Cracking a skill-specific interview, like one for Tractor and ATV operation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Tractor and ATV operation Interview

Q 1. Describe your experience operating different types of tractors.

My experience encompasses a wide range of tractors, from compact utility tractors ideal for smaller properties and landscaping to larger agricultural tractors used for extensive fieldwork. I’ve operated wheel tractors, offering maneuverability and versatility, and tracked tractors, known for their superior traction in challenging terrain. Specifically, I’m proficient with various makes and models including John Deere, Massey Ferguson, and Kubota, each with its own unique characteristics in terms of horsepower, transmission type (manual, semi-automatic, or fully automatic), and hydraulic systems. For instance, I’ve used a John Deere 5083E for hay baling, demonstrating expertise in operating its power-take-off (PTO) system and managing the baler’s intricate mechanisms. On the other hand, operating a Kubota BX23S required a different approach focusing on precise maneuvering in tighter spaces. This diverse experience allows me to adapt quickly to different machine requirements and operational environments.

Q 2. Explain the pre-operational checks you perform on a tractor before use.

Pre-operational checks are crucial for safe and efficient tractor operation. My routine involves a systematic approach, starting with a visual inspection. This includes checking for any leaks of fluids like oil, fuel, or coolant. I then examine the tires for proper inflation and wear, ensuring there’s no damage or debris embedded. The next step is to check all the safety features—the brakes, lights, PTO engagement, and the three-point hitch—to ensure they are functioning correctly. A quick walk-around is important for looking for any loose bolts, wires, or other potential hazards. I’ll also check the fuel and hydraulic fluid levels. Finally, before starting the engine, I always ensure that the parking brake is engaged. Think of it like a pre-flight check for an airplane – meticulous attention to detail is paramount.

Q 3. How do you maintain proper tractor safety procedures?

Maintaining proper tractor safety procedures is non-negotiable. This begins with the pre-operational checks mentioned earlier. Beyond that, I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and sturdy work boots. I’m extremely cautious about the tractor’s surroundings, particularly avoiding overhead obstructions or uneven terrain. When working near roads, I use appropriate warning devices to alert others. I also never operate a tractor when fatigued or under the influence of any substance. Furthermore, I make sure all passengers are in designated safety areas and understand the operation procedures. I regularly maintain a safe distance from the PTO, and never dismount the tractor until the PTO is fully disengaged and the engine is switched off. Finally, I adhere to all relevant regulations and guidelines specific to the location and tasks at hand.

Q 4. What are the different types of hitches used on tractors?

Tractors utilize several types of hitches to connect implements. The most common is the three-point hitch, which uses two lower links and a top link to attach implements like plows, harrows, and mowers. This system allows for adjustable height and tilt control. Category 1 and Category 2 three-point hitches are common sizes, with Category 2 being larger for heavier implements. Another hitch type is the quick-attach hitch, which allows for rapid implement changes without manual adjustments. Then there’s the drawbar hitch, located at the rear of the tractor, mainly used for pulling trailers or other heavy loads. Finally, front hitches allow for attaching implements to the front of the tractor, increasing versatility and efficiency. The specific hitch type used depends on the implement and the type of work being performed. For example, a Category 2 three-point hitch is often used for a large disc harrow, while a drawbar hitch would be suitable for pulling a heavy wagon.

Q 5. Describe your experience with various tractor implements (e.g., plow, harrow, mower).

My experience with tractor implements is extensive. I’m proficient in operating a variety of implements, including plows for tilling, harrows for smoothing soil, cultivators for weed control, mowers for cutting grass and hay, and various balers for hay production. Each implement requires a different level of skill and understanding. For example, setting the correct plow depth involves adjusting the three-point hitch and understanding the soil conditions to avoid damage to the plow or the soil itself. Operating a disc mower requires paying attention to ground speed and overlap to ensure uniform cutting. Similarly, baling hay necessitates understanding the baler’s settings to achieve the correct bale density and size. Proper adjustments and maintenance are key to maximizing efficiency and safety with these implements.

Q 6. How do you troubleshoot common tractor mechanical issues?

Troubleshooting common tractor mechanical issues starts with a systematic approach. I begin by identifying the problem precisely—is it an engine problem, a hydraulic issue, a transmission malfunction, or something else? I would then check for obvious problems like low fluids or loose connections. I use diagnostic tools, such as pressure gauges for hydraulic systems and multimeters for electrical problems, to pinpoint the fault. My knowledge of tractor mechanics allows me to isolate the problem area. For example, if the tractor won’t start, I would check the battery, starter motor, and fuel system. If the hydraulics are malfunctioning, I would check fluid levels, filters, and the hydraulic pump itself. Simple problems can often be solved on-site, while more complex issues may necessitate the help of a specialist or workshop. I prioritize safety during troubleshooting, ensuring the engine is off and the tractor is secure before any hands-on inspection.

Q 7. What is your experience with GPS-guided tractors?

I have significant experience with GPS-guided tractors, utilizing precision farming technology. This involves using GPS receivers and auto-steering systems to guide the tractor along pre-programmed paths, enhancing accuracy and reducing overlap. This technology is particularly valuable for tasks like planting, spraying, and harvesting. My experience includes working with various GPS systems and understanding the data analysis associated with them. I’m comfortable calibrating the GPS systems, programming field boundaries, and interpreting the data to optimize operational efficiency and resource utilization. For instance, in a precision planting operation, GPS guidance ensures consistent seed spacing and depth, maximizing yield and reducing input costs. The technology also allows for variable rate application of fertilizers or pesticides, thereby optimizing resource use and minimizing environmental impact.

Q 8. Explain your understanding of tractor PTO (Power Take-Off) systems.

A tractor’s Power Take-Off (PTO) system is essentially a secondary power source, driven directly from the tractor’s engine. Think of it as a rotating shaft that provides power to various implements like mowers, balers, or tillers, without directly engaging the tractor’s wheels. The PTO shaft spins at a specific speed (usually 540 or 1000 RPM), dictated by the tractor’s transmission. Connecting an implement to the PTO shaft allows that implement to draw power and perform its function.

There are two main types: independent and dependent PTOs. An independent PTO can be engaged and disengaged regardless of the tractor’s clutch or gear, offering more control. A dependent PTO, on the other hand, requires the clutch to be engaged before the PTO can be activated. Safety features like PTO shields and interlocking mechanisms prevent accidental engagement and injury. For instance, when connecting a PTO-driven mower, engaging the PTO without the mower properly attached could result in serious damage or injury. Always ensure the implement is properly secured and the PTO is engaged only when it’s ready to operate.

