Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Sorting and Grading Oysters interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Sorting and Grading Oysters Interview

Q 1. Explain the different size grades for oysters.

Oyster size grading is crucial for market standardization and consumer expectations. Sizes are typically categorized by count per bushel or by shell length, varying slightly depending on regional regulations and market demands. For instance, a common grading system uses counts like ’40s’ (40-50 oysters per bushel), ’50s’ (50-60 oysters per bushel), and so on, with lower numbers indicating larger oysters. Another system measures shell length, classifying oysters into categories such as ‘small,’ ‘medium,’ ‘large,’ and ‘extra-large,’ with specific length ranges defining each category. These ranges are often regulated by governing bodies to ensure consistency.

Imagine trying to sell oysters without standardized sizing – it would be chaotic! Grading ensures that restaurants and consumers get the size they expect, leading to better customer satisfaction and fair pricing.

Q 2. Describe the process of visually inspecting oysters for quality.

Visual inspection is a critical step in oyster grading, ensuring quality and safety. We carefully examine each oyster for several key factors. First, we check the shell for any damage, such as cracks or breakage, indicative of compromised integrity. We assess the shell’s closure – a tightly closed shell generally suggests a live, healthy oyster. Then, we look at the condition of the oyster’s meat, where possible, checking for any signs of discoloration or unusual texture, indicative of spoilage or disease. We’re also looking for parasites or other foreign bodies that might be visible through the shell. Experienced graders develop a keen eye for detecting subtle signs of quality differences.

Think of it like a skilled jeweler examining a gemstone – years of experience refine the ability to spot even the smallest imperfections.

Q 3. What are the common defects found in oysters during grading?

Several defects can be found during oyster grading. Shell damage, including cracks, chips, and broken shells, is common and significantly affects the oyster’s marketability and shelf life. Discoloration of the meat (e.g., brownish hues) often indicates spoilage or disease. Abnormal texture, such as mushiness or unusual firmness, can signal bacterial contamination or other quality issues. The presence of parasites or foreign bodies within the oyster meat is a serious defect necessitating immediate rejection. Finally, excessive mud or debris attached to the shell indicates poor handling or cultivation practices.

- Shell Damage: Cracks, chips, broken shells

- Meat Discoloration: Brownish, greenish hues

- Abnormal Texture: Mushy, excessively firm

- Parasites/Foreign Bodies: Worms, debris

- Excessive Mud/Debris: Poor handling

Q 4. How do you identify and handle oysters with shell damage?

Oysters with shell damage are handled with extra care to prevent further injury and contamination. Oysters with minor cracks or chips may be salvageable, depending on the extent of the damage and the presence of any other defects. However, we would prioritize separating these from undamaged oysters to prevent cross-contamination. Severely damaged oysters are immediately rejected because they are more susceptible to bacterial contamination and spoilage. This is important to maintain food safety standards. They must be disposed of following proper sanitation protocols.

It’s like sorting apples – minor bruises are acceptable for certain uses, but rotten ones need immediate separation.

Q 5. What are the criteria for rejecting oysters?

Several criteria lead to oyster rejection. The most critical is the presence of disease or parasites, as these pose a significant health risk to consumers. Severe shell damage, indicating compromised integrity and increased vulnerability to bacterial growth, is another reason for rejection. Oysters exhibiting obvious signs of spoilage, like discoloration or foul odor, are immediately rejected. Any indication of contamination by foreign bodies or excessive mud and debris also results in rejection.

Food safety is paramount; any doubt about an oyster’s quality leads to immediate rejection.

Q 6. Explain the importance of maintaining sanitation during oyster sorting and grading.

Maintaining sanitation during oyster sorting and grading is essential for preventing contamination and ensuring food safety. This involves regular hand washing and the use of clean gloves, ensuring all equipment and surfaces are thoroughly sanitized. Any damaged or rejected oysters should be properly disposed of to prevent cross-contamination. Water used for cleaning should be regularly changed and the entire workspace should be kept clean and organized. Adherence to strict sanitation protocols is crucial to meeting food safety regulations and maintaining a high-quality product.

