The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Stump Removal and Grinding Techniques interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Stump Removal and Grinding Techniques Interview

Q 1. What are the different methods for stump removal?

Stump removal involves several methods, each with its own advantages and disadvantages. The choice depends on factors like stump size, location, access, and budget.

- Stump Grinding: This is the most common method, using a machine to grind the stump and roots into small chips, leaving behind a relatively level surface. It’s efficient and suitable for most situations.

- Stump Removal (Digging): This involves excavating the stump and roots completely. It’s more labor-intensive and disruptive but necessary for very large stumps or when complete removal is crucial. This might involve heavy machinery like excavators.

- Chemical Removal: Specialized chemicals are used to decompose the stump and roots over time. This is a slower process and may not be completely effective for all types of wood.

- Burning: While possible, burning stumps is generally discouraged due to environmental concerns and safety risks. It’s often restricted by local regulations.

For example, in a residential setting with a small to medium-sized stump, grinding is often the preferred method. For a large stump in a challenging location, excavation might be more suitable. Chemical removal might be considered when access is limited.

Q 2. Describe the process of stump grinding.

Stump grinding involves using a machine with a rotating cutting wheel or drum equipped with carbide teeth. The grinder is positioned over the stump, and the operator lowers the cutting wheel to begin grinding. The machine shreds the wood into small chips, typically 1-3 inches in size. The resulting wood chips can be left on the site as mulch or removed. The process is quite efficient, even for large stumps. Imagine a wood chipper, but specifically designed to handle stumps buried in the ground.

The process generally follows these steps:

- Assess the stump: Determine size, location, and any obstructions.

- Position the grinder: Ensure it’s stable and safe.

- Begin grinding: Lower the cutting wheel and gradually grind down the stump.

- Check for remaining roots: Grind any remaining root sections.

- Clean up: Remove the wood chips if needed.

Q 3. What safety precautions are necessary when operating a stump grinder?

Safety is paramount when operating a stump grinder. This powerful machinery can cause serious injuries if not handled correctly.

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, sturdy work boots, and gloves.

- Clear the area: Ensure the area around the grinder is free of obstructions and bystanders.

- Proper training: Only operate a grinder after receiving proper training and understanding the machine’s controls.

- Ground stability: Ensure the ground is stable to prevent the grinder from tipping over.

- Beware of flying debris: Wood chips can be thrown at high velocity, so keep a safe distance from the machine.

- Utility location: Before starting, mark and carefully avoid underground utilities (gas, water, electric).

For example, I once saw a grinder operator fail to clear the area properly. A rock was flung by the rotating drum, narrowly missing a bystander. This highlights the crucial importance of preparation and safe operating practices.

Q 4. How do you determine the appropriate size stump grinder for a job?

Choosing the right stump grinder size depends on the size and number of stumps to be removed. Several factors need consideration.

- Stump diameter: Larger stumps require grinders with larger cutting wheels or drums.

- Root system: Extensive root systems might necessitate a more powerful grinder.

- Access to the site: The grinder’s size and maneuverability should be appropriate for the site conditions.

- Type of wood: Harder woods demand more powerful machines.

- Frequency of use: Consider whether this is a one-off job or a regular task.

For instance, a small, self-propelled grinder might suffice for a few small stumps in a residential yard. A larger, more powerful machine mounted on a trailer would be necessary for a large commercial job with numerous large stumps.

Q 5. What are the common types of stump grinders and their applications?

Stump grinders come in various types, each designed for specific applications:

- Self-Propelled Grinders: These are smaller, more portable units ideal for residential work and smaller jobs where maneuverability is important. They are typically powered by a gasoline engine.

- Trailer-Mounted Grinders: Larger, more powerful grinders mounted on trailers, providing greater mobility and power for larger jobs. These often have larger cutting wheels and are ideal for commercial use.

- Vertical Grinders (also known as ‘vertical shaft grinders’): These grinders have a vertical cutting shaft extending down into the stump and are well suited for tough and hard to reach stumps. These machines provide more power and are better for larger and more challenging stumps.

- Horizontal Grinders (also known as ‘horizontal shaft grinders’): These are typically larger units that have a horizontally mounted cutting head. They are suitable for larger, commercial-scale stump removal operations.

A landscaper might use a self-propelled grinder for maintaining a residential property, whereas a tree removal company would likely use a trailer-mounted or vertical shaft grinder for larger projects.

Q 6. Explain the maintenance procedures for a stump grinder.

