Are you ready to stand out in your next interview? Understanding and preparing for Straight-Edge and Plumb Bob Use interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Straight-Edge and Plumb Bob Use Interview

Q 1. Explain the purpose of a plumb bob.

A plumb bob is a weight, typically made of metal, suspended from a string. Its primary purpose is to establish a true vertical line, essential for accurate measurements and construction in various fields like carpentry, masonry, and surveying. Think of it as a real-world representation of gravity – it always points directly downwards.

Q 2. Describe how to use a plumb bob to establish a vertical line.

To establish a vertical line using a plumb bob, simply suspend it from a point directly above where you need the vertical line. Ensure the string is taut and free from any obstructions. The point where the weight hangs will mark a perfect vertical reference point. You can then mark this point with a pencil or other marking tool. For example, when laying the foundation of a building, a plumb bob helps ensure that the corners are perfectly square and vertical, preventing structural issues later on.

Steps:

- Choose a suitable suspension point.

- Hang the plumb bob ensuring the string hangs freely.

- Allow the plumb bob to settle completely.

- Mark the point where the plumb bob string intersects your working surface.

Q 3. What are the different types of plumb bobs and their applications?

Plumb bobs come in various types, each suited for specific applications:

- Metal Plumb Bobs: These are the most common type, typically made of brass or steel. Their weight provides stability and accuracy. The heavier the bob, the less it swings in windy conditions.

- Magnetic Plumb Bobs: These include a magnet at the bottom, useful for marking vertical lines on metal surfaces.

- Self-Leveling Plumb Bobs: These incorporate a level, allowing for quick and easy vertical alignment, especially beneficial in rough terrain.

- Laser Plumb Bobs: Modern versions projecting a laser line vertically. They’re advantageous for longer distances and improved visibility.

The choice depends on factors like the task’s precision requirements, the surface material, and environmental conditions (wind, etc.). A simple brass plumb bob suffices for most carpentry work while a laser plumb bob is better suited for large-scale construction projects.

Q 4. How do you ensure accuracy when using a plumb bob?

Accuracy with a plumb bob hinges on several factors:

- Use a high-quality plumb bob: A well-made plumb bob with a pointed tip ensures precise marking.

- Ensure a stable suspension point: Avoid any movement or vibration of the suspension point. A sturdy hook or clamp will help here.

- Wait for the bob to settle completely: Allow the bob to come to rest before marking its position. Slight swaying can lead to inaccurate measurements.

- Use a clear and well-defined marking method: A sharp pencil or a fine-tipped marker prevents ambiguity in marking the vertical line.

- Check for wind and other environmental factors: Strong winds can affect the plumb bob’s accuracy; consider using a heavier plumb bob or performing work in calmer conditions.

Regularly checking your plumb bob for damage or wear will also enhance its accuracy and extend its life.

Q 5. Explain the purpose of a straight edge.

A straight edge is a tool used to create or check straight lines. It’s an indispensable tool in various trades, from woodworking to metalworking. It acts as a reference for accuracy, ensuring that surfaces or cuts are perfectly linear.

Think of it like a ruler but typically longer and more robust, designed to withstand more rigorous usage. It’s more than just a measuring device; it is an essential instrument for precise alignment.

Q 6. Describe different types of straight edges and their uses.

Straight edges come in various materials and lengths to suit various applications:

- Wood Straight Edges: Commonly used in woodworking, often made from hardwoods like maple or beech. They are lightweight and easy to handle.

- Metal Straight Edges: Made from steel or aluminum; They are more durable and less prone to warping than wooden ones. They’re often used in more demanding situations such as metalworking and machining.

- Combination Squares: These versatile tools combine a straight edge with a square head, offering multiple functions in one tool.

- Precision Straight Edges: These are manufactured to extremely tight tolerances and are essential for highly accurate work.

The choice of material depends on the precision required, working material, and the budget. A wood straight edge is adequate for hobbyist applications, while a precision ground steel straight edge is preferred for industrial precision work.

Q 7. How do you check for straightness using a straight edge?

