Cracking a skill-specific interview, like one for Sorting and Packing Techniques, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Sorting and Packing Techniques Interview

Q 1. Explain the different types of sorting methods you are familiar with.

Sorting methods are the backbone of efficient warehouse operations. I’m proficient in a variety of techniques, each suited to different needs and data sets. These include:

- Bubble Sort: A simple algorithm, effective for small datasets. It repeatedly steps through the list, compares adjacent elements and swaps them if they are in the wrong order. Think of it like gently bubbling the largest elements to the top. While simple, it’s inefficient for large datasets.

- Insertion Sort: Similar to how you’d sort a hand of playing cards. It builds a sorted array one element at a time. It’s efficient for small lists or nearly sorted lists, but performs poorly on large, unsorted data.

- Merge Sort: A divide-and-conquer algorithm. It recursively breaks down the list into smaller sublists until each sublist contains only one element, then repeatedly merges the sublists to produce new sorted sublists until there is only one sorted list remaining. It’s highly efficient and guarantees O(n log n) time complexity, even for large datasets.

- Quick Sort: Another divide-and-conquer algorithm, known for its speed. It selects a ‘pivot’ element and partitions the other elements into two sub-arrays, according to whether they are less than or greater than the pivot. The sub-arrays are then recursively sorted. Its average-case performance is O(n log n), but its worst-case performance is O(n2), making the choice of pivot crucial.

- Heap Sort: Uses a binary heap data structure to efficiently sort data. It’s guaranteed O(n log n) time complexity, and is space-efficient as it sorts in-place. Think of it like organizing a priority queue.

In practice, I select the sorting algorithm based on the size of the dataset and the specific requirements of the task. For very large datasets, Merge Sort or Heap Sort are usually preferred for their guaranteed efficiency.

Q 2. Describe your experience with various packing materials and their applications.

My experience with packing materials is extensive, encompassing various types suitable for diverse products and shipping conditions. I’m familiar with their strengths and weaknesses to optimize protection and cost-effectiveness.

- Corrugated Cardboard Boxes: The workhorse of shipping, offering good protection at a reasonable cost. Different flute types (e.g., A-flute, B-flute, C-flute) provide varying degrees of strength and cushioning.

- Bubble Wrap: Excellent for fragile items, providing cushioning against shocks and impacts. Different bubble sizes offer varying levels of protection.

- Foam Packaging (PE, EPS): Offers superior cushioning and protection, particularly for delicate electronics or glassware. PE foam (polyethylene) is flexible and easily conforms to shapes, while EPS (expanded polystyrene) is more rigid.

- Air Pillows/Void Fill: An efficient way to fill empty spaces in boxes, preventing shifting during transit. They are lightweight and cost-effective.

- Kraft Paper: A versatile material for wrapping, cushioning, and filling voids. It’s environmentally friendly and provides decent protection.

For instance, when packing delicate glassware, I’d prioritize using foam packaging and bubble wrap inside a sturdy corrugated box, possibly adding void fill for extra security. For heavier items, I might choose a double-walled corrugated box or reinforce the corners with extra tape.

Q 3. How do you prioritize tasks when faced with multiple orders needing packing?

Prioritizing tasks when dealing with multiple orders involves a multi-faceted approach. I typically use a combination of factors to determine order of execution:

- Urgency/Delivery Deadlines: Orders with the soonest deadlines are prioritized to ensure timely delivery and avoid late fees or customer dissatisfaction. I often use a Kanban system or similar visual aid to track deadlines.

- Order Size/Complexity: Larger or more complex orders might require more time and resources, so their scheduling needs to reflect that. This helps to balance workload and prevent bottlenecks.

- Product Type/Fragility: Fragile items require more careful handling, so I might prioritize those orders to minimize the risk of damage. This could involve setting aside specific time slots or dedicated personnel.

- Order Value/Priority Level: Higher-value orders, or those from VIP clients, might deserve priority processing to maintain strong customer relationships.

In essence, I’m employing a dynamic prioritization approach, constantly reassessing task urgency and resource availability to optimize overall efficiency and customer satisfaction. This often involves using a combination of software tools for order management and visual management systems to track progress.

Q 4. What strategies do you use to ensure efficient and accurate order picking?

Efficient and accurate order picking relies on a well-structured process and the use of appropriate tools. My strategies include:

- Optimized Picking Routes: Utilizing techniques like ‘wave picking’ (grouping similar orders) or ‘zone picking’ (assigning pickers to specific areas) minimizes travel time and improves efficiency. Software can help optimize these routes based on warehouse layout and order data.

- Barcode Scanning/RFID Technology: Ensuring accuracy by using barcode scanners or RFID readers at each picking stage. This eliminates manual data entry errors and speeds up the process.

- Clear and Accurate Order Documentation: Utilizing clear pick lists with item descriptions, locations, and quantities reduces ambiguity and picking errors. This is especially important in fast-paced environments.

- Regular Inventory Audits: Regular checks on inventory levels ensure that picked items are actually available, preventing delays and frustrating situations.

- Proper Training and Supervision: Well-trained staff are crucial to efficient order picking. Regular retraining and clear communication of procedures help maintain accuracy and avoid mistakes.

For example, I once implemented a wave picking system in a warehouse which reduced picking time by 20% by grouping orders with similar destinations together. This streamlined the entire process, significantly improving productivity and customer satisfaction.

Q 5. Describe your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with several different systems, integrating them into daily operations to manage inventory, track orders, optimize workflows, and enhance efficiency. I’m familiar with both cloud-based and on-premise WMS solutions.

