Are you ready to stand out in your next interview? Understanding and preparing for Subassembly installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Subassembly installation Interview

Q 1. Describe your experience with different types of subassembly fastening methods.

My experience encompasses a wide range of subassembly fastening methods, from simple mechanical fasteners to more complex techniques. I’m proficient with various screw types (machine screws, self-tapping screws, etc.), rivets, bolts, and specialized fasteners like quick-release pins or captive screws. I also have extensive experience with adhesive bonding, welding (in appropriate applications), and snap-fit designs. The selection of the appropriate method heavily depends on the material properties of the components, the required strength of the joint, the environment the assembly will operate in, and the ease of assembly and disassembly. For example, in a high-vibration environment, I’d favor stronger, more robust methods like threaded fasteners with locking compounds over simpler options like adhesives. In an application requiring frequent disassembly for maintenance, a quick-release mechanism would be preferable.

- Mechanical Fasteners: I routinely use various types of screws, bolts, nuts, and washers, ensuring proper torque is applied to avoid stripping or damaging threads.

- Adhesive Bonding: I’m familiar with various adhesive types and their applications, including cyanoacrylates (super glues) for quick bonding, epoxy resins for high-strength joints, and specialized structural adhesives for critical applications. Proper surface preparation is crucial for ensuring a strong and reliable bond.

- Welding (where applicable): In specific situations, welding may be the most suitable method, requiring appropriate safety measures and a thorough understanding of welding techniques for the specific materials.

Q 2. Explain the importance of following assembly drawings and specifications.

Following assembly drawings and specifications is paramount for ensuring the quality, safety, and functionality of the final product. These documents provide a blueprint, outlining the precise sequence of steps, the necessary components, and the tolerances for each part. Deviation from these specifications can lead to misalignment, component failure, and even safety hazards. Think of it like following a recipe – if you skip steps or use the wrong ingredients, the outcome won’t be as intended. In my experience, meticulously following these guidelines not only prevents errors but also facilitates efficient assembly and troubleshooting. For instance, a misinterpretation of a drawing could lead to installing a component incorrectly, requiring disassembly and potentially causing damage to other parts.

Q 3. How do you ensure the quality and accuracy of your subassembly installations?

Quality and accuracy are maintained through a multi-faceted approach. This starts with a thorough understanding of the assembly drawings and specifications. I then carefully inspect each component for defects before installation. During assembly, I regularly check for proper alignment and fit. Specialized tools, like torque wrenches, are used to ensure proper tightening of fasteners, preventing damage and guaranteeing consistent joint strength. Finally, a thorough inspection of the completed subassembly is conducted to verify its compliance with the specifications. This includes dimensional checks, visual inspections for flaws, and functional testing where applicable. Documentation of each step is critical for traceability and quality control. For example, I always record the torque applied to each fastener, which is invaluable if a problem occurs later.

Q 4. What troubleshooting techniques do you employ when encountering issues during subassembly installation?

Troubleshooting is a critical part of the subassembly installation process. My approach is systematic and involves several steps. Firstly, I carefully review the assembly drawings and specifications to ensure I haven’t missed a step or misinterpreted an instruction. Secondly, I visually inspect the components for any damage or defects. If the issue persists, I systematically check each connection and fastener, verifying that they are properly installed and tightened. I frequently utilize measuring tools like calipers and micrometers to verify dimensions and alignment. If the problem is still unresolved, I consult with more senior engineers or refer to relevant technical documentation for guidance. Documentation of each troubleshooting step is crucial for future reference and to prevent recurring issues. For example, if I encounter a recurring alignment problem, I might document the solution and propose improvements to the assembly process or design.

Q 5. Describe your experience with various hand tools and power tools used in subassembly installation.

My experience with hand and power tools is extensive and covers a wide range of equipment necessary for efficient and safe subassembly installation. Common hand tools include screwdrivers (various types and sizes), wrenches (open-ended, box-end, socket), pliers, and various measuring instruments like calipers and micrometers. Power tools include electric and pneumatic screwdrivers for efficient and consistent tightening, drills, and specialized tools such as rivet guns or crimpers, depending on the fastening methods. I am adept at selecting the appropriate tool for the task at hand and I always prioritize safety by using tools in accordance with manufacturer guidelines and wearing appropriate personal protective equipment (PPE).

