Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Trackside Infrastructure Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Trackside Infrastructure Maintenance Interview

Q 1. Describe your experience with track geometry measurements and corrections.

Track geometry measurements are crucial for ensuring safe and efficient railway operations. We use sophisticated equipment like track geometry cars, which utilize laser and inertial measurement units to precisely measure parameters like track gauge (distance between rails), alignment (straightness of the track), level (elevation differences), and cross-level (difference in elevation between the two rails). These measurements are then compared against pre-defined tolerances.

Corrections involve several steps. First, we analyze the measurement data to identify areas requiring attention. Small deviations might only necessitate minor adjustments, such as tamping (compacting the ballast underneath the sleepers). More significant deviations may require more extensive work, such as lifting and realigning the track, replacing damaged sleepers, or even adjusting the rail itself. For example, if the track gauge is consistently outside the acceptable range, we’d use specialized equipment to spread or close the rails to the correct measurement. This process is iterative, with repeat measurements to verify that corrections are effective and within tolerance. We also maintain detailed records of all measurements and corrections, enabling trend analysis and predictive maintenance.

In my experience, I’ve overseen the correction of significant track misalignments caused by ground settlement after heavy rainfall, utilizing both manual and automated track maintenance equipment to restore the track to its optimal geometry. Understanding the interplay between soil conditions, track design, and the effectiveness of various correction methods is key to maintaining a safe and efficient railway network.

Q 2. Explain the different types of rail fasteners and their applications.

Rail fasteners are critical for securing the rails to the sleepers (ties) and maintaining track stability. Several types exist, each suited to specific conditions and track types.

- Screw Spikes: These are simple, cost-effective fasteners involving screws driven into pre-drilled holes in the sleepers. They offer good holding power and are easy to install and maintain, but may loosen over time with vibration. Commonly used on less demanding lines.

- Clip Fasteners: These use metal clips that clamp the rail to the sleeper. They are robust, providing excellent stability and allowing for easier rail replacement compared to screw spikes. Different clip designs cater to various rail profiles and stress levels. They are prevalent in high-speed and heavy-haul rail lines.

- Elastic Fasteners: These incorporate an elastic element to absorb vibrations and reduce noise and wear. They provide superior performance in high-speed applications. These are more complex and usually more expensive.

- Pandrol Fasteners: This is a widely recognized brand of clip fasteners known for their reliability and strength. They use a resilient clip design that compensates for thermal expansion and contraction of the rails.

The choice of fastener depends on factors like track speed, traffic volume, rail profile, and sleeper material. For instance, elastic fasteners would be preferred for high-speed lines, while screw spikes might be suitable for low-speed, light-traffic branches. Regular inspection and maintenance, including tightening or replacing worn fasteners, is vital to ensure track safety.

Q 3. What are the common causes of track derailments and how can they be prevented?

Track derailments are serious incidents with potentially catastrophic consequences. They stem from various causes, often a combination of factors.

- Track Defects: Gauge widening or narrowing, misalignment, broken rails, worn-out sleepers, and inadequate ballast are prime culprits. Regular inspections and proactive maintenance are crucial to mitigate these risks.

- Rolling Stock Defects: Faulty wheels, axles, or bogies can lead to derailments. Strict adherence to maintenance schedules and regular inspections are essential.

- Environmental Factors: Excessive rainfall can cause washouts or ground settlement, destabilizing the track. Effective drainage systems and careful ground preparation during track construction are vital. Extreme temperatures can also impact rail integrity.

- Human Error: Poor track maintenance, inadequate inspection procedures, or operational errors, such as speeding, contribute to derailments.

Preventing derailments involves a multi-pronged approach: stringent track maintenance programs including regular geometry measurements and corrections, thorough inspections of rolling stock, effective drainage solutions, and a strong safety culture emphasizing strict adherence to procedures and continuous improvement in operational safety. Early detection of subtle track defects through advanced monitoring systems can also be beneficial.

Q 4. How do you perform routine inspections of track components?