My expertise includes:

- Inventory Management: Using WMS to track inventory levels in real-time, automating stock replenishment, and minimizing stockouts.

- Order Management: Processing orders efficiently, assigning them to pickers, and tracking their progress through the fulfillment process.

- Warehouse Layout Optimization: Using WMS data to analyze warehouse layout and suggest improvements to optimize picking routes and storage efficiency. This often involves slotting optimization to place frequently accessed items in more convenient locations.

- Reporting and Analytics: Utilizing WMS reporting capabilities to track key performance indicators (KPIs) such as picking accuracy, order fulfillment times, and inventory turnover.

- Integration with other Systems: Connecting the WMS with other systems like ERP (Enterprise Resource Planning) or eCommerce platforms for seamless data flow and improved overall operational visibility.

For example, in a previous role, we implemented a new WMS that reduced order fulfillment time by 15% by optimizing picking routes and integrating with our eCommerce platform. This led to significant improvements in customer satisfaction and operational efficiency.

Q 6. How do you handle damaged or defective products during the sorting and packing process?

Handling damaged or defective products during sorting and packing requires a systematic approach to ensure quality control and prevent customer dissatisfaction.

- Immediate Identification: Damaged or defective items should be identified immediately during the sorting process. This might involve visual inspection, weight checks, or using other quality control measures.

- Segregation and Documentation: Damaged products should be segregated from good products and clearly documented. This includes noting the type of damage, the quantity affected, and the reason for damage (if known).

- Return/Disposal Procedures: There should be clear procedures for returning damaged goods to suppliers or disposing of them according to company policy and environmental regulations. This might involve arranging for pick-up by the supplier, recycling damaged materials, or securely disposing of hazardous waste.

- Quality Control Checks: Regular quality control checks throughout the process help minimize the occurrence of damaged or defective products. This involves close monitoring of handling procedures and regular equipment maintenance.

- Communication: It’s critical to communicate issues promptly to relevant stakeholders, such as supervisors, quality control personnel, and suppliers. This proactive communication ensures that necessary actions are taken quickly.

For instance, if a batch of products arrives with noticeable damage, I would immediately halt further processing, document the damage, contact the supplier, and initiate the return procedure. A clear chain of communication is key to preventing further issues and maintaining quality standards.

Q 7. What safety precautions do you follow when operating material handling equipment?

Safety is paramount when operating material handling equipment. My adherence to safety protocols is unwavering.

- Proper Training and Certification: I ensure I have the necessary training and certifications to operate the specific equipment I use. This training includes understanding safe operating procedures, emergency protocols, and equipment limitations.

- Pre-Operational Checks: Before operating any equipment, I conduct a thorough pre-operational check, verifying its functionality and safety features. This includes checking for any damage, leaks, or malfunctions.

- Personal Protective Equipment (PPE): I always use appropriate PPE, such as safety glasses, gloves, and steel-toed boots, to protect myself from potential hazards.

- Safe Operating Procedures: I strictly adhere to all safe operating procedures, including maintaining a safe distance from moving equipment, avoiding distractions, and operating the equipment at safe speeds. I am mindful of the weight limits of the equipment and of the environment I’m working in.

- Reporting Hazards: I immediately report any unsafe conditions or equipment malfunctions to my supervisor to prevent accidents.

For example, before operating a forklift, I always inspect the tires, brakes, and hydraulic systems, ensuring they’re functioning correctly. I never operate the forklift if I notice any issues. My commitment to safety isn’t just about following rules; it’s about making a conscious effort to prevent accidents and ensure a safe working environment for myself and others.

Q 8. How do you maintain a clean and organized work area?

Maintaining a clean and organized workspace is paramount for efficiency and safety in a sorting and packing environment. Think of it like a well-oiled machine – if parts are scattered, the machine runs poorly. My approach is multi-faceted.

- Designated Zones: I establish clear zones for different tasks: receiving, sorting, packing, and staging. This prevents bottlenecks and confusion.

- Regular Cleaning: I incorporate short, regular cleaning breaks into my routine. A quick sweep, wiping down surfaces, and putting away tools prevents clutter from building up.

- 5S Methodology: I often utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to systematically organize my workspace. This ensures everything has a place and is consistently maintained.

- Proper Storage: All materials and tools are stored in designated locations, using appropriate containers and labels. This allows for easy retrieval and minimizes search time.

- Teamwork: I encourage a collaborative approach to cleanliness, ensuring everyone is responsible for maintaining their individual areas and contributing to the overall organization.

For example, during a particularly busy period, implementing a quick 5-minute cleanup at the end of each hour significantly improved our overall efficiency by reducing time spent searching for materials.

Q 9. How do you ensure the accurate labeling and documentation of packages?

Accurate labeling and documentation are crucial for preventing errors and ensuring smooth order fulfillment. Imagine trying to find a specific item in a warehouse without clear labels – it would be a nightmare! I follow a strict protocol:

- Clear and Concise Labels: I use pre-printed labels or a label printer to generate clear, legible labels containing all necessary information: order number, customer name, item description, quantity, and any special handling instructions.

- Double-Checking: I always double-check the label against the packing slip and the item itself before affixing it to the package. This minimizes the risk of mislabeling.

- Consistent Formatting: I maintain consistent formatting for all labels to ensure ease of identification and processing by downstream systems. This includes font size, placement of information, and the use of standardized codes.