Understanding PTO speed and the specific requirements of different implements is crucial for safe and efficient operation. Using the wrong PTO speed can damage the implement or the tractor itself. For example, a hay baler may require a 540 RPM PTO, while a high-speed mower may operate optimally at 1000 RPM. The operator’s manual provides detailed specifications for each implement.

Q 9. How do you handle different terrain conditions while operating a tractor?

Handling different terrain conditions effectively requires adjusting the tractor’s speed, gear selection, and possibly tire pressure. On steep slopes, for instance, I would engage a lower gear to maintain control and reduce the risk of slippage or rollover. Using differential lock is also extremely beneficial in challenging terrain like mud or snow to prevent wheel spin. In rocky areas, I would reduce speed to avoid damaging the tractor’s undercarriage or the implements.

I always assess the terrain before operating the tractor, identifying potential hazards such as ditches, rocks, or uneven ground. My approach involves careful observation and proactive adjustments. For example, if I encounter a particularly soft area, I might shift the weight distribution by adjusting the load on the implements. Experience teaches you to anticipate and react to changing conditions quickly and smoothly, ensuring both safety and efficiency.

Tire pressure adjustment can significantly impact traction. Lowering tire pressure on softer surfaces like mud increases the contact area with the ground, improving grip. Conversely, higher pressure is preferable on hard, compacted surfaces. Knowing how to fine-tune these settings makes a world of difference in maintaining traction and preventing damage to the tractor and the environment.

Q 10. What safety measures do you take when working with a tractor near power lines?

Safety near power lines is paramount. The most crucial step is to never operate a tractor closer than the specified minimum distance, which is often indicated on warning signs and in the operator’s manual. This minimum distance varies depending on the voltage of the lines. Before any work is initiated, a thorough risk assessment must be conducted, and in many cases a professional line clearance specialist should be consulted.

I always check for overhead lines before beginning any work and maintain a safe distance. If there’s any uncertainty, I’ll contact the utility company to determine the safest approach or even halt operations. I also make sure that the height of the equipment, including any attachments, never approaches power lines, and I would never operate the tractor in windy conditions that could potentially bring power lines down. It’s crucial to remember that even accidental contact can be fatal.

Additionally, I’d ensure all workers are briefed on power line safety procedures and are aware of the potential dangers involved. Clear communication and a cautious approach are critical to prevent accidents.

Q 11. Describe your experience operating ATVs in various terrains.

My ATV operating experience spans various terrains, from muddy fields and forested trails to rocky mountain paths and sandy beaches. Each environment demands a different riding technique and demands consideration of specific challenges. For example, tackling steep inclines necessitates careful speed control and proper body positioning to maintain balance and avoid tipping over. In muddy conditions, maintaining momentum is crucial to prevent getting stuck, requiring strategic throttle management and skillful navigation.

In forested trails, navigating narrow passages requires precise steering and awareness of obstacles. Slow speeds and meticulous observation prevent collisions with trees, rocks, or uneven terrain. On sandy terrain, lower tire pressure can greatly improve traction, but high speeds may increase the likelihood of getting stuck or losing control. Experience across diverse settings teaches one to adapt to the terrain’s nuances, optimizing riding style for safety and efficiency.

I have also operated ATVs carrying cargo or towing small trailers, which require a more cautious approach due to the added weight and altered center of gravity. This involves selecting appropriate gears, maintaining slower speeds on challenging terrain, and ensuring proper weight distribution. Adaptability and careful planning are key to safe and efficient operation in any circumstance.

Q 12. What safety equipment do you use while operating an ATV?

Safety equipment is non-negotiable when operating an ATV. The basics include a helmet – always full face for maximum protection–, goggles or eye protection to shield from debris, long sleeves and pants to protect the skin from scrapes and abrasion, sturdy gloves for enhanced grip and protection, and over-the-ankle boots to support the ankles and protect against impacts.

In more challenging terrains or situations, I would add additional safety gear, such as a chest protector, knee and elbow pads, and possibly a neck brace for added safety in the event of a fall. It’s always preferable to be over-prepared than under-prepared. Remember, safety equipment isn’t just about protecting yourself from injuries, it enhances confidence and allows for safer, more focused riding.

Q 13. How do you maintain an ATV to ensure its proper functioning?

ATV maintenance is essential for ensuring its longevity and safe operation. Regular maintenance includes checking vital fluids like engine oil, coolant, and brake fluid, and replacing them according to the manufacturer’s recommendations. I also regularly inspect the air filter, spark plug, and drive belts, replacing them as needed.

Tire pressure should be checked frequently and adjusted for different terrains. Chain lubrication and brake inspection are also crucial. I also pay attention to the overall condition of the machine, checking for any loose bolts, worn parts, or signs of damage. Regular cleaning helps prevent corrosion and keeps the machine in top working order. A properly maintained ATV not only operates efficiently but also reduces the risk of breakdowns and accidents. Preventative maintenance is far less expensive than unexpected repairs.

Q 14. Explain the different types of ATV tires and their suitability for different conditions.

ATV tires are broadly classified by their tread pattern and construction, each designed for specific conditions.

- Aggressive/Knobby Tires: These tires feature deep, widely spaced lugs, providing exceptional traction in mud, sand, and rocky terrain. However, they offer less grip on paved surfaces and may result in a rougher ride.

- Intermediate Tires: These tires have a more moderate tread pattern, offering a compromise between off-road performance and on-road comfort. They are suitable for a variety of surfaces, from trails to light-duty road use.

- Street/Road Tires: These tires have a smooth tread pattern and focus on on-road performance and comfort. They may lack traction in loose or off-road conditions.

The choice of tires depends entirely on the intended use of the ATV. Someone primarily using their ATV for hunting on forest trails may opt for aggressive tires, whereas an ATV used primarily for transportation around a farm or ranch might favor a more balanced intermediate tire. For example, on a trip through a muddy field, knobby tires would vastly improve performance compared to road tires. Understanding these differences allows for better adaptation to different terrains and helps increase the overall efficiency and safety of ATV operations.

Q 15. How do you handle emergency situations while operating an ATV?

Handling ATV emergencies requires a calm and methodical approach. My first priority is always safety – both mine and others’ in the vicinity. This involves immediately assessing the situation. Is there an immediate threat like a fire, or a rollover? If so, my actions are dictated by the urgency. For example, if the ATV is on fire, I’d immediately evacuate the area, call emergency services and try to extinguish the fire with the available means if it is safe to do so. If it’s a rollover, ensuring personal safety is paramount; I’d check for injuries and seek assistance if needed. Then I’d secure the vehicle to prevent further accidents.

