Unlock your full potential by mastering the most common Strong understanding of design principles, materials engineering, and manufacturing techniques interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Strong understanding of design principles, materials engineering, and manufacturing techniques Interview

Q 1. Explain the difference between tensile and compressive strength.

Tensile strength and compressive strength both describe a material’s ability to withstand force, but they differ in the *type* of force they resist. Tensile strength measures a material’s resistance to being pulled apart, while compressive strength measures its resistance to being squeezed or crushed.

Imagine a rope being pulled from both ends (tensile). The rope’s tensile strength determines how much force it can withstand before breaking. Now imagine a concrete pillar supporting a building (compressive). The pillar’s compressive strength determines how much weight it can bear before it crumbles.

Materials often exhibit different tensile and compressive strengths. For example, steel has high tensile and compressive strength, making it ideal for structures. Concrete, however, excels in compression but has relatively low tensile strength, hence the use of reinforcing steel bars (rebar) in concrete structures to handle tensile forces.

Q 2. Describe your experience with CAD software.

I have extensive experience with various CAD software packages, including SolidWorks, AutoCAD, and Fusion 360. My expertise spans 2D drafting and 3D modeling, encompassing part design, assembly modeling, and finite element analysis (FEA). In a recent project designing a complex robotic arm, I leveraged SolidWorks to create the detailed 3D model, conduct kinematic simulations to ensure smooth operation, and generate manufacturing drawings for CNC machining. I’m proficient in using parametric modeling techniques to efficiently manage design changes and ensure consistency across different design iterations. My skills also extend to surface modeling and creating high-quality renderings for presentations and client communication.

Q 3. What are the advantages and disadvantages of different manufacturing processes (e.g., injection molding, CNC machining)?

Different manufacturing processes each have their own advantages and disadvantages. Let’s compare injection molding and CNC machining:

- Injection Molding:

- Advantages: High production rates, low cost per unit for high-volume production, complex geometries possible, good surface finish.

- Disadvantages: High initial tooling costs, limited material choices, not suitable for low-volume production.

- CNC Machining:

- Advantages: High precision, wide range of materials can be used, suitable for low-volume production and prototyping, complex geometries possible.

- Disadvantages: Lower production rates compared to injection molding, higher cost per unit for high-volume production, potential for tool wear.

The choice depends heavily on factors like production volume, required precision, material choice, and budget. For example, a high-volume consumer product like a plastic toy would be ideally suited for injection molding, whereas a small batch of highly precise metal parts for aerospace application would likely necessitate CNC machining.

Q 4. How do you select materials for a specific application?

Material selection is a critical process that requires careful consideration of various factors. I typically follow a structured approach:

- Define Requirements: Clearly specify the application’s functional requirements (strength, stiffness, weight, temperature resistance, corrosion resistance, etc.) and environmental conditions (temperature, humidity, chemicals).

- Identify Candidate Materials: Based on the requirements, identify a shortlist of potential materials. This often involves consulting material property databases and considering relevant standards.

- Evaluate Material Properties: Compare the properties of the candidate materials against the specified requirements. This might involve using FEA or other analytical tools to predict material performance under specific loads and conditions.

- Consider Manufacturing Processes: Assess the manufacturability of each material using the chosen manufacturing process. Some materials are more easily machined or molded than others.

- Cost Analysis: Compare the cost of each material, including material cost, processing cost, and potential lifecycle costs.

- Make Selection: Based on the evaluation, select the optimal material considering a balance of performance, cost, and manufacturability.

For instance, when designing a bicycle frame, I might consider materials like steel, aluminum, or carbon fiber. Steel offers high strength but is heavier. Aluminum is lighter but may not offer the same strength. Carbon fiber offers high strength-to-weight ratio but is more expensive. The final selection would depend on the desired performance characteristics and the target cost.

Q 5. Explain the concept of fatigue failure.

Fatigue failure occurs when a material fails under repeated cyclic loading, even if the maximum stress in each cycle is below the material’s ultimate tensile strength. Imagine repeatedly bending a paperclip back and forth – eventually, it will break, even though a single bend wouldn’t break it. This is fatigue failure.

The key factors influencing fatigue failure are the magnitude of the cyclic stress, the number of cycles, the material’s properties, and the presence of any stress concentrators (e.g., cracks, notches). To mitigate fatigue failure, designers often employ techniques such as increasing material strength, reducing stress concentrations through proper design, using fatigue-resistant materials, and implementing surface treatments to improve fatigue life. In aircraft design, fatigue failure is a significant concern, and rigorous testing and analysis are employed to ensure the structural integrity of aircraft components.