Routine track inspections are a cornerstone of railway safety. These are typically conducted on a regular schedule, with the frequency depending on the track’s condition, usage, and speed limits. Inspections involve a visual assessment of all track components, covering everything from the rails and sleepers to the ballast and drainage systems.

We utilize a systematic approach, often walking the track, carefully examining each component for signs of damage, wear, or degradation. This involves checking for:

- Rails: Look for cracks, corrosion, head wear, gauge variations, and rail breaks.

- Sleepers: Check for cracks, splitting, decay, and proper alignment.

- Fasteners: Examine for looseness, corrosion, or damage, ensuring they securely hold the rail to the sleeper.

- Ballast: Assess ballast condition for cleanliness, drainage, proper depth, and signs of settlement or fouling.

- Drainage: Check the functionality of drainage ditches and culverts to ensure adequate water removal.

Advanced technologies, such as track inspection vehicles, are increasingly used to supplement manual inspections providing detailed data on track geometry and identifying subtle defects. Defects identified during inspection are recorded and prioritized for repair. Regular reporting and documentation are critical for ensuring accountability and tracking the condition of the track over time.

Q 5. Describe your experience with track drainage systems and maintenance.

Effective track drainage systems are essential for maintaining track stability and preventing washouts. Poor drainage can lead to ground saturation, resulting in track settlement, erosion, and ultimately, derailments.

The systems involve a combination of elements:

- Ballast: Well-graded ballast is porous and allows water to drain quickly. Regular cleaning to remove debris is vital.

- Ditches and Side Drains: These direct water away from the track bed. Regular cleaning of these ditches is essential to maintain their effectiveness. Blockages can lead to water accumulation and subsequent problems.

- Cross Drains: These are installed under the track to collect and channel water away from the track bed. These should be inspected regularly to ensure they are functioning properly.

- Culverts: These are larger structures used to carry water under the track, often necessary for crossing streams or watercourses. Regular inspections are crucial to check for blockages or damage.

Maintenance includes regular cleaning and clearing of ditches, culverts, and drains, ensuring proper functionality. This might involve manual cleaning or specialized equipment depending on the scale and type of drainage system. Inspections after periods of heavy rainfall are crucial to identify and address any issues that may have arisen. In one instance, I oversaw a project to improve drainage on a section of track prone to washouts by installing additional cross drains and widening existing ditches. This significantly reduced the risk of future problems.

Q 6. What are the safety procedures you follow when working on or near railway tracks?

Safety is paramount when working on or near railway tracks. We strictly adhere to a comprehensive set of safety procedures:

- Risk Assessment: Before commencing any work, a thorough risk assessment is carried out to identify potential hazards and implement control measures. This assessment takes into account the specific task, location, and environmental conditions.

- Permit-to-Work System: A formal permit-to-work system ensures that all necessary precautions are in place before work begins. This system outlines the specific tasks, personnel involved, and safety measures required.

- Personal Protective Equipment (PPE): Appropriate PPE, such as high-visibility clothing, safety helmets, gloves, and safety boots, is mandatory at all times. The PPE selection is determined by the specific risks involved.

- Train Protection Procedures: Stringent train protection procedures are followed to ensure that no trains enter the work zone while maintenance or repairs are being conducted. This might involve using track circuits, speed restrictions, or even complete track closures.

- Communication: Clear and consistent communication is essential between workers, supervisors, and train controllers. This ensures everyone is aware of the work being done and any potential risks.

- Emergency Procedures: Well-defined emergency procedures are in place to handle unexpected events such as injury or equipment failure. These procedures must be understood and practiced by all personnel.

Regular safety training is provided to ensure that all personnel are aware of and comply with safety regulations. A culture of safety is promoted through continuous improvement and regular audits.

Q 7. Explain your understanding of different track welding techniques.

Track welding techniques are essential for creating continuous, smooth rail lengths, minimizing rail joints that can be sources of noise, vibration, and track instability. Several techniques exist:

- Thermite Welding: This is a fusion welding process using a thermite reaction to generate the heat necessary to melt the rail ends. It’s a relatively simple and portable method, suitable for various field conditions. However, it generates significant heat and requires careful handling.

