Cracking a skill-specific interview, like one for Supply Chain Management and Optimization, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Supply Chain Management and Optimization Interview

Q 1. Explain the bullwhip effect and how to mitigate it.

The bullwhip effect is a phenomenon in supply chains where demand variability increases as you move upstream in the supply chain. Imagine a simple whip: a small flick at the end (consumer demand) creates a much larger movement at the handle (supplier). This distortion leads to inaccurate forecasts, excessive inventory at some points, stockouts at others, and ultimately increased costs.

Mitigation Strategies:

- Information Sharing: Implement systems (e.g., collaborative planning, forecasting, and replenishment – CPFR) that allow all parties in the supply chain (retailers, distributors, manufacturers) to share real-time demand data. This reduces forecasting errors.

- Demand Stabilization: Strategies like everyday low pricing (EDLP), reducing promotional variability and focusing on consistent demand can flatten the demand curve.

- Reduce Lead Times: Shorter lead times decrease the impact of demand fluctuations as changes are reflected faster throughout the supply chain. This can involve optimizing logistics, choosing closer suppliers, or implementing just-in-time (JIT) inventory.

- Buffer Stock Optimization: Strategically placing safety stock at various points in the supply chain can help mitigate unforeseen disruptions and fluctuating demands. Careful analysis is needed to determine optimal stock levels for different product categories and points in the chain.

- Vendor-Managed Inventory (VMI): Allow key suppliers to manage inventory levels at your facilities. This leverages their expertise and closer access to demand information.

Example: A retailer experiences a slight increase in demand for a particular product. This small increase triggers a larger order from the distributor, who then places an even larger order with the manufacturer. This escalating effect leads to excess inventory at the manufacturer and distributor while the retailer struggles to meet actual customer demand.

Q 2. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO, EOQ).

I have extensive experience with various inventory management techniques. The choice of method depends heavily on the nature of the product, its demand variability, storage costs, and potential for obsolescence.

- FIFO (First-In, First-Out): This method ensures that the oldest inventory is used first. It’s ideal for perishable goods and those with a short shelf life. It minimizes waste and reduces the risk of spoilage. For example, a grocery store using FIFO for dairy products ensures freshness.

- LIFO (Last-In, First-Out): This method prioritizes the newest inventory first. It’s often used for non-perishable goods where the cost of goods sold is a major consideration. LIFO can be tax-advantageous in inflationary environments. An example could be a lumber yard with consistent product flows.

- EOQ (Economic Order Quantity): This is a mathematical model that calculates the optimal order quantity to minimize the total inventory costs (holding costs and ordering costs). I have used EOQ models in conjunction with forecasting data to optimize replenishment cycles for various products. It’s vital to understand the limitations of EOQ, such as the assumption of constant demand and lead times. Using this model successfully requires incorporating realistic lead time and demand variability estimates.

Beyond these, I’m also familiar with techniques like ABC analysis (prioritizing inventory based on value and usage), safety stock calculations, and implementing inventory management software to gain real-time visibility and control.

Q 3. How do you measure supply chain efficiency?

Supply chain efficiency is measured using a combination of metrics focusing on cost, speed, and quality. There’s no single perfect metric; the best approach involves a holistic view.

- Inventory Turnover: Measures how efficiently inventory is used. A high turnover rate suggests efficient management.

Inventory Turnover = Cost of Goods Sold / Average Inventory - Lead Time: The time it takes to fulfill an order, from the moment it’s placed to delivery. Shorter lead times indicate greater efficiency.

- Order Fulfillment Rate: The percentage of orders fulfilled on time and in full (OTIF). High OTIF rates signal a highly efficient operation.

- Perfect Order Rate: A more comprehensive measure than OTIF, considering factors like accurate order, timely delivery, and damage-free products. A higher rate signals overall efficiency and quality.

- Total Supply Chain Cost: The sum of all costs associated with managing the supply chain (inventory, transportation, warehousing, etc.). Efficient supply chains strive to minimize these costs.

It’s crucial to consider the specific context when selecting and interpreting these metrics. For example, a retailer focusing on fast fashion might prioritize lead time reduction, while a food distributor might focus on minimizing spoilage and maximizing the perfect order rate.

Q 4. What are the key performance indicators (KPIs) you track in supply chain management?

The KPIs I track depend on the specific goals of the organization and the industry, but some key ones consistently provide vital insights into supply chain performance:

- On-Time Delivery Rate: Percentage of deliveries that arrive on or before the scheduled delivery date.

- Inventory Turnover Rate: As mentioned earlier, this indicates how effectively inventory is managed.

- Fill Rate: Percentage of customer demand satisfied directly from stock.

- Perfect Order Rate: A holistic measure encompassing on-time delivery, complete orders, and no errors or damage.

- Customer Order Cycle Time: Time from order placement to customer delivery.

- Supply Chain Costs (as a percentage of revenue): A critical indicator of efficiency and profitability.

- Transportation Costs: Percentage of total supply chain costs attributed to transportation.

