Cracking a skill-specific interview, like one for Supply Chain Management and Procurement, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Supply Chain Management and Procurement Interview

Q 1. Explain the bullwhip effect and how to mitigate it.

The bullwhip effect is a phenomenon in supply chains where demand variability increases as you move upstream—from the end customer to the raw material supplier. Imagine a whip: a small flick at the end creates a large swing at the handle. Similarly, a small change in customer demand can cause exponentially larger fluctuations in orders placed further up the supply chain. This leads to inefficiencies like excess inventory, lost sales, and increased costs.

Mitigating the bullwhip effect requires collaborative efforts across the supply chain. Key strategies include:

- Improved Information Sharing: Implementing systems like point-of-sale (POS) data sharing with suppliers provides real-time visibility into actual customer demand, reducing forecasting errors. For example, a retailer sharing daily sales data with its distributor allows for more accurate replenishment orders.

- Demand Forecasting Techniques: Employing sophisticated forecasting methods that consider seasonality, trends, and external factors can provide more accurate demand predictions. Collaborative forecasting, where multiple parties in the chain participate in the process, enhances accuracy further.

- Inventory Optimization: Implementing strategies like Vendor Managed Inventory (VMI), where suppliers manage inventory levels based on retailer data, reduces the need for large safety stocks and minimizes the impact of demand variations. Using techniques like Just-in-Time (JIT) inventory also minimizes buffer stocks.

- Strategic Partnerships: Building strong, collaborative relationships with suppliers fosters trust and facilitates smoother information exchange. This often leads to better coordination of production and distribution.

- Reduced Lead Times: Shortening lead times (the time between placing an order and receiving the goods) reduces the time it takes to respond to demand changes, diminishing the amplification effect.

For instance, a company facing erratic demand for its product might implement a VMI system with its key supplier. This allows the supplier to manage inventory levels based on real-time sales data from the company’s POS system, thereby reducing the likelihood of stockouts or overstocking.

Q 2. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO, JIT).

I have extensive experience with various inventory management techniques, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and JIT (Just-in-Time). Each has its strengths and weaknesses.

- FIFO (First-In, First-Out): This method assumes that the oldest inventory is sold first. It’s simple to implement and minimizes the risk of obsolescence, particularly for perishable goods. For example, a grocery store would typically use FIFO for its produce section to ensure freshness.

- LIFO (Last-In, First-Out): This method assumes that the newest inventory is sold first. While it can be advantageous for tax purposes in certain jurisdictions (resulting in lower taxable income during inflation), it increases the risk of obsolescence and spoilage for products with shorter shelf lives.

- JIT (Just-in-Time): This is a lean inventory management system aiming to minimize inventory holding costs by receiving materials only when needed for production. It requires precise demand forecasting and strong supplier relationships. A manufacturer of automotive parts often uses JIT to reduce storage space and holding costs. Successful implementation hinges on reliable supply chain partners and robust inventory control systems.

In practice, I often tailor the approach to specific product characteristics and market conditions. For instance, a company might use FIFO for perishable goods and JIT for components with stable demand.

Q 3. What are the key performance indicators (KPIs) you track in supply chain management?

The KPIs I track in supply chain management are categorized to provide a holistic view of performance. Key areas and their associated KPIs include:

- Inventory Management: Inventory turnover rate, stockout rate, inventory holding costs, days of inventory on hand.

- Procurement: Purchase order cycle time, supplier lead time, on-time delivery rate, cost savings from negotiations.

- Logistics and Transportation: Freight costs, on-time delivery rate, order fulfillment cycle time, damage rate during transit.

- Customer Service: Order accuracy, customer satisfaction rate, perfect order percentage (combines on-time delivery, order accuracy, and complete order).

- Supply Chain Costs: Total cost of ownership (TCO), cost per unit, cost reduction percentage.

- Sustainability: Carbon footprint, waste reduction rate, use of sustainable packaging.

I regularly analyze these KPIs to identify areas for improvement and track progress towards strategic goals. For example, a high stockout rate might indicate a need to improve demand forecasting or supplier relationships. Similarly, high freight costs could prompt a review of transportation modes and routes.

Q 4. How do you manage supplier relationships and negotiate contracts?

Managing supplier relationships and negotiating contracts is crucial for efficient and reliable supply chain operations. I approach this in a strategic and collaborative manner. Building strong relationships starts with:

- Supplier Selection: A thorough selection process considers factors like financial stability, quality certifications, production capacity, and ethical practices. I leverage tools like supplier scorecards to objectively assess potential partners.

- Communication and Collaboration: Open and transparent communication is paramount. Regular meetings, performance reviews, and collaborative problem-solving are crucial to building trust and addressing challenges proactively.

- Performance Monitoring: Consistent monitoring of supplier performance based on pre-defined KPIs (e.g., on-time delivery, quality, cost) helps identify areas for improvement and holds suppliers accountable.

- Contract Negotiation: I aim for win-win agreements. This involves understanding the supplier’s cost structure and leveraging market knowledge to achieve mutually beneficial pricing and terms. I often utilize various negotiation techniques, such as principled negotiation, to reach favorable outcomes while maintaining a strong working relationship.

