Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Tanker and Railcar Handling interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Tanker and Railcar Handling Interview

Q 1. Describe your experience with different types of tanker trucks and railcars.

My experience encompasses a wide range of tanker trucks and railcars, categorized primarily by the material they transport. For example, I’ve worked extensively with:

- Pressure tank trucks: These are used for transporting liquefied gases like propane or ammonia, requiring specialized pressure-relief valves and robust construction to withstand high internal pressures. I’ve overseen the loading and unloading of these, emphasizing the crucial safety protocols involved in handling compressed gases.

- Vacuum tank trucks: These are ideal for materials like asphalt or molasses that require suction for transfer. My experience includes optimizing pumping speeds and ensuring minimal product loss during transfer. I also have experience with various vacuum truck types, like those equipped with heating capabilities for high-viscosity materials.

- Non-pressure tank trucks: These carry liquids like gasoline, diesel, or chemicals in bulk. My work here includes overseeing the proper filling levels to avoid overfilling and ensuring compliance with weight restrictions. I’ve dealt with various types and sizes of non-pressure tanks, including those with compartments for different products.

- Railcars: My experience extends to a variety of railcars, including general service tank cars, pressure tank cars, and cryogenic tank cars. The complexities of railcar handling, especially in switching yards and terminal operations, are familiar to me, including coupling and uncoupling procedures, and the unique safety considerations involved in working with rail infrastructure.

This varied experience allows me to adapt quickly to different tank configurations and material handling challenges.

Q 2. Explain the process of loading and unloading hazardous materials from tankers and railcars.

Loading and unloading hazardous materials is a highly regulated and complex process prioritizing safety. It begins with a thorough pre-operation inspection of the tanker or railcar, including checking for leaks, verifying the proper identification of the material, and ensuring all safety equipment is functional. The process then follows these steps:

- Preparation: This involves checking all relevant documentation – shipping papers, safety data sheets (SDS), and emergency response plans. The receiving facility must be prepared for the delivery, with proper grounding and bonding procedures in place to prevent static electricity buildup.

- Connection: Secure connections are paramount. Specialized hoses and fittings are used, matched to the specific material and pressure rating. Visual inspection before and after connection is crucial to ensure a leak-free seal.

- Transfer: The transfer process is monitored closely, using flow meters and pressure gauges to control the rate and ensure no spillage. Emergency shutdown procedures must be readily accessible and understood by all personnel.

- Disconnection: Upon completion, the connections are carefully disconnected, ensuring all residual material is drained and there is no dripping or leakage. A final inspection is conducted.

- Post-Transfer Procedures: This involves proper documentation of the transfer, including the quantity transferred, any incidents, and a final check of the container for any leaks. Waste generated during cleaning must also be handled according to regulations.

For highly volatile materials, specialized loading arms and vapor recovery systems are employed to minimize emissions.

Q 3. How do you ensure the safety of tanker and railcar operations?

Safety is paramount. We employ a multi-layered approach:

- Pre-operational Inspections: Thorough checks of the tanker or railcar, including its structural integrity, valves, fittings, and safety devices. This ensures that everything is in perfect working order before operations commence.

- Personal Protective Equipment (PPE): Appropriate PPE, including respirators, gloves, eye protection, and protective clothing, is mandatory for all personnel handling hazardous materials. Training on the proper use of this equipment is essential.

- Emergency Response Planning: We develop and practice comprehensive emergency response plans specific to each material and location. This includes spill response protocols, evacuation procedures, and emergency contact information. Regular drills ensure preparedness.

- Grounding and Bonding: Preventing static electricity buildup is crucial when transferring flammable liquids. Proper grounding and bonding procedures are strictly followed.

- Lockout/Tagout Procedures: These procedures ensure that equipment is de-energized and locked out before maintenance or repair work, preventing accidental injury.

- Training and Competency: All personnel are thoroughly trained and certified in the safe handling of hazardous materials, emphasizing safe practices and emergency procedures. Regular refresher courses are conducted.

Safety is not just a checklist; it’s a mindset integrated into every aspect of our operations.

Q 4. What are the common regulations and compliance requirements for handling tankers and railcars?

Regulations governing tanker and railcar handling are stringent and vary by jurisdiction, but common themes include:

- Department of Transportation (DOT) Regulations (USA): These cover hazardous materials classification, packaging, labeling, and transportation. Compliance is crucial, and violations can lead to significant penalties.

- Environmental Protection Agency (EPA) Regulations (USA): These cover spill prevention, control, and countermeasures (SPCC) plans, ensuring environmental protection. Regular audits and reporting are required.

- Occupational Safety and Health Administration (OSHA) Regulations (USA): These focus on worker safety and health, mandating proper training, PPE, and safe work practices. Regular inspections and record-keeping are essential.

- International Maritime Organization (IMO) Regulations: For international transport by sea, the IMO’s International Maritime Dangerous Goods (IMDG) code sets the standards. These standards often mirror or surpass those of individual nations.