- Inventory Holding Costs: Costs associated with storing inventory.

- Lead Time: The overall time it takes to fulfill an order.

- Logistics Service Provider (LSP) Performance Metrics: KPIs related to the performance of the third-party logistics providers.

I regularly monitor these KPIs using dashboards and reporting tools to identify areas for improvement and ensure the supply chain operates efficiently and effectively.

Q 5. Explain your experience with forecasting methods.

My experience encompasses several forecasting methods, each with its strengths and weaknesses. The best method depends on factors such as data availability, forecast horizon, and product characteristics.

- Qualitative Methods: These rely on expert judgment and opinions, such as market research or Delphi technique. Useful when historical data is limited or unreliable.

- Quantitative Methods: These use mathematical models and historical data to predict future demand. Examples include:

- Moving Average: A simple technique that averages demand over a specific period. Useful for stable demand patterns.

- Exponential Smoothing: A more sophisticated method that assigns exponentially decreasing weights to older data. It adapts better to changing demand patterns than moving averages.

- ARIMA (Autoregressive Integrated Moving Average): A complex statistical model that captures complex patterns in historical data. Suitable for identifying trends and seasonality.

- Causal Forecasting: This method incorporates external factors like economic indicators or promotional campaigns to improve forecast accuracy.

In practice, I often combine qualitative and quantitative methods. For instance, I might use quantitative models to generate a baseline forecast and then adjust it based on insights from sales teams or market research. Regularly reviewing and updating forecasting models is essential to ensure they remain accurate and relevant.

Q 6. How do you handle supply chain disruptions?

Handling supply chain disruptions requires a proactive and robust approach. My strategy involves:

- Risk Assessment and Mitigation: Regularly identifying potential disruptions (e.g., natural disasters, political instability, supplier failures) and developing contingency plans.

- Diversification: Sourcing materials and services from multiple suppliers to reduce dependence on any single source.

- Inventory Management: Maintaining appropriate safety stock levels to buffer against unforeseen events.

- Real-time Monitoring and Communication: Implementing systems to track inventory levels, transportation status, and supplier performance in real-time. Effective communication throughout the supply chain is crucial to share information quickly and make timely decisions.

- Scenario Planning: Simulating different disruption scenarios to test the resilience of the supply chain and identify vulnerabilities.

- Collaboration and Partnerships: Working closely with suppliers and customers to coordinate responses to disruptions.

- Agile Supply Chain Practices: Implementing flexible strategies that enable the supply chain to adapt quickly to changes in demand or supply.

Example: During a natural disaster, a robust supply chain might quickly switch to alternate suppliers or transportation routes, minimizing the impact on customers. Effective communication with customers and transparency about any potential delays build trust and mitigate negative repercussions.

Q 7. Describe your experience with different transportation modes and their trade-offs.

My experience includes working with various transportation modes, each with its own strengths and weaknesses. The optimal mode depends on factors such as cost, speed, reliability, and the type of goods being transported.

- Road Transportation (Trucking): Highly flexible and cost-effective for shorter distances, especially for smaller shipments. However, it can be slower than other modes for long distances.

- Rail Transportation: Cost-effective for bulk shipments over long distances. Less flexible than trucking and can be slower for shorter routes.

- Air Transportation: Fastest mode for time-sensitive goods, but it is the most expensive.

- Sea Transportation (Shipping): Most cost-effective for large, low-value goods transported over long distances. However, it’s significantly slower than other modes.

- Intermodal Transportation: Combines different modes (e.g., rail and trucking) to optimize cost and speed. For example, shipping containers might travel by sea to a port and then by truck to the final destination.

I often use transportation management systems (TMS) to optimize route planning, carrier selection, and shipment tracking. Analyzing transportation costs and service levels are critical for cost optimization and ensuring timely delivery.

Q 8. Explain your experience with warehouse management systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. They’re software solutions that manage and optimize all aspects of warehouse functionality, from receiving and putaway to picking, packing, and shipping. My experience encompasses implementing, configuring, and troubleshooting various WMS platforms, including:

- Manhattan Associates WMS: I’ve led projects involving the full lifecycle – from needs assessment and system selection to customization, training, and go-live support. This included integrating the WMS with our existing ERP system to ensure seamless data flow.

- Blue Yonder WMS: I’ve worked extensively with its advanced features like slotting optimization and labor management to improve warehouse productivity. In one project, we used Blue Yonder’s analytics dashboards to identify and eliminate bottlenecks in our picking process, resulting in a 15% reduction in order fulfillment time.

- Oracle WMS: My experience here involved optimizing warehouse layout and processes to maximize space utilization and minimize travel time for pickers. This involved leveraging the system’s reporting capabilities to identify areas for improvement.

Beyond specific platforms, my expertise extends to WMS functionality such as inventory control, cycle counting, order management, and reporting. I understand the importance of integrating WMS with other supply chain systems to create a holistic view of inventory and operations. I am proficient in data analysis using WMS generated reports to identify inefficiencies and drive continuous improvement.

