the common challenges you face when sorting and classifying linen?

Several common challenges arise when sorting and classifying linen.

- Mixed Linen Types: Dealing with a mix of different types of linen, such as sheets, towels, and gowns, can lead to delays if not properly sorted.

- Soiled Linen Handling: Safe and hygienic handling of soiled linen is crucial to prevent cross-contamination and maintain a safe working environment.

- Damage Identification: Identifying and separating damaged or stained linen requires careful inspection to prevent further contamination or repairs.

- Inventory Discrepancies: Maintaining accurate linen counts and identifying discrepancies can be challenging, leading to potential shortages or overstocking.

- Staff Training: Ensuring consistent application of sorting and classification standards across the team through proper training.

Implementing clear guidelines, providing adequate training, and utilizing appropriate tools and technology can significantly mitigate these challenges. Regular monitoring and adjustments to processes are essential for continuous improvement.

Q 15. How do you handle emergency situations, such as a shortage of clean linen?

A linen shortage is a serious operational challenge. My approach is multifaceted and prioritizes immediate action alongside long-term preventative measures. First, I would immediately assess the severity and nature of the shortage – is it a specific linen type, a general lack across the board, or a temporary issue? This assessment guides my response.

Immediate Actions:

- Inventory Re-allocation: I’d meticulously check all linen storage areas to identify any overlooked or mislabeled items that can be quickly deployed. This includes potentially moving less critical linen from areas with excess to those facing shortages.

- Prioritization: If the shortage is severe, I’d prioritize linen distribution to areas with the most urgent needs, like operating rooms or patient care units, potentially delaying less critical areas temporarily.

- Communication: Transparent communication with all relevant departments (housekeeping, laundry, management) is crucial. This ensures everyone is aware of the situation and cooperates effectively. This also involves informing patients of potential minor delays in linen changes, emphasizing the importance of maintaining cleanliness and hygiene.

Long-Term Preventative Measures:

- Improved Inventory Management: Regular and accurate linen counts, coupled with robust inventory management software, can help to predict shortages and allow for timely ordering of replacements.

- Par levels optimization: Defining and maintaining appropriate par levels (the minimum stock level of each linen type) can prevent running out of essential items.

- Vendor Relationship Management: Strong relationships with linen suppliers can ensure prompt delivery in case of unexpected issues or increased demand.

For example, during a busy holiday period once, we faced a temporary shortage of bath towels. By re-allocating towels from less frequented areas and emphasizing guest understanding, we minimized the impact and quickly resolved the situation through expedited delivery from our supplier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different linen folding techniques?

My experience encompasses a wide range of linen folding techniques, tailored to different linen types and intended use. Proficiency in various folding styles is essential for optimizing storage space, maintaining linen quality, and ensuring a professional presentation. I am skilled in:

- Standard Folding: The basic, neat fold suitable for most linens, like sheets and pillowcases.

- Hospital Corner Folding: This technique creates a crisp, professional fold ideal for hospital settings and ensures the linen stays flat.

- Butterfly Fold: An efficient method for folding towels, resulting in a compact and visually appealing presentation.

- Mitered Corner Fold: A more elaborate fold, mainly used for decorative linens or those meant for display, enhancing the aesthetic appeal of the linen.

- Modified Rolls: Used for items like blankets and towels, this method optimizes storage space and allows for efficient inventory management.

The choice of folding technique is not arbitrary. For instance, while butterfly folds are efficient for towels, a hospital corner fold might be preferred for bedsheets to ensure cleanliness and easy placement on beds. The efficiency and aesthetics each folding style offers make it crucial to the proper organization and visual appeal of linen.

Q 17. Describe your understanding of linen hygiene and sanitation standards.

Linen hygiene and sanitation are paramount in any healthcare or hospitality setting. My understanding encompasses both the practical application of cleaning and sanitizing procedures and the adherence to relevant standards and regulations. This involves:

- Pre-sorting and segregation: Separating soiled linen from clean linen, often based on the level of soiling (e.g., heavily soiled, lightly soiled), to prevent cross-contamination.

- Appropriate washing temperatures: Using the correct water temperature and detergent based on the linen type to kill bacteria and remove stains effectively. High temperatures (at least 71°C/160°F) are typically required for effective sterilization of many linen types.

- Drying protocols: Utilizing industrial dryers with adequate airflow and time to ensure complete drying, preventing the growth of mold or mildew.

- Ironing and pressing (where appropriate): Proper ironing helps to remove wrinkles and create a professional finish, but it’s essential to use the right heat setting to prevent damage to the fabric.

