Preparation is the key to success in any interview. In this post, we’ll explore crucial Splitting and Stacking interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Splitting and Stacking Interview

Q 1. Explain the different techniques for splitting logs of varying sizes and densities.

Splitting logs effectively depends heavily on the wood’s size and density. For smaller, softer woods like pine, a simple splitting maul or axe might suffice. However, larger, denser hardwoods like oak require more robust tools and techniques.

- Smaller, Softer Woods: A splitting maul, axe, or even a strong wedge driven with a sledgehammer works well. The key is to strike accurately at the grain to create a clean split.

- Larger, Denser Woods: For these, a hydraulic log splitter is often necessary. These machines provide the power needed to efficiently split even the most stubborn logs. If a hydraulic splitter isn’t available, a combination of wedges (both driving wedges and splitting wedges) and a sledgehammer can be used. Often, multiple strikes and strategic wedge placement are needed.

- Knotty or Crooked Logs: These present a special challenge. I usually start by trying to split through the areas between knots. Sometimes, pre-drilling a hole in the knot area can help prevent the tool from bouncing off. For really stubborn knots, I might use a smaller, more specialized wedge to work my way around the knot.

Choosing the right tool for the job is crucial for both efficiency and safety. Improper technique can lead to injuries or damaged tools.

Q 2. Describe the safety procedures you follow when operating splitting and stacking equipment.

Safety is paramount when working with splitting and stacking equipment. My safety procedures always begin with a thorough inspection of the equipment before each use. This includes checking for any damage to handles, blades, or hydraulic systems (for splitters). I always wear appropriate personal protective equipment (PPE), including:

- Safety glasses or a face shield: To protect against flying wood chips and debris.

- Heavy-duty gloves: To protect my hands from blisters and cuts.

- Steel-toed boots: To protect my feet from dropped tools or logs.

- Hearing protection: Especially when operating power tools like hydraulic splitters.

I also ensure I have a clear and safe work area, free from obstructions. When using a hydraulic splitter, I never place my hands or feet near the splitting mechanism while it’s operating. After completing the work, I always clean and store equipment properly to prevent accidents.

I frequently re-evaluate my workspace for safety and make changes as needed. For example, if I am working in a wet area, I might use anti-slip mats to minimize the risk of slips and falls.

Q 3. How do you ensure the efficient and safe stacking of split wood?

Efficient and safe stacking is crucial for proper wood drying and easy access. I always aim for a stable, organized stack that minimizes the risk of collapse. My approach involves:

- Creating a solid base: I start with a layer of larger, thicker pieces to create a stable foundation.

- Alternating log lengths: I mix shorter and longer pieces to prevent gaps and improve stability.

- Creating air circulation: I leave space between each log to allow air to circulate for proper drying. This reduces chances of mold growth.

- Building layers evenly: Each layer is carefully constructed to prevent leaning or uneven distribution of weight.

- Considering the wood’s weight: Very large stacks require more support, sometimes in the form of timbers laid across the pile to prevent collapse.

I ensure the stack is protected from rain and snow. A simple tarp or a lean-to style structure often suffices. Proper stacking ensures the wood dries correctly and stays free from damage. A haphazardly stacked pile can quickly become unstable and lead to potential injury.

Q 4. What are the common problems encountered during splitting and stacking, and how do you address them?

Common problems during splitting and stacking include encountering exceptionally hard or knotty wood, dealing with equipment malfunctions, and facing adverse weather conditions.

- Hard or Knotty Wood: As mentioned previously, strategic wedge placement and the use of a hydraulic splitter are often the solution. Pre-drilling can also help.

- Equipment Malfunctions: Regular maintenance is key. For hydraulic splitters, checking fluid levels and ensuring proper lubrication is crucial. If a problem occurs, I immediately shut down the machine and address the issue before resuming work.

- Adverse Weather: Working in rain or snow can lead to safety risks. I always pause work during heavy rain or storms. Proper covering of stacked wood is essential to prevent water damage.

- Back Injuries: Lifting heavy logs correctly is crucial. Using proper lifting techniques and avoiding overexertion help prevent back injuries. If lifting a particularly large piece, I often enlist assistance.

Problem-solving in this field is about recognizing the challenges, using the correct tools and techniques, and prioritizing safety. Experience teaches you how to adapt to unexpected difficulties.

Q 5. How do you maintain the quality and condition of split wood during storage?

Maintaining the quality and condition of split wood during storage is critical for ensuring it burns well later. Proper drying is essential and depends on factors like air circulation and weather protection.

