Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Thin Film Optics interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Thin Film Optics Interview

Q 1. Explain the concept of thin film interference.

Thin film interference is a phenomenon arising from the interaction of light waves reflected from the top and bottom surfaces of a thin film. Imagine a soap bubble: its iridescent colors are a direct result of this interference. When light strikes the film, a portion reflects from the top surface, and another portion transmits through, reflects from the bottom surface, and then re-emerges. These two reflected waves interfere with each other; constructively if their path difference is a multiple of the wavelength, resulting in a bright reflection, or destructively if the path difference is an odd multiple of half the wavelength, resulting in a dark reflection. This interference depends critically on the film’s thickness, the refractive indices of the film and surrounding media, and the wavelength of light. The resulting color or intensity depends on these factors, hence the varied colors in a soap bubble or oil slick.

Mathematically, the condition for constructive interference is given by 2nt = mλ, and for destructive interference, 2nt = (m + 1/2)λ, where ‘n’ is the refractive index of the film, ‘t’ is the thickness of the film, ‘m’ is an integer (order of interference), and ‘λ’ is the wavelength of light.

Q 2. Describe different thin film deposition techniques (e.g., sputtering, evaporation).

Several techniques exist for depositing thin films, each with its own advantages and disadvantages. Two common methods are:

- Sputtering: This involves bombarding a target material (the material you want to deposit as a thin film) with energetic ions (usually Argon). This process ejects atoms from the target, which then travel and deposit onto a substrate. Think of it like tiny cannonballs knocking atoms off the target and sending them to stick onto your desired surface. Different sputtering techniques exist, such as DC sputtering, RF sputtering, and magnetron sputtering, each offering varying levels of control and deposition rates.

- Evaporation: In thermal evaporation, the source material is heated in a vacuum until it vaporizes. The vapor then travels to the substrate, where it condenses to form a thin film. This is similar to boiling a substance, but in a vacuum to ensure the evaporated atoms travel directly to the substrate without scattering. Electron beam evaporation is a more sophisticated version of this technique that offers better control over the evaporation rate and material purity.

Q 3. What are the advantages and disadvantages of each deposition method?

Let’s compare the advantages and disadvantages of sputtering and evaporation:

- Sputtering:

- Advantages: High deposition rate for some materials, good step coverage (ability to coat complex 3D shapes uniformly), relatively low substrate temperature.

- Disadvantages: Can introduce impurities from the sputtering gas, more complex equipment, can damage sensitive substrates.

- Evaporation:

- Advantages: Relatively simple equipment, high purity films achievable, good control over film thickness.

- Disadvantages: Lower deposition rate compared to sputtering, poor step coverage, can be challenging for high melting point materials.

The best choice depends on the specific application and material properties.

Q 4. How do you characterize the thickness and refractive index of a thin film?

Characterizing thin films involves precise measurements of their thickness and refractive index. Several methods exist:

- Ellipsometry: This optical technique measures the change in polarization of light reflected from the film. By analyzing the polarization change, both thickness and refractive index can be determined with high precision. It’s like probing the film with polarized light to reveal its hidden properties.

- Profilometry: This technique uses a mechanical stylus or optical methods to measure the surface profile of the film. The difference in height between the substrate and the film surface gives the thickness. This is similar to using a ruler, but on a microscopic scale.

- Spectrophotometry: Measuring the transmission and reflection spectra of the film allows one to extract the optical constants, including the refractive index. This method relies on how the film interacts with light of various wavelengths.

The choice of method depends on factors such as required accuracy, film properties, and available equipment.

Q 5. Explain the concept of optical monitoring during deposition.

Optical monitoring during deposition allows for real-time control of the film thickness and other properties. This is crucial for achieving the desired optical performance. Typically, a small portion of the light emitted from a light source shines through the growing film. The intensity of this transmitted (or reflected) light is measured and used as feedback to control the deposition process. A quartz crystal microbalance (QCM) can also be used to monitor the mass deposited on the substrate which allows for thickness calculation. This feedback loop ensures consistent film thickness and quality. Imagine a self-regulating system ensuring your film grows perfectly as intended.

