Are you ready to stand out in your next interview? Understanding and preparing for Timber Utilization interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Timber Utilization Interview

Q 1. Explain the different methods of timber harvesting.

Timber harvesting methods are broadly categorized by how trees are felled and extracted. The choice depends on factors like terrain, tree density, environmental concerns, and the desired timber quality.

- Clearcutting: This involves removing all trees from a designated area. It’s efficient for even-aged stands but can lead to soil erosion and habitat loss if not managed properly. Imagine clearing a whole field – that’s clearcutting.

- Shelterwood Cutting: A gradual removal process where mature trees are selectively harvested over several years, leaving some trees for seed production and shade. Think of it as thinning a forest gradually.

- Seed-Tree Cutting: Similar to shelterwood but leaves only a few seed trees to regenerate the stand. This method is best suited for species that regenerate well from seeds.

- Selection Cutting: Individual trees are harvested based on their size, quality, and species. This method maintains a diverse forest structure but can be less efficient than clearcutting.

- Commercial Thinning: Removing smaller, less desirable trees to improve the growth of remaining trees. This is like pruning a garden – removing weaker plants to allow stronger ones to thrive.

Each method has its own set of environmental and economic implications, and foresters carefully select the approach that best balances these factors for a specific site.

Q 2. Describe the process of timber grading and its importance.

Timber grading is the process of classifying logs or lumber based on their quality and suitability for specific uses. This is crucial because it directly impacts the value and end application of the timber. Graders assess various factors to determine the grade.

- Strength: The ability to withstand stress and load without breaking.

- Straightness: How straight the grain is; crooked grain reduces strength and usability.

- Knots: The presence and size of knots, which are branches embedded in the wood, affect structural integrity.

- Decay: Presence of fungal or insect damage, significantly reducing strength and durability.

- Shake: Separation of the wood grain.

For instance, a high-grade piece of lumber might be used for structural beams in a building, while lower grades might be suitable for pallets or less demanding applications. Proper grading ensures that timber is used efficiently and safely, preventing structural failures or unnecessary waste.

Q 3. What are the key factors influencing timber prices?

Timber prices are influenced by a complex interplay of supply and demand factors. Think of it as a marketplace for a natural resource.

- Supply: Availability of timber from various sources, affected by forest growth rates, harvesting practices, and environmental regulations.

- Demand: Driven by construction activity (housing, infrastructure), furniture manufacturing, pulp and paper production, and other wood-based industries.

- Species: Certain species are more valuable than others due to their strength, appearance, or workability (e.g., hardwoods like oak are generally more expensive than softwoods like pine).

- Grade: Higher grades command higher prices due to superior quality and suitability for high-value applications.

- Transportation Costs: Logistical challenges and fuel prices can significantly affect the final price.

- Global Market Conditions: International trade and economic factors also play a role.

For example, a surge in housing construction could lead to increased demand and higher timber prices. Conversely, a decrease in global economic activity might dampen demand and lower prices.

Q 4. Discuss the different types of wood defects and their impact on utilization.

Wood defects significantly affect the utilization and value of timber. Understanding these defects is vital for proper grading and efficient use of wood.

- Knots: Branches embedded in the wood, reducing strength and impacting appearance. Large knots can weaken structural members.

- Checks: Splits or cracks in the wood, often radiating from the center. These reduce the strength and make the wood more susceptible to decay.

- Decay: Fungal or insect damage, weakening the wood and rendering it unsafe for structural applications.

- Shake: A separation between the wood grain. It affects the strength and stability of the timber.

- Warping: Changes in the shape of the wood due to uneven drying or stress. This makes it difficult to work with and affects its aesthetic appeal.

The impact depends on the type, size, and location of the defect. A small knot in a piece of furniture lumber might be acceptable, but a large, rotten knot in a structural beam is unacceptable. Proper inspection and grading help to minimize the negative consequences of defects.

Q 5. Explain the role of sustainable forestry practices in timber utilization.

Sustainable forestry practices are essential for ensuring the long-term availability of timber resources while protecting the environment. It’s about responsible resource management.

- Reforestation: Planting new trees to replace those harvested, ensuring a continuous supply of timber.

- Reduced-Impact Logging (RIL): Techniques that minimize damage to the forest ecosystem during harvesting.

- Selective Harvesting: Removing only mature or less desirable trees, preserving the overall forest structure and biodiversity.

- Forest Certification: Third-party certification programs (like FSC) ensure that timber comes from sustainably managed forests.

- Protection of biodiversity: Maintaining a variety of tree species and habitat for wildlife.

Sustainable forestry not only ensures a continuous supply of timber but also protects vital ecosystems, preserving biodiversity, preventing soil erosion, and mitigating climate change. It’s a win-win for both the timber industry and the environment.

Q 6. What are the environmental considerations in timber harvesting and processing?

Environmental considerations in timber harvesting and processing are paramount. Uncontrolled harvesting can have severe consequences.

- Deforestation and habitat loss: Clearcutting large areas can destroy wildlife habitats and disrupt ecosystems.

- Soil erosion: Removing tree cover increases the risk of soil erosion and water pollution.

- Water pollution: Runoff from logging operations can contaminate waterways with sediment and chemicals.

- Greenhouse gas emissions: Burning or decomposing logging residues can release greenhouse gases into the atmosphere.