To check for straightness using a straight edge, simply place the straight edge along the surface you want to inspect. Look closely along the entire length of the straight edge to detect any gaps or deviations between the edge and the surface. If you see any light passing between the straight edge and the surface it indicates the surface is not straight. You can use a feeler gauge or a thin piece of paper to check for tiny gaps. This process ensures that edges, cuts, or surfaces are perfectly aligned and meet the required tolerances.

Example: When building a wall, you’d use a straight edge to check if the top of the wall is perfectly horizontal. Any deviation would mean adjusting the wall until it aligns perfectly with the straight edge.

Q 8. How do you ensure the accuracy of a straight edge?

Ensuring the accuracy of a straight edge is paramount for precise construction. Think of it like this: your straight edge is the foundation upon which you build accuracy. Any inaccuracy in the straight edge will propagate throughout your entire project. There are several ways to check for accuracy:

Visual Inspection: Carefully examine the edge for any bends, knicks, or imperfections. Hold it up to a strong light and look for any deviations from perfect straightness. Even a tiny bend can throw off measurements significantly.

Comparison with a Known Standard: If you have a certified straight edge or a high-precision laser level, compare your straight edge against this standard. Any discrepancy will highlight the error in your tool.

Testing using Triangles: Place two precisely square metal triangles against the edge; the gap between the two triangles should be consistent across the length of the straight edge. Any variation shows a deviation from straightness.

Three-Point Test: Place the straight edge against a surface and mark points at both ends and the middle. Check if the points align perfectly. This helps identify even subtle bends or curves.

Regular inspection and calibration is essential. A damaged straight edge should be replaced immediately.

Q 9. What are the common errors when using a straight edge and plumb bob?

Common errors when using a straight edge and plumb bob often stem from carelessness or inadequate setup. These include:

Improper Straight Edge Placement: Not ensuring the straight edge is firmly placed against the reference surface, leading to inaccurate alignment and measurements.

Plumb Bob Swinging: Wind or vibrations can cause the plumb bob to swing, resulting in inaccurate marking of vertical points. This is particularly problematic with longer plumb bobs.

Incorrect Reading of the Plumb Bob: Misinterpreting the plumb bob’s position when transferring vertical alignment from the plumb bob line to the straight edge.

Straight Edge not Perfectly Straight: As discussed earlier, a faulty straight edge will lead to errors across all measurements.

Parallax Error: Reading the mark on the straight edge from an angle instead of directly above or below it, which can create a measurement error.

Q 10. How do you compensate for inaccuracies in using a straight edge and plumb bob?

Compensation for inaccuracies involves careful techniques and double-checking. Here’s how you can approach it:

Multiple Measurements: Take multiple measurements from different points and orientations; averaging the results minimizes the effect of individual errors.

Careful Setup: Ensure a stable base and minimize any movement during measurements. For instance, secure the straight edge with clamps where appropriate.

Wind Protection: Use a wind break to shield the plumb bob from wind currents if necessary.

Calibration/Replacement: If the tools are demonstrably inaccurate, calibrate or replace them. This eliminates systematic errors.

Check for Alignment: Before using the tools, verify their alignment with each other. Make sure the straight edge is positioned precisely, and the plumb bob hangs freely and vertically.

The key is to be meticulous and systematic in your approach. Remember that accuracy is not about a single perfect measurement; it’s about minimizing errors through careful technique and redundancy.

Q 11. Explain how to use a plumb bob and straight edge together to establish a square corner.

Establishing a square corner using a plumb bob and straight edge is a fundamental skill in construction. Here’s how:

Establish a Baseline: Lay your straight edge along one side of the desired square corner.

Mark the Point: Use the plumb bob to accurately mark a point on the ground or base directly beneath one end of the straight edge.

Measure the Desired Distance: Measure the desired length along the straight edge.

Mark the Second Point: Using a different point on your plumb bob string, mark the desired distance along the straight edge.

Establish the Second Line: Place the straight edge from the first point, using the second point as a guide. Draw a line along the edge.

Check the Squareness: Measure the diagonal distances across the square to ensure they are equal. This confirms the accuracy of your square corner. If the diagonals aren’t equal, you need to adjust your corner.

This process ensures that the corner is precisely 90 degrees.

Q 12. Describe how you would use a plumb bob and straight edge to transfer measurements.

Transferring measurements using a plumb bob and straight edge is straightforward. Imagine you need to transfer a measurement from a wall to the floor:

Mark the Point: Measure the distance on the wall and mark it clearly.

