Preparation is the key to success in any interview. In this post, we’ll explore crucial Troubleshoot electrical problems interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Troubleshoot electrical problems Interview

Q 1. Explain the process of troubleshooting a faulty circuit breaker.

Troubleshooting a faulty circuit breaker involves a systematic approach prioritizing safety. First, always turn off the power at the main breaker panel before attempting any inspection. Then, visually inspect the breaker itself. Look for any signs of damage like scorch marks, arcing, or a tripped mechanism. A tripped breaker will be in the ‘off’ position, even if you haven’t manually turned it off.

If the breaker is tripped, try resetting it by switching it to the ‘off’ position and then back to the ‘on’ position. If it trips immediately, this indicates a persistent fault in the circuit it protects. This could be an overloaded circuit, a short circuit, or a ground fault.

If the breaker doesn’t trip, but the circuit still isn’t working, check the outlets and appliances on that circuit. If the problem persists after checking appliances, further investigation is needed, possibly using a multimeter to check for voltage at the breaker and at outlets within the circuit.

Important Note: If you’re uncomfortable working with electricity, always consult a qualified electrician. Improper handling can lead to serious injury or damage.

Q 2. Describe your experience with using multimeters to diagnose electrical problems.

Multimeters are indispensable tools for diagnosing electrical problems. I’ve extensively used them to measure voltage, current, and resistance. For instance, I once used a multimeter to troubleshoot a flickering light. By measuring the voltage at the light fixture and comparing it to the voltage at the breaker, I identified a loose connection within the wiring.

Another example involved a faulty appliance. Using the multimeter’s resistance setting, I checked the appliance’s continuity to identify a broken heating element. Knowing how to properly use a multimeter’s various functions – such as AC/DC voltage, current, resistance, and continuity – is crucial for pinpointing electrical issues, saving time and preventing further damage. Proper safety precautions, including wearing insulated gloves and using appropriate safety glasses, are also paramount.

Q 3. How do you identify and resolve short circuits?

Short circuits occur when an unintended path of low resistance allows current to flow outside the intended circuit, often causing overheating and potential fire hazards. Identifying them requires careful observation and testing. The symptoms can include tripped breakers, blown fuses, burning smells, or unusually warm wires.

To resolve a short circuit, I’d first isolate the circuit by turning off the breaker. Then, I’d carefully inspect the wiring and connections within that circuit, looking for any damaged insulation, loose connections, or wires touching each other. A multimeter can help pinpoint the exact location of the short by measuring the resistance between wires. Repair involves replacing damaged wire, tightening loose connections, and ensuring proper insulation. In cases of extensive damage, replacing the entire section of wiring might be necessary. Remember: safety always comes first.

Q 4. What are the common causes of ground faults, and how do you troubleshoot them?

Ground faults happen when electrical current flows unexpectedly into the ground, typically through a faulty appliance or damaged wiring. This can cause shock hazards and potentially damage equipment. Common causes include worn or damaged insulation, water ingress into wiring, faulty appliances with exposed wires, and deteriorated grounding connections.

Troubleshooting ground faults involves using a ground fault circuit interrupter (GFCI) tester to check outlets and appliances. I would also use a multimeter to check the resistance of the grounding wire and the continuity of the ground path. If a ground fault is detected, the problem source needs to be located and repaired. This could involve replacing faulty appliances, repairing or replacing damaged wiring, or fixing a faulty grounding connection. Regular inspections and maintenance can prevent ground faults.

Q 5. Explain your experience with interpreting electrical schematics and wiring diagrams.

I’m proficient in interpreting electrical schematics and wiring diagrams, which are essential for understanding the layout and functionality of electrical systems. Schematics show the electrical components and their connections in a simplified, symbolic form, while wiring diagrams illustrate the physical layout of wires and components. I’ve used them extensively for troubleshooting and designing electrical systems.

For example, recently I used a schematic to trace a faulty connection in a complex control system. By analyzing the schematic, I quickly identified the relevant components and used a multimeter to verify the signal path and identify the broken connection which was then repaired. My ability to read and interpret these diagrams allows for efficient diagnosis and repair of electrical problems and is essential for any electrical work.