- Relationship Management: Investing time in building rapport and fostering strong personal connections with key supplier contacts is often key to long-term success.

For example, I once successfully negotiated a long-term contract with a key supplier by demonstrating the value of a collaborative approach. By offering them increased volume and guaranteed business in exchange for price concessions and improved delivery reliability, both parties achieved better outcomes.

Q 5. Explain your understanding of risk management in supply chain operations.

Supply chain risk management involves identifying, assessing, and mitigating potential disruptions that could impact the flow of goods and services. A comprehensive approach includes:

- Risk Identification: This involves systematically identifying potential risks across the entire supply chain, from raw material sourcing to final product delivery. I use tools like SWOT analysis and risk mapping to systematically identify these risks.

- Risk Assessment: Once identified, risks are assessed based on their likelihood and potential impact. This helps prioritize mitigation efforts. Techniques like Failure Mode and Effects Analysis (FMEA) are useful here.

- Risk Mitigation: This phase involves developing and implementing strategies to reduce the likelihood or impact of identified risks. Strategies can include diversifying suppliers, building safety stock, developing contingency plans, and investing in supply chain visibility technologies.

- Monitoring and Review: Continuously monitoring the supply chain for emerging risks and regularly reviewing the effectiveness of mitigation strategies is crucial for maintaining resilience.

For instance, a company facing geopolitical instability in a key sourcing region might mitigate risk by diversifying its sourcing to multiple locations or building up strategic inventory. Regular risk assessments allow for proactive adaptation to changing circumstances.

Q 6. How do you forecast demand and manage supply chain volatility?

Forecasting demand and managing supply chain volatility are intertwined challenges. I use a combination of quantitative and qualitative methods for accurate demand forecasting:

- Quantitative Methods: Time series analysis, moving averages, exponential smoothing, and regression analysis are used to identify trends and patterns in historical data. These methods are valuable for understanding past performance but need additional context.

- Qualitative Methods: Gathering input from sales teams, market research, and industry experts helps incorporate insights beyond historical data, allowing for more robust forecasting. This captures external factors that purely quantitative models might miss.

- Causal Forecasting: This method explores the relationships between different factors (economic indicators, marketing campaigns) and demand. By understanding these correlations, one can predict the impact of changes on future demand.

- Scenario Planning: This involves developing multiple scenarios (e.g., optimistic, pessimistic, most likely) to prepare for different potential outcomes. This helps build flexibility into the supply chain strategy.

Managing volatility involves a combination of inventory management techniques (as discussed earlier), flexible production capacity, and strong supplier relationships. Having access to real-time data and robust communication systems is also crucial for timely responses to sudden shifts in demand or disruptions.

Q 7. Describe your experience with different transportation modes and their selection criteria.

My experience encompasses various transportation modes, each with its own advantages and disadvantages. The selection criteria depend on factors like:

- Cost: The cost per unit transported varies significantly across modes. Truck transport is generally cost-effective for shorter distances, while rail or sea transport is preferable for larger volumes and longer distances.

- Speed: Air freight is the fastest but most expensive option. Truck transport offers a balance between speed and cost, while rail and sea transport are significantly slower.

- Reliability: The reliability of different modes varies depending on factors like weather conditions and infrastructure. Air freight is generally considered the most reliable, but disruptions due to weather or air traffic control are possible.

- Capacity: Different modes have different capacity limitations. Sea freight can handle the largest volumes, followed by rail, then truck, and finally air freight.

- Suitability of Goods: Perishable goods typically require faster modes like air freight, while non-perishable goods may be suitable for slower and more cost-effective options.

- Environmental Impact: Consideration of the environmental footprint of transportation is increasingly important. Sea and rail freight generally have a smaller carbon footprint than road transport.

I often optimize transportation strategies by using a combination of modes. For example, a company might use sea freight for bulk transport from overseas suppliers, then switch to truck transport for the final delivery to customers.

Q 8. What is your experience with warehouse management systems (WMS)?

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. They are software solutions that manage and optimize the movement and storage of goods within a warehouse, from receiving to shipping. My experience encompasses implementing, configuring, and managing various WMS platforms, including blue-yonder, Manhattan Associates, and SAP EWM. I’ve worked with both cloud-based and on-premise solutions.

In a previous role, we implemented a new WMS to replace a legacy system. This involved a detailed needs assessment, selecting the right vendor, customizing the software to our specific requirements (including integrations with our ERP and transportation management systems), and managing the entire implementation process, including user training and go-live support. The result was a significant improvement in order accuracy, reduced cycle times, and optimized inventory levels, leading to a substantial increase in efficiency and cost savings.

I am proficient in using WMS functionalities such as inventory tracking, order fulfillment, slotting optimization, and labor management. I understand the importance of integrating WMS with other supply chain systems for end-to-end visibility and control. I’m also experienced in optimizing WMS configurations to improve performance metrics such as pick accuracy and put-away efficiency.