Think of a surgical operation – the level of cleanliness required is very similar in our work.

Q 7. Describe your experience with different oyster varieties and their grading requirements.

My experience encompasses a range of oyster varieties, each with its unique grading characteristics. For example, Kumamoto oysters, known for their small size and delicate flavor, are graded using different size scales compared to larger oysters like Pacifics. The shell shape and texture also influence grading. Pacific oysters often have deeper cups than Kumamotos, requiring slightly different handling during sorting. Furthermore, the grading criteria can also vary based on the intended market – wholesale versus retail, requiring different size specifications and handling.

Each oyster type has its personality, and we need to understand them to properly grade them.

Q 8. How do you ensure consistent grading throughout the process?

Consistent oyster grading is crucial for maintaining quality and meeting market demands. We achieve this through a multi-pronged approach, starting with standardized training for all our graders. Each grader receives thorough instruction on the size and shape specifications for each grade, using visual aids and hands-on practice. We also employ calibrated measuring tools like oyster gauges and sizing templates to ensure objective measurements, regardless of the grader. Regular quality checks are implemented throughout the process, where a supervisor randomly samples graded oysters to verify accuracy against the established standards. Discrepancies trigger retraining or adjustments to the grading process. Imagine it like baking a cake – you need consistent measurements to ensure a consistent result. In our case, consistent grading ensures consistent product quality and customer satisfaction.

Q 9. What are the safety regulations you must follow while handling oysters?

Oyster handling involves strict adherence to food safety regulations. This includes maintaining a clean and sanitized work environment, following personal hygiene protocols like wearing gloves and hairnets, and ensuring proper refrigeration to prevent bacterial growth. We meticulously check for and remove any oysters exhibiting signs of damage or disease. Compliance with local and national shellfish sanitation regulations is paramount; this often involves regular testing for harmful bacteria and adherence to specific handling procedures outlined by health authorities. Failing to comply with these regulations poses serious health risks and can lead to significant legal consequences. Think of it as a surgical procedure – precision and sterility are essential to ensure a safe and healthy outcome.

Q 10. How do you handle a situation where there’s a large volume of oysters to be processed?

High-volume oyster processing demands efficient strategies and potentially increased personnel. We implement a streamlined workflow, dividing tasks among teams specializing in different stages – from initial cleaning and sorting to grading and packing. We might utilize automated sorting equipment (discussed in the next answer) for larger sizes and grades, reserving manual grading for more nuanced distinctions. Effective communication between teams is essential to avoid bottlenecks. We also prioritize efficient storage and transportation to minimize delays and spoilage. Imagine a well-oiled machine – each part plays its role smoothly and efficiently to produce the final product on time and in full.

Q 11. Describe your experience with different oyster sorting equipment.

My experience encompasses a range of oyster sorting equipment, from basic manual sizing tools to advanced automated systems. Manual methods involve using oyster gauges and templates to measure individual oysters, which is effective for smaller volumes but time-consuming for larger ones. Automated sorters utilize sophisticated technology such as optical scanners and robotic arms to rapidly measure and sort oysters according to size and even shape. These machines significantly increase throughput and reduce labor costs, but they can be expensive to purchase and maintain. Each type has its strengths and weaknesses; choosing the right equipment depends on factors such as volume, budget, and the desired level of precision. I’ve found that a combination of manual and automated systems is often the most effective approach for optimal efficiency and accuracy.

Q 12. How do you manage time effectively during peak oyster processing seasons?

Peak seasons demand meticulous time management. We utilize detailed production schedules to forecast demand and optimize resource allocation. This includes adjusting staffing levels, coordinating with suppliers for timely oyster deliveries, and ensuring maintenance on equipment is completed before the peak period. We track progress using real-time dashboards that provide clear visibility of output and potential bottlenecks. Effective communication and collaboration between teams are crucial to navigate the increased workload efficiently. We also prioritize preventative measures to avoid disruptions, like having backup equipment and trained personnel ready. Think of it like conducting an orchestra; each musician needs to be ready at the right time to produce the most beautiful sound.

