Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Train Car Switching interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Train Car Switching Interview

Q 1. Describe the different types of railcar couplings.

Railcar couplings are the critical connection points between individual railcars, enabling the formation of trains. The most common type is the Janney coupler, a knuckle-type coupler that allows for both vertical and horizontal movement during train operation. This flexibility is essential for navigating curves and absorbing shocks. There are variations within the Janney design to accommodate different railcar types and weights. Less common, but still used in certain specialized applications, are the tightlock couplers, which offer greater strength and security but less flexibility. Finally, there are historical types, like the older link-and-pin couplers which are largely obsolete but might still be found on preserved heritage equipment.

- Janney Coupler: The standard automatic coupler, allowing for quick connection and disconnection.

- Tightlock Coupler: Used for high-stress applications requiring maximum security.

- Link-and-Pin Coupler: An older, less efficient design, largely replaced by the Janney coupler.

Q 2. Explain the process of coupling and uncoupling railcars.

Coupling and uncoupling railcars involves a series of careful steps to ensure safety and efficiency. With Janney couplers, the process is largely automated. For coupling, the knuckles on the couplers need to be aligned. Then, the cars are carefully pushed together, allowing the knuckles to engage automatically. A visual check is always crucial to verify the connection. Uncoupling involves operating a lever on the coupler’s side, disengaging the knuckle. This should only be performed when the train is stationary and the brakes are applied. A specific type of uncoupling device can also be used from the ground for added safety. With tightlock couplers, the procedure is more involved and usually requires more manual intervention. Safety is paramount during both coupling and uncoupling, involving strict adherence to signaling procedures and the presence of ground personnel to ensure the operation’s safety and to give warnings to nearby workers and bystanders.

Q 3. How do you ensure the safety of yourself and others during switching operations?

Safety during switching operations is paramount. It’s a team effort, relying on a combination of procedures, equipment, and communication. This includes always conducting thorough pre-shift inspections of equipment, ensuring clear communication with fellow crew members using hand signals or radios, and adhering strictly to established safety rules. We must carefully observe and follow the safety protocols set forth in company regulations and industry standards. Wearing high-visibility clothing, using appropriate personal protective equipment (PPE) such as gloves and safety shoes, and being vigilant about the surroundings are essential for personal safety. Blind spots near moving equipment should always be checked and any unsafe conditions reported immediately. In my experience, regular safety briefings reinforce these principles, ensuring we all stay aware of potential hazards and best practices.

Q 4. What are the common causes of derailments during switching?

Derailments during switching operations often stem from several factors. Excessive speed is a leading cause, particularly around curves or switches. Improperly set switches can cause a car to derail as it attempts to traverse a misaligned track. Defective track, such as broken rails or improperly maintained ties, creates unsafe conditions. Overloaded cars can put excessive stress on the track, increasing the risk. Finally, human error, including incorrect coupling, failure to properly secure handbrakes, and mistakes in operating switching equipment, plays a significant role in many derailments. Preventing these requires meticulous track maintenance, rigorous adherence to speed limits and safety procedures, and thorough training for all personnel involved.

Q 5. Describe your experience with various switching techniques.

My experience encompasses a range of switching techniques, including conventional switching using locomotives, and remote-controlled switching using specialized equipment. I’m proficient in various methodologies such as single-car switching, multiple-car switching, and cut-and-shuffle operations in both flat and hump yards. For example, in a busy classification yard, I’ve efficiently organized and directed the movement of hundreds of cars daily using hump switching, a technique that uses gravity to sort cars into different tracks based on their destination. I’ve also worked with various types of locomotives and rolling stock, adapting my techniques to their specific characteristics. Experience in this area is not only about technical ability, but also about good judgment, anticipation, and teamwork.

Q 6. How do you manage railcar movements in a busy yard environment?

Managing railcar movements in a busy yard necessitates efficient planning and coordination. This involves utilizing advanced technologies such as computerized switching systems and track diagrams to optimize car movements, reducing congestion and delays. Effective communication with fellow switchers, conductors, and yardmasters is crucial to ensure everyone’s awareness of ongoing operations and to avoid conflicts. Prioritization of car movements based on urgency and destination is essential, focusing on timely departure of outbound trains. Strict adherence to safety protocols, particularly around high-traffic areas, is always maintained. Experience in this setting is all about finding the right balance between speed and safety. It is a dynamic environment and you need to be able to react quickly and efficiently, while always prioritizing safety.

Q 7. Explain your understanding of train consist and its importance in switching.

The train consist refers to the complete list of railcars making up a particular train, including their order and type. This is crucial in switching because it dictates the precise sequence of car movements needed during both formation and dismemberment of trains. Knowing the train consist allows switchers to efficiently assemble and break down trains by placing cars in the correct order based on their destination. This prevents unnecessary shuffling and reduces delays. Furthermore, the train consist provides critical information about weight distribution, car types (tankers, reefers, etc.), and any special handling requirements, impacting safe and efficient switching and subsequent train operation.

Q 8. How do you prioritize tasks during peak switching hours?

Prioritizing tasks during peak switching hours requires a strategic approach combining pre-planning and real-time adaptation. Think of it like conducting an orchestra – each instrument (railcar) needs to be in the right place at the right time.

My approach starts with reviewing the day’s switching plan. I identify high-priority tasks based on factors like deadlines (e.g., outbound trains scheduled for departure), urgency (e.g., perishable goods), and customer requirements. I then allocate resources – locomotives, crews, and track space – efficiently to tackle these priorities first.

