The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Storage and Handling of Hazardous Materials interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Storage and Handling of Hazardous Materials Interview

Q 1. What are the key elements of a comprehensive hazardous materials storage plan?

A comprehensive hazardous materials storage plan is crucial for safety and compliance. It’s like a detailed blueprint ensuring everything is in its right place and handled correctly. Key elements include:

- Inventory Control: A precise list of all hazardous materials stored, including quantities, locations, and Material Safety Data Sheets (MSDS).

- Storage Area Design: Dedicated, well-ventilated storage areas designed to prevent spills, leaks, and incompatible material interactions. This might include separate areas for flammables, oxidizers, and corrosives.

- Segregation and Compatibility: Storing incompatible materials apart to avoid dangerous reactions. For example, never store strong oxidizers near flammable materials.

- Spill Containment: Using spill pallets, berms, or other containment systems to prevent spills from spreading.

- Emergency Preparedness: Designated emergency contact information, evacuation plans, and procedures for handling spills or leaks.

- Training and Education: Ensuring all personnel handling hazardous materials are properly trained in safe handling procedures, emergency response, and the use of personal protective equipment (PPE).

- Security Measures: Access control to prevent unauthorized access to storage areas.

- Regular Inspections: Frequent inspections to identify and address potential hazards, ensuring labels are intact and proper storage conditions are maintained.

Imagine a warehouse storing chemicals; a good plan ensures that acids are far from bases, flammables are in a separate, fire-resistant area, and proper signage is everywhere. Without a solid plan, a small incident could quickly escalate into a major disaster.

Q 2. Explain the different classes of hazardous materials and their associated risks.

Hazardous materials are classified into different classes based on their inherent hazards. Think of it like sorting different types of garbage for recycling – each class needs specific handling. The major classes include:

- Class 1: Explosives: Materials capable of mass detonation or rapid decomposition, posing a significant blast and fragmentation hazard. Examples: Dynamite, fireworks.

- Class 2: Gases: Compressed, liquefied, or dissolved gases that can be flammable, non-flammable, or toxic. Examples: Propane, oxygen, chlorine.

- Class 3: Flammable Liquids: Liquids that can easily ignite and burn. Examples: Gasoline, acetone.

- Class 4: Flammable Solids: Solids that can easily ignite and burn. Examples: Matches, magnesium.

- Class 5: Oxidizers and Organic Peroxides: Materials that readily release oxygen or other oxidizing substances, causing or enhancing combustion. Examples: Hydrogen peroxide, ammonium nitrate.

- Class 6: Toxic and Infectious Substances: Materials that are poisonous or cause disease. Examples: Pesticides, biological agents.

- Class 7: Radioactive Materials: Materials that emit ionizing radiation. Examples: Uranium, plutonium.

- Class 8: Corrosive Materials: Materials that cause visible destruction or irreversible alterations to living tissue. Examples: Sulfuric acid, sodium hydroxide.

- Class 9: Miscellaneous Hazardous Materials: Materials that do not fit into other classes but present a hazard during transport. Examples: Lithium batteries, asbestos.

Each class carries different risks, requiring specific storage, handling, and transportation procedures. Misclassifying a hazardous material can have severe consequences.

Q 3. Describe the proper procedures for handling a hazardous materials spill.

Handling a hazardous materials spill requires immediate action and a methodical approach. Think of it like fighting a fire – speed and the right equipment are crucial. The steps generally involve:

- Evacuation and Isolation: Evacuate the immediate area and establish a perimeter to prevent further exposure.

- Assessment: Identify the spilled material, its quantity, and potential hazards. Consult the MSDS.

- Personal Protective Equipment (PPE): Don appropriate PPE such as respirators, gloves, protective suits, and eye protection – the type will depend on the hazardous material.

- Containment: Contain the spill using absorbent materials, berms, or other containment methods to prevent its spread.

- Cleanup: Use the appropriate cleanup methods outlined in the MSDS. This may involve neutralization, absorption, or other specialized techniques.

- Disposal: Dispose of the contaminated materials and cleanup materials according to regulations.

- Reporting: Report the spill to the relevant authorities (e.g., OSHA, local emergency services).

Remember, safety is paramount. If unsure about handling a specific spill, always contact emergency services and qualified hazardous materials professionals.

Q 4. What are the relevant OSHA regulations regarding hazardous materials?