Q 6. How do you handle discrepancies between assembly drawings and actual components?

Discrepancies between assembly drawings and actual components require immediate attention and careful analysis. The first step involves a thorough verification of the part numbers and specifications to ensure that the correct components have been procured. If the discrepancy is confirmed, I immediately escalate the issue to the appropriate engineering team or project manager. Depending on the nature and severity of the discrepancy, a possible solution might involve using an alternate component that meets the functional requirements or modifying the assembly process. Clear documentation of the discrepancy, the actions taken, and the resolution is crucial. This helps prevent similar issues in the future and keeps a record of any design or manufacturing deviations.

Q 7. What are your methods for preventing damage to sensitive components during installation?

Protecting sensitive components is essential. My approach involves using appropriate handling techniques, such as wearing clean gloves to prevent contamination or scratching. I use soft-jawed pliers or specialized tools to grip components without causing damage. Protective materials like masking tape, foam padding, or specialized fixtures are employed to prevent scratches or impacts during assembly. In some cases, specialized tools or jigs are utilized to ensure accurate placement and prevent misalignment or damage during installation. A methodical approach and respect for the components are key to prevent damage and ensure a high-quality result.

Q 8. Explain your understanding of torque specifications and their importance.

Torque specifications are the precise amount of rotational force required to tighten a fastener, like a screw or bolt, to the correct tension. Think of it like this: too loose, and the connection will fail; too tight, and you risk stripping the threads or damaging the material. The importance lies in ensuring the structural integrity and reliable function of the assembled component.

Every fastener has a recommended torque value, usually specified in inch-pounds (in-lb) or Newton-meters (Nm). These values are determined through engineering calculations considering factors like material strength, thread size, and the required clamping force. Using a torque wrench is crucial, as it prevents over-tightening or under-tightening. Improper torque can lead to component failure, leaks, or even safety hazards.

For example, in assembling a circuit board, applying the correct torque to the screws holding the board to the chassis is critical. Too much torque could crack the board, while too little could result in a loose connection leading to poor electrical contact or vibration issues. I always meticulously follow the manufacturer’s specified torque values and use calibrated torque wrenches to ensure accuracy and repeatability.

Q 9. How do you maintain a clean and organized workspace during subassembly installation?

Maintaining a clean and organized workspace is paramount for efficient and error-free subassembly installation. Think of it like this: a cluttered workspace is a recipe for dropped screws, damaged components, and mistakes. My approach focuses on several key aspects.

- Designated areas: I have specific areas for tools, components, waste, and finished assemblies. This prevents confusion and makes it easy to locate items quickly.

- Regular cleanup: I clean up my workspace frequently throughout the assembly process, not just at the end. This keeps things organized and prevents small parts from getting lost or mixed up.

- Component organization: I use labeled containers and trays to store components, preventing accidental mixing and ensuring quick access to the necessary parts. This is especially important when working with numerous small parts.

- ESD protection: In electronics assembly, anti-static mats and wrist straps are essential to prevent electrostatic discharge damage.

By consistently maintaining a clean and organized workspace, I improve efficiency, reduce errors, and ensure the safety and quality of the final product. For example, during a recent project assembling complex sensor modules, maintaining a clean workspace allowed me to spot a misplaced resistor quickly, preventing a potentially costly mistake.

Q 10. What safety precautions do you follow during subassembly installation?

Safety is my top priority during subassembly installation. I adhere to a strict set of safety precautions, including:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves (depending on the materials handled), and anti-static wrist straps (for electronics). I always ensure my PPE is in good condition and properly worn.

- Proper tool usage: I use the correct tools for each task and ensure they are in good working order. This prevents accidents caused by faulty tools.

- Ergonomics: I maintain a good posture and take regular breaks to prevent strain and fatigue. I use appropriate workstations and support systems for optimal comfort and safety.

- ESD precautions: I follow strict ESD procedures, including using anti-static mats, wrist straps, and handling components appropriately.

- Hazardous materials handling: If working with hazardous materials (e.g., chemicals, solvents), I wear appropriate PPE and follow all safety data sheet (SDS) guidelines.

- Emergency procedures: I’m familiar with the emergency procedures in my workplace and know how to respond to incidents like fires, chemical spills, or injuries.