Real-time adjustments are crucial. Unexpected delays, such as a mechanical issue with a railcar or congestion in a particular area, necessitate a dynamic shift in priorities. I use constant communication with the yardmaster and other crews to monitor the situation, re-evaluate the task list, and make informed decisions on the fly. For example, if a key outbound train is delayed due to a mechanical problem, I’ll temporarily re-prioritize tasks to expedite its preparation.

Q 9. What safety protocols do you follow when working with different types of railcars?

Safety is paramount when handling diverse railcars. Different types of railcars present unique hazards – tank cars carrying hazardous materials require extra precautions, while oversized or heavy-haul cars necessitate careful maneuvering and securing.

- Pre-Trip Inspection: Before commencing any switching operation, a thorough inspection of both the locomotives and the railcars is mandatory. This includes checking for brake functionality, coupling integrity, and any visible damage. Specific attention is paid to placards and markings indicating the contents of tank cars.

- Proper Braking and Securing: Hand brakes are applied on all railcars not under locomotive control. Couplers must be securely engaged to prevent separation. For hazardous materials, additional securing measures might be needed.

- Communication: Clear and consistent communication through hand signals and radios is critical to maintain situational awareness among the crew and surrounding workers.

- Awareness of Hazards: Specific safety measures depend on the type of railcar being handled. For example, when handling tank cars, I would be extra cautious about avoiding sparks or sources of ignition.

Always following these protocols helps minimize risks and ensure a safe working environment.

Q 10. How do you handle unexpected situations or equipment malfunctions during switching?

Unexpected situations are part and parcel of train car switching. My approach involves a calm, systematic response focusing on safety first.

- Assessment: The first step is a quick and thorough assessment of the situation – what went wrong, what’s the immediate impact, and what are the potential hazards?

- Safety Measures: Implement immediate safety protocols to prevent further incidents or injuries. This might involve stopping operations, securing equipment, and warning others in the area.

- Problem Solving: Depending on the nature of the malfunction, I may attempt a temporary fix or initiate the proper procedures to request assistance (e.g., calling for a mechanic, informing the yardmaster).

- Communication: I communicate the issue and its resolution clearly and concisely to other team members and relevant personnel.

- Documentation: After the situation is resolved, detailed documentation of the event, the corrective actions taken, and any lessons learned is crucial for future prevention. This contributes to continuous improvement in safety and efficiency.

For example, if a coupler malfunctions, I’d immediately stop the operation, apply hand brakes, signal others to stay clear, and contact the maintenance crew.

Q 11. Describe your experience using hand signals and radio communication in a yard environment.

Hand signals and radio communication are the lifeblood of efficient and safe yard operations. Think of them as the conductor’s baton and the orchestra’s score, ensuring all instruments (locomotives and railcars) play together harmoniously.

Proficiency in standard hand signals is essential. I’m very familiar with all the signals, including those for starting, stopping, backing up, and changing direction. Radio communication is vital for coordinating movements among the crew, the yardmaster, and other personnel. Clear, concise messages are essential to avoid misinterpretations, especially in busy yards. For instance, before a switching maneuver, I’d use the radio to confirm the location of other crews and confirm that the track is clear.

I’ve developed a habit of confirming instructions using a combination of both visual and verbal communication to minimize misunderstandings, enhancing safety and efficiency. A simple example is confirming a signal by stating ‘Understood, backing up now’ over the radio while performing the action.

Q 12. Explain your knowledge of track geometry and its impact on switching operations.

Track geometry – the alignment, curvature, and elevation of tracks – significantly impacts switching operations. Think of it as the stage for our railcar ‘actors’; a poorly designed stage will lead to a chaotic performance.

Understanding track curvature is crucial for negotiating curves safely. Sharp curves require slower speeds and careful control to prevent derailments. The track’s elevation (superelevation) is also important. It compensates for centrifugal force on curves, ensuring smoother and safer transitions. Poor track geometry can lead to increased wear and tear on rolling stock, reduce speed limits, and potentially cause derailments. In my experience, a well-maintained track with optimized geometry significantly increases efficiency and minimizes the risk of accidents during switching operations. I always take into account the limitations imposed by track geometry when planning movements and setting speeds.

Q 13. How do you ensure the proper placement and securing of railcars?

Proper placement and securing of railcars are critical for safety and efficiency. This is akin to carefully placing pieces on a chessboard; improper placement can lead to a checkmate (an accident or operational disruption).

Placement depends on the yard’s layout, the type of railcar, and the intended destination. I ensure railcars are placed according to the switching plan, leaving sufficient clearance between cars and avoiding obstructions. Securing railcars involves applying hand brakes securely on all cars not under locomotive control and ensuring couplers are firmly engaged. I always double-check the position and security of each railcar before moving on to the next task. For high-value or sensitive cargo, I may use additional securing measures, such as wheel chocks, to ensure stability. Thorough verification and documentation are key to prevent future complications.

Q 14. How familiar are you with the various types of switching equipment (e.g., locomotives, switch engines)?

I’m very familiar with a range of switching equipment, and my expertise extends beyond simply operating it. I understand their capabilities, limitations, and maintenance needs. This knowledge allows me to select the appropriate equipment for each switching task and to anticipate potential problems.

- Locomotives: I’m experienced with various types of locomotives, from road switchers to dedicated yard engines, understanding their horsepower, tractive effort, and control systems. I know how to select the right locomotive for specific tasks, considering factors like the weight of the cars and the terrain.

