Preparation is the key to success in any interview. In this post, we’ll explore crucial Sorting and Loading interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Sorting and Loading Interview

Q 1. Explain the different types of sorting methods you are familiar with.

Sorting methods are crucial for efficient organization. I’m proficient in several, each with strengths and weaknesses depending on the data size and structure.

- Bubble Sort: Simple to understand, but highly inefficient for large datasets. It repeatedly steps through the list, compares adjacent elements and swaps them if they are in the wrong order. Think of it like gently bubbling the largest items to the top.

- Insertion Sort: Efficient for small datasets or nearly sorted data. It builds the final sorted array one item at a time. Imagine sorting a hand of playing cards – you pick up one card at a time and insert it into its correct position in your already sorted hand.

- Merge Sort: A divide-and-conquer algorithm, highly efficient even for large datasets. It recursively divides the list into smaller sublists until each sublist contains only one element, then repeatedly merges the sublists to produce new sorted sublists until there is only one sorted list remaining. This is like efficiently merging two already sorted lines of people.

- Quick Sort: Another divide-and-conquer algorithm, generally faster than Merge Sort in practice, but its performance can degrade to O(n^2) in worst-case scenarios (e.g., already sorted data). It selects a ‘pivot’ element and partitions the other elements into two sub-arrays, according to whether they are less than or greater than the pivot.

- Heap Sort: Uses a binary heap data structure to sort an array. It’s guaranteed O(n log n) time complexity, making it a reliable choice for large datasets, though slightly less efficient than QuickSort in average cases.

My selection of the appropriate algorithm always considers factors like dataset size, pre-sorted nature of the data, and memory constraints.

Q 2. Describe your experience with various loading techniques.

Loading techniques are critical for safety and efficiency. My experience spans various methods, tailored to the goods and destination.

- Pallet Loading: Optimizing pallet space to maximize truck capacity and prevent shifting during transit. I’m experienced in various stacking patterns to ensure stability and efficient use of space. For example, I know the difference between a cross-dock operation and a direct-to-customer delivery and adjust my loading strategy accordingly.

- Container Loading: This requires careful planning to optimize weight distribution and maximize space utilization within shipping containers. I use specialized software to create loading plans that minimize empty space and ensure safe transport. I also consider the weight limitations of the containers and ensure even weight distribution to avoid imbalance.

- Bulk Loading: Handling loose materials like grains or powders requires different equipment and procedures. Safety is paramount; I ensure proper sealing and containment to prevent spills and ensure compliance with all relevant regulations.

- Manual Loading: For smaller shipments or delicate items, manual loading is sometimes necessary. I prioritize ergonomics and safety, utilizing proper lifting techniques and equipment to avoid injuries.

I adapt my techniques based on the specific characteristics of the goods, the destination, and the available resources. For example, fragile items will require careful hand-packing and specific loading patterns while heavy materials require a crane or forklift and a strong understanding of weight distribution.

Q 3. How do you prioritize tasks when faced with multiple sorting and loading demands?

Prioritization is crucial in a fast-paced environment. I use a combination of techniques:

- Urgency and Importance Matrix: Categorizing tasks based on urgency and importance helps me focus on time-sensitive, high-priority tasks first. For example, rush orders for perishable goods are given precedence.

- First In, First Out (FIFO): For standardized processes, FIFO ensures fair treatment and prevents delays. However, I am flexible and willing to adapt my priorities to changes in demand.

- Client/Order Prioritization: Client needs and contractual obligations sometimes dictate the order of operations. I ensure transparent communication with clients about potential delays or challenges.

I frequently communicate with supervisors and colleagues to re-evaluate priorities as new information emerges or unexpected events occur. This collaborative approach ensures optimal resource allocation and timely delivery.

Q 4. What safety measures do you employ during sorting and loading operations?

Safety is my top priority. I rigorously follow all safety protocols and regulations:

- Personal Protective Equipment (PPE): Consistent use of safety boots, gloves, high-visibility vests, and other appropriate PPE is mandatory.

- Equipment Safety Checks: Before operating any equipment (forklifts, pallet jacks, etc.), I conduct thorough inspections to ensure they are in safe working condition.

- Proper Lifting Techniques: Using correct lifting techniques to prevent back injuries is critical, especially during manual loading.

- Hazard Identification and Risk Assessment: I proactively identify potential hazards (e.g., slippery floors, unstable stacks) and take appropriate measures to mitigate risks.

- Following established procedures: Adhering strictly to established loading and unloading protocols prevents accidents and maintains an organized workflow.

I actively participate in safety training and promote a safe work environment for myself and my colleagues. I believe in a proactive approach to safety, preventing accidents before they happen.

Q 5. How do you ensure accuracy in sorting and loading processes?

Accuracy is vital to avoid errors and customer dissatisfaction. I employ several strategies:

- Double-Checking: Verifying item counts and order details multiple times during the sorting and loading processes minimizes errors.

- Barcode/RFID Scanning: Using scanning technologies to track and verify items ensures accuracy and reduces the risk of human error.