- Proper Stacking: As mentioned, this is key for air circulation. A poorly stacked pile will dry poorly and potentially lead to rot or insect infestation.

- Protection from the Elements: A tarp or lean-to is essential to protect the wood from rain and snow. This is crucial to prevent excessive moisture absorption.

- Ground Conditions: Raising the stack slightly off the ground allows better air circulation and reduces the risk of moisture absorption from the soil. I might use pallets or timbers for this purpose.

- Insect Control: In some climates, insect infestation can be a problem. I usually inspect the wood regularly and use appropriate treatments or repellents if necessary.

Well-maintained wood not only burns better but also lasts longer, reducing the need to split and stack more wood. Following these simple guidelines can save time and money in the long run.

Q 6. Describe your experience with different types of splitting tools and equipment.

My experience encompasses a range of splitting tools and equipment, from basic hand tools to powered hydraulic splitters.

- Axes and Mauls: These are great for smaller logs and offer a good workout! I’ve used various sizes and weights, finding that the right size for the task is critical.

- Wedges and Sledgehammers: These are indispensable for larger logs and particularly tough pieces of wood, especially when combined with a maul or splitting axe for initial cracks. Different wedge materials offer different strengths and resistances.

- Hydraulic Log Splitters: These are my go-to for large quantities of wood or very large logs. I’m experienced with both vertical and horizontal splitters, understanding their strengths and weaknesses and choosing based on the size and type of wood.

- Specialty Tools: For particularly challenging logs, I’ve even used specialized wedges, such as those with a curved blade or a tapered design, designed to handle difficult knots.

Each tool has its place, and choosing the right tool for the job is key to efficient and safe wood splitting. A keen understanding of each tool’s properties and limitations is critical for skilled work.

Q 7. How do you assess the quality of wood before splitting and stacking?

Assessing wood quality before splitting is crucial for efficiency and ensuring proper drying and burning. My assessment includes checking several factors:

- Species: Different species have different densities and splitting characteristics. Knowing the species helps me choose the appropriate tool and technique.

- Moisture Content: Freshly cut wood is much harder to split than seasoned wood. Assessing the moisture level helps determine the difficulty of the splitting process.

- Rot or Decay: I check for any signs of rot or decay. Severely affected wood is unsuitable for splitting and should be discarded.

- Knots and Cracks: The presence of knots and cracks influences the splitting process. I identify these areas to plan my approach accordingly.

- Insect Infestation: Checking for signs of insect damage is important to prevent spreading infestations to the rest of my woodpile.

Careful assessment before splitting saves time and effort and ensures that only good-quality wood ends up in the stack. Discarding unsuitable wood prevents wasted effort and potential safety hazards.

Q 8. Explain your experience with inventory management in a wood processing environment.

Inventory management in wood processing is crucial for efficient operations and profitability. It involves tracking the quantity and quality of raw materials (logs) and finished products (split and stacked wood). My experience includes utilizing both manual and computerized inventory systems. In one role, I implemented a barcoding system to track wood from the moment it arrived at the yard until it was sold, significantly reducing errors and improving accuracy. This allowed for better forecasting of demand, minimizing waste from overstocking or understocking, and optimizing production scheduling. We also categorized wood based on species, size, and quality to facilitate efficient order fulfillment and pricing. Regular inventory audits ensured data integrity and identified any discrepancies promptly.

For example, we used a software system that integrated with our cutting and stacking machines to automatically update inventory levels after each processing run. This real-time tracking gave us immediate insight into our stock levels, enabling quick adjustments to production based on current orders and predicted demand.

Q 9. How do you ensure the proper handling and storage of split wood to prevent damage or deterioration?

Proper handling and storage of split wood is essential to prevent degradation and maintain its value. Key aspects include:

- Protection from the elements: Split wood should be covered or stored under a roof to prevent moisture absorption, which leads to rot and mold. Properly constructed wood sheds or covered storage areas are ideal.

- Air circulation: Adequate airflow is necessary to prevent excessive moisture buildup. Stacking wood with gaps between pieces allows for better air circulation and faster drying.

- Ground elevation: Storing wood directly on the ground exposes it to moisture from the soil. Using pallets or other elevated structures keeps it dry.

- Pest control: Insects and rodents can damage stored wood. Regular inspection and preventative measures like using pest repellent are crucial.

- Stacking techniques: Proper stacking prevents collapse and maximizes storage space. Uniform stacks with cross-bracing are more stable and less prone to damage.

For instance, I’ve overseen the implementation of a system where wood was stacked in uniformly sized cribs with tarps over the tops, providing both protection from the weather and allowing for controlled drying. This significantly reduced losses due to deterioration.