For less critical situations, like a mechanical failure, I’d carefully assess the problem, and if safe to do so, attempt basic troubleshooting. I’d try to find shelter from the elements, contact assistance, and wait for help. I always carry a fully charged cell phone, a first-aid kit, and emergency supplies including a whistle. Regular safety checks and preventative maintenance significantly minimize emergency situations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with ATV winches and their safe operation.

I’m proficient in operating and maintaining ATV winches. These are crucial for recovery in challenging terrains. Safe operation begins with selecting the right winch for the ATV’s capacity and expected loads. Overloading a winch can lead to serious damage or injury. Before engaging the winch, I always properly secure the anchor point— ensuring it’s strong enough to withstand the anticipated pull – a strong tree or a robust recovery point on another vehicle. I use a snatch block to increase pulling power when needed, but correctly attaching it and maintaining the proper angle is crucial to prevent damage. I’m well-versed in the different winching techniques including proper communication with others if a team is involved, and I always wear appropriate safety gear such as gloves, eye protection, and a helmet.

I’m also familiar with common winch problems like cable spooling issues and how to effectively address them. I understand the importance of regular inspection and maintenance to prevent failure and ensure the winch’s longevity and safe operation.

Q 17. What are the limitations of ATVs in terms of load capacity and terrain?

ATVs, while versatile, have inherent limitations. Their load capacity is significantly lower than that of a tractor. Exceeding the manufacturer’s specified weight limits can lead to instability, damage, or rollover. Terrain limitations also exist. While ATVs can handle rough terrain, their ground clearance and suspension restrict them in extremely muddy, rocky, or deeply rutted areas. Steep slopes and loose surfaces, such as sand or snow, also present challenges. Factors like tire condition, rider skill, and the ATV’s specific features further influence their capabilities.

For example, a small ATV might only carry a couple of hundred pounds of payload, whereas a larger utility ATV might carry significantly more, but still a fraction of a tractor’s capacity. Trying to navigate a steep, muddy incline with an overloaded ATV could easily lead to a dangerous situation.

Q 18. How do you assess the stability of an ATV before operating it?

Assessing ATV stability before operation is a crucial safety step. I start with a visual inspection; checking tire pressure (they should be properly inflated), looking for any signs of damage to the tires, wheels, or frame. I then check the overall condition of the ATV – are the suspension components intact? Is there any obvious damage to the steering or braking systems? Next, I carefully examine the ground conditions. Are there any significant hazards such as loose rocks, deep mud, or hidden obstacles? I avoid operating an ATV that displays any signs of instability, loose components, or visible damage.

I also consider the terrain and the load to be carried; a heavier load reduces stability, especially on steep inclines or uneven surfaces. Finally, I always test the brakes and steering before riding. The pre-ride checks significantly increase the safety factor and significantly reduce the possibility of an accident.

Q 19. What is your experience with ATV maintenance and repair?

I have extensive experience in ATV maintenance and minor repairs. This includes regular lubrication, fluid checks (engine oil, transmission oil, coolant), and cleaning. I’m comfortable replacing air filters, spark plugs, and belts. I also know how to inspect and adjust brakes, cables, and chains. For more complex repairs, like engine overhauls or major suspension work, I’ll consult a qualified mechanic or utilize a specialized repair manual.

Regular maintenance, including cleaning the ATV after each use, extends its lifespan and prevents problems from arising. For instance, neglecting to regularly check and clean the air filter can reduce engine performance and cause premature wear and tear. A well-maintained ATV is a safer ATV.

Q 20. Describe your knowledge of ATV safety regulations.

My knowledge of ATV safety regulations is comprehensive. I’m familiar with all relevant local, state, and federal laws concerning ATV operation, including licensing requirements, age restrictions, and speed limits. I understand the importance of wearing a helmet and other protective gear, and I’m aware of the restrictions on riding on public roads unless specifically permitted. I’m also aware of the regulations pertaining to alcohol and drug consumption while operating an ATV. The regulations vary by location, so staying informed is key. I always prioritize safety and ensure my operation adheres to all applicable laws.

I frequently check for updated regulations to ensure compliance and safe operation.

Q 21. How do you handle fuel and oil maintenance for tractors and ATVs?

Fuel and oil maintenance for tractors and ATVs is critical for optimal performance and longevity. For both, I always use the correct type and grade of fuel and oil specified by the manufacturer. I regularly check oil levels using the dipstick, ensuring it’s within the recommended range. Low oil levels indicate a leak or potential engine damage, which needs immediate attention. I also check for oil leaks and discoloration, which might indicate a problem. Regular oil changes are crucial, following the manufacturer’s recommended intervals. For fuel, I carefully check for leaks and ensure the fuel system is clean and free from debris. I avoid overfilling the fuel tank to prevent spills and potential fire hazards.

For tractors, which usually have larger fuel and oil capacities, the process is similar but requires handling larger quantities. The same emphasis on using the correct fluids and regular maintenance applies. Ignoring these routine checks can lead to costly repairs, downtime, and potential safety issues.

Q 22. Explain your experience with hydraulic systems in tractors and ATVs.

Hydraulic systems are the lifeblood of modern tractors and ATVs, providing power for everything from lifting implements to powering steering. My experience encompasses both the practical application and the underlying principles. I’m proficient in diagnosing and repairing leaks, identifying faulty components like pumps, cylinders, and valves, and understanding the role of hydraulic fluid in the system’s overall performance. For example, on a recent project involving a tractor with a malfunctioning three-point hitch, I systematically checked for leaks, tested the hydraulic pump pressure, and ultimately replaced a faulty hydraulic control valve, restoring full functionality. In ATVs, the hydraulic system is often simpler, typically used for braking, but understanding the principles remains crucial for effective troubleshooting and maintenance. I am familiar with different types of hydraulic systems, including open-center and closed-center systems, and their respective advantages and disadvantages.

I’ve also worked with various hydraulic components such as pressure relief valves, directional control valves, and flow control valves and have a solid grasp of hydraulic schematics and troubleshooting guides. This involves tracing fluid lines, measuring pressures, and understanding pressure drops to pinpoint the root cause of a problem. I frequently use pressure gauges, flow meters and specialized diagnostic tools for troubleshooting hydraulic systems.

Q 23. How do you ensure proper tire pressure in tractors and ATVs?