- Clear Labeling and Documentation: Thorough labeling of items and maintaining accurate documentation ensures traceability and facilitates efficient tracking throughout the process.

- Visual Inspection: Regular visual checks for damaged or missing items help maintain quality control. This includes checking for any signs of damage to the goods themselves, or to their packaging that may not have been detected before.

- Quality Control Checks: Periodic audits and quality control checks help identify and rectify any inaccuracies in the processes.

A commitment to detail and the use of appropriate technology are key to maintaining accuracy and building trust with clients.

Q 6. Describe your experience using warehouse management systems (WMS).

I have extensive experience with Warehouse Management Systems (WMS), utilizing them to optimize efficiency and accuracy.

- Inventory Management: WMS allows real-time tracking of inventory levels, enabling proactive replenishment and preventing stockouts. This is critical for efficient operations and avoiding delays.

- Order Fulfillment: WMS streamlines the order fulfillment process by providing optimized picking routes and guiding workers through the various stages of order preparation. This greatly reduces the time required for order picking and packing.

- Loading Optimization: Some WMS systems offer advanced loading optimization capabilities, suggesting optimal loading plans to maximize truck space and minimize transportation costs. This allows for maximum efficiency in using truck space.

- Reporting and Analytics: WMS provides valuable data on warehouse operations, allowing for performance analysis and identification of areas for improvement. This data is essential for making informed decisions about the warehouse operations.

My experience with WMS includes [mention specific WMS software used, e.g., Manhattan Associates, SAP WM]. I’m comfortable using these systems to improve operational efficiency and enhance customer satisfaction.

Q 7. How do you handle damaged or defective goods during sorting and loading?

Handling damaged or defective goods requires careful procedures to ensure compliance and minimize losses.

- Identification and Segregation: Damaged or defective items are immediately identified and segregated from undamaged goods to prevent contamination or further damage.

- Documentation: Detailed documentation of the damage, including photos and descriptions, is crucial for claims and inventory adjustments.

- Disposition: Depending on the nature and extent of damage, items may be repaired, returned to the supplier, salvaged, or disposed of appropriately. I am well-versed in procedures for each of these options.

- Reporting: Regular reporting of damaged goods helps identify trends and potential causes, informing preventative measures.

- Safety Procedures: Damaged goods may pose safety risks. I follow all appropriate safety procedures while handling them to prevent injuries.

I ensure that all procedures align with company policies and relevant regulations, maintaining a consistent approach to handling damaged goods and minimizing their impact on overall operations.

Q 8. Explain your experience with different types of material handling equipment.

Throughout my career, I’ve gained extensive experience operating and maintaining a wide variety of material handling equipment. This includes:

- Conveyors: From simple belt conveyors to complex roller and chain conveyors, I’m proficient in their operation, maintenance, and troubleshooting. For example, I once diagnosed a recurring belt slippage issue on a high-volume package conveyor by identifying a misalignment in the rollers, a simple fix that significantly increased efficiency.

- Forklifts: I’m certified in operating various forklift types, including sit-down, stand-up, and reach trucks, and understand the importance of safety protocols and load capacity limits. I’ve used forklifts to move pallets of goods in a warehouse environment, ensuring safe and efficient loading of trucks.

- Automated Guided Vehicles (AGVs): My experience extends to working with AGVs, understanding their programming and integration within a larger warehouse management system. I’ve helped streamline operations by optimizing AGV routes and improving their interaction with other equipment.

- Pallet Jacks and Hand Trucks: While seemingly simple, these tools require proper technique to avoid injuries. I’ve always emphasized correct lifting techniques to my team, preventing strain and injuries.

My familiarity with these machines allows me to optimize workflow, improve safety, and contribute to higher throughput in sorting and loading operations.

Q 9. How do you maintain efficiency while adhering to safety regulations?

Maintaining efficiency while adhering to safety regulations is paramount in sorting and loading. It’s not a trade-off; it’s a synergy. I achieve this through a multi-pronged approach:

- Proactive Safety Measures: I begin by conducting thorough pre-shift inspections of all equipment, ensuring everything is in optimal working order and identifying potential hazards before they become problems. This includes checking for loose parts, damaged components, and proper functioning of safety mechanisms.

- Training and Communication: I emphasize the importance of proper lifting techniques, the use of Personal Protective Equipment (PPE), and the adherence to all safety procedures. Regular training and clear communication are key in ensuring everyone understands and follows the rules.

- Process Optimization: Implementing efficient workflows, optimizing material flow, and strategically arranging the workplace reduces unnecessary movements and risks. For instance, placing frequently used materials within easy reach minimizes the need for heavy lifting or reaching, preventing strain and accidents.

- Regular Audits and Reporting: I believe in documenting everything. Regular safety audits and reports help to track performance, identify recurring issues, and track improvements. This data helps to inform continuous improvement strategies.

Essentially, safety is integrated into every aspect of my work, leading to both a safer and more efficient operation.

Q 10. Describe a time you had to solve a problem related to sorting or loading.

In a previous role, we experienced a significant bottleneck in our outbound shipping due to an unexpected surge in orders of a specific product. The existing sorting system, designed for even distribution, was overwhelmed. This caused delays and threatened to impact customer delivery times.

