Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Supplier sourcing and material procurement interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Supplier sourcing and material procurement Interview

Q 1. Explain your experience with different sourcing strategies (e.g., competitive bidding, negotiation, reverse auctions).

Sourcing strategies are crucial for securing the best possible materials at optimal prices. My experience encompasses a range of approaches, each suited to different situations and supplier dynamics.

- Competitive Bidding: This involves soliciting bids from multiple pre-qualified suppliers for the same goods or services. It’s ideal for standardized products where quality is consistent across vendors. For example, I recently used competitive bidding for office supplies, receiving five bids and ultimately selecting the supplier offering the best price-quality ratio. This ensured we got a great deal without compromising quality.

- Negotiation: This strategy is best for complex or unique requirements where a close collaborative relationship with the supplier is essential. It involves direct discussions to reach mutually agreeable terms, focusing on factors beyond just price, such as delivery schedules and payment terms. In a recent project involving custom-designed parts, negotiation was critical to fine-tuning specifications and ensuring timely delivery.

- Reverse Auctions: In this electronic bidding process, suppliers compete to offer the lowest price in real-time. It’s efficient for standardized products with numerous potential suppliers but requires careful management to avoid compromising quality for price. I’ve employed reverse auctions successfully for bulk purchasing of raw materials, resulting in substantial cost savings.

My approach involves selecting the strategy best aligned with the specific needs of the procurement, considering factors like market conditions, product complexity, and desired supplier relationship.

Q 2. Describe your process for supplier selection and evaluation.

Supplier selection is a rigorous process focused on identifying and qualifying suppliers capable of consistently meeting our requirements. My process follows these key steps:

- Requirement Definition: Clearly defining our needs – specifications, quality standards, quantity, and delivery timelines – is paramount.

- Supplier Identification: We use a combination of market research, industry databases, and referrals to identify potential suppliers.

- Pre-qualification: A thorough assessment of each supplier’s financial stability, production capacity, quality management systems (ISO 9001 certification is a key indicator), and environmental compliance is crucial. This often involves site visits and audits.

- Supplier Evaluation: This involves a formal scoring system that weighs factors like price, quality, delivery performance, and technological capabilities.

- Negotiation and Contract Award: Once a suitable supplier is identified, detailed contract negotiations are undertaken, ensuring all aspects are clearly defined and legally sound.

Think of it like choosing a partner for a long-term project. You wouldn’t just pick the cheapest option without checking their credibility and capabilities first. The same applies to supplier selection; thorough vetting leads to long-term success.

Q 3. How do you manage supplier relationships and performance?

Managing supplier relationships and performance requires a proactive and collaborative approach. This isn’t just about placing orders; it’s about building strong partnerships.

- Regular Communication: Maintaining open and transparent communication channels, including regular meetings and performance reviews, is key to addressing concerns early on.

- Performance Monitoring: We track key performance indicators (KPIs) such as on-time delivery, quality defect rates, and response times to identify areas for improvement. We utilize a supplier performance management system to track this data and generate reports.

- Continuous Improvement: We work collaboratively with our suppliers to identify and implement improvements in processes, quality, and efficiency. This might involve joint problem-solving workshops or process optimization initiatives.

- Collaboration and Trust: Building trust and mutual respect is crucial. We foster collaborative relationships based on transparency, fairness, and mutual benefit. This might involve shared risk and reward mechanisms.

- Supplier Development: For critical suppliers, we may invest in their capacity building through training or technology upgrades. This ensures they remain capable of meeting our future needs.

For example, when a supplier faced production delays due to unforeseen circumstances, we worked with them to implement corrective actions and find alternative solutions, ensuring minimal disruption to our production.

Q 4. What are your key performance indicators (KPIs) in procurement?

My key performance indicators (KPIs) in procurement are designed to measure efficiency, cost savings, and supplier performance. They include:

- Cost Savings: Percentage reduction in material costs year-over-year.

- On-Time Delivery: Percentage of orders delivered on or before the agreed-upon date.

- Quality Defects: Number of defective items received from suppliers.

- Supplier Lead Time: Time taken from order placement to delivery.

- Inventory Turnover: How quickly inventory is sold or used.

- Procurement Cycle Time: Time taken from initiating a purchase request to receiving the goods.

These KPIs are regularly monitored and reported to management, allowing for data-driven decision-making and continuous improvement initiatives. They also help us assess supplier performance and identify areas requiring attention.

Q 5. How do you mitigate supply chain risks?

Mitigating supply chain risks is crucial in today’s volatile global environment. My approach is multifaceted:

- Supplier Diversification: Avoiding over-reliance on a single supplier by sourcing from multiple geographically diverse sources reduces vulnerability to disruptions in any one location.

- Risk Assessment: Regularly assessing potential disruptions, such as political instability, natural disasters, or supplier financial difficulties, is key. We use a formal risk assessment framework to identify and prioritize these risks.

- Inventory Management: Maintaining appropriate safety stock levels for critical materials provides a buffer against unexpected delays or shortages.

- Contractual Safeguards: Contracts should include clauses addressing potential disruptions, including force majeure and penalty clauses for non-performance.

- Supply Chain Visibility: Employing technology to track materials throughout the supply chain provides real-time insights into potential issues and enables proactive intervention.

- Relationship Management: Building strong relationships with key suppliers fosters collaboration and provides early warning of potential problems.

For instance, during the recent pandemic, our diversified supplier base and proactive risk assessment allowed us to quickly adapt to material shortages by switching to alternative suppliers with minimal impact on production.

Q 6. Explain your experience with contract negotiation and management.

Contract negotiation and management are critical aspects of procurement, ensuring that agreements are fair, protect our interests, and ensure compliance. My experience covers the entire lifecycle:

- Preparation: Thorough preparation, including defining clear requirements, understanding market prices, and identifying potential risks, is essential. We develop detailed negotiation strategies based on our needs and the supplier’s capabilities.

- Negotiation: This involves skillful communication, compromise, and value creation to reach mutually acceptable terms. We focus on ensuring clarity in specifications, payment terms, delivery schedules, and dispute resolution mechanisms.

- Contract Drafting and Review: Legal counsel reviews the final contract to ensure it accurately reflects the agreed terms and protects our interests.

- Contract Management: Once the contract is signed, we actively monitor performance, address any disputes, and ensure compliance with all terms and conditions. We use contract management software to centralize and track all agreements.

A key example involves a recent negotiation where we successfully secured favorable terms for a long-term contract, including volume discounts and performance-based incentives. This resulted in significant cost savings over the contract’s lifetime.

Q 7. How do you handle supplier issues or disruptions?

Handling supplier issues or disruptions requires a structured and proactive approach. My strategy involves:

- Immediate Response: Upon discovering a problem (e.g., late delivery, quality defects), we immediately contact the supplier to understand the root cause and potential solutions.