- Biodiversity loss: Removing large tracts of forest reduces biodiversity and can lead to the extinction of plant and animal species.

Sustainable harvesting practices, coupled with proper processing techniques (minimizing waste, using clean energy), help to mitigate these environmental impacts. Certification schemes and stricter regulations further contribute to environmentally responsible timber production.

Q 7. Describe the different wood preservation techniques.

Wood preservation techniques aim to extend the lifespan of wood by protecting it from decay, insects, and fire. These methods are crucial for enhancing the durability and value of timber, especially in outdoor applications.

- Pressure Treatment: Wood is placed in a pressure vessel and treated with preservatives under pressure, forcing the chemicals deep into the wood. This is a common method for fence posts, decking, and utility poles.

- Thermal Modification: Heating wood to high temperatures alters its cellular structure, making it more durable and resistant to decay. This process is environmentally friendly, using no chemicals.

- Chemical Treatment (Surface Application): Applying preservatives like paint, stains, or sealants to the surface of wood provides a degree of protection. This is less effective than pressure treatment but suitable for some applications.

- Incising: Creating shallow cuts on the wood surface to increase the penetration of preservatives during pressure treatment.

The choice of preservation technique depends on the wood species, intended use, and the level of protection required. Proper wood preservation is essential for ensuring the longevity and safety of wood structures and products.

Q 8. How do you assess the quality of timber?

Assessing timber quality involves a multifaceted approach, considering several key factors. Think of it like grading a diamond – you look at several aspects to determine its value. We start with visual inspection, checking for defects like knots, cracks, decay, and discoloration. The size and shape of the log are also critical. Larger, straighter logs generally yield more high-quality lumber. Then, we move to more advanced techniques. Moisture content is determined using a moisture meter, impacting strength and dimensional stability. Specific gravity, which indicates density, is another key factor – denser wood is usually stronger and more durable. Finally, mechanical testing can provide quantitative data on strength properties, crucial for structural applications. For example, a log with significant decay would be graded lower and likely destined for pulpwood rather than construction lumber.

- Visual Inspection: Assessing knots, cracks, decay, and discoloration.

- Moisture Content Measurement: Using a moisture meter.

- Specific Gravity Determination: Assessing wood density.

- Mechanical Testing: Measuring strength properties.

Q 9. Explain the process of converting logs into lumber.

Converting logs into lumber is a multi-stage process, a bit like transforming raw ingredients into a delicious meal. It starts with log debarking, removing the bark to prevent contamination and improve efficiency. Next comes sawing, where the log is cut into planks using various techniques like sawing or gang sawing. The choice of technique depends on the log size, desired lumber dimensions, and sawmill capacity. Following sawing, the planks undergo drying to reduce moisture content, preventing warping and improving dimensional stability. Kiln drying is a common method, offering precise control over the drying process. Finally, the dried lumber is graded and sorted according to quality standards, ensuring it meets specific applications. For instance, high-quality lumber might be used for furniture, while lower-grade lumber could be suitable for pallets.

- Debarking: Removing the bark.

- Sawing: Cutting logs into planks.

- Drying: Reducing moisture content.

- Grading and Sorting: Categorizing lumber based on quality.

Q 10. What are the different uses of timber by-products?

Timber by-products, often seen as waste, are valuable resources. Imagine the scraps from building a house – they aren’t useless! Sawdust and wood chips are widely used in the production of particleboard and oriented strand board (OSB). Bark can be used as fuel, mulch, or in some cases, even extracted for tannins used in leather production. Wood shavings can find their way into animal bedding or packaging materials. Even wood residues from the milling process can be used to generate energy through biomass boilers. The key is to find creative ways to utilize these by-products, promoting sustainability and reducing waste.

- Sawdust and Wood Chips: Used in particleboard and OSB production.

- Bark: Fuel, mulch, tannin extraction.

- Wood Shavings: Animal bedding, packaging.

- Wood Residues: Biomass energy generation.

Q 11. Describe the various types of wood-based panels and their manufacturing processes.

Wood-based panels are engineered products offering versatility and cost-effectiveness. They’re like building blocks for larger structures. Particleboard is made by bonding wood particles with resin under heat and pressure. It’s relatively inexpensive and widely used in furniture and construction. Medium-density fiberboard (MDF) uses finer wood fibers, resulting in a smoother, denser panel ideal for cabinetry and molding. Oriented strand board (OSB) uses wood strands oriented in layers, creating a strong and cost-effective panel used extensively in construction, particularly for sheathing. The manufacturing processes generally involve preparing the wood particles or strands, mixing with resin and other additives, forming the panel under heat and pressure, and then finishing. The specific process varies depending on the type of panel being produced.

- Particleboard: Wood particles bonded with resin.

- MDF: Fine wood fibers, smoother finish.

- OSB: Wood strands oriented in layers.

Q 12. What are the key considerations for designing efficient sawmill operations?

Designing efficient sawmill operations requires a holistic approach. Think of it as orchestrating a well-oiled machine. Optimizing log flow is crucial – minimizing handling and maximizing throughput. This involves strategic placement of equipment and effective material handling systems. Efficient sawing techniques, leveraging advanced technology like computerized log scanning and optimizing cutting patterns, play a vital role in maximizing lumber yield. Careful planning of the drying process is also crucial to minimize energy consumption and maintain lumber quality. Finally, efficient waste management systems are essential to minimize environmental impact and recover valuable by-products. For example, a sawmill might implement a closed-loop system to recycle sawdust for fuel, reducing waste and operational costs.