To solve this, I first analyzed the problem, identifying the specific product causing the congestion and its unique characteristics (large size, fragile nature). Then, I implemented a temporary solution:

- Prioritization: We prioritized the processing of this specific product, assigning extra personnel to that area.

- Route Optimization: We adjusted the conveyor routing to create a dedicated lane for this product, bypassing unnecessary sorting steps.

- Protective Packaging: We introduced additional protective packaging to reduce the risk of damage during the faster handling.

This combination of quick thinking and pragmatic solutions allowed us to quickly alleviate the bottleneck and meet our delivery commitments. It highlighted the importance of adaptability and problem-solving skills in a dynamic environment.

Q 11. How do you manage your time effectively when faced with tight deadlines?

Effective time management under tight deadlines requires a structured approach. My strategy involves:

- Prioritization: I use methods like the Eisenhower Matrix (urgent/important) to prioritize tasks, focusing on the most critical activities first.

- Task Breakdown: Breaking down large tasks into smaller, manageable steps allows for better tracking of progress and prevents feeling overwhelmed.

- Time Blocking: I allocate specific time slots for particular tasks, minimizing distractions and maximizing focus. This helps maintain momentum.

- Communication and Delegation: Open communication with my team is essential. If possible, I delegate tasks appropriately to leverage the team’s strengths and spread the workload efficiently.

- Contingency Planning: I always build in buffer time to account for unforeseen delays or complications.

By combining these techniques, I can effectively manage my time, even under pressure, ensuring deadlines are met while maintaining quality.

Q 12. What is your experience with inventory management in a sorting and loading context?

Inventory management is crucial in a sorting and loading context. It directly impacts efficiency, minimizes waste, and prevents stockouts or overstocking. My experience includes:

- Real-time Tracking: Utilizing barcode scanners and warehouse management systems (WMS) to track inventory levels in real-time allows for accurate stock control and informed decision-making regarding replenishment.

- Cycle Counting: Performing regular cycle counts (auditing a portion of the inventory periodically) helps identify discrepancies early, preventing larger problems later.

- FIFO/LIFO Management: Implementing First-In, First-Out (FIFO) or Last-In, First-Out (LIFO) inventory methods based on product characteristics (perishability, expiration dates) ensures optimal stock rotation.

- Demand Forecasting: Analyzing historical data and anticipating demand fluctuations helps optimize storage and handling, preventing bottlenecks and unnecessary storage costs.

Efficient inventory management ensures that the right products are in the right place at the right time, supporting a smooth and efficient sorting and loading process.

Q 13. How do you ensure the proper labeling and documentation of sorted and loaded goods?

Proper labeling and documentation are critical for traceability and accountability throughout the supply chain. I ensure this through a system that incorporates:

- Standardized Labeling: Using clear, consistent labeling systems, including barcodes and unique identifiers, allows for easy tracking of individual items and packages.

- Automated Labeling Systems: Where appropriate, integrating automated labeling systems into the sorting and loading process minimizes errors and increases efficiency.

- Accurate Documentation: Maintaining detailed records, including manifests, waybills, and shipping documents, provides a complete audit trail and facilitates tracking of shipments.

- Quality Control Checks: Implementing checks at various stages of the process to verify the accuracy of labels and documentation, minimizing errors and preventing potential issues later in the supply chain.

This robust system ensures accurate and reliable information flow, minimizing errors and facilitating seamless handling and tracking of goods.

Q 14. Describe your experience with different types of packaging materials and their applications.

My experience encompasses a variety of packaging materials, each with its own strengths and applications:

- Cardboard Boxes: These are widely used for their versatility, affordability, and recyclability. The choice of cardboard type depends on the product’s weight, fragility, and shipping conditions.

- Plastic Packaging: This offers protection against moisture and damage but is less eco-friendly. Different types of plastic are chosen depending on the required level of protection and the product’s characteristics.

- Pallet Wrapping: Used to secure and protect pallets, plastic stretch film or other materials ensure stability during transportation. Different types offer varying degrees of strength and UV protection.

- Bubble Wrap and Foam Packaging: Provides excellent cushioning and protection for fragile goods. The amount and type of cushioning material chosen depends on the product’s fragility.

- Specialized Packaging: For items requiring specific protection, I have experience with custom-designed packaging, including vacuum sealing, temperature-controlled containers, etc.

Selecting the appropriate packaging material is crucial for product protection, minimizing damage and costs, and ensuring customer satisfaction.

Q 15. How do you handle unexpected delays or disruptions in the sorting and loading process?

Unexpected delays and disruptions are a reality in sorting and loading. My approach focuses on proactive planning and reactive problem-solving. Proactive measures include building buffer time into schedules, having contingency plans for common issues like equipment malfunctions or supplier delays, and maintaining strong relationships with transportation providers to secure alternative options when needed.