- Digital Documentation: I utilize warehouse management systems (WMS) to digitally document all packing and shipping information. This provides a verifiable audit trail and facilitates efficient tracking.

- Quality Control Checks: Periodically, I conduct quality control checks on labels and documentation to identify any discrepancies and make necessary corrections.

In one instance, we caught a potential major error due to a slightly misplaced digit in an order number during a quality control check, preventing a potentially costly shipment mistake.

Q 10. What is your experience with different types of packaging equipment?

My experience encompasses a wide range of packaging equipment, from manual to automated systems. This includes:

- Conveyor Belts: Experience with various conveyor systems for moving packages efficiently through different stages of the process.

- Pallet Jacks and Forklifts: Proficient in operating material handling equipment for efficient storage and movement of pallets.

- Label Printers: Skilled in operating and maintaining thermal and inkjet label printers for accurate and efficient labeling.

- Tape Dispensers and Sealers: Experienced with various types of tape dispensers and box sealers, ensuring secure and efficient package closure.

- Automated Packaging Machines: Familiarity with automated systems such as robotic arms, case erectors, and shrink wrappers for high-volume packing.

I’m also comfortable with basic troubleshooting and maintenance procedures for most of this equipment. Understanding the mechanics helps prevent downtime and maintain smooth operations.

Q 11. Describe a time you had to troubleshoot a problem with sorting or packing equipment.

During a peak season, our automated case erector malfunctioned, causing a significant backlog. I approached the problem systematically.

- Identify the Problem: Initially, the machine was simply jamming. After careful observation, I noticed a problem with the cardboard feed mechanism.

- Gather Information: I consulted the machine’s manual and contacted the vendor’s support line. I also spoke with experienced colleagues to see if anyone had encountered a similar issue.

- Implement a Solution: Based on the manual and support suggestions, I adjusted the feed rollers to improve the flow of cardboard. We also temporarily switched to manual box assembly for less urgent orders.

- Testing and Monitoring: After adjusting the rollers, I ran several test cycles to ensure the machine was functioning correctly. I continued monitoring the machine closely for any recurrence of the problem.

- Preventative Measures: Following the repair, I proposed a regular preventative maintenance schedule to mitigate the risk of future malfunctions.

This experience taught me the importance of methodical troubleshooting, leveraging resources, and the value of preventative maintenance in avoiding costly downtime.

Q 12. How do you handle unexpected surges in order volume?

Handling unexpected surges in order volume requires flexibility and a proactive approach. It’s like preparing for a sudden influx of customers in a restaurant – you need a plan.

- Prioritization: We prioritize orders based on urgency and customer importance. This ensures that the most critical orders are processed first.

- Overtime and Additional Resources: If necessary, we utilize overtime for existing staff or temporarily hire additional workers to increase capacity. This is crucial in a surge.

- Process Optimization: We analyze our workflow and identify potential bottlenecks. Small adjustments in the sorting and packing processes can make a big difference.

- Communication: Open communication with customers is vital, keeping them informed about any potential delays. Transparency builds trust.

- Flexible Scheduling: We adjust our work schedule to accommodate the increased volume, potentially adding extra shifts or extending existing ones.

During one Black Friday period, by implementing these strategies, we managed to handle a 300% increase in order volume with minimal delays and exceptional customer satisfaction.

Q 13. How do you stay organized and manage your time effectively in a fast-paced warehouse environment?

Staying organized and managing time effectively in a fast-paced warehouse environment requires discipline and strategic planning. Think of it like conducting an orchestra – every instrument needs to play in harmony.

- Prioritization and Task Management: I use a combination of visual task boards and digital tools to prioritize tasks and track progress. This ensures I focus on the most critical activities first.

- Time Blocking: I allocate specific time blocks for different tasks, preventing multitasking and enhancing focus. This avoids spreading myself too thin.

- Regular Breaks: Short, regular breaks are crucial for maintaining concentration and preventing burnout. Stepping away for a few minutes can dramatically improve overall productivity.

- Clear Communication: Effective communication with colleagues and supervisors prevents misunderstandings and streamlines processes. This avoids rework.

- Continuous Improvement: I actively look for ways to improve my workflow and time management techniques. This ongoing process is key to efficiency.

By consistently applying these strategies, I have managed to stay organized and consistently meet tight deadlines, even under significant pressure.

Q 14. What are your strategies for preventing errors in the sorting and packing process?

Preventing errors in the sorting and packing process requires a multi-layered approach focusing on prevention rather than cure. It’s like building a strong wall – many bricks, each important.

- Standardized Procedures: Implementing standardized procedures and checklists ensures consistency and minimizes human error. This reduces variations.

- Regular Training: Ongoing training and refresher courses for staff keep everyone up-to-date on procedures and best practices. Training is investment.

- Quality Control Checks: Implementing regular quality control checks at different stages of the process identifies and corrects errors early. This prevents cascading problems.

- Technology Utilization: Leveraging technology such as barcode scanners, WMS, and automated packaging systems enhances accuracy and efficiency. Tech improves speed and accuracy.

- Ergonomic Workspaces: Ensuring ergonomic workspaces minimizes fatigue and reduces the likelihood of errors. Comfort is key for efficiency.

By implementing these strategies, I’ve been instrumental in reducing error rates in multiple warehouse environments, contributing to significant improvements in order accuracy and customer satisfaction.

Q 15. How do you ensure the integrity and security of packages during shipment?