- Optimized Log Flow: Minimizing handling, maximizing throughput.

- Efficient Sawing Techniques: Maximizing lumber yield.

- Controlled Drying Process: Minimizing energy use, maintaining quality.

- Effective Waste Management: Minimizing environmental impact.

Q 13. Explain the principles of forest inventory and its application in timber utilization.

Forest inventory is the systematic process of collecting and analyzing data about forests. It’s like taking a census of the trees. It provides crucial information on tree species, size, density, and overall forest health. This data is vital for timber utilization planning, enabling sustainable harvesting practices and efficient resource allocation. Different inventory methods exist, ranging from simple visual assessments to sophisticated remote sensing techniques. Data analysis allows foresters to estimate timber volume, assess growth rates, and plan for future harvests, ensuring the long-term health and productivity of the forest. For example, a forest inventory might reveal that a particular area has a high concentration of mature trees ready for harvesting, guiding sustainable timber extraction.

- Data Collection: Tree species, size, density, forest health.

- Data Analysis: Estimating timber volume, assessing growth rates.

- Sustainable Harvesting Planning: Ensuring long-term forest health.

Q 14. How does climate change impact timber growth and utilization?

Climate change significantly impacts timber growth and utilization. Think of it as altering the recipe for tree growth. Increased temperatures and altered precipitation patterns affect tree growth rates, species distribution, and susceptibility to pests and diseases. More frequent and intense extreme weather events, such as droughts and wildfires, can cause significant damage to forests, reducing timber availability and quality. Changes in climate also influence the properties of wood, potentially affecting its strength and durability. Furthermore, changing environmental conditions can necessitate adaptations in forestry practices and timber utilization strategies, emphasizing sustainable practices and resilience to climate change impacts. For instance, droughts can lead to slower tree growth, requiring longer rotations between harvests, and increasing the need for drought-resistant tree species.

- Altered Growth Rates: Temperature and precipitation changes.

- Increased Pest and Disease Susceptibility: Weakened trees.

- Extreme Weather Events: Wildfires and damage.

- Changes in Wood Properties: Strength and durability affected.

Q 15. What are the economic implications of sustainable timber management?

Sustainable timber management, while initially requiring higher upfront investment, offers significant long-term economic benefits. It ensures the continuous availability of timber resources, preventing resource depletion and the associated economic losses. This creates a stable and predictable supply chain, benefiting industries reliant on timber.

- Increased profitability: Certified sustainably managed forests often command premium prices, leading to higher profits for producers.

- Reduced risk: Sustainable practices mitigate risks associated with deforestation, soil erosion, and biodiversity loss, which can have significant economic consequences.

- Enhanced market access: Many markets are increasingly demanding sustainably sourced timber, giving sustainably managed operations a competitive edge.

- Job creation: Sustainable forestry often involves more labor-intensive practices, potentially creating more jobs in rural communities.

- Carbon sequestration: Forests act as carbon sinks, and sustainable management enhances their capacity to sequester carbon, creating opportunities in carbon markets.

For example, a company certified by the Forest Stewardship Council (FSC) can often charge a higher price for their lumber, making sustainable practices economically viable. Conversely, ignoring sustainable practices can lead to fines, loss of market access, and reputational damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different methods for measuring timber volume.

Measuring timber volume is crucial for accurate inventory, sales, and harvest planning. Several methods are employed, each with its strengths and weaknesses:

- Cubing: This involves direct measurement of the length, width, and height of each log. It’s accurate but time-consuming and unsuitable for large-scale assessments.

- Volume tables: These use pre-calculated relationships between tree diameter and height to estimate volume. They are faster than cubing but rely on accurate diameter and height measurements and the applicability of the chosen table to the specific species and stand conditions.

- Tree scaling: A skilled scaler estimates the volume of each log based on experience and visual assessment. It’s relatively quick but depends on the scaler’s expertise and can be less precise than other methods.

- Remote sensing: Techniques like LiDAR (Light Detection and Ranging) and aerial photography, coupled with sophisticated software, provide efficient volume estimations over large areas. While expensive initially, they offer significant time and cost savings in the long run, especially in inaccessible terrains.

Choosing the appropriate method depends on factors like the scale of the operation, accuracy requirements, available resources, and terrain. For a small logging operation, cubing might be sufficient, while a large forest management company might prefer remote sensing for inventory purposes.

Q 17. Explain the role of technology in modern timber utilization.

Technology plays a transformative role in modern timber utilization, boosting efficiency, precision, and sustainability. Examples include:

- GPS and GIS: Precise mapping and navigation during harvesting operations minimize waste and ensure compliance with regulations.

- Harvest simulators: Software that models different harvesting scenarios to optimize yield and minimize environmental impact.

- Automated harvesting equipment: Machines equipped with sensors and advanced controls increase efficiency, safety, and precision in felling, delimbing, and processing.

- Remote sensing: Provides real-time data on forest health, growth rates, and pest infestations, enabling proactive management.

- Precision sawing: Optimizes log utilization by minimizing waste during processing. This can involve computer-controlled sawmills and log scanning systems.