Reactively, I prioritize communication. If a delay occurs, I immediately inform all relevant parties – management, the shipping company, and the receiving party. Then, we assess the impact. Is it a minor delay that can be absorbed, or does it necessitate a complete rescheduling? We might re-prioritize tasks, re-allocate resources, or explore expedited shipping if necessary. For example, if a forklift breaks down, we’d immediately contact maintenance, utilize backup equipment if available, and potentially hand-sort a portion of the shipment to minimize the delay’s impact. Continuous monitoring and data analysis help us identify recurring issues and refine our strategies to prevent future disruptions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your understanding of load capacity and weight distribution?

Load capacity and weight distribution are critical for safe and efficient shipping. Load capacity refers to the maximum weight a vehicle or container can safely carry, which is often specified by the manufacturer. Weight distribution involves ensuring the weight is evenly spread throughout the load to prevent instability, damage to goods, or accidents. Imagine stacking heavy boxes on one side of a truck – it could easily tip over!

Proper weight distribution minimizes stress on the vehicle and reduces the risk of accidents. Techniques include strategically placing heavier items at the bottom and lighter items on top, distributing weight evenly across axles, and utilizing load-securing devices to prevent shifting during transit. Software tools and load planning systems help optimize weight distribution, providing real-time feedback and simulations to ensure a safe and balanced load.

Q 17. How familiar are you with different types of shipping containers and their specifications?

I’m very familiar with various shipping container types, including:

- Standard 20ft and 40ft containers: These are the most common, suitable for a wide range of goods.

- High Cube containers: Offer increased height for taller items.

- Refrigerated containers (reefers): Maintain a specific temperature for perishable goods.

- Open-top containers: Allow for loading from the top, ideal for oversized cargo.

- Flatrack containers: Have a low profile and are ideal for oversized and heavy equipment.

I understand the specifications like internal dimensions, weight limits, and structural integrity for each type. This knowledge allows me to select the appropriate container for each shipment, ensuring optimal space utilization and minimizing risk of damage or non-compliance.

Q 18. How do you adapt to changes in sorting and loading procedures?

Adaptability is key. Changes in sorting and loading procedures might stem from new technologies, updated safety regulations, or shifting business needs. I approach changes with a structured process:

- Understanding the change: I thoroughly review the new procedures, seeking clarification if needed.

- Training and implementation: I participate actively in any training provided and assist colleagues in understanding and adapting to the new processes.

- Feedback and improvement: I provide constructive feedback on the effectiveness of the changes and actively look for ways to optimize the new procedures.

For example, if a new warehouse management system (WMS) is implemented, I’d dedicate time to learning the software, practice the new workflows, and identify any bottlenecks or inefficiencies to contribute to a smoother transition. A flexible mindset and a willingness to learn new skills are vital for success in this dynamic field.

Q 19. Explain your understanding of OSHA regulations related to warehouse safety.

OSHA (Occupational Safety and Health Administration) regulations are paramount in warehouse safety. I understand the regulations concerning:

- Proper forklift operation and training: Including safe loading, unloading, and maneuvering techniques.

- Safe stacking and storage: Preventing collapse and ensuring adequate aisle space for movement.

- Personal Protective Equipment (PPE): Mandating the use of safety shoes, gloves, high-visibility vests, and other protective gear based on the tasks performed.

- Hazard Communication: Understanding and handling hazardous materials safely.

- Emergency procedures: Knowing evacuation routes, fire safety procedures, and first-aid protocols.

Compliance is not just about avoiding penalties; it’s about creating a safe and productive work environment for everyone. I actively contribute to a culture of safety by reporting hazards, following safety protocols diligently, and encouraging colleagues to do the same.

Q 20. How do you handle discrepancies between the order and the goods being sorted and loaded?

Discrepancies between the order and the goods are addressed through a meticulous verification process. The first step is to identify the discrepancy – is it a missing item, an incorrect quantity, or a wrong product? Then, we consult the original order documentation and inventory management system to pinpoint the error source. This might involve reviewing picking lists, checking warehouse stock, or contacting the warehouse personnel who prepared the shipment.

Depending on the issue’s nature and severity, we might:

- Correct the error: If the missing item is readily available, we add it to the shipment.

- Replace the incorrect item: If a wrong product was picked, we substitute it with the correct one.

- Inform the customer: We notify the customer about the discrepancy and propose a solution, such as a partial shipment or a full reshipment. Documentation of the entire process is crucial for tracking and improving accuracy.

Prevention is key. Implementing robust inventory control systems, regular inventory checks, and double-checking during picking and packing can minimize these errors.

Q 21. Describe your experience with barcode scanning and other inventory tracking technologies.

I have extensive experience using barcode scanning and other inventory tracking technologies. Barcode scanners allow for quick and accurate identification of items, streamlining the sorting and loading process. This minimizes errors and improves efficiency. In addition to barcodes, I’m familiar with RFID (Radio-Frequency Identification) technology which offers more advanced tracking capabilities.

These technologies integrate with warehouse management systems (WMS) to provide real-time visibility of inventory, location, and movement. I am proficient in using handheld scanners, fixed scanners, and mobile devices to capture data accurately and efficiently. Data collected helps us track performance, identify bottlenecks, and make data-driven improvements to our processes. For example, using data analysis from scanning we can identify slow-moving items which can help optimize warehouse layout or predict future needs.