Q 13. Explain the different methods used to measure oyster size.

Oyster size measurement employs various methods, primarily focusing on shell length and sometimes volume. Shell length is the most common method and usually measured using calibrated gauges or rulers, with oysters categorized into size grades based on these measurements (e.g., small, medium, large). Sometimes, volume (or weight) is also used, particularly for shucked oysters or when determining the overall yield. This often involves using weighing scales. The specific grading scales and units of measurement (e.g., inches, centimeters, ounces, grams) vary depending on local regulations and market demands. The consistency of measurement is critical to avoid disputes and ensure fair pricing.

Q 14. What is your understanding of traceability and record keeping in oyster processing?

Traceability and record-keeping are fundamental to maintaining food safety and meeting regulatory requirements. Every stage of the process, from harvest location and date to processing and distribution, is meticulously documented. This often involves using unique identifiers (like lot numbers) to track batches of oysters throughout their journey. Detailed records of temperature monitoring, sanitation procedures, and any quality control checks are maintained for full transparency and accountability. This information is readily available to regulatory bodies and consumers, ensuring confidence in the safety and origin of the oysters. Robust record-keeping is crucial not only for complying with regulations but also for identifying and addressing any potential issues with product quality or safety.

Q 15. Describe your experience working under pressure and meeting deadlines.

Working in oyster processing often means juggling multiple tasks under tight deadlines, especially during peak seasons. I thrive in this environment. For example, during a recent harvest where a storm threatened to delay our processing, we implemented a streamlined sorting and grading system. By delegating tasks efficiently and focusing on the most critical steps first (prioritizing the highest-quality oysters for immediate shipment), we managed to process everything before the storm hit. My experience also includes working with automated systems which further enhance the speed and efficiency of the process. This requires me to be able to quickly troubleshoot any technical issues while maintaining the pace of operations. I am adept at prioritizing tasks, anticipating bottlenecks, and motivating my team to meet challenging deadlines under pressure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle disagreements or conflicts with colleagues regarding oyster grading?

Disagreements regarding oyster grading can arise, but I believe in open and respectful communication. For instance, if a colleague and I disagree on the grade of a particular oyster, I first seek to understand their reasoning. We may examine the oyster together, referencing the established grading standards (size, shell condition, meat quality). We might even consult a more senior grader to provide an objective opinion. My goal is always to find a consensus based on the established criteria rather than letting personal preferences dominate. If a resolution cannot be reached, I’ll bring it to the supervisor, ensuring that the decision is both fair and aligned with our company’s standards.

Q 17. What are the key indicators of freshness in oysters?

Oyster freshness is crucial for both quality and safety. Key indicators include:

- Shell Condition: Fresh oysters have tightly closed shells. If the shell is open and doesn’t close when tapped, it’s a sign of spoilage.

- Smell: Fresh oysters should have a clean, slightly sweet, briny scent. Any foul or ammonia-like smell indicates spoilage.

- Liquor Appearance: The liquor (liquid inside the shell) should be clear and not cloudy or discolored.

- Meat Appearance: The oyster meat should be plump, firm, and moist, not shrunken or slimy. Its color varies depending on the species and location but should be consistent within the batch.

Beyond these visual cues, proper temperature control throughout the supply chain is paramount to ensure freshness.

Q 18. How do you identify and prevent cross-contamination during oyster processing?

Cross-contamination is a serious concern in oyster processing. We employ rigorous procedures to prevent it. This includes:

- Dedicated Workstations: Separate areas are designated for receiving, sorting, cleaning, and packing to prevent cross-contamination between different stages.

- Sanitation Protocols: All equipment and surfaces are thoroughly cleaned and sanitized between batches. We frequently use approved food-grade sanitizers.

- Protective Gear: Employees wear gloves, aprons, and hairnets to prevent contamination from personal contact.

- Temperature Control: Maintaining appropriate temperatures slows bacterial growth and minimizes the risk of contamination.

- Traceability Systems: Thorough record-keeping allows for rapid identification and removal of any contaminated batches.