Regular maintenance is crucial to extend the life and ensure the safe operation of a stump grinder. This involves:

- Regular inspections: Check for wear and tear on the cutting teeth, belts, and other components.

- Blade sharpening: Sharpen or replace the cutting teeth as needed to maintain cutting efficiency and prevent damage to the grinder.

- Lubrication: Regularly lubricate moving parts according to the manufacturer’s instructions.

- Engine maintenance: Follow the manufacturer’s guidelines for engine maintenance, including oil changes, air filter replacement, and spark plug cleaning.

- Belt adjustments: Keep the belts properly adjusted to prevent slippage and damage.

- Storage: Store the grinder in a dry, protected place when not in use.

Ignoring maintenance can lead to premature wear, breakdowns, and potentially unsafe operating conditions. A well-maintained grinder will not only work more efficiently but will also significantly extend its service life and improve its safety.

Q 7. How do you handle underground utilities during stump removal?

Handling underground utilities during stump removal requires extreme caution to prevent damage and potential injury.

- Call before you dig: Always contact your local utility companies before starting any excavation work to have them mark the location of underground lines.

- Use caution: Exercise extreme care around marked utility lines. Avoid digging or operating machinery near them.

- Consider non-excavation methods: If utilities are close to the stump, consider using methods like stump grinding that don’t require extensive excavation.

- Hire professionals: For jobs near or involving complex utility layouts, it’s best to hire professionals experienced in excavation and utility safety.

Ignoring this crucial step can have devastating consequences, from damage to essential services to serious injury or even fatality. Protecting underground utilities is not merely a safety precaution but a legal and ethical responsibility.

Q 8. What are the environmental considerations for stump removal?

Environmental considerations in stump removal are paramount. We must minimize soil disturbance to protect existing plant life and prevent soil erosion. The method chosen – grinding versus excavation – significantly impacts this. Grinding creates less soil disturbance but generates wood debris that needs proper disposal. Excavation, while more disruptive initially, allows for complete removal and potentially re-use of the soil. We also consider the potential impact on water resources. Improper disposal of wood chips or chemicals used in stump removal can contaminate water sources. Therefore, we always adhere to local environmental regulations and best practices such as using biodegradable lubricants and responsibly disposing of all waste.

For example, on a recent project near a wetland, we opted for stump grinding to avoid disturbing the delicate ecosystem. The resulting wood chips were then used for landscaping mulch on site, minimizing waste and maximizing resource utilization.

Q 9. How do you assess the risk of root damage to surrounding plants?

Assessing the risk of root damage to surrounding plants requires a thorough pre-removal assessment. We carefully examine the size and extent of the root system of the target stump, paying close attention to its proximity to other plants. Larger trees naturally have more extensive root systems, increasing the risk of damage to neighboring plants. We use a combination of visual inspection and, if necessary, ground-penetrating radar to map the root system’s reach. This helps us determine the safest approach, whether it’s careful hand-digging around sensitive roots or employing a more aggressive grinding technique farther from the at-risk plants. We always prioritize protecting established landscaping and strive to minimize any disruption.

For instance, when removing a large oak next to a mature rose garden, we used a smaller, more maneuverable stump grinder, and worked slowly and methodically to ensure the rose bushes were left undisturbed.

Q 10. Describe your experience with different types of stump grinding equipment.

My experience encompasses a wide range of stump grinding equipment, from small, walk-behind units ideal for residential jobs to large, powerful machines mounted on tractors or trailers for larger commercial projects. I’ve worked with various brands and models, each with its strengths and weaknesses. Smaller units offer excellent maneuverability in tight spaces but have limitations in stump size and removal depth. Larger units handle larger stumps with ease but require more space and are less suitable for delicate situations. I’m proficient in operating both hydraulic and electric stump grinders, understanding the nuances of each type, including their power sources, cutting mechanisms, and safety features.

For example, on a recent large-scale land clearing project, we used a powerful trailer-mounted stump grinder with a high horsepower engine and aggressive cutting teeth to efficiently remove numerous large stumps. On a residential project needing to remove several small stumps around a foundation, a smaller, walk-behind unit was a better option.

Q 11. What are the signs of a malfunctioning stump grinder?

Several signs indicate a malfunctioning stump grinder. Reduced cutting efficiency, where the grinder struggles to chew through wood or requires multiple passes, is a common indicator. Unusual noises, such as grinding, squealing, or banging sounds, often point to worn components or mechanical issues. Overheating, excessive vibration, and hydraulic leaks are also major red flags. If the grinder’s controls become unresponsive or erratic, there could be an electrical fault. Regular maintenance, including inspecting the cutting teeth, checking hydraulic fluid levels, and examining belts and pulleys, helps prevent such malfunctions.