Q 6. What are the different types of optical coatings?

Optical coatings come in a wide variety, each designed to fulfill a specific function:

- Anti-reflection coatings: Minimize reflection to maximize transmission of light.

- High-reflection coatings: Maximize reflection of light within a specific wavelength range (e.g., mirrors).

- Bandpass filters: Transmit light within a specific wavelength range and reflect light outside this range (e.g., used in laser systems).

- Dichroic mirrors: Reflect light of certain wavelengths and transmit others (e.g., in color displays).

- Polarizing coatings: Transmit light of a specific polarization state and reflect or absorb the orthogonal state.

These coatings find applications in diverse fields, such as optical instrumentation, displays, and solar energy technologies.

Q 7. How do anti-reflection coatings work?

Anti-reflection (AR) coatings reduce unwanted reflections by destructive interference. A single-layer AR coating uses a thin film with a refractive index that is the geometric mean of the refractive indices of air and the substrate. The thickness is chosen such that the reflections from the top and bottom surfaces of the coating interfere destructively for a specific wavelength (usually in the visible spectrum). Multilayer AR coatings use multiple layers with different refractive indices to broaden the wavelength range over which reflection is minimized. This leads to greater transmission. Think of it as carefully controlling the phases of the reflected waves to cancel each other out. This dramatically reduces glare and improves the efficiency of optical components such as lenses and solar cells.

Q 8. Describe the design of a high-reflectivity coating.

A high-reflectivity coating, also known as a dielectric mirror, is designed to reflect a specific range of wavelengths with very high efficiency. This is achieved by carefully selecting the refractive indices and thicknesses of multiple thin-film layers. The design leverages the principle of constructive interference. Light reflecting from the interfaces between layers interferes constructively, enhancing the reflection at the desired wavelengths. Conversely, destructive interference minimizes transmission and absorption.

A common design is a multilayer stack of alternating high- and low-refractive index materials. For instance, a typical design might use layers of titanium dioxide (TiO2, high index) and silicon dioxide (SiO2, low index). The thicknesses of these layers are precisely controlled to create a quarter-wave stack, where the optical thickness of each layer is a quarter of the desired wavelength. This ensures maximum constructive interference for that wavelength. To broaden the reflection band, more layers are added, and the layer thicknesses are carefully tailored using design software. The number of layers directly influences the reflectivity and bandwidth. A greater number of layers increases the reflectivity and broadens the wavelength range reflected, but adds to manufacturing complexity and cost.

Imagine it like a series of carefully calibrated echoes. Each layer reflects a portion of light, and these reflections combine to create a powerful reflected wave, much stronger than a single reflection would achieve. The specific design depends on the desired wavelength range, the required reflectivity, and the available materials.

Q 9. Explain the concept of optical transfer function (OTF).

The Optical Transfer Function (OTF) describes how a thin film optical system transfers spatial frequencies from the object plane to the image plane. It’s a crucial parameter in assessing the imaging quality of a system. The OTF is a complex function that accounts for both the amplitude and phase changes introduced by the system. It’s essentially a combined representation of the Modulation Transfer Function (MTF) and the Phase Transfer Function (PTF).

The MTF quantifies the system’s ability to transfer contrast at different spatial frequencies. A high MTF indicates good contrast preservation. The PTF describes phase shifts introduced across different spatial frequencies. Phase distortions can cause blurring and artifacts in the image. The OTF is important because it considers both the amplitude (contrast) and phase (sharpness) information. This complete picture allows for a better evaluation of the optical performance.

In thin film design, the OTF is particularly relevant when considering the impact of surface roughness, scattering losses, and other imperfections on the final image quality, especially in applications like imaging or microscopy. For instance, a thin film with significant surface roughness will have a lower OTF at high spatial frequencies, leading to reduced resolution and image blurring.

Q 10. What are the key parameters to consider when designing a thin film coating?

Designing a thin film coating involves careful consideration of several key parameters:

- Wavelength Range: The specific wavelengths that need to be reflected, transmitted, or absorbed. This defines the operating spectral range of the coating.