Training on proper hygiene practices is an integral part of employee onboarding.

Q 19. What are the common industry standards for oyster grading?

Industry standards for oyster grading vary slightly depending on the region and market, but several common factors are considered:

- Size: Oysters are typically graded according to shell size, often using specific measurements or size ranges (e.g., small, medium, large).

- Shell Condition: The presence of damage, deformities, or excessive fouling (attached organisms) impacts grade.

- Meat Condition: The quality and quantity of oyster meat play a crucial role in grading. Factors like plumpness, color, and texture are assessed.

- Taste and Aroma: Sensory evaluation, while subjective, often plays a part, especially in higher-grade oysters.

These grading criteria are typically defined in detailed protocols by regulatory bodies or industry organizations. These guidelines not only ensure product quality but also help maintain market consistency and consumer trust.

Q 20. Describe your knowledge of different oyster harvesting techniques.

Oyster harvesting techniques vary depending on the species, water depth, and location. Some common methods include:

- Hand Harvesting: Divers or workers wade into shallow waters to collect oysters by hand. This is labor-intensive but minimizes damage to the oyster beds.

- Dredging: A dredge, a type of scoop or rake, is dragged along the seabed to collect oysters. This method is faster but can be less selective and potentially damaging to the environment.

- Tonging: Long tongs are used to lift oysters from the seabed. This technique is more selective than dredging but still requires significant effort.

Sustainable harvesting practices are essential to ensure the long-term health of oyster populations. This includes adhering to catch limits, respecting seasonal closures, and utilizing methods that minimize environmental impact.

Q 21. How do you maintain the quality of oysters during storage and transportation?

Maintaining oyster quality during storage and transportation relies on proper temperature control and handling. Oysters are highly perishable and must be kept cold to slow down bacterial growth. This typically involves:

- Refrigeration: Oysters should be stored at temperatures between 33°F and 40°F (0°C and 4°C). Rapid cooling after harvest is critical.

- Proper Packing: Oysters should be packed carefully to minimize damage during transport. Using appropriate containers and cushioning materials is important.

- Transportation: Refrigerated trucks or other means of transport must maintain consistent cold temperatures throughout the journey. Regular monitoring of temperatures throughout storage and transport is key.

- Humidity Control: Keeping the oysters in a humid environment prevents them from drying out.

Adherence to these practices ensures that oysters reach consumers in optimal condition, maintaining freshness and preserving their delicate flavors.

Q 22. What is your experience with oyster packaging and labeling procedures?

Oyster packaging and labeling are crucial for maintaining product quality and meeting regulatory requirements. My experience encompasses the entire process, from selecting appropriate packaging materials based on oyster size and intended shelf life to ensuring accurate and compliant labeling. This includes clearly displaying information mandated by agencies like the FDA, such as the harvest date, packing date, shellfish growing area identification, and any relevant warnings or handling instructions. For example, I’ve worked extensively with various packaging types, including mesh bags for live oysters, ice-packed containers for shorter transport times, and vacuum-sealed pouches for extended shelf life. Labeling accuracy is paramount; any inaccuracies can lead to significant problems, including consumer safety risks and legal repercussions. I meticulously ensure that every label matches the contents of each package, employing robust quality control checks at every stage of the process. We use barcodes for traceability and inventory management, contributing to improved efficiency and reduction of waste.

Q 23. Describe your understanding of food safety regulations concerning oysters.

Food safety regulations surrounding oysters are extremely stringent due to the risk of harmful bacteria and biotoxins. My understanding encompasses a broad range of regulations, including those set by the FDA, NOAA, and state-level agencies. These regulations cover aspects like harvesting areas, water quality testing, handling practices, temperature control during storage and transportation, and traceability systems. For instance, I’m well-versed in the National Shellfish Sanitation Program (NSSP) guidelines, which establish standards for the safe harvesting, processing, and distribution of shellfish. Crucially, I understand the importance of maintaining proper temperature control (generally below 45°F or 7°C) throughout the entire supply chain to prevent bacterial growth. Any deviation from these regulations can lead to severe consequences, including product recalls, fines, and potential health risks to consumers. I regularly attend industry updates to stay abreast of the latest regulatory changes and best practices.