- Storage conditions: Maintaining clean and well-ventilated storage areas to prevent the buildup of dust, moisture, and pests.

- Adherence to infection control protocols: Strict adherence to guidelines set by organizations like the CDC (Center for Disease Control) or local health authorities ensures safety and prevents the spread of infection.

Regular inspections and staff training on proper handling procedures are also crucial elements in maintaining linen hygiene standards. For instance, ensuring staff wear appropriate personal protective equipment (PPE) like gloves when handling soiled linens is non-negotiable.

Q 18. How do you ensure the proper storage of different linen types?

Proper linen storage is vital for maintaining cleanliness, preventing damage, and optimizing efficiency. My approach involves organizing and storing different linen types according to their characteristics and use. This includes:

- Designated Storage Areas: Separate, well-ventilated areas for clean and soiled linen are essential to prevent contamination. These areas should be well-lit and accessible for efficient retrieval.

- Categorization and Labeling: Clear labeling systems, potentially using color-coded shelving or bins, help in quickly identifying and locating specific types of linen (e.g., sheets, towels, pillowcases). This improves efficiency and minimizes the risk of misplacement.

- Stacking and Folding Techniques: Proper stacking prevents wrinkles and minimizes damage. The chosen stacking technique may vary depending on the type of linen and available storage space.

- Storage Containers: Using appropriate containers (shelving, drawers, bins) helps protect linens from dust, moisture, and pests. For example, using airtight containers for storage in humid environments can prevent mold growth.

- Rotation of Stock (FIFO): Utilizing a First-In, First-Out (FIFO) system ensures that older linens are used before newer ones, minimizing the risk of linen degradation due to prolonged storage.

For example, we use a color-coded system for towels: white for guest rooms, blue for staff, and green for special use. This immediately helps identify which towels should be used where and simplifies linen organization.

Q 19. What are your methods for preventing linen loss or theft?

Preventing linen loss or theft requires a combination of physical security measures and procedural controls. My strategies include:

- Secure Storage Areas: Limiting access to linen storage areas and using locks and security systems helps prevent unauthorized access.

- Inventory Control Systems: Regular inventory checks, coupled with barcode or RFID tracking, provide an accurate account of linen stock levels, quickly identifying any discrepancies.

- Staff Training and Accountability: Educating staff on linen handling procedures and emphasizing their responsibility in preventing loss or theft is critical.

- Regular Audits: Periodic audits can detect potential issues or weaknesses in the existing procedures and identify areas for improvement.

- Surveillance Systems (if appropriate): In high-risk environments, security cameras can deter theft and provide evidence in case of loss.

- Clear Linen Tracking Systems: Numbering or tagging linens (if cost-effective) allows for easy tracking and identification of any missing items.

For example, implementing a system where staff sign out linens and account for any shortages significantly reduced losses. Combining this with regular inventory checks made it easier to catch and address any issues promptly.

Q 20. Explain your experience with working under pressure and meeting deadlines.

I thrive under pressure and consistently meet deadlines. My ability to manage multiple tasks efficiently stems from a well-structured approach and a keen awareness of priorities. I’m proficient in using time-management techniques such as prioritizing tasks, breaking down large projects into smaller, manageable steps, and setting realistic deadlines.

For example, during a period of high occupancy at a previous role, I efficiently organized and managed a large linen inventory, ensuring timely delivery to all departments while maintaining high standards of cleanliness and hygiene. This was achieved through delegating tasks, prioritizing urgent requests, and using my organizational skills to streamline the workflow.

I’m also adept at adapting to unexpected changes and challenges. In situations with tight deadlines, I can quickly assess the situation, re-prioritize tasks, and efficiently manage resources to meet the requirements while maintaining quality.

Q 21. How do you adapt to changes in workflow or linen handling procedures?

Adaptability is crucial in linen handling. I approach changes in workflow or procedures with a proactive and positive attitude. My approach is:

- Open Communication: Actively participate in meetings discussing changes, asking clarifying questions, and ensuring a complete understanding of the new procedures.

- Training and Learning: Embrace opportunities for training on new methods and technologies. I focus on understanding the rationale behind changes to maximize effectiveness.

- Flexibility and Patience: Be flexible and patient during the transition period. Acknowledge that adjustments take time and focus on achieving mastery of the new procedures.

- Feedback and Improvement: Proactively offer feedback on the effectiveness of new procedures, highlighting any potential challenges or areas for improvement.

- Documentation: Ensure all new procedures are clearly documented and readily accessible for reference.