- Problem Diagnosis: We work with the supplier to determine the exact nature of the problem, its impact on our operations, and potential corrective actions. This might involve detailed data analysis and root cause analysis.

- Corrective Actions: We collaborate with the supplier to implement corrective actions, such as expediting shipments, addressing quality issues, or implementing process improvements. Depending on the severity, this might involve penalties stipulated in the contract.

- Contingency Planning: For critical disruptions, we activate our contingency plans, which might involve sourcing from alternative suppliers, adjusting production schedules, or using inventory reserves.

- Documentation and Lessons Learned: We meticulously document all aspects of the issue, the corrective actions taken, and lessons learned. This ensures similar problems are avoided in the future.

For example, when a key supplier experienced a fire, we immediately activated our contingency plan, sourcing from backup suppliers and adjusting our production schedule to minimize disruption to our customers.

Q 8. Describe your experience with different procurement systems or software.

Throughout my career, I’ve worked extensively with various procurement systems and software, ranging from simple spreadsheet-based solutions to sophisticated enterprise resource planning (ERP) systems and specialized procurement platforms. My experience includes using systems like SAP Ariba, Coupa, Oracle Procurement Cloud, and smaller, industry-specific solutions. Each system has its own strengths and weaknesses, but generally, I look for features that support the entire procurement lifecycle, from requisitioning and sourcing to purchase order management, invoice processing, and contract management. For example, in a previous role, we migrated from a legacy system to Coupa. This transition involved a thorough analysis of our existing processes, data migration, user training, and ongoing optimization. The result was a significant improvement in efficiency, transparency, and cost savings due to improved automation and reporting capabilities. I’m comfortable adapting to new systems quickly, and proficient in leveraging the data and analytics offered by these platforms to support strategic decision-making.

Q 9. How do you ensure compliance with procurement regulations?

Ensuring compliance with procurement regulations is paramount. My approach involves a multi-faceted strategy. First, I ensure a thorough understanding of all applicable laws, regulations, and company policies. This includes familiarizing myself with local, national, and international regulations, as well as industry-specific compliance requirements. Secondly, I develop and implement clear internal controls and processes to ensure that all procurement activities adhere to these regulations. This might involve implementing checklists, approval workflows, and regular audits. For example, ensuring compliance with the Sarbanes-Oxley Act (SOX) or the Foreign Corrupt Practices Act (FCPA) requires meticulous record-keeping, transparent bidding processes, and conflict-of-interest policies. Finally, I maintain ongoing training and education for the procurement team to ensure everyone understands and adheres to the regulations. This includes regular updates on changes in legislation and best practices. I also proactively monitor our systems for any deviations from established compliance measures, using data analytics to identify and address potential risks.

Q 10. How do you manage costs and optimize spending?

Cost management and spending optimization are critical aspects of procurement. My strategies focus on several key areas. First, I leverage data analytics to identify spending patterns and areas for potential savings. This involves analyzing historical data, identifying high-value items, and examining the costs of different suppliers. Second, I implement strategic sourcing strategies, such as competitive bidding, negotiation, and leveraging economies of scale to secure better prices. Third, I focus on optimizing inventory management to minimize holding costs and waste. This includes implementing techniques like Just-in-Time (JIT) inventory management or vendor-managed inventory (VMI). Fourth, I look for opportunities to consolidate suppliers, negotiate volume discounts, and explore alternative sourcing options, including exploring offshoring or nearshoring strategies when appropriate and considering their impact on quality, lead time, and overall costs. For example, in a previous project, by negotiating better payment terms with a key supplier, we were able to improve our cash flow and free up working capital.

Q 11. What is your experience with total cost of ownership (TCO)?

Total Cost of Ownership (TCO) is a critical lens through which I evaluate procurement decisions. It goes beyond simply considering the initial purchase price of a good or service; instead, it encompasses all direct and indirect costs associated with the item throughout its entire lifecycle. This includes factors like acquisition costs, operating costs (energy consumption, maintenance), disposal costs, and even the potential impact on productivity. For example, choosing a lower-priced piece of equipment might seem attractive initially but might lead to higher maintenance and repair costs over its lifespan. By carefully analyzing the TCO of different options, we can make informed decisions that minimize the overall cost of ownership. I use specialized software and spreadsheets to model TCO, including all relevant factors, to support data-driven decision-making. This allows me to present a comprehensive cost analysis to stakeholders, justifying choices based on long-term value rather than short-term savings.

Q 12. Describe your experience with different procurement methodologies (e.g., Lean, Six Sigma).

I have experience applying various procurement methodologies, including Lean and Six Sigma. Lean principles emphasize eliminating waste and streamlining processes throughout the procurement lifecycle. This involves identifying and removing non-value-added activities, reducing lead times, and improving efficiency. Six Sigma, on the other hand, focuses on reducing variation and improving quality through data-driven analysis and process improvement. In practice, I often combine elements of both methodologies. For example, using Lean principles to map the procurement process to identify bottlenecks and then using Six Sigma tools like DMAIC (Define, Measure, Analyze, Improve, Control) to systematically address the identified issues. A successful project involved using these methodologies to reduce the procurement cycle time by 30% and improve supplier delivery performance significantly. These improvements resulted in reduced inventory holding costs and improved customer satisfaction.

Q 13. How do you identify and evaluate potential cost savings opportunities?

Identifying and evaluating cost savings opportunities requires a proactive and systematic approach. It starts with a thorough understanding of our current spending patterns. I typically begin by analyzing historical procurement data, identifying high-volume or high-cost items, and comparing our prices to market benchmarks. This analysis often reveals areas ripe for negotiation or process improvement. Further investigation might involve exploring alternative suppliers, negotiating better contract terms, or implementing cost-reduction strategies such as consolidating orders, standardizing parts, or exploring alternative materials. For example, by analyzing our spending on office supplies, we identified an opportunity to negotiate a volume discount with a major supplier. In addition, I actively seek out industry best practices and innovative solutions to optimize spending. This often involves attending industry conferences and networking with other procurement professionals.

Q 14. How do you ensure the quality of procured goods and services?

Ensuring the quality of procured goods and services is crucial. My approach involves a combination of preventative measures and robust quality control processes. Before selecting a supplier, I conduct thorough due diligence, evaluating their quality management systems, certifications (e.g., ISO 9001), and track record. We use a robust supplier selection process that includes supplier audits and performance evaluations. Once a supplier is selected, ongoing quality control measures are implemented, including regular inspections of incoming materials, robust quality assurance processes throughout production, and ongoing performance monitoring. We use Key Performance Indicators (KPIs) to track supplier performance, such as on-time delivery, defect rates, and customer satisfaction. Non-conformance reports are meticulously analyzed to identify root causes and implement corrective actions. Furthermore, we build strong relationships with our suppliers to foster open communication and collaboration in addressing quality concerns promptly and effectively.