OSHA (Occupational Safety and Health Administration) has numerous regulations concerning hazardous materials, primarily under 29 CFR 1910.1200 (Hazard Communication Standard) and other specific standards based on material type. These regulations mandate:

- Hazard Communication: Employers must inform employees about the hazards of the chemicals they handle through SDSs and labels.

- Employee Training: Workers must receive training on hazardous materials they handle, including safe handling, PPE, and emergency procedures.

- Personal Protective Equipment (PPE): Employers must provide appropriate PPE and ensure its proper use.

- Medical Surveillance: In certain cases, medical surveillance may be required for employees handling hazardous materials.

- Storage and Handling Procedures: Regulations outline safe storage, handling, and disposal practices.

- Record Keeping: Maintaining records of hazardous materials used and training provided.

Non-compliance can result in substantial fines and legal repercussions. Regular safety audits and ongoing training are key to maintaining OSHA compliance.

Q 5. How do you ensure compliance with DOT regulations for transporting hazardous materials?

Ensuring compliance with DOT (Department of Transportation) regulations for transporting hazardous materials is crucial for public safety. It’s like following traffic laws – ignoring them can have severe consequences. Key aspects include:

- Proper Classification and Labeling: Materials must be accurately classified according to the hazardous materials table and appropriately labeled according to DOT regulations. This includes using the correct hazard class labels and placards.

- Packaging Requirements: Materials must be packaged and contained according to DOT specifications to prevent leaks or spills during transportation.

- Shipping Papers: Accurate shipping papers (bills of lading) must accompany shipments, detailing the hazardous materials being transported.

- Driver Training: Drivers must be trained in handling hazardous materials and emergency response procedures.

- Vehicle Requirements: Vehicles must meet specific DOT standards, such as proper ventilation and emergency equipment.

- Emergency Response Plan: Having a detailed emergency response plan in case of accidents or spills during transportation.

Failure to comply can lead to hefty fines, accidents, and environmental damage. Regular training and meticulous record-keeping are paramount.

Q 6. What are the different types of personal protective equipment (PPE) used when handling hazardous materials?

The type of personal protective equipment (PPE) used when handling hazardous materials depends on the specific hazards involved. It’s like choosing the right tool for a job – a screwdriver won’t work for hammering. Common types include:

- Respiratory Protection: Respirators (e.g., air-purifying respirators, self-contained breathing apparatus) to protect against airborne hazards.

- Eye Protection: Safety glasses, goggles, or face shields to protect against splashes or airborne particles.

- Hand Protection: Gloves made from appropriate materials (e.g., nitrile, neoprene, butyl rubber) resistant to the specific hazardous material.

- Body Protection: Protective suits (e.g., Tyvek suits, chemical-resistant suits) to prevent skin contact with hazardous materials.

- Foot Protection: Safety boots to protect against spills or falling objects.

- Hearing Protection: Ear plugs or muffs to protect against loud noises from machinery or processes.

Choosing the correct PPE requires a thorough hazard assessment and understanding the properties of the hazardous material being handled. Improper PPE can lead to serious injuries or even fatalities.

Q 7. Explain the importance of proper labeling and signage for hazardous materials.

Proper labeling and signage are essential for hazardous materials handling and storage. It’s like road signs – they guide and warn us. They convey critical information at a glance and prevent accidents:

- Labels: Labels on containers provide detailed information about the hazardous material, including its identity, hazards, and handling precautions. They are mandated by OSHA’s Hazard Communication Standard.

- Signage: Signage in storage areas warns of hazards and provides guidance on appropriate behavior. This might include warning signs about flammables, corrosives, or other hazards, as well as directional signs and emergency contact information.

- Color-coding: Color-coding systems help quickly identify the type of hazard. For instance, red might indicate flammability, while yellow might indicate reactivity.

- Pictograms: Standardized pictograms are used on labels and signs to quickly communicate the nature of the hazard (e.g., flame for flammability, skull and crossbones for toxicity).

Clear and consistent labeling and signage significantly reduce the risk of accidents and injuries by ensuring everyone is aware of potential hazards and how to handle them safely. A well-labeled storage area instantly communicates potential risks, promoting safer operations.

Q 8. Describe your experience with hazardous waste disposal procedures.