Q 6. Describe your understanding of different types of stress and strain.

Stress and strain are fundamental concepts in materials science. Stress is the internal force per unit area within a material caused by an external load, while strain is the resulting deformation or change in shape or size of the material. They are related through the material’s constitutive law, often described by Young’s Modulus for elastic materials.

Several types of stress exist, including:

- Tensile stress: Caused by pulling forces.

- Compressive stress: Caused by pushing forces.

- Shear stress: Caused by forces acting parallel to a surface.

- Bending stress: A combination of tensile and compressive stress.

- Torsional stress: Caused by twisting forces.

Strain can be:

- Elastic strain: Reversible deformation; the material returns to its original shape when the load is removed.

- Plastic strain: Permanent deformation; the material retains some deformation even after the load is removed.

Understanding these concepts is crucial for designing structures and components that can withstand the expected loads without failure.

Q 7. How do you ensure the quality of a manufactured product?

Ensuring product quality involves a multi-faceted approach, starting from the design phase and extending through manufacturing and beyond. Key strategies include:

- Design for Manufacturing (DFM): Designing products that are easily and cost-effectively manufactured with minimal defects.

- Material Selection and Testing: Choosing appropriate materials and rigorously testing their properties to ensure they meet specifications.

- Process Control: Implementing robust manufacturing processes with well-defined parameters and regular monitoring to maintain consistency.

- Quality Control (QC) and Quality Assurance (QA): Implementing inspection procedures at various stages of the manufacturing process to identify and correct defects. QA focuses on preventing defects in the first place.

- Statistical Process Control (SPC): Using statistical methods to monitor and control process variability.

- Non-Destructive Testing (NDT): Employing techniques like ultrasonic inspection or X-ray inspection to detect internal flaws without damaging the product.

- Documentation and Traceability: Maintaining detailed records of materials, processes, and inspections for traceability.

A robust quality management system, often based on ISO 9001 standards, provides a framework for implementing and maintaining these practices.

Q 8. What are your experiences with different types of manufacturing tolerances?

Manufacturing tolerances define the permissible variation in a product’s dimensions, properties, or performance characteristics. They’re crucial because achieving perfect precision is impossible and often uneconomical. Tolerances are specified using various systems, and understanding them is vital to ensuring product functionality and interchangeability.

- Geometric Dimensioning and Tolerancing (GD&T): This system uses symbols to specify tolerances on features like size, form, orientation, location, and runout. For instance, a cylindrical shaft might specify a diameter tolerance of ±0.05mm, indicating the actual diameter can fall within a range of 0.05mm above or below the nominal value. A GD&T callout might also specify permissible surface roughness.

- Statistical Tolerancing: This approach accounts for the statistical distribution of manufacturing variations. It considers the probability of a part falling outside the acceptable range, allowing for slightly looser individual tolerances while ensuring a high percentage of acceptable parts.

- Process Capability Studies: These studies analyze the inherent variability of a manufacturing process. By determining the process capability (Cp or Cpk), manufacturers can assess whether the process can consistently produce parts within the specified tolerances. A Cp/Cpk value greater than 1 indicates the process is capable.

In my experience, I’ve worked extensively with GD&T, implementing it in the design and manufacturing of precision components for aerospace applications. I’ve also leveraged statistical tolerancing to optimize manufacturing processes and reduce costs without compromising quality. For example, in a project involving the manufacturing of high-precision gears, we used statistical tolerancing to relax individual component tolerances while maintaining the overall gear meshing accuracy within acceptable limits.

Q 9. Describe your experience with design for manufacturing (DFM).

Design for Manufacturing (DFM) is a crucial methodology that integrates manufacturing considerations into the design process from the outset. The goal is to optimize designs for efficient and cost-effective production while maintaining quality and functionality. This involves considering factors like material selection, manufacturing processes, assembly methods, and tooling.

- Material Selection: Choosing materials readily available and easily machinable or formable is essential. Considering material properties’ impact on the manufacturing process, such as machinability (for CNC machining) or formability (for sheet metal stamping), is crucial.

- Process Selection: DFM dictates the optimal manufacturing process (injection molding, casting, machining, etc.) based on part geometry, material, and desired quantity. The choice directly affects cost and lead times.