- Local Ordinances: Many jurisdictions have additional local regulations that further refine safety and environmental protection standards.

Staying updated on these regulations and adapting operational procedures to meet them is an ongoing process.

Q 5. Describe your experience with different types of tank cleaning procedures.

Tank cleaning procedures are chosen based on the material previously carried and the subsequent use of the tank. Methods vary in complexity and stringency:

- Simple Washing: Using water or a mild detergent solution to remove residues of non-hazardous materials. This is often suitable for tanks carrying non-hazardous liquids like water or certain food products.

- Chemical Cleaning: Employing specialized solvents or detergents to remove stubborn residues or hazardous materials. This requires careful selection of cleaning agents to ensure compatibility and avoid cross-contamination. Waste disposal is a major consideration.

- Steam Cleaning: Using high-pressure steam to remove residues. This is often effective but requires careful control to avoid damage to the tank. It is suitable for many different products and is effective for many solids.

- In-Place Cleaning (CIP): Used in some rail tank car settings, this involves using cleaning solutions circulated through a closed system within the car itself. This is more efficient and reduces water usage.

After cleaning, the tank must be thoroughly inspected and rinsed to ensure complete removal of all cleaning agents and residues. Documentation of the entire cleaning process is crucial for compliance.

Q 6. How do you handle emergencies involving tanker and railcar leaks or spills?

Emergency response to tanker or railcar leaks or spills is a critical aspect of our operations. Our response follows a well-defined plan:

- Initial Response: Immediately isolate the area, preventing further spread of the spill. Evacuate personnel if necessary.

- Emergency Notification: Contact relevant emergency services (fire department, hazmat team, environmental authorities) immediately. Provide them with all relevant information, including the type and quantity of the spilled material.

- Containment: Employ containment measures such as booms, absorbent pads, and berms to prevent further spread of the spill into waterways or sensitive environments. We utilize appropriate personal protective equipment throughout.

- Recovery: Recover the spilled material using appropriate techniques, possibly involving vacuum trucks, pumps, and specialized equipment.

- Cleanup: Thoroughly clean the affected area, removing all traces of the spilled material. Soil sampling and remediation might be required.

- Documentation: Detailed records of the incident, response procedures, and cleanup efforts must be maintained for regulatory compliance and future reference.

Regular training and drills ensure our team is prepared to handle emergencies effectively and efficiently, minimizing environmental impact and protecting human health.

Q 7. Explain your knowledge of different types of valves and fittings used in tanker and railcar systems.

Tanker and railcar systems utilize a variety of valves and fittings, each with a specific function and safety considerations:

- Gate Valves: These are used for on/off control of fluid flow. They are robust but can be slow-acting. They are a common valve for large railcars and some tankers.

- Ball Valves: These provide quick on/off control. They are relatively compact and have a simple design. They can be used on many different applications but are frequently found on smaller tankers.

- Butterfly Valves: These are another quick on/off option offering a compact design, useful in larger pipeline systems connected to tankers.

- Globe Valves: These provide precise flow control and are often used in regulating pressure or flow rate. They are used for many processes.

- Check Valves: These prevent backflow of liquids, essential in preventing contamination or reversing the flow of liquids.

- Pressure Relief Valves: These protect tanks from overpressurization, automatically releasing excess pressure to prevent ruptures. They are particularly crucial in pressure tank cars and trucks.

- Fittings: Various fittings (flanges, unions, couplings) are used to connect hoses and pipes to valves and the tank itself. They must be compatible with the material being transported and the system pressure.

The selection of valves and fittings is dictated by factors such as the material being handled, pressure requirements, flow rate, and safety considerations. Regular inspection and maintenance are critical to ensure their continued function and prevent leaks.

Q 8. What are the different types of inspections performed on tankers and railcars?

Tanker and railcar inspections are crucial for safety and regulatory compliance. They range from simple visual checks to complex, specialized examinations. Types of inspections include:

- Pre-trip Inspections: These are mandatory before each trip and cover everything from tire pressure and brake functionality to examining the tank itself for leaks, corrosion, or damage. Think of it like a car’s pre-drive check, but much more comprehensive.

- In-service Inspections: These occur during the operational life of the tanker or railcar, often at scheduled intervals or triggered by specific events (e.g., a minor accident). They might focus on specific components based on usage and risk.

- Post-trip Inspections: These happen after each trip to assess the condition of the vehicle and identify any damage that may have occurred during transport. They’re essential for preventing future issues.

- Annual/Periodic Inspections: More thorough inspections, usually conducted annually or at other defined intervals, depending on regulations and the vehicle’s age and use. They often involve specialized equipment and expertise.

- Specialized Inspections: These inspections target specific components or aspects of the vehicle. For example, a pressure test might be performed on the tank, or a thorough examination of the unloading valves may be conducted.

The specific inspection procedures and frequency are usually defined by regulatory bodies (like the DOT in the US) and company-specific safety protocols.