Align the Plumb Bob: Hold the plumb bob directly over the marked point on the wall. Ensure the string hangs freely and directly below the point.

Mark the Floor: Mark the point where the plumb bob string intersects with the floor. This accurately transfers the vertical measurement.

Verify: Double check the measurement again to make sure that there were no errors in the process.

This process ensures that the measurement is accurately transferred to the ground, even across different levels.

Q 13. How do you account for wind conditions when using a plumb bob?

Wind can significantly affect the accuracy of a plumb bob. Here’s how to account for it:

Windbreaks: The simplest approach is to use a windbreak – a temporary shield made of wood, cardboard, or even your body – to protect the plumb bob from wind currents. This will ensure that the bob stays still and you get accurate readings.

Weighted Bob: Heavier plumb bobs are less affected by wind than lighter ones. Consider using a heavier plumb bob for windy conditions.

Calm Conditions: Ideally, perform this work when wind is minimal. If there is a significant breeze, wait for a calmer period. Postponing the work may be the best course of action to avoid errors.

Multiple Readings: Even with windbreaks, take multiple readings and average them to reduce the impact of random wind fluctuations.

Remember, a slight breeze can significantly affect the accuracy, particularly with long plumb bobs.

Q 14. What safety precautions should be taken when using a plumb bob and straight edge?

Safety is paramount when using a plumb bob and straight edge. Always:

Wear Safety Glasses: Protect your eyes from falling debris or accidental impacts.

Check for Obstructions: Ensure the area below the plumb bob is clear of people or obstacles.

Proper Tool Handling: Avoid dropping or throwing the tools.

Secure the Straight Edge: If using a long straight edge, make sure it’s securely supported to prevent it from falling and causing injury.

Work Area Clearance: Maintain a clear work area to prevent tripping hazards and allow for free movement.

Appropriate Clothing: Wear appropriate clothing and footwear that will not get caught on tools or materials.

By following these simple safety precautions, you can ensure that the task is completed without incidents.

Q 15. How do you maintain a plumb bob and straight edge?

Maintaining a plumb bob and straight edge is crucial for ensuring accurate measurements and construction. For a plumb bob, this primarily involves cleaning the point to prevent damage and ensure it remains sharp. Regularly check the string for fraying or damage and replace it as needed. A damaged string can lead to inaccurate readings. Store the plumb bob in a protective case to prevent damage to the point and string. For a straight edge, cleanliness is also key. Wipe it down after each use to remove dust, debris, or any materials that could interfere with its accuracy. Regularly inspect the edge for any bends, chips, or warping. If you notice any damage, it’s crucial to repair or replace the straight edge.

Think of it like caring for your tools – a well-maintained tool performs better and lasts longer. Just as a chef needs sharp knives, a carpenter needs a sharp plumb bob point and an unblemished straight edge.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the limitations of a plumb bob and straight edge?

While incredibly useful, plumb bobs and straight edges have limitations. Plumb bobs are susceptible to wind interference, especially in outdoor environments. A slight breeze can cause the bob to swing, affecting the accuracy of the vertical alignment. They’re also limited by their length; you can’t use a short plumb bob to establish a vertical reference over a significant distance. Straight edges, similarly, have limitations in length. They are only as accurate as their manufacture, and even the finest straight edges can have minute imperfections. For large spans, using a straight edge requires careful handling to avoid sag or warping, especially with longer and thinner materials. Also, both tools are primarily one-dimensional: they indicate verticality or straightness along a single line.

Q 17. Describe a situation where you had to use a plumb bob to solve a problem.

During a recent renovation project, we needed to ensure a newly constructed wall was perfectly plumb (perfectly vertical). We used a plumb bob to achieve this. First, we established a reference point at the top of the wall. Then, we suspended the plumb bob from this point, ensuring the string hung freely. The point of the bob indicated the exact vertical line. By marking this line on the floor and the wall’s base, we could check the wall’s alignment. Any deviation from the plumb bob’s line indicated the necessary adjustments for perfect verticality. This was critical to ensure the wall’s stability and the overall structural integrity of the building.

Q 18. Describe a situation where you had to use a straight edge to solve a problem.