- Simplification: Designing parts with fewer features, simpler geometries, and standardized components reduces manufacturing complexity and costs. For example, avoiding sharp corners or undercuts can reduce machining time and prevent tooling issues.

- Assembly Considerations: Designing for ease of assembly reduces manufacturing time and improves assembly quality. This includes considering factors such as fastener accessibility and part tolerances.

In a previous project, applying DFM principles to a complex electronic enclosure resulted in a 20% reduction in manufacturing costs and a 15% shorter lead time. This was achieved by simplifying part geometry, optimizing material selection for injection molding, and designing for easier assembly.

Q 10. Explain your understanding of finite element analysis (FEA).

Finite Element Analysis (FEA) is a computational method used to predict the behavior of physical structures and components under various loading conditions. It works by dividing a complex structure into smaller, simpler elements (finite elements), and then applying mathematical equations to analyze the stress, strain, and displacement within each element. This allows engineers to simulate real-world scenarios and optimize designs for strength, stiffness, and durability.

- Meshing: The first step involves creating a mesh, a network of elements that represents the structure’s geometry. A finer mesh offers higher accuracy but requires more computational resources.

- Material Properties: Accurate material properties are crucial for reliable results. These properties, like Young’s modulus and Poisson’s ratio, define the material’s behavior under stress.

- Boundary Conditions: FEA requires defining boundary conditions, specifying how the structure is supported or loaded. These conditions simulate the real-world environment.

- Solver: A solver then applies the governing equations to calculate the stress, strain, and displacement within each element. Post-processing tools visualize the results.

I’ve used FEA extensively to analyze stress concentrations in complex parts, predict fatigue life, and verify the structural integrity of designs before prototyping. For example, in a project involving the design of a pressure vessel, FEA helped identify critical stress points and optimize the wall thickness to meet safety standards. This prevented costly failures during testing and deployment.

Q 11. How do you handle design changes during the manufacturing process?

Handling design changes during manufacturing is a critical aspect of project management. It requires careful coordination, communication, and a structured approach.

- Engineering Change Order (ECO): Any design change requires a formal ECO, documenting the change, its justification, and its impact on manufacturing. This ensures traceability and avoids misunderstandings.

- Impact Assessment: Before implementing a change, a thorough impact assessment is crucial. This evaluates the effect on cost, schedule, quality, and other relevant factors. This might involve re-analyzing FEA models or conducting further testing.

- Communication: Effective communication with all stakeholders (designers, manufacturers, clients) is essential. Regular updates and meetings help keep everyone informed and aligned.

- Version Control: Using a version control system for design files helps manage revisions and ensures everyone works with the latest approved version.

- Prototyping: If the change is significant, creating and testing a prototype before full-scale implementation can validate its functionality and manufacturability.

In one instance, a late-stage design change required modifying a crucial component’s geometry. By employing a rigorous ECO process, we carefully assessed the impact, revised the manufacturing plan, and managed the change effectively without significant delays or cost overruns.

Q 12. What are some common material defects and how can they be prevented?

Material defects can significantly impact product quality and reliability. Understanding their causes and implementing preventative measures is essential.

- Porosity: Pores or voids within a material reduce its strength and can lead to premature failure. This can be caused by improper casting, sintering, or welding processes. Prevention involves optimizing process parameters and using high-quality materials.

- Inclusions: Foreign particles within the material can act as stress concentrators, reducing strength and ductility. These can be prevented by ensuring material purity and using proper processing techniques.

- Cracks: Cracks weaken materials and can propagate under stress, leading to catastrophic failure. They can be caused by thermal stresses, improper processing, or fatigue. Prevention requires careful thermal management, avoiding excessive stress, and proper heat treatment.

- Segregation: Uneven distribution of components within an alloy can lead to variations in properties. This can be addressed by using proper mixing and processing techniques.

In my experience, detecting and preventing porosity in aluminum castings was critical to ensuring the integrity of aircraft components. Careful control of casting parameters, including melt temperature and pouring rate, was crucial in minimizing porosity.

Q 13. Explain the importance of material selection in product design.

Material selection is a fundamental aspect of product design, impacting cost, performance, durability, and sustainability. A wrong choice can lead to product failure, increased costs, or even safety hazards.

- Performance Requirements: The choice is guided by the product’s required properties (strength, stiffness, hardness, corrosion resistance, thermal conductivity, etc.). For example, a high-strength steel might be selected for a structural component, while a corrosion-resistant aluminum alloy could be used for an exterior panel.