Q 9. How do you maintain accurate records and documentation for tanker and railcar operations?

Maintaining accurate records is paramount for safety, regulatory compliance, and efficient operations. We utilize a combination of digital and physical methods:

- Electronic Logging Devices (ELDs): ELDs automatically record crucial information like location, speed, hours of service, and potentially even pre-trip inspection results. This is a huge advancement in ensuring accuracy and reducing paperwork.

- Digital Inspection Checklists: These allow drivers and inspectors to electronically record inspection findings, including photos of any damage. This helps streamline the process and minimize discrepancies. The system typically generates a report that is automatically archived.

- Bill of Lading (BOL): This crucial document details the shipment’s origin, destination, contents, quantity, and other relevant information. It’s a critical component of our records.

- Maintenance Logs: Detailed records of all maintenance, repairs, and inspections are kept for each tanker and railcar. These are essential for tracking the vehicle’s history and anticipating future maintenance needs. Think of this as a medical record for the vehicle.

- Incident Reports: Any accidents, near misses, or mechanical issues are thoroughly documented, providing valuable data for safety improvements. This provides a feedback loop to prevent recurrence.

All records are stored securely and are readily accessible for audits and analysis. We maintain a strict chain of custody and follow all relevant data security protocols.

Q 10. How do you communicate effectively with dispatchers and other team members during tanker and railcar operations?

Clear and timely communication is critical in tanker and railcar operations. We use a multi-faceted approach:

- Two-way Radios: For immediate communication with dispatchers during transit, reporting delays, changes in route, or any issues requiring immediate attention. Think of them as a lifeline during transport.

- Mobile Phones/Satellite Phones: For more complex communications or when radio communication is unavailable. Satellite phones provide a backup for remote areas.

- Dispatch Software: Most companies use software to track vehicles, communicate schedules, and provide updates to drivers and receivers. This centralizes information and enhances overall efficiency.

- Pre-planned Communication Schedules: Regular check-ins with dispatchers are scheduled throughout the trip, reducing reliance on only reactive communication.

- Standardized Communication Protocols: We use clear and concise terminology to ensure everyone understands messages quickly and accurately. This reduces the risk of misinterpretations that could lead to accidents.

We emphasize clear, concise messages, confirming receipt and understanding to avoid errors. In emergency situations, clear and concise communication is paramount.

Q 11. Describe your experience with pre-trip inspections of tankers and railcars.

Pre-trip inspections are a cornerstone of safe operations. My experience involves a thorough, methodical approach following a standardized checklist. I always start with a visual inspection, checking for:

- Leaks: Inspecting all seams, valves, and fittings for any signs of leaks, paying close attention to the tank’s bottom and welds.

- Corrosion: Checking for rust, pitting, or other signs of corrosion on the tank, chassis, and undercarriage. These can compromise structural integrity.

- Damage: Looking for dents, scratches, or any other signs of physical damage that could affect the tank’s integrity or safety.

- Tires: Checking tire pressure, tread depth, and overall condition. Proper tire inflation is crucial for handling and stability.

- Brakes: Testing the brakes and checking brake lines for leaks or damage. Proper functioning brakes are critical for safety.

- Lighting and Signals: Ensuring all lights, reflectors, and signals are functioning correctly. This is essential for visibility.

- Emergency Equipment: Confirming the presence and functionality of emergency equipment, such as fire extinguishers, first-aid kits, and warning triangles.

I document all findings on the appropriate checklist and report any issues immediately. If a significant problem is discovered, the vehicle is taken out of service until it’s repaired. This meticulous process is non-negotiable, prioritizing safety over expediency.

Q 12. How do you manage time constraints and deadlines while ensuring safety in tanker and railcar operations?

Balancing time constraints with safety is a constant challenge. My approach focuses on prioritization and proactive planning:

- Efficient Routing and Scheduling: Working with dispatchers to optimize routes, considering traffic conditions and potential delays to minimize transport time.

- Proactive Maintenance: Regular maintenance prevents unexpected breakdowns that cause delays and disruptions, and keeps vehicles in optimal condition to minimize the risk of safety incidents.

- Effective Communication: Maintaining clear communication with dispatchers and other team members keeps everyone informed of any issues that might impact the schedule, allowing for adjustments.

- Prioritization of Safety: Never compromising safety for speed. If a situation arises that compromises safety, the schedule is adjusted accordingly. Safety always takes precedence.

- Emergency Preparedness: Knowing how to handle unexpected events, like mechanical failures or accidents, so that we can respond effectively and safely.

I often use time management techniques to prioritize tasks. The key is to anticipate potential problems and develop contingency plans to minimize delays without compromising safety.

Q 13. Explain your knowledge of different types of tank materials and their compatibility with different products.

Understanding tank materials and their compatibility is essential. Different materials have different properties that make them suitable for various products. Here are some common examples:

- Stainless Steel: Highly resistant to corrosion, making it ideal for a wide range of chemicals and food-grade products. However, it can be expensive.