Q 6. How do you diagnose and repair faulty wiring in a building?

Diagnosing and repairing faulty wiring in a building is a systematic process. I always start by isolating the affected area by switching off the relevant circuit breaker. Next, I use a multimeter to test for voltage and continuity to pinpoint the exact location of the fault. Visual inspection of the wiring for signs of damage, such as exposed wires, insulation breakdown, or loose connections, is critical.

The repair process depends on the nature of the fault. This might involve replacing damaged sections of wire, tightening loose connections, or addressing corrosion. If the damage is extensive, I would consider rerouting the wiring. It is very important to ensure the wiring meets building codes and safety standards. Throughout the entire process, proper safety practices are followed to prevent electric shock and injury.

Q 7. Describe your experience troubleshooting motor control circuits.

Motor control circuits are crucial in many industrial and commercial applications. My experience troubleshooting these circuits includes identifying problems with motor starters, overload relays, control relays, and wiring. I’ve used multimeters extensively to check voltage, current, and continuity in these circuits. For example, I once diagnosed a motor that wouldn’t start by using a multimeter to measure the voltage at the motor terminals and subsequently finding a fault in a control relay.

Troubleshooting often involves checking the various components within the motor control circuit, including the power supply, starters, overload relays, limit switches and safety interlocks. I analyze the system’s schematics to follow the control logic and then use a multimeter or specialized test equipment to check each component’s operation. A thorough understanding of the control logic, ladder diagrams, and proper safety measures is critical for effective troubleshooting.

Q 8. How do you troubleshoot problems with three-phase power systems?

Troubleshooting three-phase power systems requires a systematic approach. It begins with understanding the system’s configuration – delta or wye – and the expected voltage and current levels. I typically start by visually inspecting the system for obvious problems like loose connections, damaged conductors, or tripped breakers. Then, I use specialized instruments like multimeters and clamp meters to measure voltage, current, and power factor in each phase. An imbalance in these readings across the three phases is a strong indicator of a problem.

For example, if one phase shows significantly lower voltage than the others, it could be due to a loose connection, a faulty transformer winding, or a high impedance in the circuit. If the current is abnormally high in one phase, this might signify an overloaded circuit or a short circuit. Power factor readings help identify reactive power issues, often caused by inductive loads like motors. Further investigation might involve tracing the wiring, performing insulation resistance tests, and using motor testing equipment to diagnose motor problems. I always document my findings meticulously, as this allows for easier diagnosis and ensures the solution is properly implemented.

In one instance, I worked on a factory assembly line that experienced consistent shutdowns. The three-phase power supply was fluctuating wildly, leading to the failure of many components. Through a systematic approach, checking connections, phase voltages and currents and using a power quality analyzer, I discovered a failing capacitor bank causing the issue. Replacing the bank completely resolved the issue and saved the company considerable downtime and replacement costs.

Q 9. What safety precautions do you take when troubleshooting high-voltage systems?

Safety is paramount when working with high-voltage systems. I adhere to strict lockout/tagout procedures, ensuring that the power is completely isolated and locked out before commencing any work. I always use appropriate personal protective equipment (PPE), including insulated gloves, safety glasses, and arc flash protective clothing, rated for the voltage level. I never work alone; a qualified colleague is always present to monitor the situation and provide assistance. Before performing any measurements, I verify that the system is indeed de-energized using a non-contact voltage tester. Furthermore, I always follow the relevant safety regulations and company procedures to the letter.

Imagine working on a substation – the consequences of a mistake are catastrophic. The respect for high voltage is ingrained, and even seemingly small steps have safety implications. The use of proper equipment, double checking and having a colleague verify each step, and following established procedures are non-negotiable elements of my work strategy.

Q 10. Explain your experience with using diagnostic software for electrical systems.

