Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Subsurface Irrigation Management interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Subsurface Irrigation Management Interview

Q 1. Explain the principles of subsurface irrigation.

Subsurface irrigation (SSI) delivers water directly to the root zone of plants, below the soil surface, through a network of buried pipes and emitters. Unlike surface irrigation methods, it minimizes water loss due to evaporation and runoff, improving water use efficiency. The principles revolve around controlled water delivery, minimizing surface wetting, and optimizing water infiltration into the soil profile to promote root development and nutrient uptake.

Imagine it like a sophisticated drip system for your garden, but underground. Instead of watering the surface, which leads to evaporation and potential weed growth, SSI delivers water directly where it’s needed most: to the roots.

Q 2. What are the advantages and disadvantages of subsurface irrigation compared to surface irrigation?

Subsurface irrigation offers several advantages over surface irrigation methods:

- Higher water use efficiency: Reduced evaporation and runoff significantly conserve water.

- Improved soil aeration: The soil surface remains dry, improving aeration and reducing the risk of soil compaction.

- Reduced weed growth: The surface remains dry, suppressing weed germination and growth.

- Better control of salinity: Less surface evaporation minimizes salt accumulation at the soil surface.

- Suitable for various soil types: Adaptable to many soil conditions, though drainage is crucial.

However, SSI also has some disadvantages:

- Higher initial cost: Installation is more expensive than surface methods.

- Potential for emitter clogging: Requires regular maintenance to prevent clogging from sediment or other debris.

- Difficult to inspect and repair: Locating and repairing leaks or clogged emitters can be challenging.

- Not suitable for all crops: Some crops with shallow root systems might not benefit as much.

- Requires skilled installation: Proper design and installation are crucial for optimal performance.

Q 3. Describe different types of subsurface irrigation systems (e.g., drip, porous pipe).

Various subsurface irrigation systems exist, each with its own characteristics and suitability:

- Drip Irrigation (Subsurface): Uses small emitters that deliver water slowly and directly to the root zone. This is highly efficient but can be prone to clogging if the water isn’t filtered properly.

- Porous Pipe Irrigation: Employs perforated or porous pipes that release water uniformly along their length. It’s simpler to install than drip but may have less precise water delivery.

- Tile Drainage Systems (Modified for Irrigation): These are traditionally used for drainage, but can be adapted for subsurface irrigation by reversing the flow and carefully managing water pressure.

- Subsurface Trickle Irrigation: Similar to drip irrigation, but often uses larger emitters for a higher flow rate.

The choice of system depends on factors like soil type, crop requirements, water availability, and budget.

Q 4. How do you determine the appropriate spacing and depth for subsurface irrigation emitters?

Determining the appropriate spacing and depth of subsurface emitters involves several factors:

- Crop Root System: Emitter spacing should match the lateral spread of the root system to ensure uniform moisture. Shallow-rooted crops need closer spacing.

- Soil Type: Soil texture and infiltration rate greatly influence water distribution. Sandy soils require closer spacing and may need shallower placement than clay soils.

- Water Application Rate: Emitter flow rates and spacing must be balanced to avoid over-saturation or localized waterlogging.

- Water Quality: High sediment levels may require wider spacing or more frequent flushing.

Soil studies and hydrological modeling can assist in determining optimal spacing and depth. A common approach is to conduct field trials with different emitter configurations to observe the effectiveness and adjust accordingly.

Q 5. What factors influence the selection of subsurface irrigation equipment?

Several factors influence the choice of subsurface irrigation equipment:

- Cost: Initial investment, operation, and maintenance costs should be considered.

- Water Source and Quality: The system must be compatible with the available water source and handle potential issues like sediment or salinity.

- Soil Conditions: Soil type, texture, and drainage influence emitter selection and layout.

- Climate: Evapotranspiration rates and rainfall patterns affect irrigation scheduling.

- Crop Requirements: Water needs, root depth, and planting density must be taken into account.

- Land Topography: Slopes and terrain affect system design and installation.

- Automation Potential: Sensors and automated control systems can improve efficiency and reduce labor.

A detailed feasibility study that considers all these factors is vital before making equipment selections.

Q 6. How do you design a subsurface irrigation system for a specific crop and soil type?

Designing an SSI system starts with a thorough site assessment. This involves:

- Soil analysis: Determine texture, structure, infiltration rate, and water holding capacity.

- Crop requirements: Assess water needs, root depth, and growth stages.

- Hydrological modeling: Simulate water movement in the soil to predict water distribution and optimize emitter placement.

- Emitter selection: Choose emitters appropriate for soil type, water quality, and water application rate.

- Layout design: Determine emitter spacing, depth, and pipe layout based on modeling results and site constraints.

- System components: Select pumps, filters, pressure regulators, and other necessary equipment.

- Installation: Ensure proper installation to avoid leaks and maintain uniform water distribution.

- Monitoring and management: Implement a system for monitoring soil moisture, water use, and system performance.

For example, a sandy soil would require more frequent, lower-volume irrigation with closely spaced emitters compared to a clay soil that retains water longer. A deep-rooted crop would necessitate deeper emitter placement.

Q 7. Explain the importance of soil drainage in subsurface irrigation.

Adequate soil drainage is paramount for successful subsurface irrigation. Poor drainage can lead to:

- Waterlogging: Excess water saturates the soil, reducing oxygen availability to roots and potentially harming plant growth.

- Salinity buildup: Poor drainage allows salts to accumulate in the root zone, harming plants.