These advancements enable data-driven decision-making, reducing costs, improving efficiency and enabling more sustainable forestry practices. For example, the use of GPS-guided harvesters ensures less damage to remaining trees and soil, compared to traditional methods.

Q 18. Discuss the challenges and opportunities in the timber industry.

The timber industry faces both challenges and opportunities:

Challenges:

- Fluctuating timber prices: Global markets influence prices, leading to uncertainty and potential financial risk for businesses.

- Environmental regulations: Stringent regulations on sustainable harvesting and environmental protection can increase operational costs.

- Labor shortages: Finding and retaining skilled workers is a growing concern in many regions.

- Climate change: Increased frequency of extreme weather events (droughts, wildfires, storms) threatens forest health and productivity.

- Competition from alternative materials: The timber industry faces competition from substitutes like steel, concrete, and plastics.

Opportunities:

- Growing demand for sustainable products: Consumers are increasingly conscious of environmental issues, creating demand for sustainably sourced timber.

- Innovation in timber processing: New technologies improve efficiency and create opportunities for higher-value products.

- Bioenergy potential: Wood residues can be used to generate renewable energy, creating additional revenue streams.

- Value-added products: The focus is shifting from raw timber to value-added products like engineered wood, creating new market niches.

- Carbon sequestration potential: Forests play a crucial role in carbon sequestration, offering potential in carbon markets.

Successfully navigating these challenges and capitalizing on opportunities requires a strategic approach that combines sustainable practices, technological innovation, and effective market positioning.

Q 19. How do you manage risks associated with timber harvesting operations?

Managing risks in timber harvesting operations requires a multi-faceted approach. A robust risk management plan should include:

- Pre-harvest planning: Thorough site assessment, including terrain analysis, identification of hazards (e.g., unstable trees, steep slopes), and development of a detailed harvesting plan.

- Worker training and safety protocols: Comprehensive training programs for all personnel, emphasizing safe operating procedures, hazard recognition, and emergency response.

- Equipment maintenance and inspection: Regular maintenance schedules and pre-operation checks for all equipment to prevent malfunctions and accidents.

- Emergency response planning: Developing and practicing emergency response procedures for various scenarios, such as accidents, fires, and weather events.

- Environmental monitoring: Tracking key environmental indicators during and after harvesting to ensure compliance with regulations and minimize environmental impact.

- Insurance and liability coverage: Adequate insurance coverage to protect against potential financial losses from accidents, injuries, or environmental damage.

For example, using pre-harvest simulations to identify potential hazards allows for adjustments to the harvesting plan, minimizing risks and maximizing worker safety. Regular safety inspections can prevent equipment malfunctions, minimizing costly downtime and potential accidents.

Q 20. What are the key regulations affecting timber utilization in your region?

(Note: This answer will need to be tailored to your specific region. I cannot provide region-specific regulations without that information. However, I can give examples of common regulations.)

Key regulations affecting timber utilization typically include:

- Sustainable forestry certification schemes: Requirements for sustainable harvesting practices, often involving third-party certification (e.g., FSC, PEFC).

- Environmental protection laws: Regulations aimed at minimizing the environmental impact of harvesting, including protection of water bodies, endangered species, and sensitive ecosystems.

- Forest management plans: Mandatory plans outlining sustainable harvesting practices, reforestation efforts, and other forest management activities.

- Occupational safety and health regulations: Regulations ensuring the safety and well-being of workers in timber harvesting and processing operations.

- Transportation regulations: Rules governing the transport of timber, including load limits, vehicle safety, and environmental protection measures.

These regulations aim to ensure responsible and sustainable timber utilization. Non-compliance can lead to fines, penalties, and potential legal action.

Q 21. Describe your experience with timber transportation and logistics.

(Note: This answer requires personal experience which I, as an AI, do not possess. I will provide a general answer.)

My experience with timber transportation and logistics encompasses various aspects including:

- Route planning and optimization: Selecting efficient routes to minimize transportation time and costs while considering road conditions, load limits, and environmental constraints.

- Load securing and safety: Ensuring proper securing of timber loads to prevent accidents and damage during transport. This often includes compliance with regulations for load size and weight.

- Fleet management: Managing a fleet of trucks, trailers, and other vehicles to ensure timely and efficient transportation.

- Logistics coordination: Coordinating with various stakeholders, including harvesting crews, processing plants, and customers, to ensure the smooth flow of timber products.

- Inventory management: Tracking timber inventory throughout the supply chain to ensure accurate stock levels and minimize losses.

Efficient timber transportation and logistics are critical for minimizing costs and maximizing the value of harvested timber. Optimizing routes, utilizing appropriate equipment, and effective coordination contribute to the overall profitability and sustainability of the timber industry.

Q 22. Explain your understanding of forest certification schemes (e.g., FSC, PEFC).

Forest certification schemes, such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC), are voluntary standards that ensure responsible forest management. They provide a framework for sustainable forestry practices, verifying that timber comes from well-managed forests that meet specific environmental, social, and economic criteria. Think of it like a ‘seal of approval’ for sustainably sourced wood.

FSC focuses on high environmental standards, promoting biodiversity, protecting endangered species, and minimizing the impact on ecosystems. PEFC, while also prioritizing sustainability, offers a broader approach, encompassing a wider range of forest management practices and national certification systems.