Maintaining proper tire pressure is critical for both tractor and ATV operation, impacting fuel efficiency, traction, and tire lifespan. The correct pressure varies significantly depending on the machine, the type of tire, the load being carried, and the terrain. I always consult the manufacturer’s recommendations found in the owner’s manual, typically displayed on a sticker on the machine itself. For tractors, this is particularly important because under-inflation can lead to excessive tire wear and reduced traction, while over-inflation risks damage to the tire and a harsher ride. For ATVs, the impact is slightly different. Incorrect pressure affects handling and can increase the risk of rollovers or punctures.

To ensure correct pressure, I use a reliable tire pressure gauge. It’s crucial to check the pressure when the tires are cold, as the pressure will increase as the tires heat up from use. Regular checks are recommended, especially before and after extended periods of inactivity or heavy use. Adjusting the pressure involves using a suitable air compressor or pump, carefully inflating to the specified pressure. I always record the pressure and keep a log of maintenance activities to track trends and ensure everything remains within manufacturer’s specifications.

Q 24. Describe your understanding of different transmission types in tractors.

Tractors employ various transmission types, each with its advantages and disadvantages. The most common are manual transmissions, hydrostatic transmissions, and powershift transmissions. Manual transmissions are simple and reliable, offering precise control but demanding operator skill and effort. They typically utilize gears selected by a lever or clutch pedal. Powershift transmissions provide smooth gear changes under load, making them suitable for heavy-duty applications. They offer the advantages of faster shifting compared to manual transmissions, often using hydraulic systems to facilitate gear changes.

Hydrostatic transmissions use hydraulic pumps and motors to provide infinitely variable speeds without using gears. This offers exceptional control for tasks requiring fine adjustments, especially in applications such as mowing or loader operations. They allow for very precise speed control and are often found on smaller tractors. My experience includes working with all three types. I understand the operating principles of each, including clutch mechanisms, gear ratios, and hydraulic circuits. I can diagnose and rectify issues related to each transmission type, from simple gear adjustments to more complex hydraulic repairs.

Q 25. How do you perform preventative maintenance on tractors and ATVs?

Preventative maintenance is key to extending the lifespan and ensuring the reliable operation of both tractors and ATVs. My approach is systematic and comprehensive. It involves regular checks of all major components and fluids. For tractors, this includes engine oil and filter changes, transmission fluid checks, coolant levels, hydraulic fluid checks and condition, brake inspection, tire pressure checks, and lubrication of moving parts. For ATVs, the process is similar but often simpler due to the smaller size and less complex systems. It includes regular fluid checks (engine oil, transmission oil, brake fluid, coolant), chain lubrication (if applicable), air filter inspection and replacement, and brake inspection.

I also conduct visual inspections for leaks, wear and tear, or any damage to components. I maintain detailed records of all maintenance performed, including dates, services completed, and any parts replaced. Following the manufacturer’s recommended maintenance schedules is crucial and serves as a baseline for my preventative maintenance strategies. Additionally, I pay close attention to any unusual sounds, vibrations, or performance issues, as these may indicate underlying problems that require attention.

Q 26. What is your experience with loading and unloading equipment onto trailers?

Loading and unloading equipment onto trailers requires careful planning, appropriate equipment, and a keen understanding of safety procedures. My experience involves working with various types of trailers, including those with ramps, winches, and specialized attachments. I am proficient in securing equipment using appropriate straps, chains, and chocks to prevent movement during transport. I always assess the weight and dimensions of the equipment to ensure it is safely and legally loaded within the trailer’s capacity.

The process depends heavily on the equipment being moved and the trailer’s specifications. For instance, loading a small ATV might only require a ramp, while a large tractor might necessitate a winch or specialized loading equipment. Safety is paramount. I always utilize appropriate safety equipment, including gloves, eye protection, and safety shoes. Before each operation, I perform a pre-operation inspection of both the tractor/ATV and the trailer, checking brakes, lights, and securing mechanisms. My method is always one of careful planning and cautious execution, ensuring safe handling and preventing potential damage to the equipment or injury to personnel.

Q 27. Explain your understanding of environmental regulations related to tractor and ATV operation.

Environmental regulations concerning tractor and ATV operation vary by jurisdiction but generally focus on minimizing pollution and soil erosion. I am well-versed in these regulations and ensure that all my operations comply with local and national guidelines. This includes understanding and adhering to emission standards for exhaust gases, minimizing fuel spills, and practicing responsible disposal of used oils, filters, and other waste materials. Properly maintained equipment is a key part of environmental compliance.

Furthermore, I understand the importance of minimizing soil compaction and erosion during land management activities. My operating practices aim to reduce the impact on the environment through the use of appropriate techniques, minimizing the disturbance of natural habitats, and adhering to any specific restrictions imposed by environmental agencies. Staying informed about updates to environmental regulations is an ongoing process, and I actively seek out relevant training and resources to ensure continued compliance.

Q 28. Describe a time you had to troubleshoot a complex mechanical issue on a tractor or ATV.

During a hay baling operation, a tractor’s hydraulic system suddenly failed, causing the baler to stop functioning. The initial diagnosis pointed to a possible hydraulic pump issue, but a thorough inspection revealed that the problem wasn’t as simple. The pressure relief valve was malfunctioning, not allowing sufficient hydraulic pressure to reach the baler’s mechanisms.

I systematically checked each component of the hydraulic system, using a pressure gauge and various diagnostic tools to measure pressures at different points. My process involved: 1) Checking for leaks. 2) Measuring hydraulic fluid level and quality. 3) Inspecting filters for blockages. 4) Testing the hydraulic pump. 5) Verifying the operation of the directional control valves. 6) Finally, pinpointing the faulty pressure relief valve. By understanding the hydraulic system’s workings and systematically eliminating potential causes, I correctly diagnosed the issue and replaced the faulty valve. The baler was up and running again within a reasonable timeframe, showcasing my problem-solving skills and hydraulic system expertise. This experience reinforced the importance of a methodical approach when dealing with complex mechanical issues.

Key Topics to Learn for Tractor and ATV Operation Interview

- Safe Operation Procedures: Understanding pre-operation checks, safe operating practices, and emergency procedures for both tractors and ATVs. This includes knowing how to identify and mitigate potential hazards.

- Equipment Maintenance: Knowledge of routine maintenance tasks, troubleshooting common mechanical issues, and recognizing when professional servicing is required. Practical experience detailing specific maintenance tasks performed will be valuable.