- Switch Engines: I’m proficient in operating switch engines, understanding their unique capabilities in maneuvering and switching railcars within confined spaces.

- Other Equipment: My familiarity extends to other equipment used in switching operations, such as retarders (used to control the speed of railcars on inclines), air compressors, and various communication systems.

This comprehensive knowledge enables me to efficiently and safely manage switching operations, selecting the right tools for the job and preventing equipment-related delays or hazards.

Q 15. Explain your understanding of train braking systems and their relevance to switching.

Train braking systems are crucial for safe and efficient switching operations. They control the speed and stopping distance of railcars, preventing accidents and damage. Understanding these systems is paramount for any switch operator. There are primarily two types: automatic and manual.

- Automatic braking systems (like the Automatic Air Brake system) use compressed air to apply brakes across multiple cars simultaneously. A failure in one car’s brakes can trigger an emergency brake across the entire train. This is vital during switching, as the sudden stopping of a single car in a sequence can cause a collision.

- Manual braking systems are used for individual cars, often requiring hand brakes to be applied. While less common for large-scale switching, they play a role in securing cars that might need to remain stationary during a sorting process.

For example, imagine a situation where I’m coupling a loaded tanker car to a string of empty boxcars. Accurate control of the braking system is vital. If I’m not careful and use too much force when coupling, the automatic brakes could engage, potentially causing a derailment or collision. Conversely, insufficient braking could lead to runaway cars, posing a severe safety risk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate records of railcar movements and locations?

Maintaining accurate records of railcar movements and locations is crucial for efficiency and safety. We use a combination of manual and automated systems. Traditionally, switch lists – physical documents detailing the cars’ origins, destinations, and movement within the yard – were paramount. Today, many yards use sophisticated computer systems.

These systems use various tracking technologies, including:

- RFID tags attached to railcars, allowing for automated tracking via scanners.

- GPS tracking on locomotives and specialized railcars provides real-time location data.

- Yard management systems (YMS) integrate data from various sources, giving an overall view of car locations and movement patterns within the yard.

All movements are meticulously logged, ensuring accountability and allowing for efficient retrieval of specific cars or identification of delays. Any discrepancies are immediately investigated to ensure the integrity of the system.

For instance, if a particular car isn’t located where it should be according to the system, we launch an investigation, which might include reviewing security footage or conducting a thorough yard inspection.

Q 17. Describe your experience working with different types of freight cars (e.g., tankers, boxcars, hoppers).

My experience encompasses a wide range of freight cars. Each type requires specific handling procedures due to differences in weight, size, and contents.

- Tank cars necessitate extra caution due to their hazardous contents. They require meticulous inspections before coupling, paying close attention to valves and securing mechanisms to avoid spills or leaks.

- Boxcars, used for general cargo, require attention to loading weight distribution to prevent damage. I ensure the proper placement of bracing to secure the load during transit.

- Hopper cars, used for bulk materials like grain or coal, require attention to their unloading mechanisms and proper cleaning between different types of cargo.

I recall one instance where we had to handle a damaged boxcar. It involved careful assessment of the structural integrity before attempting any movement. We had to use specialized equipment and procedures to avoid further damage and ensure the safety of the crew.

Q 18. How do you identify and report safety hazards in the yard environment?

Safety is the paramount concern in any yard environment. I regularly inspect the yard for hazards, reporting any issues immediately. My observations include:

- Track conditions – looking for broken rails, damaged ties, or obstructions.

- Equipment condition – inspecting locomotives, railcars, and switching equipment for defects.

- Environmental hazards – identifying potential spills, leaks, or weather-related issues (like ice or snow accumulation).

- Signage and lighting – ensuring adequate visibility and clear warnings are in place.

I use the company’s designated reporting system, usually a digital platform, to log every hazard. This ensures prompt action by the appropriate teams, preventing accidents and maintaining a safe work environment. A specific example is when I discovered a potential derailment hazard – a small rock embedded within a rail. I immediately reported it, and the maintenance crew fixed it before it could cause any issues.

Q 19. What are the regulations and procedures related to hazardous materials handling during switching?

Regulations governing hazardous materials are strict and require thorough understanding. These regulations detail handling procedures, safety equipment required, and emergency response protocols. Key aspects include:

- Proper labeling and placarding of hazardous materials cars.

- Designated routes and handling procedures within the yard to prevent accidental mixing or spills.

- Emergency response plans outlining actions to take in the event of a leak or spill.

- Emergency equipment availability and familiarity with its use, such as spill kits and personal protective equipment (PPE).

For example, transporting flammable materials requires specialized cars and designated routes that avoid sensitive areas. Proper training and adherence to the Emergency Response Guidebook (ERG) are crucial. Failure to comply leads to severe penalties and jeopardizes the safety of workers and the environment.

Q 20. How do you ensure the efficient flow of railcars through the yard?

Efficient railcar flow is achieved through careful planning and execution. This involves:

- Optimizing switching sequences – minimizing unnecessary movements and delays.

- Effective use of yard space – efficient placement of railcars to minimize congestion.

- Clear communication – coordination with other yard personnel and train crews.

- Proactive problem-solving – anticipating potential bottlenecks and addressing them before they occur.

Imagine a scenario with many inbound trains needing processing. Careful sequencing of the switching movements is crucial. A poorly planned sequence could lead to significant delays and congestion, reducing overall yard efficiency. My expertise lies in minimizing such situations by optimizing the train assembly process.

Q 21. Explain your understanding of train scheduling and its influence on switching operations.