- Aluminum: Lightweight and corrosion-resistant, often used for transporting petroleum products and some chemicals. However, it’s less resistant than stainless steel to certain chemicals.

- Carbon Steel: Strong and relatively inexpensive but susceptible to corrosion, often requiring protective coatings for certain applications. Commonly used for less corrosive products.

- Fiberglass Reinforced Plastic (FRP): Lightweight and corrosion-resistant, suitable for transporting various chemicals but less durable than metals under high stress.

Compatibility is determined by factors like the chemical properties of the product, temperature, and pressure. Using the wrong material can lead to product degradation, tank failure, and serious safety hazards. We always consult material compatibility charts and adhere to strict guidelines to ensure safe transport.

Q 14. How do you address mechanical issues that arise with tankers and railcars?

Addressing mechanical issues requires a systematic approach. My experience covers:

- Immediate Assessment: First, we assess the severity of the issue, determining whether it’s a minor problem or requires immediate action.

- Safety First: Always prioritize safety. If the issue poses a safety risk, the vehicle is secured and kept out of operation until repaired.

- Troubleshooting: We systematically identify the root cause of the problem, checking relevant components and systems.

- Repair or Replacement: Depending on the problem, we either repair the component or replace it with a suitable part.

- Documentation: All repairs, maintenance, and part replacements are thoroughly documented to maintain a complete history of the vehicle.

- Communication: We keep dispatchers and other relevant parties informed of the situation and any delays it might cause.

If the problem is beyond our capability, we contact specialized repair crews or bring in qualified technicians. In critical situations, we may need to temporarily transfer the cargo to another tanker or railcar.

Q 15. Describe your experience with the use of various safety equipment for tanker and railcar operations.

Safety is paramount in tanker and railcar operations. My experience encompasses the comprehensive use of various safety equipment, including but not limited to:

- Personal Protective Equipment (PPE): This includes specialized clothing such as flame-resistant coveralls, safety glasses, gloves (chemical-resistant for specific products), and steel-toe boots. I’ve always emphasized the importance of proper PPE selection based on the specific hazards involved, such as the material being handled and the environment.

- Respiratory Protection: Working with volatile or toxic substances necessitates the use of respirators, chosen based on the specific substance’s hazards (e.g., organic vapor cartridges, air-purifying respirators, or SCBA for confined spaces). I have experience fitting and training personnel on the proper use and maintenance of these devices.

- Emergency Shutdown Systems: I’m proficient in operating and maintaining emergency shutdown systems (ESD) for loading and unloading operations. This includes understanding the various alarm systems, isolating valves, and emergency response procedures. For instance, I’ve personally responded to a simulated leak situation utilizing the ESD system, demonstrating effective containment and minimizing the environmental impact.

- Leak Detection and Repair Equipment: This includes specialized tools for detecting leaks (e.g., ultrasonic leak detectors) and equipment for temporary repairs. I have hands-on experience repairing minor leaks on tankers and understanding the procedures for larger leaks, involving emergency response teams.

- Specialized Equipment for Specific Materials: Handling hazardous materials necessitates specific equipment based on their properties. For instance, handling cryogenic materials requires specialized insulation and handling procedures, to which I’m thoroughly trained.

Regular inspection and maintenance of all safety equipment are critical. I follow strict protocols to ensure all equipment is functioning correctly and immediately report any malfunctioning equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper segregation of incompatible materials during tanker and railcar handling?

Proper segregation of incompatible materials is crucial to prevent dangerous chemical reactions. My approach involves a multi-faceted strategy:

- Understanding Material Compatibility: I begin by thoroughly reviewing the Safety Data Sheets (SDS) for all materials to identify potential incompatibilities. This includes looking for reactivity hazards, such as exothermic reactions or the formation of toxic gases upon contact.

- Physical Segregation: In practice, this means using dedicated tankers or railcars for each incompatible material. For instance, oxidizers should never be stored near flammable materials. I always ensure there’s sufficient physical separation between tanks, potentially using barriers or dedicated loading areas.

- Operational Procedures: Clear operational procedures dictate the loading and unloading sequence, to prevent mixing. We carefully plan the order of operations to minimize the risk of contact between incompatible substances. For instance, cleaning of equipment must be performed thoroughly after handling one material before handling another incompatible substance.

- Documentation and Training: Detailed records of materials handled and their compatibility are meticulously maintained. Furthermore, comprehensive training for all personnel on these procedures is critical. This involves regular training sessions and mock emergency situations to familiarize the team with the correct procedures.

By strictly adhering to these practices, we proactively mitigate risks arising from incompatible materials. A real-world example of this involved preventing a potential explosion by meticulously segregating a highly reactive chemical from its potential oxidizer during simultaneous transport.

Q 17. Explain your understanding of the transportation of dangerous goods regulations (e.g., DOT, IATA).