- Angle of Incidence: The angle at which light strikes the coating. This significantly impacts the interference effects and the overall performance, especially for angled applications.

- Substrate Material: The material upon which the coating is deposited. Its refractive index and surface properties influence the design.

- Refractive Indices of Coating Materials: The choice of materials significantly affects the achievable performance. High refractive index contrast between layers enhances reflectivity or other desired effects.

- Layer Thicknesses: Precise control of layer thickness is crucial for achieving the desired interference effects. These are often quarter-wave or half-wave thicknesses, but more complex designs may use other multiples of the wavelength.

- Number of Layers: The number of layers directly impacts the performance. More layers improve the performance, but increase complexity and cost. There’s a tradeoff between performance and practicality.

- Tolerances: Manufacturing tolerances must be considered to ensure that the final coating meets the specifications. Tight tolerances lead to better performance but are often more expensive.

- Durability and Environmental Stability: The chosen materials must be durable and stable under operating conditions, such as temperature, humidity, and exposure to chemicals.

These parameters are interdependent, and an iterative design process often employs optimization algorithms to find the best solution for a given application.

Q 11. How do you model the optical properties of a thin film stack?

The optical properties of a thin film stack are modeled using the transfer matrix method (TMM), also known as the characteristic matrix method. This method is based on considering each layer as a matrix that represents the change in the electric and magnetic fields as light propagates through it. The overall transfer matrix for the entire stack is obtained by multiplying the individual layer matrices.

For a single layer, the matrix relates the amplitudes of the forward and backward propagating waves at the layer’s boundaries. Then, by cascading the matrices for each layer, one can calculate the overall reflection and transmission coefficients for the entire stack. From there, one can extract properties like reflectivity, transmissivity and absorptivity.

The calculations involve complex numbers to account for the phase shifts at each interface. The result gives the reflectance and transmittance as a function of wavelength and angle of incidence. The process can be implemented computationally using software packages or programming languages like MATLAB or Python.

Example (simplified): A simple two-layer stack would involve multiplying two 2x2 matrices. The exact form of the matrices depends on the layer properties (refractive index, thickness) and the wavelength of light.

Q 12. What software or tools do you use for thin film design and simulation?

For thin film design and simulation, I utilize several software packages depending on the project’s specifics and complexity. Popular commercial options include:

- Essential Macleod: A widely used software package known for its user-friendly interface and robust capabilities in thin film design and optimization.

- TFCalc: Another powerful commercial tool with advanced features for thin film simulation and analysis.

For more customized or research-oriented tasks, I also utilize scripting languages such as MATLAB and Python, alongside specialized libraries like PyCMAT (a Python library for thin film calculations). This level of control allows for the development of custom algorithms and optimization strategies tailored to specific applications.

The choice of software depends on factors such as the complexity of the design, the required level of accuracy, the available budget, and my familiarity with the specific tools.

Q 13. Describe your experience with different types of substrates.

My experience encompasses a wide range of substrates, including:

- Glass: Commonly used substrates, including BK7, fused silica, and various specialty glasses with different refractive indices and thermal properties. The choice depends on the application’s spectral range and environmental conditions.

- Silicon: Often used in semiconductor applications and requires careful consideration of surface preparation and cleaning before coating deposition.

- Polymers: Such as polycarbonate and acrylic, offer flexibility and low cost but might have limitations in terms of temperature resistance and scratch resistance.

- Metals: Metallic substrates, such as aluminum and stainless steel, are used in specialized applications and present unique challenges in terms of surface preparation and adhesion of the thin films.

Each substrate type requires specific pre-treatment procedures to ensure good adhesion and minimize defects. Surface cleanliness and roughness are paramount to achieving high-quality coatings. The choice of substrate is often determined by the application itself: a high-precision optical instrument will require a high-quality substrate like fused silica, while a more rugged application might use a polymer substrate. Understanding the substrate’s properties and its interaction with the coating is critical for successful thin film design and deposition.

Q 14. How do you handle defects and imperfections in thin films?