In practice, companies achieving certification undergo rigorous audits to ensure compliance. This involves reviewing forest management plans, assessing harvesting techniques, evaluating social impacts on local communities, and ensuring chain of custody—tracking the timber from forest to final product. This transparency reassures consumers and businesses about the origin and sustainability of their timber purchases. For example, a furniture manufacturer might choose FSC-certified timber to demonstrate its commitment to environmental responsibility and attract environmentally conscious customers.

Q 23. How do you ensure the safety of workers in timber harvesting and processing?

Worker safety is paramount in timber harvesting and processing. It’s not just a matter of compliance but a fundamental aspect of ethical and responsible operations. My approach is multi-faceted and includes:

- Comprehensive Training Programs: Regular, thorough training on safe operating procedures for all machinery, including felling, skidding, and milling equipment. This includes hands-on practice and refresher courses.

- Personal Protective Equipment (PPE): Ensuring workers consistently use appropriate PPE, such as helmets, safety glasses, high-visibility clothing, hearing protection, and steel-toe boots, tailored to the specific task.

- Regular Safety Inspections: Implementing frequent inspections of equipment and work areas to identify and rectify potential hazards promptly. This includes checking machinery for proper function and identifying potential trip hazards.

- Emergency Response Plans: Developing and regularly practicing emergency response plans for accidents, injuries, or natural disasters. This ensures a swift and coordinated response in case of unforeseen events.

- Clear Communication and Reporting Systems: Establishing clear communication channels for reporting hazards, near misses, and accidents. This fosters a culture of proactive safety where workers feel comfortable reporting issues without fear of reprisal.

For instance, in one project, we implemented a new system for pre-felling assessments that significantly reduced the risk of tree falls. This involved using advanced technology and risk assessment matrices to plan felling operations more safely.

Q 24. Describe your experience with inventory management systems for timber.

I have extensive experience with timber inventory management systems, employing both traditional methods and advanced technologies. Traditional methods involve ground surveys, using tools like calipers and measuring tapes to assess tree diameters and heights. This data is then used to estimate timber volume per hectare. However, this is time-consuming and labor-intensive.

More advanced systems integrate Geographic Information Systems (GIS) and remote sensing technologies, such as LiDAR (Light Detection and Ranging). LiDAR uses laser pulses to create highly accurate 3D models of the forest, allowing for precise measurements of tree characteristics and volume estimations over large areas. This data is then inputted into specialized software for analysis and inventory management. We use this data for optimal harvesting planning, minimizing environmental impact and maximizing yield. For example, using GIS, we can pinpoint areas with high-value timber species and plan harvesting routes to minimize damage to other areas.

Q 25. What are your strategies for reducing waste in timber processing?

Reducing waste in timber processing requires a holistic approach, starting with careful planning and extending throughout the entire process. My strategies include:

- Optimized Log Sorting and Grading: Efficiently sorting logs by size and quality to maximize yield from each log and minimize offcuts. This minimizes waste by using the most appropriate sawmill equipment for each log size and quality.

- Advanced Sawmill Technology: Utilizing modern sawmills with advanced computer-controlled cutting systems that optimize cutting patterns to minimize waste. This often includes optimizing the board dimensions based on market demands.

- Value-Added Products from Residues: Developing strategies to utilize sawmill residues (bark, sawdust, shavings) for value-added products like biomass fuel, engineered wood products (OSB, MDF), or mulch. This not only reduces waste but also generates additional revenue streams.

- Continuous Improvement Programs: Implementing processes to monitor waste generation and identify areas for improvement. Regularly reviewing processes to optimize cutting patterns and utilization rates.

In one project, we implemented a new log sorting system that reduced waste by 15% by optimizing log allocation to different sawing lines. This resulted in significant cost savings and improved profitability.

Q 26. Explain the different types of sawmills and their capabilities.

Sawmills come in a variety of types, each with its own capabilities and best suited for different applications. Some key examples include:

- Circular Sawmills: These are the most common type, utilizing a large circular saw blade to cut logs into lumber. They are relatively simple, inexpensive, and versatile, but may generate more sawdust than other types.

- Band Sawmills: These use a thin, continuous blade, resulting in less kerf (sawdust) and a higher yield than circular sawmills. They are ideal for processing larger logs and producing higher-quality lumber but are more expensive to maintain.

- Gang Sawmills: These employ multiple saw blades to cut several boards simultaneously from a single log. They are highly productive but require specific log sizes and are less adaptable to varying log dimensions.

- Chipper-Canter Sawmills: These combine a canter (which removes slabs from logs) with a chipper to process logs quickly. They are very efficient in processing large volumes of logs but are less versatile than other sawmill types.

The choice of sawmill type depends on factors such as log size, desired lumber quality, production volume, and budget constraints. A small-scale operation might use a circular sawmill, whereas a large-scale industrial operation would likely use a more advanced band sawmill or chipper-canter system.

Q 27. Describe your experience with quality control in a sawmill environment.

Quality control in a sawmill is crucial for producing high-quality lumber that meets market demands. My experience involves a multifaceted approach including:

- Log Inspection: Careful inspection of incoming logs to identify defects and assess their suitability for different products. This includes checking for rot, insect damage, and other imperfections.

- Sawing Process Monitoring: Monitoring the sawing process to ensure that the saw blades are sharp, aligned correctly, and operating at optimal speeds. This prevents defects like tear-out and reduces waste.