Following these safety precautions minimizes risks and ensures a safe working environment. For instance, using safety glasses prevented an eye injury when a small metal fragment flew off during drilling in a recent project.

Q 11. Describe your experience working with jigs, fixtures, and other assembly aids.

Jigs, fixtures, and other assembly aids are indispensable tools that significantly enhance efficiency and accuracy in subassembly installation. Jigs are tools that guide the assembly process, ensuring consistent placement and alignment of components. Fixtures hold the work piece securely during assembly. Think of them as carefully designed guides and clamps that help to achieve perfect results repeatedly.

My experience includes working with a wide range of jigs and fixtures, from simple hand-held guides for small components to complex automated systems used in high-volume production. I’m proficient in using various types of clamps, holding devices, and alignment tools to ensure precise component placement and secure fastening. I can also adapt or modify existing jigs and fixtures, or even design new ones, to meet the specific requirements of a given assembly task. For example, I once designed a simple jig to aid in the consistent alignment of small LED components during circuit board assembly, which significantly reduced assembly time and improved yield.

I’m comfortable using both manual and automated assembly equipment and can troubleshoot issues that arise during the use of these aids. Understanding their proper use and maintenance is critical to ensuring the accuracy and quality of my work.

Q 12. How do you prioritize tasks and manage your time effectively during assembly?

Effective task prioritization and time management are essential skills in subassembly installation, especially when handling multiple projects with tight deadlines. My approach combines planning, organization, and efficient execution.

- Task breakdown: I begin by breaking down complex tasks into smaller, more manageable sub-tasks. This makes the overall project less daunting and allows for better progress tracking.

- Prioritization: I prioritize tasks based on urgency, dependencies, and impact on the overall project. This ensures that critical tasks are addressed first.

- Time estimation: I realistically estimate the time required for each sub-task, factoring in potential delays. This helps me create a realistic schedule and manage my time effectively.

- Scheduling: I use scheduling tools (digital calendar, to-do list) to track progress and ensure I stay on schedule. This helps avoid falling behind on deadlines.

- Flexibility: I’m flexible and adapt to unexpected changes or delays. This ensures that the overall project timeline isn’t significantly impacted by minor setbacks.

For example, during a recent project involving multiple subassemblies, I used a Gantt chart to visualize task dependencies and deadlines, allowing me to effectively allocate time and resources and ensuring timely completion of the entire assembly.

Q 13. What experience do you have with different soldering techniques?

My soldering experience encompasses various techniques, including through-hole soldering, surface mount soldering (SMT), and specialized soldering for high-reliability applications. Through-hole soldering involves joining components with leads that pass through holes in a printed circuit board (PCB). SMT involves soldering components directly onto the surface of a PCB. These techniques demand precision and attention to detail to avoid damage to components and ensure reliable connections.

I’m proficient in using different types of soldering irons, including those with adjustable temperature control, and various solder types (e.g., lead-free, leaded). I understand the importance of proper solder joint formation and can identify and correct defects. Furthermore, I have experience with specialized techniques such as reflow soldering for SMT components, often used in automated assembly lines. I have a strong understanding of how to prevent issues such as cold solder joints or bridging.

My experience also includes working with specialized soldering techniques for applications demanding high reliability, including ultrasonic soldering, and various specialized fluxes.

Q 14. Explain your understanding of ESD (Electrostatic Discharge) precautions.

Electrostatic discharge (ESD) is a sudden flow of electricity between two objects with different electrical potentials. In electronics assembly, even a small ESD event can damage sensitive components, leading to malfunctions or complete failure. Understanding and implementing ESD precautions is crucial for preventing such damage.

My ESD awareness includes understanding the principles of ESD generation and how it can affect electronic components. I consistently use anti-static mats, wrist straps connected to a grounded point, and anti-static bags and containers for storing and transporting sensitive components. I also follow proper handling procedures, minimizing physical contact with sensitive components and avoiding sudden movements that can generate static electricity. I ensure all my work surfaces are properly grounded and regularly inspect my ESD equipment for proper function.

For example, during a recent project involving high-end microprocessors, my adherence to strict ESD precautions ensured no component damage occurred, contributing significantly to the successful completion of the assembly without any failures caused by static electricity.

Q 15. How familiar are you with various types of connectors and their applications?