- Flash Butt Welding: This is an electric resistance welding process. The rail ends are heated using electric current until molten, and then pressed together under pressure. It’s a highly efficient method for producing strong, smooth welds. However, it requires specialized and expensive equipment.

- Electrogas Welding: This is another arc welding process which is suitable for heavier sections of rail in a shop environment. It offers good control over the welding parameters but isn’t always ideal for on-site repairs.

The choice of welding technique depends on factors like the rail type, budget, access to equipment, and the location of the weld. Thermite welding is more common for on-site repairs due to its portability, while flash butt welding is preferred for mass production in rail manufacturing yards. Proper weld quality control is essential, and each weld is typically inspected to ensure it meets stringent quality standards. Non-destructive testing methods are often employed to confirm weld integrity.

Q 8. How do you identify and address issues related to ballast fouling?

Ballast fouling is a significant issue in track maintenance, referring to the contamination of the ballast (the crushed stone supporting the sleepers) with fine materials like clay, silt, or dust. This reduces the ballast’s drainage capacity, leading to issues like track settlement, increased maintenance needs, and potential derailments. Identifying ballast fouling involves visual inspections, looking for areas where the ballast appears clogged or discolored. We also use specialized equipment like ballast cleaners which can analyze ballast condition and identify contamination levels. Addressing ballast fouling typically involves cleaning the ballast using specialized machines. These machines can remove the contaminated material, aerate the remaining ballast to improve drainage, and sometimes even replace sections of severely fouled ballast. For example, on a recent project, we used a high-pressure water jet system to clean ballast under a heavily trafficked section of track. This significantly improved drainage and stabilized the track bed.

We also employ preventative measures such as regular vegetation control to prevent organic matter from accumulating in the ballast.

Q 9. Describe your experience with track maintenance using specialized equipment.

My experience with specialized track maintenance equipment is extensive. I’ve operated and overseen the use of machines such as ballast regulators, tampers, and rail grinders. Ballast regulators even out the ballast bed, ensuring proper support for the sleepers. Tampers compact the ballast, providing a stable base for the track. Rail grinders smooth out the rail surface, removing imperfections and extending rail life. For instance, on a high-speed rail line, we used a high-production tamper to ensure optimal track geometry after major ballast cleaning. The precision of this equipment is critical to maintaining speed and safety standards. I also have experience with ultrasonic rail flaw detection systems, which use sound waves to identify internal rail defects that are otherwise invisible.

Q 10. Explain the process of repairing damaged rail sections.

Repairing damaged rail sections is a critical aspect of track maintenance. The process depends on the extent of the damage. Minor damage, such as surface cracks, might only require grinding to restore the rail profile. More significant damage, like broken rails or severe corrosion, often necessitates rail replacement. This involves precise cutting of the damaged section, using specialized equipment like a rail saw, and then welding in a new section of rail. The welding process is carefully controlled to ensure the new section is seamlessly integrated with the existing track. After welding, the weld is inspected rigorously, often using non-destructive testing methods, to ensure its strength and integrity. Proper alignment and securing of the new rail segment is also crucial, often involving the use of hydraulic jacks and specialized tools.

In extreme cases where significant track damage occurs, we might employ temporary repairs to restore functionality while a more permanent solution is implemented. For example, we’ve used emergency rail clamps to temporarily secure a broken rail before a permanent replacement could be installed, minimizing disruption to service.

Q 11. How do you ensure compliance with safety regulations during track maintenance?

Safety is paramount in track maintenance. We adhere strictly to all relevant regulations and safety procedures. This includes thorough risk assessments before any work commences, clear communication among the team, the use of personal protective equipment (PPE) such as high-visibility clothing, safety helmets, and gloves, and the implementation of traffic control measures to prevent accidents involving trains. We often work under strict speed restrictions or complete track closures to ensure worker safety. We also maintain detailed safety records and conduct regular safety training sessions for all personnel. Before any major maintenance activity begins, detailed method statements are prepared and reviewed, taking into account all potential hazards and mitigation strategies. This structured approach ensures a safe and productive work environment.