Q 9. How do you optimize logistics networks for cost and efficiency?

Optimizing logistics networks for cost and efficiency requires a holistic approach, considering various factors including transportation modes, warehouse locations, inventory levels, and supplier relationships. It’s like designing a finely tuned machine where every part works in harmony.

My approach involves using a combination of analytical tools and best practices. This starts with a thorough network design analysis, leveraging tools like network optimization software to evaluate different scenarios and identify optimal locations for warehouses and distribution centers. We consider factors such as transportation costs, lead times, customer proximity, and tax implications.

For example, in a previous project, we used simulation modeling to evaluate the impact of adding a regional distribution center. The simulation showed a significant reduction in delivery times and transportation costs, leading to improved customer satisfaction and cost savings. Beyond location, we also focus on optimizing transportation routes, leveraging technology like route optimization software and negotiating favorable rates with carriers. We also implement strategies like consolidating shipments and utilizing efficient transportation modes to minimize costs.

Finally, continuous monitoring and improvement are crucial. Regularly reviewing key performance indicators (KPIs) such as delivery times, transportation costs, and inventory levels allows us to identify areas for improvement and make data-driven adjustments.

Q 10. What is your approach to resolving supply chain disruptions?

Resolving supply chain disruptions requires a proactive and agile approach. Think of it as firefighting, but with a focus on prevention and quick response.

My approach is based on a three-pronged strategy: Prevention, Mitigation, and Recovery. Prevention involves building resilient supply chains by diversifying suppliers, holding safety stock, and developing contingency plans for potential disruptions. Mitigation focuses on identifying and addressing potential disruptions as early as possible. This includes establishing robust monitoring systems to track potential risks, such as geopolitical instability or natural disasters.

For example, during the pandemic, we proactively identified potential supply shortages and worked with our suppliers to secure alternative sourcing options. This involved renegotiating contracts, exploring new suppliers, and even investing in domestic manufacturing capabilities. When disruptions do occur, a rapid recovery is essential. This involves activating our contingency plans, collaborating closely with our suppliers and customers, and using data analytics to understand the impact and prioritize our response efforts. We might leverage alternative transportation modes, explore expedited shipping options, and communicate transparently with stakeholders to manage expectations.

Q 11. Explain your experience with different procurement processes (e.g., RFQ, RFP, RFX).

I have extensive experience with various procurement processes, including Request for Quotation (RFQ), Request for Proposal (RFP), and Request for Information (RFI), collectively often referred to as RFX. These processes are the building blocks of effective sourcing and procurement.

An RFQ is used for straightforward procurements where price is the primary decision factor. An RFP is used for more complex procurements where a detailed proposal outlining the supplier’s approach, capabilities, and pricing is required. An RFI is a preliminary step used to gather information from potential suppliers before deciding on the most appropriate procurement method (RFQ or RFP).

My experience includes developing and managing the entire procurement lifecycle, from defining requirements and selecting suppliers to contract negotiation and supplier performance management. I am proficient in using e-procurement systems to streamline the process and ensure transparency. For example, in one project, we implemented a new e-procurement system which automated many manual processes, reduced procurement lead times, and improved compliance.

Q 12. How do you ensure supplier compliance with ethical and sustainability standards?

Ensuring supplier compliance with ethical and sustainability standards is critical for building a responsible and sustainable supply chain. It’s not just about ticking boxes; it’s about embedding ethical and sustainable practices into the very core of our procurement strategy.

My approach involves a multi-faceted strategy including: Supplier Audits, Codes of Conduct, and Continuous Monitoring. We conduct regular audits to assess supplier compliance with our ethical and sustainability standards, covering areas such as labor practices, environmental impact, and human rights. We establish clear codes of conduct that outline our expectations for suppliers and require them to sign agreements affirming their commitment to these standards.

We also use technology to track and monitor supplier performance, looking at key indicators such as waste reduction, energy consumption, and employee well-being. This data-driven approach allows us to identify areas for improvement and work collaboratively with suppliers to address any compliance gaps. Non-compliance can result in corrective action plans or, in severe cases, termination of the supplier relationship.

Q 13. Describe your experience with implementing and managing supplier diversity programs.

Implementing and managing supplier diversity programs is crucial for promoting inclusivity and creating a more equitable business ecosystem. It’s about actively seeking out and supporting businesses owned by underrepresented groups.

My experience includes developing and implementing supplier diversity programs that focus on identifying and engaging diverse suppliers across various categories. This involves establishing clear goals and targets for diverse supplier spend, creating a robust supplier registration process, and providing training and support to diverse suppliers. We actively participate in industry events and networking opportunities to identify potential diverse suppliers.

We also build strong relationships with diverse supplier organizations to foster collaboration and create a supportive ecosystem. We track progress against our diversity goals and regularly report on our performance to stakeholders. The benefits extend beyond compliance; diverse suppliers often bring unique perspectives and innovative solutions, strengthening our overall supply chain.

Q 14. How do you utilize technology to improve supply chain efficiency?

Technology plays a pivotal role in improving supply chain efficiency. It’s the engine that drives optimization and visibility.