Q 10. What is your experience with using mechanized splitting and stacking equipment?

I have extensive experience operating and maintaining various mechanized splitting and stacking equipment, including hydraulic splitters, conveyor systems, and automated stacking machines. My experience ranges from smaller, portable machines suitable for smaller-scale operations to larger industrial-sized equipment used in high-volume processing facilities. I’m proficient in operating these machines safely and efficiently, adhering to all safety protocols. I’m also familiar with the maintenance requirements of this machinery, performing regular checks and preventative maintenance to prevent breakdowns and ensure optimal performance. I understand the importance of regular lubrication, blade sharpening, and hydraulic fluid checks to keep the equipment running smoothly.

For example, I once worked with a system that integrated a hydraulic splitter with a conveyor belt and automated stacker. This streamlined the entire process, significantly increasing output and reducing labor costs. I was responsible for ensuring the proper functioning of this integrated system, which included troubleshooting minor issues and performing preventative maintenance.

Q 11. Describe a time you had to troubleshoot a problem with splitting or stacking equipment.

During a particularly busy season, our main hydraulic splitter developed a persistent leak in the hydraulic line. This led to a significant drop in splitting capacity, threatening to delay orders. Instead of immediately calling for a costly repair, I followed a systematic troubleshooting approach:

- Safety first: I secured the machine, ensuring it was completely shut down and isolated before beginning any troubleshooting.

- Visual inspection: I carefully examined all hydraulic lines and fittings, looking for visible damage or leaks.

- Pressure test: I used a pressure gauge to check the hydraulic system’s pressure, identifying a significant drop in pressure, pinpointing the problem area.

- Temporary fix: I temporarily sealed the leak using a hydraulic hose clamp, restoring some functionality, preventing total shutdown.

- Permanent repair: I then contacted a hydraulic specialist who replaced the damaged section of the hydraulic line permanently.

This methodical approach allowed us to minimize downtime and maintain production, avoiding costly delays and lost revenue.

Q 12. How do you prioritize tasks when faced with multiple demands during splitting and stacking operations?

Prioritizing tasks during splitting and stacking operations requires a balanced approach considering urgency, impact, and resource allocation. I typically use a combination of methods:

- Urgency/Importance Matrix: I categorize tasks based on their urgency and importance, prioritizing those that are both urgent and important. This ensures that time-sensitive tasks with major impact are tackled first.

- Order fulfillment: Meeting customer deadlines is a primary concern. Tasks directly related to fulfilling orders are given high priority.

- Preventative maintenance: Regular maintenance tasks, though not always urgent, are vital for preventing major equipment failures. I schedule these strategically to minimize disruptions.

- Work allocation: If managing a team, I assign tasks based on individual skill sets and workload, ensuring efficient resource utilization.

For example, if I have a large urgent order, I would prioritize splitting and stacking that wood first, even if other tasks like cleaning are also important. I’d then delegate the cleaning to another worker, or schedule it during a less busy period.

Q 13. Describe your understanding of wood types and their optimal splitting techniques.

Understanding wood types and their properties is crucial for efficient splitting. Different species have varying densities and grain patterns, affecting their splitting behavior.

- Hardwoods (e.g., oak, maple): Tend to be denser and require more force to split. Often benefit from using wedges or splitting mauls.

- Softwoods (e.g., pine, fir): Generally easier to split due to their lower density and straighter grain. Can often be split with a simple axe or splitting maul.

- Knots and grain patterns: Knots and irregular grain patterns can make splitting difficult. Adjusting the splitting angle or using wedges can help overcome these challenges.

For instance, when splitting oak, I would use a heavier maul and focus on precise strikes to avoid shattering the wood. When working with pine, a lighter axe would suffice due to its easier splitting properties.

Q 14. How do you maintain a clean and organized workspace during splitting and stacking operations?

Maintaining a clean and organized workspace is vital for safety, efficiency, and overall productivity. This includes:

- Regular cleanup: Removing debris, sawdust, and scraps after each splitting and stacking operation. This prevents tripping hazards and keeps the area safe.

- Organized storage: Properly storing tools, equipment, and materials prevents clutter and increases efficiency.

- Designated areas: Having specific areas for different tasks – like a dedicated area for splitting and another for stacking – helps keep the workspace organized.

- Waste management: Properly disposing of waste materials, such as bark and sawdust, in designated areas. This helps maintain a clean and safe environment.

For example, I would always start my day by inspecting the workspace for any potential safety issues and cleaning any debris from the previous day. At the end of the day, I’d ensure all tools and equipment are stored away safely and properly, ready for the next day’s work.