- Reduced nutrient uptake: Waterlogged soils limit root access to nutrients.

- Increased disease incidence: Waterlogged conditions favor the development of root diseases.

Before implementing SSI, assess soil drainage characteristics. If drainage is poor, consider installing drainage systems in conjunction with the irrigation system or selecting alternative irrigation methods. Maintaining adequate soil drainage is critical to optimizing subsurface irrigation’s effectiveness and avoiding potential problems.

Q 8. Describe methods for monitoring soil moisture in subsurface irrigation systems.

Monitoring soil moisture is crucial for efficient subsurface irrigation. We need to ensure the water reaches the roots without over-saturating the soil. Several methods exist, each with its strengths and weaknesses.

- Soil moisture sensors: These are direct methods, providing real-time data. Different types exist: tensiometers measure soil water tension (how tightly the water is held by the soil), capacitance probes measure the dielectric constant of the soil (related to water content), and neutron probes use radiation to gauge soil moisture (though less common now due to safety concerns). We select the sensor based on soil type and irrigation goals. For instance, a sandy soil requires a different sensor setup than a clay soil.

- Time Domain Reflectometry (TDR): This method uses electromagnetic pulses to measure the soil’s dielectric constant, accurately reflecting soil moisture content. TDR systems are relatively robust and provide good spatial resolution.

- Water content reflectometers: These hand-held devices can quickly assess soil moisture in specific areas. Although they are less accurate than the previously mentioned methods, they are useful for quick evaluations.

- Indirect methods: These involve using plant indicators like leaf water potential or soil water balance models based on rainfall, evapotranspiration, and irrigation data. This requires considerable experience and understanding of the local climate.

Choosing the right method depends on budget, desired precision, and the scale of the irrigation system. A large-scale commercial operation might use a network of sensors and data logging systems, whereas a small-scale home irrigation project might use a simpler, hand-held sensor.

Q 9. How do you manage water pressure and flow in subsurface irrigation systems?

Managing water pressure and flow in subsurface irrigation is vital for uniform water distribution and efficient irrigation. Improper management leads to uneven watering, waterlogging, or insufficient moisture.

- Pressure-regulating valves: These are essential for maintaining consistent water pressure throughout the system, especially in undulating terrain or systems with varying pipe lengths. They prevent high pressure in some areas that could damage the pipes or lead to preferential flow.

- Flow meters: These devices monitor the water flow rate at different points in the system. This helps to identify blockages, leaks, or sections with low flow, improving distribution uniformity.

- Proper pipe sizing: Selecting the right pipe diameter is critical. Using excessively small pipes will increase pressure and can lead to clogging; using pipes that are too large is inefficient and wasteful.

- Emitter selection: Emitters (e.g., porous pipes, drip emitters) are chosen based on the soil type and desired flow rates. They’re designed to release water evenly, avoiding localized saturation.

- Control systems: Automated systems employing sensors and controllers optimize water pressure and flow according to soil moisture levels and weather conditions, ensuring efficiency and minimizing waste.

Imagine a system where the pressure is too high near the water source; this would lead to saturation in that area and insufficient irrigation further down the line. Pressure regulators and flow meters are crucial to avoid this scenario.

Q 10. What are common problems associated with subsurface irrigation, and how do you troubleshoot them?

Subsurface irrigation, while efficient, isn’t without its challenges. Common problems include clogging, uneven water distribution, and leaks.

- Clogging: This is frequently caused by fine sediments in the irrigation water. We address this by pre-filtering the water.

- Uneven water distribution: This may result from variations in soil properties (e.g., compaction, root density), improper emitter spacing, or pressure imbalances. We troubleshoot this by carefully mapping the system, checking pressure and flow rates, and potentially adjusting emitter spacing or installing pressure regulators.

- Leaks: Leaks can lead to substantial water loss. Regular system inspections and pressure tests help in early leak detection. We locate leaks by observing water puddles, significant pressure drops, or using specialized leak detection equipment.

- Corrosion: Depending on the soil conditions and water quality, pipes and emitters can corrode. Choosing corrosion-resistant materials can prevent this.

Troubleshooting involves systematically checking each component of the system. Starting with a visual inspection, followed by pressure and flow rate measurements, can often quickly pinpoint the issue. In some cases, specialized equipment or soil analysis may be necessary.

Q 11. Describe methods for preventing clogging in subsurface irrigation systems.

Preventing clogging is crucial for the longevity and efficiency of subsurface irrigation. Several strategies can minimize clogging:

- Water filtration: Installing filters at the water source removes sediments and other particles that can clog emitters. The filter type (e.g., sand filter, screen filter) should be selected based on the water quality.

- Proper emitter selection: Selecting self-cleaning emitters can help reduce clogging. Emitters with larger openings are less prone to clogging, though they may have slightly higher flow rates.

- Regular flushing: Periodically flushing the system with clean water can remove accumulated sediments. We can use increased pressure for a short duration to clear out any blockages, but this should be done carefully to avoid damaging the system.

- Water quality monitoring: Regularly monitoring the water quality helps in identifying potential clogging agents. This allows for proactive measures to mitigate clogging.

- Proper system design: Careful system design, which includes consideration of soil types, water quality, and potential clogging agents, is a key preventative measure.

Think of it like keeping your arteries clear; regular maintenance prevents blockages. Similarly, proactive measures in subsurface irrigation prevent costly repairs and water wastage.

Q 12. How do you maintain and repair subsurface irrigation equipment?

Regular maintenance and timely repairs are crucial for optimal performance and longevity of subsurface irrigation systems.