- Manufacturing Processes: Material selection must consider the intended manufacturing processes. A material easily machinable for CNC milling might not be suitable for injection molding.

- Cost: The cost of materials can significantly impact the overall product cost. Balancing performance requirements with cost-effectiveness is essential.

- Sustainability: Environmental concerns are increasingly important. Choosing recyclable, readily available, or low-impact materials contributes to sustainable design.

In designing a bicycle frame, for example, a lightweight, high-strength aluminum alloy would be preferred over a heavier, less durable steel. This reduces weight for better performance while considering cost-effectiveness and ease of manufacturing.

Q 14. Describe your experience with different types of testing (e.g., tensile testing, impact testing).

Various testing methods are crucial to validate material properties and component performance.

- Tensile Testing: This fundamental test determines a material’s tensile strength, yield strength, elongation, and modulus of elasticity by applying a controlled tensile force until failure. This provides insight into the material’s strength and ductility.

- Impact Testing: This test evaluates a material’s resistance to sudden impact loads, providing information about its toughness and fracture resistance. The Charpy or Izod impact test is commonly used.

- Fatigue Testing: This determines the material’s endurance limit, or the maximum stress it can withstand for a given number of cycles without failure. This is crucial for components subjected to repeated loading.

- Hardness Testing: This measures the material’s resistance to indentation or scratching, providing insight into its surface hardness and wear resistance. Methods include Rockwell, Brinell, and Vickers hardness testing.

- Creep Testing: Creep testing assesses a material’s deformation under constant stress and elevated temperatures over time, providing valuable data for high-temperature applications.

In my work, I’ve conducted extensive tensile and fatigue testing on various materials to determine their suitability for specific applications. For example, in a project involving the design of a high-performance engine component, fatigue testing was used to verify the component’s ability to withstand cyclic loading under demanding operating conditions.

Q 15. How do you balance design aesthetics with manufacturability?

Balancing aesthetics and manufacturability is a crucial aspect of successful product design. It’s essentially finding the sweet spot between a visually appealing product and one that’s feasible and cost-effective to produce. This often involves iterative design processes and close collaboration between designers and manufacturing engineers.

For example, a beautifully curved surface might look stunning, but it could be incredibly difficult and expensive to mold. To balance this, designers might explore alternative manufacturing processes like sheet metal forming or 3D printing, or they might slightly adjust the curve to make it more amenable to traditional injection molding. This might involve adding strategically placed ribs for structural support without compromising the overall aesthetic significantly.

Another example is the choice of materials. A material might have excellent aesthetic qualities but be difficult to work with or lack the necessary strength or durability. This necessitates considering material properties closely and potentially substituting with a similarly aesthetic, yet more manufacturable material. A careful analysis of material costs and processing requirements is also essential.

- Early Collaboration: Involving manufacturing engineers early in the design phase is crucial. Their input can prevent costly design changes later.

- Design for Manufacturing (DFM): Applying DFM principles, which emphasizes designing products considering manufacturing constraints, from the outset is key.

- Tolerance Analysis: Understanding and defining acceptable tolerances in the design prevents costly rework.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common manufacturing challenges and how have you overcome them?

Common manufacturing challenges include inconsistent material quality, equipment malfunctions, and skilled labor shortages. I’ve encountered these firsthand on several projects. One project involved producing a complex plastic part with intricate geometries. Initial runs suffered from inconsistencies in the part’s dimensions, leading to high rejection rates.

To overcome this, we systematically analyzed each stage of the manufacturing process. This involved examining the injection molding machine settings, the quality of the raw plastic pellets, and the cooling process. We discovered that variations in the ambient temperature were affecting the cooling rate, causing dimensional inconsistencies. Implementing a controlled temperature environment in the molding area significantly improved part quality and reduced waste.

Another challenge was integrating a new robotic assembly line. Initial integration was fraught with programming errors and unexpected downtime. We addressed this by developing a structured testing and debugging process that involved incremental implementation and thorough testing of each module. We also invested in training our technicians on the new robotic system, ensuring smoother operation and reduced downtime.

Q 17. Explain your understanding of lean manufacturing principles.

Lean manufacturing emphasizes maximizing customer value while minimizing waste. This is achieved by streamlining processes, eliminating unnecessary steps, and continually improving efficiency. It’s based on a set of core principles that revolve around respecting people, continuous improvement, and the elimination of all forms of waste.