I leverage various technologies, including: ERP systems, WMS, TMS, and advanced analytics. Enterprise Resource Planning (ERP) systems provide a centralized platform for managing all aspects of the business, from procurement to sales. Transportation Management Systems (TMS) optimize transportation planning and execution, reducing costs and improving delivery times. Advanced analytics tools, such as predictive modeling and machine learning, help us forecast demand, optimize inventory levels, and identify potential disruptions early on. Blockchain technology is being explored for enhancing supply chain transparency and traceability.

For instance, in a previous role, we used predictive analytics to forecast demand with greater accuracy, reducing inventory holding costs and avoiding stockouts. The implementation of a new TMS resulted in a 15% reduction in transportation costs. By embracing technology, we’re not just automating tasks; we’re gaining deeper insights, making better decisions, and building a more agile and responsive supply chain.

Q 15. What is your understanding of Total Landed Cost (TLC)?

Total Landed Cost (TLC) represents the complete cost of getting a product to your warehouse, ready for sale or use. It’s more than just the purchase price; it encompasses all expenses incurred from the origin of the product to its final destination. Think of it as the true, all-inclusive price tag.

- Purchase Price: The initial cost of the goods.

- Shipping Costs: Freight, insurance, customs duties, and port charges.

- Customs Duties and Taxes: Tariffs and other import/export taxes levied by governments.

- Insurance: Covering potential damage or loss during transit.

- Handling and Storage: Costs associated with warehousing and logistics at various points in the supply chain.

- Inspection Fees: Costs incurred for quality checks at various stages.

- Currency Fluctuations: Changes in exchange rates impacting the final cost.

Example: Imagine importing furniture from overseas. TLC would include the cost of the furniture itself, ocean freight, customs duties, insurance, inland transportation to your warehouse, and any handling fees. Understanding TLC is crucial for accurate pricing and profit margin calculations. Ignoring hidden costs can significantly impact profitability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with lean manufacturing principles in a supply chain context.

Lean manufacturing principles, focused on eliminating waste and maximizing efficiency, are deeply integrated into my supply chain approach. In my previous role at XYZ Corporation, we implemented several lean initiatives, significantly reducing lead times and inventory holding costs. We used a combination of techniques such as:

- Value Stream Mapping: Identifying and eliminating non-value-added steps in the supply chain process. This involved analyzing the entire flow of materials and information, from raw materials to finished goods, and pinpointing bottlenecks or inefficiencies.

- 5S Methodology: Organizing the workplace to improve efficiency and reduce waste (Sort, Set in Order, Shine, Standardize, Sustain). This involved implementing clear labeling, standardized storage locations, and regular clean-up routines in our warehouse.

- Kaizen Events: Conducting short, focused improvement projects involving cross-functional teams to tackle specific problems. One such event resulted in a 15% reduction in our order fulfillment time.

- Kanban System: Implementing a pull system for inventory management, ensuring that only necessary materials are ordered and produced at the right time. This greatly reduced our inventory holding costs and minimized waste due to obsolescence.

These efforts collectively resulted in a 20% reduction in lead times and a 10% decrease in inventory holding costs. Lean principles are not just about cost reduction; they also improve quality, increase flexibility, and enhance customer satisfaction.

Q 17. How do you measure the return on investment (ROI) of supply chain initiatives?

Measuring the ROI of supply chain initiatives requires a clear understanding of both costs and benefits. It’s not just about immediate cost savings, but also about long-term improvements in efficiency, customer satisfaction, and risk mitigation. I typically employ a multi-faceted approach:

- Cost Reduction: Quantify the reduction in inventory holding costs, transportation expenses, procurement costs, etc. This involves comparing pre- and post-implementation data.

- Efficiency Gains: Measure improvements in lead times, order fulfillment rates, and on-time delivery performance. These improvements translate to increased operational efficiency and potential for revenue growth.

- Revenue Enhancement: Track increases in sales due to improved supply chain responsiveness and enhanced product availability.

- Risk Mitigation: Quantify the reduction in risks associated with supply disruptions, stockouts, and quality issues. This can be challenging to quantify directly, but qualitative assessments can be incorporated into the ROI calculation.

- Customer Satisfaction: Improved delivery times and product availability contribute to higher customer satisfaction, which can be measured through surveys and feedback mechanisms.

Example: Implementing a new warehouse management system might involve an upfront investment. The ROI is calculated by comparing the investment cost against the savings achieved from reduced labor costs, improved inventory accuracy, and reduced storage space. A clear ROI calculation demonstrates the financial viability and value of such initiatives to stakeholders.

Q 18. How would you handle a situation where a key supplier is experiencing a production delay?

A key supplier’s production delay is a serious issue demanding immediate action. My approach involves a structured, multi-pronged response:

- Immediate Communication: Establish open communication with the supplier to understand the root cause of the delay, its potential duration, and mitigation strategies they’re implementing.

- Impact Assessment: Assess the impact of the delay on our production schedule, customer commitments, and overall business operations. This involves examining the inventory levels of the affected component and potential alternative sources.