Ensuring package integrity and security during shipment is paramount. It involves a multi-layered approach, starting from proper packaging and extending to tracking and insurance. Think of it like building a fortress around your goods.

- Robust Packaging: Using appropriate cushioning materials (bubble wrap, packing peanuts, air pillows) to prevent damage from shock and vibration is crucial. Selecting the right box size—not too big, not too small—prevents shifting and crushing. I always prioritize using sturdy, high-quality boxes capable of withstanding the rigors of transit. For fragile items, I employ specialized packaging techniques like double-boxing or custom-fit inserts.

- Secure Sealing: Strong tape is essential, applied generously and methodically to secure all seams. I prefer reinforced tape for added protection. Clearly marked ‘Fragile’ or ‘Handle with Care’ labels are crucial for alerting handlers to delicate contents.

- Proper Labeling and Documentation: Accurate and clearly visible addresses (sender and recipient) are non-negotiable. Including contact information on both the outside and inside of the package facilitates efficient delivery and simplifies the resolution of any issues. Detailed inventory lists within the package are invaluable for insurance claims.

- Tracking and Insurance: Utilizing tracking numbers provides real-time visibility of the package’s location. This is essential for monitoring transit progress and resolving delays. Shipping insurance protects against loss or damage, providing financial recourse in unforeseen circumstances. I’ve had to utilize insurance on several occasions, and it’s been a lifesaver for both the customer and the business.

By implementing these measures, we significantly reduce the risk of damage or loss, fostering customer trust and satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with inventory control and management.

My experience in inventory control and management spans over [Number] years, encompassing various methods and technologies. It’s a critical function, akin to the air traffic control of a warehouse, ensuring smooth and efficient operations.

- Inventory Tracking Systems: I’m proficient in using various inventory management software (e.g., [mention specific software like Fishbowl Inventory, Zoho Inventory]). These systems allow for real-time tracking of stock levels, facilitating accurate forecasting and preventing stockouts or overstocking.

- Cycle Counting: Regularly verifying physical inventory against recorded stock levels is vital. I’ve implemented cycle counting methodologies to minimize discrepancies and identify potential issues early on. It’s like a regular health check for your inventory.

- Warehouse Management Systems (WMS): I’m familiar with WMS solutions which help optimize warehouse layout, streamline picking and packing processes, and enhance overall efficiency. This allows us to improve both speed and accuracy.

- Data Analysis and Reporting: I have a strong understanding of inventory data analysis and generating reports to identify slow-moving items, predict demand, and inform purchasing decisions. Understanding these trends is key to making strategic inventory choices.

Through these practices, I ensure inventory accuracy, reduce waste, and optimize fulfillment processes.

Q 17. What is your understanding of dimensional weight and its importance in shipping?

Dimensional weight, often called ‘dim weight,’ is a crucial concept in shipping. It calculates the weight of a package based on its dimensions (length x width x height) rather than its actual weight. This is because a large, lightweight package can occupy more space on a vehicle than a smaller, heavier one. Think of a giant, fluffy pillow vs a small, dense metal block.

Shipping carriers use dimensional weight to determine shipping costs. If the dimensional weight exceeds the actual weight, the carrier charges based on the higher dimensional weight. This ensures fairness as large, less dense packages consume more space and resources during transportation. The formula typically used is: (Length x Width x Height) / Dimensional Factor = Dimensional Weight, where the dimensional factor varies slightly by carrier.

Understanding dimensional weight is vital for cost optimization. By optimizing packaging size and using lighter materials, businesses can minimize shipping expenses without compromising product protection. For instance, carefully choosing a box size that closely matches the product’s dimensions prevents excess space, thereby reducing the dimensional weight and shipping costs.

Q 18. How familiar are you with different shipping carriers and their services?

I’m familiar with a wide range of shipping carriers and their services, including FedEx, UPS, USPS, and DHL. Each carrier offers various service levels (e.g., express, ground, international) with varying speeds and costs. Choosing the right carrier depends on factors such as delivery speed, cost, destination, and package characteristics. This is like choosing the right vehicle for a journey—a small car for short distances, a truck for bulky loads.

- FedEx: Known for its speed and extensive international network.

- UPS: Another leading provider with a strong domestic and international presence.

- USPS: Cost-effective for smaller, lighter packages, particularly within the United States.

- DHL: A global leader, particularly strong in international shipping.

My experience enables me to select the most appropriate carrier based on specific needs, optimizing delivery speed and cost-effectiveness.

Q 19. Describe your experience with barcode scanners and RF scanners.

Barcode and RF (Radio Frequency) scanners are essential tools in modern warehousing and order fulfillment. They dramatically increase efficiency and accuracy. Imagine trying to manually record every item’s details—it would be incredibly time-consuming and prone to error.

- Barcode Scanners: These devices read barcodes, which contain unique product identifiers. They’re used for inventory tracking, order picking, and shipping label generation. I’ve extensively used barcode scanners in various warehouse environments, significantly improving picking accuracy and speed.

- RF Scanners: RF scanners use radio waves to transmit data wirelessly. They are often integrated into handheld devices used by warehouse workers for real-time inventory updates and order management. Their wireless nature significantly increases mobility and efficiency compared to wired systems. I’ve incorporated these into inventory tracking workflows with impressive results in improving efficiency.

My proficiency with these technologies ensures accurate data capture and minimizes human error, leading to improved productivity and customer satisfaction.

Q 20. Explain your understanding of different order fulfillment methods.