My familiarity with connectors extends across a wide range of types, each suited for specific applications. Think of connectors as the crucial handshake points in any electronic system, ensuring reliable signal and power transmission. I’m proficient with various connector families, including:

- Crimp connectors: These are widely used for wire-to-wire or wire-to-board connections, offering cost-effectiveness and versatility. I’ve extensively used them in automotive harnessing, ensuring proper crimping force for reliable connections to prevent signal loss or short circuits.

- Solder connectors: Often preferred for higher current applications or when superior durability is needed, solder connectors offer excellent conductivity. I have experience with surface mount technology (SMT) connectors often found in smaller consumer electronics.

- Screw-type connectors: Ideal for applications requiring frequent disconnections or in environments where vibration is a concern, providing a secure and reliable connection. I’ve used these extensively in industrial control systems.

- Modular connectors: Offering standardized interfaces and ease of assembly, these are prevalent in data communications and networking. My experience includes working with RJ45 connectors (Ethernet) and USB connectors.

- Specialized connectors: This category includes D-Subminiature (D-sub) connectors for serial communication, circular connectors for harsh environments (like underwater applications), and fiber optic connectors for high-bandwidth data transmission. Each application demands a careful selection of the appropriate connector type based on the needs of the circuit, environmental factors, and cost considerations.

Choosing the right connector isn’t just about the type; it’s also about factors like the wire gauge, environmental sealing requirements (IP ratings), and the connector’s current and voltage ratings. Making the wrong choice can lead to system failures and even safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with cable harnessing and routing.

Cable harnessing and routing is a crucial part of my skillset, demanding precision and an understanding of both electrical and mechanical principles. Think of it as the circulatory system of an electronic device – efficiently delivering power and signals to various components. My experience involves:

- Harness design and fabrication: I’m proficient in reading and interpreting wiring diagrams to create efficient and organized cable harnesses. This includes determining optimal cable routing to minimize interference and ensure proper signal integrity, managing slack, and using appropriate cable ties and clamps.

- Component labeling and identification: Accurate and clear labeling is essential for troubleshooting and maintenance. I meticulously label all wires and connectors according to industry best practices.

- Strain relief: Proper strain relief techniques are crucial to prevent damage to connections from movement or vibration. This involves the use of proper strain relief boots and clamps.

- Routing in confined spaces: Many assemblies present challenges with limited space. I’m skilled at navigating these constraints, utilizing space efficiently to create a robust and functional harness.

For example, in one project involving a complex robotics system, I designed and assembled a cable harness with over 100 individual wires, carefully routing them to minimize electromagnetic interference (EMI) and ensuring the longevity and reliability of the system. This involved understanding the specific requirements of each component and its sensitivity to signal noise.

Q 17. What is your experience with automated assembly equipment?

My experience with automated assembly equipment encompasses a range of technologies designed to enhance efficiency and precision. This includes:

- Automated wire harnessing machines: These machines can automate wire cutting, stripping, crimping, and termination processes, significantly increasing production speed and consistency compared to manual assembly. I’m familiar with programming and operating such machines, ensuring they are properly calibrated and maintained.

- Pick-and-place machines: Used for placing small components onto printed circuit boards (PCBs) with high accuracy, these are essential for surface mount technology (SMT) assembly. I have experience in setting up and troubleshooting these machines.

- Robotics systems: Advanced robotic systems are capable of performing complex assembly tasks, including the integration of subassemblies into larger systems. I’ve worked alongside robotic systems, understanding their capabilities and limitations.

Utilizing these machines requires a deep understanding of their programming, safety protocols, and maintenance requirements. For instance, I’ve trouble-shot issues with a pick-and-place machine by analyzing error codes and adjusting its parameters to ensure consistent component placement and prevent defects.

Q 18. How do you ensure compliance with industry standards and regulations?

Compliance with industry standards and regulations is paramount in subassembly installation. My approach involves a multi-faceted strategy:

- Understanding relevant standards: I’m familiar with standards such as IPC (Institute for Printed Circuits) standards for electronic assembly, as well as industry-specific regulations for various applications (e.g., automotive, aerospace). This includes understanding standards related to safety, environmental protection, and quality control.

- Following documented procedures: Adherence to established work instructions, quality control procedures, and safety protocols is crucial. I meticulously follow these guidelines throughout each step of the assembly process.

