Cracking a skill-specific interview, like one for Traceability and Record Keeping, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Traceability and Record Keeping Interview

Q 1. Explain the importance of traceability in your field.

Traceability, in the context of record-keeping, is the ability to track a product, process, or event throughout its lifecycle. It’s essentially creating a detailed history, allowing us to answer the crucial ‘who, what, when, where, and why’ questions at any point. Its importance is paramount because it ensures product quality, facilitates recall processes (in case of defects), supports regulatory compliance, and ultimately protects consumers. Imagine a pharmaceutical company: traceability ensures that every pill can be traced back to its source materials, manufacturing process, and distribution path. Without it, a contaminated batch could be devastating and extremely difficult to contain.

In simpler terms, traceability is like leaving a trail of breadcrumbs—allowing you to follow the journey of anything from its origin to its final destination. This is crucial for managing risk, improving efficiency, and building trust.

Q 2. Describe different traceability methods and their applications.

Several methods exist for achieving traceability, each with its strengths and weaknesses. They range from simple manual systems to sophisticated, automated solutions.

- Barcodes and QR codes: These are widely used for simple tracking, offering quick and easy identification of items. Imagine scanning a barcode on a food product; you can immediately access its origin and processing details.

- RFID (Radio-Frequency Identification): RFID tags provide more robust tracking capabilities than barcodes, allowing for real-time monitoring of items even without line-of-sight. This is useful in supply chain management, where pallets or containers can be tracked as they move.

- Serial numbers: Assigning unique serial numbers to individual items allows for precise tracking from creation to disposal. This is common in high-value electronics or medical devices.

- Blockchain technology: This offers a secure and transparent way to record events chronologically and immutably. Each transaction is verified and added to the chain, making tampering extremely difficult. This is proving increasingly valuable in supply chains for goods requiring high security and transparency.

- Database systems: Sophisticated database systems allow for storing and managing large amounts of traceability data, enabling analysis and reporting. These systems can integrate with other systems like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) for comprehensive tracking.

The choice of method depends on factors such as the complexity of the product, the required level of detail, and the budget available.

Q 3. What are the key challenges in maintaining accurate records?

Maintaining accurate records presents many challenges, primarily revolving around data management and human error.

- Data entry errors: Human error in data entry is a significant source of inaccuracies. Typos, incorrect selections, or missing data can compromise the entire traceability system.

- Data inconsistency: Different formats, naming conventions, or data structures across various systems can lead to inconsistencies and difficulties in analysis.

- Data loss or corruption: Hardware failures, software glitches, or accidental deletions can lead to significant data loss, undermining the traceability system.

- Lack of standardization: A lack of standardized procedures and protocols for data collection and management can hinder accuracy and consistency.

- System integration issues: Integrating different systems within an organization can be complex and often leads to data silos and inaccuracies.

- Data security breaches: Unauthorized access to traceability data can lead to manipulation, loss, or corruption.

Addressing these challenges requires a robust system with data validation checks, appropriate data backup and recovery mechanisms, and rigorous training for personnel involved in data handling.

Q 4. How do you ensure data integrity in a traceability system?

Ensuring data integrity is crucial for reliable traceability. This involves a multi-pronged approach:

- Data validation: Implementing data validation rules and checks at the point of data entry helps prevent errors and inconsistencies. For example, checks can be set to ensure that dates are in the correct format, numerical values are within a valid range, or that mandatory fields are filled.

- Audit trails: Maintaining detailed audit trails of all data changes, including who made the changes, when, and what changes were made, is critical for identifying and rectifying errors.

- Access control: Implementing strict access control mechanisms ensures that only authorized personnel can access and modify data, minimizing the risk of unauthorized changes or deletions. Role-based access control is highly recommended.

- Data backups and recovery: Regular backups of the traceability data are essential to recover data in case of system failures or data corruption. A robust recovery plan is also crucial to minimize downtime and data loss.

- Data encryption: Encrypting sensitive data at rest and in transit protects against unauthorized access and data breaches.

- Regular system audits: Conducting regular audits of the traceability system can help identify potential weaknesses and ensure the system continues to meet its intended purpose.

These measures work together to create a system that is reliable, accurate, and resistant to data manipulation.

Q 5. What are the regulatory requirements for traceability in your industry?

Regulatory requirements for traceability vary considerably depending on the industry. In the pharmaceutical industry, for instance, regulations like Good Manufacturing Practices (GMP) and the Drug Supply Chain Security Act (DSCSA) mandate stringent traceability requirements for pharmaceuticals. In the food industry, regulations like the Food Safety Modernization Act (FSMA) require detailed traceability of food products to ensure safety and prevent contamination. Medical device manufacturers must comply with regulations like the FDA’s Quality System Regulation (QSR). These regulations typically mandate specific record-keeping practices, including detailed documentation of processes, materials used, and distribution channels. Non-compliance can lead to significant penalties, including fines and product recalls.

Staying current on regulatory updates is crucial; my experience includes proactive monitoring of relevant regulations and adapting our systems and processes to maintain compliance.

Q 6. Explain your experience with traceability software or systems.

Throughout my career, I’ve worked extensively with various traceability software and systems. Early in my career, I utilized simpler systems involving spreadsheets and barcoding. These systems worked well for smaller scale operations, but limitations became evident with increased scale and complexity. This led me to working with enterprise-level solutions – specifically, I have extensive experience implementing and managing systems that integrate with ERP and MES. These enterprise systems allow for comprehensive tracking, real-time monitoring, and robust reporting. One notable project involved implementing a blockchain-based traceability solution for a global food supplier. This project required careful planning, thorough testing, and collaboration with various stakeholders to ensure seamless integration across the entire supply chain. The result was a significant increase in transparency and efficiency, allowing for rapid identification and resolution of issues.

Q 7. How do you handle discrepancies or errors in traceability records?

Discrepancies or errors in traceability records require immediate attention to maintain data integrity. My approach involves a systematic investigation:

- Identify the discrepancy: Determine the nature and extent of the error or discrepancy.

- Investigate the cause: Determine the root cause of the error. Was it human error, a system glitch, or a process failure?

- Document the findings: Thoroughly document the discrepancy, the investigation process, and the conclusions.

- Correct the error: Implement the necessary corrections to the traceability records. This might involve updating data, rectifying processes, or retraining personnel.

- Implement preventative measures: Identify and implement measures to prevent similar errors from occurring in the future. This may involve revising procedures, improving data validation, or upgrading systems.