Q 24. How would you identify and address a potential biotoxin contamination event?

Identifying and addressing a biotoxin contamination event requires immediate and decisive action. The first step involves recognizing the potential symptoms, which might include unusual oyster mortality in the growing area or reports of illness in consumers. We would then initiate a thorough investigation, including testing the oysters and the surrounding water for the presence of biotoxins (like PSP, DSP, or ASP) using standard laboratory procedures. If contamination is confirmed, we’d immediately initiate a recall of the affected product, notifying relevant authorities (like the FDA and state health departments) and our distributors. Simultaneously, we would thoroughly clean and sanitize all affected equipment and facilities to prevent further contamination. Traceability systems are vital in such situations, allowing us to pinpoint the exact source of the contamination and quickly identify and isolate the affected batches. We would also work with experts to determine the root cause of the contamination and implement corrective actions to prevent future occurrences. Open communication with regulators and consumers is crucial throughout the entire process.

Q 25. What are your experience with oyster depuration?

Oyster depuration is a crucial process for improving the safety and quality of oysters by reducing bacterial contamination. My experience with depuration involves understanding the principles of controlled water purification, including the use of UV sterilization and ozone treatment. This process involves placing oysters in a carefully controlled environment with clean, aerated seawater for a specific period to allow them to naturally purge themselves of harmful bacteria. The effectiveness of depuration depends on various factors, such as water quality, oyster size, and temperature. I have worked with both land-based and in-water depuration systems. I meticulously monitor the water parameters (temperature, salinity, dissolved oxygen, and bacterial levels) throughout the process and use various tests to evaluate the efficacy of the depuration, confirming the reduction of bacterial loads before releasing the oysters for sale. Accurate record-keeping and adherence to regulatory standards are paramount throughout the depuration cycle.

Q 26. How would you address an oyster grading discrepancy between you and a colleague?

Grading discrepancies between colleagues are addressed through a collaborative and objective process. First, we would calmly review the oysters in question together, clarifying our respective grading criteria. The NSSP provides specific size classifications, which we would use as the basis for our discussion. We might use calibrated tools like oyster gauges to ensure objective measurements. If the discrepancy persists, we’d refer to established company grading protocols and potentially consult with a senior supervisor or expert to resolve the issue. The goal is to arrive at a consensus using a standardized approach, ensuring consistency and fairness. It’s vital to maintain a professional and respectful dialogue throughout this process, recognizing that differences in perception can happen but seeking to find common ground. Documenting the resolution helps to prevent future misunderstandings and ensures that everyone is on the same page.

Q 27. Describe the ideal working environment for efficient oyster sorting and grading.

An ideal oyster sorting and grading environment prioritizes efficiency, hygiene, and worker well-being. This includes a well-lit, spacious facility with adequate work surfaces and proper drainage systems to manage waste and water. The area should be kept clean and sanitized to minimize bacterial contamination and comply with food safety regulations. Proper temperature control is essential, maintaining the oysters at the appropriate temperature throughout the process. Ergonomic workspaces are crucial to prevent injuries from repetitive tasks and promote the comfort of the workers. Furthermore, having appropriate equipment, such as calibrated oyster gauges, scales, and containers for size separation is crucial. Sufficient storage space for graded oysters is also necessary, maintaining the cold chain throughout the process. A well-designed environment contributes directly to the quality of the product and the productivity of the team.

Q 28. What steps would you take to improve the efficiency of the oyster sorting process?

Improving the efficiency of the oyster sorting process requires a multi-pronged approach. Firstly, optimizing the workspace layout and workflow can significantly reduce handling time. This might involve implementing a more efficient sorting line, using conveyor belts or automated sorting systems for larger operations. Investing in appropriate equipment like electronic scales and size-grading machines can also enhance speed and accuracy. Training employees on proper sorting techniques and providing them with the necessary tools can greatly enhance productivity. Regular quality control checks at various stages of the process would help catch and rectify errors early on. Introducing data-driven approaches through tracking metrics like sorting time, waste, and accuracy can also highlight areas for improvement and support continuous enhancement. Regular maintenance of equipment and effective team communication are equally vital for maintaining high efficiency levels.