- Specialized Attachments & Implements: Familiarity with various attachments used with tractors (e.g., plows, mowers, loaders) and their appropriate application. Understanding ATV attachments (e.g., trailers, sprayers) and their safe operation is also crucial.

- Terrain Navigation & Maneuverability: Demonstrating an understanding of safe operation on various terrains, including slopes, uneven ground, and obstacles. Practical experience navigating challenging environments will be highly beneficial.

- Environmental Awareness: Knowledge of environmentally responsible operating practices, including fuel efficiency, minimizing soil compaction, and proper waste disposal.

- Regulations & Compliance: Familiarity with relevant safety regulations and legal requirements for operating tractors and ATVs. This includes understanding licensing and permit requirements.

- Problem-Solving & Troubleshooting: The ability to describe how you approach diagnosing and resolving mechanical problems, as well as handling unexpected situations during operation.

Next Steps

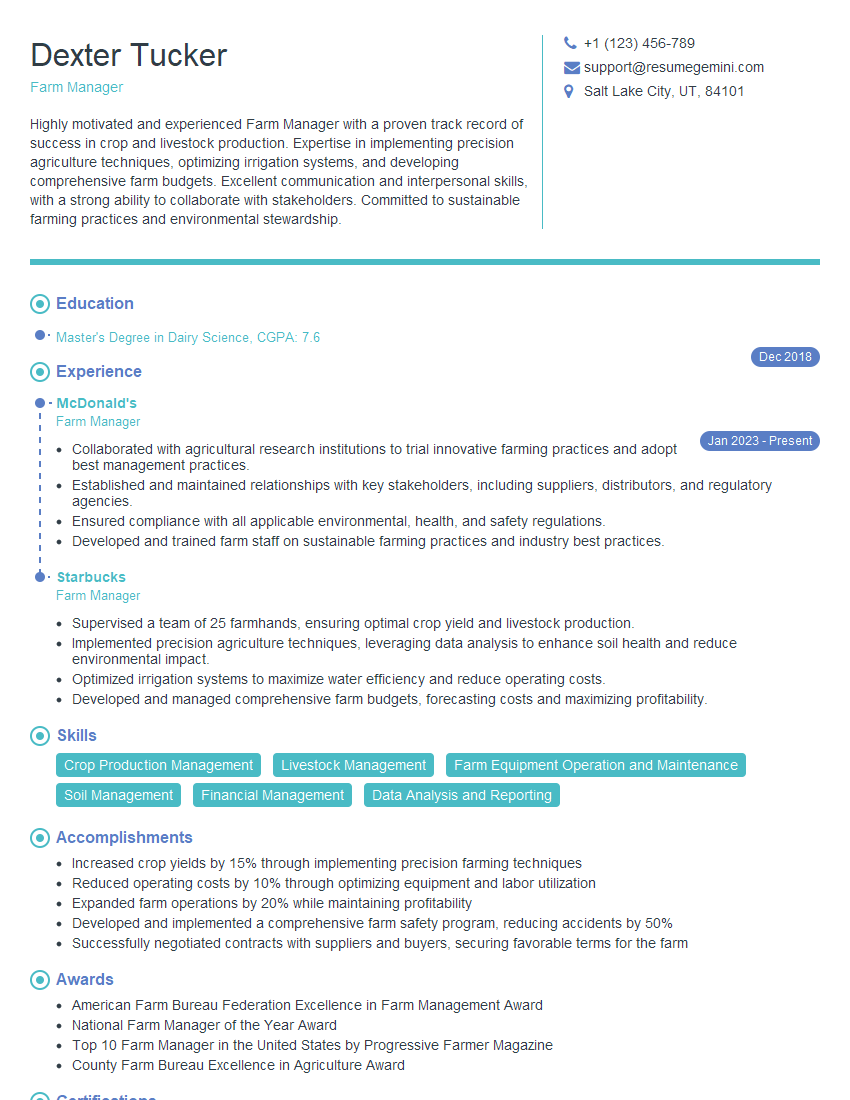

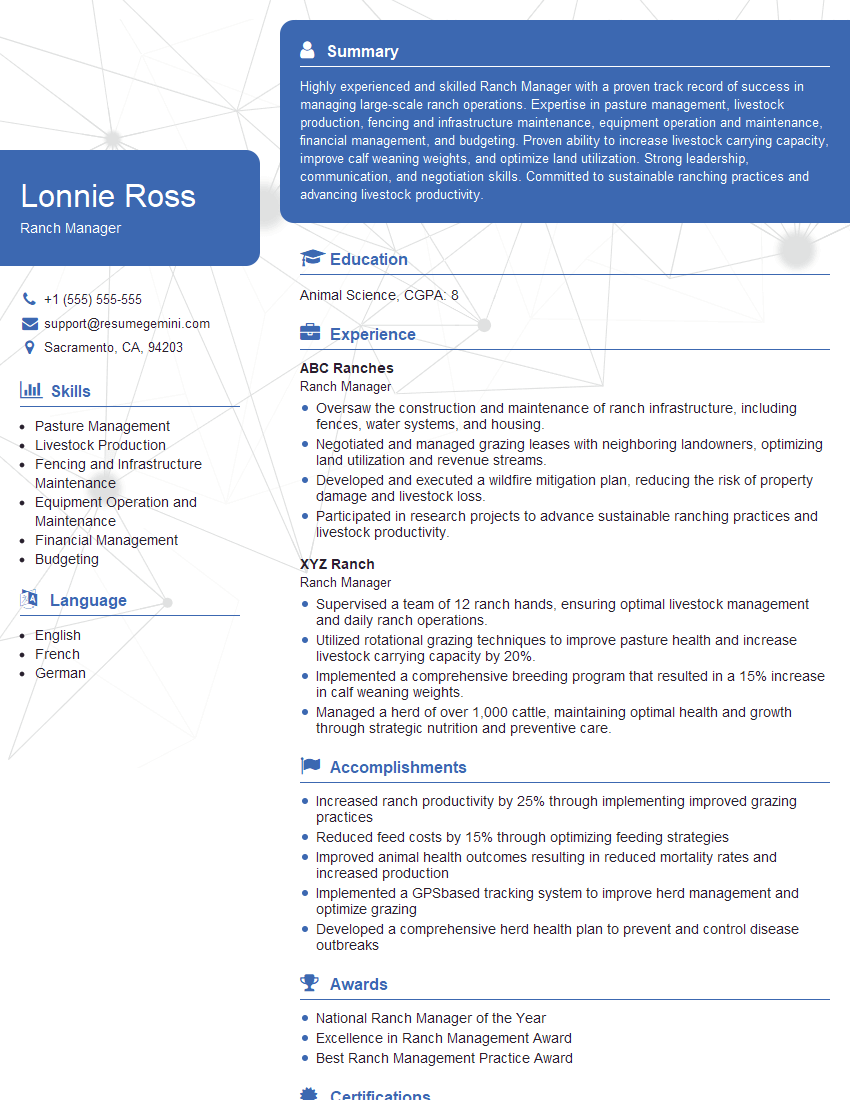

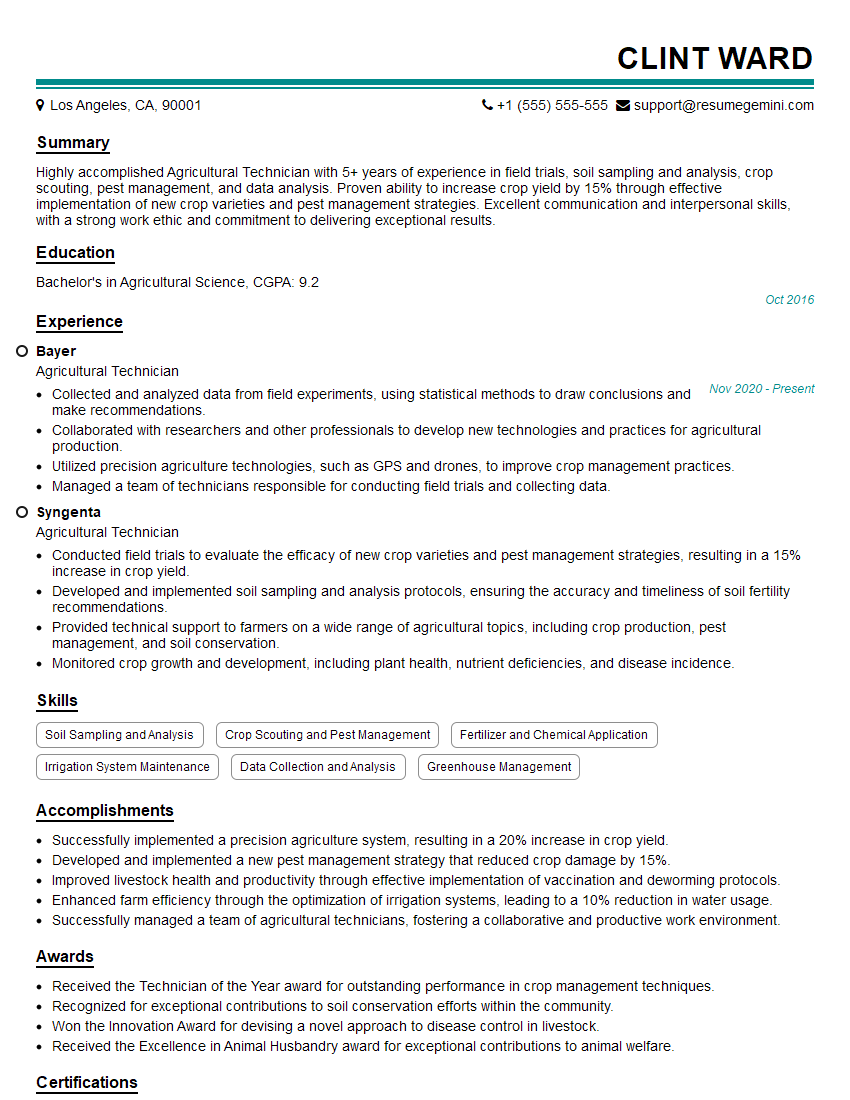

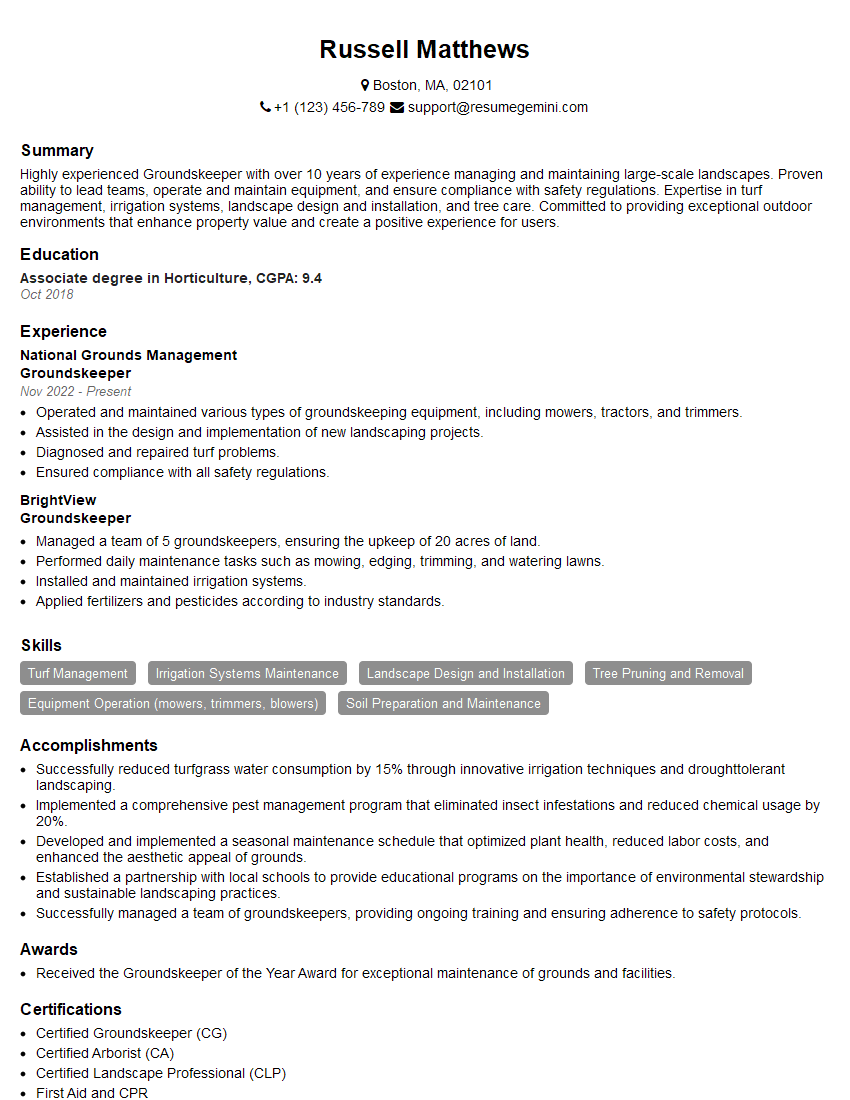

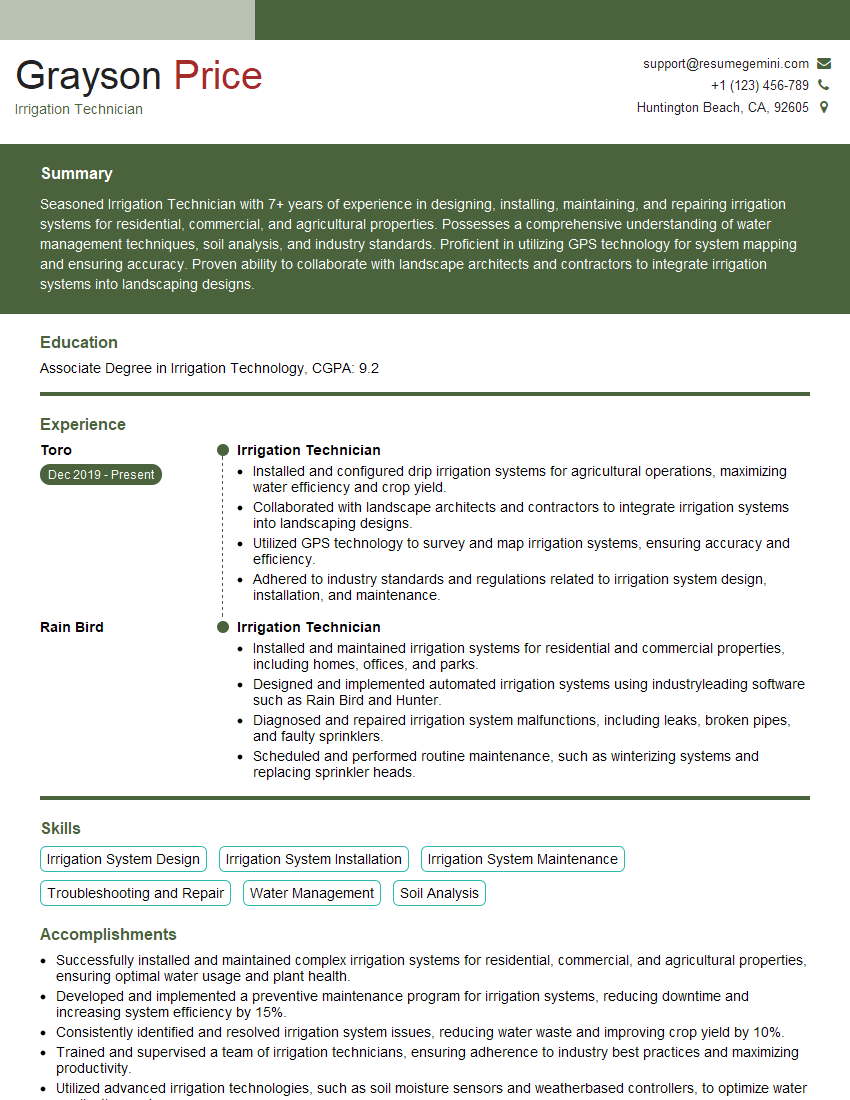

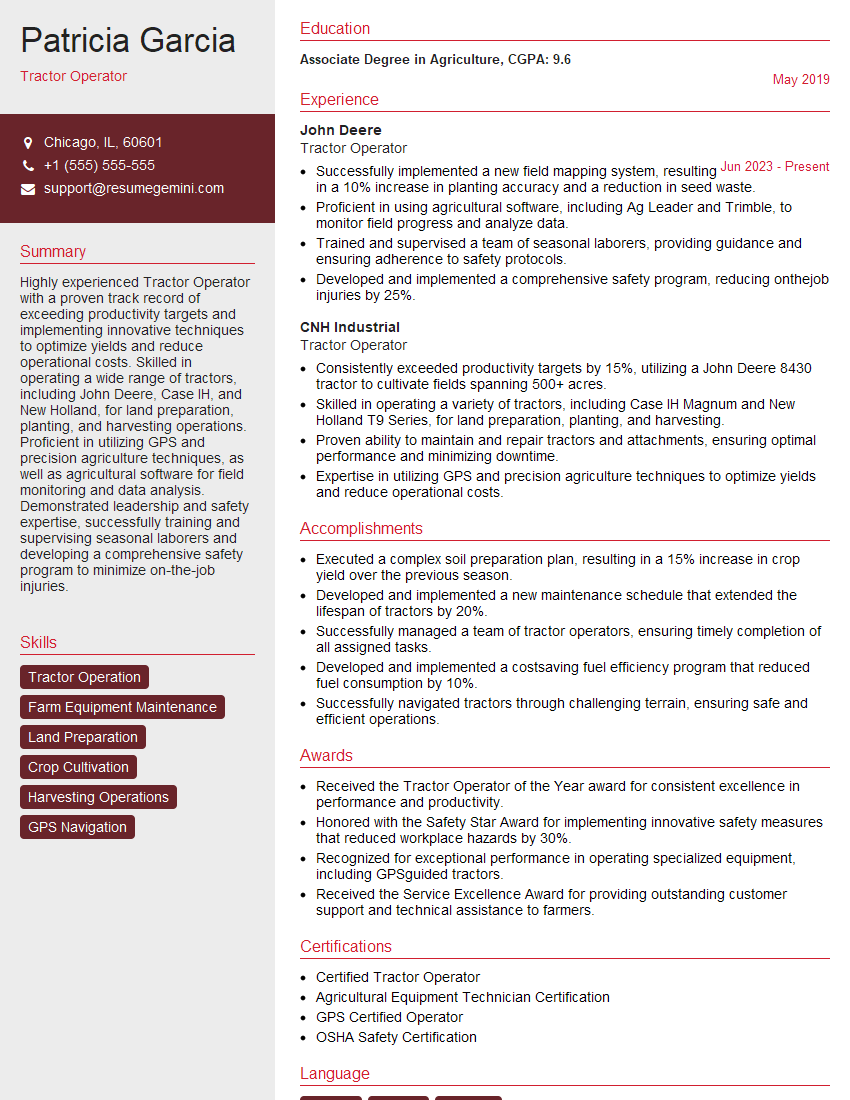

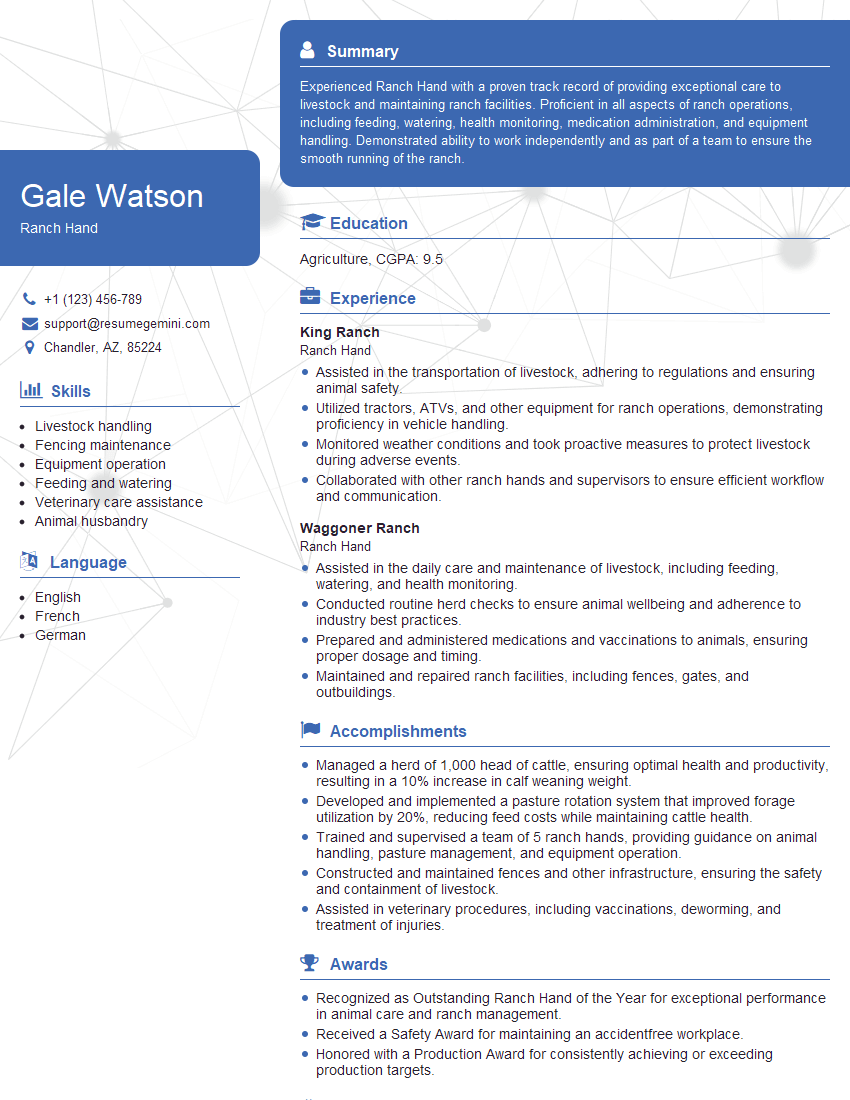

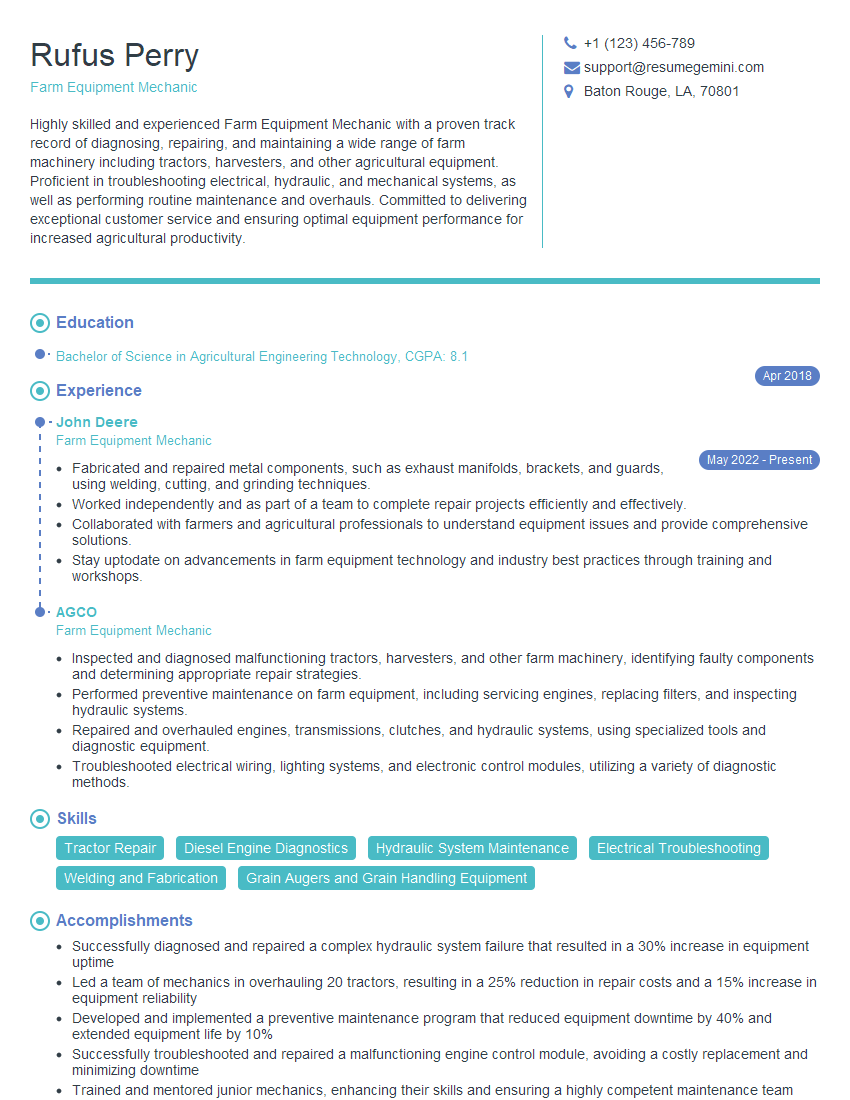

Mastering tractor and ATV operation opens doors to a variety of rewarding careers in agriculture, landscaping, construction, and more. These skills are highly sought after, leading to stable employment and potential for career advancement. To significantly improve your job prospects, it’s vital to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out from the competition. They offer examples of resumes tailored to the Tractor and ATV operation field to guide you. Invest time in crafting a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good