- Notify relevant stakeholders: If the discrepancy has significant implications (e.g., product recall), relevant stakeholders (e.g., regulatory bodies, customers) need to be notified immediately.

The key is to maintain a clear, documented audit trail of the entire process, ensuring transparency and accountability.

Q 8. Describe a time you improved a traceability system or process.

In a previous role at a pharmaceutical manufacturing plant, we faced challenges with our batch traceability system. It relied heavily on manual data entry, leading to inconsistencies and delays in identifying the source of potential product defects. To improve this, I spearheaded the implementation of a new automated system using barcode scanning at each stage of the manufacturing process. This automated data capture significantly reduced human error and created a more accurate and reliable record. We integrated this system with our existing ERP (Enterprise Resource Planning) software for seamless data transfer and reporting.

Before the improvement: Tracing a batch back to its source materials could take days, involving manual searches through paper records and spreadsheets. This delayed investigations into quality issues, causing significant production downtime and potential financial losses.

After the improvement: We reduced batch tracing time to minutes. The new system provided immediate access to complete batch history, including materials used, manufacturing parameters, and testing results. This improved our responsiveness to quality issues, enhanced regulatory compliance, and streamlined our recall procedures. It also allowed us to proactively identify trends and prevent future problems. The transition involved thorough training for employees, meticulous data migration from the old system, and ongoing monitoring to ensure system accuracy.

Q 9. How do you ensure the confidentiality and security of traceability data?

Ensuring the confidentiality and security of traceability data is paramount. This requires a multi-layered approach encompassing physical, technical, and procedural safeguards.

- Physical Security: Data centers housing traceability databases should have restricted access, surveillance systems, and environmental controls to protect against physical threats.

- Technical Security: We use encryption both in transit and at rest to protect data from unauthorized access. Access control measures, like role-based permissions and strong passwords, restrict access to authorized personnel only. Regular security audits and penetration testing identify and address vulnerabilities. We also employ data loss prevention (DLP) tools to monitor and prevent sensitive data from leaving the controlled environment.

- Procedural Security: Our procedures dictate strict protocols for data handling, including data access logs, regular data backups, and incident response plans. We conduct regular employee training on data security best practices and the importance of protecting confidential information. We also adhere to relevant data privacy regulations, such as GDPR or CCPA, depending on the region.

Imagine a scenario where traceability data for medical devices is compromised. The consequences could be devastating, ranging from patient safety risks to massive financial penalties and reputational damage. Therefore, a robust security framework is not optional but critical.

Q 10. What metrics do you use to measure the effectiveness of a traceability system?

Measuring the effectiveness of a traceability system involves both quantitative and qualitative metrics.

- Accuracy: The percentage of accurate records in the system. We frequently conduct data validation exercises to ensure data accuracy.

- Completeness: The proportion of transactions or events recorded within the system. Gaps in data indicate weaknesses in the system’s coverage.

- Timeliness: The speed and efficiency of data entry and retrieval. We aim for near real-time data entry for critical processes.

- Traceability Efficiency: The time required to trace a product or material back to its origin. Improvements in this metric highlight the effectiveness of implemented changes.

- User Satisfaction: User feedback through surveys and regular check-ins helps understand the usability and effectiveness of the system from the perspective of those using it daily.

- Compliance Rate: The percentage of audits passed without any non-conformances related to the traceability system demonstrates compliance with relevant regulations.

By continuously monitoring these metrics, we can identify areas for improvement and ensure our system remains effective and reliable.

Q 11. Explain the concept of a ‘traceable chain of custody’.

A traceable chain of custody refers to the documented and unbroken chronological record of the possession, handling, and transfer of an item from its origin to its final destination. Each step in the chain includes verifiable information such as date, time, location, person or entity involved, and any relevant changes to the item’s condition.

Think of a piece of evidence in a criminal investigation. The chain of custody ensures that the evidence remains unaltered and its integrity is maintained from the crime scene to the courtroom. If any link in the chain is broken or uncertain, the evidence’s admissibility may be questioned. Similarly, in food safety or pharmaceuticals, a strong chain of custody ensures that products can be traced back to their source materials to quickly identify and address potential contamination or quality issues. The concept applies equally to other industries such as manufacturing, logistics, and supply chain management where provenance and product history are crucial.

Q 12. How do you manage large volumes of traceability data?

Managing large volumes of traceability data requires a robust and scalable database system capable of handling the processing and storage of a high volume of records. We utilize database technologies such as cloud-based solutions (e.g., AWS, Azure) or distributed databases to handle large datasets efficiently. Furthermore, data warehousing and business intelligence tools enable effective analysis and reporting from this data.

We also implement data compression techniques to reduce storage requirements and optimize query processing. Data deduplication strategies are employed to prevent duplicate entries. Regular data cleanup and archiving ensure the database’s efficiency and effectiveness. The use of advanced indexing and query optimization further improves system performance. Finally, employing a well-defined data governance process is key. This includes establishing clear data standards, roles and responsibilities, and processes for data quality control.

Q 13. What are the benefits of implementing a robust traceability system?

Implementing a robust traceability system brings several key benefits:

- Improved Product Quality and Safety: Rapid identification and resolution of quality issues, leading to fewer product recalls and enhanced consumer confidence.

- Enhanced Regulatory Compliance: Meeting industry standards and regulatory requirements with greater ease, minimizing the risk of penalties and reputational damage. Industries with stringent regulations such as pharmaceuticals and food processing rely heavily on traceability systems.

- Increased Efficiency and Productivity: Streamlined processes, reduced manual intervention, and faster problem-solving. This translates directly to cost savings and improved operational efficiency.

- Better Supply Chain Management: Improved visibility into the supply chain, allowing for better inventory management and quicker response to disruptions.

- Stronger Brand Reputation: Demonstrating a commitment to quality and transparency enhances brand trust and loyalty among consumers.

- Reduced Waste: Pinpointing the source of defects can minimize losses associated with spoiled goods or faulty products.

In essence, a well-designed traceability system is a strategic asset that protects a business from risks and enhances its efficiency and reputation.

Q 14. How do you validate the accuracy of traceability data?

Validating the accuracy of traceability data is an ongoing process requiring a multi-pronged approach.

- Data Reconciliation: Regular comparison of data from various sources (e.g., manufacturing equipment, laboratory systems, manual records) helps identify discrepancies.

- Data Validation Rules: Implementing data validation rules and checks during data entry to prevent inaccurate or illogical data from entering the system. This includes range checks, consistency checks, and cross-referencing.