Q 15. Explain your experience with working in a team environment during splitting and stacking.

Teamwork is crucial in splitting and stacking, especially in fast-paced lumber yards. In my previous role, we worked in teams of three, each with specialized tasks. One person would operate the splitting machine (if applicable), another would sort the split lumber by size and grade, and the third would stack the lumber neatly on pallets according to specified stacking patterns. Effective communication was key; we used hand signals to ensure safety around machinery and to coordinate the flow of materials. We also held regular briefings to discuss any challenges or changes in the work order, ensuring everyone was on the same page. For example, when a large order of specific wood dimensions came in, we’d adjust our workflow to prioritize that order, communicating clearly and proactively with each other to meet the deadline.

A successful team relies on mutual respect and understanding of each other’s roles. For instance, if the splitting machine operator experienced a jam, the others wouldn’t just wait; they’d assist with clearing the jam, ensuring minimal downtime. Open communication and mutual support were vital to our team’s overall efficiency and safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of your work during inventory management in a lumber yard?

Accuracy in lumber yard inventory is paramount. We used a combination of physical counts, barcode scanning, and inventory management software to maintain accuracy. Each pallet was barcoded, and during receiving and shipping, the barcode system meticulously tracked inventory movements. Regular physical counts, often done at the end of each day or at the beginning of the week, were used to cross-reference with the software data and identify any discrepancies. Discrepancies were immediately investigated to pinpoint the source of error (e.g., incorrect barcode scanning, damaged labels, theft). We implemented a system of ‘cycle counting’, where specific sections were counted daily to minimize the time it took to perform a full inventory check, thus preventing large-scale errors.

Beyond the technology, meticulous attention to detail was key. Correctly identifying wood species, sizes, and grades was critical. Clear labelling and organizing the lumber based on consistent standards prevented mixing of different types, resulting in accurate inventory counts and minimal errors. We also regularly calibrated the scanning equipment to ensure data accuracy.

Q 17. Describe a time you had to adapt to unexpected changes during splitting and stacking operations.

One time, a major storm caused a power outage during peak operation. We had a large shipment to get out that day. Our initial plan was disrupted because our splitting machine and barcode scanner were down. However, we quickly adapted. We reverted to manual splitting techniques using axes and mauls, prioritizing hand splitting for the highest-priority order. We organized the stacking by hand, carefully recording counts on paper, then inputting that data into the software once power was restored. Our manager helped to expedite communication with the client about the slight delay. While the manual process was slower, it prevented a major backlog and kept the client informed. We learned the value of having backup plans for unforeseen circumstances.

Q 18. How do you follow company safety regulations and procedures during your work?

Safety was the top priority. We followed all company safety regulations diligently. This included wearing appropriate personal protective equipment (PPE), such as steel-toed boots, safety glasses, gloves, and hearing protection, especially when using machinery. We always followed the safety procedures for using each piece of equipment, such as the splitting machine, forklifts, and hand tools. Regular safety training and toolbox talks ensured that we were up-to-date with the latest safety guidelines. We also reported any unsafe conditions or accidents immediately to our supervisor. For example, if a piece of equipment appeared malfunctioning, we immediately reported it and ceased using it until it was repaired. Maintaining a clean and organized work area was also a major part of preventing accidents.

Q 19. Explain your understanding of proper lifting techniques to avoid injury.

Proper lifting techniques are vital to prevent back injuries. The key principles are to keep the load close to the body, bend at the knees and hips (not the waist), and maintain a straight back. Using leg muscles instead of back muscles minimizes strain. For heavier pieces, we always used mechanical aids such as forklifts or pallet jacks. When lifting manually, we always had a partner to help when needed, especially for longer or awkward-shaped pieces. If a lift felt too heavy or awkward, we would always prioritize finding alternative methods. Prioritizing safety ensured that everyone remained injury-free and productive.

Q 20. What is your experience with using hand tools in splitting and stacking?

My experience with hand tools is extensive. I’m proficient in using axes, mauls, wedges, and splitting hammers, ensuring proper techniques for each tool to prevent injury and maximize efficiency. Regular sharpening and maintenance of these tools is crucial for safety and optimal performance. Understanding wood grain and knowing where to strike for clean splits is paramount. For example, using a wedge effectively to split stubborn logs requires careful placement and force application to avoid damaging the tool or the wood. I’m also skilled at using measuring tapes and other hand tools for precise measurements and marking wood for cutting or processing.

Q 21. How do you handle different weather conditions during splitting and stacking operations?