For example, a persistent squealing sound could indicate a problem with the bearings, while excessive vibration might suggest an imbalance in the cutting head.

Q 12. How do you troubleshoot common stump grinder problems?

Troubleshooting stump grinder problems starts with a thorough safety inspection, ensuring the machine is properly shut down and secured. Then, I systematically check for the causes of the malfunction. A reduced cutting efficiency could mean dull or damaged teeth, requiring sharpening or replacement. Unusual noises might indicate worn bearings or a loose component. Overheating could point towards a lack of lubrication or a problem with the cooling system. Hydraulic leaks require immediate attention and often need professional repair. Electrical issues might require specialized expertise.

For instance, if the grinder is overheating, I’d first check the oil levels and then inspect the cooling fan for obstructions. If there’s a hydraulic leak, I would shut down the machine immediately and contact a qualified technician.

Q 13. What is the proper procedure for disposing of grinding debris?

Proper disposal of grinding debris is crucial to avoid environmental hazards. In many cases, the wood chips are small enough to be used as mulch or landscaping material. If the material is clean and free from contaminants, it can often be re-used on the property or even sold commercially. If re-use isn’t an option, then disposal at a designated landfill or composting facility is necessary. We always follow local regulations and obtain any necessary permits for disposal. This ensures responsible environmental stewardship and avoids any potential fines or legal repercussions.

For instance, in some jobs, the finer wood chips are used as a soil amendment, improving soil drainage and enriching the soil.

Q 14. What are the different types of cutting teeth used in stump grinders?

Stump grinders utilize different types of cutting teeth depending on the specific application and the type of wood being processed. Common types include carbide-tipped teeth, which are extremely durable and ideal for hard woods, and high-speed steel teeth, which are more affordable but may wear out faster. Some teeth are designed for aggressive cutting, ideal for larger, tougher stumps, while others provide a finer grind for a more refined finish. The choice of teeth depends heavily on the specific job requirements and the characteristics of the wood to be processed.

For example, when working with extremely hard hardwoods like oak, carbide-tipped teeth are essential to avoid premature wear. For softer woods, a less aggressive high-speed steel tooth may be sufficient.

Q 15. How do you handle stumps located in difficult-to-access areas?

Accessing stumps in tricky locations requires creative problem-solving. We assess the situation first, considering factors like terrain, proximity to structures, and the stump’s size. For example, if a stump is nestled deep within a dense thicket, we might employ small, maneuverable stump grinders with extended reach. If the terrain is too steep or uneven for machinery, we’ll resort to manual methods, potentially using hand tools like axes and shovels, ensuring careful safety precautions. In cases with limited access, we may use smaller, specialized equipment that can navigate narrow pathways or be disassembled for easier transport. We always prioritize safety and minimize environmental impact. For instance, we might use ropes and pulleys to lower equipment into a steep area or carefully plan our movements to avoid damaging surrounding vegetation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the limitations of stump grinding?

Stump grinding isn’t a perfect solution for every situation. Its limitations primarily revolve around depth and root systems. Grinders primarily remove the above-ground portion of the stump and a few inches below the surface. Large, deep root systems might remain, potentially causing problems later on. Also, grinding might not be suitable for stumps near underground utilities, as the grinder could unintentionally damage them. Finally, while the resulting wood chips are typically useful for landscaping, they can be too large or dense for certain applications and the process still leaves a significant amount of wood in the ground. It’s important to evaluate the total depth of the root system and whether those roots present a risk or would be a hindrance to future plans for that land.

Q 17. When is stump removal more appropriate than stump grinding?

Stump removal (complete excavation) is preferred over grinding when dealing with exceptionally large stumps, stumps with extensive and deep root systems that could interfere with future construction or planting, or when the location is close to underground utilities or structures. For example, if a large stump is in the way of a new building foundation, complete removal is necessary to ensure the foundation’s stability. Similarly, if a stump is close to a water main, grinding risks damage to the pipe. We always perform a thorough site assessment before recommending either method. The goal is to eliminate the stump completely, ensuring there are no residual parts, rather than just reducing it to woodchips.

Q 18. How do you calculate the cost of a stump removal or grinding job?