Q 15. What is your experience with supplier development programs?

Supplier development programs are crucial for building a robust and reliable supply chain. They involve strategically improving the capabilities of existing or potential suppliers to meet our evolving needs. This isn’t just about finding the cheapest option; it’s about fostering long-term partnerships that deliver consistent quality, on-time delivery, and innovation.

In my previous role at Acme Corp, we implemented a supplier development program focused on improving a key supplier’s manufacturing processes. We identified bottlenecks in their production line through site visits and process mapping. We then provided them with training on lean manufacturing principles, helped them invest in new equipment, and offered mentorship from our internal engineering team. The result? A 20% increase in their production efficiency and a 15% reduction in defect rates. This not only benefited the supplier but also ensured a stable supply of high-quality components for our products.

Another example involved working with a smaller, more agile supplier to help them scale up their operations to meet increased demand. We provided financial support, helped them secure necessary certifications, and assisted with their expansion into a larger facility. This allowed us to tap into a valuable source of innovation and ensure our supply chain remained resilient in the face of growing demand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with e-procurement and digital tools.

E-procurement and digital tools are transforming how we manage sourcing and procurement. I have extensive experience using various platforms, including Ariba, Coupa, and SAP SRM. These systems streamline the entire process, from requisitioning to invoice processing, significantly improving efficiency and transparency.

For example, using Ariba’s sourcing module, I’ve successfully run competitive bidding processes for complex components, resulting in cost savings of up to 10%. The platform’s reporting capabilities also provide valuable insights into spending patterns and supplier performance. Beyond transactional systems, I’m proficient in using data analytics tools to identify trends and predict future demand, which allows for proactive planning and more effective negotiation strategies.

Moreover, I’ve championed the adoption of digital tools within our procurement organization, which includes implementing a centralized procurement portal, enhancing collaboration with internal stakeholders, and using robotic process automation (RPA) to automate repetitive tasks. This digital transformation has resulted in reduced processing time, increased accuracy, and greater overall efficiency.

Q 17. How do you prioritize procurement activities?

Prioritizing procurement activities requires a strategic approach that considers several critical factors. I typically use a framework that incorporates urgency, impact, and risk. This means evaluating each procurement activity based on how quickly it’s needed, its impact on business operations, and the potential risks associated with delays or failures.

- Urgency: Items critical to immediate production or essential services are prioritized first. Think of a critical component for a product launch or a crucial material needed to maintain essential services.

- Impact: Activities with the highest impact on the business, such as procuring large volumes of raw materials or key components, receive priority. Delays here could have significant financial and operational repercussions.

- Risk: Activities with a high risk of supply disruption, such as sourcing from a single supplier or relying on materials with long lead times, are prioritized to ensure continuity of operations. This might involve securing alternative sources or building buffer stock.

This framework ensures that we focus our resources effectively, mitigating risks and maximizing the value we deliver to the business.

Q 18. Explain your experience with forecasting demand and managing inventory.

Accurate demand forecasting and inventory management are essential for maintaining a cost-effective and efficient supply chain. My experience involves using a variety of forecasting techniques, including moving averages, exponential smoothing, and more sophisticated statistical models like ARIMA. The choice of method depends on factors such as the predictability of demand and the availability of historical data.

For instance, when forecasting demand for seasonal products, I’ve successfully used time series analysis to identify trends and seasonality. This allowed us to optimize inventory levels, minimizing storage costs and reducing the risk of stockouts or excess inventory. I also leverage collaborative forecasting techniques, engaging with sales and marketing teams to understand market trends and incorporate their insights into the forecasting process. This ensures a more accurate and reliable forecast.

Inventory management involves balancing the costs of holding inventory with the risks of stockouts. I’m familiar with various inventory control models like EOQ (Economic Order Quantity) and safety stock calculations, which help determine optimal order quantities and maintain appropriate safety levels to ensure sufficient stock while minimizing holding costs. The use of ERP systems further helps streamline inventory tracking and optimize warehouse management.

Q 19. How do you build strong relationships with internal stakeholders?

Building strong relationships with internal stakeholders is paramount to effective procurement. It’s about understanding their needs, communicating clearly, and building trust. I approach this by actively engaging with stakeholders across different departments, such as engineering, manufacturing, and operations, to understand their requirements, priorities, and challenges.

For example, I regularly hold meetings with engineering teams to discuss upcoming product designs and ensure that sourcing strategies are aligned with product development plans. I maintain open communication channels, using regular updates, reports, and presentations to keep stakeholders informed about procurement activities and any potential challenges. Proactive communication helps avoid misunderstandings and ensures that everyone is on the same page. I also strive to understand the business context of their requests – why a specific material or service is needed and what its impact is on the overall business objectives.

Finally, actively seeking feedback and demonstrating responsiveness to stakeholder concerns helps solidify relationships. When I make a mistake, I admit it, address it and learn from it. Transparency and accountability are key to building credibility and trust.

Q 20. How do you manage conflicts between internal stakeholders and suppliers?

Conflicts between internal stakeholders and suppliers are inevitable. My approach to managing these conflicts involves a collaborative and solution-oriented strategy. The first step is to understand the root cause of the conflict, whether it’s a disagreement on specifications, timelines, quality, or pricing. I facilitate open communication between all parties, ensuring that everyone has an opportunity to express their concerns and perspectives.

For instance, if a supplier fails to meet a delivery deadline, I work with both the supplier and the internal stakeholder to identify the reasons for the delay and develop a mitigation plan. This might involve adjusting delivery schedules, finding alternative sources, or implementing corrective actions to prevent future issues. I use active listening, empathy, and conflict resolution techniques to facilitate a mutually acceptable solution. The goal isn’t to assign blame but to find a solution that protects the business interests while maintaining strong supplier relationships.

Documentation is critical in conflict resolution. Maintaining clear records of all communications, agreements, and actions taken helps ensure accountability and facilitates efficient resolution. In cases of significant disputes, I may involve legal counsel to ensure compliance and protect the company’s interests.

Q 21. Describe your experience with sourcing in different geographic locations.

Sourcing in different geographic locations adds complexity but offers opportunities for cost savings, access to specialized skills and resources, and diversification of the supply chain. My experience includes sourcing from various regions, including Asia, Europe, and North America. Each region presents unique challenges and opportunities.

For example, sourcing from Asia often provides cost advantages but requires careful consideration of lead times, quality control, and geopolitical risks. I’ve successfully managed complex supply chains involving multiple suppliers across different countries, using robust contract management processes, regular audits, and strong communication channels. In Europe, I’ve focused on building relationships with suppliers who have strong environmental, social, and governance (ESG) credentials, aligning with the company’s sustainability goals.