- Documentation and traceability: Maintaining detailed records of all materials used, assembly steps performed, and tests conducted is crucial for traceability and compliance audits. This is essential for demonstrating compliance with regulatory requirements.

- Continuous improvement: Staying current with changes in standards and best practices is important. I participate in training and professional development to maintain my knowledge base.

For example, in an automotive project, I ensured compliance with ISO TS 16949 standards, focusing on process control, defect prevention, and continuous improvement to meet the high standards of the automotive industry.

Q 19. Describe your experience with testing and inspection procedures for subassemblies.

Testing and inspection procedures are critical to ensuring the quality and reliability of subassemblies. My experience includes:

- Visual inspection: Thorough visual inspection for any defects, misalignments, or damage to components is the first step. I use magnifying aids where necessary for thorough examination.

- Functional testing: This involves verifying that the subassembly functions correctly according to its specifications. This can include testing electrical continuity, signal integrity, and operational performance.

- Mechanical testing: Where applicable, mechanical testing (e.g., stress testing, vibration testing) is performed to ensure the subassembly can withstand expected operating conditions.

- Environmental testing: Depending on the application, environmental tests (e.g., temperature cycling, humidity testing) might be necessary to verify robustness under extreme conditions.

- Documentation of test results: All test results are meticulously documented and analyzed to identify any trends or areas for improvement.

In one instance, I identified a recurring issue with a particular connector failing under vibration testing. By systematically analyzing the test results and reviewing the assembly process, I identified a flaw in the strain relief technique, which was subsequently corrected, improving the reliability of the final product.

Q 20. How do you document your work and track progress during assembly?

Documentation and progress tracking are essential for maintaining a high level of accuracy and accountability. My approach includes:

- Work orders and routing sheets: These documents outline the steps involved in the assembly process, ensuring consistent execution.

- Bill of materials (BOM): A detailed BOM ensures that all necessary components are available and that the correct versions are used.

- Inspection checklists: These checklists guide the inspection process, ensuring that all critical points are checked.

- Digital tracking systems: Many companies utilize digital tracking systems, such as Enterprise Resource Planning (ERP) software, to monitor progress and manage inventory. I’m proficient in using these systems for tracking materials, time spent on tasks, and overall project progress.

I always maintain clear and concise documentation. This allows for seamless handover of projects, facilitates troubleshooting if problems arise, and provides a valuable record for future reference and continuous improvement.

Q 21. What is your experience with working from schematics and diagrams?

Working from schematics and diagrams is fundamental to my work. My experience includes:

- Reading and interpreting schematics: I can confidently interpret various types of schematics, including electrical schematics, mechanical drawings, and wiring diagrams. This includes understanding component symbology, reference designators, and connection points.

- Identifying components and their functions: I can identify components and trace signals through the schematics to understand their role within the overall system.

- Using schematics to troubleshoot: When problems arise, I use schematics to systematically trace the signal path and pinpoint the source of the issue.

- Working with different CAD software: I’m proficient in using various CAD software packages to review and interpret electronic design automation (EDA) files.

For example, I recently used schematics to trace a faulty signal in a complex circuit board. By carefully following the signal path indicated in the schematic, I quickly identified a poorly soldered connection that was causing the malfunction. This demonstrates the critical importance of accurate schematics and the ability to interpret them effectively.

Q 22. Describe a situation where you had to resolve a complex subassembly installation problem.

During a critical project involving the installation of a complex sensor subassembly for a high-precision medical device, we encountered a recurring issue: inconsistent sensor readings. Initial troubleshooting pointed to faulty sensors, leading to several costly replacements. However, the problem persisted. After meticulously reviewing the assembly process and analyzing the sensor data, I discovered that minute variations in the torque applied during the final tightening stage of the subassembly were causing subtle misalignments within the sensor housing. This led to pressure imbalances affecting the sensor’s accuracy. To solve this, I implemented a standardized torque wrench calibration protocol across all assembly stations and incorporated a visual alignment check into the procedure. This resulted in a significant reduction in defective units and a substantial improvement in sensor accuracy, saving the company significant time and resources.

Q 23. What is your understanding of different types of adhesives and their applications?