- Audits and Inspections: Regular audits and site inspections can verify that the traceability system is functioning correctly and that data is being recorded accurately and completely. This might involve physical verification of stock or equipment against recorded data.

- Sampling and Testing: Random sampling of products and testing against recorded data allows verification of consistency. This helps detect potential errors or inconsistencies in the traceability data.

- Cross-referencing: Comparing data against other independent sources can provide additional validation of the data’s accuracy. Using multiple data capture methods helps verify data integrity.

By implementing these validation methods, we ensure that the data in our traceability system is reliable and supports informed decision-making and helps maintain compliance.

Q 15. How do you collaborate with different teams to maintain traceability?

Maintaining traceability across different teams requires a collaborative approach built on clear communication and standardized procedures. I believe in fostering a culture of shared responsibility where each team understands its role in the overall traceability process. This involves regular meetings, shared dashboards visualizing the traceability data, and the use of a common platform for record-keeping.

For example, in a pharmaceutical manufacturing setting, I would work closely with the research and development team to ensure that all experimental data, formulations, and test results are meticulously documented and linked to the final product. Similarly, I’d collaborate with the manufacturing team to ensure that each batch of product is uniquely identified and its production process tracked in detail. Finally, the quality control team needs to have seamless access to this information to ensure regulatory compliance.

Effective collaboration relies on using a structured system, such as a shared database or a dedicated traceability management software, to eliminate data silos and improve transparency. Regular audits of the system and team performance ensure continuous improvement and prevent breakdowns in the traceability chain.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different record-keeping formats (paper, digital)?

My experience spans both paper-based and digital record-keeping systems. While paper systems offer a degree of familiarity and simplicity, their limitations in terms of searchability, data integrity, and scalability are significant. Digital systems, however, provide a much more powerful tool for managing large volumes of data, enabling quick retrieval and analysis.

In my previous roles, I’ve worked with both. Initially, we relied on a paper-based system for managing research notes and test results, which proved cumbersome and error-prone. The transition to a digital system using a LIMS (Laboratory Information Management System) significantly improved our efficiency and reduced the risk of errors. This transition also facilitated better data analysis and report generation. Moreover, using a digital system allowed for improved audit trails, making compliance with regulatory requirements significantly simpler.

My proficiency includes various digital record-keeping formats such as relational databases (e.g., SQL), cloud-based platforms (e.g., SharePoint), and specialized traceability software. The choice of system depends heavily on the specific needs and context, but the overarching principle is to ensure that the system is secure, accessible, and auditable.

Q 17. How do you handle record retention and disposal procedures?

Record retention and disposal are governed by legal and regulatory requirements, which vary depending on the industry and geographical location. My approach involves a structured process incorporating several key steps:

- Policy Development: Establishing a clear and comprehensive retention policy outlining retention periods for different record types. This policy should align with industry best practices and relevant regulations.

- Record Management System: Implementing a robust record management system to track the lifecycle of records from creation to disposal, ensuring proper version control and access control.

- Regular Audits: Conducting regular audits to ensure compliance with the retention policy and identify any gaps in the system.

- Secure Disposal: Using secure disposal methods to protect sensitive information, such as shredding for paper records and secure deletion for digital records. This often includes generating audit trails for disposal.

- Documentation: Meticulously documenting all retention and disposal procedures, ensuring that the process is transparent and auditable.

For example, in a regulated industry like pharmaceuticals, retention periods can be extensive, extending for many years. A detailed record of disposal, with timestamps and personnel involved, is essential for demonstrating compliance during regulatory inspections.

Q 18. Explain your understanding of data governance in the context of traceability.

Data governance, in the context of traceability, refers to the policies, processes, and procedures that ensure the accuracy, integrity, and accessibility of traceability data throughout its lifecycle. It’s about establishing a framework for managing data from its creation to its final disposition, guaranteeing that it remains reliable and trustworthy.

Key elements of data governance for traceability include:

- Data Quality: Implementing processes to ensure that the data collected is accurate, complete, and consistent. Data validation and error checking are crucial here.

- Data Security: Implementing measures to protect the data from unauthorized access, modification, or disclosure, such as access controls and encryption.

- Data Accessibility: Ensuring that authorized personnel have timely access to the data when needed. This includes appropriate data storage and retrieval mechanisms.

- Data Retention: Defining clear retention policies and procedures for managing the lifecycle of traceability data, as discussed previously.

- Compliance: Ensuring that the data governance framework aligns with relevant regulations and industry standards.

Think of it like building a house; the foundation is the data governance policy that guides all actions and ensures a solid framework for accurate and reliable traceability. Without this foundation, the traceability system becomes unreliable and prone to errors.

Q 19. Describe your experience with implementing or improving record-keeping systems.

I’ve been involved in several projects focused on implementing and improving record-keeping systems. One notable project involved migrating a manufacturing company from a primarily paper-based system to a fully integrated digital system. This involved several steps:

- Needs Assessment: Identifying the company’s current record-keeping challenges and defining the requirements for the new system.

- System Selection: Evaluating and selecting a suitable software solution based on functionality, scalability, and integration with existing systems.

- Data Migration: Developing a plan for migrating existing paper-based records to the new digital system, including data cleaning and validation.

- Training and Support: Providing comprehensive training to users on the new system and establishing ongoing support mechanisms.

- Process Optimization: Integrating the new system into existing workflows and optimizing processes to maximize efficiency.

The results were remarkable. We saw a significant reduction in errors, improved data accessibility, streamlined reporting, and enhanced regulatory compliance. The project also led to a reduction in storage costs and improved data security. Each step involved careful planning, stakeholder engagement, and change management. Successful implementation involved addressing concerns and providing adequate support to all team members throughout the entire transition.

Q 20. How do you ensure the traceability of products through the supply chain?

Ensuring product traceability throughout the supply chain requires a comprehensive approach involving unique product identification, data capture at each stage, and secure data exchange between different entities. This often involves the use of technologies such as barcodes, RFID tags, and blockchain.

The process typically starts with assigning a unique identifier to each product at the point of manufacture. This identifier is then tracked throughout the supply chain, from raw material sourcing to distribution to the end consumer. Data at each stage, such as manufacturing date, location, and processing details, is captured and linked to the unique product identifier. Secure data sharing between suppliers, manufacturers, distributors, and retailers is crucial. This might involve using secure data exchange platforms or integrating systems across the supply chain.