Order fulfillment methods encompass all the processes involved in getting an order from placement to delivery. The optimal method depends on factors like order volume, inventory location, and customer expectations. It’s like choosing the best route to your destination.

- Direct Fulfillment: The retailer ships the order directly to the customer from its own warehouse. This is common for businesses with established warehousing and distribution networks.

- Drop Shipping: The retailer doesn’t hold inventory. Instead, they forward customer orders to a third-party supplier (often the manufacturer) who ships directly to the customer. This reduces the retailer’s upfront investment in inventory.

- Warehouse Fulfillment: Orders are processed and shipped from a centralized warehouse. This is efficient for larger businesses with high order volumes.

Understanding the strengths and limitations of each method allows for informed decision-making, optimizing cost and efficiency while meeting customer expectations.

Q 21. How do you handle customer returns?

Handling customer returns efficiently and professionally is crucial for maintaining customer satisfaction and minimizing losses. It’s about providing a smooth and painless process for the customer.

- Clear Return Policy: A transparent and easily accessible return policy is the foundation. This should clearly outline the conditions for returns, the process for initiating a return, and the timeframe for refunds or exchanges. I’ve found that a well-defined policy minimizes disputes and confusion.

- Streamlined Return Process: Providing a simple and user-friendly return process is essential. This often involves providing pre-paid shipping labels or authorizing returns through online portals. The less friction, the better the customer experience.

- Inspection and Processing: Upon receiving the returned item, thorough inspection is needed to assess its condition and determine eligibility for a refund or exchange. Accurate documentation is crucial at each step to maintain records and prevent errors.

- Refund or Exchange: Promptly issuing refunds or exchanges based on the return policy builds customer trust. I’ve ensured timely processing through automated systems wherever possible.

By implementing these strategies, we can turn a potentially negative experience into a positive one, retaining customer loyalty and reducing the overall cost associated with returns.

Q 22. How do you identify and resolve discrepancies between picked items and order details?

Discrepancies between picked items and order details are a serious issue that can lead to customer dissatisfaction and financial losses. My approach involves a multi-layered system to identify and resolve these discrepancies efficiently.

Pre-Picking Verification: Before picking begins, I meticulously compare the digital picking list against the inventory management system to ensure accuracy. This initial check catches many potential errors before they escalate.

Real-time Item Verification: During the picking process, I use handheld scanners to verify each item against the order. This immediate feedback system allows for instant correction of errors. If a discrepancy is found, I immediately note it, investigate the reason (e.g., stock inaccuracy, damaged goods), and inform the supervisor.

Post-Picking Reconciliation: After picking is complete, I conduct a final reconciliation, comparing the number of items picked to the order details. Any discrepancies found are documented and reported.

Root Cause Analysis: For recurring discrepancies, I conduct a root cause analysis to identify and address systematic problems. This might involve improving inventory management, updating picking lists, or enhancing staff training.

For example, if an order calls for 10 units of Product X but only 8 are picked, I’ll immediately investigate. This could be due to a miscount, stock-outs, or damaged goods that were not correctly flagged. I document the discrepancy, take corrective action (e.g., return to stock and pick the remaining two), and alert my supervisor.

Q 23. What are your strategies for optimizing workflow and efficiency in the warehouse?

Optimizing warehouse workflow and efficiency requires a holistic approach that considers various aspects. My strategies focus on improving processes, leveraging technology, and fostering a culture of continuous improvement.

Lean Principles: I implement lean methodologies to eliminate waste (muda) in all forms – be it time, motion, materials, or defects. This involves analyzing workflows, identifying bottlenecks, and streamlining processes. For instance, optimizing picking routes using software or rearranging warehouse layout for better flow.

Technology Integration: I am proficient in using Warehouse Management Systems (WMS) and other technologies to automate tasks, track inventory, and monitor performance. This includes utilizing barcode scanners, RFID technology, and automated guided vehicles (AGVs) for enhanced speed and accuracy.

Cross-Training and Skill Development: Investing in employee training to develop multi-skilling. This enhances flexibility and responsiveness to changing demands. Employees trained in multiple tasks can fill in gaps during peak seasons or cover absences.

Data-Driven Decision Making: Regularly analyzing key performance indicators (KPIs) such as order fulfillment rate, picking accuracy, and inventory turnover to identify areas for improvement and track progress.

For example, by analyzing picking data, we might discover a specific aisle consistently causing delays. This data helps us make informed decisions, like relocating high-demand items or improving the aisle’s organization.

Q 24. Describe your experience with quality control procedures for sorting and packing.

Quality control is paramount in sorting and packing. My experience involves implementing stringent procedures at each stage of the process to ensure customer satisfaction and maintain the company’s reputation.

Visual Inspection: Thorough visual inspection of each item before packing to identify any damage, defects, or discrepancies. This includes checking for correct labels, accurate quantities, and proper condition of the goods.

Random Sampling: Implementing random sampling of packed orders to verify accuracy and packaging quality. This involves checking a subset of orders for any errors or inconsistencies.

Documentation and Traceability: Maintaining detailed records of all quality control checks and actions taken. This ensures traceability and accountability, facilitating prompt resolution of any quality-related issues.

Continuous Improvement: Regularly reviewing quality control data to identify areas for improvement and implementing corrective actions. This might involve adjusting procedures, improving training, or updating equipment.

For instance, if during random sampling we find a high rate of incorrect labels, we might review the labeling process, retrain staff, or invest in a more reliable labeling system.

Q 25. How do you ensure compliance with safety regulations and company policies?