Cost calculation is multifaceted. We consider stump size (diameter and height), accessibility (difficult-to-reach locations increase costs), the type of removal (grinding vs. excavation), soil type (rocky soil requires more effort), and disposal needs (hauling away wood chips or excavated material). For grinding, we typically use a pricing structure based on stump diameter. Excavation is quoted individually as it involves more variable factors. We also include travel time and any extra labor expenses like dealing with unusually hard or rocky soil. Providing a free, accurate estimate, based on a site visit is crucial for a fair price and client satisfaction.

Q 19. What are the legal requirements for stump removal in your area?

Legal requirements vary by location. Typically, we need to comply with local tree removal ordinances, especially if the stump is on public property or within a protected area. This might involve obtaining permits, following specific procedures, and adhering to environmental regulations regarding waste disposal. For example, we need to ensure that the disposal of wood chips and debris complies with local regulations to avoid unnecessary fines and ensure ecological practices. We always keep ourselves updated on all relevant regulations and inform our clients of any necessary permits or approvals.

Q 20. How do you ensure the safety of yourself and others during stump removal?

Safety is paramount. We use appropriate personal protective equipment (PPE) including safety glasses, hearing protection, sturdy work boots, and gloves. We ensure the work area is clear of obstructions and bystanders. When operating machinery, we follow all manufacturer safety guidelines. Before starting any work, we carefully inspect the site for potential hazards like underground utilities or unstable ground. When working in close proximity to structures, extra safety measures are implemented. Regular equipment maintenance and training further enhance safety. We clearly communicate safety protocols with our team and clients before, during, and after the job.

Q 21. Describe your experience working with different soil types.

My experience encompasses diverse soil types, each presenting unique challenges. Clay soils can be incredibly tough, requiring more powerful equipment and potentially extra time for excavation. Sandy soils are generally easier to work with, but can pose challenges in stability, especially when excavating. Rocky soils necessitate specialized equipment, sometimes requiring blasting or specialized tools to remove the stump and surrounding rocks. Loamy soils usually present a balance of ease of working and stability. Understanding the soil type ahead of time allows us to optimize our approach, select the appropriate equipment, and accurately estimate the time and resources needed for a successful project. We always conduct thorough soil tests or assessments on-site to avoid unforeseen problems and ensure the safety and efficiency of the process.

Q 22. How do you deal with stumps containing metal or other obstructions?

Dealing with stumps containing metal or other obstructions requires a cautious and methodical approach. Ignoring them can lead to significant damage to equipment and potential injury. My first step is always a thorough pre-grind assessment. This involves using a metal detector to pinpoint the location and size of any metallic objects. For smaller pieces of metal, I might be able to grind around them carefully. However, for larger or deeply embedded objects like old pipes or rebar, a different strategy is necessary.

In such cases, I might use a combination of techniques. This could include carefully excavating around the obstruction to remove it before grinding, or using a smaller, more maneuverable grinder to work around the obstruction. If the obstruction is too large or difficult to remove, I will inform the client of the additional challenges and costs associated with safely completing the job. Safety is paramount, and sometimes, the best solution is to adjust the grinding plan to accommodate the unexpected.

For example, I once encountered a stump with an embedded section of old corrugated metal roofing. Simply grinding over it would have risked damaging the grinder’s teeth. Instead, I carefully excavated around the metal, removed it, and then proceeded with the stump grinding. This extra step added time, but it ensured a safe and efficient job completion.

Q 23. What is your experience with different brands of stump grinders?

Throughout my career, I’ve operated a variety of stump grinder brands, including Vermeer, Rayco, and Toro. Each brand offers unique features and advantages. For instance, Vermeer grinders are renowned for their durability and powerful performance, making them ideal for larger, more challenging stumps. Rayco grinders often excel in maneuverability, perfect for working in tighter spaces. Toro models frequently provide a good balance of power and ease of operation.

My experience extends beyond simply operating these machines; I understand their maintenance requirements and troubleshooting procedures. This knowledge enables me to identify potential issues quickly and maintain optimal machine performance. I can efficiently diagnose problems like worn teeth, hydraulic leaks, and engine issues, minimizing downtime and ensuring efficient job completion. Choosing the right grinder for a specific job is critical, and my experience with these different brands allows me to make informed decisions based on the job site conditions and the size and type of stumps involved.

Q 24. How do you handle customer complaints or unexpected problems on a job site?

Handling customer complaints or unexpected problems on a job site requires a professional and proactive approach. My priority is always to address the issue quickly and transparently. Open communication is key. I begin by actively listening to the customer’s concerns and thoroughly understanding their perspective. This involves asking clarifying questions and ensuring I fully grasp the nature of the problem.