Hazardous waste disposal involves a multi-step process ensuring environmental protection and compliance with regulations. It begins with proper segregation and containment of waste streams according to their hazardous characteristics (e.g., flammability, toxicity, reactivity). This often requires specialized containers and labeling. Next, waste undergoes characterization, which determines its exact composition and classifies it according to relevant regulations (like RCRA in the US). This characterization may involve laboratory testing. Then comes the selection of an appropriate disposal method. Options include incineration, landfilling in specially designed hazardous waste landfills, chemical treatment, or recycling. Each method is chosen based on the waste’s properties and regulatory requirements. Finally, meticulous record-keeping is crucial, documenting every step of the process, from generation to final disposal. This ensures traceability and allows for audits to maintain compliance. For example, in my previous role at a chemical manufacturing plant, we handled spent solvents through a licensed hazardous waste contractor who specialized in solvent incineration. We meticulously tracked every drum of waste, ensuring proper manifests and documentation were maintained for regulatory compliance and internal auditing.

Q 9. How do you conduct a risk assessment for hazardous materials handling operations?

A thorough risk assessment for hazardous materials handling starts with identifying potential hazards. This includes evaluating the inherent dangers of each material handled (e.g., toxicity, flammability, reactivity), and considering the operational processes involved (e.g., storage, transport, mixing). Next, we identify who might be exposed to those hazards – workers, the public, or the environment. We then analyze the likelihood of those hazards causing harm, considering factors like frequency of exposure and control measures in place. Finally, we assess the severity of the potential harm – from minor irritation to catastrophic events. This qualitative or quantitative analysis leads to a risk ranking, prioritizing high-risk activities and informing control measures. Consider a scenario with highly reactive chemicals. A risk assessment might highlight the risk of explosions during mixing if inappropriate procedures or equipment are used. Implementing stricter procedures, using specialized equipment (like explosion-proof vessels), and providing specialized PPE to workers would lower that risk. The results of the risk assessment directly inform the development of a safe work procedure.

Q 10. What is your experience with inventory control systems for hazardous materials?

Effective inventory control for hazardous materials is paramount for safety and compliance. We utilize specialized software systems designed for tracking hazardous materials, integrating with our chemical inventory database. These systems track material quantities, location, expiration dates, and associated safety data sheets (SDS). This real-time tracking allows for efficient management of stock levels, preventing shortages or overstocking. Features such as automated alerts for nearing expiration dates prevent the use of degraded materials, and a robust search function ensures quick retrieval of safety information. Barcoding or RFID tagging can further enhance accuracy and efficiency. In one project, we implemented a system that automatically generated alerts for upcoming inspections or regulatory compliance deadlines associated with specific materials, eliminating manual tracking of these important dates and improving our compliance rate.

Q 11. Explain the importance of emergency response planning for hazardous materials incidents.

Emergency response planning for hazardous materials incidents is critical for protecting personnel, property, and the environment. A well-developed plan includes pre-emergency planning, which involves hazard identification, risk assessment (as discussed earlier), and defining roles and responsibilities within the emergency response team. The plan must detail emergency procedures, including evacuation routes, containment strategies, and communication protocols. This also encompasses training exercises and drills to ensure preparedness and effective coordination among team members. It’s crucial to establish clear communication channels with local emergency services, providing them with accurate information on stored materials and potential hazards. A comprehensive plan helps mitigate the consequences of an incident by reducing response times, minimizing exposure, and guiding effective cleanup. For example, having pre-established emergency contact lists with local fire departments and HAZMAT teams, along with detailed facility maps, can significantly reduce response times in an emergency situation.

Q 12. Describe your experience with training employees on hazardous materials handling procedures.

Training employees on hazardous materials handling is a crucial aspect of safety management. Training programs must be tailored to the specific hazards encountered in the workplace and include both theoretical and practical components. Theoretical training includes covering relevant regulations (OSHA, EPA, etc.), understanding SDSs, and recognizing hazard symbols. Practical training involves hands-on demonstrations of safe handling procedures, use of personal protective equipment (PPE), and emergency response protocols. We use a combination of classroom lectures, videos, and hands-on workshops to provide a comprehensive understanding of the risks and necessary safety precautions. Regular refresher training and competency assessments are crucial to maintain skills and reinforce safe working practices. For instance, we simulated spill response scenarios during training exercises, which enhanced employee skills and confidence in handling actual incidents.

Q 13. How do you ensure the safety of personnel during hazardous materials handling operations?