Weather conditions significantly impact splitting and stacking operations. In extreme heat, we schedule work during cooler parts of the day and take frequent breaks to avoid heatstroke. We also ensure adequate hydration. In wet weather, the wood becomes heavier and more slippery, increasing the risk of slips and falls. We use extra caution, and ensure the working area is properly drained and as dry as possible. In snowy or icy conditions, we prioritize safety above all else and may postpone operations until the weather improves, always prioritizing safety over productivity.

Q 22. Describe your knowledge of the different types of wood products produced from splitting and stacking operations.

Splitting and stacking operations produce a variety of wood products, depending on the intended use and the species of wood. The most common products include:

- Firewood: This is perhaps the most common product, ranging from small kindling pieces to large logs suitable for fireplaces or wood stoves. The size and length are typically determined by customer preference or the type of appliance it’s intended for.

- Lumber: While often produced through more sophisticated milling processes, rough-cut lumber can be a byproduct of splitting, especially if the wood is of high quality and suitable dimensions. This might involve splitting larger logs into more manageable planks before further processing.

- Wood chips and mulch: Smaller pieces resulting from splitting can be used to create wood chips for landscaping mulch or as fuel for industrial applications. The size consistency is important here, as too much variation can impact the efficiency of use.

- Posts and stakes: Depending on the type of wood and splitting technique, straight, strong pieces can be produced for fencing posts, stakes for gardening, or other construction applications. The key here is ensuring the pieces are both durable and straight enough for the intended purpose.

The type of wood also significantly impacts the final product. Hardwoods like oak tend to split cleanly and produce more durable products compared to softer woods like pine, which may be more suitable for firewood or smaller projects.

Q 23. How do you deal with challenging or difficult pieces of wood?

Dealing with challenging pieces requires a combination of skill, the right tools, and careful planning. Knots, twisting grain, and embedded materials are all potential obstacles. For example, a large knot might require a different splitting technique; instead of trying to split through it directly, I might work around it, making several smaller cuts to separate the knot from the rest of the wood.

Sometimes, a maul or splitting axe is necessary, but for particularly stubborn pieces, a wedge and sledgehammer can provide the extra force needed. In extreme cases, the wood might need to be re-oriented and approached from a different angle or even cut into smaller, more manageable sections before splitting.

Safety is paramount when dealing with difficult pieces. I always ensure I’m using appropriate personal protective equipment (PPE), such as safety glasses and gloves, and never attempt to force a split. A poorly executed split can cause injury and damage tools.

Q 24. Describe your understanding of the importance of maintaining proper workflow for efficiency.

Maintaining a proper workflow is crucial for efficiency and safety in splitting and stacking. A well-organized process minimizes wasted time and movement. My workflow typically follows these steps:

- Preparation: Clear the work area, gather necessary tools (axes, mauls, wedges, etc.), and assess the wood to determine the best splitting strategy.

- Splitting: Efficient splitting techniques, appropriate tool selection, and working methodically (e.g., splitting larger pieces into smaller ones first) are key.

- Stacking: Simultaneously stack as you split to reduce the need for excessive movement. Utilize a consistent stacking pattern to maximize space and stability.

- Organization: Maintain a clean and organized workspace. Stacking should be orderly to facilitate easy access and prevent accidents.

This structured approach streamlines the process, preventing unnecessary backtracking and improving overall productivity. For instance, I never leave a stack incomplete; finishing a stack encourages better work habits and contributes to a clean and safe work area.

Q 25. What is your experience with handling and stacking different sizes and shapes of wood?

My experience encompasses handling and stacking a wide range of wood sizes and shapes. I am comfortable working with everything from small kindling to large logs exceeding several feet in length and varying thicknesses. The techniques adapt to the size and shape. Smaller pieces can be easily handled and stacked, while larger pieces require more careful planning and potentially the use of machinery or assistance.

Irregularly shaped pieces pose a unique challenge, but with experience, the best approach becomes intuitive. I ensure the wood is stable when stacking to avoid tipping and injury. Knowing how to best orient each piece and incorporate it into the stack contributes to stability and efficient space use.

For example, I might use smaller pieces to fill gaps between larger logs in a stack, creating a more stable structure. This knowledge of both the material and efficient stacking patterns allows me to work effectively and safely with all sizes and shapes.

Q 26. How do you ensure the stability of wood stacks to prevent collapse?

The stability of wood stacks is critical to prevent collapse, which can lead to injury or damage. I ensure stability through several key strategies:

- Solid Foundation: The base of the stack needs to be level and sturdy. I often use larger, heavier pieces as a foundation, creating a strong base to support the upper layers.