Adhesives are crucial for subassembly installation, offering strong bonds and precise positioning. The choice depends heavily on the materials being joined and the environmental conditions. For instance:

- Cyanoacrylate (Super Glue): Excellent for quick bonding of small parts with high surface tension, but vulnerable to temperature and chemical degradation. I’ve used it extensively in the assembly of small electronic components.

- Epoxy Resins: Offer robust, durable bonds and good chemical resistance, ideal for high-stress applications. In a past project, epoxy was key to securing a large heat sink to a power module.

- Anaerobic Adhesives: Cure in the absence of oxygen, creating a tight seal between metal parts. These are invaluable for preventing leaks in hydraulic or pneumatic subassemblies.

- Silicone Sealants: Offer flexibility and excellent resistance to temperature fluctuations and vibration, perfect for applications requiring shock absorption.

Proper surface preparation is critical for any adhesive to perform optimally. This often involves cleaning and degreasing the surfaces prior to application, to ensure a strong bond.

Q 24. Explain your experience with using measuring instruments like calipers and micrometers.

Calipers and micrometers are indispensable tools in my work. I use calipers daily for quick, precise measurements of dimensions like part thickness and width, particularly when verifying component tolerances during the assembly process. For instance, when checking the gap between a bearing and its housing, calipers provide the necessary accuracy. Micrometers, on the other hand, offer even greater precision, often down to thousandths of an inch, crucial for verifying critical dimensions or verifying the accuracy of machined parts. I rely on them when inspecting parts that require extremely tight tolerances before installation. Regular calibration of these instruments is essential to maintain accuracy and prevent errors during assembly.

Q 25. How do you identify and address potential assembly errors?

Identifying assembly errors is a proactive process beginning with a thorough understanding of the assembly drawings and specifications. I use a multi-pronged approach:

- Visual Inspection: A careful visual examination at each stage of the process often reveals obvious defects like misaligned parts or missing components.

- Dimensional Verification: Using measuring instruments like calipers and micrometers, I verify critical dimensions to ensure components meet specifications and proper tolerances are maintained.

- Functional Testing: Once the subassembly is complete, I perform functional tests to ensure it operates as designed. This could involve checking electrical connections, measuring output power, or verifying mechanical movement.

- Statistical Process Control (SPC): For high-volume assembly, implementing SPC helps to monitor variations in the process and detect potential problems before they lead to significant defects. This involves tracking key metrics like torque values, dimensions, and defect rates.

Addressing errors involves documenting the issue, investigating the root cause, and implementing corrective actions to prevent recurrence. This might involve refining the assembly process, adjusting tolerances, or re-training personnel.

Q 26. Describe your experience working under pressure and meeting deadlines.

I thrive under pressure and have a proven track record of meeting tight deadlines. During the launch of a new product line, we were under immense pressure to meet the market demand. This involved working extended hours, coordinating with multiple teams, and managing a fast-paced assembly line. Through effective planning, delegation, and clear communication, we successfully met all deadlines without compromising on quality. The key was prioritizing tasks, effectively managing resources, and proactively addressing any potential delays. My experience has taught me that a calm and organized approach under pressure is more effective than frantic reactivity.

Q 27. How familiar are you with different types of manufacturing processes?

My familiarity with manufacturing processes extends across several areas:

- CNC Machining: I understand the principles of CNC machining and its role in creating precise components for subassemblies.

- Injection Molding: I’m knowledgeable about injection molding, a process vital for producing many of the plastic components used in subassemblies.

- Sheet Metal Fabrication: I’m aware of different sheet metal processes used in creating housings and other structural components.

- 3D Printing (Additive Manufacturing): I understand the capabilities and limitations of additive manufacturing for creating prototypes and customized parts.

This breadth of knowledge allows me to effectively collaborate with various manufacturing teams, ensuring that the design of subassemblies is optimized for efficient and cost-effective production.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of $[Lower Bound] to $[Upper Bound] annually, depending on the comprehensive benefits package and the specific responsibilities involved.

Key Topics to Learn for Subassembly Installation Interview

- Understanding Subassembly Drawings and Specifications: Interpreting technical drawings, understanding tolerances, and identifying critical dimensions.

- Tools and Equipment Proficiency: Demonstrating familiarity with hand tools, power tools, and specialized equipment commonly used in subassembly installation.

- Safe Work Practices and Procedures: Highlighting knowledge of relevant safety regulations, risk assessments, and proper use of Personal Protective Equipment (PPE).