Ensuring personnel safety during hazardous materials handling operations requires a multi-faceted approach. It begins with risk assessment and implementing appropriate control measures, such as engineering controls (e.g., ventilation systems, enclosed equipment), administrative controls (e.g., safe work procedures, job rotation), and personal protective equipment (PPE). The selection of PPE is critical and depends on the specific hazard; it might range from gloves and eye protection to respirators and specialized suits. Regular inspections of equipment and facilities are necessary to identify and rectify any potential hazards. Implementing a robust permit-to-work system can prevent unauthorized access to hazardous areas or activities. Continuous monitoring of worker health through regular medical check-ups and exposure monitoring programs is also crucial to early detection of any adverse health effects. Thorough investigation of any incidents, including near misses, helps identify areas for improvement and prevent future accidents. A safety culture fostering open communication and encouraging employees to report hazards proactively is vital for safety.

Q 14. What is your understanding of Material Safety Data Sheets (MSDS)?

Material Safety Data Sheets (MSDS), now known as Safety Data Sheets (SDS), are standardized documents providing comprehensive information about the hazards associated with a chemical product and how to work safely with it. They contain crucial details about the chemical’s properties (physical, chemical, toxicological), potential health effects of exposure, recommended handling procedures, storage requirements, and emergency response information. SDSs are legally required for most hazardous chemicals, and accessing and understanding them is crucial for anyone working with hazardous materials. For example, an SDS might specify the need for respiratory protection when handling a specific chemical due to its vapor toxicity, or it might provide instructions for spill cleanup procedures. Failure to consult and follow the information provided in the SDS can result in serious accidents or health consequences. Regularly reviewing and updating SDSs for chemicals in use is important, as chemical composition and safety recommendations can evolve.

Q 15. Explain the process of selecting appropriate containment systems for hazardous materials.

Selecting the right containment system for hazardous materials is crucial for safety and regulatory compliance. It’s not a one-size-fits-all approach; the choice depends on several factors, primarily the properties of the hazardous material itself. We need to consider its physical state (solid, liquid, gas), reactivity, flammability, toxicity, and potential for environmental contamination.

- Material Compatibility: The container must be chemically compatible with the hazardous material to prevent reactions or degradation. For example, using a metal container for a highly corrosive acid would be disastrous.

- Strength and Durability: The container must withstand the physical stresses of handling, transport, and storage. This includes pressure changes (for gases), impacts, and temperature fluctuations.

- Leakproof Design: The container and its closure system must prevent leaks or spills. This might involve secondary containment measures, as we’ll discuss later.

- Regulatory Compliance: Containers must meet all relevant regulations, such as those set by OSHA (Occupational Safety and Health Administration) and DOT (Department of Transportation). These regulations often specify the type of container, labeling requirements, and handling procedures.

- Ease of Handling: The container should be easily manageable by trained personnel, considering its size, weight, and the handling equipment available.

For instance, a highly reactive chemical might require a specialized container made of inert materials like stainless steel or high-density polyethylene, while a less reactive liquid could be stored in a standard HDPE drum. Each selection must be meticulously documented.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage the segregation of incompatible hazardous materials?

Segregation of incompatible hazardous materials is paramount to prevent dangerous reactions. Incompatible materials are those that can react violently when mixed, potentially causing fires, explosions, or the release of toxic gases. The process involves careful planning and implementation:

- Hazard Identification: First, we identify all hazardous materials present, determining their chemical properties and potential incompatibilities through Safety Data Sheets (SDS).

- Compatibility Chart: We consult compatibility charts or matrices that specify which materials should not be stored together. These charts are often provided by chemical suppliers or regulatory bodies.

- Spatial Separation: Incompatible materials are stored in separate areas, often in different buildings or storage facilities. If this isn’t feasible, they are separated by significant distances within a single facility, using fire-resistant barriers or other physical separations.

- Dedicated Storage Areas: We designate specific storage areas for different hazard classes (e.g., flammables, oxidizers, corrosives) with clearly marked signage.

- Inventory Management: A robust inventory management system helps track the location and quantity of each hazardous material, ensuring proper segregation is maintained.

Imagine storing a strong oxidizer (like potassium permanganate) near a flammable solvent. Mixing these could lead to a fire or explosion. Strict segregation prevents this scenario.

Q 17. What is your experience with the use of secondary containment?

Secondary containment is a critical aspect of hazardous material management. It provides an extra layer of protection, preventing spills from reaching the environment in case of a primary container failure. My experience includes designing, implementing, and inspecting secondary containment systems for various applications. These include:

- Spill Pallets: These are low-profile trays placed beneath containers to capture spills.

- Berms: Earthen or concrete barriers surrounding storage tanks or other large containers to contain a spill.

- Dikes: Similar to berms but usually smaller and used for smaller containers.