- Interlocking Pattern: Rather than simply stacking pieces vertically, I interlock them, creating a more complex and robust structure. This minimizes gaps and improves the stack’s overall stability.

- Even Weight Distribution: I strive for even weight distribution throughout the stack, avoiding the concentration of heavy pieces in one area. This helps to prevent tilting or uneven settling.

- Regular Checking: Especially in areas prone to strong winds or heavy rain, I periodically check the stacks for any signs of instability. Early detection prevents potential collapses.

- Proper Stacking Height: The height of a stack should be proportional to its base, preventing the risk of tipping. Very tall stacks should have particular attention paid to stability.

Think of it like building a brick wall—each brick supports the next, creating an overall structure. The same principle applies to stacking wood, requiring careful consideration of weight, size, and alignment.

Q 27. Describe your experience with using measuring tools to determine the size and quantity of wood.

Accurate measuring is essential for determining the size and quantity of wood, especially when fulfilling customer orders or invoicing for work. I use a variety of tools, depending on the specific need. These include:

- Measuring tapes: For measuring the length and width of individual pieces and overall stack dimensions.

- Rulers: For precise measurements of shorter pieces or when determining the cross-sectional area of wood.

- Calipers: For more precise measurements of diameter or thickness, especially when dealing with round logs.

- Volume calculations: Depending on the desired accuracy and amount of wood, calculating the volume (length x width x height) can provide an accurate estimation of quantity.

Accurate measurement ensures that customers receive the quantity they ordered and facilitates fair compensation for work performed. I always double-check my measurements to minimize errors and ensure accuracy.

Q 28. How do you adapt your techniques for splitting and stacking based on the customer’s specific needs?

Adaptability is key when it comes to fulfilling customer needs. The splitting and stacking techniques adjust based on the customer’s requests, including:

- Size and length specifications: Customers often require specific sizes for firewood, landscaping, or other applications. I carefully adapt my splitting techniques to produce pieces that meet these requirements precisely.

- Type of wood: Different woods have different splitting properties. I adjust my approach accordingly; hardwoods may require more force, while softer woods are easier to split but might require different stacking techniques to maintain stability.

- Quantity: Large orders necessitate efficient techniques and may require additional support or equipment to ensure timely delivery.

- Delivery and stacking arrangements: The customer’s expectations regarding delivery and stacking (e.g., placement in a specific area, loose piles versus organized stacks) heavily influence my approach.

For example, a customer might need uniformly sized firewood for an indoor fireplace. This demands precise splitting and careful selection of suitable wood pieces. In contrast, a bulk order of wood chips for landscaping can utilize less precise splitting as long as size consistency is within acceptable ranges.

Key Topics to Learn for Splitting and Stacking Interview

- Data Structures & Algorithms for Splitting: Understand the efficiency of various algorithms (e.g., divide and conquer) in splitting large datasets or tasks. Consider the impact of data structures (arrays, linked lists, trees) on splitting performance.

- Optimal Splitting Strategies: Explore different approaches to splitting, such as balanced vs. unbalanced splitting, and their implications for efficiency and resource allocation. Analyze scenarios where different strategies are most suitable.

- Parallel Processing and Splitting: Learn how to leverage parallel processing techniques (multithreading, multiprocessing) to enhance the speed of splitting operations, particularly with large datasets. Consider thread synchronization and data consistency.

- Stacking Techniques and Optimization: Investigate various methods for stacking processed data or results from the splitting process. Explore techniques for optimizing stack memory management and minimizing overhead.

- Error Handling and Exception Management: Develop robust error handling strategies to manage potential issues during the splitting and stacking processes, such as data inconsistencies or resource limitations. Practice effective debugging techniques.

- Performance Analysis and Tuning: Understand how to profile and analyze the performance of splitting and stacking algorithms. Learn to identify bottlenecks and optimize code for improved efficiency and scalability.

- Practical Applications & Case Studies: Review real-world examples of splitting and stacking in different domains (e.g., image processing, large-scale data analysis, machine learning). Understand how the concepts translate to practical scenarios.