Q 12. What are the common types of rail defects and how are they detected?

Rail defects can significantly impact safety and operational efficiency. Common defects include head checks (surface cracks on the rail head), internal flaws (cracks or voids within the rail), gauge corrosion (wear and tear on the sides of the rail), and squats (flattening of the rail head). Detection methods are crucial for identifying these defects. We routinely utilize visual inspection, but more advanced techniques are also used, such as ultrasonic testing (UT), magnetic particle inspection (MPI), and eddy current testing (ECT). UT uses sound waves to detect internal flaws, MPI uses magnetic fields to detect surface flaws, and ECT uses electromagnetic induction to detect surface and near-surface flaws. The choice of testing method depends on the specific type of defect being investigated and the rail’s condition. Regular inspection using a combination of these methods ensures early detection and prevents catastrophic failures.

Q 13. Describe your experience with switch and crossing maintenance.

Switch and crossing maintenance is highly specialized, requiring a deep understanding of the intricate mechanisms involved. These components are critical for routing trains, and their proper functioning is essential for safe and efficient rail operations. My experience includes regular inspections of switch points, detecting and correcting wear and tear, lubrication, and the adjustment of various components to ensure smooth operation. We also utilize specialized tools and equipment for repairing or replacing worn parts and ensure correct alignment to prevent derailments. For example, I have extensive experience in using precision measuring tools to check the alignment and geometry of switch points and crossings. Furthermore, understanding the different types of switches and crossings and their maintenance requirements is critical to this role. Proper maintenance of these critical points is crucial for railway safety and efficiency.

Q 14. Explain the importance of regular track inspections and maintenance.

Regular track inspections and maintenance are absolutely crucial for ensuring the safety and reliability of rail operations. Neglecting maintenance can lead to track deterioration, derailments, and significant disruptions. Regular inspections, which can range from simple visual checks to sophisticated non-destructive testing, allow for early detection of defects such as rail cracks, ballast fouling, and sleeper damage. This enables timely repairs, preventing small problems from escalating into major safety hazards. Moreover, consistent maintenance extends the lifespan of track infrastructure, reducing overall maintenance costs in the long run. A proactive maintenance approach is far more cost-effective than reactive repairs after a failure has already occurred. Think of it like regular servicing of a car; preventative maintenance avoids costly breakdowns.

Q 15. How do you manage track maintenance projects effectively?

Effective track maintenance project management hinges on meticulous planning, resource allocation, and risk mitigation. It starts with a thorough assessment of the track’s condition, identifying areas needing attention through regular inspections and data analysis (e.g., ultrasonic testing for rail flaws). This informs the creation of a detailed project plan, outlining tasks, timelines, resource requirements (personnel, equipment, materials), and budget. We utilize project management software to track progress, manage resources, and identify potential delays. For example, a major ballast renewal project might involve multiple phases: surveying, material procurement, track removal, ballast placement, track relaying, and final testing. Each phase has its own detailed schedule and milestones. Regular progress meetings with all stakeholders, including engineers, contractors, and operational staff, ensure everyone is aligned and any issues are addressed promptly. Effective communication is key to preventing cost overruns and delays.

Consider a scenario where we’re facing unexpected rain during a ballast renewal. The project plan should include contingency plans to address this, perhaps involving temporary halting of work, adjusting the schedule, or deploying appropriate drainage solutions. Post-project reviews are crucial to identify areas for improvement and inform future projects. We analyze the actual costs and schedules against the plan to understand variances and identify best practices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators for track maintenance?