Train scheduling directly impacts switching operations. The arrival and departure times of trains dictate the flow of railcars through the yard. Coordination is key.

Accurate scheduling allows for efficient resource allocation and minimizes delays. When a train is unexpectedly delayed, it affects the entire yard’s switching schedule, creating potential bottlenecks. We have to adapt and re-sequence switching tasks to maintain a smooth flow.

For instance, if a train carrying high-priority cargo is delayed, we need to adjust the switching priorities to ensure its timely processing and departure. This may involve temporarily prioritizing that train’s cars over others, even if it means delaying other operations.

Q 22. How do you handle communication with train crews and other yard personnel?

Effective communication is the backbone of safe and efficient train car switching. I utilize a multi-faceted approach, combining clear, concise verbal instructions with visual aids where necessary. With train crews, I use standardized radio protocols, ensuring every instruction is precise and unambiguous. For instance, when directing a coupling maneuver, I’ll specify the exact car number, the coupling location, and the required speed. With other yard personnel, such as switch operators and maintenance crews, I maintain open channels of communication, using a combination of radio, written work orders, and face-to-face briefings. Regular briefings before significant switching operations, outlining the plan and potential challenges, are vital for coordination. I also actively listen to feedback and address concerns promptly, fostering a collaborative environment where safety is paramount.

For example, if a crew is having difficulty with a specific coupling, I wouldn’t just repeat the instructions, but investigate the potential cause – whether it’s coupler malfunction, track alignment, or even weather conditions – and provide support to overcome the problem. Clear and timely communication prevents misunderstandings, reduces delays, and significantly enhances safety.

Q 23. What are your experience and knowledge of different types of switches and turnouts?

My experience encompasses a wide range of switches and turnouts, including both manual and remotely controlled systems. I’m familiar with various types, such as slip switches, crossover switches, and facing-point switches. I understand their mechanical workings, including the use of points, frogs, and switch machines. I’m proficient in identifying and troubleshooting common issues, such as points binding, rail misalignment, or malfunctioning switch machines. I also have a solid understanding of the safety mechanisms involved, such as derailers and locking devices. The use of modern signaling systems integrated with the switches is also crucial, as they contribute to the safe and efficient operation of the railway and prevent collisions. My knowledge of different switch types allows me to select the appropriate type for a given switching task, ensuring efficiency and safety. For instance, the choice between a facing-point switch and a trailing-point switch is governed by train movement direction and speed.

Furthermore, I’m well-versed in the maintenance and inspection procedures required to ensure the safe and reliable operation of these vital components. This includes visual inspections, testing switch operation, and recognizing indications of wear and tear.

Q 24. Explain your understanding of the role of a Yardmaster in supervising switching activities.

The Yardmaster is the central figure in overseeing the intricate ballet of railcar switching. They’re responsible for the overall coordination of switching activities within a yard, ensuring the safe, efficient, and timely movement of trains and individual cars. This includes planning the switching sequences, assigning tasks to crews and personnel, monitoring progress, and resolving any issues that may arise. They act as a central point of communication, coordinating between train crews, switch operators, and other yard personnel. Essentially, the Yardmaster acts as an air traffic controller for the rail yard.

Think of it like orchestrating a complex symphony. Each instrument (train crew, switch operator) has its part to play, and the Yardmaster ensures each part is played at the right time, in the right way, to create a harmonious outcome – the efficient and safe movement of trains. Their role is critical to prevent conflicts, bottlenecks, and unsafe practices.

Q 25. Describe your experience with using yard management systems and technologies.

I’m proficient in using various yard management systems (YMS), including those that integrate with train control systems and real-time tracking technologies. These systems typically provide detailed information about train composition, car locations, and scheduled movements. I have experience using such systems to plan switching sequences, optimize car placement, and monitor operational efficiency. The software often provides tools for modeling the yard, simulating switching maneuvers, and automatically generating work orders. I can effectively input and retrieve data, analyze reports, and troubleshoot system problems. My experience also covers using handheld devices such as barcode scanners and tablets to update car location information, verify contents, and ensure accurate documentation.

For example, I’ve used YMS to identify the optimal sequence for assembling a specific train, minimizing the number of moves and maximizing throughput. This not only reduces operational costs but also improves safety by minimizing the time cars spend in the yard.

Q 26. How do you deal with conflicting priorities or competing deadlines while managing railcar switching?

Conflicting priorities are a common occurrence in railcar switching. My approach involves a systematic prioritization framework. I begin by clearly identifying all deadlines and constraints and assessing the relative importance of each task. This involves considering factors such as the urgency of shipments, the potential impact of delays, and any safety implications. I use a combination of techniques, such as creating detailed schedules and allocating resources effectively, to ensure that all crucial tasks are completed within their respective timeframes. Communication is key; I proactively inform all stakeholders of any potential delays or adjustments, fostering transparency and preventing misunderstandings.

Imagine having to assemble several outgoing trains with different deadlines. I would start by prioritizing trains with the most stringent deadlines, allocating resources accordingly. For less urgent trains, I would adjust the sequence to minimize impact while ensuring the overall efficiency of yard operations.

Q 27. What are your troubleshooting skills related to railcar malfunctions during switching?

Troubleshooting railcar malfunctions during switching demands a systematic approach. My approach involves a combination of visual inspection, communication with train crews, and utilizing relevant diagnostic tools. I start by assessing the nature of the malfunction – is it a mechanical issue, a braking problem, or a faulty coupling? Visual inspection helps to identify obvious problems, such as damaged wheels, broken couplers, or leaks. I then communicate with the train crew to gather additional information and determine if any unusual occurrences preceded the malfunction. For more complex issues, I may utilize specialized diagnostic equipment to pinpoint the cause.