- Contingency Planning: Develop and implement a contingency plan. This might involve expediting existing orders, exploring alternative suppliers (even if it means higher costs temporarily), re-prioritizing production schedules, or negotiating flexible delivery schedules with customers.

- Risk Mitigation: Implement measures to mitigate the risk of future delays. This might include diversifying the supplier base, building strategic inventory buffers for critical components, or establishing stronger collaborative relationships with suppliers.

- Root Cause Analysis: Following resolution, perform a thorough root cause analysis to understand the factors contributing to the delay and prevent similar incidents in the future. This could involve evaluating supplier processes, logistics, and quality control procedures.

Example: Facing a chip shortage, we immediately communicated with our key supplier, understanding the global semiconductor industry constraints. We initiated negotiations with secondary suppliers, expedited existing orders, and transparently communicated the potential delay to our customers, offering flexible solutions.

Q 19. Describe your experience with different sourcing strategies (e.g., single sourcing, multi-sourcing).

My experience encompasses various sourcing strategies, each with its own advantages and disadvantages. The optimal choice depends on factors like product criticality, supplier reliability, cost considerations, and risk tolerance.

- Single Sourcing: This involves relying on a single supplier for a specific component or product. Benefits include building strong relationships, achieving economies of scale, and potentially securing better pricing. However, it introduces higher risk of disruption if the sole supplier faces issues.

- Multi-Sourcing: This involves spreading the risk by using multiple suppliers for the same product or component. It enhances supply chain resilience by mitigating the impact of disruptions from a single supplier. However, it can be more complex to manage and may lead to higher administrative costs and potential inconsistencies in quality.

- Dual Sourcing: A hybrid approach, utilizing two suppliers with the primary supplier providing the majority of supplies, and the secondary supplier serving as a backup. This balances risk mitigation with cost-efficiency and relationship management.

Example: For a critical component, I might use dual sourcing, maintaining a primary supplier with proven reliability while having a secondary supplier ready to step in if needed. For less critical items, multi-sourcing could be beneficial to leverage competitive pricing and reduce dependence on any single supplier. The selection depends on a thorough risk assessment and cost-benefit analysis.

Q 20. What is your understanding of blockchain technology’s application in supply chain?

Blockchain technology offers transformative potential for supply chain management by enhancing transparency, traceability, and security. Its decentralized, immutable ledger can track products and materials throughout their journey, providing verifiable data at each stage.

- Improved Traceability: Blockchain enables end-to-end tracking of products, providing insights into their origin, handling, and movement. This is particularly beneficial for industries with stringent regulatory requirements, like food and pharmaceuticals.

- Enhanced Transparency: All participants in the supply chain can access the shared, immutable ledger, improving visibility and collaboration. This minimizes information asymmetry and builds trust among stakeholders.

- Increased Security: The cryptographic nature of blockchain enhances data security and protects against tampering or fraud. This reduces the risk of counterfeiting and ensures product authenticity.

- Streamlined Processes: Automating data recording and sharing reduces paperwork and manual processes, improving efficiency and reducing operational costs.

Example: Imagine tracking a shipment of coffee beans from farm to consumer. Blockchain can record every step, from harvesting to roasting, ensuring the quality and origin are verifiable. This improves transparency for consumers and reduces the risk of fraud or mislabeling.

Q 21. How do you manage inventory obsolescence and disposal?

Managing inventory obsolescence and disposal requires a proactive and multi-faceted approach. Ignoring this can lead to significant financial losses and environmental concerns.

- Demand Forecasting: Accurate demand forecasting is crucial to minimize the risk of overstocking and obsolescence. This involves utilizing sophisticated forecasting techniques and taking into account market trends and seasonality.

- Inventory Control: Implementing robust inventory management systems, including FIFO (First-In, First-Out) and regular stock audits, helps identify slow-moving or obsolete items early on.

- Early Warning System: Establishing an early warning system to monitor inventory levels and identify items at risk of obsolescence. This enables timely interventions, such as discounting or promotional campaigns.

- Inventory Optimization: Implementing inventory optimization techniques, such as ABC analysis, helps prioritize focus on high-value items and minimize risk for less critical items.

- Disposal Strategies: Develop appropriate disposal strategies for obsolete inventory, considering environmental regulations and ethical considerations. This could involve recycling, donations to charities, or safe disposal according to applicable regulations.

Example: We regularly review our inventory using ABC analysis, focusing on high-value, slow-moving ‘A’ items to avoid obsolescence. For ‘C’ items, we implement a strict inventory control process with regular audits to prevent excessive buildup. Obsolete items are either recycled, donated, or disposed of responsibly in accordance with environmental standards.

Q 22. Explain your experience with customs brokerage and international trade regulations.