For instance, when our laundry facility implemented new automated sorting machinery, I readily participated in the training program and actively helped other team members adapt. By understanding the new technology and workflow, I was able to enhance efficiency and improve team performance during the transition. Providing feedback on the initial setup also led to a better integration of the new system.

Q 22. Describe a time you had to troubleshoot a problem in a linen processing area.

One time, we experienced a significant backlog in our linen processing due to a malfunctioning sorting machine. The machine, responsible for separating soiled linens by color and type, was jamming repeatedly. This led to a build-up of unprocessed linen and threatened to disrupt the hospital’s supply. My first step was to systematically check the machine’s diagnostics. The error code indicated a problem with the sensor responsible for differentiating colors. We tried restarting the machine, which didn’t resolve the issue. Then, we checked the sensor for any physical damage or obstruction. After a thorough inspection, we discovered a small piece of metal lodged within the sensor, preventing accurate readings. We carefully removed the obstruction, cleaned the sensor, and restarted the machine. To prevent future incidents, we implemented a more rigorous daily inspection of the machine, including a check of the sensor’s functionality.

This experience reinforced the importance of meticulous diagnostics and preventive maintenance in maintaining efficient linen processing. It also highlighted the need for teamwork; I collaborated with a maintenance technician to ensure the machine’s timely repair. Finally, it underscored the impact of even small problems on the overall workflow and the criticality of prompt resolution.

Q 23. How do you maintain accuracy while performing repetitive tasks?

Maintaining accuracy in repetitive tasks is crucial in linen processing. To avoid errors, I use a combination of techniques. Firstly, I establish a structured workflow. For example, I might follow a checklist to ensure each step – sorting, counting, stacking – is completed accurately. Secondly, I employ visual cues. Imagine differentiating between slightly different shades of white sheets. I might group them by subtle shade variations to help ensure uniformity. Thirdly, I use regular self-checks. After sorting a batch of linen, I visually inspect it to verify my work. Regular breaks also help prevent fatigue-induced errors, ensuring attention to detail.

I also use counting methods like grouping items into sets of five or ten, and I always double-check my counts. Think of it like a cashier counting money; consistent, methodical counting prevents errors. Finally, I’m always open to feedback and use any identified mistakes as learning opportunities to further refine my process.

Q 24. What are the key indicators of linen quality?

Linen quality is judged on several key indicators. Firstly, the fiber content is important. High-quality linen often uses longer, stronger fibers resulting in a more durable and softer fabric. Secondly, thread count is a significant factor. A higher thread count generally means a denser, more durable fabric. Thirdly, the fabric construction plays a role. A tightly woven fabric will be more resistant to tearing and wear. Next, we look at the colorfastness – the ability of the fabric to retain its color even after repeated washing. Finally, shrinkage is crucial. High-quality linens should have minimal shrinkage after washing. A visual inspection checks for defects such as holes, stains, or excessive wear and tear. All these factors combine to determine the overall quality and usability of the linen.

Q 25. Explain your understanding of infection control protocols related to linen handling.

Infection control is paramount in linen handling. Our protocols strictly adhere to guidelines for handling soiled linen to prevent the spread of infections. This includes using designated containers for soiled linen, avoiding direct contact with soiled materials, and handling them carefully to avoid spreading contaminants. Proper personal protective equipment (PPE) like gloves and gowns is essential, and appropriate hand hygiene practices are strictly followed before and after handling linen. The linen is transported in sealed bags or containers, and all soiled linen is immediately processed through high-temperature washing cycles to kill any pathogens. Regular cleaning and disinfection of linen processing equipment and the surrounding area are also critical. In short, the entire process from collection to disposal is designed to minimize the risk of cross-contamination.

Q 26. How familiar are you with different laundry equipment and machinery?

I’m familiar with a wide range of laundry equipment and machinery. This includes industrial washing machines (both tunnel and batch washers), dryers (including high-extraction and tumble dryers), automated sorting systems, and linen folding machines. I’m proficient in operating and maintaining these machines, understanding their safety protocols, and recognizing potential malfunctions. My experience extends to using various types of pressing equipment, including flatwork ironers and steam presses. I also understand the importance of preventative maintenance to ensure the efficient and safe operation of these machines. I’m comfortable troubleshooting basic mechanical issues, although I know when to involve a qualified maintenance technician for more complex repairs.

Q 27. What are your strengths in terms of teamwork and communication in a laundry setting?