Next, I assess the situation objectively. Is it a simple misunderstanding? A genuine issue with the work? Or an unforeseen circumstance? Based on my assessment, I propose a solution that addresses the customer’s concerns while adhering to professional standards. This might involve re-working a portion of the job, offering a discount, or explaining the reasons behind any unexpected delays or challenges. Documentation is crucial; I maintain detailed records of all jobs, including any modifications or adjustments made to address unforeseen issues. My goal is always to ensure customer satisfaction and maintain a positive professional reputation.

For example, a client once expressed concern about the size of the grind area after a job. After discussing their expectations and reviewing the initial agreement, we agreed on a reasonable adjustment, and I completed the extra work to their satisfaction, maintaining open communication throughout the process.

Q 25. Describe your experience with operating other types of heavy equipment.

Beyond stump grinding, I’m experienced in operating a range of heavy equipment, including excavators, skid steers, and mini-loaders. This diverse experience is invaluable, as it allows me to approach stump removal projects from multiple angles. For instance, an excavator can be crucial for clearing debris, preparing the worksite, or handling large stumps that are too difficult for a grinder alone.

My proficiency with these machines allows me to maximize efficiency and safety on the job site. I can effectively coordinate the use of different pieces of equipment to complete a job efficiently and safely. This often reduces the overall project time and cost for the client. The versatility of my skills allows me to handle a wider range of tasks and makes me a more valuable asset to any team.

Q 26. What are your knowledge of relevant safety regulations and certifications?

Safety is my top priority. I hold all necessary certifications for operating heavy equipment, including my state-issued license for stump grinding and excavator operation. I am also familiar with OSHA regulations pertaining to heavy equipment operation and workplace safety. This includes understanding and complying with regulations regarding personal protective equipment (PPE), machine maintenance, and safe work practices.

My commitment to safety goes beyond simply meeting minimum requirements. I consistently undergo refresher training to stay updated on best practices and new safety technologies. I proactively identify and mitigate potential hazards on each job site, ensuring a safe working environment for myself and others. This proactive approach, coupled with my extensive experience, minimizes risks and prevents accidents.

Q 27. Explain your experience with pre-job site assessments and planning.

Pre-job site assessments are critical for a successful and efficient stump removal. My process begins with a thorough review of the client’s request, including the size, number, and location of stumps. I then visit the job site to conduct a physical assessment. This involves evaluating factors such as access to the site, the presence of underground utilities, surrounding vegetation, and the terrain.

This assessment allows me to develop a detailed plan, including the equipment needed, the appropriate grinding techniques, and the estimated time frame for completion. The plan also incorporates safety protocols to ensure that the job is completed safely and without incident. I always discuss the plan with the client to confirm their expectations and address any questions or concerns they may have. This proactive approach prevents unexpected problems and ensures a smooth and efficient job execution.

For instance, during a recent assessment, I discovered underground utility lines very close to the target stump. This required me to adjust my plan, employing more precise and cautious grinding techniques to prevent damage to the lines. This careful pre-planning saved time and prevented a potential costly error.

Q 28. Describe your approach to training new employees on safe stump grinding practices.

Training new employees involves a structured, hands-on approach that prioritizes safety. It begins with classroom instruction covering safety regulations, equipment operation, and emergency procedures. I provide comprehensive manuals and detailed explanations of safe work practices. This theoretical knowledge forms the foundation for practical training.

Practical training is conducted under my direct supervision. New employees start with observation, watching me perform different stump grinding techniques. Gradually, they progress to assisting with tasks under close guidance, building their confidence and skill. I emphasize the importance of pre-job site assessments, proper machine maintenance, and safe operating procedures. Continuous feedback and open communication are essential throughout the training process. Regular evaluations and demonstrations ensure they have fully grasped the concepts and can perform tasks safely and effectively. The goal is to instill safe work habits and empower them to become responsible and skilled stump grinders.

Key Topics to Learn for Stump Removal and Grinding Techniques Interview

- Safety Procedures and Regulations: Understanding OSHA guidelines, proper personal protective equipment (PPE), and safe work practices for stump removal and grinding.

- Stump Grinding Equipment Operation and Maintenance: Familiarization with various stump grinder models, their operational procedures, routine maintenance checks, and troubleshooting common mechanical issues.

- Stump Removal Methods: Knowledge of different stump removal techniques, including grinding, digging, and chemical removal, and the selection criteria for each method based on stump size, location, and environmental factors.