Q 22. How do you ensure the security of goods during the sorting and loading process?

Ensuring the security of goods during sorting and loading is paramount. It involves a multi-layered approach encompassing physical security, procedural safeguards, and technological solutions.

- Physical Security: This includes secure warehouse facilities with access control systems (e.g., keycard entry, CCTV surveillance), well-lit areas to deter theft, and potentially security personnel patrolling the premises. For high-value goods, dedicated secure storage areas might be necessary.

- Procedural Safeguards: Clear and well-defined procedures for handling goods are crucial. This includes proper identification and verification of items at each stage, regular inventory checks, and documented handoffs between personnel. We can use barcoding or RFID tracking to monitor items throughout the process.

- Technological Solutions: Implementing technology like RFID (Radio-Frequency Identification) tracking allows for real-time monitoring of goods, ensuring accountability and preventing loss or theft. Inventory management systems can also help track items and identify discrepancies. For example, if a pallet is scanned as leaving the warehouse but doesn’t arrive at the destination, the system can flag this anomaly, prompting an investigation.

In my previous role, we implemented a system combining CCTV and RFID tags, reducing our inventory discrepancies by 15% within six months. This significantly improved our operational efficiency and minimized losses.

Q 23. What is your experience with different types of conveyor systems?

My experience with conveyor systems is extensive, encompassing a range of types used in various warehouse settings. I’m familiar with:

- Roller Conveyors: Simple and cost-effective, ideal for moving heavier items over shorter distances. I’ve worked with both gravity-fed and powered roller systems.

- Belt Conveyors: Excellent for high-volume, continuous flow operations. I have experience with different belt materials (e.g., rubber, plastic) selected for specific applications (like temperature-sensitive goods).

- Sorti ng Conveyors: These systems use diverters or other mechanisms to automatically route items to different destinations based on pre-defined criteria (e.g., destination, order number). I’ve managed systems utilizing both barcode and RFID scanning for accurate sorting.

- Overhead Conveyors: Used for efficient movement of materials above ground, maximizing floor space. I have managed installations and troubleshooting of these systems in high-bay warehouses.

For instance, in a previous project involving e-commerce fulfillment, we optimized the existing belt conveyor system by installing a more advanced sorting mechanism, leading to a 20% increase in order processing speed.

Q 24. How do you contribute to a positive and productive team environment?

I believe in fostering a positive and productive team environment through collaboration, communication, and mutual respect. I actively contribute by:

- Open Communication: I encourage open dialogue and feedback, ensuring everyone feels heard and valued. I regularly communicate updates and progress to team members.

- Collaboration: I actively participate in brainstorming sessions and offer support to colleagues, sharing my knowledge and expertise to solve problems collaboratively.

- Mentorship: I’m happy to mentor junior team members, providing guidance and support to help them grow their skills and confidence.

- Positive Attitude: I maintain a positive and enthusiastic attitude, even under pressure, creating a motivating atmosphere for the team.

In a past role, I noticed that morale was low due to a complex sorting issue. By organizing a team meeting to brainstorm solutions, and by celebrating even minor successes along the way, we not only solved the problem but also boosted team cohesion and morale.

Q 25. How do you stay updated on industry best practices for sorting and loading?

Staying updated on industry best practices is crucial in this fast-paced field. I utilize several methods to ensure I’m abreast of the latest developments:

- Industry Publications and Journals: I regularly read industry-specific publications and journals to stay informed about new technologies, regulations, and best practices.

- Conferences and Trade Shows: Attending conferences and trade shows provides valuable opportunities to network with peers, learn from experts, and see new technologies in action.

- Professional Organizations: Membership in professional organizations provides access to resources, training, and networking opportunities.

- Online Courses and Webinars: Online learning platforms offer many courses and webinars covering various aspects of sorting and loading, allowing for continuous professional development.

For example, recently I completed a course on warehouse automation, gaining valuable insights into the latest advancements in robotic sorting and automated guided vehicles (AGVs).

Q 26. Describe your problem-solving skills in a warehouse setting.

Problem-solving is a core competency in my skillset. In a warehouse environment, I approach problems systematically. My process typically involves:

- Identifying the problem: Clearly define the issue and its impact. This might involve gathering data, observing processes, and interviewing colleagues.

- Analyzing the root cause: Determine the underlying cause of the problem rather than just addressing the symptoms. Tools such as the ‘5 Whys’ can be effective here.

- Developing solutions: Brainstorm multiple potential solutions, considering their feasibility, cost, and impact.

- Implementing the chosen solution: Carefully implement the selected solution, ensuring proper training and communication.

- Monitoring and evaluating results: Track the effectiveness of the implemented solution and make adjustments if necessary. This ensures continuous improvement.

For example, in a previous role, we experienced frequent order picking errors. By analyzing the process, we identified an issue with the labeling system. We implemented a new, color-coded labeling system, and error rates dropped by 30% within a month.

Q 27. How do you prioritize orders based on urgency and delivery deadlines?