Think of it like baking a cake: A lean approach would involve having all ingredients measured and ready before you begin, using the right tools for the job, ensuring a smooth workflow, and minimizing spills or unnecessary steps. Every action is carefully considered to achieve the perfect cake with minimal waste of time, effort, and resources.

- Waste Reduction (Muda): Identifying and eliminating seven types of waste: transportation, inventory, motion, waiting, overproduction, over-processing, and defects.

- Just-in-Time (JIT) Inventory: Maintaining minimal inventory levels to reduce storage costs and minimize waste.

- Continuous Improvement (Kaizen): Constantly seeking ways to improve processes, no matter how small the improvement.

- Value Stream Mapping: Visualizing the entire process to identify areas of inefficiency.

Q 18. Describe your experience with process improvement methodologies (e.g., Six Sigma, Kaizen).

I have extensive experience with Six Sigma and Kaizen methodologies. Six Sigma is a data-driven approach focused on reducing process variation and defects, aiming for near-perfection (3.4 defects per million opportunities). Kaizen, on the other hand, emphasizes incremental and continuous improvement through small, ongoing changes suggested by employees.

In one project, we used Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, Control) methodology to address a high defect rate in a particular component. We defined the problem, measured the defect rate, analyzed the root causes using statistical tools, implemented corrective actions, and established controls to prevent future recurrences. This resulted in a significant reduction in defects and improved customer satisfaction.

Kaizen has been instrumental in fostering a culture of continuous improvement in various teams. By regularly conducting Kaizen events, we encourage employees to identify and suggest improvements in their work processes. These suggestions, even seemingly minor ones, collectively contribute to significant overall efficiency gains.

Q 19. How do you manage project timelines and budgets in a manufacturing environment?

Managing project timelines and budgets in manufacturing requires meticulous planning and proactive monitoring. It starts with a detailed project plan that includes well-defined tasks, responsibilities, and deadlines. We utilize project management software to track progress, manage resources, and identify potential delays early on. Regular status meetings with stakeholders are essential to keep everyone informed and address any emerging issues promptly.

Budget management involves creating a comprehensive budget that accounts for all costs, including materials, labor, equipment, and overhead. We track expenses carefully and compare them against the budget regularly. Any significant deviations require immediate investigation and corrective actions. Contingency planning is also vital to accommodate unforeseen challenges or cost overruns.

For example, in a recent project, we anticipated a potential delay in the delivery of a crucial component. By proactively contacting the supplier and exploring alternative sourcing options, we mitigated the risk of project delays and kept the project on schedule and within budget.

Q 20. Explain your understanding of supply chain management.

Supply chain management encompasses the entire process of getting raw materials, transforming them into finished goods, and delivering them to the end customer. Effective supply chain management involves optimizing every link in the chain to ensure efficient flow of goods and information.

This includes supplier selection, inventory management, logistics, and relationship management. Choosing reliable and efficient suppliers is critical. Effective inventory management minimizes storage costs and ensures timely availability of materials. Optimizing logistics, such as transportation and warehousing, reduces lead times and minimizes costs. Strong relationships with suppliers and customers are essential for collaborative problem-solving and efficient communication.

For instance, utilizing a Vendor Managed Inventory (VMI) system can improve efficiency. In a VMI system, suppliers take responsibility for managing inventory levels at the manufacturing facility, ensuring optimal stock levels and reducing the burden on internal teams.

Q 21. How do you ensure the safety of workers in a manufacturing setting?

Worker safety is paramount in any manufacturing setting. It’s not just an ethical responsibility but a legal requirement. A comprehensive safety program involves multiple layers of protection, starting with thorough risk assessments of every process and workstation.

We provide comprehensive training on safety procedures, the use of personal protective equipment (PPE), and emergency response protocols. Regular safety inspections and audits are crucial to identify potential hazards and ensure compliance with safety regulations. Furthermore, implementing robust safety protocols, such as lockout/tagout procedures for machinery maintenance and implementing ergonomic design principles to minimize repetitive strain injuries, are vital.

Creating a strong safety culture, where employees are empowered to report hazards and participate actively in safety initiatives, is critical. Regular safety meetings and open communication channels contribute to a more proactive and safer work environment.

Q 22. Describe your experience with different types of joining techniques (e.g., welding, bonding).