Key Performance Indicators (KPIs) for track maintenance are crucial for assessing effectiveness and ensuring safety. They fall broadly into three categories: safety, quality, and efficiency. Safety KPIs might include the number of derailments, near misses, and incidents related to track maintenance activities. Quality KPIs focus on the track’s condition, including measurements of track geometry (alignment, level, gauge), ballast condition, and the rate of track defect occurrence. For instance, we monitor the number of defects detected per kilometer of track inspected. Efficiency KPIs measure the cost and time taken to complete maintenance tasks. These include metrics such as cost per kilometer maintained, time taken to complete a specific task (e.g., rail grinding), and the utilization rate of equipment and personnel. Regular monitoring of these KPIs allows us to identify trends, predict potential problems, and optimize maintenance strategies. For example, a consistent increase in track geometry defects might indicate a need for more frequent maintenance or a change in maintenance techniques.

Q 17. Describe your experience with different types of signaling systems.

My experience encompasses a range of signaling systems, from traditional relay-based systems to modern computer-based interlocking systems. I’ve worked extensively with systems like the older style electro-mechanical relays which are largely being replaced by more modern solid-state interlockings. I’m familiar with the principles behind different signaling technologies, including the use of track circuits for train detection, axle counters, and various types of signals (e.g., color light, semaphore). I understand the importance of signal maintainability, safety integrity levels (SILs), and the rigorous testing procedures necessary to ensure their reliable operation. I’ve also been involved in the implementation of Automatic Train Control (ATC) and other advanced train control systems, understanding their integration with the signaling infrastructure. For example, I’ve overseen the upgrade from a traditional relay-based interlocking to a modern computerized system, which involved detailed planning, testing, and coordination with train operations to minimize disruption.

Q 18. How do you troubleshoot issues with track circuits?

Troubleshooting track circuits involves a systematic approach. First, a visual inspection of the track circuit components is necessary, checking for any obvious damage to the rails, bonding wires, or the track circuit cable. Then, we use specialized testing equipment, such as a track circuit tester, to measure the electrical resistance and continuity of the circuit. A high resistance reading might indicate a broken rail bond, a faulty insulator, or vegetation growth interfering with the circuit. Low resistance could indicate a short circuit. We then isolate the problem area section by section and systematically replace or repair the faulty component. For example, if the test reveals a high resistance in a specific section, we’d carefully examine the rails, bonds, and insulators in that area, looking for signs of corrosion, damage, or debris. Sometimes, a simple cleaning can resolve the issue; other times, replacement of a damaged component is required. Documentation is essential; thorough record keeping ensures future maintenance is easier and allows for trend analysis.

Q 19. Explain your understanding of track alignment and its importance.

Track alignment refers to the precise positioning of the rails to maintain a smooth and safe path for trains. This involves ensuring the rails are correctly aligned in both the vertical (level) and horizontal (gauge and alignment) planes. Proper track alignment is critical for several reasons: it enhances train speed and safety by minimizing stresses on the train’s components, reduces wear and tear on the wheels and rails, increases passenger comfort, and prevents derailments. We use specialized equipment like laser-guided alignment systems and measuring instruments to check track geometry. Deviations from the specified alignment tolerances are corrected through track adjustments involving lining (adjusting horizontal alignment) and leveling (adjusting vertical alignment). These adjustments typically involve the use of specialized machinery such as tampers and shims. Regular monitoring and adjustment of track alignment are essential to maintain safe and efficient railway operations. A misaligned track can cause increased wear on the track structure and rolling stock, potentially leading to premature failure and costly repairs.

Q 20. What are the environmental considerations for track maintenance?

Environmental considerations are paramount in track maintenance. We must minimize the environmental impact of our operations, complying with all relevant regulations. This includes managing waste, reducing noise and air pollution, and protecting local ecosystems. For example, ballast cleaning and disposal need careful management to avoid soil contamination. The use of environmentally friendly materials in track construction and maintenance is increasingly important. We often use recycled materials where possible and choose products that have a lower carbon footprint. When working near water bodies or sensitive habitats, we take extra precautions to prevent pollution and habitat disruption. This often involves creating temporary barriers or utilizing specialized equipment to minimize impact. Proper planning and implementation of environmental protection measures are critical to the sustainability of track maintenance operations and maintaining a positive relationship with local communities.

Q 21. How do you manage risks associated with trackside maintenance?