Q 9. What is your experience with different types of warehousing (e.g., cross-docking, consolidation)?

My experience spans various warehousing strategies, each tailored to specific business needs.

- Cross-docking: This involves receiving goods and immediately shipping them to another location without storage. I’ve been instrumental in designing and implementing cross-docking operations for a major retailer, optimizing the flow of goods and minimizing handling costs. This required meticulous coordination with suppliers and carriers to ensure timely delivery and efficient product flow.

- Consolidation Warehousing: This involves combining shipments from multiple suppliers into a single shipment to a customer. I’ve implemented consolidation strategies that significantly reduced transportation costs by optimizing shipment consolidation and carrier selection. This involved negotiating favorable rates with carriers and developing a robust tracking system to monitor shipments.

- Value-Added Services Warehousing: I have experience managing warehouses that provide additional services such as kitting, labeling, and packaging, adding value to products before they reach the end customer. This requires careful process mapping, quality control measures, and often, specialized equipment and trained personnel.

Understanding the strengths and limitations of each warehousing type is crucial for optimizing the supply chain. The choice depends on factors like product characteristics, transportation costs, and customer demand. For instance, perishable goods might be better suited for cross-docking to minimize storage time, whereas bulky items might be better handled through consolidation to reduce shipping fees.

Q 10. How do you ensure supply chain security?

Supply chain security is paramount. My approach is multi-layered and encompasses:

- Physical Security: This includes implementing access controls, surveillance systems (CCTV), and secured storage areas to prevent theft and unauthorized access. I’ve overseen the implementation of robust security protocols in multiple warehouse environments, including biometric access systems and alarm systems.

- Cybersecurity: Protecting sensitive data from cyber threats is crucial. This involves implementing strong passwords, firewalls, intrusion detection systems, and regular security audits. I’ve worked closely with IT teams to ensure WMS and other supply chain systems are protected from cyberattacks.

- Transportation Security: Securing goods during transit requires careful carrier selection, using GPS tracking, and potentially employing specialized security measures for high-value shipments. I have experience negotiating contracts that include security provisions and tracking systems.

- Vendor Security: Vetting suppliers to ensure they meet security standards is critical. This includes assessing their security protocols, performing background checks, and regularly reviewing their performance. I’ve developed vendor security questionnaires and implemented a robust vendor compliance program.

A proactive approach, combining preventative measures with regular audits and vulnerability assessments, is key to minimizing risks. Staying updated on emerging threats and best practices is vital in maintaining robust supply chain security.

Q 11. Explain your understanding of Lean principles in supply chain management.

Lean principles focus on eliminating waste and maximizing value in all aspects of the supply chain. My understanding encompasses the core principles of Lean, including:

- Value Stream Mapping: Identifying and eliminating non-value-added activities in the entire supply chain process. I’ve used value stream mapping to analyze and optimize order fulfillment processes, reducing lead times and improving efficiency.

- Kaizen (Continuous Improvement): Implementing small, incremental changes to improve processes over time. I’ve fostered a culture of Kaizen within teams by encouraging employees to identify and suggest improvements.

- 5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain): Organizing the workplace to improve efficiency and reduce waste. I’ve successfully implemented 5S in warehouse environments, leading to improved safety, reduced search times, and better overall organization.

- Just-in-Time (JIT) Inventory Management: Minimizing inventory holding costs by receiving materials only when needed. I’ve helped implement JIT systems, resulting in reduced storage costs and improved inventory turnover.

Lean principles aren’t just about cost reduction; they also contribute to improved quality, increased customer satisfaction, and enhanced employee engagement. A successful Lean implementation requires a commitment to continuous improvement and a culture of collaboration across the entire supply chain.

Q 12. Describe your experience with Six Sigma methodologies in supply chain optimization.

Six Sigma methodologies provide a data-driven approach to process improvement, aiming to reduce defects and variability. My experience involves applying DMAIC (Define, Measure, Analyze, Improve, Control) to optimize various supply chain processes.

- Define: Clearly defining the problem, goals, and scope of the project. For instance, defining a project to reduce late deliveries.

- Measure: Collecting data to understand the current state of the process, such as delivery times, defect rates, and customer complaints. This might involve using statistical process control charts.

- Analyze: Identifying the root causes of the problem using tools like fishbone diagrams and Pareto charts. This stage often involves root cause analysis to pinpoint the core issues driving the defects.

- Improve: Developing and implementing solutions to address the root causes. This could involve implementing new technologies, training staff, or modifying processes.

- Control: Monitoring the improved process to ensure the gains are sustained. This involves establishing control charts and regularly monitoring key performance indicators (KPIs).

In one project, we used Six Sigma to reduce the defect rate in our packaging process by 80%, leading to significant cost savings and improved customer satisfaction. Six Sigma’s structured approach ensures a data-driven, systematic improvement of processes, leading to sustainable results.

Q 13. How do you manage supplier relationships?