Key Topics to Learn for Sorting and Grading Oysters Interview

- Oyster Anatomy and Morphology: Understanding the physical characteristics of oysters is fundamental to accurate grading. This includes recognizing different species and their variations.

- Grading Standards and Regulations: Familiarize yourself with industry-standard grading systems (e.g., size, shape, shell condition). Knowing relevant regulations and certifications is crucial.

- Quality Assessment Techniques: Learn how to assess oyster quality based on factors like shell closure, meat condition, and overall appearance. Practice your observation skills.

- Sorting Equipment and Methods: Understand the various tools and machinery used in oyster sorting and grading processes. This includes manual sorting and automated systems.

- Hygiene and Safety Protocols: Demonstrate knowledge of food safety regulations and best practices for handling oysters to maintain hygiene and prevent contamination.

- Yield and Efficiency Calculations: Be prepared to discuss methods for calculating yield and optimizing sorting efficiency. This often involves understanding volume and weight measurements.

- Problem-Solving in Oyster Sorting: Consider scenarios where you might encounter issues (e.g., damaged oysters, unusual sizes). Practice explaining how you would address these challenges.

- Communication and Teamwork: Effective communication and collaboration are key in a fast-paced environment. Be ready to discuss how you work within a team.

Next Steps

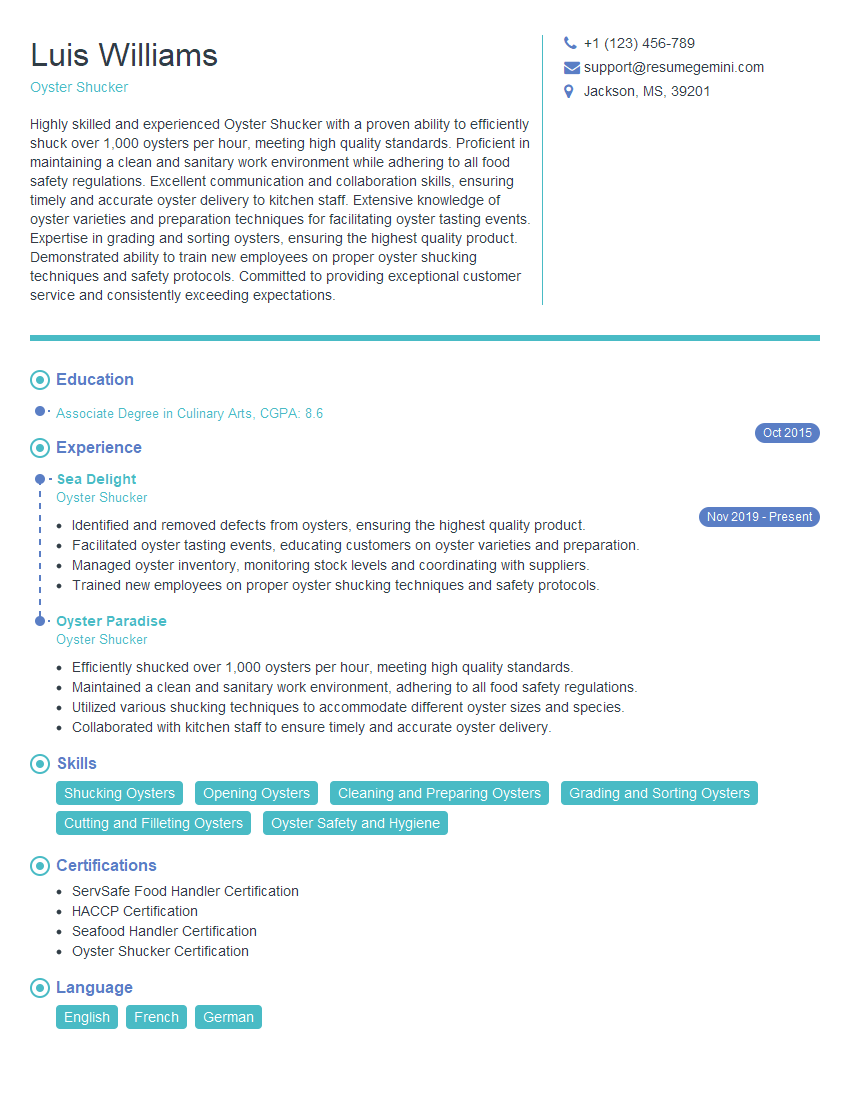

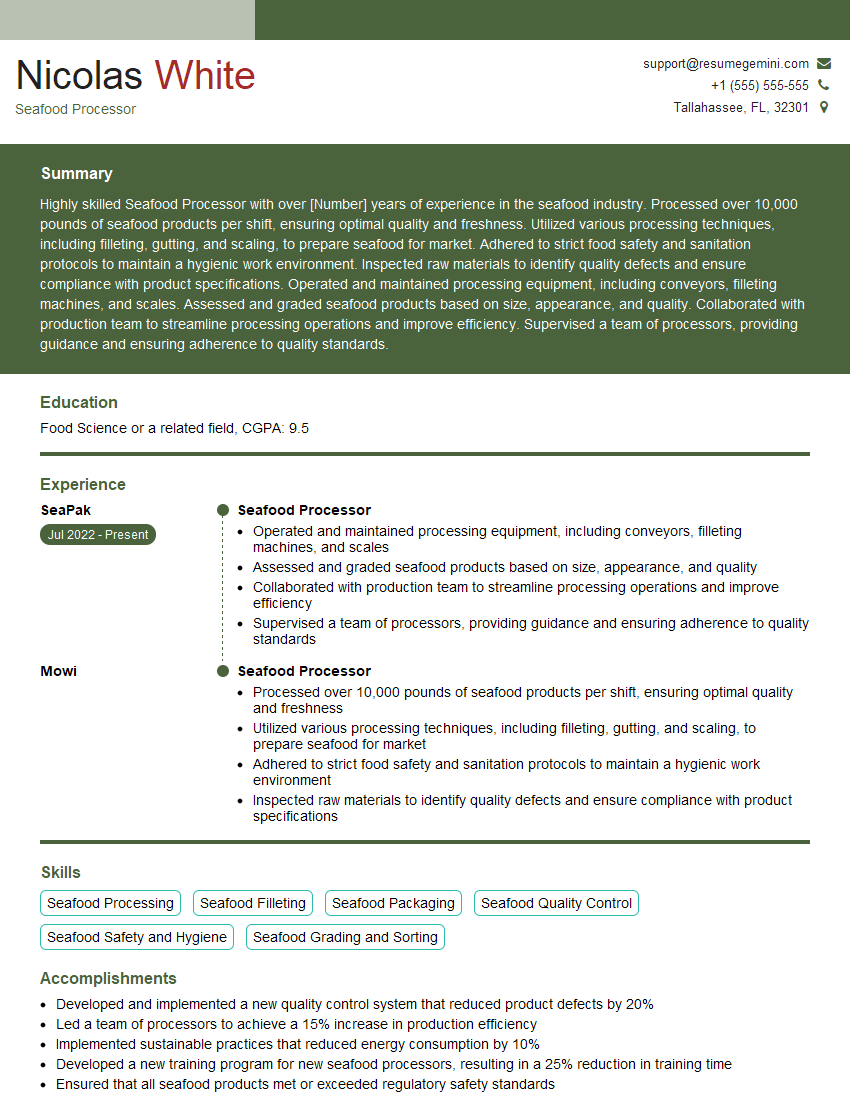

Mastering the art of sorting and grading oysters opens doors to a rewarding career in the aquaculture industry, offering opportunities for advancement and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume, highlighting your skills and experience in this specialized field. Examples of resumes tailored to Sorting and Grading Oysters are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).