My experience with customs brokerage and international trade regulations is extensive. I’ve managed the import and export of goods across various countries, navigating the complexities of documentation, tariffs, and regulatory compliance. This includes a deep understanding of Incoterms (International Commercial Terms), which define the responsibilities of buyers and sellers in international trade. For example, I’ve successfully managed shipments under both DDP (Delivery Duty Paid) and FOB (Free On Board) terms, ensuring seamless delivery while adhering to all relevant regulations. I’m proficient in using various customs brokerage software to generate necessary documentation, track shipments, and manage customs declarations accurately and efficiently. I’ve also successfully resolved several customs audits and disputes, demonstrating my ability to proactively mitigate risks and ensure compliance with evolving international trade laws. Specifically, I have experience with the Harmonized System (HS) codes, crucial for accurate classification of goods and determining applicable tariffs. My practical experience includes navigating complex regulatory changes like those introduced with Brexit and the ongoing adjustments to trade relationships between major economies. I understand the importance of maintaining meticulous records to demonstrate compliance, and I employ a proactive approach to identify and address potential compliance issues before they escalate.

Q 23. Describe your experience with demand planning and sales & operations planning (S&OP).

Demand planning and Sales & Operations Planning (S&OP) are critical for aligning supply with demand. My experience involves using various forecasting techniques, including statistical models like ARIMA and exponential smoothing, to predict future demand. I’ve worked with cross-functional teams, including sales, marketing, and operations, to develop accurate demand forecasts. This includes incorporating qualitative insights from sales representatives and market research to refine quantitative forecasts. In S&OP meetings, I’ve facilitated collaborative discussions to align sales targets with production capacity and inventory levels. For instance, in a previous role, we implemented a new S&OP process that improved forecast accuracy by 15%, resulting in a significant reduction in inventory holding costs and improved customer service levels. My experience extends to capacity planning, ensuring that sufficient resources are available to meet the forecasted demand. I’ve also worked with inventory optimization techniques to minimize stockouts and excess inventory. The key to effective S&OP is open communication and data-driven decision-making. We regularly reviewed and adjusted forecasts based on actual sales data and market conditions. This iterative process allowed us to adapt to changing market dynamics and maintain an optimal balance between supply and demand.

Q 24. How do you ensure data accuracy and integrity in your supply chain operations?

Data accuracy and integrity are fundamental to effective supply chain management. I employ a multi-pronged approach, starting with data governance. This involves establishing clear data ownership, defining data standards, and implementing data validation rules at various points in the supply chain. We use master data management systems to maintain accurate and consistent information on products, suppliers, customers, and locations. Data quality checks and audits are performed regularly to identify and correct errors. For example, we use data cleansing techniques to remove duplicates, correct inconsistencies, and fill in missing values. Automation plays a significant role; we use automated data extraction and integration tools to minimize manual data entry and reduce the risk of human error. We also leverage technologies like blockchain for enhanced transparency and traceability. Finally, regular training is provided to staff on data management best practices. This comprehensive strategy ensures that the data used for decision-making is reliable and accurate, reducing the likelihood of costly mistakes and improving overall supply chain efficiency.

Q 25. Explain your experience with supply chain analytics and data-driven decision making.

My experience with supply chain analytics and data-driven decision-making is extensive. I leverage various analytical tools and techniques, including statistical modeling, data visualization, and machine learning, to analyze large datasets and extract meaningful insights. I’ve utilized tools such as Power BI and Tableau to create dashboards that provide real-time visibility into key supply chain metrics, such as inventory levels, lead times, and transportation costs. This allows for proactive identification of potential problems and informed decision-making. For example, by analyzing historical data on transportation costs, we identified an opportunity to optimize our shipping routes, resulting in a 10% reduction in transportation expenses. Similarly, using predictive analytics, we were able to forecast potential disruptions in our supply chain, allowing us to implement mitigation strategies and minimize the impact on our operations. I’m comfortable interpreting complex statistical outputs and translating them into actionable insights for business stakeholders. The focus is on using data to make evidence-based decisions that optimize efficiency, reduce costs, and enhance customer satisfaction. We constantly look for ways to improve our analytical capabilities by incorporating new technologies and techniques.

Q 26. What are your strengths and weaknesses in supply chain management?

My strengths in supply chain management lie in my analytical skills, my ability to collaborate effectively with cross-functional teams, and my proactive approach to problem-solving. I am adept at identifying inefficiencies and developing data-driven solutions to improve supply chain performance. My experience with various forecasting techniques and analytics tools allows me to make informed decisions and anticipate potential challenges. One area where I consistently excel is in building strong relationships with suppliers, fostering collaboration and mutual trust to ensure a reliable and cost-effective supply of materials. A weakness I am actively working to improve is delegation. While I am capable of handling multiple tasks simultaneously, I am learning to effectively delegate tasks to team members to leverage their skills and improve team efficiency. This involves clearly defining responsibilities, providing sufficient training, and establishing clear communication channels. I’ve already started implementing strategies to address this, including regular check-ins with my team members and the implementation of project management tools to streamline workflow and task assignments.

Q 27. How do you stay updated on industry trends and best practices in supply chain?