Defects and imperfections in thin films can significantly impact their performance. I handle these challenges through a multi-pronged approach:

- Careful process control: Precise control of the deposition process is key. This includes controlling parameters like deposition rate, substrate temperature, pressure, and vacuum level. The use of high-quality materials and advanced deposition techniques such as sputtering or evaporation further minimizes defects.

- Characterization and analysis: Thorough characterization of the deposited films is crucial. Techniques like optical spectroscopy, atomic force microscopy (AFM), and scanning electron microscopy (SEM) are utilized to identify and quantify defects. This allows for timely adjustments in the deposition process or selection of alternative coating materials.

- Defect modeling and mitigation: Computational modeling can help identify the potential sources of defects and guide strategies for their mitigation. Understanding the root causes (e.g., substrate defects, impurities in the coating materials, non-uniform deposition) allows for targeted solutions.

- Post-deposition treatments: In certain cases, post-deposition treatments like annealing or ion-beam modification can help to improve the film quality and reduce the impact of some defects.

The approach depends on the nature and severity of the defects. In some cases, the defects might be unavoidable and require adjustments to the specifications or acceptance criteria. Other times, minor adjustments to the deposition process will resolve the issue.

Q 15. Explain the concept of stress in thin films and its impact on performance.

Stress in thin films refers to the internal forces within the film caused by differences in the thermal expansion coefficients of the film and the substrate, or by the deposition process itself. Think of it like a tiny, strained membrane stretched over a surface. This stress can be either tensile (pulling outwards) or compressive (pushing inwards). High stress levels can severely impact film performance.

- Impact on Optical Properties: Stress can induce birefringence (a change in refractive index depending on the polarization of light), leading to degraded optical performance, particularly in applications like polarizers and waveplates.

- Impact on Mechanical Properties: High tensile stress can lead to cracking and delamination (separation) of the film from the substrate, rendering the coating useless. Compressive stress can cause buckling or blistering.

- Impact on Adhesion: Stress can significantly weaken the adhesion between the film and substrate, leading to premature failure.

For example, in a solar cell application, stress-induced cracking can disrupt the electrical conductivity of the transparent conductive oxide (TCO) layer, reducing the efficiency of the cell. Careful control of deposition parameters and selection of appropriate materials is crucial to minimize stress.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality control of thin film coatings?

Quality control of thin film coatings is a multi-faceted process that begins with the selection of high-purity materials and extends throughout the entire deposition process. It involves meticulous monitoring and characterization at each step.

- In-situ monitoring: Techniques like optical emission spectroscopy (OES) allow real-time monitoring of the plasma during deposition, providing information about the film’s composition and uniformity. This allows for immediate adjustments if needed.

- Ex-situ characterization: After deposition, a range of techniques are used to assess film quality. These include:

- Thickness measurement: Using techniques like profilometry or ellipsometry to ensure the film is the desired thickness.

- Refractive index measurement: Using ellipsometry or spectrophotometry to verify the optical properties and assess potential stress-induced changes.

- Surface roughness analysis: Using atomic force microscopy (AFM) or scanning electron microscopy (SEM) to evaluate the surface quality and assess the presence of defects like pinholes.

- Stress measurement: Using techniques like curvature measurement to quantify the stress in the film.

- Adhesion testing: Using techniques like scratch testing or tape testing to determine the adhesion of the film to the substrate.

Statistical process control (SPC) is used to track key parameters and identify potential problems before they significantly impact the quality of the final product. Think of it as a continuous feedback loop ensuring consistency and excellence.

Q 17. What are the challenges in scaling up thin film deposition processes?

Scaling up thin film deposition processes presents significant challenges, primarily related to maintaining uniformity and reproducibility across larger substrates or higher throughput.

- Uniformity: Ensuring the film’s thickness, composition, and properties remain consistent across a larger area is difficult. This often requires careful design of the deposition system, including the substrate holder geometry and the source configuration. Imagine trying to paint a house perfectly uniformly with a single brush – the larger the area, the harder it becomes!

- Reproducibility: Maintaining consistent film quality from batch to batch, especially at higher production rates, is crucial. This demands precise control over process parameters such as temperature, pressure, and deposition rate. Robust process control and rigorous quality control measures are necessary.