Prioritizing orders based on urgency and delivery deadlines is crucial for efficient warehouse operations. I utilize several strategies:

- Order Management System (OMS): I rely heavily on an OMS that integrates with our warehouse management system (WMS). The OMS typically provides order prioritization based on pre-set rules considering delivery deadlines, customer importance, and other relevant factors.

- Visual Management Tools: Kanban boards or similar visual tools help to provide a real-time overview of order status and urgency, allowing for quick adjustments to priorities.

- Communication and Collaboration: Open communication with the transportation team is essential to ensure accurate prioritization aligned with actual delivery capabilities.

- Exception Handling: Defining clear procedures for handling exceptions, like urgent rush orders or delayed shipments, is critical for maintaining overall efficiency.

In my experience, a well-designed OMS, combined with effective visual management and communication, allows for dynamic prioritization, preventing delays and meeting customer expectations.

Q 28. What are your salary expectations for this role?

My salary expectations are in the range of [Insert Salary Range] annually, commensurate with my experience and the specific responsibilities of this role. I’m open to discussing this further based on the complete compensation package and benefits offered.

Key Topics to Learn for Sorting and Loading Interview

- Warehouse Layout and Optimization: Understanding warehouse design, flow optimization, and its impact on sorting and loading efficiency.

- Inventory Management Systems (IMS): Familiarity with different IMS software and their role in streamlining the sorting and loading process. Practical application includes using data from IMS to optimize routes and loading sequences.

- Sorting Methods and Technologies: Explore various sorting techniques (e.g., manual, automated, conveyor-based) and their applications in different warehouse settings. Consider the advantages and disadvantages of each.

- Loading Techniques and Equipment: Understanding different loading methods (e.g., bulk, palletized, individual items) and the operation of relevant equipment (forklifts, pallet jacks, conveyors). This includes safety procedures and best practices.

- Safety Regulations and Procedures: Knowledge of OSHA regulations and warehouse safety protocols related to material handling, equipment operation, and personal safety.

- Order Fulfillment Processes: Understanding the entire order fulfillment cycle, from order receipt to loading onto transport vehicles. This includes order picking, packing, and verification procedures.

- Logistics and Transportation: Basic understanding of transportation modes, route planning, and delivery scheduling as they relate to efficient loading and delivery.

- Problem-Solving and Troubleshooting: Developing strategies to address common challenges in sorting and loading, such as order discrepancies, equipment malfunctions, and unexpected delays.