For example, if a car’s brakes are malfunctioning, I will first visually inspect the brake system. If no obvious problems are found, I’ll work with the train crew to attempt an air-pressure test to diagnose issues with the air system. In the event of a coupler malfunction, understanding whether it’s a knuckle problem, a yoke issue, or a locking mechanism failure, is key to guiding the repair decision.

Q 28. Describe your problem-solving approach to resolving complex switching scenarios.

Solving complex switching scenarios requires a structured approach. I typically start by visualizing the problem, often using diagrams or software simulations to represent the yard layout and the desired train composition. I then break down the problem into smaller, more manageable steps, creating a detailed switching plan that outlines the sequence of moves required to achieve the desired outcome. This plan considers various factors, such as track capacity, train length, and the availability of personnel and equipment. Throughout the process, I regularly monitor progress, adapt to unforeseen circumstances, and make adjustments as needed. The key is to anticipate potential bottlenecks or complications and to have contingency plans in place to minimize disruptions. If challenges persist, I will consult with experienced colleagues and leverage expertise from different departments to collaboratively find a resolution.

For instance, a complex scenario might involve rearranging numerous cars within a congested yard to assemble multiple trains simultaneously. My approach would involve creating a detailed schedule that minimizes conflict, sequences tasks for maximum efficiency, and prioritizes critical movements. Thorough planning, combined with adaptability and effective communication, is crucial for effectively resolving complex switching problems.

Key Topics to Learn for Train Car Switching Interview

- Fundamentals of Train Car Coupling and Uncoupling: Understanding the mechanics, safety procedures, and different coupling types (e.g., knuckle couplers).

- Switching Techniques and Maneuvers: Mastering various switching techniques like kicking, shoving, and using helper engines, including their practical application in different yard layouts.

- Railroad Signaling and Communication Systems: Knowledge of interpreting signals, understanding radio communication protocols, and adhering to safety regulations.

- Track Diagrams and Yard Layout: Interpreting and utilizing track diagrams to plan efficient switching operations and anticipate potential bottlenecks.

- Safety Regulations and Procedures: Deep understanding of all relevant safety rules, emergency procedures, and the importance of teamwork in maintaining a safe working environment.

- Train Car Classification and Handling: Understanding different types of train cars, their weight capacities, and appropriate handling techniques to avoid damage or accidents.

- Troubleshooting and Problem-Solving: Developing the ability to quickly identify and resolve issues that may arise during switching operations, such as coupler malfunctions or track obstructions.

- Operational Efficiency and Optimization: Strategies for maximizing efficiency in switching operations, minimizing delays, and contributing to overall yard productivity.