- Throughput: Increasing deposition rate while preserving quality presents a challenge. This requires optimized chamber design, efficient gas handling, and sophisticated control systems.

- Cost: Scaling up involves significant investment in larger equipment, increased material costs, and potentially more complex automation.

For example, scaling up the production of flexible displays requires large-area deposition of transparent conductive oxides on flexible substrates, demanding precise control over deposition uniformity and maintaining the integrity of the thin film on the delicate substrates.

Q 18. How do you address environmental concerns related to thin film deposition?

Environmental concerns associated with thin film deposition primarily revolve around the use and release of hazardous materials. Many deposition techniques employ precursor gases that can be toxic, such as silane (SiH4) or various metal-organic compounds.

- Waste management: Careful management of waste products, including spent gases and contaminated materials, is vital. This usually involves the use of scrubbing systems to capture and neutralize hazardous gases and proper disposal of solid wastes.

- Process optimization: Developing deposition techniques that minimize the use of hazardous materials and reduce waste generation is critical. This includes exploring alternative precursor materials and optimizing process parameters to enhance efficiency.

- Closed-loop systems: Designing closed-loop systems that recycle or recover precursor materials can dramatically reduce waste and minimize environmental impact.

- Green chemistry principles: The adoption of green chemistry principles, such as using less hazardous solvents and developing environmentally benign synthetic routes, is essential in the pursuit of sustainable thin film deposition.

For instance, the use of atomic layer deposition (ALD) allows for precise control over film thickness, reducing material waste compared to other techniques. The development of more environmentally friendly precursors is an active area of research.

Q 19. Explain the impact of temperature on thin film properties.

Temperature plays a crucial role in determining the properties of thin films. It influences the microstructure, stress, and ultimately the performance of the film.

- Microstructure: Higher temperatures often lead to increased grain size and improved crystallinity, affecting mechanical properties, like hardness and toughness. Think of it like baking a cake – higher temperatures lead to a more solid structure.

- Stress: Thermal mismatch between the film and substrate leads to stress, with this stress being more pronounced at higher temperature differences. Rapid cooling can increase tensile stress, while slow cooling can help minimize it.

- Phase transitions: Temperature can induce phase transitions in the film, changing its crystal structure and affecting its optical and electrical properties.

- Adhesion: Temperature can influence the diffusion of atoms at the film-substrate interface, affecting the adhesion strength. Too high a temperature can lead to interdiffusion and weaken adhesion, while too low a temperature might result in poor bonding.

For instance, in the fabrication of optical coatings, precise temperature control is critical during deposition to ensure the desired refractive index and minimize stress-induced birefringence. Annealing at a specific temperature after deposition can also improve the film’s properties.

Q 20. Describe your experience with different types of thin film materials.

My experience encompasses a wide range of thin film materials, including:

- Dielectrics: Such as silicon dioxide (SiO2), titanium dioxide (TiO2), and hafnium oxide (HfO2), used extensively in optical coatings for anti-reflection, high-reflection, and bandpass filters. I’ve worked with various deposition techniques, including sputtering and chemical vapor deposition (CVD), to optimize their properties for specific applications.

- Metals: Like aluminum (Al), silver (Ag), and gold (Au), used in applications ranging from electrical contacts to reflective coatings. I have experience in optimizing their deposition parameters to achieve high reflectivity and low resistivity.

- Semiconductors: Such as silicon (Si), indium tin oxide (ITO), and cadmium telluride (CdTe), for applications like solar cells and transistors. My work has focused on controlling the film’s crystallinity and doping to achieve the desired electrical conductivity and bandgap.

- Organic materials: Including polymers and small organic molecules, for applications like flexible electronics and organic light-emitting diodes (OLEDs). I’ve been involved in developing deposition processes that maintain the structural integrity and functionality of these delicate materials.

Each material presents unique challenges and requires optimization of the deposition parameters for optimal performance. My work has emphasized understanding the interplay between material properties, deposition techniques, and application requirements.

Q 21. How do you measure the adhesion of a thin film to a substrate?