Managing supplier relationships is crucial for a successful supply chain. My approach focuses on building strong, collaborative partnerships based on mutual trust and transparency. This involves:

- Strategic Supplier Selection: Carefully evaluating potential suppliers based on criteria like quality, reliability, cost, and capacity. This often involves a thorough supplier assessment process.

- Performance Monitoring: Regularly tracking supplier performance against key metrics such as on-time delivery, quality, and responsiveness. This uses performance dashboards and regular performance reviews.

- Collaboration and Communication: Maintaining open and regular communication with suppliers to address issues proactively and foster collaboration. This includes regular meetings and joint problem-solving sessions.

- Continuous Improvement: Working with suppliers to identify and implement improvements in their processes to enhance efficiency and quality. This often involves joint improvement projects.

- Conflict Resolution: Developing mechanisms for resolving conflicts fairly and efficiently, focusing on finding mutually beneficial solutions. This involves clear communication and a focus on long-term partnership.

Building strong relationships with suppliers leads to improved collaboration, reduced costs, and a more resilient supply chain. It’s an investment in long-term success.

Q 14. What is your experience with contract negotiation?

Contract negotiation is a critical skill in supply chain management. My approach involves a combination of preparation, strategic planning, and effective communication.

- Preparation: Thoroughly researching market prices, understanding supplier capabilities, and defining clear objectives before entering negotiations. This involves understanding the market dynamics and having clear benchmarks.

- Strategic Planning: Developing a negotiation strategy that considers different scenarios and potential outcomes. This involves identifying key leverage points and potential compromises.

- Effective Communication: Clearly communicating our needs and expectations while actively listening to the supplier’s perspective. This involves building rapport and fostering a collaborative negotiation environment.

- Risk Management: Identifying and mitigating potential risks associated with the contract, such as price fluctuations, supply disruptions, and performance issues. This includes careful drafting of contract terms and conditions.

- Win-Win Outcomes: Aiming for mutually beneficial agreements that balance the interests of both parties. This requires a collaborative approach rather than an adversarial one.

Successful contract negotiation results in favorable terms, minimizes risks, and ensures a strong foundation for a long-term, mutually beneficial relationship with suppliers.

Q 15. Explain your understanding of risk management in supply chain.

Supply chain risk management is the proactive identification, assessment, and mitigation of potential disruptions that could impact the flow of goods and services. It’s about anticipating problems before they arise and having strategies in place to minimize their impact. Think of it like insurance for your supply chain – you hope you never need it, but having it provides peace of mind and protects you from potentially devastating losses.

A comprehensive approach involves several key steps:

- Identification: Pinpointing potential risks. This could involve anything from natural disasters and political instability to supplier failures, cybersecurity breaches, or even unexpected spikes in demand.

- Assessment: Evaluating the likelihood and potential impact of each identified risk. This often involves using risk matrices to prioritize which risks require the most attention.

- Mitigation: Developing strategies to reduce the likelihood or impact of identified risks. This could include diversifying suppliers, implementing robust inventory management systems, investing in robust IT infrastructure, or establishing contingency plans.

- Monitoring and Review: Continuously tracking risks and the effectiveness of mitigation strategies. Supply chain risks are dynamic, and what works today might not work tomorrow.

For example, a company relying heavily on a single supplier in a politically unstable region might mitigate risk by developing relationships with alternative suppliers in more stable locations. This diversification reduces the impact should the primary supplier experience disruptions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with supply chain analytics and data analysis.

My experience with supply chain analytics and data analysis is extensive. I’ve leveraged data-driven insights to optimize various aspects of the supply chain, from forecasting demand and optimizing inventory levels to improving logistics and identifying cost savings opportunities. I’m proficient in using various statistical methods and analytical tools including regression analysis, time series forecasting, and data visualization techniques.

In a previous role, I used R and Python to build predictive models for demand forecasting. These models significantly improved forecast accuracy, leading to a reduction in inventory holding costs and improved customer service levels. We analyzed historical sales data, macroeconomic indicators, and even social media sentiment to create more accurate forecasts. Specifically, I implemented an ARIMA model which improved forecast accuracy by 15%, resulting in a considerable reduction in stockouts and overstocking.

I’m also experienced in using data visualization tools like Tableau and Power BI to create dashboards that provide real-time insights into supply chain performance. This allows for quick identification of bottlenecks, anomalies, and potential areas for improvement.

Q 17. How do you use technology to improve supply chain efficiency?

Technology is crucial for enhancing supply chain efficiency. I’ve utilized various technological solutions to streamline processes, improve visibility, and optimize decision-making across the supply chain.

- Supply Chain Planning Software (SCP): These software solutions help optimize inventory levels, production schedules, and transportation routes, minimizing costs and maximizing efficiency. Examples include SAP SCM and Oracle SCM.

- Transportation Management Systems (TMS): TMS software optimizes logistics by selecting the most efficient transportation modes, routes, and carriers, reducing shipping costs and transit times.

- Warehouse Management Systems (WMS): WMS solutions automate warehouse operations, improving inventory accuracy, order fulfillment speed, and overall efficiency. This includes features like automated picking, packing, and shipping.