My understanding of dangerous goods regulations, including DOT (Department of Transportation) in the US and IATA (International Air Transport Association) regulations for air transport, is comprehensive. I know that these regulations establish stringent standards for the safe transportation of hazardous materials. These regulations cover:

- Classification of Dangerous Goods: Accurate identification and classification of dangerous goods according to their hazard class (e.g., flammable liquids, toxic substances, corrosive materials) are paramount. Misclassification can lead to serious consequences.

- Packaging and Labeling: Regulations dictate specific packaging requirements based on the substance’s properties. Appropriate labeling is essential for clear identification of the hazardous material and its associated risks. This includes proper use of hazard labels and markings, as dictated by international standards such as UN numbers and GHS pictograms.

- Shipping Papers and Documentation: Accurate shipping documentation is legally mandated. This ensures emergency responders have access to critical information about the transported materials. I’m experienced in completing all necessary paperwork and verifying its accuracy.

- Emergency Response Information: Emergency response plans must be developed and implemented. This ensures immediate action is taken in case of accidents or spills. I’m familiar with various emergency response procedures and contact information for relevant authorities.

- Training and Competency: Personnel involved in handling dangerous goods must receive adequate training to understand and comply with all regulations.

Non-compliance with these regulations carries significant penalties and poses severe safety risks. A strong understanding of these regulations ensures safe and compliant transportation practices, protecting people and the environment.

Q 18. How do you use technology to improve efficiency and safety in tanker and railcar operations?

Technology plays a vital role in enhancing efficiency and safety. My experience includes:

- GPS Tracking and Monitoring: Real-time tracking of tankers and railcars allows for efficient route planning and immediate response to any deviations or emergencies. This allows for proactive management of deliveries and monitoring of potential delays.

- Telematics Systems: These provide data on vehicle conditions, such as speed, location, and temperature. This enables predictive maintenance and timely identification of potential mechanical issues, reducing breakdowns and associated risks.

- Automated Loading and Unloading Systems: Advanced systems automate parts of the loading and unloading process, improving efficiency and reducing human error. This decreases the risk of spills or accidents during loading/unloading operations.

- Data Analytics and Predictive Modeling: Data analysis helps identify trends and patterns in accidents or near misses, allowing for proactive risk mitigation strategies. Predictive modeling allows us to forecast potential issues and proactively address them.

- Electronic Documentation and Reporting: Electronic systems streamline documentation and reporting, reducing paperwork and improving accuracy. This ensures that all compliance-related documentation is immediately accessible and consistently accurate.

Implementing these technologies has significantly improved safety and efficiency, reducing operational costs and enhancing the overall safety of our operations.

Q 19. Describe your experience with different types of loading and unloading equipment.

My experience includes operating a variety of loading and unloading equipment:

- Bottom Loading Arms: Used for safely loading and unloading liquids from the bottom of tankers. I understand the procedures for connecting, securing, and operating these arms, ensuring a leak-free transfer.

- Top Loading Arms: Used for loading and unloading liquids from the top of tankers. Again, proper connection, security, and operation are paramount to prevent spills or overfills.

- Pumps and Metering Systems: Precisely control the flow rate and volume of liquids during loading and unloading. I’m skilled in operating and maintaining these systems, ensuring accuracy and efficiency.

- Railcar Unloading Systems: These include various methods for unloading liquids and gases from railcars, depending on the type of product and its properties. This includes understanding pressure-relief valves and other safety systems involved.

- Specialized Equipment for Specific Products: Different products require specialized handling equipment. For instance, cryogenic liquids require specialized equipment to handle their extreme temperatures and pressures. I’m experienced in safely operating this specialized equipment.

I prioritize safety and efficiency in the selection and operation of these systems, always ensuring compliance with safety regulations and procedures.

Q 20. What are some common causes of accidents in tanker and railcar operations, and how can they be prevented?

Several factors contribute to accidents in tanker and railcar operations. Some common causes include:

- Human Error: This is a significant contributor, including improper procedures, lack of training, fatigue, and inadequate supervision. Implementing rigorous training programs, strict adherence to protocols, and robust supervision significantly mitigate this risk.

- Equipment Failure: Mechanical failures in tankers, railcars, or loading/unloading equipment can lead to accidents. Regular inspections and preventative maintenance are key to minimize this risk.

- Lack of Proper Segregation: Failure to properly segregate incompatible materials can lead to hazardous reactions. Strict adherence to segregation protocols and documentation is vital.

- Improper Handling of Dangerous Goods: Failure to follow regulations regarding the handling and transport of dangerous goods increases accident risks. Comprehensive training on dangerous goods regulations and their practical applications is essential.

- Environmental Factors: Extreme weather conditions can increase the risk of accidents. Risk assessments must take weather into consideration, and procedures should account for inclement weather.

Prevention involves a multi-pronged approach encompassing comprehensive training, regular equipment inspections and maintenance, strict adherence to safety regulations, thorough risk assessments, and the implementation of safety management systems. Regular safety audits and emergency response drills are crucial for maintaining a high level of safety.