Successfully managing geographically diverse sourcing requires a deep understanding of the local regulatory environments, cultural nuances, and logistical considerations. This often involves building strong relationships with local agents or partners who can provide support and expertise in navigating these complexities. Risk management is crucial, as geopolitical instability, currency fluctuations, and trade regulations can significantly impact the supply chain. Diversification strategies, including establishing multiple suppliers in different regions, are essential to mitigate these risks.

Q 22. What is your experience with sustainable procurement practices?

Sustainable procurement is a crucial aspect of modern sourcing, going beyond simply acquiring goods and services at the best price. It involves integrating environmental and social considerations into all stages of the procurement process, from supplier selection to waste management.

In my previous role at Acme Corp, we implemented a comprehensive sustainable procurement program. This included:

- Supplier Audits: We conducted rigorous audits to assess suppliers’ environmental performance, including carbon emissions, waste reduction efforts, and adherence to ethical labor practices.

- Green Procurement Policies: We developed and enforced policies prioritizing eco-friendly products and services, such as recycled paper and energy-efficient equipment. For example, we switched from single-use plastic packaging to biodegradable alternatives, resulting in a 25% reduction in plastic waste.

- Lifecycle Assessment: We started incorporating lifecycle costing into our sourcing decisions, taking into account the environmental impact throughout the product’s entire lifespan, from raw material extraction to disposal.

- Collaboration with Suppliers: We actively collaborated with our suppliers to encourage and support their sustainability initiatives, such as providing training on waste management best practices.

This holistic approach resulted in significant improvements in our company’s environmental footprint and strengthened relationships with environmentally conscious suppliers.

Q 23. How do you analyze market trends and industry changes to inform sourcing decisions?

Analyzing market trends and industry changes is fundamental to effective sourcing. I employ a multi-pronged approach, combining quantitative and qualitative data analysis.

- Market Research: I regularly monitor industry publications, attend trade shows, and leverage market intelligence platforms to stay abreast of emerging technologies, supply chain disruptions, and price fluctuations. For instance, I recently identified a potential shortage of a key raw material by analyzing industry reports and speaking with industry experts, enabling us to secure a long-term contract with a reliable supplier before the price surged.

- Supplier Relationship Management (SRM): Maintaining strong relationships with key suppliers provides invaluable insights into their operational capabilities, challenges, and future plans. Regular communication and collaborative problem-solving help in predicting potential risks and opportunities.

- Data Analysis: I utilize data analytics tools to track key metrics such as supplier performance, pricing trends, and market demand. This data-driven approach allows for proactive adjustments to sourcing strategies and mitigation of potential risks.

- Risk Assessment: I conduct thorough risk assessments to identify potential supply chain vulnerabilities such as geopolitical instability, natural disasters, and technological advancements. This allows for the development of contingency plans to ensure business continuity.

By combining these methods, I can proactively anticipate changes in the market and make informed sourcing decisions that minimize risks and maximize value.

Q 24. Explain your experience with different types of contracts (e.g., fixed-price, cost-plus).

I have extensive experience negotiating and managing various contract types, each with its own advantages and disadvantages.

- Fixed-Price Contracts: These contracts specify a fixed price for goods or services, offering price certainty for the buyer. However, they can be less flexible and may not account for unforeseen changes in circumstances. For example, a fixed-price contract is suitable for standardized products with well-defined specifications.

- Cost-Plus Contracts: These contracts reimburse the supplier for their actual costs plus a predetermined markup or fee. This offers more flexibility for complex projects or those with uncertain specifications, but it may lead to higher overall costs if not properly managed. A cost-plus contract might be ideal for a customized software development project.

- Time and Materials Contracts: These contracts specify an hourly rate for labor and a separate cost for materials. This is a suitable option for projects with variable scope and duration, but it requires careful monitoring to avoid cost overruns. A renovation project could benefit from this type of contract.

- Incentive Contracts: These contracts include incentives for meeting certain performance targets. These help to motivate suppliers to improve efficiency and quality. An example would be offering a bonus for early delivery of critical components.

The choice of contract type depends heavily on the specific project requirements, risk tolerance, and the nature of the supplier relationship.

Q 25. How do you measure the effectiveness of your procurement strategies?

Measuring the effectiveness of procurement strategies is critical for continuous improvement. I use a combination of key performance indicators (KPIs) to track performance across various aspects.

- Cost Savings: Tracking cost reductions compared to previous periods or industry benchmarks. For example, we achieved a 10% reduction in material costs by negotiating better terms with our suppliers.

- Supplier Performance: Monitoring on-time delivery, quality of goods, and adherence to contractual obligations through supplier scorecards and regular performance reviews.

- Process Efficiency: Measuring the time taken to complete procurement cycles, identifying bottlenecks, and implementing improvements to optimize processes. We streamlined our purchasing process using an automated procurement system, reducing processing time by 50%.

- Risk Management: Tracking the frequency and impact of supply chain disruptions, and evaluating the effectiveness of risk mitigation strategies.

- Sustainability Metrics: Measuring the environmental and social impact of procurement activities, such as carbon footprint, waste reduction, and ethical sourcing practices.

Regular reporting and analysis of these KPIs provide valuable insights into the effectiveness of our strategies and inform necessary adjustments.

Q 26. Describe your experience with supplier diversity initiatives.

Supplier diversity initiatives are essential for promoting fairness and inclusion within the supply chain. My experience includes actively seeking out and engaging with diverse suppliers, including those owned by women, minorities, veterans, and people with disabilities.

- Supplier Databases: I maintain and update databases of diverse suppliers, actively seeking out new vendors through networking events, industry associations, and online platforms.

- Mentorship Programs: We implemented mentorship programs to help diverse suppliers develop the skills and knowledge needed to compete for larger contracts.

- Targeted Outreach: We conduct targeted outreach campaigns to attract diverse suppliers, participating in events specifically focused on minority-owned businesses.

- Performance Monitoring: We track the performance of diverse suppliers to ensure they are provided with fair opportunities and support.

Beyond the ethical imperative, supplier diversity brings valuable perspectives, innovations, and strengthens community relationships. It contributes to a more resilient and dynamic supply chain.

Q 27. How do you handle ethical dilemmas in procurement?

Ethical dilemmas in procurement are inevitable. My approach involves a structured framework for addressing these situations:

- Identify the Issue: Clearly define the ethical conflict. For example, a supplier may offer a significantly lower price but with questionable labor practices.

- Gather Information: Thoroughly investigate the situation, gathering all relevant facts and perspectives. This might include reviewing supplier audits, consulting with legal counsel, and engaging with relevant stakeholders.

- Evaluate Options: Consider different courses of action, weighing their ethical, legal, and business implications. We might choose to negotiate stricter terms with the supplier, find an alternative supplier, or escalate the issue to senior management.

- Document Decisions: Meticulously document the decision-making process, including the ethical considerations and rationales behind the chosen course of action.