For example, a food manufacturer might use barcodes to track individual packages of their product through their processing and distribution network. This allows them to quickly identify and isolate products in the event of a recall, minimizing the impact on consumers and their brand reputation. Similarly, in the pharmaceutical industry, unique serial numbers are often used for enhanced track and trace.

Q 21. What are the potential risks associated with inadequate traceability?

Inadequate traceability poses significant risks across various industries. These risks can be categorized into several key areas:

- Product Recalls: Inability to quickly identify and trace affected products during a recall, leading to significant financial losses and reputational damage.

- Counterfeit Products: Difficulty in distinguishing genuine products from counterfeit ones, leading to potential safety hazards and economic losses.

- Supply Chain Disruptions: Lack of visibility into the supply chain makes it harder to manage disruptions, leading to delays and potential stockouts.

- Regulatory Non-Compliance: Failure to meet regulatory requirements for traceability can result in penalties, fines, and legal action.

- Safety Hazards: Inability to track the origin and handling of products can compromise safety, especially in industries such as pharmaceuticals and food.

- Brand Damage: Loss of consumer trust and damage to brand reputation due to safety concerns or lack of transparency.

For example, a lack of traceability in a food supply chain could lead to a widespread contamination event that is difficult to contain, resulting in significant health risks and economic consequences. A pharmaceutical company facing a counterfeit drug issue due to weak traceability measures could also face huge legal and financial repercussions.

Q 22. How do you address traceability challenges in a complex supply chain?

Addressing traceability challenges in a complex supply chain requires a multi-faceted approach. Think of it like assembling a complex puzzle – each piece needs to be accounted for and connected correctly. The key is to establish a robust, end-to-end system that captures information at every stage, from raw material sourcing to final product delivery. This includes identifying all stakeholders and establishing clear communication channels.

- Standardize Data Collection: Implementing consistent data formats and collection methods across all tiers of the supply chain is crucial. This prevents inconsistencies and improves data integration.

- Utilize Technology: Blockchain technology, RFID tracking, and barcode systems can enhance visibility and accuracy throughout the supply chain. Imagine each product having a unique digital passport that tracks its journey.

- Collaboration and Partnerships: Open communication and collaboration with suppliers, manufacturers, distributors, and retailers are essential. Sharing data securely and transparently is key to a successful traceability program.

- Regular Audits and Reviews: Periodic audits help to identify weaknesses and ensure the system’s effectiveness. Regular reviews of the entire traceability process allows for continuous improvement and adaptation.

- Traceability Mapping: Create a comprehensive map of the supply chain to visualize the flow of materials and products. This helps identify potential bottlenecks or areas vulnerable to traceability gaps.

For example, in the food industry, a lack of traceability can lead to massive recalls if a contaminated batch is identified. A robust traceability system allows quick identification and isolation of the affected product, minimizing the impact of the contamination event.

Q 23. Describe your experience with audits related to traceability and record-keeping.

I’ve been involved in numerous audits related to traceability and record-keeping, across diverse industries including food manufacturing, pharmaceuticals, and high-tech manufacturing. These audits typically assess compliance with industry standards (e.g., ISO 9001, GMP, FSSC 22000) and regulatory requirements. My role often involves reviewing documentation, observing processes, and interviewing personnel to verify the accuracy and completeness of traceability records.

One particular audit I recall involved a food manufacturer. During the audit, we discovered a gap in their traceability system for a specific ingredient. The missing information created uncertainty about the product’s origin and potential risks. This highlighted the importance of robust data capture at each stage of the production process. We worked with them to implement corrective actions, including upgrading their record-keeping system and training employees on proper data entry procedures.

Audits are not just about finding problems; they provide invaluable insights into how to improve traceability. They help identify areas for optimization and highlight the need for continuous improvement in the overall record-keeping process. The findings are used to strengthen traceability and ensure that the organization meets both internal and external requirements.

Q 24. How do you use technology to improve traceability and record-keeping processes?

Technology plays a vital role in enhancing traceability and record-keeping. It’s about transforming data into actionable intelligence. I’ve extensively used various technologies, including:

- Enterprise Resource Planning (ERP) Systems: These systems integrate different aspects of a business, providing a centralized repository for all traceability data.

- Supply Chain Management (SCM) Software: These tools facilitate real-time tracking of materials and products throughout the supply chain, improving visibility and efficiency.

- Barcode and RFID Systems: These technologies allow for automatic data capture, reducing manual data entry errors and improving accuracy.

- Blockchain Technology: This offers a secure, transparent, and tamper-proof way to track products, providing enhanced confidence in the integrity of traceability data.

- Data Analytics Tools: These tools allow for the analysis of large datasets to identify trends, patterns, and potential areas for improvement in the traceability system.

For instance, I helped a pharmaceutical company implement an RFID system to track medications from manufacturing to distribution. This system improved the accuracy of inventory management and helped to quickly identify and locate any batches with quality issues. The combination of technologies leads to a stronger, more efficient traceability system.

Q 25. What are your strategies for preventing data loss or corruption?

Preventing data loss or corruption is paramount. It’s like safeguarding your most valuable asset. My strategies include:

- Data Backup and Recovery Systems: Regular backups to offsite locations, using both local and cloud storage, are essential to ensure business continuity in case of a system failure or disaster. We should also test the backup and recovery process regularly.

- Data Validation and Integrity Checks: Implementing data validation rules and checks at each stage of data entry ensures accuracy and consistency. This can include checksums and other validation techniques.

- Access Control and Security Measures: Limiting access to traceability data to authorized personnel only and using strong passwords and encryption to protect the data from unauthorized access or modification is vital.

- Redundancy and Failover Systems: Implementing redundant systems and failover mechanisms ensures that traceability data remains accessible even in case of a system failure. Think of it like having a spare tire for your car.

- Regular Data Audits and Reconciliation: Regular audits help to identify inconsistencies and potential data corruption issues. Reconciling data across different systems helps maintain data integrity.

For example, in a manufacturing environment, using a version control system for documentation prevents accidental overwrites and allows tracking of changes.

Q 26. How do you manage traceability records in the event of a recall or product issue?

Managing traceability records during a recall or product issue is critical. Speed and accuracy are paramount. This is like having a detailed map to quickly pinpoint the affected area. My process involves:

- Immediate Isolation and Containment: Quickly identify and isolate the affected product or batch to prevent further distribution.

- Data Retrieval and Analysis: Retrieve relevant traceability data to pinpoint the origin, distribution channels, and affected parties. This could involve querying databases and examining records.

- Communication and Collaboration: Effectively communicate with relevant stakeholders, including customers, suppliers, and regulatory bodies. Transparent communication is crucial.