- Site Assessment and Planning: Ability to assess the worksite, identify potential hazards, plan the removal process efficiently, and communicate effectively with clients and team members.

- Soil and Root System Understanding: Knowledge of different soil types and their impact on stump removal, understanding root systems and their potential challenges during the process.

- Environmental Considerations: Awareness of environmentally friendly practices, minimizing ground disturbance, and proper disposal of removed materials.

- Customer Service and Communication: Effective communication skills to interact with clients, answer questions, address concerns, and provide professional service.

- Problem-Solving and Troubleshooting: Ability to identify and resolve unexpected issues during the stump removal process, such as encountering buried utilities or encountering unusually hard or large roots.

Next Steps

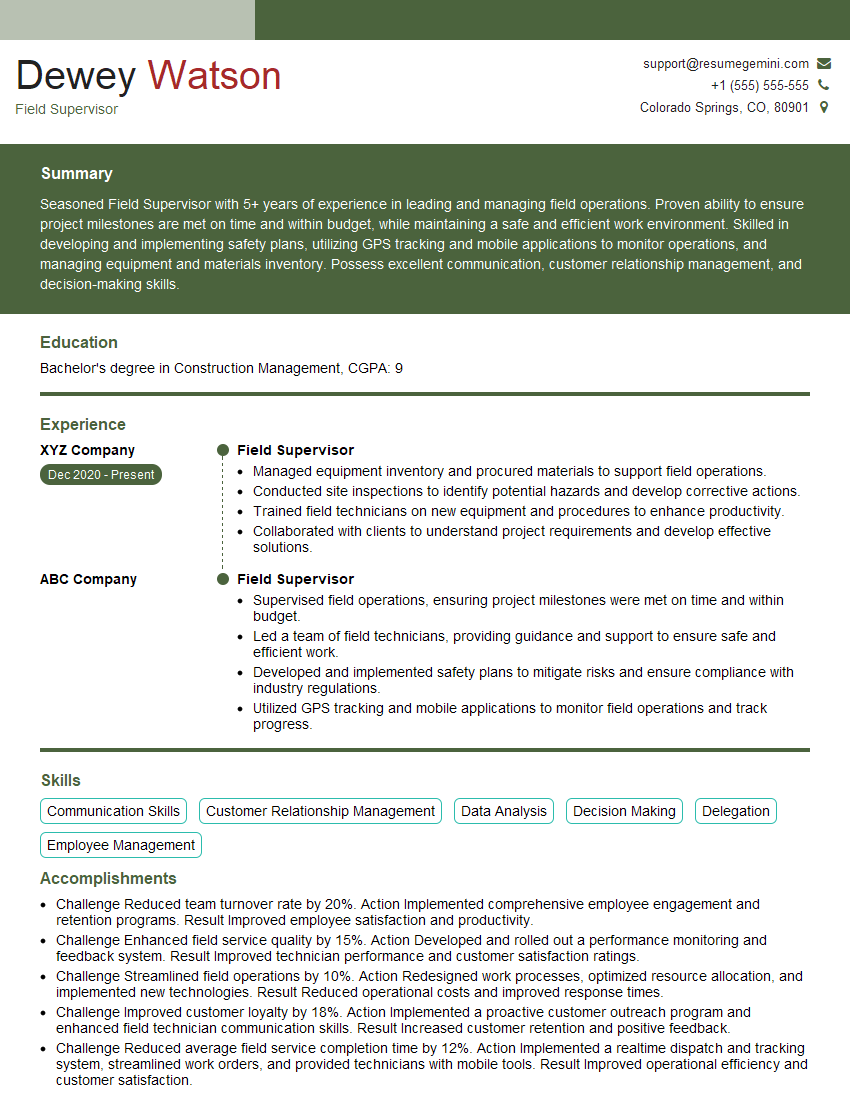

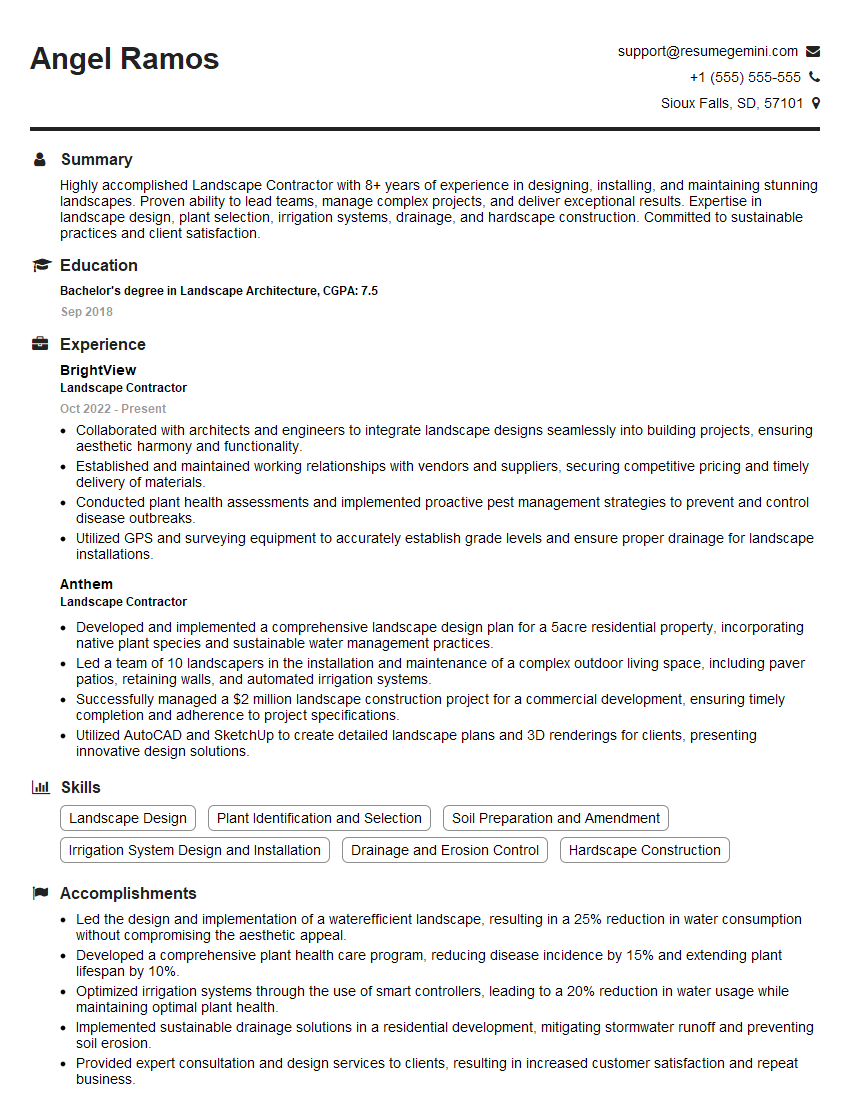

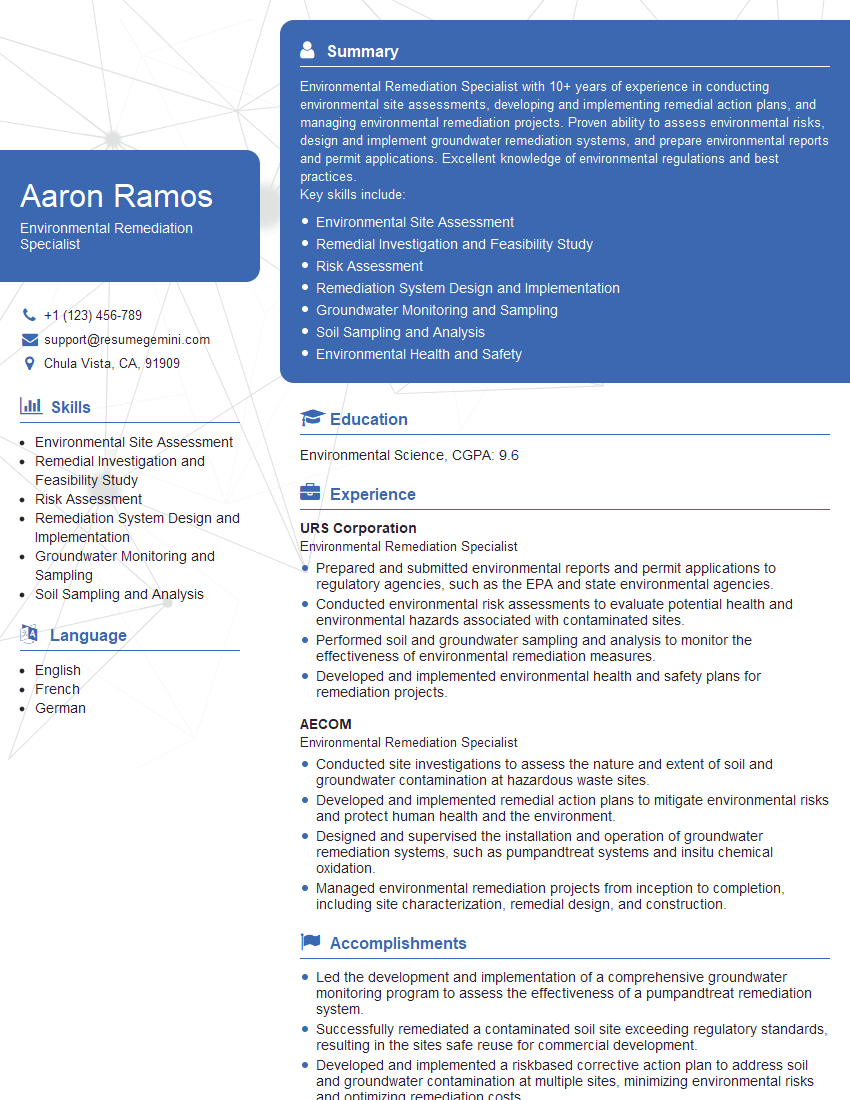

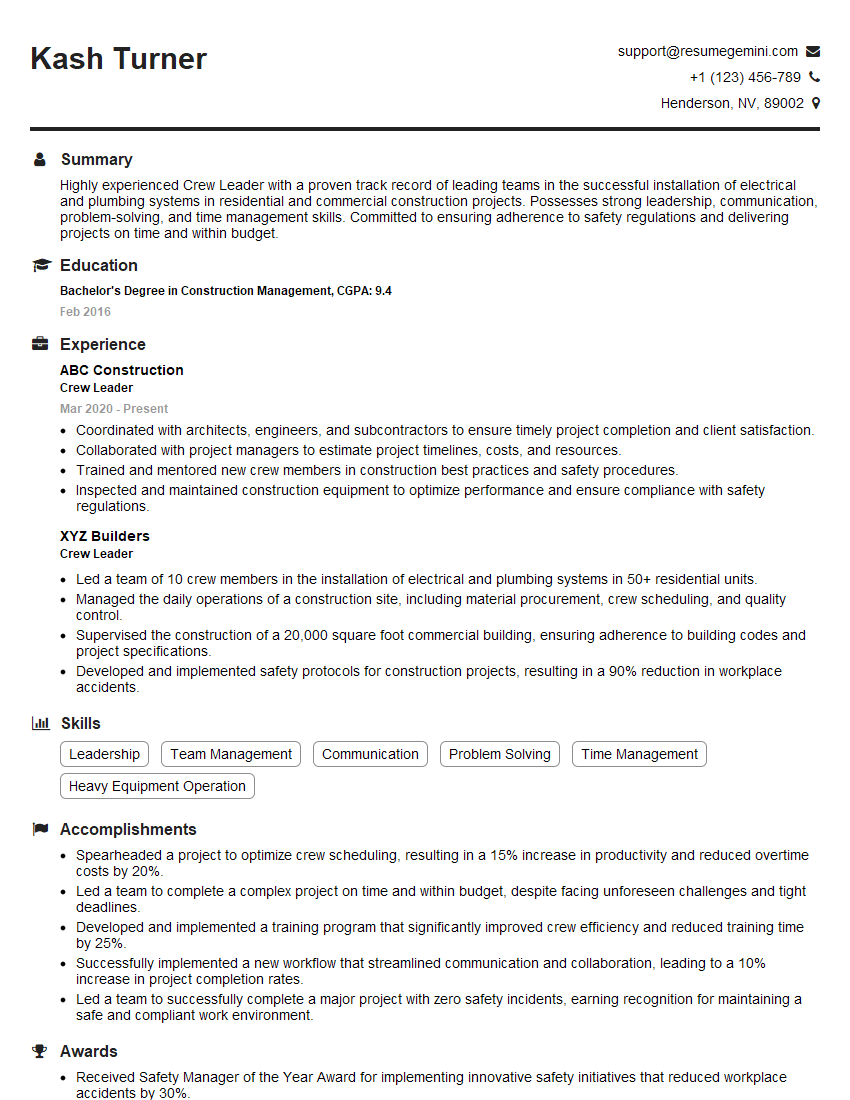

Mastering Stump Removal and Grinding Techniques opens doors to rewarding careers with excellent growth potential. A strong understanding of these techniques demonstrates your practical skills and commitment to safety, making you a highly desirable candidate. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional resume tailored to showcase your skills effectively. Examples of resumes tailored to Stump Removal and Grinding Techniques are available to further guide your preparation. Invest the time in crafting a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good