- Blockchain Technology: Blockchain can improve transparency and traceability throughout the supply chain, enhancing security and accountability.

- Internet of Things (IoT): IoT devices embedded in assets like containers or trucks provide real-time tracking and monitoring of goods, improving visibility and enabling proactive management of potential disruptions.

For example, implementing a TMS in a previous role reduced transportation costs by 10% by optimizing routes and carrier selection. Similarly, the adoption of a WMS reduced order fulfillment time by 20% through automation and improved inventory management.

Q 18. Explain your experience with different supply chain software solutions.

I have extensive experience working with various supply chain software solutions, including:

- Enterprise Resource Planning (ERP) systems: Such as SAP, Oracle, and Infor, for integrated management of various business processes, including supply chain activities.

- Supply Chain Planning (SCP) systems: Including SAP SCM, Oracle SCM, and Blue Yonder, for demand planning, inventory optimization, and production scheduling.

- Transportation Management Systems (TMS): Like Oracle Transportation Management and Blue Yonder Luminate, for route optimization, carrier selection, and shipment tracking.

- Warehouse Management Systems (WMS): Such as Manhattan Associates WMS and Blue Yonder WMS, for automating warehouse operations and improving inventory visibility.

My expertise extends beyond merely using these systems. I understand their underlying functionalities, data structures, and limitations. This allows me to effectively configure and customize these systems to meet specific business needs, and to identify and resolve any issues that may arise.

Moreover, my experience includes integrating these different systems to create a cohesive and efficient supply chain ecosystem. For example, integrating a WMS with an ERP system ensures seamless data flow between warehouse operations and overall business processes.

Q 19. What is your approach to problem-solving in a complex supply chain environment?

My approach to problem-solving in a complex supply chain environment is systematic and data-driven. I utilize a structured approach, often employing the DMAIC (Define, Measure, Analyze, Improve, Control) methodology or similar frameworks.

- Define: Clearly define the problem, its scope, and its impact on the supply chain. This involves gathering data and information to understand the problem thoroughly.

- Measure: Gather relevant data to quantify the problem’s magnitude and identify key performance indicators (KPIs) to track progress.

- Analyze: Analyze the collected data to identify the root causes of the problem using tools like root cause analysis (RCA), Pareto charts, and fishbone diagrams.

- Improve: Develop and implement solutions to address the root causes. This might involve process improvements, technological upgrades, or changes in supplier relationships.

- Control: Monitor the implemented solutions and adjust as needed to ensure long-term improvements. Regularly review KPIs to assess the effectiveness of the changes.

For instance, if facing persistent delays in delivery, I would systematically investigate potential causes, such as transportation inefficiencies, warehouse bottlenecks, or supplier issues. By analyzing data on delivery times, transportation modes, and warehouse operations, I can pinpoint the root causes and implement solutions such as optimizing transportation routes, investing in automation technologies for the warehouse, or negotiating improved service level agreements with suppliers.

Q 20. How do you handle conflicting priorities in a demanding supply chain role?

Handling conflicting priorities in a demanding supply chain role requires strong prioritization and communication skills. I use a structured approach:

- Prioritization Matrix: I create a matrix ranking priorities based on urgency and importance. This allows me to focus on the most critical tasks first. Urgent and important tasks get immediate attention, while less urgent but important tasks are scheduled appropriately.

- Stakeholder Management: I actively communicate with all stakeholders to ensure everyone understands the priorities and the rationale behind the decisions. Transparency and open communication are vital in navigating competing demands.

- Negotiation and Compromise: Sometimes compromise is necessary. I work collaboratively with stakeholders to find mutually acceptable solutions that balance competing objectives, while ensuring the overall goals of the supply chain remain in focus.

- Data-Driven Decisions: I use data to support my prioritization decisions, demonstrating the rationale and impact of choices. This helps to gain buy-in from stakeholders and to justify trade-offs.

For example, if faced with simultaneously needing to reduce costs and improve on-time delivery, I might prioritize investments in technology that improve efficiency and reduce both costs and lead times, thereby addressing both conflicting priorities.

Q 21. Describe a time you had to make a critical decision under pressure in a supply chain setting.

In a previous role, we experienced an unexpected disruption due to a major port strike. This threatened to severely impact our inbound shipments and lead to significant production delays and customer dissatisfaction. We were under immense pressure to find a solution quickly.

My immediate response involved assembling a crisis management team, leveraging my expertise in risk mitigation. We explored alternative transportation modes, like rail and trucking, and negotiated with alternative ports and carriers. We also engaged directly with our key suppliers to coordinate efforts and to jointly address the situation. The decision to utilize a less efficient, but available, transportation mode required careful evaluation of the trade-offs – higher costs versus preventing significant production delays.

Despite the increased costs, we successfully mitigated the disruption, minimizing the impact on production schedules and customer deliveries. This experience reinforced the importance of proactive risk management, robust contingency planning, and effective collaboration across the supply chain. It showcased the need for agile decision-making under pressure and the importance of clear communication and teamwork.