In a laundry setting, teamwork and communication are essential. My strengths lie in effective collaboration. I understand the importance of clear, concise communication within a team, whether it’s coordinating tasks, reporting issues, or seeking assistance. I proactively communicate potential problems to prevent delays or bottlenecks. I’m a strong team player, comfortable working alongside others to meet shared goals. My approach is to actively listen to colleagues’ suggestions, offering my support and contributing my expertise to create a collaborative and efficient work environment. I also actively contribute to resolving conflicts constructively, ensuring positive team dynamics are maintained. For example, I’ve worked with colleagues to adjust workflow to optimize linen sorting, leading to reduced processing times and improved efficiency.

Q 28. Describe your experience working with different linen materials (cotton, polyester, blends).

I have extensive experience working with various linen materials, including cotton, polyester, and their blends. Cotton is a naturally absorbent fabric that’s comfortable but can wrinkle easily and require careful handling to prevent shrinkage. Polyester is more wrinkle-resistant and durable but may not be as absorbent as cotton. Blends combine the advantages of both; for instance, a cotton-polyester blend might offer both absorbency and wrinkle resistance. My understanding of these material properties guides my approach to sorting, washing, and handling each type. For example, I would use different washing temperatures and cycles for cotton and polyester blends to prevent damage. I know which fabrics require gentler handling to prevent damage and what drying methods are suitable to maintain the quality and longevity of each material.

Key Topics to Learn for Sorting and Classifying Linen Interview

- Understanding Linen Types: Learn to identify different types of linen (e.g., sheets, towels, uniforms) and their characteristics (material, size, condition).

- Sorting Techniques: Master efficient sorting methods based on factors like color, size, material, and condition. Consider the impact of different sorting strategies on workflow efficiency.

- Quality Control Procedures: Understand how to identify damaged, stained, or otherwise unusable linen items and the appropriate procedures for handling them.

- Classification Systems: Familiarize yourself with various classification systems used in laundry facilities or healthcare settings. Be prepared to discuss the advantages and disadvantages of different systems.

- Inventory Management: Understand the importance of accurate linen inventory tracking and how it contributes to efficient operations and cost control. Explore methods for maintaining accurate records.

- Safety and Hygiene Protocols: Demonstrate knowledge of appropriate safety procedures and hygiene practices to ensure a safe and clean working environment. This includes handling soiled linen and using equipment safely.

- Problem-Solving in Linen Handling: Practice identifying and resolving common issues that may arise during the sorting and classifying process, such as discrepancies in linen counts or damaged items.

- Technological Applications: Explore the use of technology in linen management, such as barcode scanners or automated sorting systems.