I’m proficient in using various diagnostic software packages for electrical systems. This includes software that interfaces with PLCs and other industrial controllers, allowing for data logging, real-time monitoring, and troubleshooting of system faults. I have considerable experience with software that provides trend analysis of historical data, which is invaluable for identifying recurring problems or predicting potential failures. Some specific examples include (but are not limited to) using Schneider Electric’s EcoStruxure Power Monitoring Expert software, Rockwell Automation’s FactoryTalk AssetCentre, and various SCADA systems to access and diagnose problems in remote locations. These systems allow me to pinpoint the root cause much faster than traditional methods, thus significantly reducing downtime and expenses.

For example, in one project, using FactoryTalk AssetCentre to monitor motor vibrations and temperatures, I identified a pattern in a specific motor’s readings that correlated with production slowdowns. We were able to perform a preventative motor replacement based on this, avoiding a costly unexpected failure during peak production.

Q 11. How do you troubleshoot problems with programmable logic controllers (PLCs)?

Troubleshooting PLCs involves a combination of hardware and software diagnostics. I start by visually inspecting the PLC for any physical damage or loose connections. Then, I use the PLC’s programming software to monitor the status of inputs, outputs, and internal variables. I look for discrepancies between the expected values and the actual values. Logic errors within the PLC’s program are identified by stepping through the code and analyzing the sequence of operations. Using the PLC’s diagnostic tools, I look for any error codes that the PLC might have generated. If the issue is hardware related, I may need to replace faulty components, but this would be preceded by further diagnostics with multimeter and oscilloscope.

For instance, if a conveyor belt stops unexpectedly, I might use the PLC’s programming software to examine the inputs from sensors monitoring the belt’s position and speed. Perhaps a sensor is malfunctioning and reporting an incorrect value, triggering a safety stop. This could be confirmed via direct sensor testing and appropriate replacements.

Q 12. Describe your experience with troubleshooting industrial control systems.

My experience with industrial control systems spans various sectors, including manufacturing, process control, and power generation. I’ve worked on systems involving PLCs, SCADA systems, and various field devices, such as sensors, actuators, and motor drives. My troubleshooting approach in this area emphasizes a holistic perspective, considering the interaction of all system components. I often employ a top-down approach, starting with the overall system behavior and progressively narrowing down to individual components. Effective troubleshooting involves utilizing system documentation, understanding the control logic, and utilizing diagnostic tools provided by the various equipment manufacturers.

A project example includes working with a large chemical plant. They were experiencing intermittent shutdowns in their reactor control system. By meticulously examining data logs from the SCADA system, I noticed a correlation between pressure fluctuations and the shutdowns. Further investigation revealed a faulty pressure sensor, leading to incorrect readings and the automatic safety shutdown sequence being triggered. Replacing the faulty sensor resolved the issue.

Q 13. How do you troubleshoot problems with electrical distribution systems?

Troubleshooting electrical distribution systems involves checking the integrity of the entire system from the main power source to the individual branch circuits. I begin by examining the main switchboard, looking for tripped breakers or unusual readings on ammeters and voltmeters. Then, I systematically work my way down the distribution network, inspecting transformers, panel boards, and individual circuits. Testing tools like multimeters, clamp meters, and insulation testers are crucial in identifying faults. Thermal imaging cameras can be used to detect overheating equipment, indicating potential problems like loose connections or high resistance. I would also check for ground faults using specialized equipment.

Imagine a power outage affecting part of a building. I would begin by checking the main breaker. If it’s fine, I would systematically move down through sub-panels, isolating sections to identify the affected circuit, and finally to the source of the problem: a faulty appliance, overloaded circuit, or wiring issue.

Q 14. What are the common causes of electrical fires, and how do you prevent them?

Common causes of electrical fires include overloaded circuits, faulty wiring, damaged insulation, loose connections, and overheating equipment. Overloaded circuits occur when too many appliances or devices draw more current than the circuit is designed to handle. Faulty wiring, such as damaged or improperly installed conductors, can lead to short circuits. Damaged insulation can expose wires, increasing the risk of short circuits and electric shocks. Loose connections create resistance and generate heat, potentially igniting nearby materials. Overheating components such as motors, transformers, or light fixtures can also cause fires.