Q 22. How do you ensure compliance with relevant regulations in supply chain management?

Ensuring compliance in supply chain management is paramount. It involves understanding and adhering to a complex web of regulations, varying by industry, geography, and product. My approach is multi-faceted.

- Proactive Risk Assessment: I begin by identifying all applicable regulations – from customs and trade laws (e.g., tariffs, sanctions, import/export controls) to environmental regulations (e.g., waste disposal, emissions standards) and labor laws (e.g., fair wages, safe working conditions). This involves utilizing specialized compliance software and collaborating with legal counsel.

- Implementation of Control Systems: Once regulations are identified, robust systems and processes are implemented to ensure ongoing compliance. This includes documenting procedures, conducting regular audits (both internal and external), and using technology such as blockchain to track product provenance and verify compliance data.

- Training and Education: Employees across the supply chain need thorough training on relevant regulations. This ensures everyone understands their responsibilities and how non-compliance can lead to legal repercussions and reputational damage. Regular updates and refresher courses are vital, given the evolving nature of regulations.

- Continuous Monitoring and Improvement: Compliance isn’t a one-time event; it’s an ongoing process. I utilize key performance indicators (KPIs) to monitor compliance effectiveness and implement corrective actions as needed. This includes regular reporting and analysis to identify areas for improvement and potential risks.

For example, in a previous role managing a global apparel supply chain, we implemented a system that tracked every garment from raw material sourcing to final sale, ensuring compliance with fair labor practices and environmental standards across all partner factories. This involved regular on-site audits, transparent communication with suppliers, and the use of a specialized software to manage certifications and compliance data.

Q 23. What is your understanding of sustainability in supply chain management?

Sustainability in supply chain management goes beyond simply being environmentally friendly. It’s about integrating economic, social, and environmental considerations into every aspect of the supply chain, creating long-term value for all stakeholders. It’s a holistic approach.

- Environmental Sustainability: This involves minimizing environmental impact throughout the supply chain, from reducing carbon emissions in transportation and manufacturing to responsible sourcing of raw materials and minimizing waste generation. This often involves embracing circular economy principles, focusing on resource efficiency and waste reduction.

- Social Sustainability: This focuses on ethical labor practices, fair wages, safe working conditions, and community development within the supply chain. This requires engaging with suppliers to ensure compliance with ethical standards and supporting their improvement initiatives.

- Economic Sustainability: This refers to creating a financially viable and resilient supply chain. This involves diversifying sourcing, improving operational efficiency, and building strong, long-term relationships with suppliers. This ensures the supply chain can withstand economic fluctuations and disruptions.

A practical example is the shift towards sustainable packaging. Many companies are replacing traditional plastics with biodegradable or recyclable materials, reducing waste and their carbon footprint. This requires collaboration with suppliers to source sustainable alternatives and invest in new packaging technologies.

Q 24. Explain your experience with global supply chains.

My experience with global supply chains spans over [Number] years, encompassing various industries, including [mention industries]. I’ve managed supply chains across multiple continents, dealing with the unique challenges and opportunities each presents.

- Navigating Geopolitical Risks: I’ve successfully managed supply chains during periods of geopolitical instability, adapting strategies to mitigate risks associated with tariffs, trade wars, and political unrest. This involved diversifying sourcing, securing alternative transportation routes, and building robust contingency plans.

- Cultural Sensitivity and Communication: Working with international suppliers requires a high degree of cultural sensitivity and effective communication. I’ve built strong relationships with suppliers across diverse cultures by fostering trust, understanding their needs, and adapting my communication style to effectively convey expectations and objectives.

- Managing Complex Logistics: Global supply chains involve intricate logistics, including international shipping, customs clearance, and regulatory compliance. My experience includes optimizing logistics networks, leveraging technology to improve visibility and efficiency, and negotiating favorable transportation rates.

- Supply Chain Resilience: I’ve developed and implemented strategies to improve supply chain resilience against various disruptions, including natural disasters, pandemics, and unforeseen events. This includes building strong relationships with multiple suppliers, implementing inventory management strategies to buffer against disruptions, and using advanced analytics to predict potential disruptions.

For instance, during the recent global pandemic, I successfully navigated significant disruptions in the supply chain for a major electronics manufacturer by proactively identifying alternative sourcing options and implementing robust risk mitigation strategies. This involved leveraging our existing relationships with suppliers, rapidly adapting to changing market conditions and collaborating closely with logistics partners.

Q 25. How do you stay up-to-date with the latest trends and technologies in supply chain management?

Staying current in the dynamic field of supply chain management requires a multi-pronged approach.

- Industry Publications and Conferences: I regularly read industry publications such as Supply Chain Dive, Journal of Business Logistics and attend conferences like Gartner Supply Chain Symposium. This provides exposure to the latest trends, technologies, and best practices.