My experience encompasses a wide range of joining techniques, crucial for assembling components into functional units. I’ve extensively worked with welding, specifically MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and resistance welding, selecting the appropriate method based on material compatibility, required strength, and aesthetic considerations. For example, TIG welding offers excellent precision for thin-walled stainless steel components in medical devices, while MIG welding is more efficient for mass production of steel structures. Beyond welding, I’m proficient in adhesive bonding, utilizing various epoxy and cyanoacrylate resins for joining dissimilar materials or where heat-sensitive components are involved. This is particularly important in electronics assembly where high-strength, thermally stable bonds are essential. I also have experience with mechanical fastening, including riveting, bolting, and screwing, which are often chosen for their ease of disassembly and ability to handle high loads in applications like automotive parts.

- MIG Welding: High deposition rate, suitable for mass production.

- TIG Welding: Precise control, ideal for intricate designs and thin materials.

- Adhesive Bonding: Versatile, joins dissimilar materials without heat, suitable for sensitive components.

- Mechanical Fastening: Easily disassembled, strong in high-load applications.

Q 23. Explain your understanding of surface treatments and their impact on material properties.

Surface treatments significantly alter material properties, enhancing performance and longevity. They can improve corrosion resistance, wear resistance, lubricity, or even change the aesthetic appeal. Consider anodizing aluminum: This electrochemical process creates a hard, oxide layer, greatly increasing corrosion resistance and providing a durable, aesthetically pleasing finish. This is crucial for architectural applications or outdoor equipment. Another example is powder coating, which offers excellent durability and a wide range of colors. It’s widely used in furniture and automotive parts to provide scratch and chip resistance. For enhanced wear resistance, I’ve utilized techniques like physical vapor deposition (PVD) to create thin, hard coatings on cutting tools, extending their lifespan significantly. The choice of surface treatment hinges on the material, the intended application, and the desired properties. Each treatment impacts things like surface roughness, hardness, and chemical reactivity.

- Anodizing: Enhances corrosion resistance and aesthetic appeal in aluminum.

- Powder Coating: Provides excellent durability and a wide color range.

- Physical Vapor Deposition (PVD): Creates hard, wear-resistant coatings.

Q 24. What are some common sustainability considerations in manufacturing?

Sustainability is paramount in modern manufacturing. Key considerations include minimizing waste, reducing energy consumption, and utilizing eco-friendly materials. This involves optimizing material usage through techniques like lean manufacturing to eliminate waste and improve efficiency. Switching to renewable energy sources for powering manufacturing processes plays a crucial role in reducing carbon footprint. Choosing recycled or bio-based materials over virgin materials further decreases environmental impact. End-of-life considerations are also vital; designing products for recyclability or reuse extends their lifespan and minimizes landfill waste. Implementing these practices not only benefits the environment but can also improve a company’s bottom line through reduced operating costs and enhanced brand reputation.

- Lean Manufacturing: Optimizes material usage and minimizes waste.

- Renewable Energy: Reduces carbon footprint.

- Recycled/Bio-based Materials: Decreases environmental impact.

- Design for Recyclability/Reuse: Extends product lifespan and minimizes waste.

Q 25. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a critical tool for ensuring consistent product quality and identifying potential issues before they escalate. My experience involves implementing and interpreting control charts, like X-bar and R charts, to monitor key process parameters. By analyzing data collected during manufacturing, we can detect trends, variations, and outliers, allowing for timely interventions. For instance, in a plastic injection molding process, we might monitor the weight of each part produced. Deviations from the target weight could signal problems with the mold, material flow, or machine settings. SPC helps prevent defects, improve efficiency, and ensures products meet specifications consistently. Beyond basic control charts, I have experience with more advanced techniques like capability analysis, which assesses a process’s ability to meet customer requirements.

Q 26. How do you troubleshoot manufacturing problems?

Troubleshooting manufacturing problems requires a systematic approach. I typically start with a thorough analysis of the problem, collecting data and visually inspecting the affected components or processes. This helps identify the root cause, which is often not immediately obvious. For example, if a batch of parts has a high defect rate, I might investigate the raw materials, the machine settings, the operator technique, or the environment. I use various tools – including statistical analysis, process flow diagrams, and failure mode and effects analysis (FMEA) – to understand the problem’s scope and identify potential causes. Once the root cause is identified, I implement corrective actions, verify their effectiveness, and document the findings to prevent recurrence. This process often involves collaboration with other engineers and technicians to find optimal solutions.

Q 27. Explain your experience with automation in manufacturing.