Next Steps

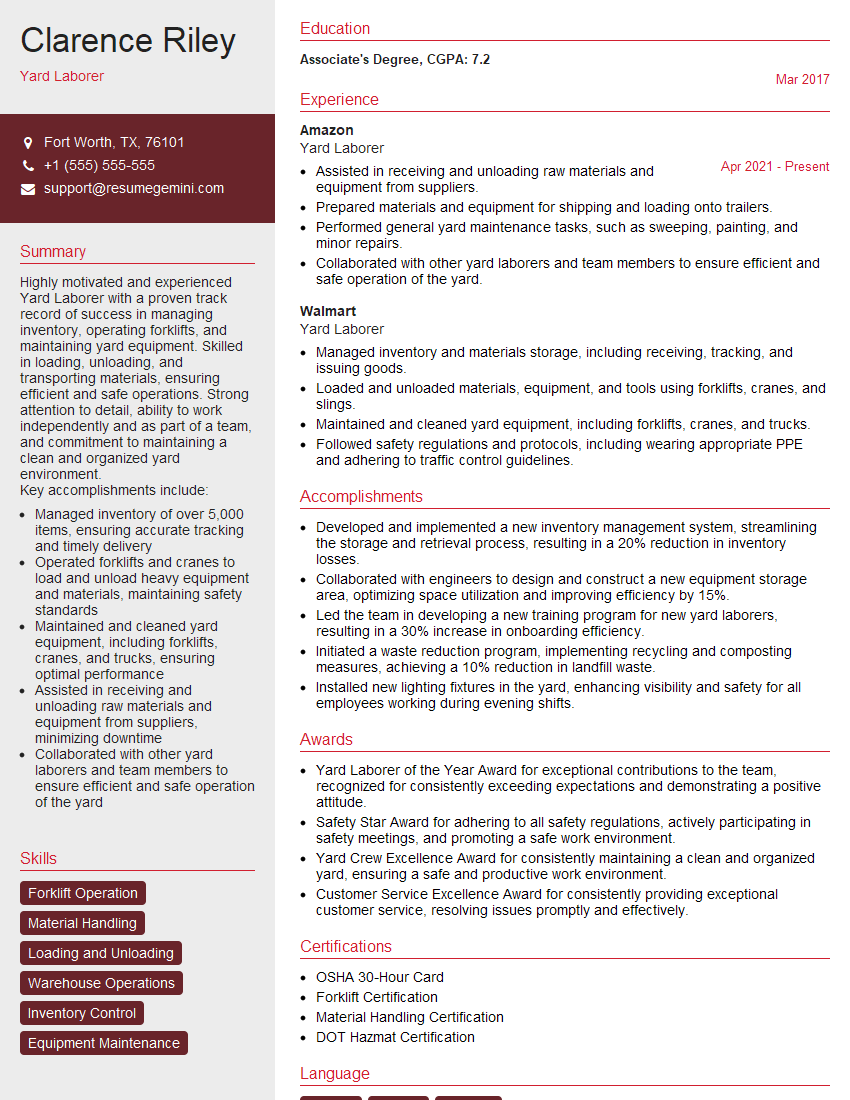

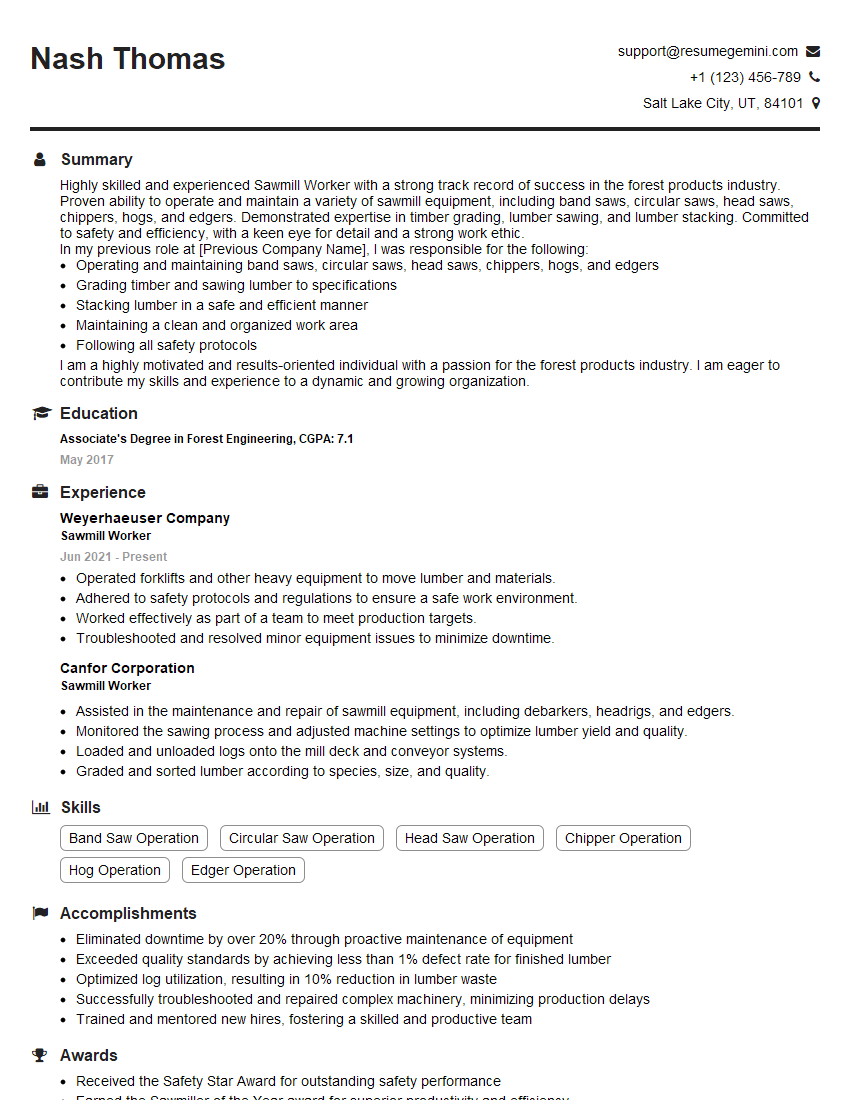

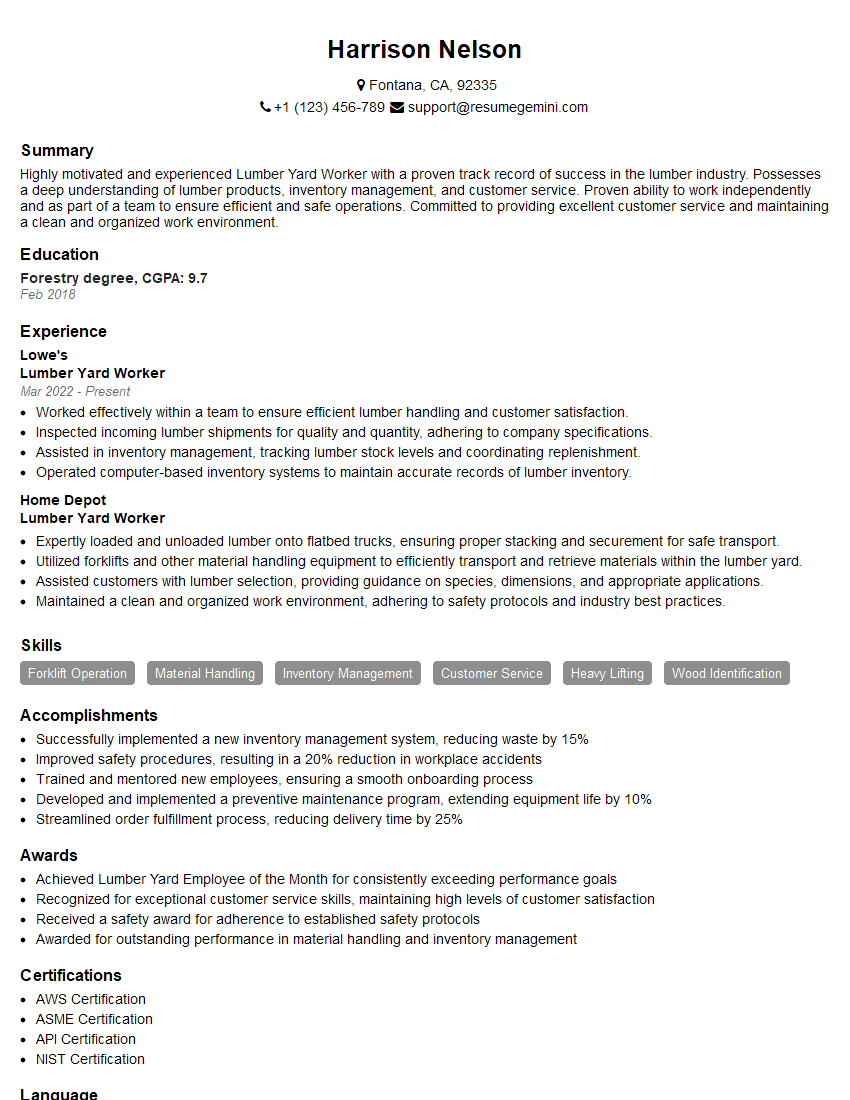

Mastering Splitting and Stacking techniques significantly enhances your problem-solving skills and demonstrates a strong grasp of fundamental computer science principles, highly valued in many tech roles. This expertise translates into efficient solutions and optimized performance, making you a more competitive candidate. To further boost your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills effectively. Examples of resumes tailored to showcase Splitting and Stacking expertise are available within ResumeGemini to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good