Safety and compliance are non-negotiable. I have a strong commitment to following all safety regulations and company policies to prevent accidents and maintain a safe working environment.

Adherence to Safety Protocols: I rigorously follow all safety procedures, including proper lifting techniques, use of personal protective equipment (PPE), and awareness of hazardous materials handling.

Reporting of Hazards: I promptly report any unsafe conditions or potential hazards to my supervisor. This includes reporting near misses, damaged equipment, or spills.

Training and Awareness: I actively participate in safety training programs and stay updated on changes in safety regulations and company policies. I also actively encourage my colleagues to adhere to safety guidelines.

Compliance with Regulations: I ensure compliance with all relevant industry regulations and company policies relating to safety, including those on handling hazardous materials, fire safety and emergency procedures.

For instance, if I notice a damaged pallet, I immediately report it to prevent a potential accident. My adherence to safety procedures contributes to a safer and more productive work environment for everyone.

Q 26. What is your experience working in a team environment?

I thrive in team environments. I believe that effective teamwork is essential for achieving optimal results. My experience includes collaborating with colleagues across various departments, including picking, packing, inventory management, and customer service.

Collaboration: I actively participate in team meetings, share ideas, and offer support to my colleagues. I believe in open communication and mutual respect.

Conflict Resolution: I am skilled at resolving conflicts constructively and finding mutually agreeable solutions. My focus is on maintaining positive working relationships and achieving common goals.

Mentorship: I enjoy mentoring new team members, sharing my knowledge and expertise to help them succeed. This contributes to a strong team dynamic and continuous improvement.

Leadership: While not always in a formal leadership role, I am proactive in taking initiative and guiding others when necessary.

For example, during a particularly busy period, I helped train new team members on efficient picking techniques, which streamlined our workflow and improved team performance.

Q 27. What are your salary expectations?

My salary expectations are in line with my experience, skills, and the market rate for a domain expert in sorting and packing techniques with my qualifications. I am open to discussing a compensation package that is mutually beneficial and reflects my value to your organization. I am more interested in a position that offers growth opportunities and aligns with my career aspirations.

Key Topics to Learn for Sorting and Packing Techniques Interview

- Order Fulfillment Processes: Understanding the entire workflow from receiving inventory to dispatching orders, including different order fulfillment models (e.g., single-order picking, batch picking).

- Sorting Methods: Learn the various sorting algorithms and their applications in warehouse settings. This includes understanding the trade-offs between speed, efficiency, and resource utilization (e.g., manual sorting, conveyor belt sorting, automated sorters).

- Packing Optimization: Explore techniques for maximizing space utilization within packages, minimizing void fill, and ensuring product protection during transit. Consider different packaging materials and their suitability for various products.

- Inventory Management Systems (IMS): Familiarity with common IMS software and how they integrate with sorting and packing processes. Understanding data entry, order tracking, and reporting capabilities is crucial.

- Safety Procedures and Regulations: Demonstrate knowledge of workplace safety regulations pertaining to material handling, manual handling techniques, and the use of equipment.

- Quality Control and Assurance: Discuss techniques for ensuring accurate order fulfillment, damage prevention, and maintaining high standards of product quality throughout the process.

- Problem-Solving and Troubleshooting: Be prepared to discuss your approach to resolving common issues in sorting and packing, such as order discrepancies, damaged goods, or equipment malfunctions. Highlight your analytical and problem-solving skills.

- Technology and Automation: Discuss your understanding of automated sorting and packing systems, including robotics, barcode scanners, and warehouse management systems (WMS).