- Secondary Containment Tanks/Drums: Containers inside larger containers, offering redundant protection.

During inspections, we assess the structural integrity of the secondary containment, ensuring that it’s leak-free and can hold the volume of the largest container it houses plus a safety margin. We also ensure proper drainage and spill response procedures are in place.

For instance, I oversaw the installation of a bermed area for the storage of 55-gallon drums of corrosive liquids, guaranteeing that a breach in any drum wouldn’t lead to environmental contamination.

Q 18. How do you ensure the integrity of hazardous materials packaging?

Maintaining the integrity of hazardous materials packaging is essential for preventing leaks, spills, and exposure. This involves multiple checks and procedures throughout the supply chain:

- Inspection Upon Receipt: Packages are inspected upon arrival for any damage, leaks, or signs of tampering. Damaged packages are immediately isolated and reported.

- Proper Handling Procedures: Adhering to appropriate handling practices during storage, transportation, and use is crucial for preventing damage.

- Regular Inspections: Stored packages are regularly inspected for signs of deterioration, leaks, or corrosion. This involves visual checks and sometimes more advanced techniques like leak detection testing.

- Appropriate Storage Conditions: Maintaining proper storage conditions, including temperature and humidity control, is essential for certain materials that might degrade under specific conditions.

- Proper Labeling and Marking: Ensuring that containers are correctly labeled with hazard warnings and handling instructions is a key aspect of preventing accidental exposure.

For example, we regularly inspect the packaging of chemicals stored in our warehouse and immediately replace containers showing signs of wear or damage. This proactive approach helps prevent accidents and maintain compliance.

Q 19. Describe your experience with hazardous materials incident investigation.

Investigating hazardous materials incidents requires a methodical approach to determine the root cause and prevent recurrence. My experience involves:

- Immediate Response and Containment: The first step is to secure the area, contain the spill or release, and ensure the safety of personnel.

- Data Collection: Gathering information is crucial. This includes documenting the event, interviewing witnesses, reviewing relevant records (SDS, permits, training records), and collecting physical evidence.

- Analysis of Evidence: Analyzing the collected data, using established methodologies, helps identify potential causes and contributing factors. This might involve chemical analysis, review of handling procedures, and assessment of equipment malfunctions.

- Root Cause Determination: The goal is to pinpoint the underlying cause of the incident, not just the immediate trigger. This involves using tools like fault tree analysis or five whys.

- Corrective Actions: Based on the findings, corrective actions are developed and implemented to prevent similar incidents from happening in the future. This might involve process changes, equipment upgrades, or enhanced training.

I once investigated an incident involving a spill of corrosive liquid. By thoroughly investigating the incident, we found the root cause was a defective valve on the storage tank. This led to the implementation of a preventative maintenance program for all valves on chemical storage tanks.

Q 20. What is your experience with the use of respiratory protection equipment?

Respiratory protection is essential when working with hazardous materials that can be inhaled. My experience includes selecting, fitting, training, and overseeing the use of various respiratory protection equipment (RPE).

- Hazard Assessment: The type of RPE needed depends on the specific hazards. A hazard assessment determines the required protection factor (how much the equipment reduces exposure).

- Proper Selection: Selecting the right respirator involves considering the type of contaminant (gas, vapor, particulate), its concentration, and the duration of exposure. Options include respirators with air-purifying cartridges, supplied-air respirators, and self-contained breathing apparatus (SCBA).

- Fit Testing: Ensuring a proper fit is paramount. Fit tests verify that the respirator seals effectively against the wearer’s face.

- Training and Competency: Users must receive comprehensive training on the proper use, maintenance, and limitations of their RPE. Regular competency assessments ensure continued proficiency.

- Maintenance and Inspection: Respirators require regular inspection and maintenance to ensure their effectiveness.

For example, when working with asbestos, we require workers to use SCBA due to the high risk associated with asbestos inhalation. Before commencing work, the proper fit test of the SCBA is ensured.

Q 21. How do you manage the disposal of expired hazardous materials?

Managing the disposal of expired or unwanted hazardous materials requires strict adherence to regulations and safety protocols. The process typically involves:

- Identification and Characterization: First, we identify the hazardous materials and determine their specific properties and waste codes. This information is usually found on the SDS.

- Waste Segregation: Expired materials are segregated according to their hazard class and compatibility to prevent dangerous reactions during handling and transport.

- Selection of a Licensed Disposal Facility: Disposal must be handled by a licensed hazardous waste disposal facility. These facilities have the necessary equipment and expertise to handle and dispose of hazardous materials safely and in compliance with regulations.