Q 21. Describe your experience with various types of railcar couplings and uncouplings.

My experience covers various types of railcar couplings and uncouplings, emphasizing safety and efficiency:

- Standard Couplers: I’m proficient in the use of standard knuckle couplers, understanding the procedures for connecting and disconnecting railcars safely. I always utilize appropriate tools and techniques to ensure a secure coupling.

- Specialized Couplers: Certain railcars, especially those carrying hazardous materials, may use specialized couplers with safety features. I’m familiar with various types of these couplers and their specific operational requirements.

- Uncoupling Procedures: Safe uncoupling procedures are followed meticulously, ensuring all pressure is relieved before attempting disconnection. I’m trained to handle emergency situations, such as coupler malfunctions.

- Safety Devices: Various safety devices are incorporated to prevent accidental uncoupling or coupling failures. I’m familiar with these devices and their functionality, such as safety pins and slack adjusters.

- Inspection and Maintenance: Regular inspection of couplings is crucial to ensure they are in good working order. Any damage or wear is promptly reported and addressed.

By following established procedures and using proper equipment, I ensure the safe and efficient coupling and uncoupling of railcars, minimizing the risk of accidents.

Q 22. Explain your understanding of the different types of tank car designs and their applications.

Tank car designs vary significantly depending on the product being transported. Understanding these differences is crucial for safe and efficient operations. Here are a few key types:

- Pressure Tank Cars: Designed to carry liquids under pressure, often used for liquefied petroleum gases (LPG) or other volatile substances. These cars have robust construction to withstand the internal pressure.

- Non-Pressure Tank Cars: Suitable for liquids that don’t require pressurization, like many petroleum products or chemicals. They typically rely on gravity for unloading.

- Insulated Tank Cars: Equipped with insulation to maintain the temperature of the transported product, crucial for sensitive materials such as cryogenic liquids (like LNG) or temperature-sensitive chemicals. These cars often incorporate specialized heating or cooling systems.

- Specialized Tank Cars: These cars are designed for specific products and may incorporate features like specialized coatings to prevent corrosion or reaction with the cargo. Examples include cars for transporting corrosive acids or highly reactive materials.

The choice of tank car is determined by the physical and chemical properties of the transported material, including its volatility, corrosiveness, viscosity, and temperature sensitivity. For example, transporting highly volatile propane requires a pressure tank car with robust safety features, while transporting viscous crude oil might use a non-pressure car with specialized heating systems for easier flow.

Q 23. How do you manage the risks associated with transporting temperature-sensitive products in tankers and railcars?

Managing risks associated with temperature-sensitive products requires a multi-layered approach. It starts with selecting the right equipment:

- Appropriate Tank Car Selection: Insulated tank cars with temperature control systems are paramount. The system’s capacity must match the product’s requirements, considering ambient conditions during transit.

- Pre-Trip Inspections: Thorough checks of the insulation, temperature control systems (heating/cooling units), and monitoring devices are critical before loading. Any malfunction must be addressed before transport.

- Loading and Unloading Procedures: Temperature monitoring throughout the loading and unloading process is essential. Rapid changes in temperature can damage the product or create hazardous situations.

- In-Transit Monitoring: Real-time temperature tracking using sensors and GPS-enabled systems allows for proactive intervention should any deviation from the specified temperature range occur. This enables quick response to prevent product spoilage or other issues.

- Documentation: Detailed records of temperature readings throughout the entire transport process are crucial for traceability and liability purposes.

A real-world example would be transporting pharmaceutical products which often require a strict temperature range of 2-8°C. Failure to maintain this range can lead to degradation and render the product ineffective or dangerous.

Q 24. What is your experience with the use of electronic logging devices (ELDs) in tanker and railcar operations?

Electronic Logging Devices (ELDs) have revolutionized record-keeping in the trucking industry, and their application is increasingly important in tanker and railcar operations, especially for over-the-road transport of goods in tankers. While ELDs are not directly installed on railcars themselves (due to the nature of rail operations), the drivers transporting tankers to and from rail yards are increasingly required to use ELDs.

My experience includes ensuring drivers are properly trained on ELD use, complying with Hours of Service regulations, and using ELD data to optimize routing and scheduling to reduce downtime and increase efficiency. We use ELD data to track driver hours, location, and speed, which allows us to identify potential compliance issues and prevent accidents. We also use the data for analysis to improve routing and reduce fuel consumption. For instance, if we notice a driver consistently exceeding speed limits, we can provide additional training to improve safety and compliance. This ensures that all legal requirements are met regarding driver hours, and ensures the efficiency of operations.

Q 25. How do you ensure compliance with weight and dimension regulations for tankers and railcars?

Compliance with weight and dimension regulations is paramount for safety and legal reasons. Overweight or oversized vehicles can damage infrastructure, cause accidents, and lead to hefty fines.