- Regular inspections: Conducting routine visual inspections to detect leaks, damaged pipes, or clogged emitters is a primary maintenance task.

- Pressure testing: Periodic pressure testing helps detect leaks and ensure proper pressure distribution.

- Cleaning and flushing: Regular cleaning and flushing of the system remove accumulated sediments and prevent clogging.

- Component replacement: Damaged or worn-out components, such as emitters, valves, or pipes, should be promptly replaced.

- Repairing leaks: Leaks should be addressed immediately to avoid water loss and potential damage to surrounding areas. This may involve patching or replacing sections of the piping.

Maintaining a logbook documenting maintenance activities and repairs can help in tracking system performance and scheduling future maintenance tasks. This is similar to maintaining a car; regular servicing prevents major issues and ensures its longevity.

Q 13. What are the energy efficiency considerations for subsurface irrigation?

Energy efficiency in subsurface irrigation focuses on minimizing energy consumption during water pumping and distribution.

- Efficient pumps: Selecting energy-efficient pumps with high-efficiency motors reduces electricity consumption. This contributes significantly to the overall sustainability and cost-effectiveness of the irrigation system.

- Optimized pressure management: Efficient pressure management reduces the work required by the pump, resulting in energy savings. This is achieved using pressure-regulating valves and proper pipe sizing.

- Automated control systems: Using automated control systems with sensors and controllers allows for precise water application based on soil moisture levels, minimizing unnecessary pumping.

- Renewable energy sources: Integrating renewable energy sources, such as solar panels, for powering the irrigation system, reduces reliance on grid electricity and decreases the environmental impact.

- Minimizing friction losses: Using smooth-walled pipes and ensuring proper pipe alignment reduce friction losses, improving pump efficiency.

Incorporating these measures can significantly reduce the energy footprint of subsurface irrigation, making it a more sustainable agricultural practice. This aligns with broader sustainability goals and can result in lower operating costs.

Q 14. How do you calculate water application rates for subsurface irrigation?

Calculating water application rates for subsurface irrigation is critical for optimal irrigation management and efficient water use. The rate depends on several factors.

- Soil type: Different soil types have varying water holding capacities. Clay soils retain more water than sandy soils.

- Crop water requirements: The water needs of the crop vary throughout its growth stages, requiring adjustments in application rates.

- Climate conditions: Temperature, wind, and solar radiation influence evapotranspiration, affecting the water requirement.

- Emitter spacing and design: Emitter spacing and discharge rate directly affect the amount of water applied per unit area.

- Soil moisture sensors: Utilizing soil moisture data provides real-time information for adaptive irrigation management, optimizing water use and preventing over-irrigation.

The calculation often involves using formulas and models that consider these factors. A simplified approach might involve estimating the crop’s evapotranspiration rate and adjusting for soil characteristics and emitter discharge. However, sophisticated irrigation scheduling software considers these factors for more precise calculations, especially for larger projects. Often, initial calculations require field experimentation to calibrate the model accurately for the specific soil type and crop.

Q 15. How does subsurface irrigation impact soil salinity?

Subsurface irrigation (SSI) can significantly impact soil salinity, often reducing it. Unlike surface irrigation, where water evaporates from the soil surface, potentially leaving behind salts, SSI delivers water below the surface. This minimizes evaporation and reduces the upward movement of saline groundwater, preventing salt accumulation at the root zone. The controlled application of water through SSI allows for better management of water-salt balance. Imagine a sponge: surface irrigation is like pouring water on top—some evaporates, leaving behind any dissolved salts. SSI is like injecting water directly into the sponge—less evaporation, less salt build-up.

For instance, in arid and semi-arid regions where salinity is a major concern, SSI has proven effective in leaching salts from the root zone. This is achieved by applying a controlled amount of water beyond the plant’s water requirements to push salts downwards below the root zone. However, improper management of SSI, such as insufficient leaching, can exacerbate salinity issues by creating a concentrated layer of salts at a deeper level.