Staying updated on industry trends and best practices is critical in the dynamic field of supply chain management. I regularly read industry publications, such as the Journal of Business Logistics and Supply Chain Management Review. I actively participate in industry conferences and webinars, networking with other professionals and learning about new technologies and strategies. I also follow leading supply chain experts on social media platforms like LinkedIn and Twitter. Moreover, I participate in professional development courses and workshops to enhance my skills and knowledge. This continuous learning ensures that I remain abreast of the latest advancements in areas such as blockchain technology, artificial intelligence, and sustainable supply chain practices. I also actively seek out case studies of successful supply chain implementations to learn from best practices and adapt them to my own work. By combining diverse learning sources, I can ensure a comprehensive understanding of current trends and best practices, and constantly look for ways to incorporate these into my work to maximize efficiency and effectiveness.

Q 28. Describe a time you had to make a difficult decision in a supply chain context.

In a previous role, we faced a major supplier disruption due to a natural disaster that significantly impacted the supply of a critical component. This threatened to halt production and severely impact our ability to meet customer orders. The initial reaction was panic, but I quickly assembled a cross-functional team to assess the situation and develop mitigation strategies. We first explored alternative suppliers, but lead times were long and the quality was questionable. Next, we carefully evaluated our inventory levels and prioritized the allocation of the remaining stock to fulfill the most critical orders. We simultaneously negotiated with our existing supplier to expedite the repair and restoration of their facilities. We had to make difficult decisions regarding which orders to prioritize and communicate potential delays to customers. While challenging, the transparent and proactive communication with our customers helped maintain their trust, minimizing the long-term damage. Through careful planning, proactive communication, and the collaboration of our team, we successfully navigated the crisis, minimizing disruption to production and preserving key customer relationships. This experience underscored the importance of having a robust risk management plan and strong supplier relationships in order to overcome unexpected challenges.

Key Topics to Learn for Supply Chain Management and Procurement Interview

- Supply Chain Strategy & Design: Understanding different supply chain models (e.g., agile, lean), network optimization, and risk mitigation strategies. Practical application: Analyzing a case study to improve efficiency and reduce costs in a given supply chain.

- Procurement & Sourcing: Negotiation techniques, supplier relationship management (SRM), total cost of ownership (TCO) analysis, and e-procurement systems. Practical application: Developing a sourcing strategy for a specific product or service, considering factors like price, quality, and risk.

- Inventory Management: Forecasting techniques, inventory control methods (e.g., EOQ, JIT), and warehouse management. Practical application: Optimizing inventory levels to minimize holding costs while ensuring sufficient stock to meet demand.

- Logistics & Transportation: Transportation modes selection, route optimization, and logistics network design. Practical application: Designing a cost-effective transportation plan for delivering goods to multiple locations.

- Demand Planning & Forecasting: Utilizing various forecasting methods (e.g., moving average, exponential smoothing) to predict future demand and optimize inventory levels. Practical application: Analyzing historical sales data to create a demand forecast for the next quarter.

- Supply Chain Technology & Analytics: Understanding the role of technology (e.g., ERP, SCM software) in supply chain management and utilizing data analytics for process improvement and decision-making. Practical application: Interpreting key performance indicators (KPIs) to identify areas for improvement within a supply chain.

- Supply Chain Risk Management: Identifying and mitigating potential risks (e.g., supplier disruptions, natural disasters) within the supply chain. Practical application: Developing a contingency plan to address potential supply chain disruptions.

- Sustainability & Ethical Sourcing: Integrating sustainable practices and ethical considerations into procurement and supply chain operations. Practical application: Evaluating suppliers based on their environmental and social responsibility performance.