I have significant experience with automation in manufacturing, focusing on improving efficiency, precision, and consistency. My work has involved integrating robots into assembly lines, implementing automated quality control systems, and utilizing Computer Numerical Control (CNC) machines for precise machining. For example, in a previous role, we automated a previously manual assembly process using robotic arms, which increased throughput by 40% and reduced labor costs significantly. Automation also minimizes human error and ensures consistent product quality. However, it’s crucial to carefully plan the automation strategy, considering factors like initial investment costs, maintenance requirements, and potential disruptions to existing workflows. A well-planned automation strategy can provide a significant return on investment and enhance overall manufacturing efficiency.

Q 28. How do you stay up-to-date with the latest advancements in materials engineering and manufacturing techniques?

Staying current in materials engineering and manufacturing is crucial. I actively participate in professional organizations like ASME and SME, attending conferences and workshops to learn about the latest advancements. I regularly read industry publications, journals, and online resources like research databases and industry blogs. This helps me stay informed about new materials, processes, and technologies. I also engage in online courses and workshops offered by universities and professional organizations to expand my knowledge and skills. Networking with other professionals through conferences and online communities also provides valuable insights and perspectives on industry trends and best practices. Continuous learning is essential in this rapidly evolving field.

Key Topics to Learn for Strong Understanding of Design Principles, Materials Engineering, and Manufacturing Techniques Interview

- Design Principles:

- Fundamental design concepts (form, function, aesthetics)

- Ergonomics and human factors in design

- Design for Manufacturing (DFM) principles and their application

- Sustainable design considerations and lifecycle analysis

- Materials Engineering:

- Material selection based on properties (strength, durability, cost)

- Understanding of material behavior under stress and strain

- Failure analysis and prevention techniques

- Material processing and characterization methods

- Manufacturing Techniques:

- Additive manufacturing (3D printing) processes and applications

- Subtractive manufacturing processes (machining, milling)

- Casting and molding techniques

- Quality control and inspection methods in manufacturing

- Understanding of manufacturing tolerances and limitations

- Problem-Solving and Application:

- Case studies demonstrating the integration of design, materials, and manufacturing