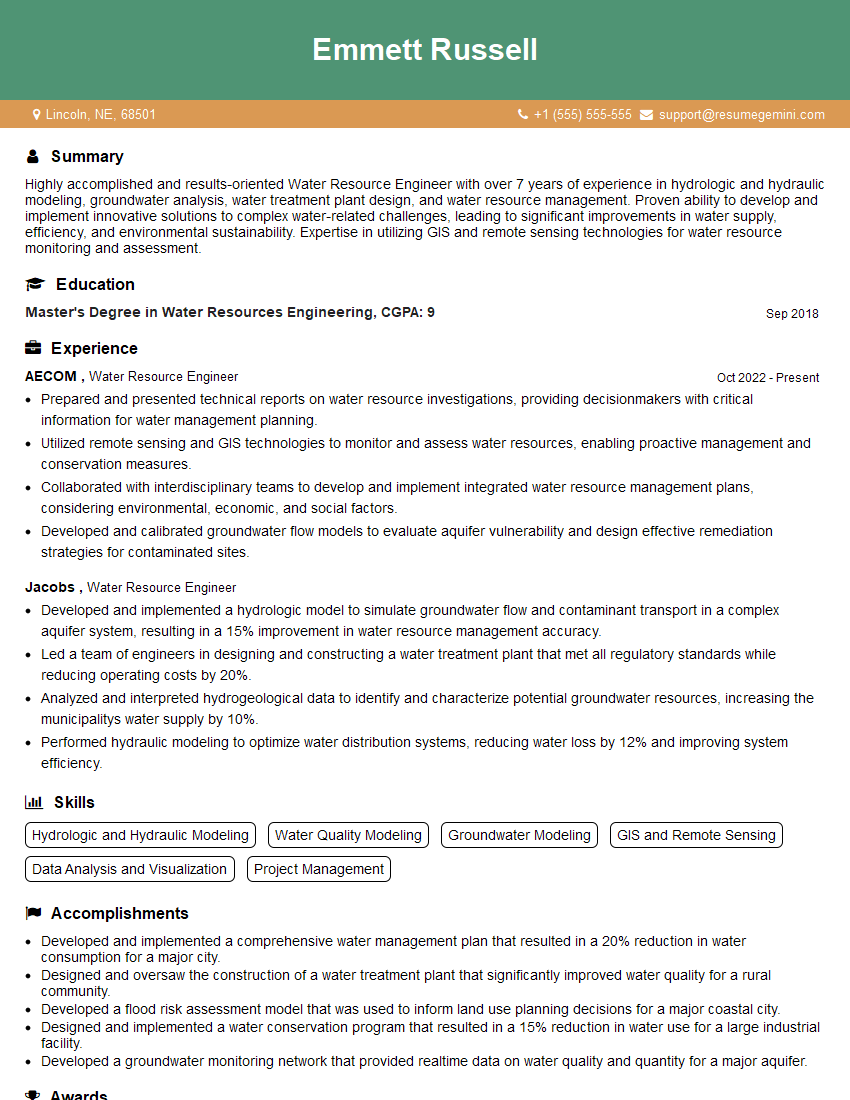

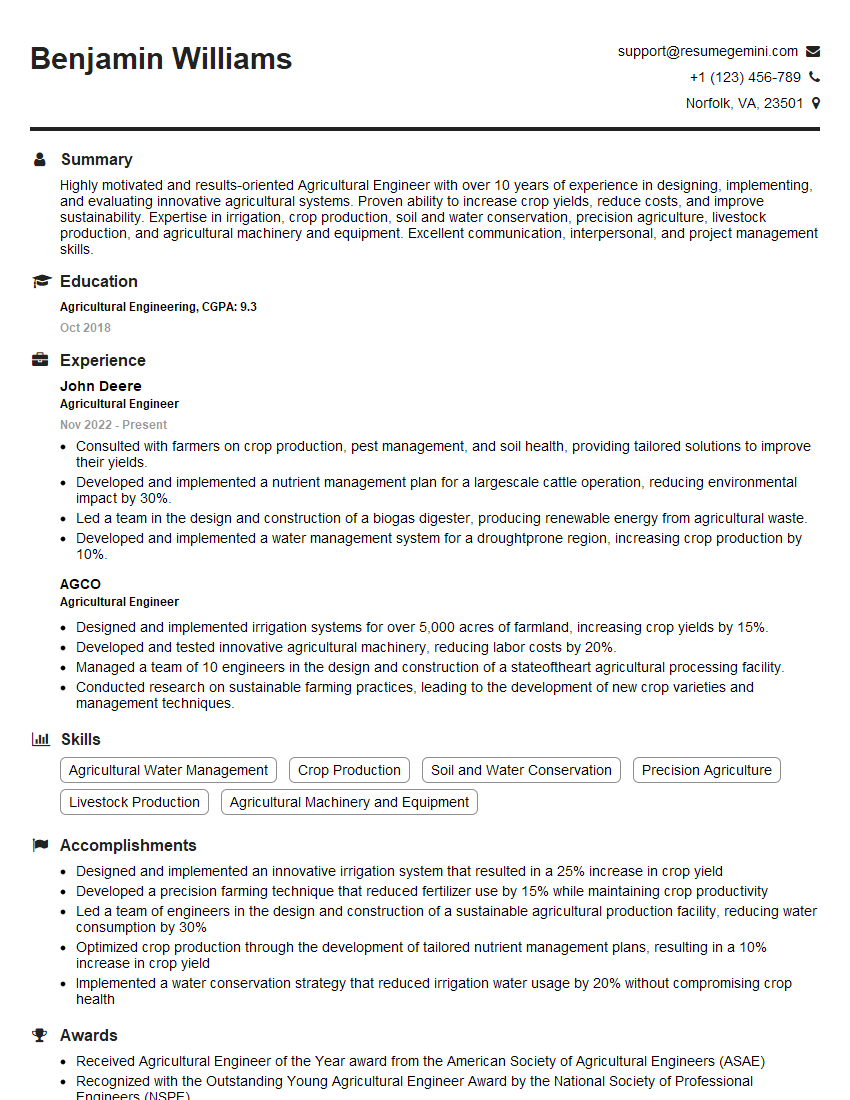

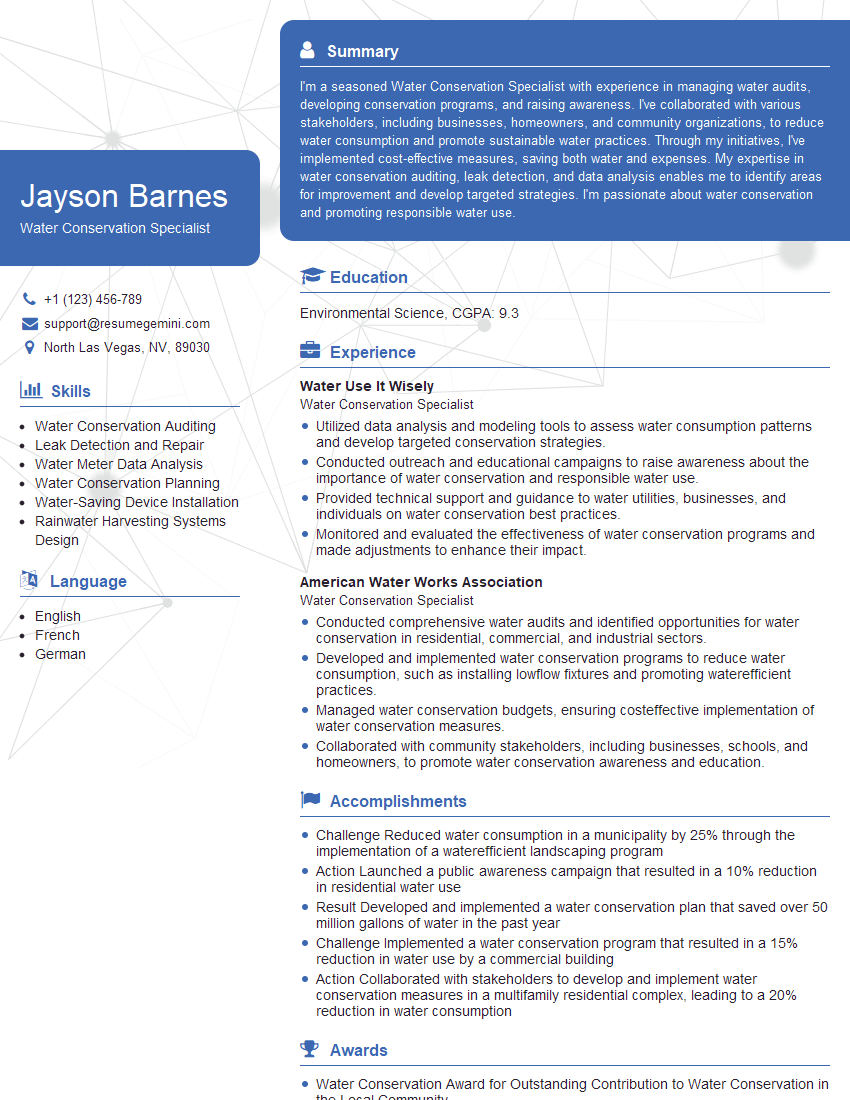