- Professional Networks: I actively participate in professional networks like APICS (The Association for Operations Management) and participate in online forums and groups to engage with other professionals and share knowledge.

- Online Courses and Webinars: Platforms like Coursera, edX, and LinkedIn Learning offer numerous courses and webinars on cutting-edge supply chain technologies and strategies. I regularly use these platforms to upskill and stay abreast of new developments.

- Technology Exploration: I actively research and explore new technologies such as AI, blockchain, and IoT, and their applications in supply chain optimization. This involves testing new tools and evaluating their potential benefits for improving efficiency, transparency, and decision-making.

For example, I recently completed a course on implementing blockchain technology for supply chain traceability, which directly enhanced my ability to design and manage more transparent and secure supply chain processes.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience, skills, and the responsibilities of this role. Based on my research and understanding of the current market rates for professionals with my qualifications in this region, I am targeting a salary range of $[Lower Bound] to $[Upper Bound]. I’m open to discussing this further and am confident that we can reach a mutually agreeable figure.

Q 27. What are your long-term career goals?

My long-term career goals involve becoming a recognized leader in supply chain optimization and sustainability. I aim to leverage my expertise to contribute to the development of innovative and efficient supply chains that are both economically viable and environmentally and socially responsible. I envision myself leading teams, mentoring others, and potentially taking on a leadership role within a large organization or even starting my own consulting firm specializing in sustainable supply chain solutions.

Q 28. Do you have any questions for me?

Yes, I have a few questions. First, could you elaborate on the company’s current approach to sustainable supply chain practices? Second, what opportunities are there for professional development and growth within the company? Third, what are the team dynamics and collaboration style within the supply chain department?

Key Topics to Learn for Supply Chain Management and Optimization Interview

- Supply Chain Design & Strategy: Understanding different supply chain models (e.g., agile, lean), network design principles, and the impact of globalization.

- Demand Forecasting & Planning: Applying forecasting techniques (e.g., time series analysis, causal models) to predict future demand and optimize inventory levels. Practical application: Developing a demand forecast for a new product launch and its impact on production planning.

- Inventory Management: Mastering inventory control techniques (e.g., EOQ, safety stock calculation) and their impact on minimizing costs and maximizing service levels. Practical application: Analyzing inventory turnover rates and identifying areas for improvement.

- Logistics & Transportation: Understanding different transportation modes, route optimization, and warehouse management strategies. Practical application: Optimizing delivery routes to minimize transportation costs and delivery times.

- Procurement & Sourcing: Negotiating contracts with suppliers, managing supplier relationships, and implementing sustainable sourcing practices. Practical application: Evaluating potential suppliers based on cost, quality, and reliability.

- Supply Chain Risk Management: Identifying and mitigating potential risks throughout the supply chain (e.g., disruptions, natural disasters). Practical application: Developing a risk mitigation plan for a specific supply chain vulnerability.

- Supply Chain Analytics & Optimization: Utilizing data analytics and optimization techniques (e.g., linear programming, simulation) to improve supply chain efficiency and performance. Practical application: Using data to identify bottlenecks and improve overall supply chain flow.

- Supply Chain Technology & Systems: Familiarity with Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), and Transportation Management Systems (TMS). Practical application: Describing how these systems integrate to support decision-making.

- Sustainability & Ethical Considerations: Understanding the environmental and social impact of supply chain decisions and implementing sustainable practices. Practical application: Analyzing the carbon footprint of a product and proposing strategies for reduction.