Measuring the adhesion of a thin film to a substrate is crucial for ensuring the long-term reliability of the coating. Several techniques are used, each with its advantages and limitations.

- Tape test: A simple and widely used method involves applying pressure-sensitive tape to the film and then peeling it off. The amount of film that is removed indicates the adhesion strength. This is a qualitative assessment, however.

- Scratch test: A diamond stylus is progressively loaded and dragged across the film surface. The load at which the film starts to delaminate or is removed provides a quantitative measure of adhesion strength. This method is better than a tape test, providing a more quantitative measure.

- Pull-off test: A specialized fixture is used to adhere to the film surface and then exerts a force to pull the film away from the substrate. The force required for delamination is measured. Provides a more precise quantitative measurement of adhesion.

- Microscratch test: Combines the features of scratch and pull-off testing. It measures both the adhesion strength and the frictional properties of the thin film.

The choice of method depends on the specific application and the desired level of accuracy. For example, a simple tape test might suffice for some applications, while a more sophisticated scratch or pull-off test might be necessary for critical applications such as aerospace or medical devices. The results are usually expressed as a critical load or pull-off force.

Q 22. Explain the concept of scattering in thin films.

Scattering in thin films refers to the redirection of light from its original path as it interacts with imperfections within the film or at its interfaces. Imagine shining a laser pointer on a perfectly smooth mirror – you get a clean reflection. Now, imagine shining it on a slightly bumpy surface; the light scatters in various directions. This is analogous to what happens in thin films.

Several factors contribute to scattering:

- Surface roughness: Microscopic irregularities on the film’s surface cause light to scatter incoherently.

- Bulk scattering: Inhomogeneities, voids, or inclusions within the film itself can also deflect light.

- Interface roughness: Roughness at the interface between different layers in a multilayer thin film causes scattering.

The degree of scattering significantly impacts the film’s optical performance. High scattering can lead to reduced transmission, increased haze, and diminished optical clarity, impacting applications like anti-reflection coatings, filters, and optical sensors. Minimizing scattering is crucial for achieving desired optical properties.

Q 23. How do you analyze the spectral characteristics of a thin film?

Analyzing the spectral characteristics of a thin film involves measuring its optical properties across a range of wavelengths. This typically involves using a spectrophotometer. The instrument measures the transmittance (light passing through), reflectance (light reflected), and possibly absorbance (light absorbed) of the film as a function of wavelength.

The resulting spectral data can be used to determine key characteristics:

- Peak wavelengths: Identifying wavelengths where transmission or reflection is maximized or minimized, relevant to filter design.

- Bandwidth: The range of wavelengths over which a specific optical property (like high reflection) is maintained.

- Refractive index dispersion: How the refractive index varies with wavelength, crucial for designing multilayer coatings.

Advanced analysis techniques such as modeling the film’s structure using transfer matrix methods (TMM) allow us to extract parameters like layer thickness, refractive indices, and absorption coefficients from the measured spectral data. This allows for precise comparisons with theoretical predictions and optimization of the film’s design.

Q 24. Describe your experience with troubleshooting thin film deposition processes.

Throughout my career, I’ve encountered various challenges in thin film deposition, requiring systematic troubleshooting. For instance, I once worked on a project where we were depositing a multilayer anti-reflection coating for solar cells. We observed lower than expected transmission.

My troubleshooting steps included:

- Careful review of the deposition parameters: Checking for inconsistencies in pressure, temperature, deposition rate, and source materials.

- Optical microscopy and profilometry: Examining the film surface for defects like pinholes, cracks, or significant roughness.

- X-ray reflectivity (XRR) and other metrology: Measuring layer thicknesses and densities to verify if the layers were deposited as designed.

- Re-evaluation of the target design: Determining if the initial design was indeed suitable and making corrections.

In this specific case, we found that the substrate cleaning process was inadequate, leading to contamination and increased scattering, thus lowering transmission. By improving the cleaning protocol, we achieved the desired optical performance.

Q 25. What is the role of surface roughness in thin film performance?

Surface roughness plays a critical role in thin film performance, primarily influencing scattering and adhesion. A rough surface increases scattering, leading to reduced transmission and reflection. Imagine trying to reflect light off a crumpled piece of aluminum foil versus a smooth, polished sheet; the rough foil scatters light more.