We were installing a long countertop. Achieving a perfectly straight line was essential for both aesthetics and functionality. To solve this, we used a long straight edge as a guide. We placed it along the proposed countertop position, ensuring it was perfectly level using a spirit level. This straight edge acted as a reference line for the installation process. By carefully following this line, we ensured the countertop was perfectly aligned and straight, preventing any unevenness or slopes. The straight edge ensured an accurate and visually appealing result.

Q 19. How would you use a straight edge and level to ensure a perfectly horizontal surface?

To ensure a perfectly horizontal surface, you’d use the straight edge and level in conjunction. First, place the straight edge across the surface you’re checking. Next, use the level on top of the straight edge. If the bubble in the level isn’t centered, the straight edge isn’t perfectly level. Adjust the surface beneath the straight edge until the bubble is centered, indicating a perfectly level line. Repeat this process along multiple points across the surface using overlapping measurements to ensure the entire surface is horizontal. This ensures accuracy. Think of it like drawing a perfectly straight and horizontal line over a large area: you use multiple short, perfectly aligned segments to create the overall effect.

Q 20. What is the importance of accuracy when using a straight edge and plumb bob in construction?

Accuracy is paramount when using a straight edge and plumb bob in construction. Inaccurate measurements can lead to structural issues, compromised safety, and costly repairs later. For example, a slightly off-plumb wall might seem minor initially but can cause significant problems over time, leading to cracks or instability. Similarly, an inaccurate straight edge used during framing can lead to doors or windows that don’t fit properly. In essence, the accuracy of these tools directly impacts the overall quality, durability, and safety of the final construction.

Q 21. How would you deal with a damaged or inaccurate plumb bob or straight edge?

Dealing with a damaged or inaccurate tool requires immediate action. For a damaged plumb bob, if the point is bent or broken, it needs replacing. If the string is frayed, it should be replaced immediately to prevent errors in measurement. A damaged straight edge, depending on the severity of the damage, might require repair (if possible) or replacement. Before using any tool, always inspect for signs of damage; using a faulty tool could lead to catastrophic errors. If you suspect inaccuracies, it’s best to calibrate the tool or use a different one to ensure precision.

Q 22. Explain the relationship between a plumb bob, a level, and a straight edge.

A plumb bob, a level, and a straight edge are fundamental tools for establishing and verifying vertical and horizontal planes in construction and surveying. They work together to ensure accuracy and precision.

- Plumb bob: This device, essentially a weighted weight on a string, defines a perfect vertical line. It’s used to locate true verticality.

- Level: A level (whether spirit level or laser level) indicates a horizontal plane. It helps establish and verify horizontal alignment.

- Straight edge: A long, perfectly straight piece of material (wood, metal, etc.) is used to check for straightness and alignment in horizontal or vertical planes. It helps verify whether a surface is truly flat or aligned.

In essence, they form a trinity of tools: the plumb bob establishes the vertical reference, the level establishes the horizontal reference, and the straight edge ensures that surfaces are aligned with these references. They are often used in conjunction to achieve accurate results.

Q 23. How would you verify the accuracy of your plumb bob?

Verifying a plumb bob’s accuracy is crucial. One method involves using a second, independently verified plumb bob. Suspend both bobs from a single point, ensuring minimal interference. If both strings consistently align, you can confirm their accuracy. Another approach involves suspending the bob and marking its position on the ground. After a period, check if the marked point remains consistent with the bob’s current position. Any significant deviation suggests inaccuracy, potentially due to a bent shaft or uneven weight distribution. Regular inspection for these issues is important for maintaining accuracy.

Q 24. What are the differences between a plumb bob and a laser level?

Plumb bobs and laser levels both serve to establish vertical and horizontal references, but differ significantly in their operation and application.

- Plumb bob: A simple, low-tech device that uses gravity to indicate a vertical line. Its accuracy depends on the quality of the bob and the string, and it’s restricted by its range and susceptibility to wind.

- Laser level: A more sophisticated electronic tool that projects a laser beam to create a precise horizontal or vertical plane. It offers greater range, speed, and convenience but requires power and can be affected by environmental conditions (e.g., dust).