Risk management in trackside maintenance is crucial for ensuring worker safety and operational efficiency. We employ a comprehensive risk assessment process that identifies potential hazards, evaluates their likelihood and severity, and implements control measures. Hazards include working at height, contact with energized equipment, moving trains, and exposure to hazardous materials. Control measures might involve implementing safe work procedures, using personal protective equipment (PPE), and employing engineering controls to isolate hazards. Regular training and competency assessment of personnel are essential. We maintain detailed records of all risk assessments, incident reports, and corrective actions. A robust communication system ensures that all workers are aware of potential hazards and safety procedures. We frequently conduct safety audits and toolbox talks to reinforce safety culture and identify potential improvements. Risk management is not a one-time activity but an ongoing process, involving continuous monitoring and review of control measures to ensure they remain effective.

Q 22. Describe your experience working in a team environment during track maintenance.

Teamwork is paramount in track maintenance. Think of it like a well-oiled machine – each person has a crucial role, and success depends on seamless coordination. In my experience, effective team dynamics involve clear communication, defined roles, and mutual respect. For instance, during a recent ballast cleaning operation, our team comprised engineers, technicians, and safety officers. The engineers oversaw the overall project, technicians operated the machinery, and safety officers ensured compliance with all regulations. Regular briefings kept everyone informed about progress, potential hazards, and any adjustments needed. We used a collaborative platform to track progress, share updates, and resolve issues instantly. This fostered a sense of shared responsibility and boosted efficiency significantly.

- Clear Communication: Daily briefings and open communication channels are essential.

- Defined Roles: Each team member understands their responsibilities, avoiding confusion and overlap.

- Mutual Respect: Valuing everyone’s contributions fosters a positive and productive work environment.

Q 23. Explain your understanding of track maintenance scheduling and planning.

Track maintenance scheduling is a complex process involving meticulous planning to minimize disruption and maximize safety. It’s like orchestrating a symphony – each instrument (maintenance task) must play at the right time to create a harmonious whole. We use sophisticated software to model the entire railway network, considering factors like traffic density, scheduled train movements, and available resources (personnel and equipment). The schedule accounts for preventative maintenance, reactive repairs, and planned upgrades. For example, we might schedule ballast cleaning during off-peak hours to minimize service disruptions. This software also incorporates risk assessments, prioritizing urgent tasks and allowing for flexible adjustments based on real-time conditions, such as unexpected weather changes.

The planning phase involves analyzing historical data to identify areas needing attention and forecasting future maintenance needs. This allows for efficient resource allocation and proactive repairs. A well-defined schedule minimizes downtime, optimizes resource utilization, and ultimately enhances safety and reliability.

Q 24. How do you utilize technology to improve track maintenance efficiency?

Technology plays a crucial role in enhancing track maintenance efficiency. Imagine using a magnifying glass to inspect a single rail – tedious and inefficient. Now, imagine using high-resolution cameras and drones to survey vast stretches of track in a fraction of the time, identifying defects with greater precision. We utilize various technologies, including:

- Geographic Information Systems (GIS): To map track infrastructure, pinpoint problem areas, and optimize maintenance routes.

- Unmanned Aerial Vehicles (UAVs) or Drones: For rapid visual inspection of track geometry, identifying defects like rail flaws, ballast degradation, and vegetation encroachment.

- Laser Scanners and 3D Modeling: To create precise models of the track geometry for detailed analysis and planning of maintenance work.

- Condition Monitoring Systems: Embedded sensors on the track collect data on various parameters (vibration, temperature, etc.), providing early warnings of potential problems.

- Predictive Maintenance Software: Analyzing data from various sources to forecast potential failures and schedule maintenance proactively.

These technologies have drastically improved our ability to perform inspections faster, diagnose problems more accurately, and implement repairs more effectively, minimizing disruptions to train services.

Q 25. What are the challenges of maintaining track infrastructure in various weather conditions?