Furthermore, surface roughness impacts the adhesion of the film to the substrate. A rough surface provides more surface area for the film to adhere to, potentially improving adhesion but also possibly leading to stress build-up if the film is unable to conform to the underlying irregularities.

Controlling surface roughness is, therefore, critical. Techniques like atomic force microscopy (AFM) and optical profilometry are employed to characterize surface roughness, while deposition techniques like sputtering and atomic layer deposition (ALD) allow for better control over film morphology and surface smoothness.

Q 26. How do you design coatings for specific wavelengths or spectral ranges?

Designing coatings for specific wavelengths or spectral ranges requires a sophisticated understanding of thin film interference and optical design software. The design process often involves utilizing transfer matrix methods (TMM) to model the optical behavior of multilayer stacks.

For example, designing a narrowband filter centered at 550 nm (green light) would involve carefully selecting layer thicknesses and refractive indices to create constructive interference at that specific wavelength while suppressing other wavelengths. This often involves alternating high and low refractive index materials to create a Bragg reflector-type structure.

Similarly, designing a broadband anti-reflection coating requires optimizing the optical path length across a wide spectral range. This often involves using gradient refractive index materials or multiple layers with slightly different properties. Commercial software tools simplify this process, allowing us to simulate the optical performance and optimize the design iteratively.

Q 27. What are your experiences with different types of optical metrology techniques?

My experience encompasses a wide range of optical metrology techniques used to characterize thin films. These techniques provide critical information for verifying the quality and performance of our coatings.

Examples include:

- Spectrophotometry: Measuring transmittance, reflectance, and absorbance as a function of wavelength, to determine optical performance.

- Ellipsometry: Determining the thickness and optical constants (refractive index, extinction coefficient) of thin films, allowing layer-by-layer characterization.

- Atomic Force Microscopy (AFM): Measuring the surface roughness and morphology at the nanometer scale.

- X-ray Reflectivity (XRR): Determining the layer thicknesses and densities in multilayer thin films.

- Optical Profilometry: Measuring surface topography, especially for thicker films.

The choice of technique depends on the specific application and the required level of detail. For example, while spectrophotometry provides overall optical performance, ellipsometry and XRR provide detailed layer-by-layer information essential for validating complex designs.

Q 28. Discuss your experience with failure analysis of thin film coatings.

Failure analysis of thin film coatings requires a systematic approach involving a combination of optical, microscopic, and spectroscopic techniques. A common failure mode is delamination, where the film separates from the substrate.

My approach involves the following steps:

- Visual inspection: Identifying the location and nature of the failure (cracks, delamination, discoloration).

- Microscopy: Using optical, scanning electron (SEM), or atomic force microscopy (AFM) to examine the microstructure and identify any defects or degradation.

- Spectroscopy: Employing techniques like X-ray photoelectron spectroscopy (XPS) or Fourier-transform infrared spectroscopy (FTIR) to analyze the chemical composition and bonding.

- Mechanical testing: Assessing adhesion strength using techniques like scratch testing or tape tests.

A recent case involved a coating delaminating after exposure to high humidity. Through detailed analysis, we determined that water ingress caused degradation at the film-substrate interface, leading to the failure. This understanding helped in redesigning the coating to enhance its moisture resistance.

Key Topics to Learn for Thin Film Optics Interview

- Interference and Diffraction: Understanding thin film interference phenomena (constructive and destructive), and how diffraction gratings impact thin film performance. Consider applications in optical coatings.

- Optical Coatings Design: Explore techniques for designing coatings with specific properties (e.g., anti-reflection, high-reflection, bandpass filters). Practice calculating layer thicknesses and materials selection.

- Material Properties and Characterization: Become familiar with the optical properties of common thin film materials (refractive index, extinction coefficient). Learn about characterization techniques like ellipsometry and spectrophotometry.

- Thin Film Deposition Techniques: Gain understanding of various deposition methods (e.g., sputtering, evaporation, CVD) and their impact on film quality and properties. Be prepared to discuss the advantages and disadvantages of each.