In short, a plumb bob is a simple, gravity-dependent tool for precise point referencing, while a laser level projects a plane that can cover much larger areas quickly, but is reliant on technology.

Q 25. When would you choose a plumb bob over a laser level, and vice-versa?

The choice between a plumb bob and a laser level depends on the specific task and its constraints.

- Choose a plumb bob when:

- High precision is required for a single point, such as establishing a precise vertical for a column base.

- Power is unavailable or impractical.

- The work environment is extremely dusty or dirty, hindering laser visibility.

- Simplicity and low cost are paramount.

- Choose a laser level when:

- A broad horizontal or vertical plane needs to be established quickly over a large area, such as setting grade for a patio.

- Precise leveling of multiple points is necessary.

- Enhanced efficiency and speed are prioritized.

Q 26. Describe a time you encountered a challenging leveling situation and how you overcame it.

During the construction of a retaining wall on uneven terrain, I faced a challenge in establishing a consistent vertical alignment for the wall’s foundation. The slope was significant, making it difficult to use a standard plumb bob effectively. The solution involved creating a series of temporary reference points along the slope using a transit level. I established a horizontal datum line and then, using the transit’s vertical angle measurement capability, I determined the precise vertical offset required at each point along the wall’s planned location. This allowed me to accurately transfer the vertical reference points required for the foundation, ensuring the wall’s vertical alignment despite the uneven ground.

Q 27. Explain how to use a straight edge to check the alignment of a wall.

To check a wall’s alignment, hold the straight edge against the wall at various points along its height and length. Check for any gaps or deviations between the straight edge and the wall’s surface. The straight edge serves as a reference to detect any bowing, sagging, or unevenness. Use a level on top of the straight edge, making multiple checks along the wall. Any significant variations indicate alignment issues. To improve accuracy, use a longer straight edge for better averaging over the wall’s length. Document any deviations and their location for further analysis and remedial action.

Q 28. How would you use a plumb bob and straight edge to establish the foundation for a building?

Establishing a building’s foundation using a plumb bob and straight edge involves several steps:

- Establish a benchmark: A permanent, stable point with a known elevation serves as the reference point.

- Set out corner points: Using measurements from the building plans, mark the corners of the foundation on the ground.

- Establish verticality: Suspend a plumb bob at each corner to define the vertical line for each corner. Mark these positions to ensure they’re vertically aligned.

- Check alignment: Employ the straight edge to verify the horizontal alignment of the marked corner points and ensure all corners are square (90-degree angles). The straight edge should span between multiple points for reliable verification.

- Excavation and formwork: Following the established corners and using the plumb bob/straight edge for verification throughout the excavation process and building the formwork. This will keep the foundation accurate and true to the design.

Regular checks using the plumb bob and straight edge throughout the foundation construction will guarantee precise alignment and verticality, ensuring a stable and true foundation.

Key Topics to Learn for Straight-Edge and Plumb Bob Use Interview

- Understanding Straight-Edges: Types of straight-edges (e.g., steel, aluminum), proper handling and care, identifying and mitigating wear and tear.

- Plumb Bob Mechanics: Principles of plumb bob operation, understanding the impact of gravity and environmental factors on accuracy, selecting appropriate plumb bob weights for different applications.

- Establishing Verticality: Precise techniques for establishing a true vertical using a plumb bob and straight-edge, common sources of error and how to minimize them.

- Practical Applications: Using straight-edges and plumb bobs in various construction scenarios (e.g., foundation layout, wall alignment, column setting), demonstrating proficiency in different environments.

- Accuracy and Precision: Measuring techniques for ensuring accuracy, understanding tolerances and limitations, troubleshooting inaccuracies.

- Safety Procedures: Safe handling practices for both tools, awareness of potential hazards, maintaining a safe work environment.

- Troubleshooting: Identifying and resolving common issues encountered while using straight-edges and plumb bobs, demonstrating problem-solving skills.

- Material Selection: Understanding the properties of different materials used in straight-edges and plumb bobs, and selecting appropriate tools for specific tasks.