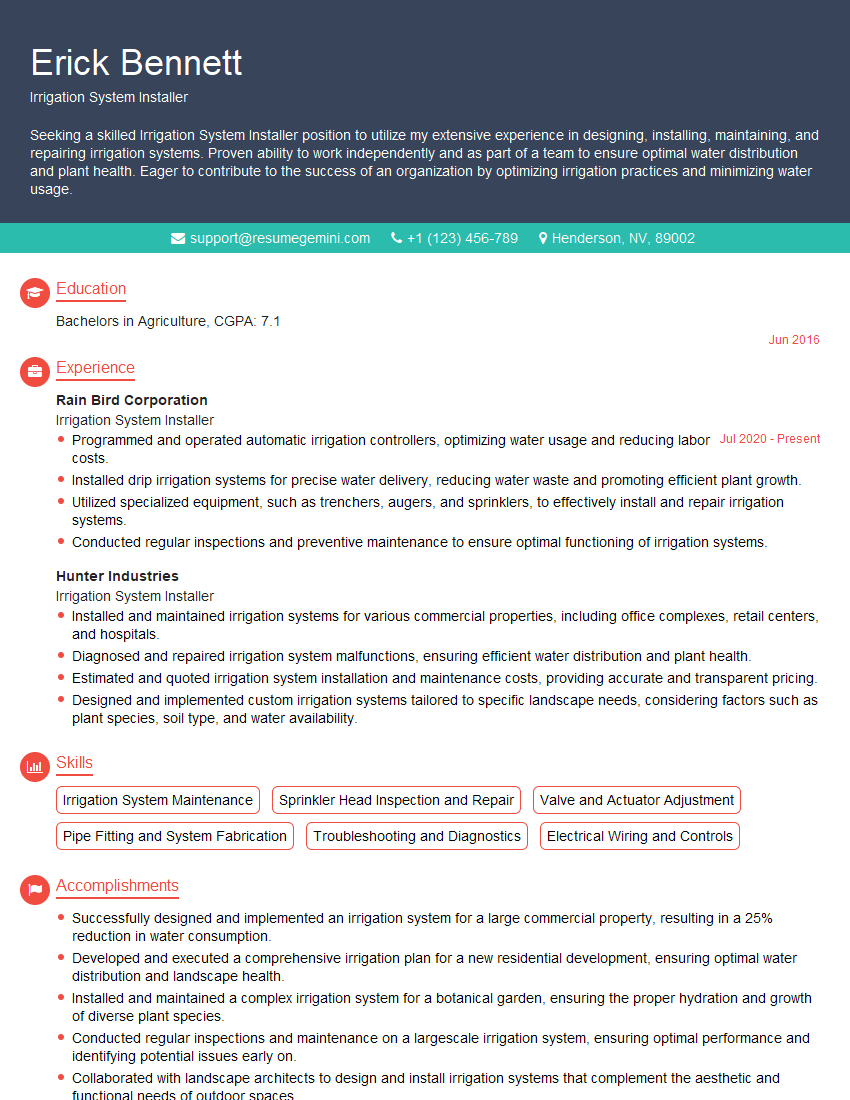

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of automation in subsurface irrigation management.