- Pre-Trip Weighing: Accurate weighing of the loaded tanker or railcar before departure is essential. This often involves certified scales at designated weigh stations.

- Route Planning: Routes must be carefully planned to account for weight and dimension restrictions on specific roads and bridges. This may involve using specialized GPS systems with weight and dimension data integrated.

- Load Optimization: Careful planning of cargo loading to minimize weight and optimize distribution within the vehicle helps prevent overloading and improves stability.

- Compliance Software: Software solutions can help calculate weight and dimensions, check route compliance, and generate necessary documentation.

- Regular Inspections: Regular maintenance and inspections ensure that the vehicle is in good working order and meets all legal requirements. This includes checking braking systems, axles, and suspension components which are particularly important when carrying heavy loads.

Failure to comply can lead to serious consequences, including accidents, vehicle damage, infrastructure damage, hefty fines, and potential legal action. Therefore a proactive approach is key. For example, exceeding axle weight limits can lead to structural damage to roads and bridges causing huge costs to repair, thus careful weight distribution and route planning are crucial.

Q 26. Describe your understanding of the different types of tank car valves and their operation.

Tank car valves are crucial for controlling the flow of liquids. Different types exist, each designed for specific purposes:

- Bottom Outlet Valves: Located at the bottom of the tank car, these valves allow for gravity unloading. They are typically equipped with various safety features like pressure relief valves.

- Top Outlet Valves: Used for loading and unloading through the top of the tank car, often utilizing pumps for faster transfer.

- Manway Valves: Large access points for inspection and cleaning of the tank car. They are not for regular product transfer and are typically sealed when not in use.

- Pressure Relief Valves: These safety valves prevent excessive pressure buildup inside the tank car, preventing ruptures and explosions. They are set to open at a predetermined pressure to release excess pressure.

- Sampling Valves: Small valves used for taking samples of the liquid to ensure product quality and composition. They allow safe and controlled sampling without significant product loss.

Understanding the operation of each valve type is essential for safe handling. For instance, improper operation of a bottom outlet valve can cause uncontrolled liquid release, while a malfunctioning pressure relief valve can lead to a dangerous pressure buildup. Regular inspection and maintenance are vital to prevent valve failures.

Q 27. How do you troubleshoot and resolve issues related to pressure and vacuum in tankers and railcars?

Troubleshooting pressure and vacuum issues requires a systematic approach. The first step is identifying the problem:

- Pressure Gauge Readings: Check pressure gauges to determine if the pressure is too high or too low, or if there are pressure fluctuations.

- Visual Inspection: Look for leaks, damage to valves, or any other visible signs of problems.

- Valve Operation: Verify proper operation of all relevant valves. A stuck-open valve may cause a pressure drop, whereas a blocked valve can cause a pressure buildup.

- Temperature Check: In some cases, temperature variations can affect pressure, especially for volatile liquids. Temperature readings should be verified.

- Product Properties: Review the properties of the transported product to better understand pressure and vacuum behaviors. For example, some volatile substances experience a significant pressure increase with increasing temperature.

Once the problem is identified, the solution depends on the specific issue. A leak might require repair or replacement of a component. A blocked valve might need cleaning or repair. In certain situations, understanding the underlying cause may require consultation with specialists and comprehensive testing.

For example, if a pressure gauge shows a significant pressure drop, we need to systematically check each valve to find which one is leaking or is not properly sealed. If we find a leak, we need to assess the severity of the leak and make appropriate repair or replacement plans, always prioritizing safety.

Q 28. Explain your experience with the use of GPS tracking and monitoring systems in tanker and railcar operations.

GPS tracking and monitoring systems are invaluable in tanker and railcar operations. They provide real-time location data, allowing for efficient monitoring and management:

- Real-time Tracking: Knowing the precise location of each tanker or railcar enables improved scheduling, route optimization, and proactive response to delays or emergencies.

- Security and Theft Prevention: GPS tracking can deter theft and help recover stolen vehicles quickly if needed. Real-time alerts can be triggered if the vehicle deviates from its planned route.

- Improved Efficiency: Real-time location information aids in optimizing delivery schedules, reducing idle time, and improving overall efficiency.

- Data Analysis: GPS data can be analyzed to identify trends, improve routes, and optimize delivery processes. For example, we can identify areas where traffic congestion frequently occurs and alter routes accordingly.

- Safety Monitoring: In some systems, speed and other driving behavior data is captured, facilitating the improvement of driver performance and safety.

Integration with other systems, such as ELDs or temperature monitoring systems, creates a comprehensive overview of operations. For example, if a temperature sensor on a tanker carrying sensitive goods registers a critical temperature change, the immediate location from the GPS tracker allows rapid intervention and minimizes potential damage or losses.

Key Topics to Learn for Tanker and Railcar Handling Interview

- Safety Procedures and Regulations: Understanding and applying relevant safety protocols, including HAZMAT handling, emergency response procedures, and lockout/tagout procedures. Practical application: Describe your experience with specific safety regulations and how you ensured compliance.