Next Steps

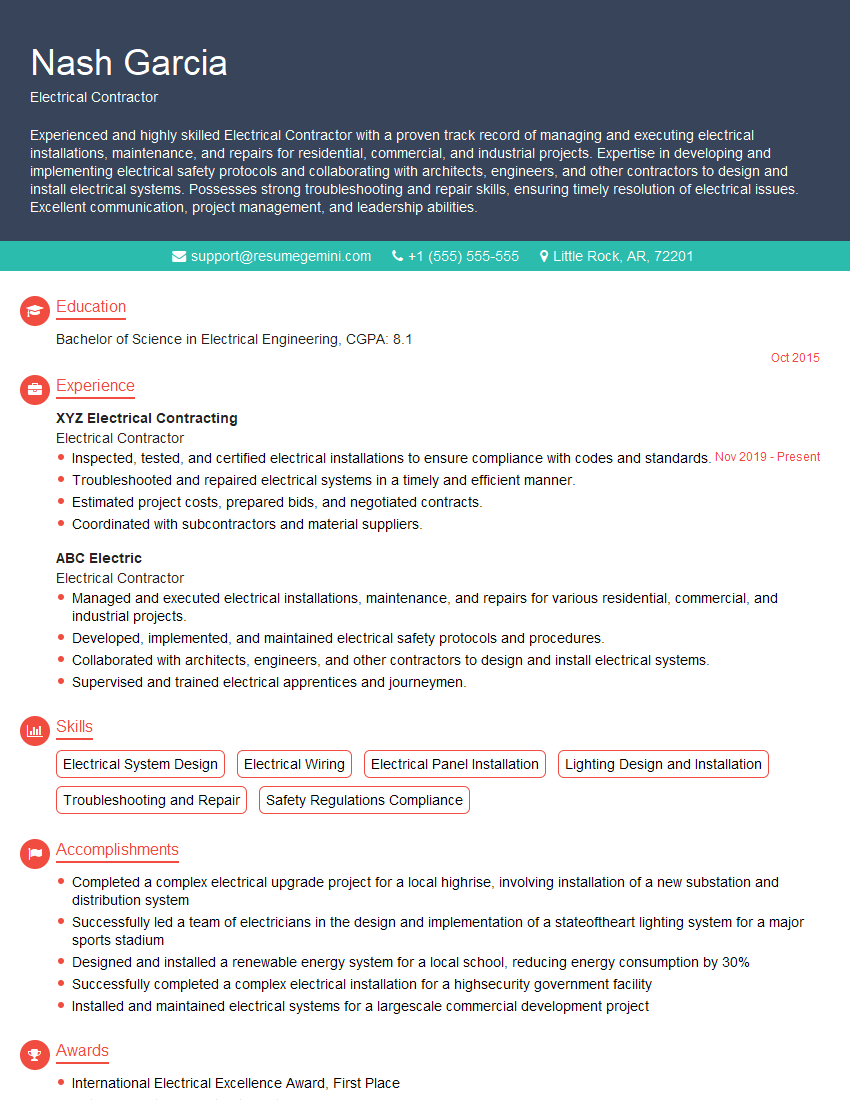

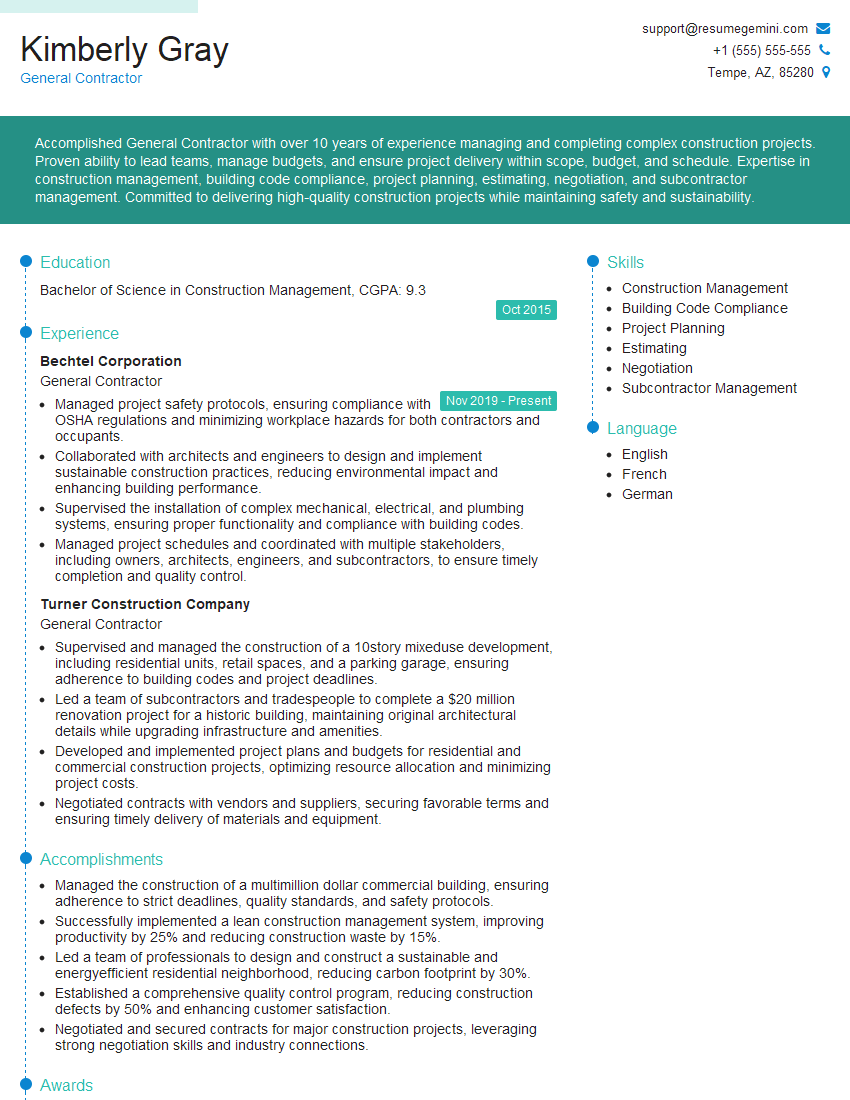

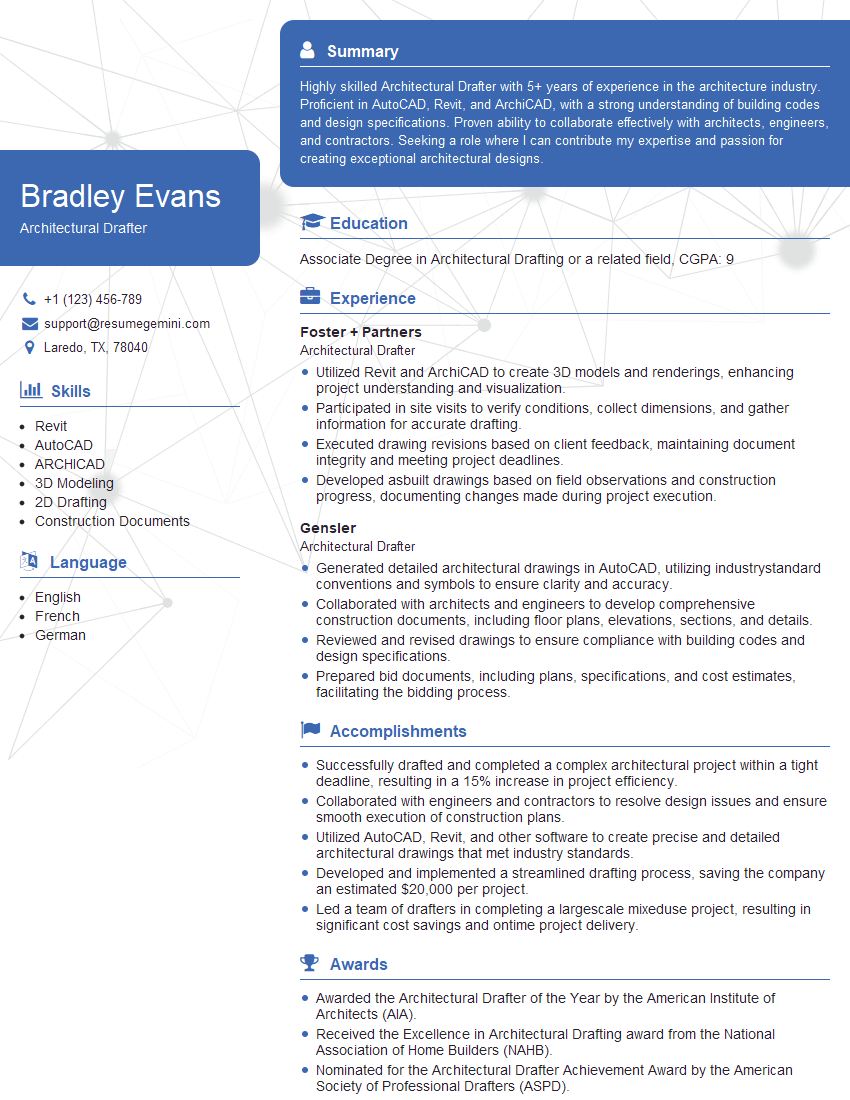

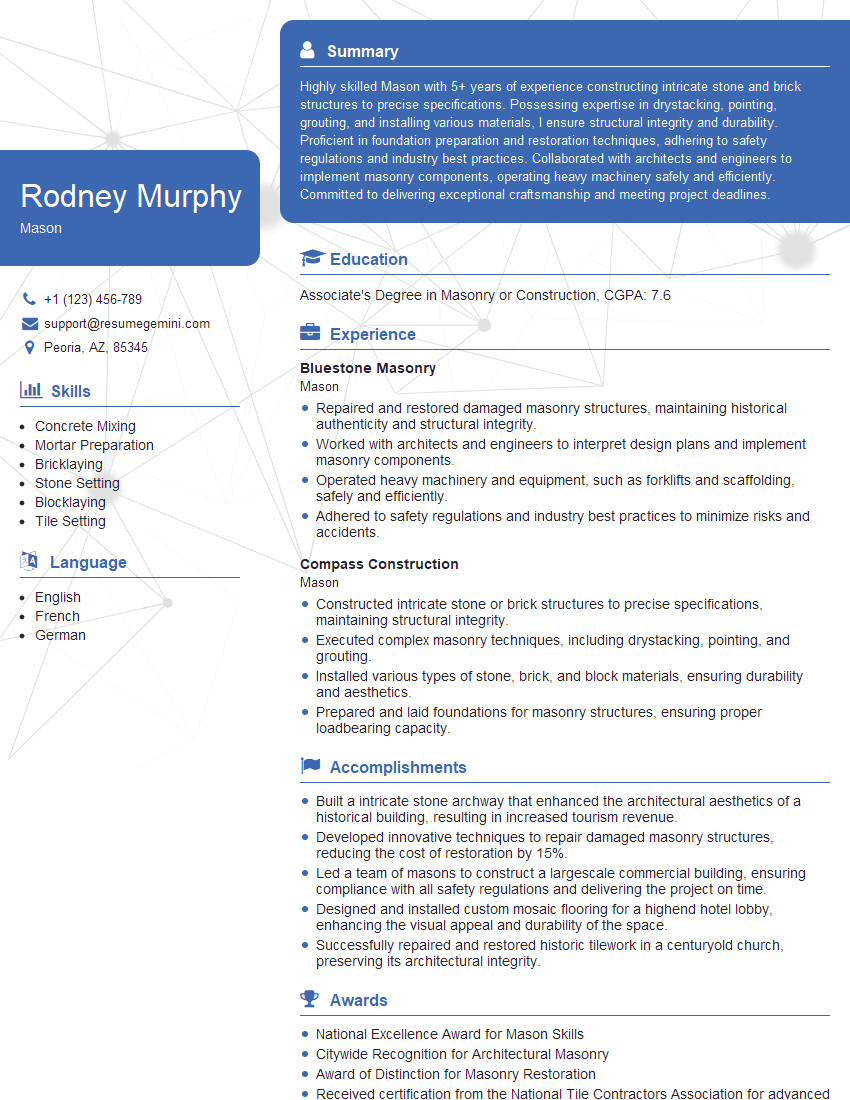

Mastering the use of straight-edges and plumb bobs is crucial for a successful career in construction and related fields. Accuracy and precision are highly valued skills, directly impacting project quality and safety. To maximize your job prospects, create an ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your skills and experience effectively. Examples of resumes tailored to Straight-Edge and Plumb Bob Use are available to help you get started. Investing time in crafting a strong resume will significantly increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good