Automation plays a crucial role in optimizing subsurface irrigation management, improving efficiency, and saving resources. Automated systems allow for precise control of water application based on real-time data like soil moisture levels, weather forecasts, and crop evapotranspiration rates. This eliminates guesswork and minimizes water waste.

Sensors embedded in the soil monitor moisture content and transmit data to a central control unit. This unit then automatically adjusts the irrigation schedule and emitter flow rates, ensuring that the plants receive the exact amount of water they need, when they need it. Automated systems often incorporate weather stations, providing crucial information for scheduling irrigation, and data loggers to help fine-tune future irrigation strategies.

Consider a large orchard: manual management of hundreds of irrigation points would be incredibly time-consuming and prone to errors. An automated system allows for consistent, precise water delivery across the entire orchard, saving labor costs and improving yields.

Q 17. What are the environmental benefits of subsurface irrigation?

Subsurface irrigation offers several significant environmental benefits, primarily related to water conservation and reduced environmental impact. Because water is applied below the surface, evaporation and runoff losses are minimized, leading to substantial water savings compared to surface irrigation methods. Reduced evaporation also lowers the energy consumption associated with pumping and transporting water.

- Water conservation: Less water is lost to evaporation and runoff.

- Reduced weed growth: The targeted water application reduces the growth of weeds.

- Improved soil structure: Even watering avoids soil compaction.

- Lower greenhouse gas emissions: Less energy is used for pumping and transportation.

- Reduced nutrient runoff: Targeted watering can decrease nutrient leaching into nearby water bodies.

For example, in regions facing water scarcity, adopting SSI can significantly reduce water stress on both the environment and agricultural production. It can also help reduce the reliance on groundwater resources, protecting these vital aquifers.

Q 18. How do you assess the economic feasibility of a subsurface irrigation project?

Assessing the economic feasibility of a subsurface irrigation project requires a thorough cost-benefit analysis. This involves evaluating the initial investment costs against the potential long-term benefits and savings.

Initial costs include: design, engineering, equipment procurement (emitters, pipes, pumps, control systems), installation, and labor. Benefits should include: increased crop yields (due to improved water use efficiency), reduced water costs (due to lower water consumption), lower labor costs (due to automation), and reduced energy costs (due to lower pumping requirements). The analysis should also consider the lifespan of the system, potential maintenance costs, and potential increases in crop prices.

A crucial element is calculating the return on investment (ROI). This requires projecting future yields and comparing the net income generated by SSI against the initial investment. Discounted cash flow analysis is a common technique used to compare future benefits with the initial cost, accounting for the time value of money.

A simplified example would be comparing the cost of installing a subsurface system for a 10-hectare field versus the annual water savings and increased yield over the system’s 15-year lifespan.

Q 19. Describe the process of selecting and installing subsurface irrigation emitters.

Selecting and installing subsurface irrigation emitters is a crucial step that significantly influences the system’s performance. The process involves considering various factors, starting with the type of emitter best suited to the soil type and crop requirements.

Emitter Selection: Several types of subsurface emitters are available, including porous pipes, drip emitters, and subsurface drip irrigation (SDI) systems. The choice depends on factors like soil texture, drainage characteristics, and plant spacing. Porous pipes are suitable for coarse-textured soils, while SDI systems are preferred for finer soils to avoid clogging. Careful consideration should be given to emitter discharge rate (flow rate), spacing, and depth of installation to ensure uniform water distribution.

Installation Process: Installation begins with designing the layout of the irrigation system, considering topography, and soil characteristics. This involves determining the placement of the main pipelines, laterals, and emitters. The pipes are then laid out, typically at a depth that provides adequate water distribution while protecting the emitters from damage. Accurate placement of emitters is crucial for even water distribution. Finally, the system is tested for leaks and uniformity of water distribution, followed by backfilling and soil compaction around the pipes.

For instance, in sandy soil, porous pipes may be the ideal choice due to their higher discharge rate, whereas in clay soils, subsurface drip emitters with pressure compensating drippers might be necessary to ensure even distribution.

Q 20. What are the challenges of using subsurface irrigation in different soil textures?

Different soil textures present unique challenges for subsurface irrigation. Soil texture significantly impacts water movement, influencing emitter selection and system design.

- Sandy Soils: High infiltration rates require emitters with higher discharge rates to prevent water from moving too quickly. Frequent, shorter irrigation cycles are often necessary. The risk of water bypassing the root zone is higher in sandy soils.

- Clay Soils: Low infiltration and high water retention can lead to emitter clogging and uneven water distribution. Emitters with lower discharge rates are often required. Proper emitter spacing is crucial to avoid localized saturation and potential root damage.

- Loamy Soils: Generally considered ideal, loamy soils provide a good balance between infiltration and water retention. They require less careful emitter selection and spacing than sandy or clay soils.

Careful site-specific considerations must be made during design and installation. In clay soils, for instance, using pressure-compensating drippers ensures uniform distribution even with varying pressures and clogging risks need to be mitigated by employing filters and regular system maintenance.

Q 21. How do you manage water quality issues in subsurface irrigation systems?

Managing water quality issues in subsurface irrigation systems is crucial to prevent clogging of emitters and potential damage to crops. Water quality problems may include high levels of salts, sediments, organic matter, or pathogens.

Prevention Strategies: Pre-treatment of irrigation water is essential. This might include filtration systems to remove suspended solids and sediment, chemical treatment to control biological growth, and appropriate chemical adjustments (e.g., acidification) to address pH imbalances. Regular maintenance, including flushing of the system to remove accumulated sediments, is also critical.