- Troubleshooting common manufacturing challenges

- Applying theoretical knowledge to real-world scenarios

Next Steps

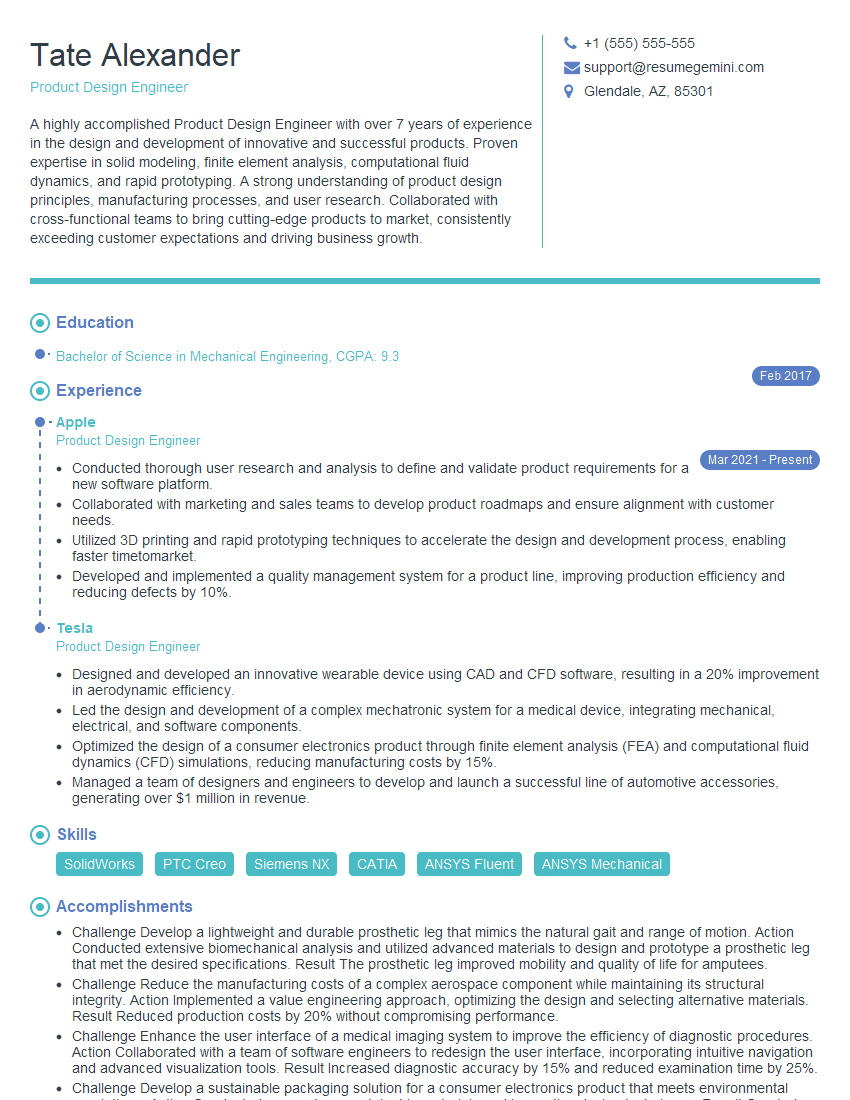

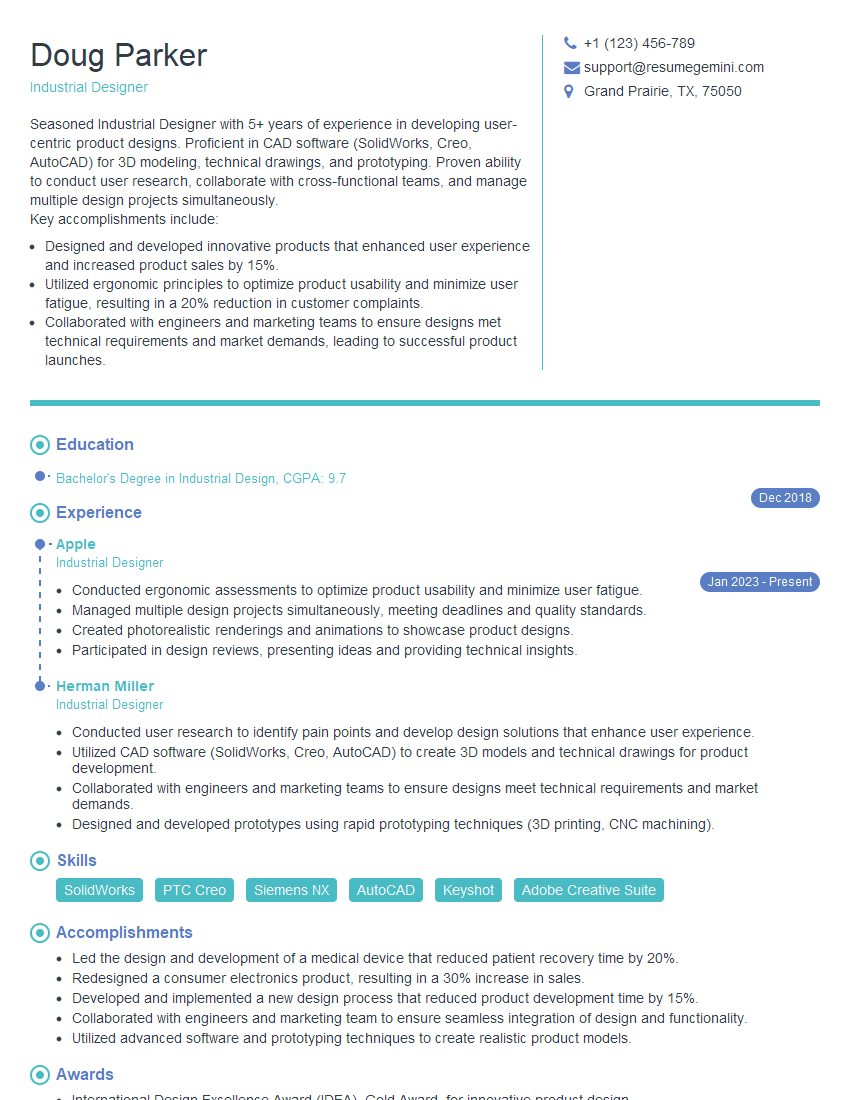

Mastering design principles, materials engineering, and manufacturing techniques is crucial for career advancement in many engineering fields. A strong foundation in these areas opens doors to exciting opportunities and allows you to contribute significantly to innovative projects. To maximize your job prospects, focus on crafting an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to showcase expertise in design principles, materials engineering, and manufacturing techniques to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good