- Proper Packaging and Labeling: Materials are packaged appropriately, ensuring that the containers are intact and properly labeled with appropriate hazard warnings and shipping information.

- Manifest Preparation and Tracking: A manifest is prepared to document the type and quantity of waste being transported and its destination. This ensures accountability and tracking throughout the disposal process.

We’ve utilized several licensed hazardous waste disposal companies over the years to handle various expired chemicals and solvents, always maintaining detailed records of the entire disposal process.

Q 22. What are the common hazards associated with handling flammable materials?

Flammable materials pose a significant risk of fire and explosion. The hazards are primarily related to their ability to ignite easily and burn rapidly, releasing significant heat and potentially toxic fumes. Common hazards include:

- Ignition Sources: Any source of heat, spark, or flame (e.g., static electricity, friction, hot surfaces, open flames) can ignite flammable materials. Imagine a simple scenario: a worker using a grinder near spilled gasoline – a disastrous combination.

- Rapid Fire Spread: Flammable liquids, gases, and even dusts can spread fire quickly, making containment difficult. A small spill can quickly engulf a large area.

- Explosive Vapors: Many flammable materials release flammable vapors that can form explosive mixtures with air. This is why proper ventilation is crucial. Think of a gas leak in a confined space; a single spark could trigger a devastating explosion.

- Burns and Injuries: Direct contact with burning materials or hot surfaces can cause severe burns. Inhalation of combustion byproducts can lead to respiratory issues.

- Property Damage: Fires involving flammable materials can cause extensive damage to buildings, equipment, and other assets. The cost associated with cleanup and recovery can be significant.

Proper storage, handling, and use of flammable materials, including appropriate personal protective equipment (PPE) and fire safety measures, are critical to mitigating these hazards.

Q 23. Explain the different types of fire suppression systems used for hazardous materials.

Several fire suppression systems are employed for hazardous materials, each suited to different types of fires and materials. The choice depends on factors like the type of flammable material, the size of the area to be protected, and the potential for rapid fire spread.

- Water Spray Systems: Effective for Class A fires (ordinary combustibles) and sometimes Class B fires (flammable liquids) – but never use water on flammable metals (Class D) or electrical fires (Class C). The water cools the burning material and reduces its flammability.

- Foam Systems: Ideal for Class B fires (flammable liquids) as they create a layer that prevents oxygen from reaching the fuel, smothering the flames. Different types of foam (e.g., AFFF, protein) are used for various flammable liquids.

- Carbon Dioxide (CO2) Systems: Effective for Class B and C fires. CO2 displaces oxygen, suffocating the fire. It leaves no residue, making it suitable for sensitive equipment.

- Dry Chemical Systems: Suitable for Class A, B, and C fires. Dry chemicals interrupt the chemical chain reaction of combustion. They’re effective but can leave a residue that requires cleanup.

- Halon Systems: Although being phased out due to environmental concerns, Halon systems were incredibly effective for Class B and C fires because they interrupt the chemical chain reaction without leaving a residue. They are still found in some legacy systems.

Each system requires regular inspection and maintenance to ensure its effectiveness in an emergency. For complex situations involving multiple hazard classes, a combination of systems might be necessary.

Q 24. How do you handle situations where hazardous materials are mixed incorrectly?

Mixing hazardous materials incorrectly can create extremely dangerous situations, leading to violent reactions, toxic gas generation, or even explosions. The immediate response depends on the specific chemicals involved and the extent of the mixing.

Never attempt to mix unknown chemicals. Always refer to the Safety Data Sheets (SDS) for each chemical involved. If unsure, treat the mixture as highly hazardous. The following steps are crucial:

- Isolate the Area: Immediately evacuate the immediate area and establish a perimeter to prevent further exposure. Alert emergency personnel.

- Assess the Situation: Identify the specific chemicals involved, the quantity mixed, and any observable changes (e.g., heat generation, gas release). Consult the SDS for each chemical to assess the potential hazards of the mixture.

- Contain the Spill: If possible, contain the mixture to prevent further spread using appropriate absorbent materials. Never attempt to neutralize the mixture without expert guidance.

- Ventilate the Area: If safe to do so, increase ventilation to disperse any toxic fumes.

- Seek Expert Assistance: Contact a hazardous materials response team or a chemical spill cleanup specialist. They have the expertise and equipment to safely handle the situation.