- Corrective Actions: Implement corrective actions to prevent future occurrences of the issue. This might involve modifying processes or improving data collection methods.

- Post-Recall Analysis: Conduct a thorough post-recall analysis to identify the root cause of the issue and improve the traceability system to prevent future events.

For instance, in a food recall scenario, we can quickly trace back the affected batch of products to their specific origin using traceability data and isolate them, preventing further distribution and protecting consumers.

Q 27. How do you ensure compliance with relevant standards (e.g., ISO, GMP)?

Ensuring compliance with relevant standards like ISO 9001, GMP, and FSSC 22000 requires a structured approach. This is about operating within a defined framework. My approach involves:

- Gap Analysis: Conducting a gap analysis to identify the differences between the current traceability system and the requirements of the relevant standards.

- Implementation of Standard Operating Procedures (SOPs): Developing and implementing clear, concise, and well-documented SOPs for all aspects of the traceability process ensures consistency and adherence to standards.

- Training and Education: Providing comprehensive training to all employees involved in the traceability process ensures that they understand their roles and responsibilities.

- Regular Audits and Reviews: Conducting regular internal audits and inviting external audits to verify compliance with the standards.

- Documentation and Record Management: Maintaining accurate and up-to-date documentation of all aspects of the traceability process ensures traceability and audit readiness.

For example, adhering to GMP guidelines in pharmaceutical manufacturing ensures that the traceability records demonstrate that the drugs are safe and meet quality specifications. We make sure our systems and procedures are aligned with all relevant regulations.

Q 28. Describe your experience with root cause analysis related to traceability issues.

Root cause analysis for traceability issues requires a systematic approach. It’s about going beyond the symptoms and uncovering the underlying cause. My approach often involves:

- Defining the Problem: Clearly define the traceability issue, including the impact and severity.

- Data Collection: Gather all relevant data, including traceability records, process documentation, and interview transcripts.

- Root Cause Identification: Use tools such as the 5 Whys or fishbone diagrams to identify the underlying causes of the issue. This involves asking ‘why’ repeatedly to get to the root of the problem.

- Corrective Actions: Develop and implement corrective actions to address the root cause and prevent recurrence.

- Verification and Validation: Verify that the implemented corrective actions are effective and validate the traceability system to ensure that the issue is resolved.

For instance, if a batch of products is mislabeled, a root cause analysis might reveal a failure in the labeling process, inadequate employee training, or a software glitch in the system. Addressing the root cause, such as implementing a double-checking mechanism or updating the software, would prevent future mislabeling events.

Key Topics to Learn for Traceability and Record Keeping Interview

- Fundamentals of Traceability: Understanding the principles of traceability, including the “why” behind implementing robust traceability systems across various industries (food, pharmaceuticals, manufacturing, etc.). Explore different traceability methods and their applications.

- Record Keeping Best Practices: Learn about regulatory compliance (e.g., FDA, ISO) and industry standards related to record keeping. Focus on data integrity, accuracy, and the importance of consistent documentation procedures.

- Data Management and Analysis: Explore practical applications of data management within traceability systems. This includes data entry, storage, retrieval, and analysis techniques to identify trends, potential issues, and areas for improvement. Understand different data formats and their suitability for traceability.

- Technology in Traceability and Record Keeping: Familiarize yourself with relevant technologies such as barcode scanning, RFID, blockchain, and specialized software solutions for managing traceability data. Understand their benefits and limitations.

- Problem-Solving and Troubleshooting: Develop your ability to identify and resolve traceability gaps, data inconsistencies, and potential system failures. Practice applying your knowledge to real-world scenarios.

- Auditing and Compliance: Understand the audit process related to traceability and record-keeping systems. Learn how to prepare for audits and ensure compliance with relevant regulations and standards.

- Different Traceability Systems: Explore various traceability system architectures and their implementation across different industries. Consider the advantages and disadvantages of each approach.