Next Steps

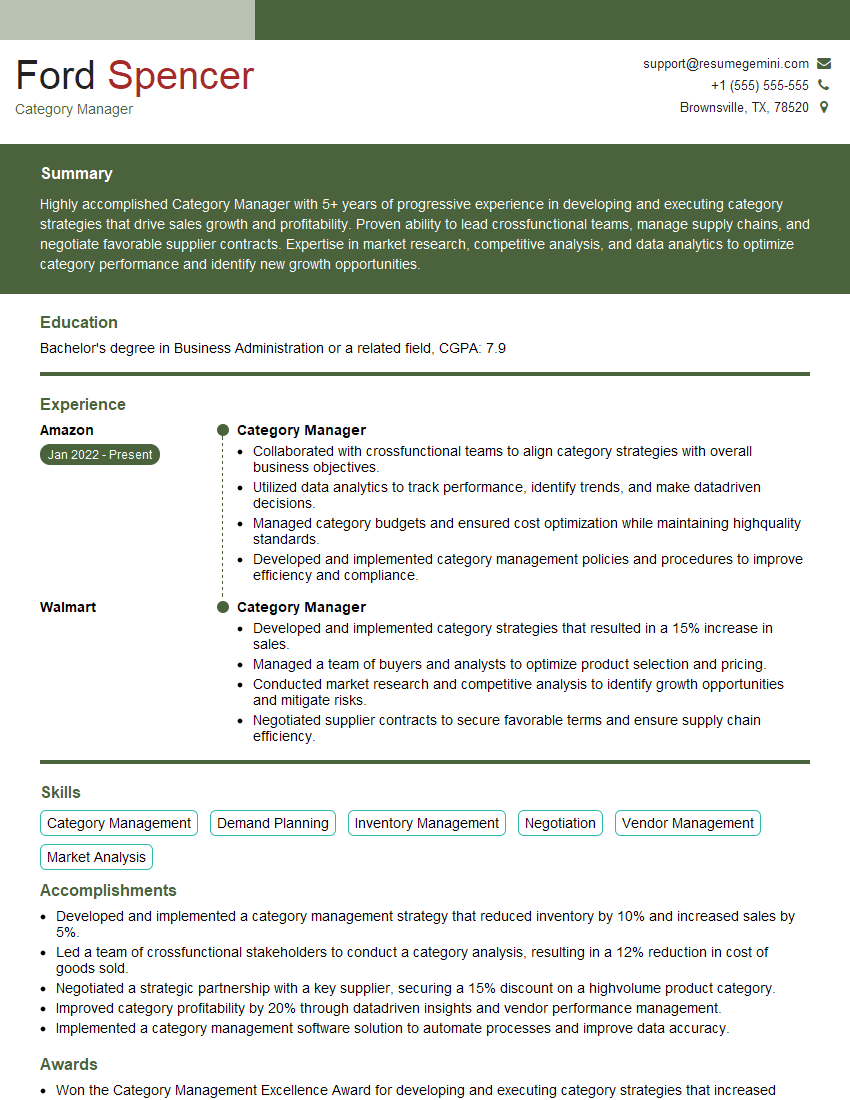

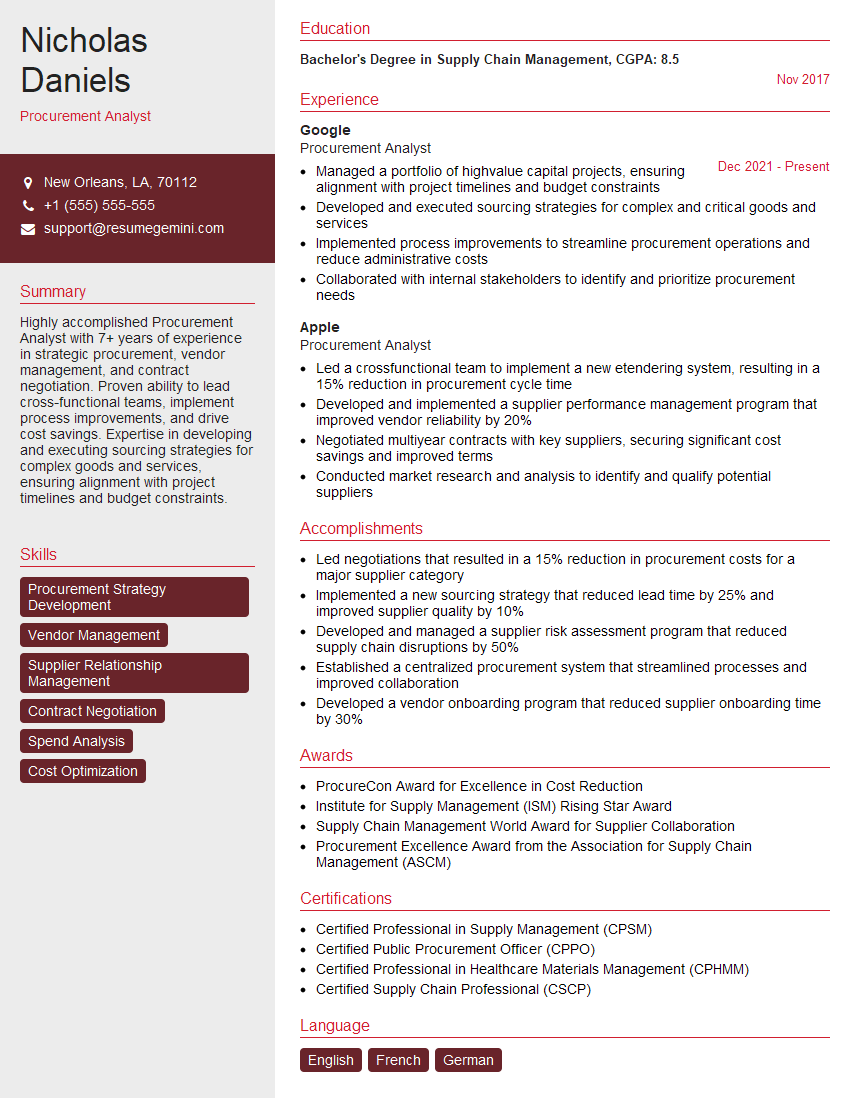

Mastering Supply Chain Management and Procurement opens doors to exciting and rewarding career opportunities, offering significant growth potential in diverse industries. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed. To enhance your resume-building experience and maximize your job prospects, we recommend using ResumeGemini. ResumeGemini provides a trusted platform for crafting professional resumes, and we offer examples of resumes specifically tailored to Supply Chain Management and Procurement to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good