Maintaining track infrastructure in diverse weather conditions presents significant challenges. Think of the difference between working on a track in a scorching desert versus a blizzard. Extreme temperatures can affect rail expansion and contraction, leading to buckling or breakage. Heavy rainfall can cause erosion and waterlogging, impacting track stability. Snow and ice accumulation can reduce traction and increase the risk of derailment. We mitigate these challenges by:

- Using specialized equipment: Snow ploughs, de-icing trains, and heated maintenance vehicles.

- Implementing robust drainage systems: To prevent waterlogging and erosion.

- Employing weather forecasting: To anticipate adverse conditions and adjust maintenance schedules.

- Using specialized materials: Rail and ballast materials resistant to extreme temperatures and corrosion.

- Implementing stringent safety protocols: For personnel working in hazardous weather conditions.

Effective planning and resource allocation are crucial in these scenarios. Regular inspections and proactive maintenance help mitigate risks and ensure the continuous operation of the railway network, regardless of the weather.

Q 26. Explain your experience with trackside communication systems.

Trackside communication systems are vital for ensuring safe and efficient operations. Think of it as the railway’s nervous system, providing constant communication between train drivers, trackside personnel, and control centers. My experience involves working with various systems, including:

- Radio communication: For real-time communication between train drivers and dispatchers.

- Train-to-ground communication systems: Allowing trains to transmit data about their condition and location.

- Fiber optic cables: Providing high-bandwidth communication for data transmission and surveillance systems.

- CCTV systems: Monitoring track conditions and personnel activity.

Ensuring the reliability and security of these systems is crucial. Regular maintenance, testing, and upgrades are necessary to prevent communication failures that could compromise safety. We also employ redundancy measures to ensure communication remains available even if one system fails.

Q 27. Describe your experience with the use of preventative maintenance strategies.

Preventative maintenance is the cornerstone of reliable track infrastructure. It’s akin to regular check-ups at the doctor – catching small problems before they become major issues. We utilize a comprehensive strategy that incorporates:

- Regular inspections: Visual inspections, ultrasonic testing, and other non-destructive testing methods to identify potential defects.

- Scheduled maintenance: Regular cleaning, lubrication, and replacement of components according to predefined schedules.

- Condition-based maintenance: Utilizing sensor data and predictive analytics to schedule maintenance based on the actual condition of the track components.

- Proactive repairs: Addressing minor defects promptly to prevent them from escalating into major problems.

This proactive approach significantly reduces the likelihood of major failures, minimizing disruptions and extending the lifespan of the track infrastructure. The cost savings from avoiding major repairs far outweigh the cost of preventative maintenance.

Q 28. How do you handle emergency situations related to track infrastructure failures?

Handling emergency situations requires a swift and coordinated response. Think of it like a fire drill – the effectiveness depends on preparedness and clear procedures. Our emergency response protocol involves:

- Immediate assessment: Quickly determining the extent of the damage and potential hazards.

- Emergency communication: Notifying relevant parties (train control, emergency services, and maintenance teams).

- Securing the area: Preventing further damage and ensuring the safety of personnel and the public.

- Implementing emergency repairs: Temporary repairs to restore train services as quickly as possible.

- Thorough investigation: Determining the cause of the failure to prevent future occurrences.

Regular training and drills are crucial in ensuring that our team can respond effectively to various emergency situations. We also maintain a detailed inventory of emergency repair materials and equipment to facilitate rapid response.

Key Topics to Learn for Trackside Infrastructure Maintenance Interview

- Track Geometry and Alignment: Understanding concepts like cant, gauge, and alignment tolerances; practical application in track inspection and maintenance procedures; troubleshooting misalignment issues.

- Ballast and Subgrade: Knowledge of ballast types, drainage systems, and subgrade stability; practical application in ballast cleaning and renewal projects; problem-solving related to ballast degradation and settlement.

- Track Components and their Maintenance: Detailed knowledge of rails, sleepers, fastenings, and their function; practical application in identifying and repairing damaged components; understanding preventative maintenance schedules.

- Signaling and Communication Systems: Basic understanding of track circuits, signaling equipment, and communication systems used in railway operations; practical application in recognizing and reporting faults; understanding safety protocols related to signaling.