- Applications of Thin Film Optics: Explore diverse applications, such as optical sensors, displays, solar cells, and optical filters. Be ready to discuss specific examples and their underlying principles.

- Problem-Solving and Analysis: Practice solving problems related to thin film design and optimization. Develop skills in analyzing experimental data and troubleshooting potential issues in thin film fabrication.

- Transfer Matrix Method (TMM): Understand and be able to apply the TMM for calculating the reflectance and transmittance of multilayer thin films.

Next Steps

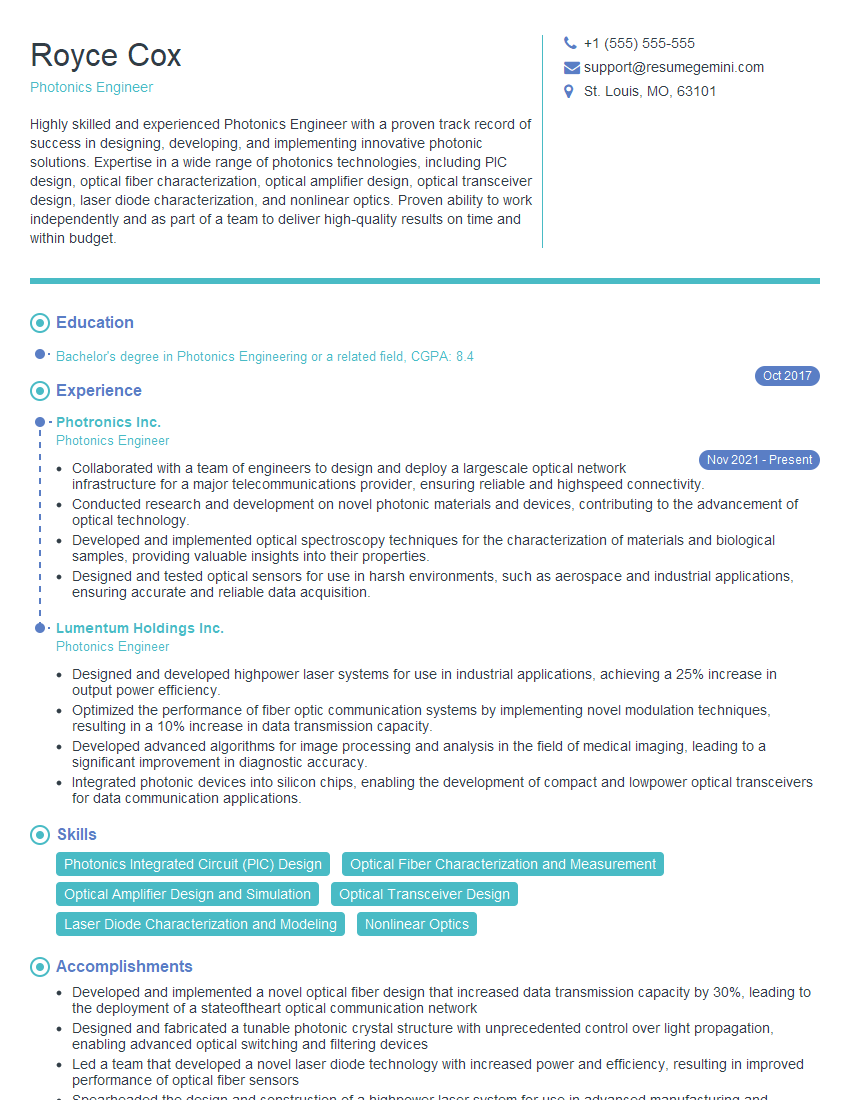

Mastering Thin Film Optics opens doors to exciting and rewarding careers in cutting-edge technologies. A strong understanding of these principles is highly sought after in various industries, leading to greater job security and career advancement. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. ResumeGemini can help you build a professional and impactful resume that highlights your expertise in Thin Film Optics. Leverage ResumeGemini’s tools and resources to create a compelling resume that stands out – examples of resumes tailored to Thin Film Optics are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good