- Implement and Monitor: Implement the chosen course of action and monitor its effectiveness, making adjustments as needed. Regular review of our ethical guidelines and training ensure consistency and accountability.

Prioritizing ethical conduct builds trust, enhances reputation, and ultimately contributes to long-term business success.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications in the field of procurement, and align with industry standards for a candidate with my skillset and proven track record of success. I am open to discussing a competitive compensation package that reflects my value contribution to your organization. I am more interested in a role offering growth opportunities and a challenging environment than focusing solely on a specific numerical figure.

Key Topics to Learn for Supplier Sourcing and Material Procurement Interviews

- Supplier Selection & Evaluation: Understanding criteria like cost, quality, reliability, and capacity. Practical application: Developing a weighted scoring system for supplier assessment.

- Negotiation & Contract Management: Mastering negotiation tactics and understanding contract terms, including pricing models, payment terms, and service level agreements. Practical application: Analyzing a sample contract and identifying potential risks or areas for improvement.

- Sourcing Strategies: Exploring different sourcing approaches (e.g., single sourcing, multiple sourcing, global sourcing) and their implications for risk management and cost optimization. Practical application: Choosing the appropriate sourcing strategy for a specific product or service based on market analysis.

- Supply Chain Risk Management: Identifying and mitigating potential disruptions, including geopolitical factors, natural disasters, and supplier performance issues. Practical application: Developing a contingency plan to address potential supply chain disruptions.

- Material Requirements Planning (MRP): Understanding demand forecasting, inventory management, and production scheduling to ensure timely material availability. Practical application: Analyzing MRP data to optimize inventory levels and reduce carrying costs.

- Procurement Technology & Systems: Familiarity with ERP systems, e-procurement platforms, and other technologies used in modern procurement. Practical application: Describing the benefits and challenges of implementing a new procurement system.

- Ethical Sourcing & Sustainability: Understanding the importance of responsible sourcing practices, including environmental and social considerations. Practical application: Developing a supplier code of conduct and implementing a monitoring program.