Monitoring and Control: Regular monitoring of water quality parameters (pH, electrical conductivity, total dissolved solids) helps detect any changes and allows for timely intervention. Pressure gauges at various points in the system can help identify potential blockages or pressure variations. A well-maintained filtration system is often the first line of defense.

For example, in areas with high salinity, a reverse osmosis system might be employed to desalinate the irrigation water before it reaches the emitters. Regular backflushing and proper filter maintenance are key to preventing clogging in systems that utilize water with high sediment loads.

Q 22. How can you optimize water use in subsurface irrigation?

Optimizing water use in subsurface irrigation hinges on precise control and efficient design. We aim to deliver the exact amount of water needed, directly to the roots, minimizing evaporation and runoff, which are significant water losses in surface irrigation methods. This is achieved through several key strategies:

- Precise Irrigation Scheduling: Utilizing soil moisture sensors and weather data allows us to schedule irrigation based on actual plant needs, rather than relying on fixed schedules. This prevents overwatering and ensures efficient water use. For example, a vineyard in a dry climate might benefit from a schedule triggered by soil moisture reaching a pre-determined threshold, instead of irrigating every three days regardless of conditions.

- Appropriate Irrigation System Design: The design must consider soil type, topography, and crop water requirements. Proper emitter spacing, line layout, and pressure regulation are crucial. A poorly designed system can lead to uneven water distribution, resulting in under- or over-irrigated areas, wasting precious water.

- Regular System Monitoring and Maintenance: This includes checking for leaks, clogged emitters, and proper pressure regulation. Regular maintenance ensures the system operates at peak efficiency, preventing water loss and ensuring even distribution. Think of it like regular car maintenance; addressing minor issues early prevents major problems and costly repairs down the line.

- Water-Smart Irrigation Technologies: Implementing technologies like variable rate irrigation (VRI), which adjusts water application based on spatial variability in water requirements, further enhances efficiency. VRI systems may use GPS data and soil maps to ensure that high-water-demand areas receive more water than those with lower needs.

Q 23. Explain the use of sensors and data loggers in subsurface irrigation management.

Sensors and data loggers are indispensable tools for precise subsurface irrigation management. They provide real-time data on soil conditions, allowing for informed irrigation decisions. Sensors typically measure soil moisture content, temperature, and salinity. Data loggers collect and store this data, often wirelessly transmitting it to a central system for analysis.

- Soil Moisture Sensors: These sensors, placed at various depths in the root zone, provide crucial information about the amount of water available to the plants. Different types of sensors exist including tensiometers, capacitance probes, and neutron probes. They help determine when and how much irrigation is needed.

- Data Loggers: These devices record sensor data at set intervals, storing it for later analysis. Some data loggers can also trigger irrigation events automatically when predetermined thresholds are met. This automates the process, allowing for precise control without constant manual monitoring.

- Real-time Monitoring and Control Systems: Combining sensors, data loggers, and irrigation controllers allows for automated and optimized irrigation based on real-time data analysis. Such systems greatly improve water-use efficiency compared to traditional, manually operated systems. For instance, imagine a large-scale farming operation using a network of soil moisture sensors and a centralized control system; this minimizes water waste and ensures even moisture across all fields.

Q 24. Describe different types of subsurface irrigation controllers and their functionality.

Subsurface irrigation controllers range from simple time-based systems to sophisticated computer-controlled units. The choice depends on the complexity and size of the irrigation system, as well as the level of automation desired.

- Time-Based Controllers: These are the simplest controllers, activating the irrigation system for predetermined durations at specific times. While easy to use, they are less efficient as they don’t adjust to changing conditions.

- Sensor-Based Controllers: These controllers integrate with soil moisture sensors and other environmental sensors. They automatically start and stop irrigation based on real-time data, optimizing water use based on plant needs. An example would be a controller that activates irrigation only when the soil moisture drops below a set threshold.

- Computer-Controlled Controllers: These advanced systems use sophisticated algorithms and weather data to create optimal irrigation schedules. They can manage multiple zones independently and account for factors like evapotranspiration and rainfall. This can significantly reduce water waste and improve crop yields compared to time-based systems.

- Smart Irrigation Controllers: These controllers incorporate features like cloud connectivity, remote monitoring, and data analysis. They leverage weather forecasts, historical data, and even machine learning algorithms to enhance efficiency and reduce water consumption. They allow for remote adjustments and monitoring, facilitating quick responses to unexpected events.

Q 25. What is your experience with subsurface drip irrigation design and installation?

My experience with subsurface drip irrigation (SDI) design and installation spans over 15 years. I’ve been involved in numerous projects ranging from small-scale residential landscapes to large-scale agricultural applications. My expertise includes all aspects, from initial site assessments and design using specialized software, to the hands-on installation and commissioning of SDI systems.

During design, I meticulously evaluate soil type, slope, and water source to optimize emitter spacing, pipe layout, and pressure regulation. I utilize computer-aided design (CAD) software to create detailed plans that ensure even water distribution across the field. During the installation phase, my team and I carefully lay out and connect the pipes, ensuring the system is properly pressurized and free of leaks. Post-installation, we thoroughly test the system to ensure its functionality and make any necessary adjustments before handing over to the client.

A recent project involved installing an SDI system for a 50-acre vineyard. Careful consideration was given to the undulating topography and sandy soil, resulting in a system that consistently delivered optimal water to each vine. The successful implementation resulted in a significant improvement in fruit yield and water-use efficiency compared to their previous surface irrigation method.