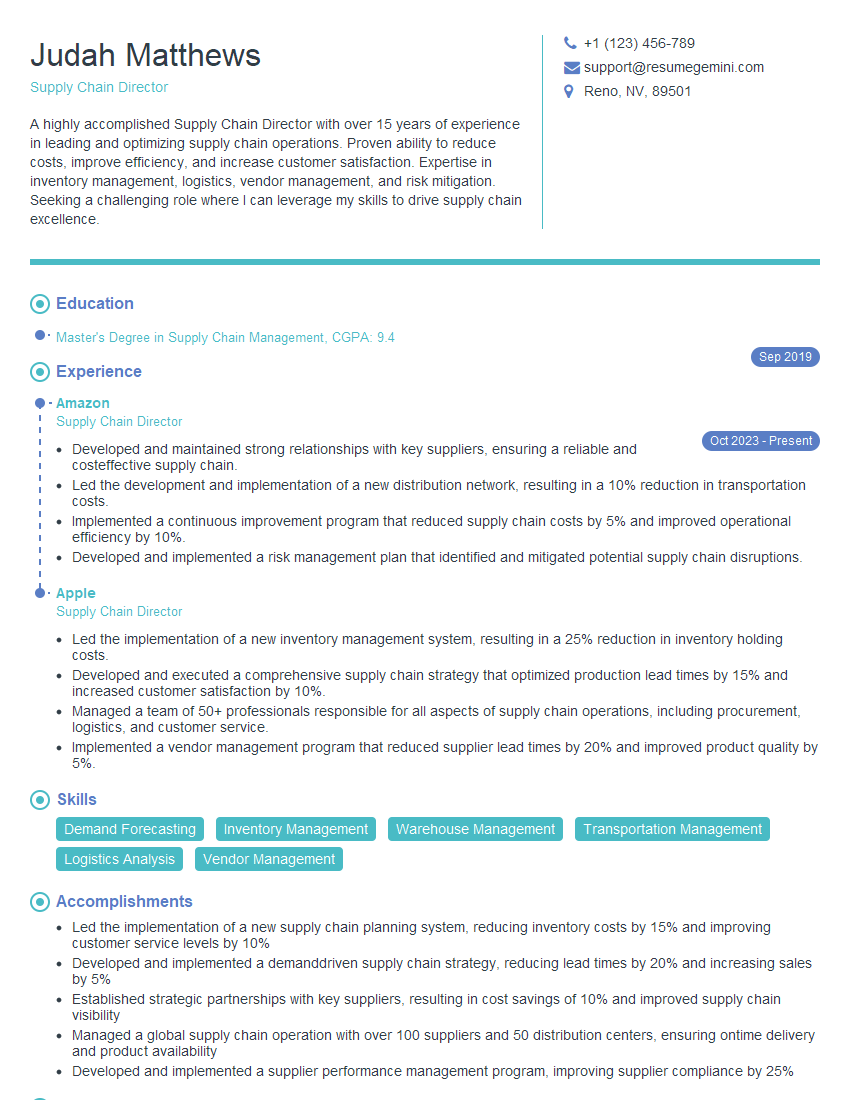

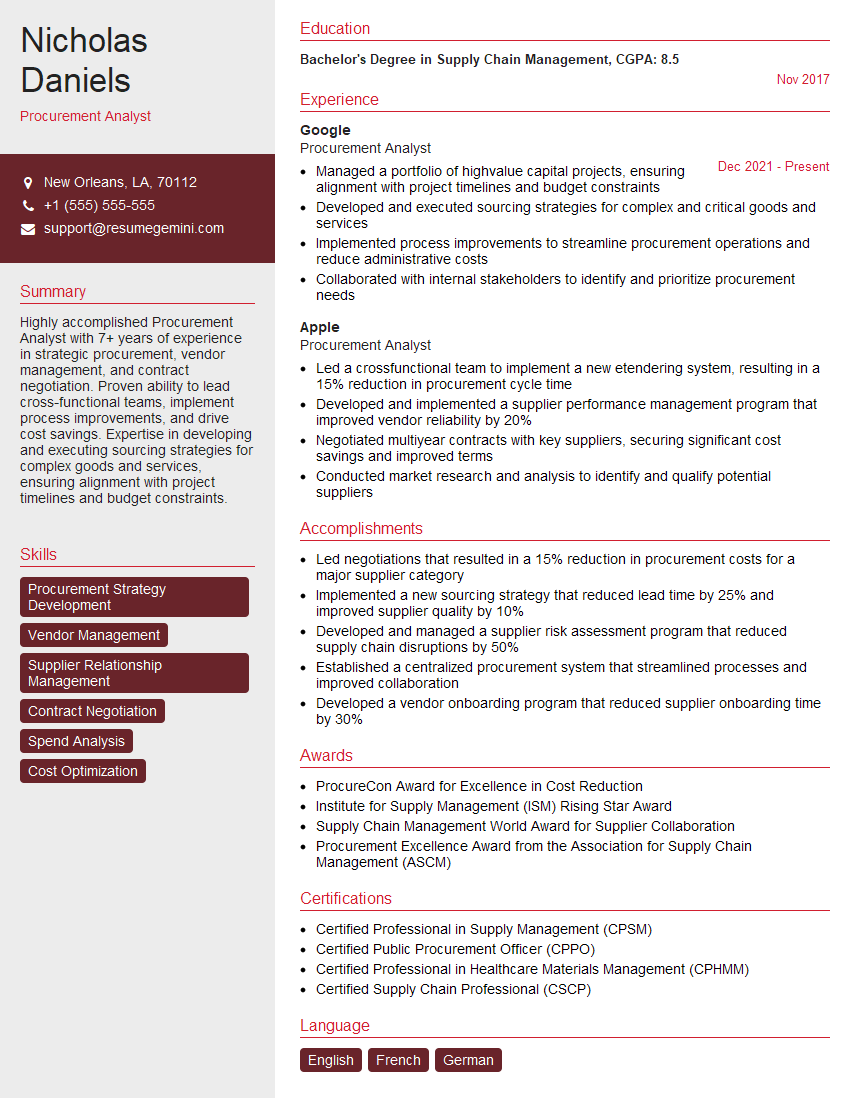

Next Steps

Mastering Supply Chain Management and Optimization opens doors to exciting and impactful careers with significant growth potential. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and compelling resume tailored to showcase your skills and experience. Examples of resumes tailored to Supply Chain Management and Optimization are available to guide you. Invest time in crafting a resume that effectively communicates your value – it’s your first impression and a key step in landing your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good