- Grading and Sorting: Implementing a rigorous lumber grading system based on industry standards to classify boards based on quality. This ensures that lumber is sorted and packaged according to its specifications.

- Moisture Content Control: Monitoring and controlling the moisture content of lumber to meet specific requirements for different applications. This prevents warping and ensures dimensional stability.

- Regular Equipment Maintenance: Ensuring that all sawmill equipment is regularly maintained and calibrated to optimize performance and prevent defects.

For example, we implemented a real-time moisture monitoring system in one sawmill which allowed for immediate adjustments to the drying process, reducing defects and improving the overall quality of the final product.

Q 28. How do you stay updated on the latest trends and technologies in timber utilization?

Staying updated on the latest trends and technologies in timber utilization is essential for remaining competitive and environmentally responsible. My approach involves:

- Industry Publications and Journals: Regularly reading industry publications and journals to keep abreast of new research, technologies, and best practices. This includes attending conferences and workshops.

- Professional Networks: Actively participating in professional organizations and networks to engage with other experts, share knowledge, and learn about emerging trends.

- Trade Shows and Conferences: Attending trade shows and conferences to see demonstrations of new equipment and technologies and network with industry leaders.

- Online Resources and Databases: Utilizing online resources and databases to access technical information, research papers, and case studies on innovative technologies in timber utilization.

- Collaboration and Knowledge Sharing: Collaborating with researchers, universities, and other industry professionals to share knowledge and learn about new developments.

For instance, I recently attended a conference where I learned about new laser scanning techniques for log sorting, which has the potential to significantly improve efficiency and reduce waste in our operations.

Key Topics to Learn for Timber Utilization Interview

- Sustainable Forestry Practices: Understanding sustainable harvesting techniques, reforestation methods, and the impact of timber utilization on forest ecosystems. Practical application includes evaluating the environmental impact of different logging methods.

- Timber Harvesting and Transportation: Knowledge of various harvesting methods (clear-cutting, selective logging), equipment used, and efficient transportation logistics. Practical application involves optimizing harvesting strategies to minimize environmental damage and maximize efficiency.

- Wood Processing and Manufacturing: Familiarity with different wood processing techniques (sawmilling, pulping, veneer production), understanding wood properties and their influence on product quality. Practical application includes troubleshooting issues in a sawmill or optimizing a production line.

- Wood Product Engineering and Design: Understanding the structural properties of wood and its applications in various industries (construction, furniture, paper). Practical application includes designing a structurally sound wooden beam or selecting appropriate wood species for a specific project.

- Timber Market Analysis and Economics: Knowledge of timber market trends, pricing strategies, and economic factors influencing the timber industry. Practical application involves forecasting timber prices or evaluating the financial feasibility of a timber project.

- Health and Safety Regulations: Understanding and adhering to all relevant health and safety regulations within the timber industry. Practical application includes identifying and mitigating potential hazards on a logging site or in a sawmill.

- Waste Management and By-Product Utilization: Exploring strategies for minimizing waste generation during timber processing and finding innovative uses for by-products. Practical application includes developing a plan to reduce waste in a sawmill or finding alternative uses for sawdust.