- Document the Incident: Thoroughly document the event, including the chemicals involved, the quantities, the actions taken, and any injuries or damage.

Prevention is key. Strict protocols for chemical storage, handling, and labeling are essential to prevent accidental mixing.

Q 25. Explain the procedures for dealing with a suspected chemical leak.

Responding to a suspected chemical leak requires a methodical and cautious approach, prioritizing safety and minimizing exposure. The exact procedures will depend on the nature of the chemical and the extent of the leak.

- Evacuate and Isolate: Evacuate the immediate area and establish a safety perimeter. The size of the perimeter will depend on the nature of the chemical and weather conditions (wind direction, etc.).

- Alert Emergency Services: Notify emergency response personnel, providing as much detail as possible, including the type and quantity of chemical involved, the location of the leak, and any observed effects.

- Assess the Situation: Observe the leak to determine the rate of release and any visible signs of hazardous effects (e.g., fumes, discoloration). Never approach the leak without proper PPE.

- Contain the Leak (If Safe): If trained and equipped to do so, and if it’s safe, attempt to contain the leak using appropriate methods (e.g., plugging the leak, diverting the flow). This should only be attempted by trained personnel with the necessary protective gear.

- Decontamination: If individuals have been exposed, implement a decontamination procedure according to established protocols. This often involves removing contaminated clothing and rinsing the affected area with water.

- Post-Incident Response: Once the leak is contained and secured, clean up the spill following established procedures and regulations. This may involve specialized equipment and personnel. Document the event thoroughly.

The key is preparedness. Regular safety drills, training on emergency procedures, and readily available SDSs are critical for effective response.

Q 26. What is your understanding of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS)?

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system designed to provide a consistent approach to classifying chemicals according to their hazards and communicating that information through labels and safety data sheets (SDSs). The goal is to improve worker safety and prevent chemical accidents globally.

Key components of the GHS include:

- Classification of Hazards: Chemicals are classified based on their physical, health, and environmental hazards (e.g., flammability, toxicity, corrosivity).

- Labeling: Standardized labels provide clear hazard information using pictograms, signal words (danger, warning), hazard statements, and precautionary statements.

- Safety Data Sheets (SDSs): Detailed information sheets provide comprehensive data on chemical properties, hazards, safe handling procedures, emergency response measures, and more.

The GHS aims to eliminate inconsistencies in chemical hazard communication across different countries and regions, facilitating better understanding and improving safety worldwide. Understanding and applying GHS standards is crucial for effective hazardous materials management.

Q 27. Describe your experience with auditing hazardous materials handling operations for compliance.

My experience with auditing hazardous materials handling operations for compliance involves conducting thorough assessments to ensure adherence to relevant regulations, standards, and best practices. This includes reviewing procedures, inspecting facilities, and verifying employee training and understanding.

My audit process typically covers:

- Documentation Review: Examining safety data sheets, emergency response plans, training records, and maintenance logs for accuracy and completeness.

- Facility Inspection: Inspecting storage areas, chemical handling equipment, spill containment systems, and emergency shower/eyewash stations for proper design, maintenance, and functionality.

- Employee Interviews: Conducting interviews with employees involved in handling hazardous materials to assess their understanding of safe practices and emergency procedures.

- Procedure Review: Analyzing existing procedures for receiving, handling, storage, disposal, and emergency response, looking for compliance with relevant standards and effective risk mitigation strategies.

- Compliance Verification: Checking for adherence to local, national, and international regulations related to hazardous materials management. This might include OSHA, EPA, or other applicable standards.

Based on the audit findings, I prepare a comprehensive report highlighting areas of compliance and non-compliance, along with recommendations for improvement. The aim is not just to identify shortcomings but to provide constructive feedback to improve safety and ensure ongoing compliance. I’ve successfully identified and addressed several critical safety hazards during my audits, preventing potential accidents and ensuring better protection of workers and the environment.

Key Topics to Learn for Storage and Handling of Hazardous Materials Interview

- Hazard Communication: Understanding SDS (Safety Data Sheets), labels, and proper communication protocols for hazardous materials. Practical application: Interpreting SDS information to determine appropriate PPE and handling procedures.

- Storage Practices: Safe storage techniques, including segregation, compatibility, and containment. Practical application: Designing a safe storage facility for various classes of hazardous materials, considering ventilation and spill containment.

- Transportation Regulations: Familiarity with DOT (Department of Transportation) regulations and other relevant transportation guidelines for hazardous materials. Practical application: Ensuring compliance during the transportation of hazardous materials, including proper documentation and emergency response planning.