Next Steps

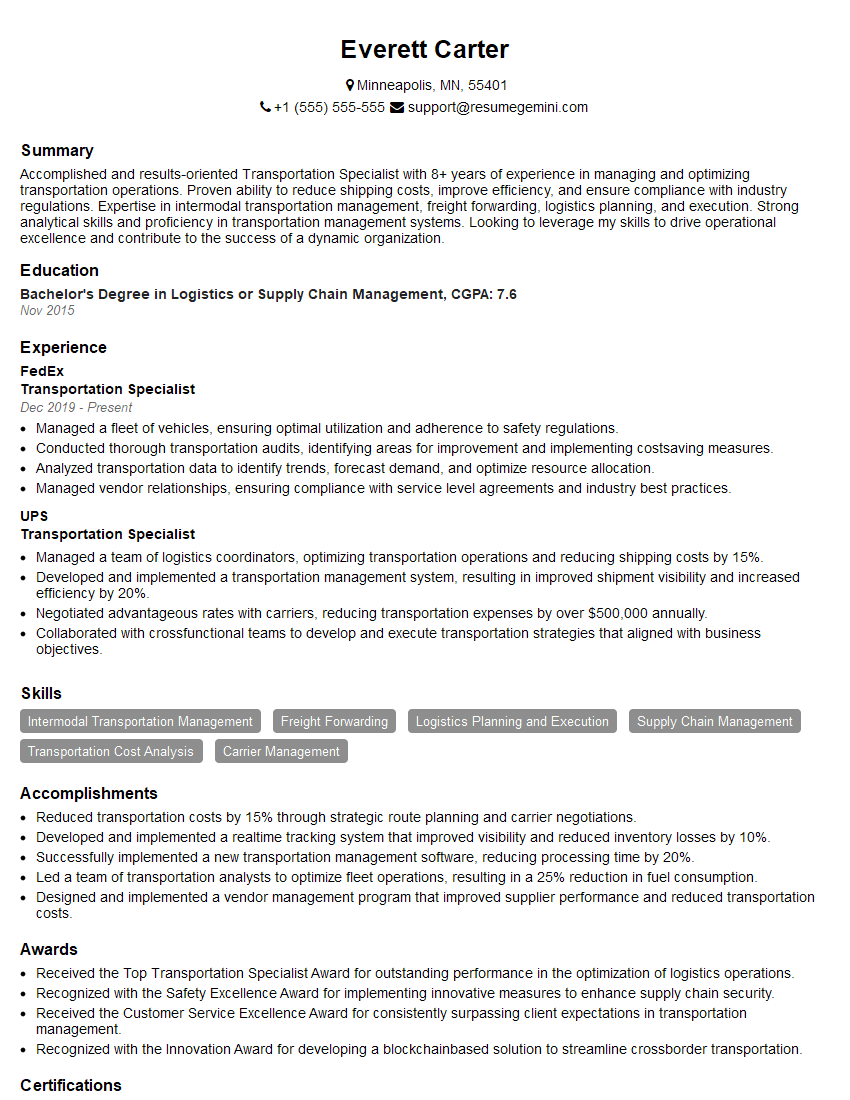

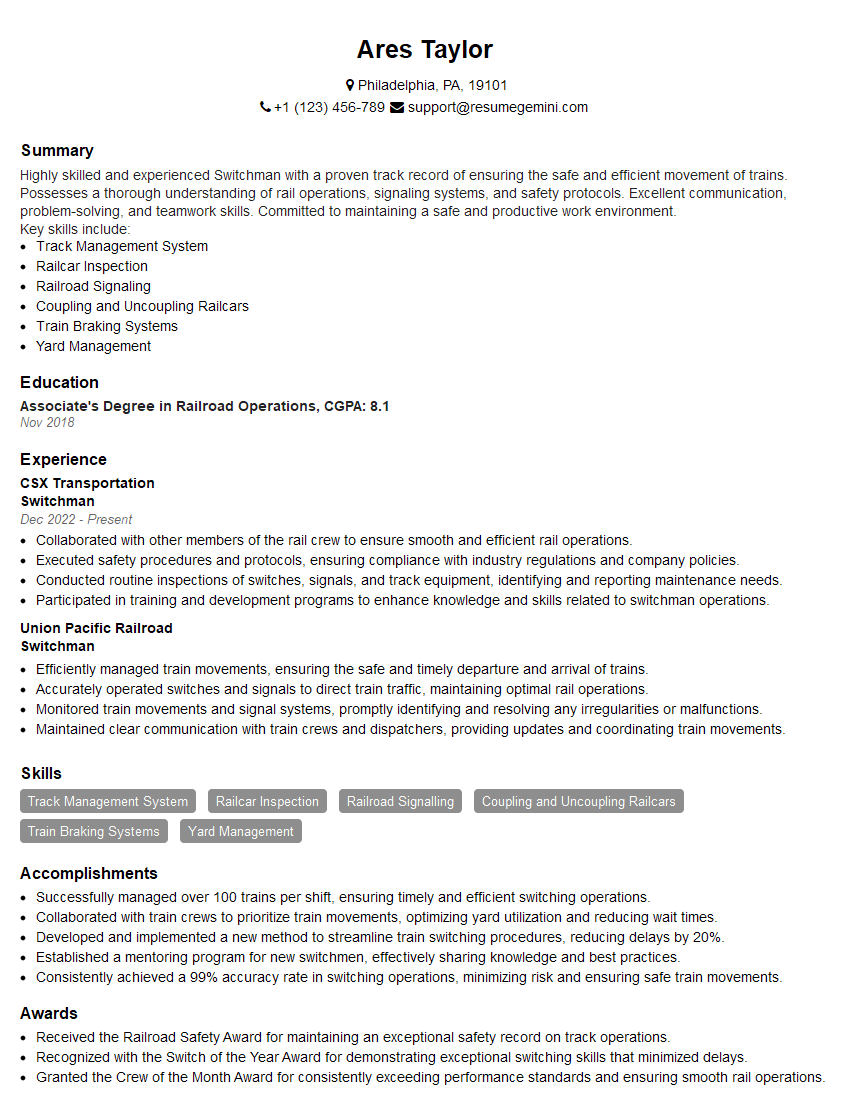

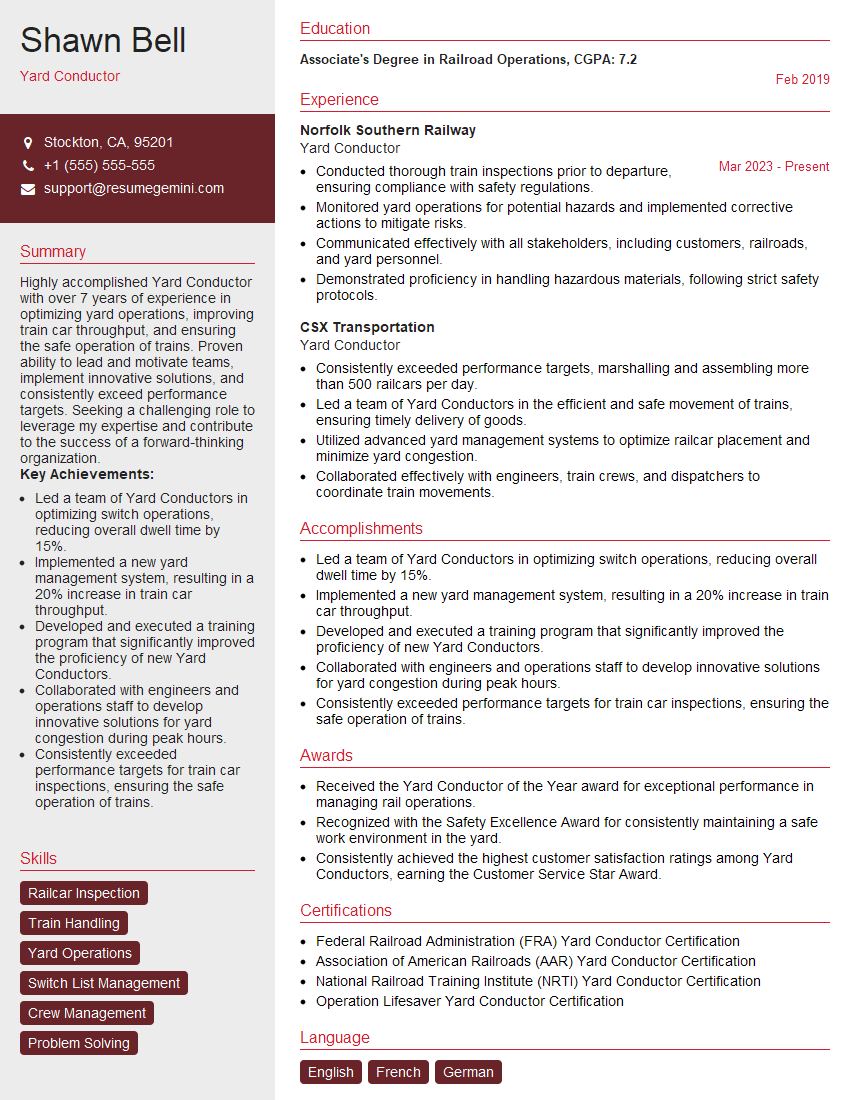

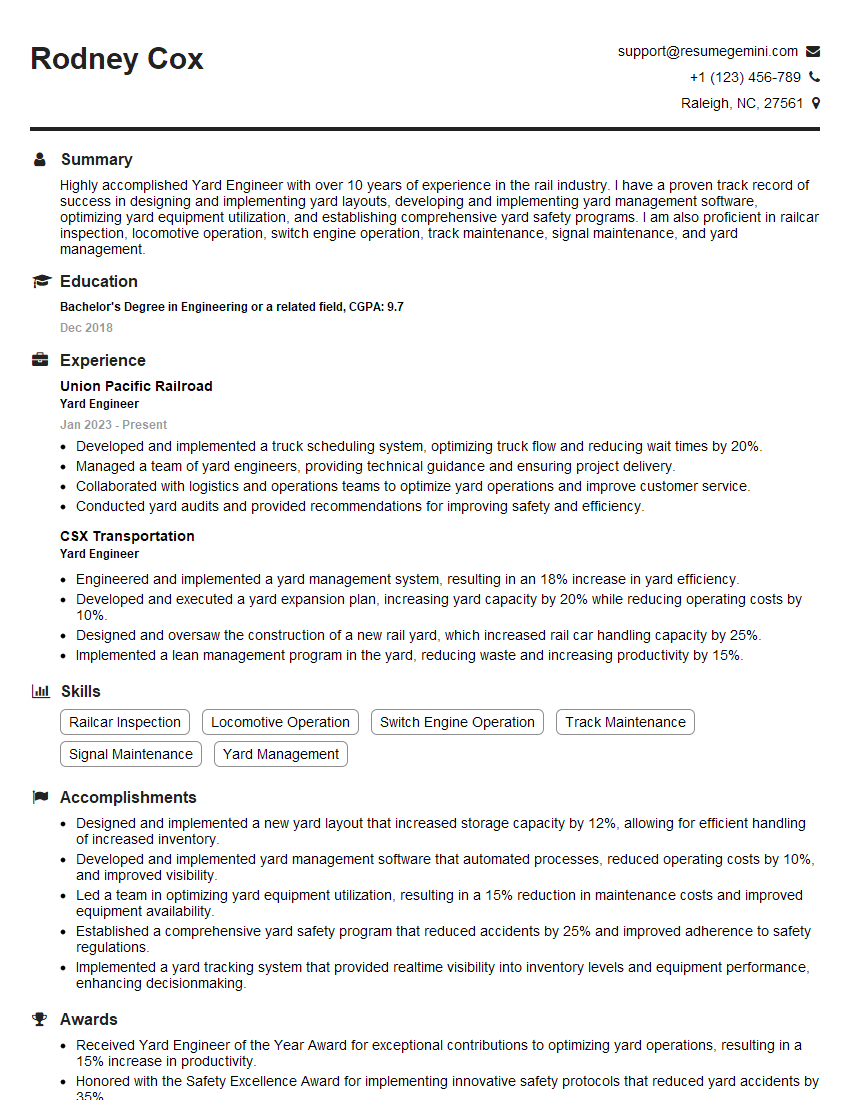

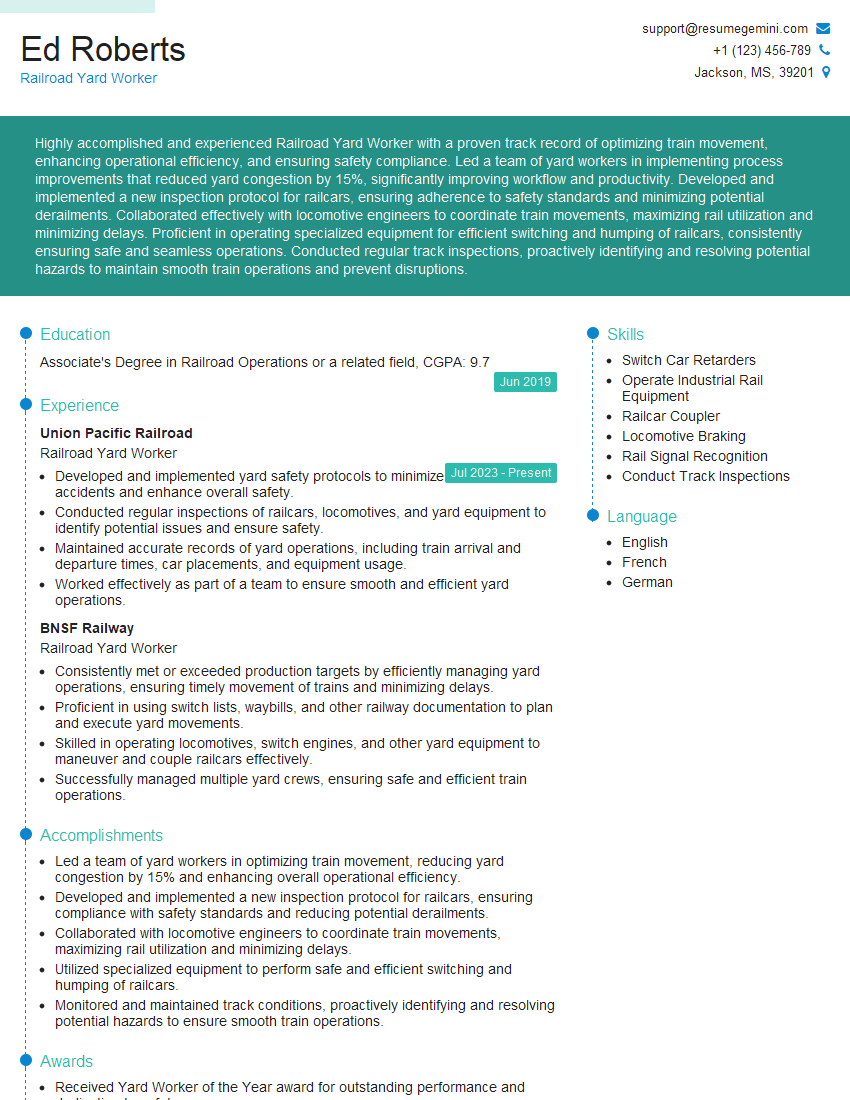

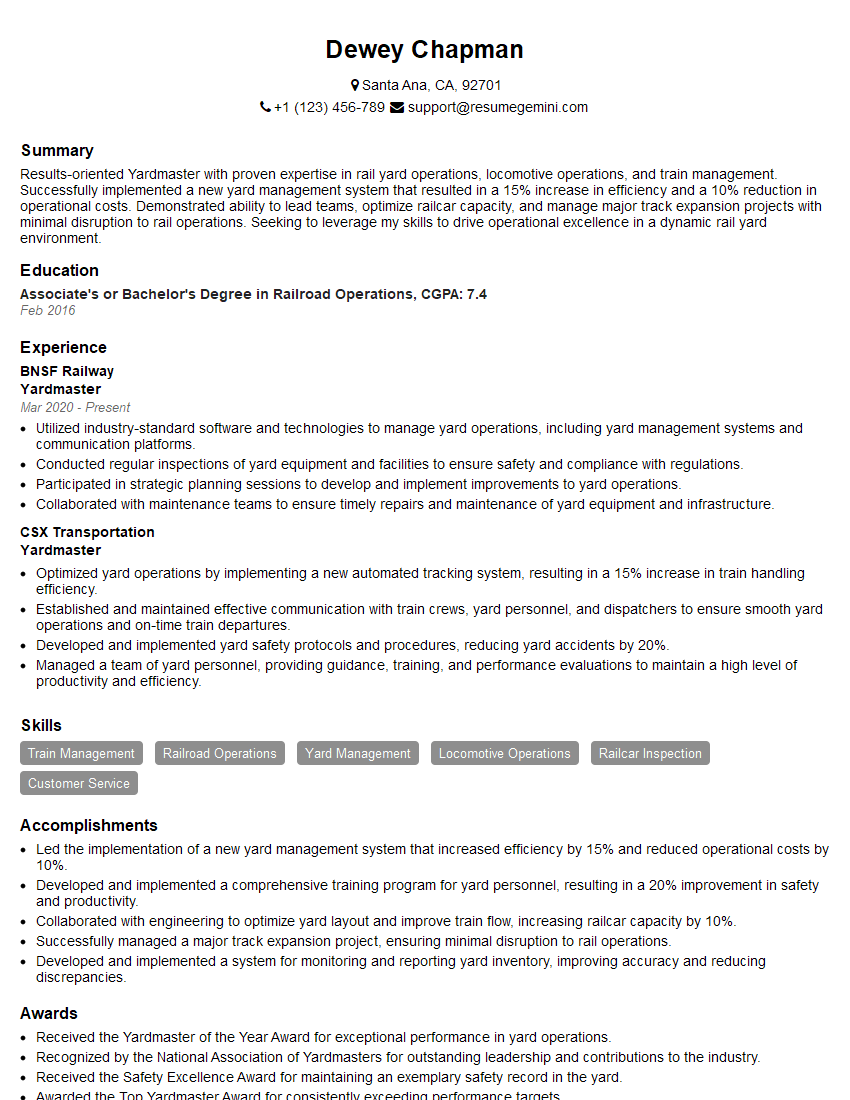

Mastering train car switching opens doors to a rewarding career with excellent growth potential within the railroad industry. This specialized skillset is highly valued, leading to increased earning potential and opportunities for advancement. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. ResumeGemini can help you build a powerful resume that highlights your expertise in train car switching, increasing your chances of landing your dream job. Examples of resumes tailored to Train Car Switching are available within ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good