Next Steps

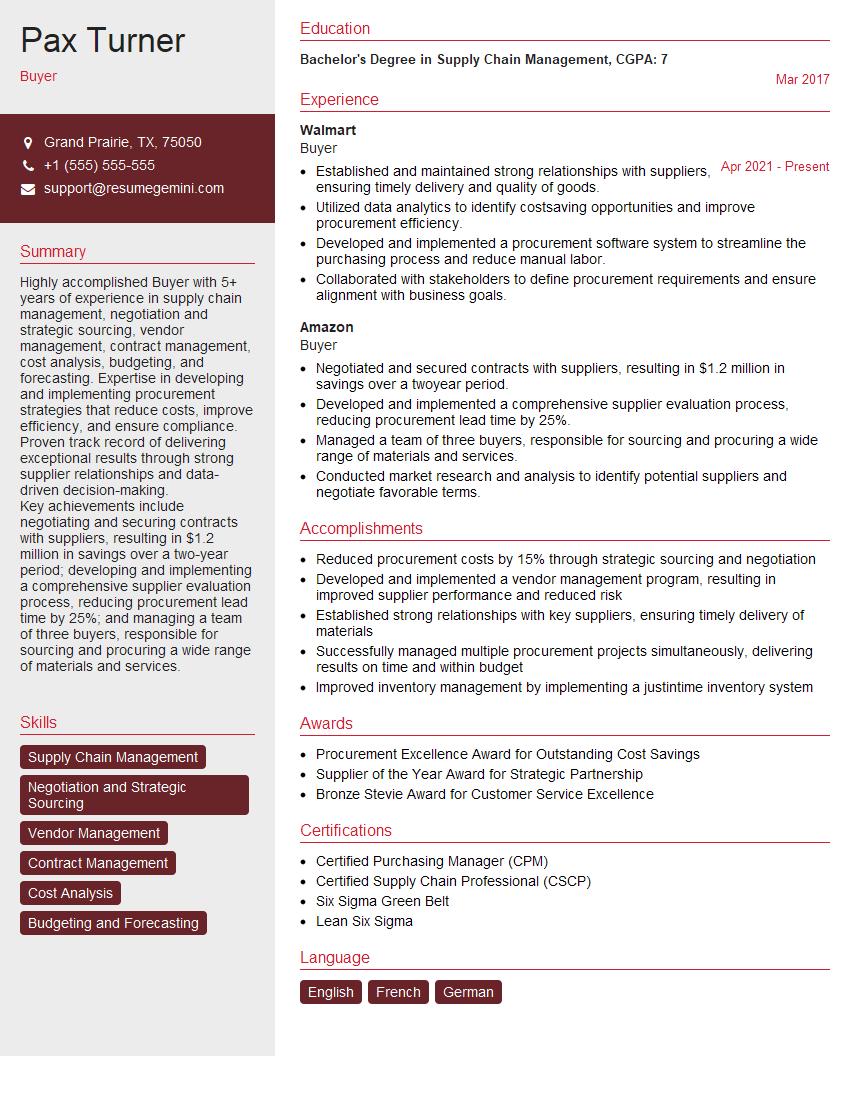

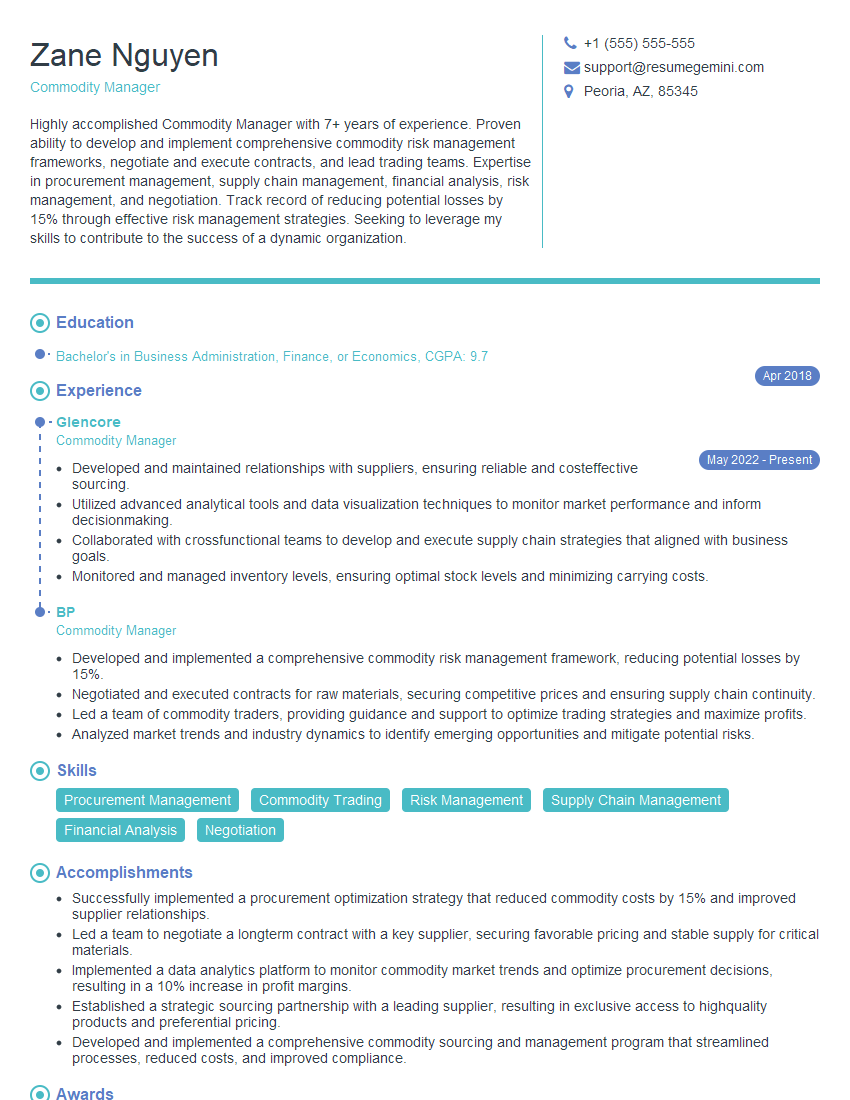

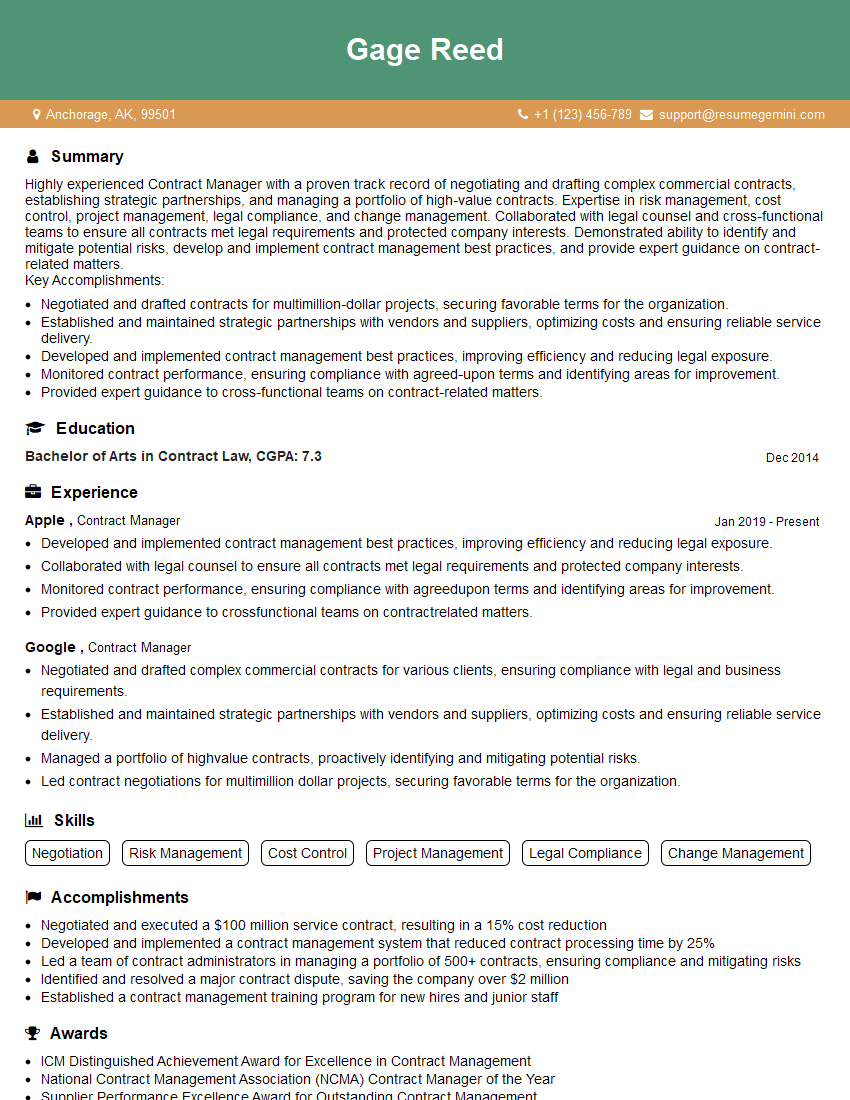

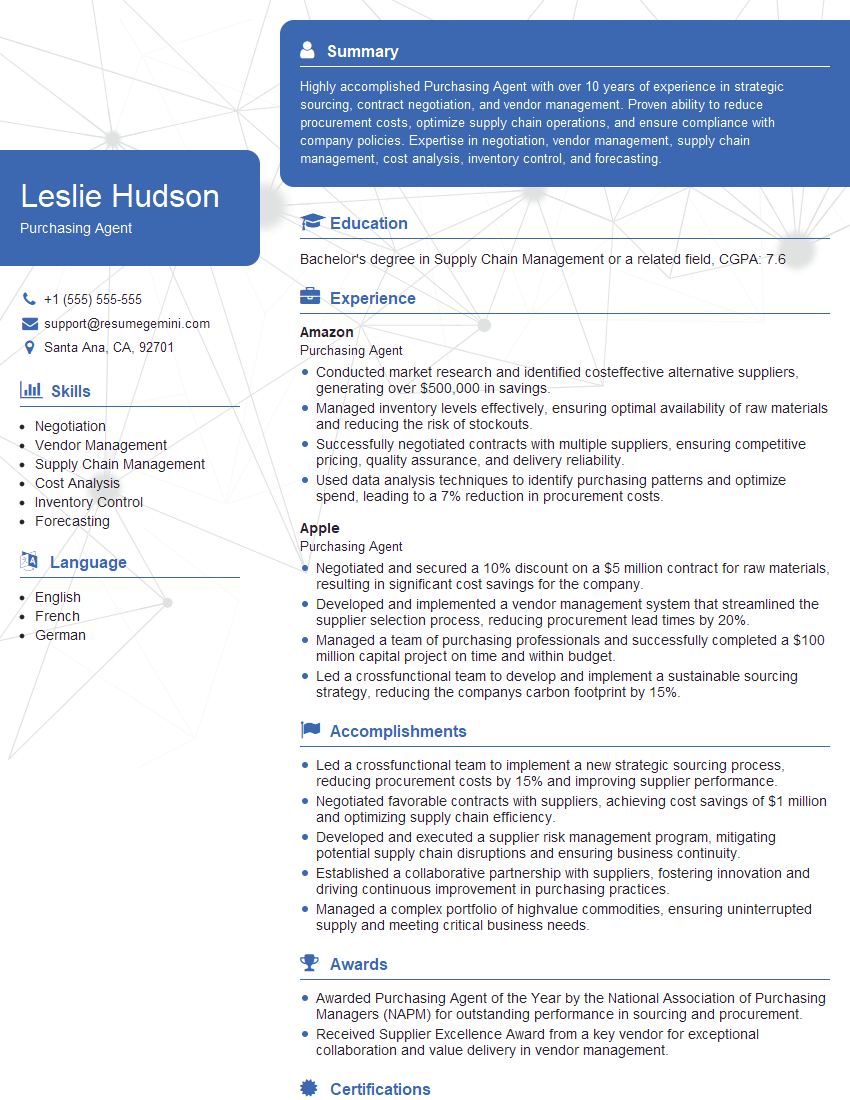

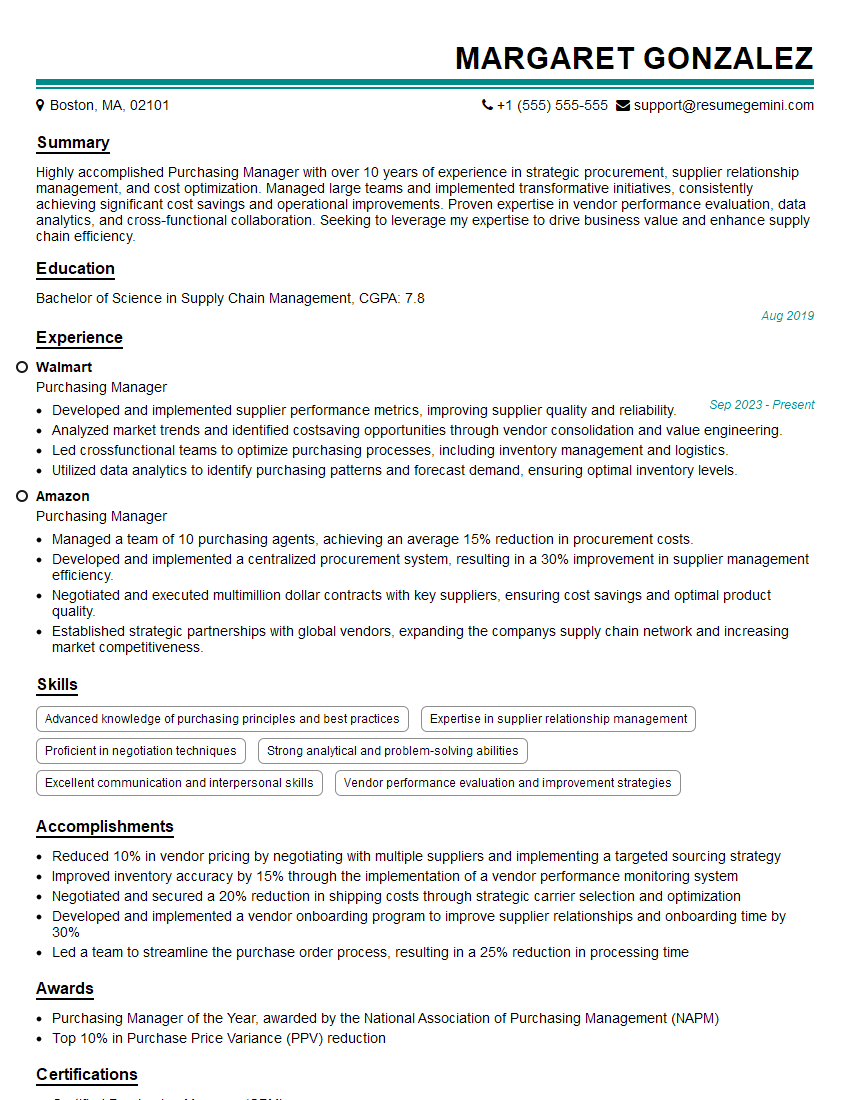

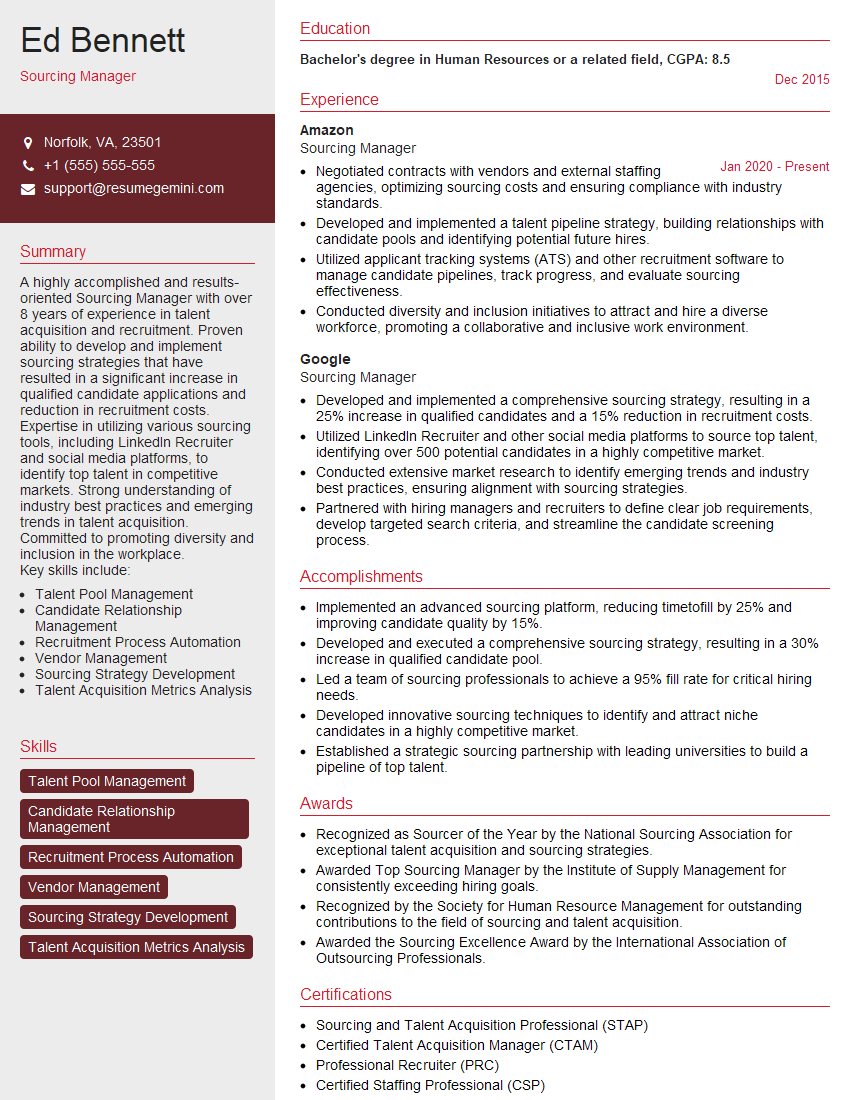

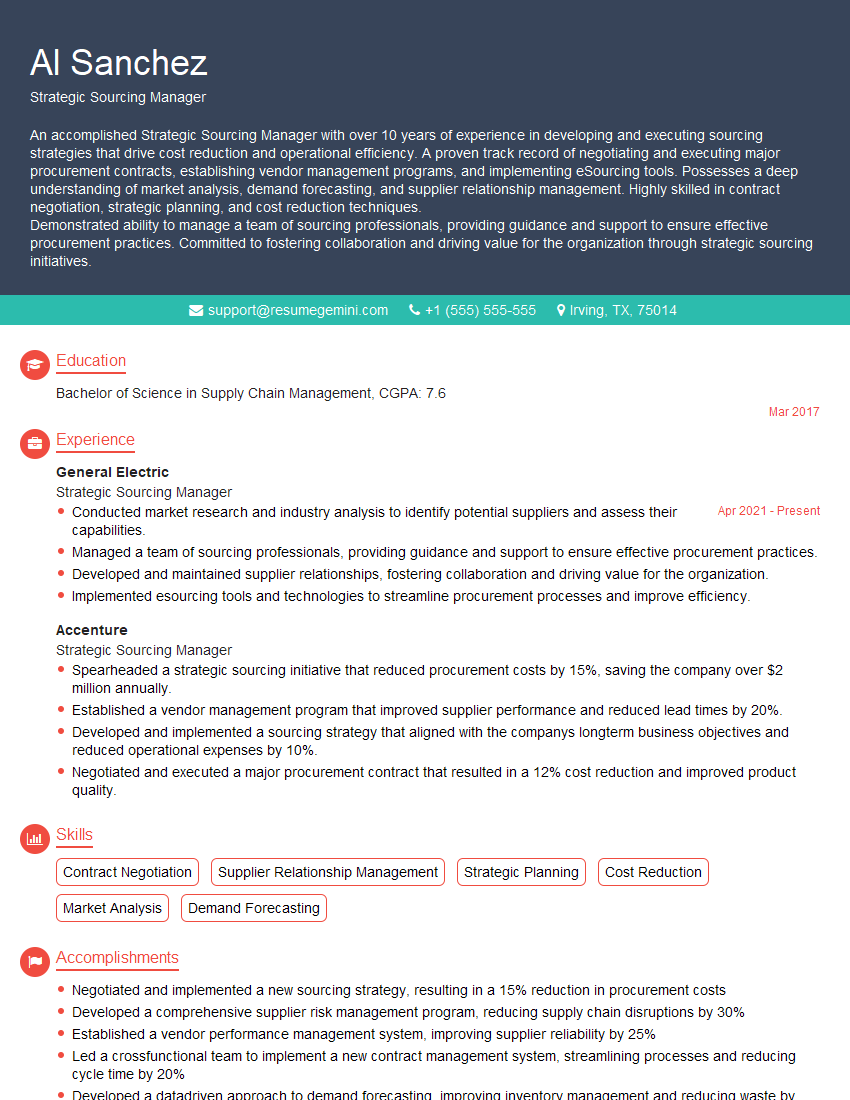

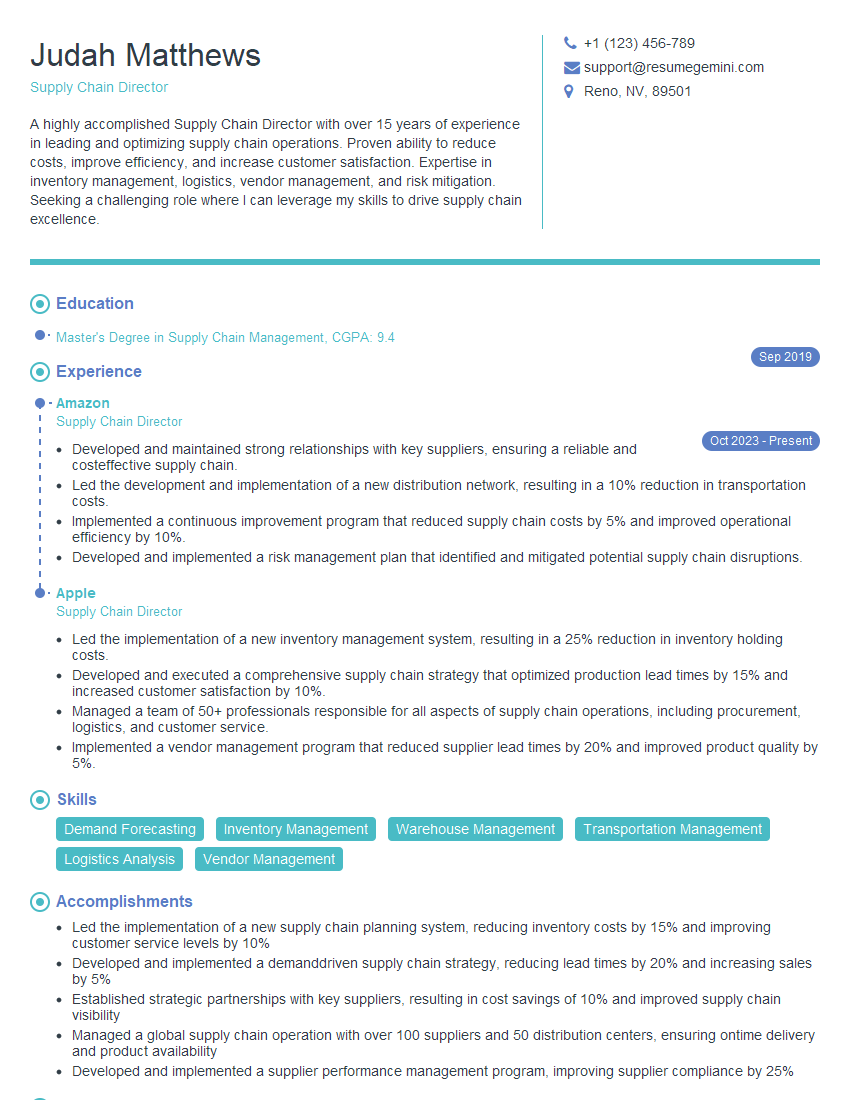

Mastering supplier sourcing and material procurement is crucial for career advancement in today’s competitive business landscape. Strong skills in this area demonstrate your ability to manage costs, optimize operations, and mitigate risks – highly valued attributes in any organization. To significantly boost your job prospects, create a resume that’s both ATS-friendly and highlights your key accomplishments and skills. ResumeGemini is a trusted resource for building professional, impactful resumes, ensuring your application stands out. Examples of resumes tailored to Supplier Sourcing and Material Procurement are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good