- Loading and Unloading Procedures: Mastering techniques for safely loading and unloading various liquids and gases from tankers and railcars, including understanding pressure, temperature, and flow rate considerations. Practical application: Detail your experience with different loading/unloading equipment and your proficiency in handling various cargo types.

- Equipment Operation and Maintenance: Familiarity with the operation and maintenance of tanker trucks, railcars, pumps, valves, and other associated equipment. Practical application: Explain your troubleshooting skills and experience with routine maintenance checks.

- Documentation and Record Keeping: Accurate and meticulous record-keeping of all handling procedures, including bills of lading, inspection reports, and maintenance logs. Practical application: Describe your experience with electronic and paper-based documentation systems and how you ensure accuracy and compliance.

- Transportation Regulations and Compliance: Thorough knowledge of relevant transportation regulations (DOT, etc.) and how to ensure compliance during all stages of handling. Practical application: Discuss your experience ensuring compliance with regulations and addressing any potential discrepancies.

- Problem-Solving and Troubleshooting: Developing effective strategies to identify and resolve issues related to equipment malfunctions, leaks, or other operational challenges. Practical application: Describe a situation where you successfully identified and solved a problem related to tanker or railcar handling.

- Communication and Teamwork: Effective communication skills to collaborate with colleagues, supervisors, and clients. Practical application: Discuss your experience working in a team environment and how you effectively communicated with others in demanding situations.

Next Steps

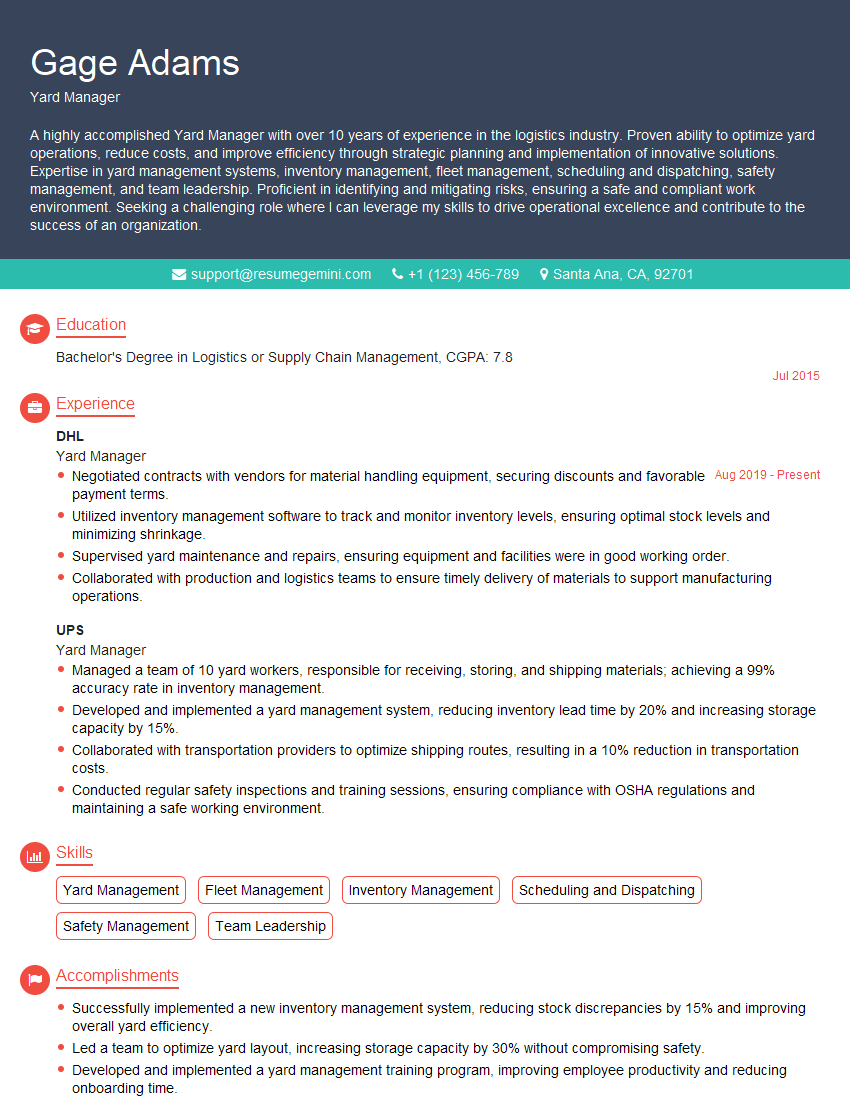

Mastering Tanker and Railcar Handling opens doors to a rewarding career with excellent growth potential in the logistics and transportation industries. A strong resume is crucial for securing your dream role. Creating an ATS-friendly resume is essential to get your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Tanker and Railcar Handling are available to help guide you in crafting your perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).