Q 26. How do you integrate subsurface irrigation with other agricultural practices?

Integrating subsurface irrigation with other agricultural practices is crucial for maximizing efficiency and sustainability. It can be seamlessly combined with various techniques:

- Precision Farming: SDI works well with precision farming techniques like variable rate fertilization. This allows farmers to apply fertilizers and water in precise amounts to specific areas, optimizing resource use and minimizing environmental impact.

- Cover Cropping: Subsurface irrigation can support the growth of cover crops, which improve soil health and reduce erosion. The irrigation system can be adjusted to meet the water needs of both the main crop and the cover crop.

- Mulching: Integrating SDI with mulching further reduces evaporation losses. The mulch layer conserves soil moisture, resulting in reduced water requirements and improved efficiency.

- No-Till Farming: Subsurface irrigation is highly compatible with no-till farming practices. The reduced soil disturbance associated with no-till agriculture benefits from the localized water application of SDI, avoiding surface compaction issues.

For instance, integrating SDI with no-till farming and cover cropping in a cornfield can improve yields while conserving water and improving soil structure. This creates a more sustainable and productive system.

Q 27. Explain the importance of regular system evaluation and maintenance for subsurface irrigation.

Regular system evaluation and maintenance are vital for ensuring the long-term performance and efficiency of a subsurface irrigation system. Neglecting maintenance can lead to reduced efficiency, water waste, and potentially costly repairs.

- Regular Inspections: Visual inspections should be carried out at least twice a year, checking for leaks, broken pipes, and clogged emitters. Early detection of problems prevents escalation.

- Pressure Testing: Periodic pressure testing is crucial to identify leaks and ensure proper pressure regulation across the system. This helps optimize water distribution and prevents unnecessary water loss.

- Flushing the System: Regular flushing of the system helps remove sediment and debris, preventing emitter clogging and maintaining efficient water flow. It’s like rinsing out a clogged sink to improve water flow.

- Data Analysis: Reviewing data from sensors and data loggers can identify trends and potential problems. This enables proactive adjustments to the irrigation schedule and prevents future issues.

Imagine a system that is not properly maintained; clogging of the emitters can lead to uneven water distribution, reduced yields, and increased water consumption. Regular maintenance ensures the system operates at peak performance, yielding economic and environmental benefits.

Q 28. How would you address a situation where water application is uneven in a subsurface irrigation system?

Uneven water application in a subsurface irrigation system is a serious issue, potentially leading to reduced crop yields and inefficient water use. Addressing this requires a systematic approach:

- Identify the Problem Areas: Use soil moisture sensors to pinpoint areas receiving insufficient or excessive water. Visual inspection of the vegetation can also highlight areas with stress symptoms. Look for wilting or yellowing plants in areas that should receive sufficient water.

- Check for Clogged Emitters: Inspect the emitters in the affected areas for blockages. Clean or replace clogged emitters to restore even water distribution. High mineral content in irrigation water may cause emitter clogging, which requires filtering the water before it enters the system.

- Examine Pipe Layout and Pressure: Ensure the pipe layout is appropriate for the topography and that the pressure is evenly distributed across all zones. Adjust pressure regulators if necessary to ensure consistent water flow to all emitters.

- Check for Leaks: Carefully inspect the entire system for leaks. Leaks can cause uneven water distribution and water waste. Repair any leaks promptly to restore system integrity.

- Adjust Irrigation Schedule: Based on soil moisture data and the identified problem areas, adjust the irrigation schedule to provide sufficient water to areas that are under-irrigated. A combination of sensor-based adjustments and localized water supplementation may be necessary.

Addressing uneven water application is a multi-step process that requires careful investigation and thoughtful solutions. It is often more cost-effective to address the problem quickly rather than wait until it becomes significantly larger.

Key Topics to Learn for Subsurface Irrigation Management Interview

- System Design & Planning: Understanding soil properties, water availability, and crop requirements to design efficient subsurface irrigation systems. Consider factors like pipe layout, emitter spacing, and pressure regulation.

- Water Management & Control: Mastering techniques for efficient water application, including scheduling, monitoring soil moisture, and adjusting irrigation based on real-time data. Explore different control systems and their applications.

- Hydraulics & Flow Dynamics: Gain a strong grasp of the principles governing water movement through subsurface systems, including pressure losses, flow rates, and emitter performance. Be prepared to discuss troubleshooting techniques related to flow issues.

- Operation & Maintenance: Learn practical aspects of system operation, including pump management, filter maintenance, and troubleshooting common problems. Develop an understanding of preventative maintenance strategies for long-term system health.

- Environmental Considerations: Understand the environmental impact of subsurface irrigation, including water conservation, nutrient management, and potential effects on soil salinity and groundwater. Be prepared to discuss sustainable practices.

- Economic Analysis & Optimization: Learn how to evaluate the economic viability of subsurface irrigation projects, considering initial investment costs, operational expenses, and potential returns. Understand different optimization techniques to maximize efficiency.

- Emerging Technologies: Familiarize yourself with modern technologies used in subsurface irrigation management, such as sensor networks, data analytics, and automation systems. Discuss their advantages and limitations.

Next Steps

Mastering subsurface irrigation management opens doors to exciting career opportunities in agriculture, water resource management, and environmental consulting. To stand out, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific demands of this field. Examples of resumes tailored to Subsurface Irrigation Management are available to guide you through the process. Investing time in crafting a strong resume significantly improves your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good