Next Steps

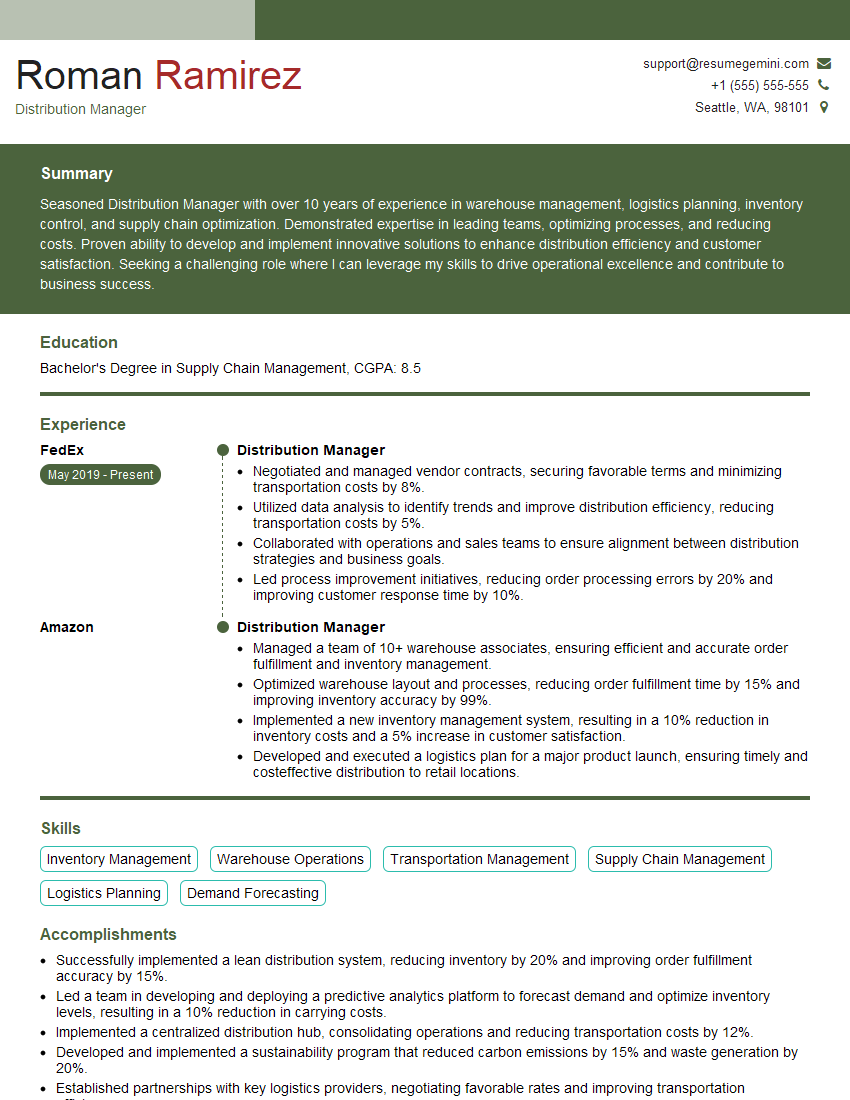

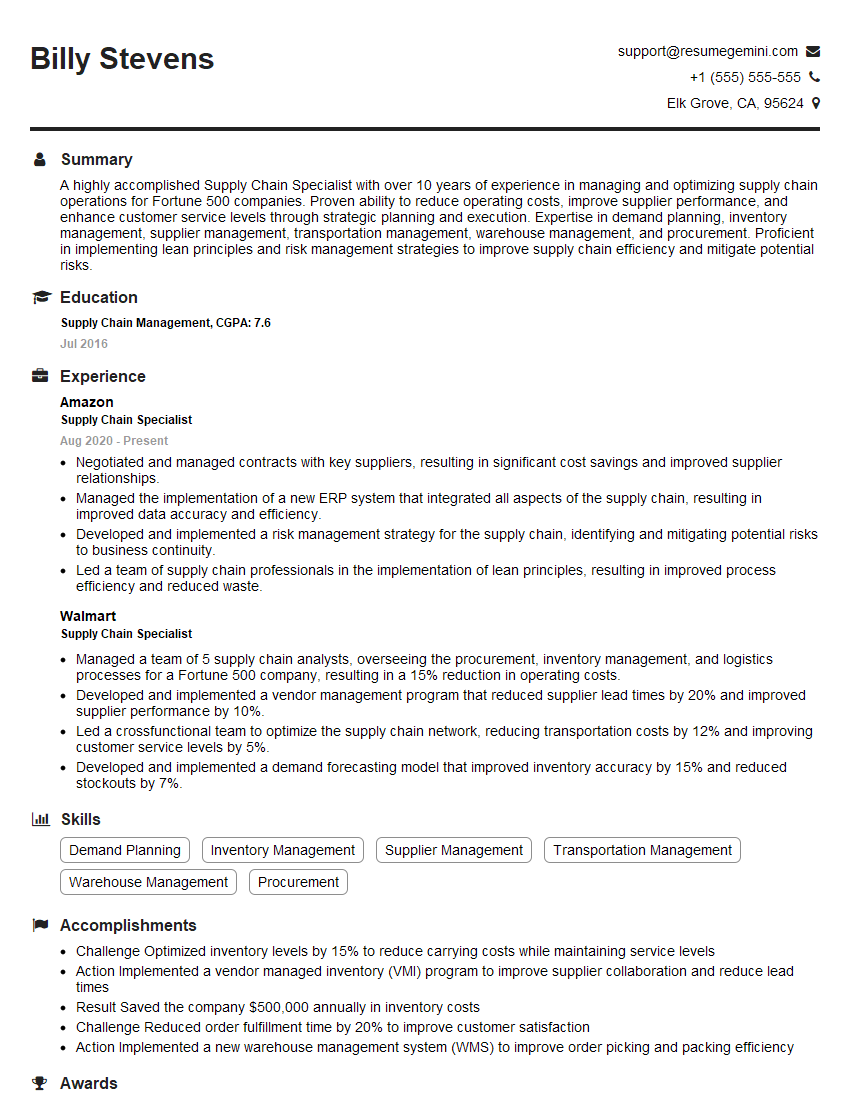

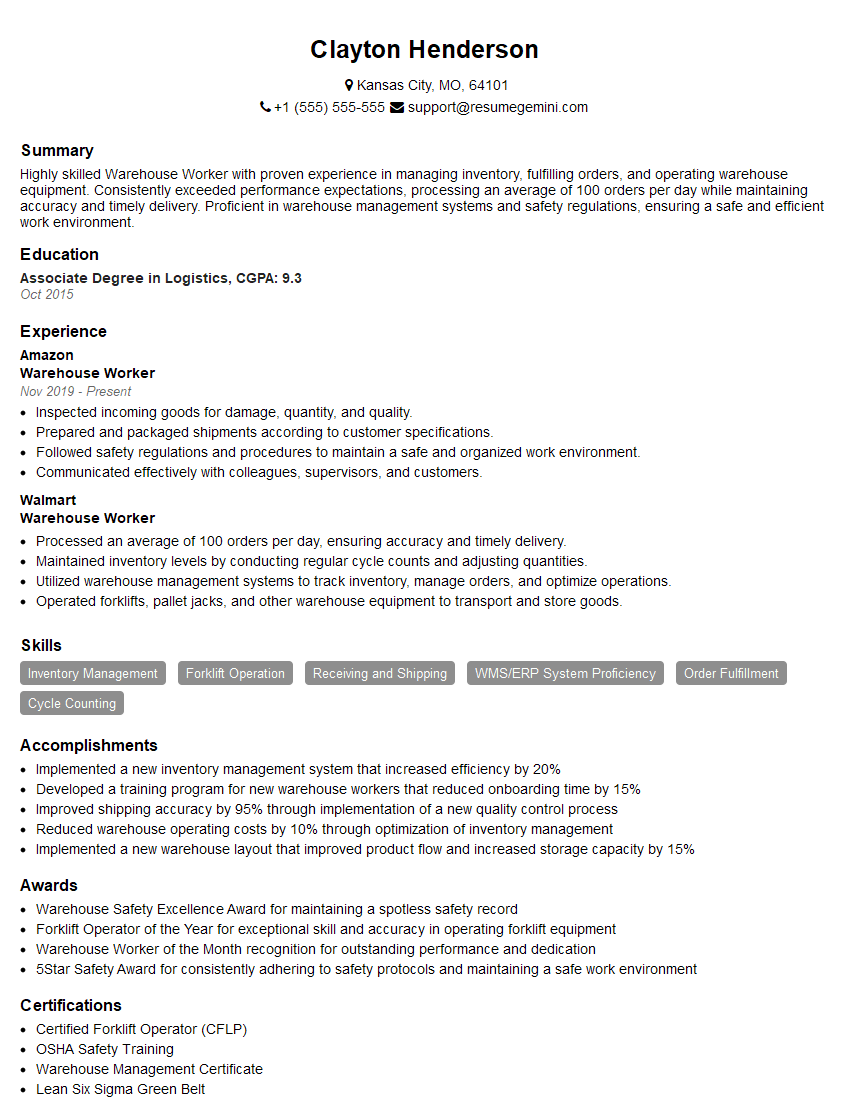

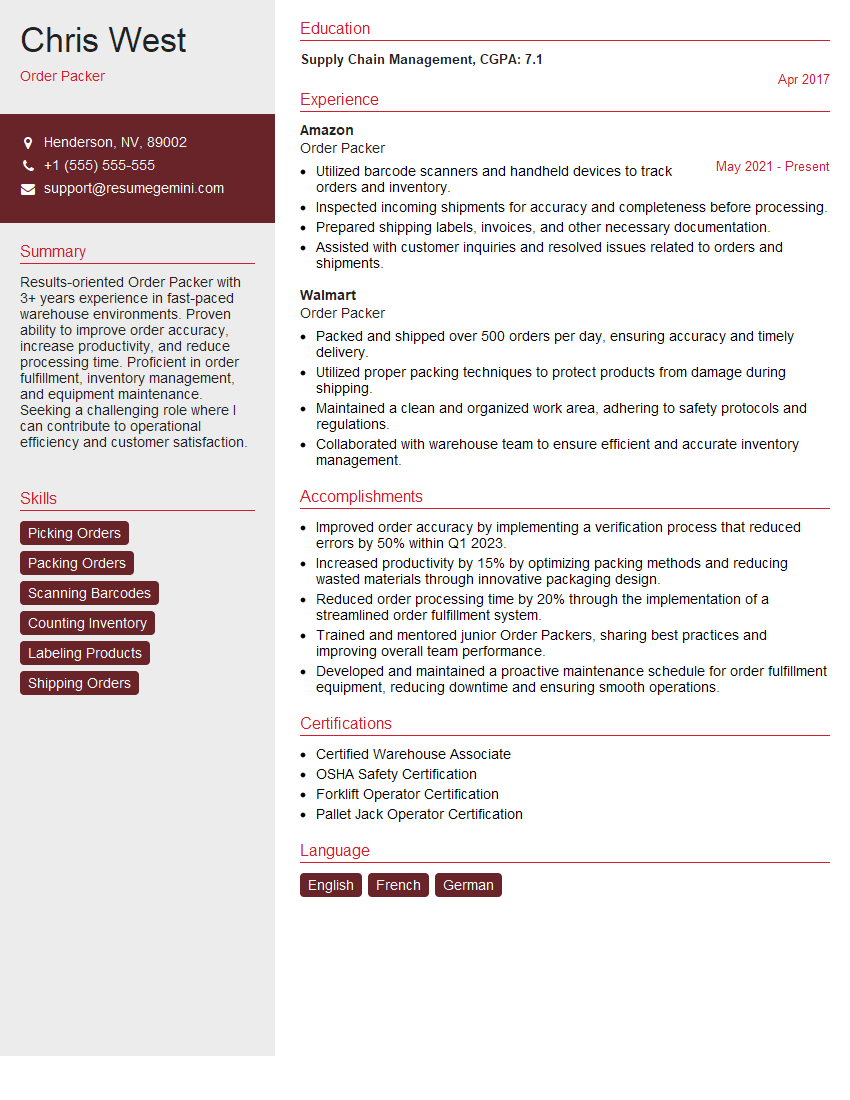

Mastering sorting and loading techniques is crucial for career advancement in logistics and warehousing. These skills are highly sought after, opening doors to diverse roles with increased responsibility and earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to the demands of the Sorting and Loading industry. Examples of resumes specifically crafted for Sorting and Loading positions are available to further assist you in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good