Next Steps

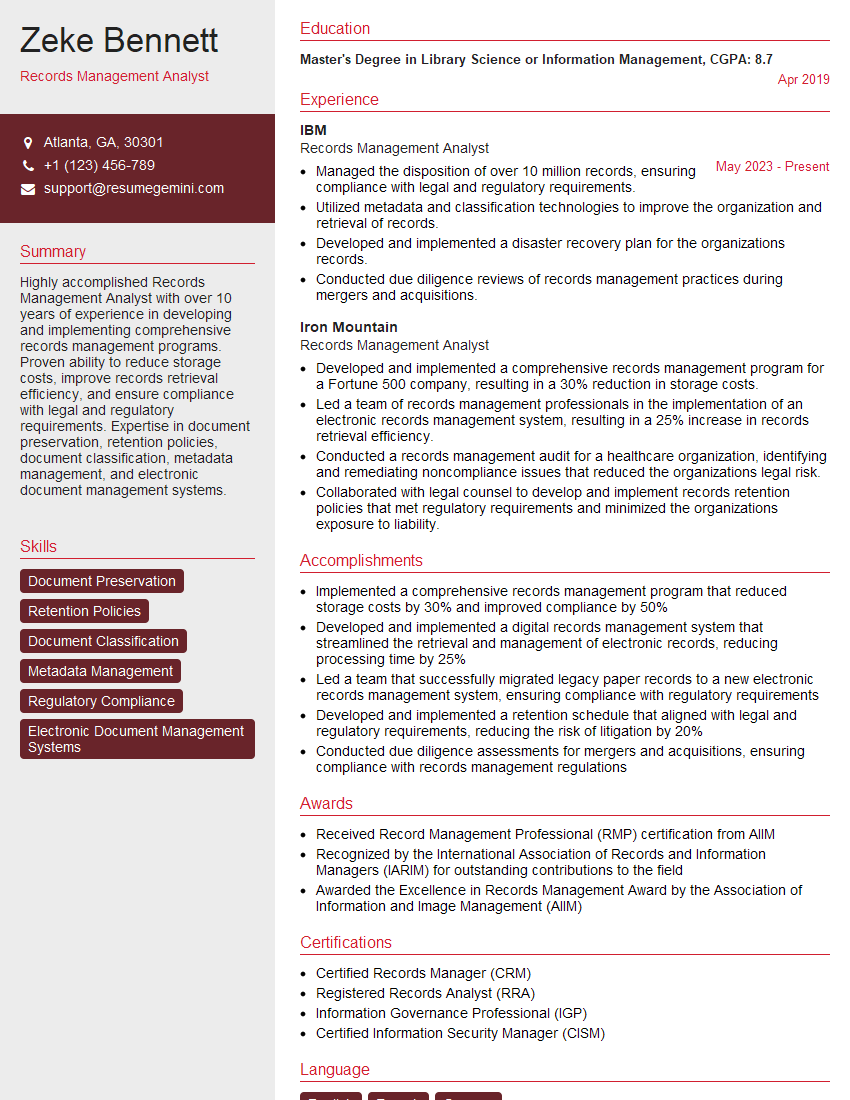

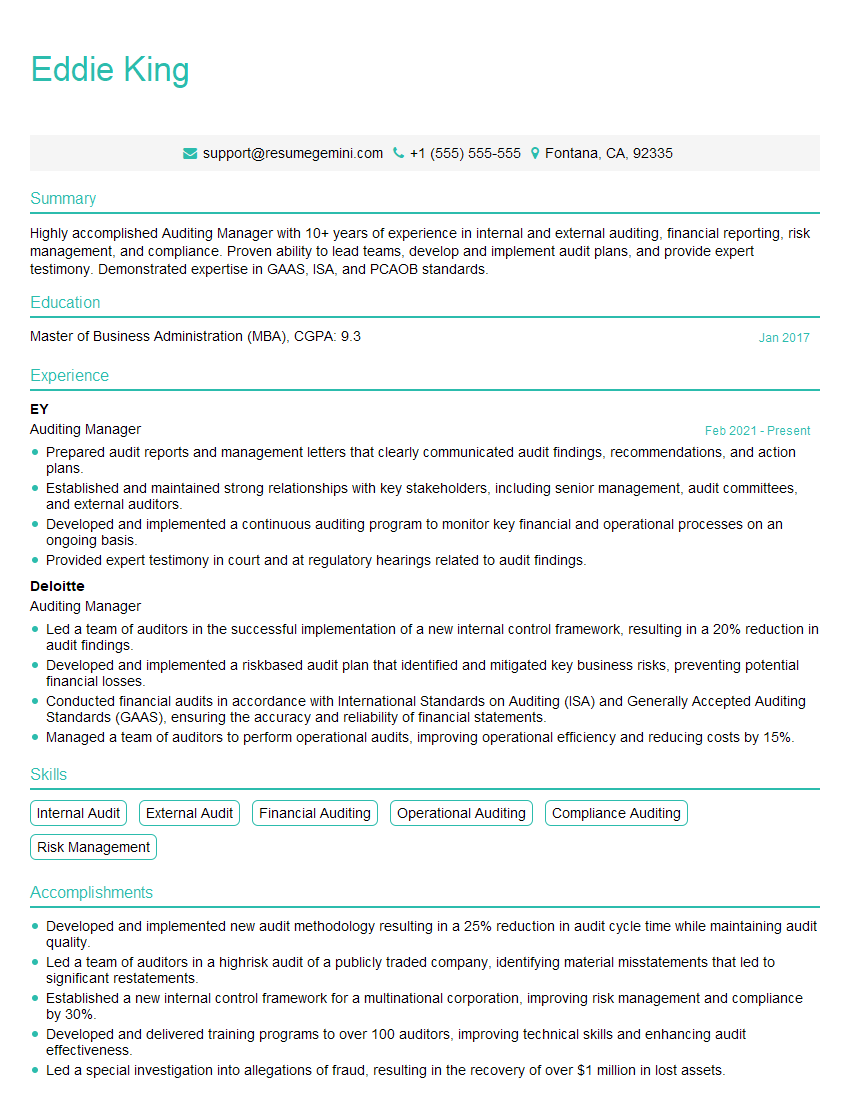

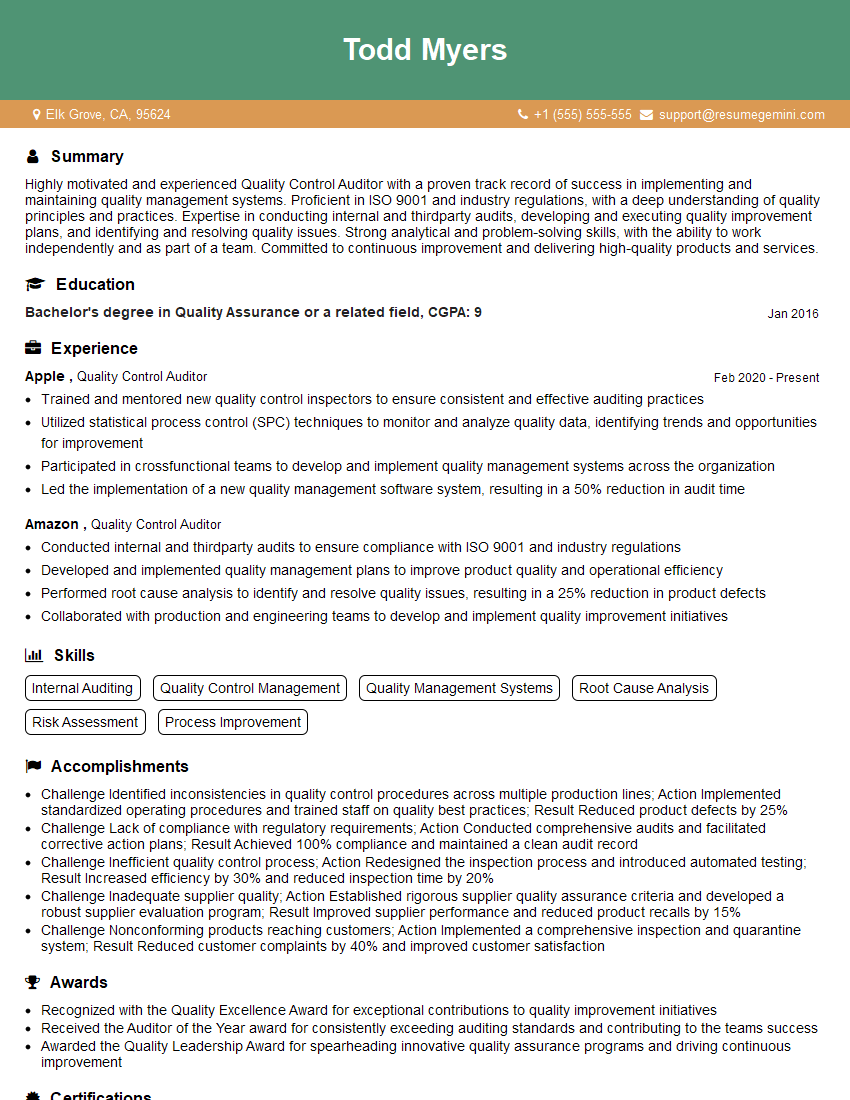

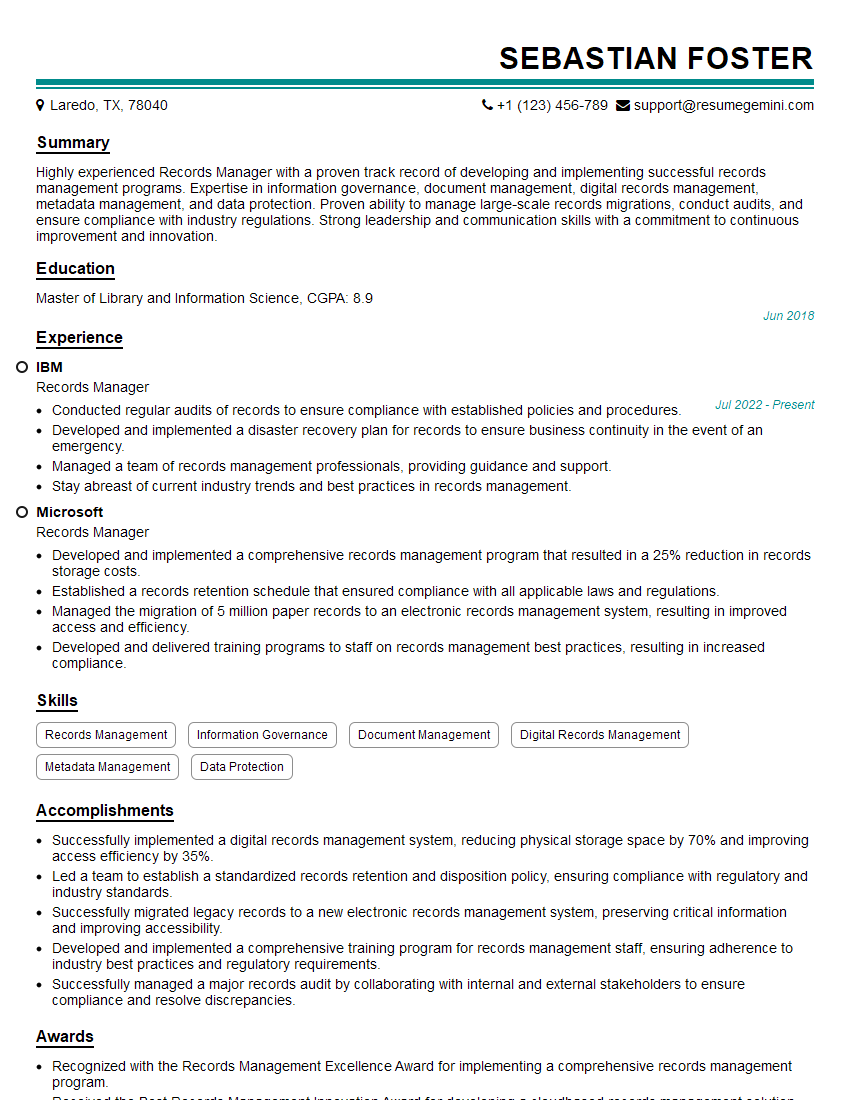

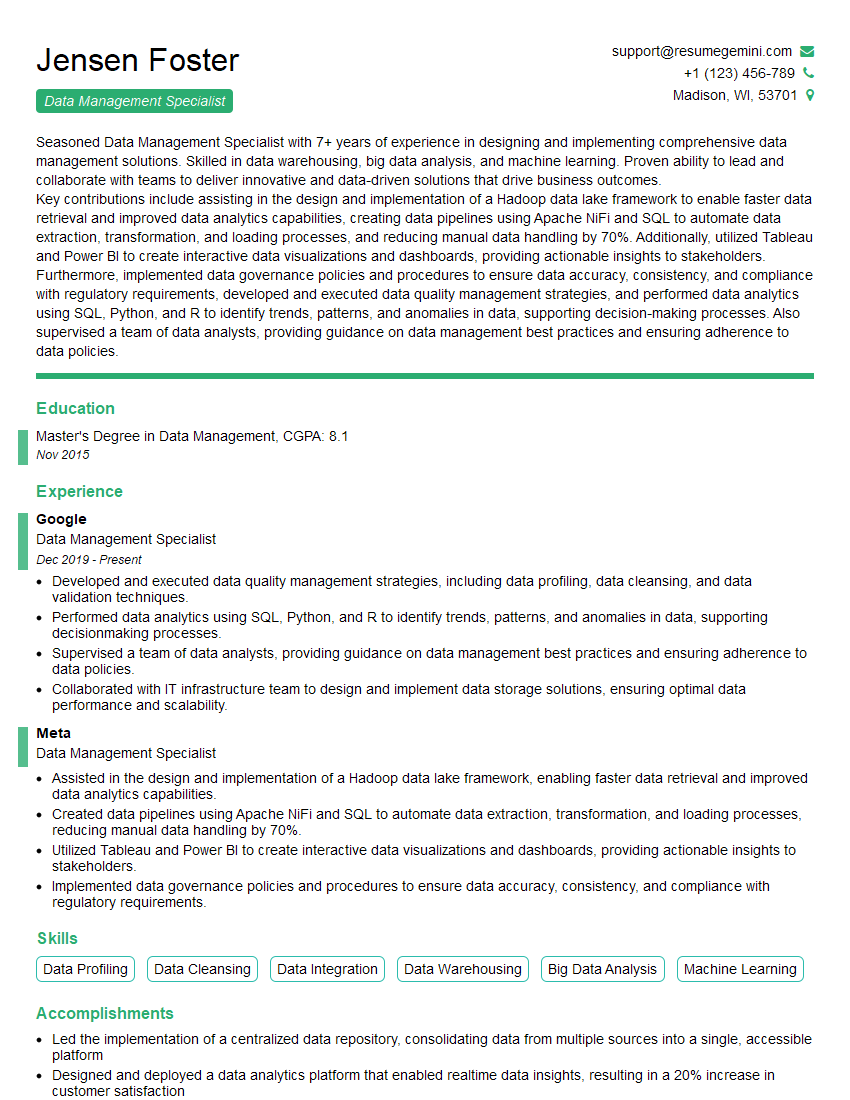

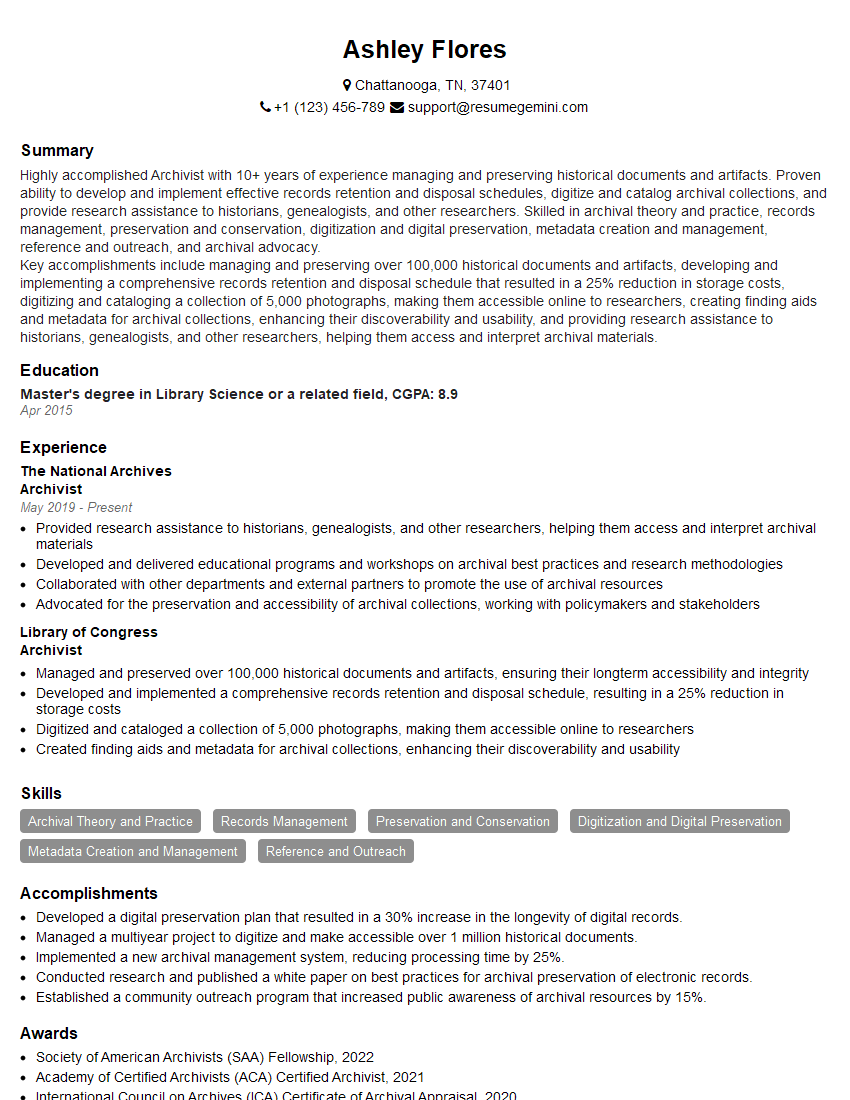

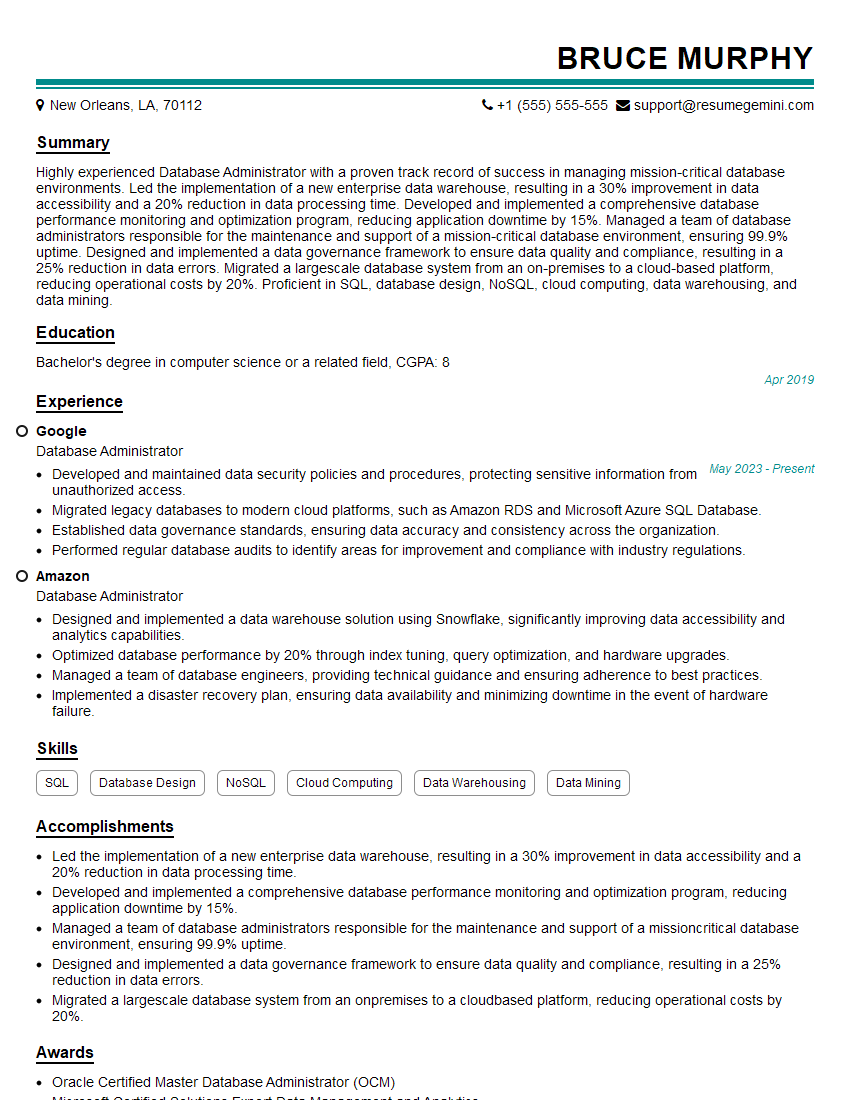

Mastering Traceability and Record Keeping opens doors to exciting career opportunities in diverse sectors demanding high levels of accuracy and regulatory compliance. A strong understanding of these concepts significantly enhances your employability and positions you for leadership roles. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Traceability and Record Keeping are available within ResumeGemini to further assist you in this process. Invest the time to present yourself powerfully – your future self will thank you!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good