- Assembly Techniques and Methodologies: Explaining different assembly methods (e.g., fastening, joining, alignment), and selecting the most appropriate technique for specific situations.

- Quality Control and Inspection: Describing procedures for inspecting subassemblies for defects, ensuring adherence to quality standards, and documenting findings.

- Troubleshooting and Problem-Solving: Illustrating your ability to identify and resolve common assembly problems, adapting to unexpected challenges, and implementing corrective actions.

- Working with Different Materials: Demonstrating experience working with various materials (e.g., metals, plastics, composites) and understanding their properties and limitations.

- Lean Manufacturing Principles (if applicable): Showcasing an understanding of efficiency, waste reduction, and continuous improvement methodologies.

- Teamwork and Communication: Emphasizing your ability to collaborate effectively with colleagues, communicate technical information clearly, and contribute to a positive team environment.

Next Steps

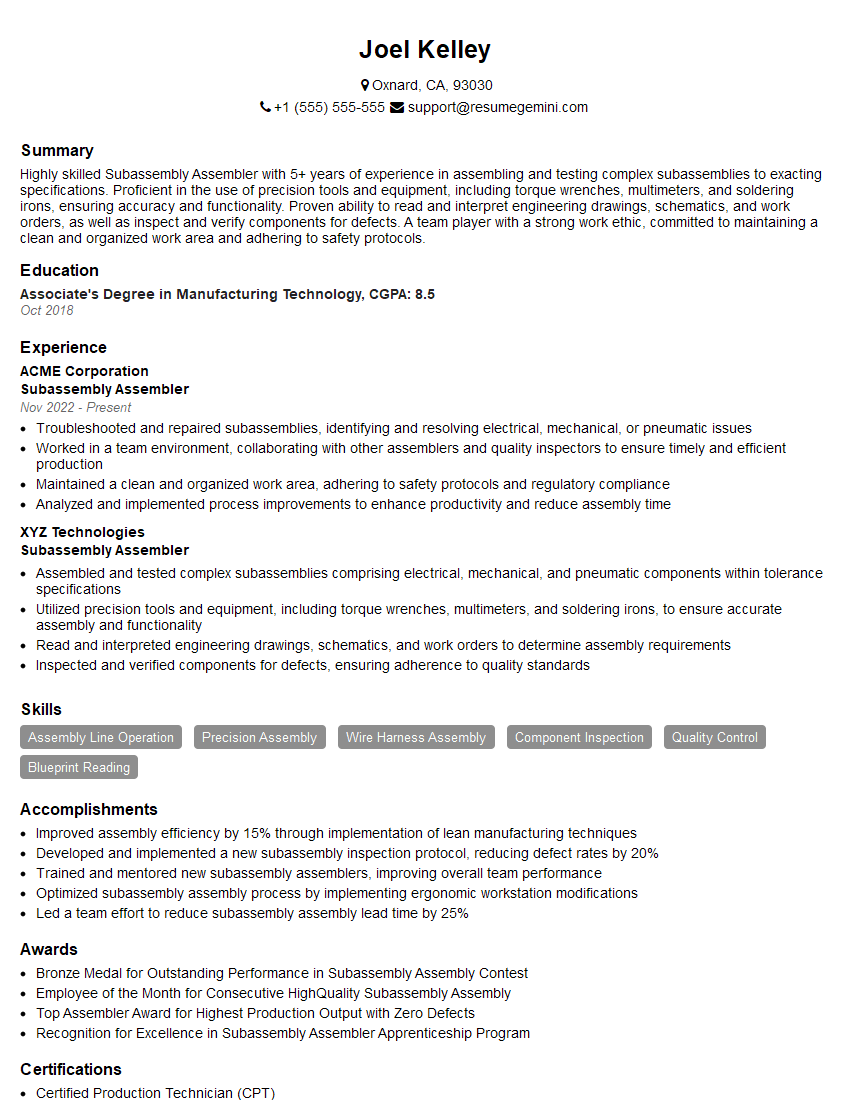

Mastering subassembly installation opens doors to exciting career opportunities in manufacturing, aerospace, automotive, and many other high-growth industries. A strong foundation in this area demonstrates valuable technical skills and attention to detail, making you a highly sought-after candidate. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. Examples of resumes tailored to subassembly installation are provided to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good