- Emergency Response: Procedures for handling spills, leaks, and other emergencies involving hazardous materials. Practical application: Developing and implementing emergency response plans, including evacuation procedures and personal protective equipment use.

- Waste Management: Proper disposal and recycling of hazardous waste materials in accordance with environmental regulations. Practical application: Selecting appropriate disposal methods based on the type and quantity of hazardous waste.

- Risk Assessment and Mitigation: Conducting risk assessments to identify potential hazards and implementing control measures to mitigate risks. Practical application: Implementing engineering controls, administrative controls, and PPE to minimize employee exposure to hazardous materials.

- Regulatory Compliance: Understanding and adhering to all relevant local, state, and federal regulations concerning the storage and handling of hazardous materials. Practical application: Maintaining accurate records and documentation to demonstrate compliance with regulations.

Next Steps

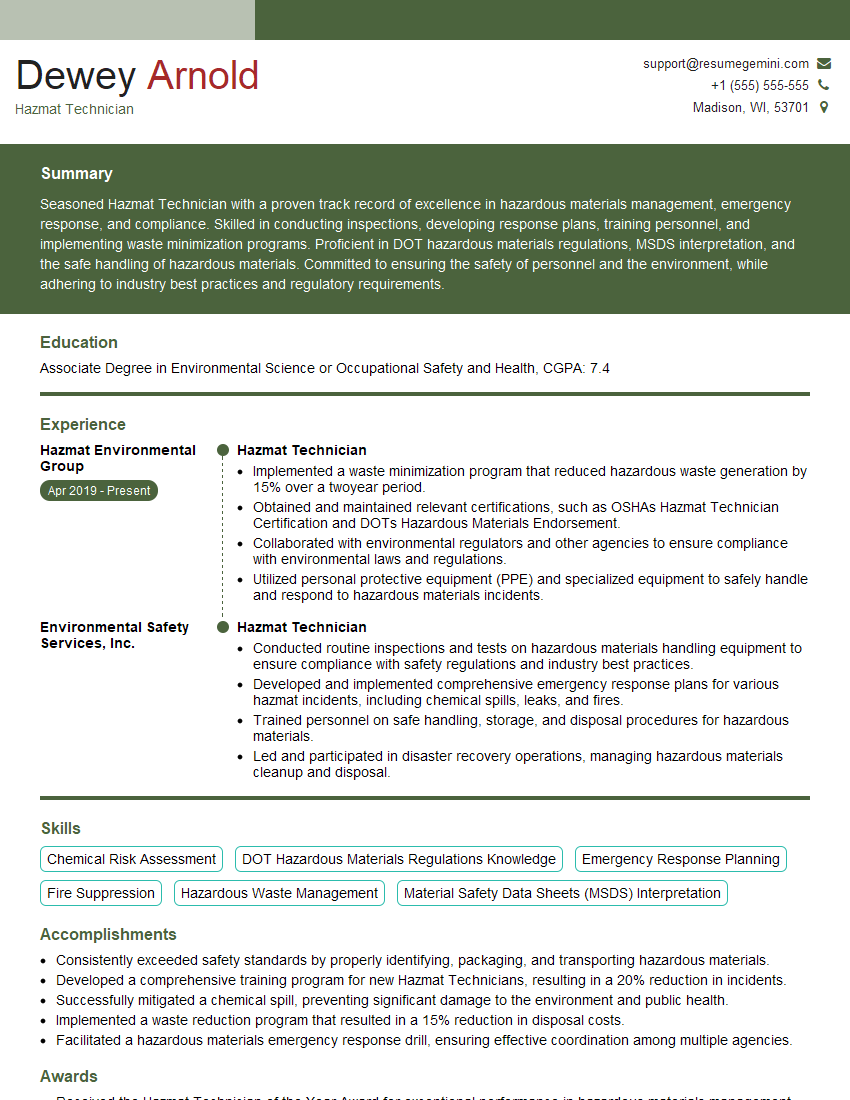

Mastering the storage and handling of hazardous materials is crucial for career advancement in many high-demand industries. Demonstrating this expertise through a well-crafted resume is essential. A strong resume, optimized for Applicant Tracking Systems (ATS), significantly increases your chances of landing an interview. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Leverage their tools and resources to create an ATS-friendly resume that highlights your skills and experience in this critical field. Examples of resumes tailored to Storage and Handling of Hazardous Materials are available to help guide your efforts.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good