Next Steps

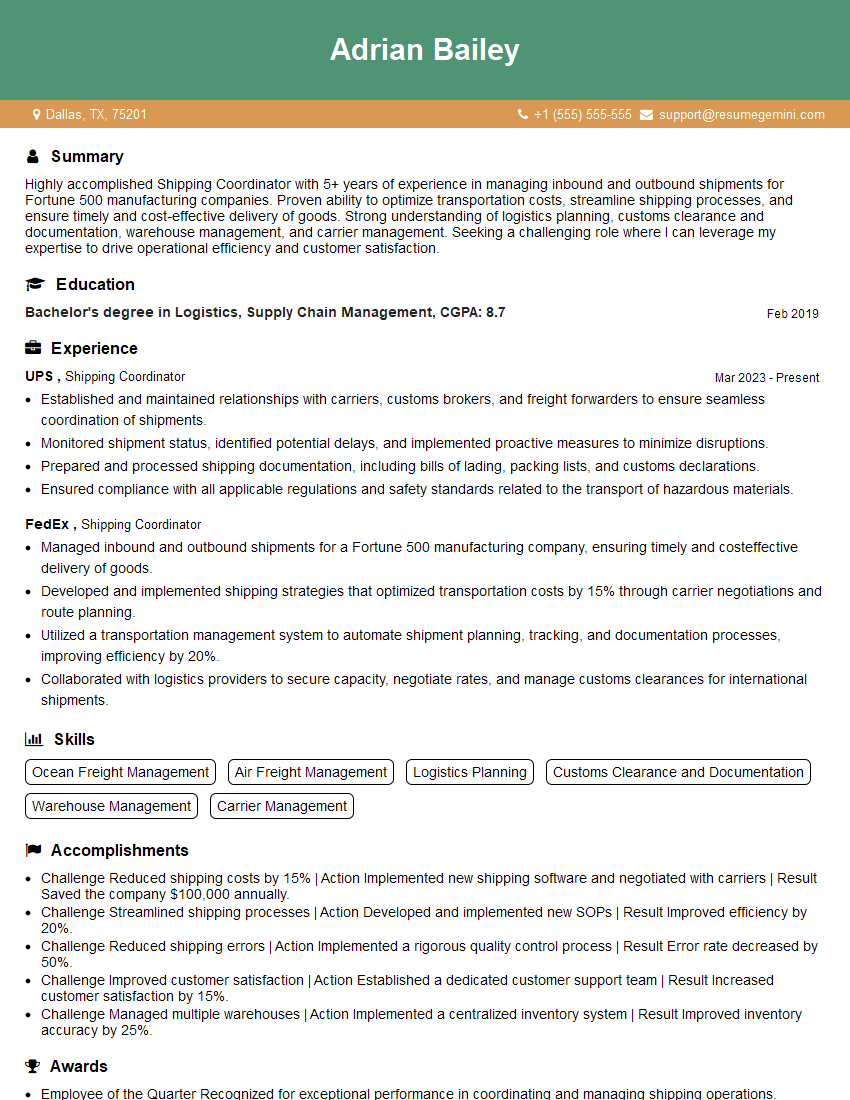

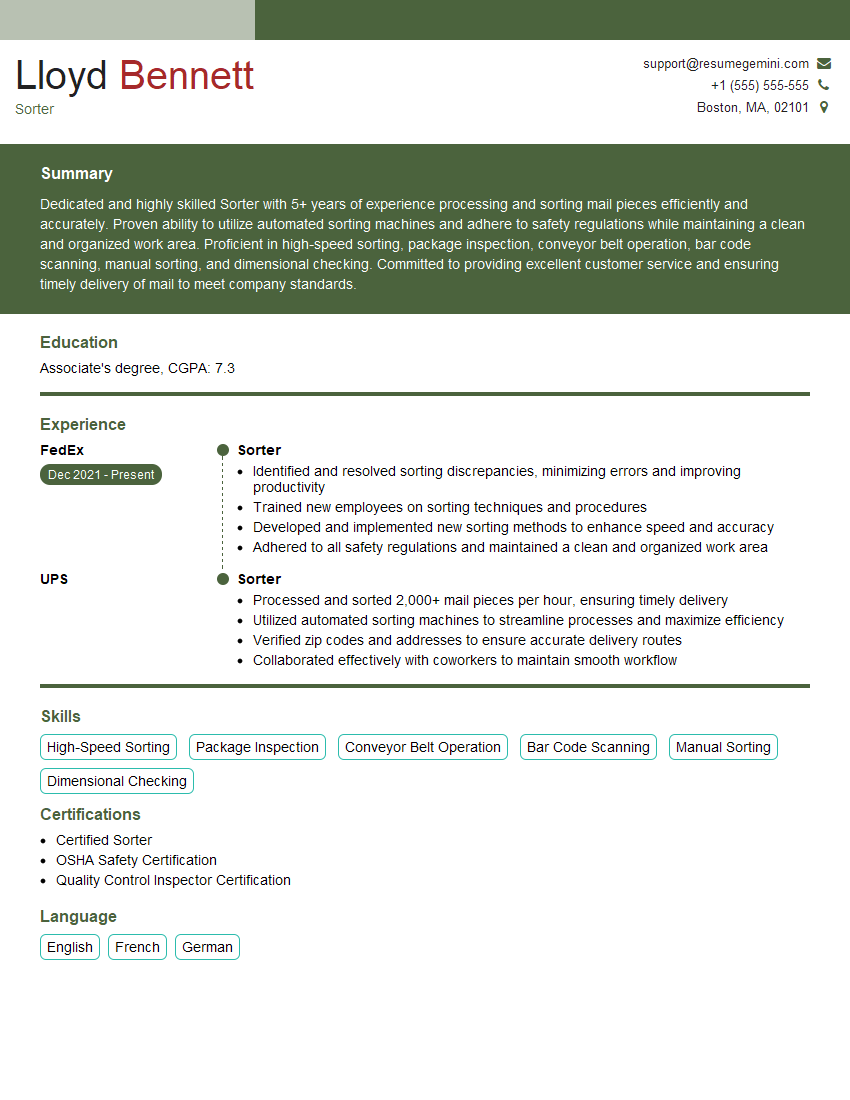

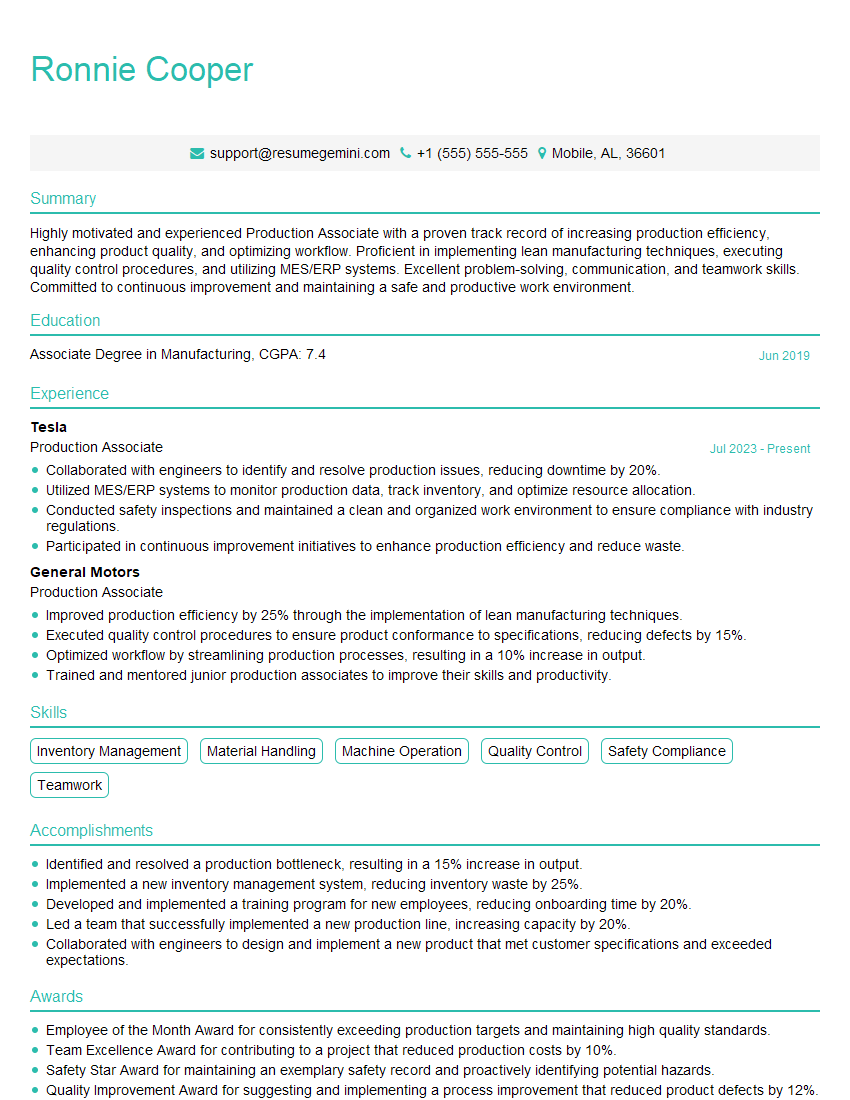

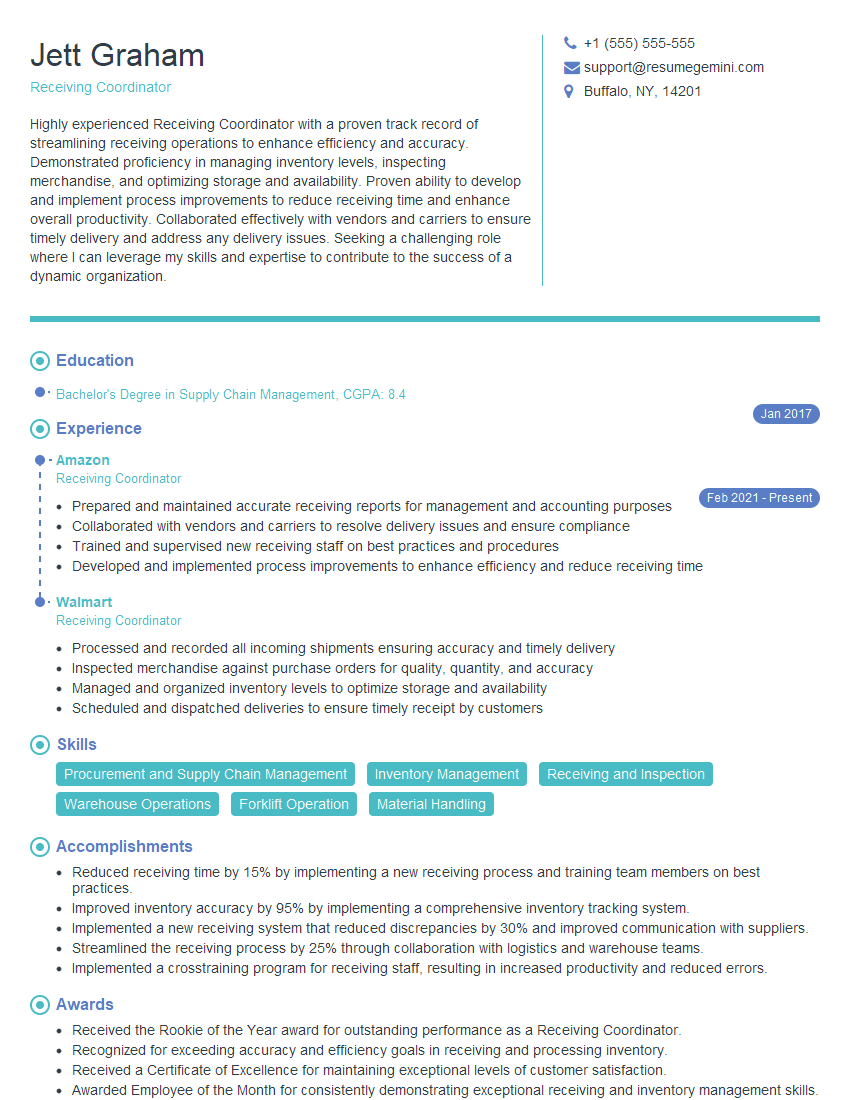

Mastering Sorting and Packing Techniques opens doors to exciting career opportunities in logistics, warehousing, and supply chain management. These skills are highly sought after and demonstrate your efficiency, accuracy, and ability to contribute to a smooth and productive work environment. To significantly boost your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource for building professional resumes that stand out. We provide examples of resumes tailored to Sorting and Packing Techniques to help you craft a compelling application that showcases your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good