Next Steps

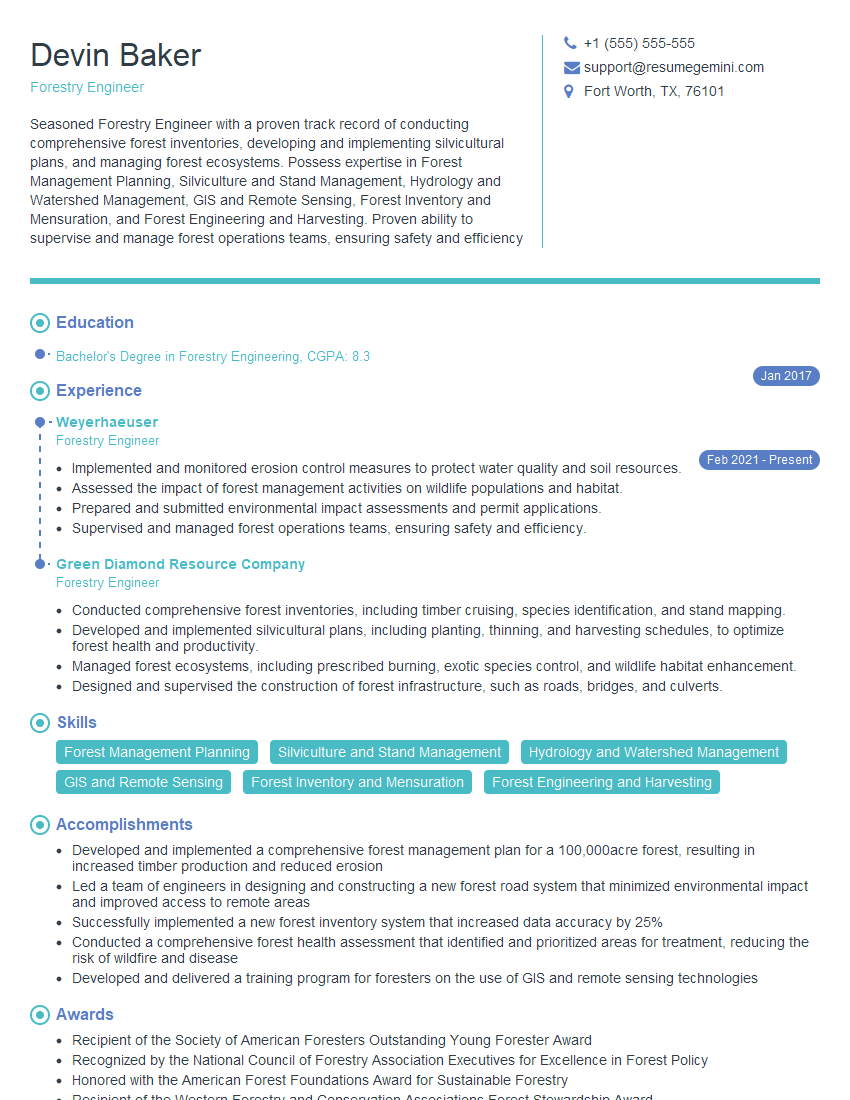

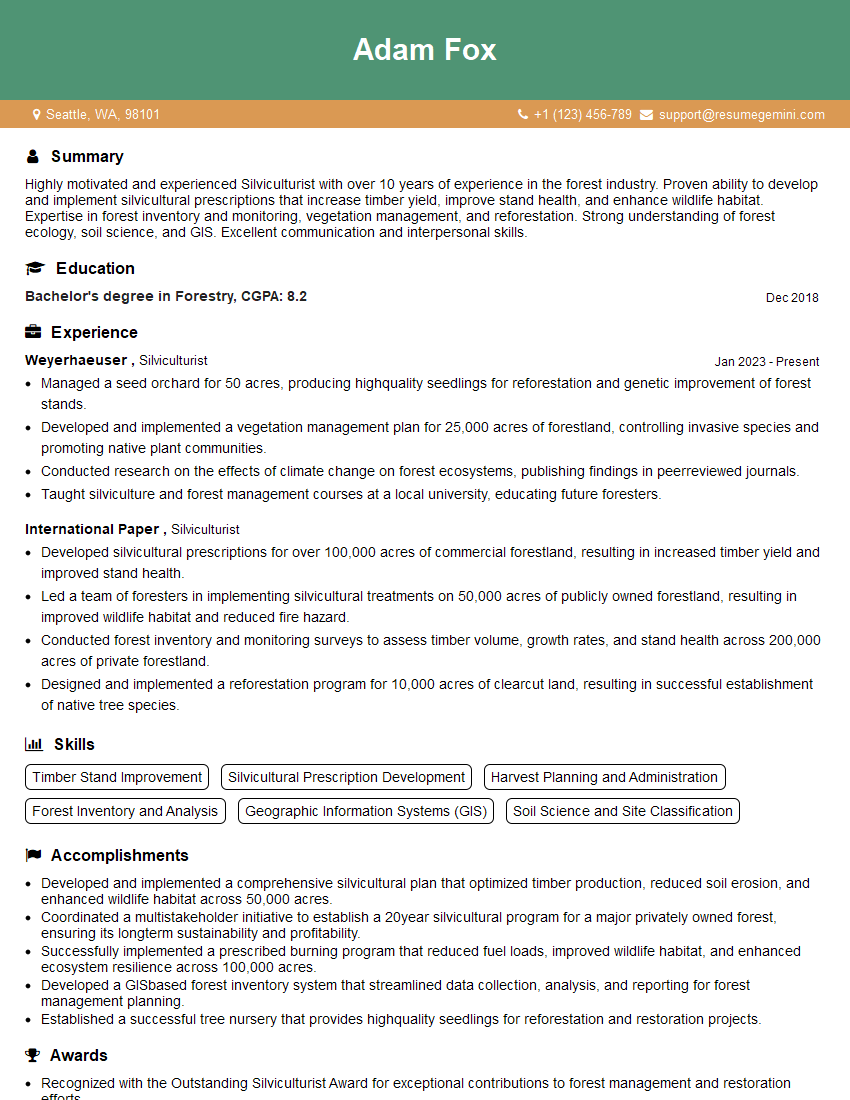

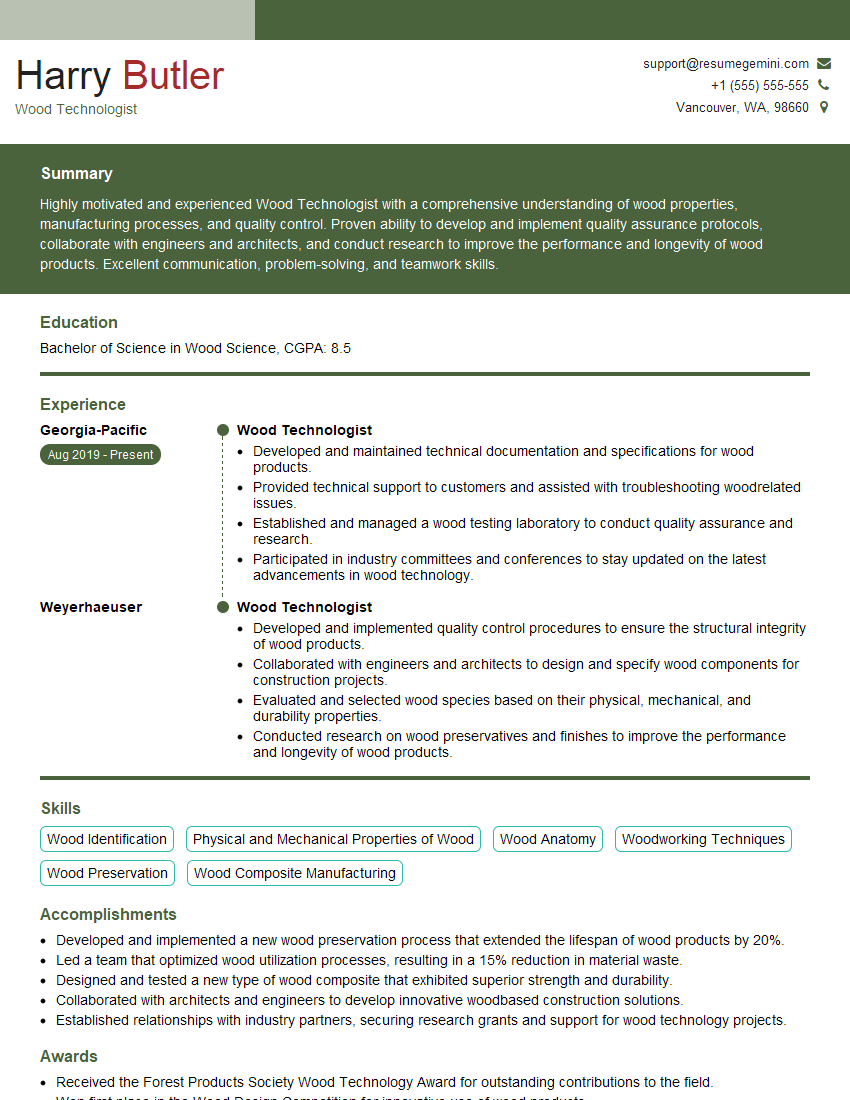

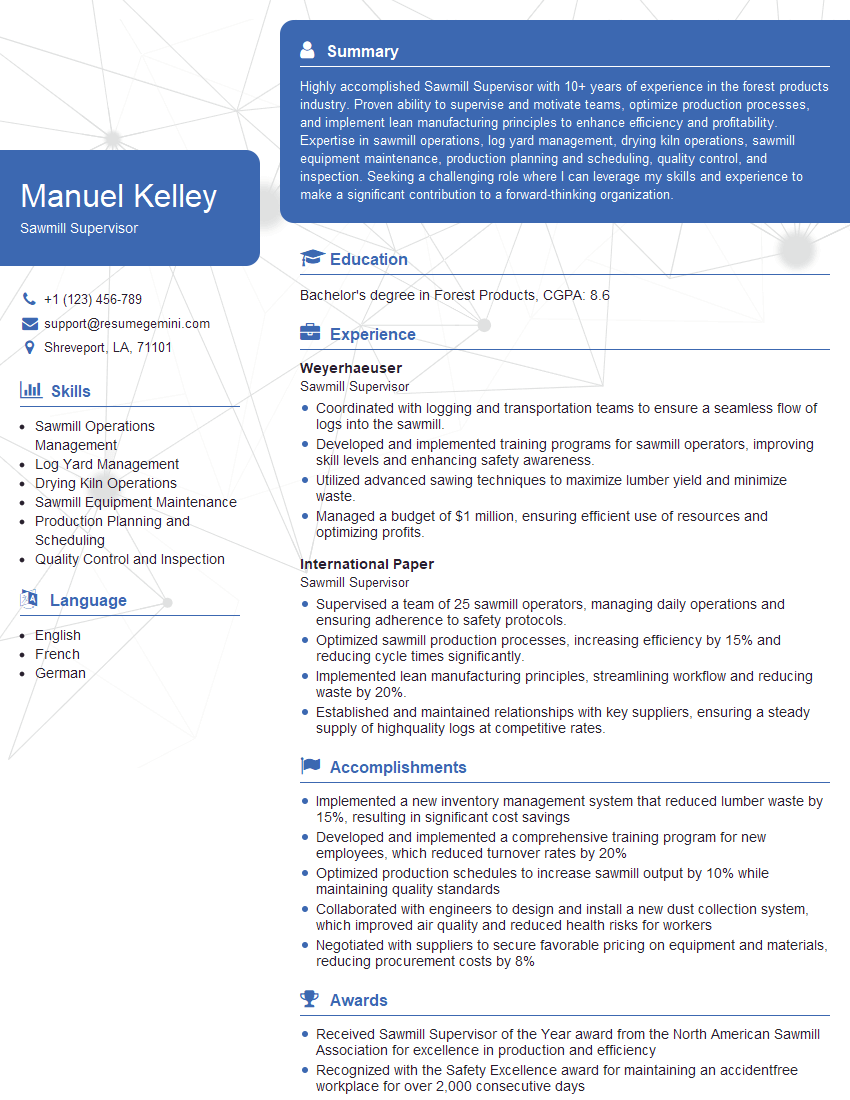

Mastering Timber Utilization opens doors to a rewarding career with significant growth potential in a vital industry. A strong understanding of these key areas will significantly enhance your interview performance and job prospects. To further increase your chances of landing your dream role, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Take advantage of their tools and resources; examples of resumes tailored to the Timber Utilization field are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good