- Safety Regulations and Procedures: In-depth knowledge of relevant safety regulations and procedures; practical application in risk assessment and safe working practices; understanding incident reporting and investigation procedures.

- Track Maintenance Equipment: Familiarity with various track maintenance machines and tools; practical application in operating and maintaining equipment; troubleshooting common equipment malfunctions.

- Track Inspection and Reporting: Understanding different inspection methods and techniques; practical application in recording defects and generating reports; using relevant software for data management.

- Welding and Cutting Techniques: Knowledge of rail welding procedures and techniques used in track maintenance; understanding safety precautions; problem solving related to weld failures.

Next Steps

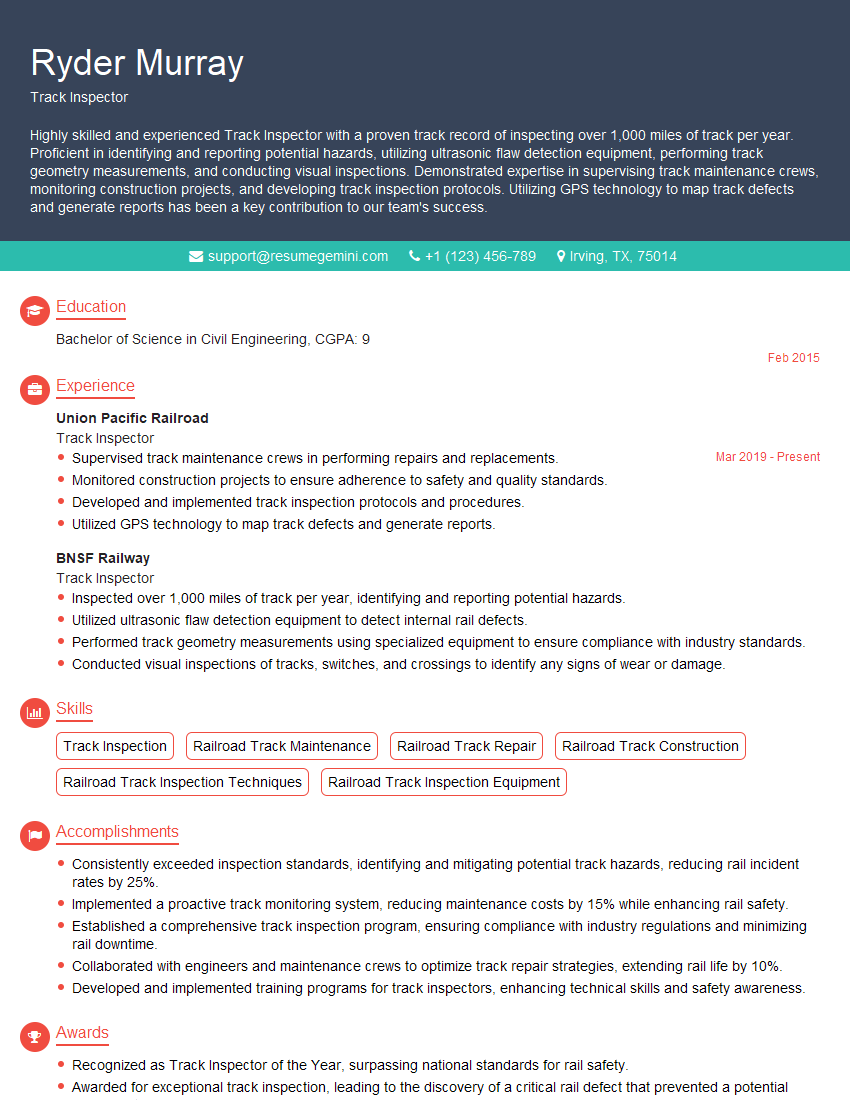

Mastering Trackside Infrastructure Maintenance opens doors to a rewarding career with excellent growth potential in a vital industry. To maximize your job prospects, a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. We provide examples of resumes tailored specifically to Trackside Infrastructure Maintenance to guide you in creating a winning application. Invest the time to craft a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good