Next Steps

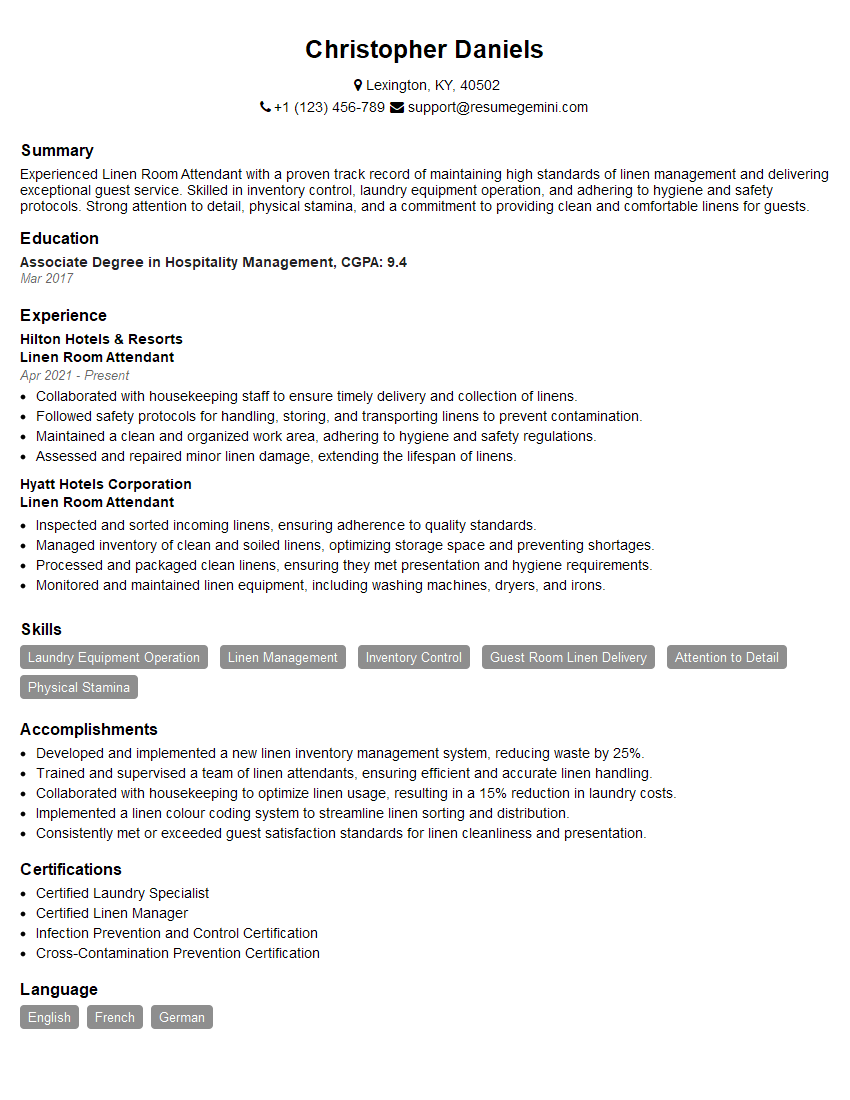

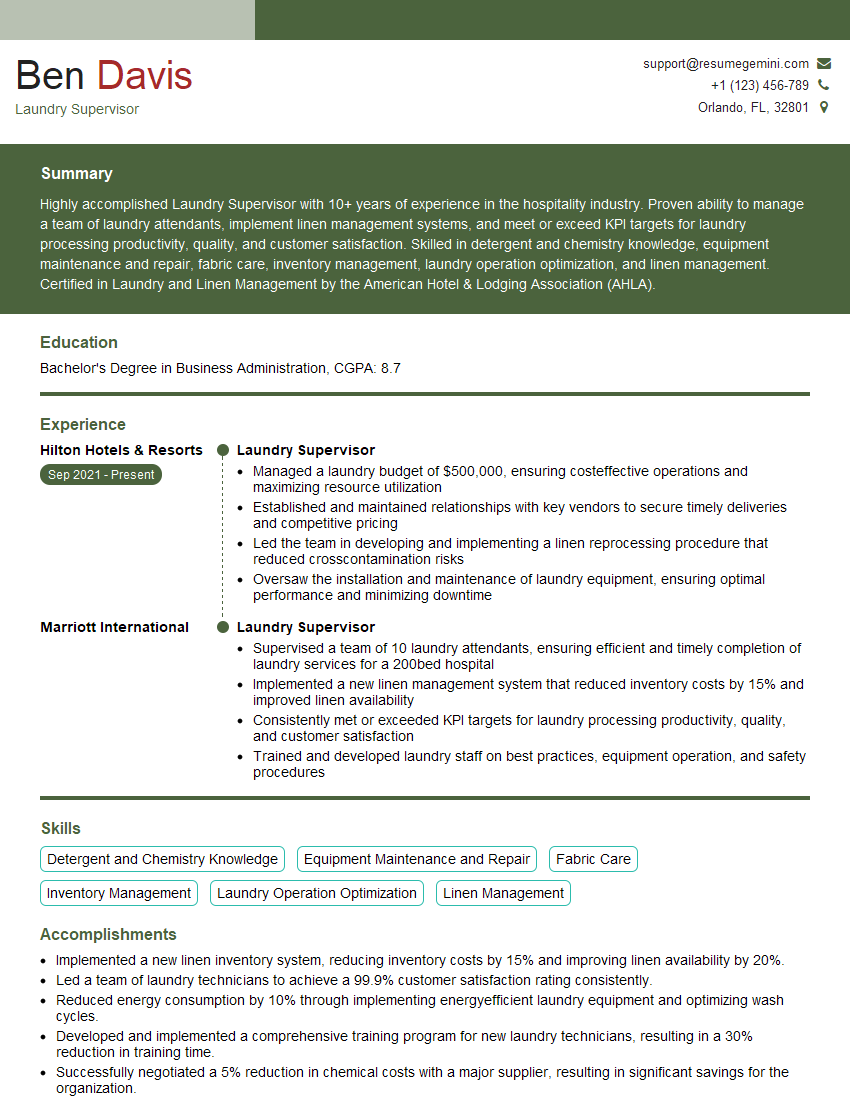

Mastering the art of sorting and classifying linen is crucial for a successful career in laundry services, hospitality, or healthcare. These skills demonstrate attention to detail, efficiency, and adherence to procedures – highly valued attributes in many industries. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Sorting and Classifying Linen roles, offering you a head start in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good