Prevention is key. Regular electrical inspections, proper installation of wiring and equipment, adhering to electrical codes, the use of surge protection devices, and ensuring that circuits aren’t overloaded all help reduce the risk. Regular maintenance, like checking connections for tightness and ensuring proper ventilation around equipment, is crucial. Furthermore, using certified electricians for installation and repairs is essential.

Q 15. Explain your experience with maintaining electrical safety in the workplace.

Maintaining electrical safety in the workplace is paramount. My approach is multifaceted and centers around proactive measures, adherence to safety regulations, and thorough training. This includes regular inspections of all electrical equipment and wiring to identify potential hazards before they become problems. I’m experienced in implementing and enforcing lockout/tagout procedures (LOTO) to prevent accidental energization during maintenance or repairs. This ensures that no one can inadvertently switch on power while someone is working on a circuit. I also focus on employee training. This involves educating workers about recognizing electrical hazards, following safe work practices, and reporting any unsafe conditions immediately. For instance, I’ve implemented training programs that cover recognizing frayed wires, understanding the dangers of overloaded circuits, and the correct use of personal protective equipment (PPE) like insulated gloves and safety glasses. Regular safety audits and documentation are crucial, and I’m skilled in conducting these and maintaining comprehensive records to demonstrate ongoing compliance with safety standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle emergency situations involving electrical hazards?

In electrical emergencies, immediate action is critical. My first step is always to ensure my own safety. This means evaluating the situation from a safe distance, assessing the risk, and avoiding direct contact. If someone is experiencing an electrical shock, the top priority is to immediately de-energize the source of the power – either by turning off a breaker or using a non-conductive tool to separate the victim from the electrical source. Never attempt this with bare hands. Calling emergency services (911) is simultaneous and crucial. Once the victim is safe, first aid should be administered if needed. Depending on the severity and cause of the electrical hazard (e.g., fire, downed power lines), evacuation procedures might be necessary. Following the emergency, a thorough investigation is conducted to determine the root cause of the incident, implement corrective actions, and prevent similar occurrences. For example, I was involved in an incident where faulty wiring caused a small fire. We immediately shut off power, evacuated, called emergency services, and later discovered a loose wire connection during the investigation. Following the incident, we updated electrical plans and replaced that section of wiring.

Q 17. Describe your experience with working with different types of electrical equipment.

My experience encompasses a wide range of electrical equipment, including low-voltage systems like those found in office settings (computers, lighting), medium-voltage equipment like industrial machinery and transformers, and high-voltage equipment used in power distribution systems. I’m proficient in working with various types of motors (AC, DC), control systems (PLCs, relays), and power distribution panels. For example, I’ve worked extensively on troubleshooting problems with three-phase motors in manufacturing plants and have experience replacing faulty components in high-voltage switchgear in substations while maintaining the utmost safety precautions. I also have a good understanding of specialized equipment like uninterruptible power supplies (UPS) crucial for critical systems.

Q 18. How do you test and verify the integrity of grounding systems?

Testing grounding systems is vital for ensuring electrical safety. I use a combination of methods to verify their integrity. A ground resistance tester is used to measure the resistance between the grounding electrode and the earth. Low resistance is desirable – ideally below 5 ohms, but the acceptable level depends on local codes and standards. I also visually inspect grounding conductors for damage, corrosion, or loose connections. Continuity testing is another critical step; using a multimeter, I check for a continuous path to earth to ensure there are no breaks in the grounding system. If the ground resistance is high or continuity is interrupted, it points to potential issues that need immediate attention, such as corroded ground rods or faulty wiring in the ground path. For example, during a recent inspection, I identified a high ground resistance at a substation and subsequently discovered that moisture had affected the grounding electrode, increasing resistance. This was rectified by replacing the electrode with a new one, significantly reducing the grounding resistance and enhancing safety.

Q 19. What is your experience with different types of wiring and cabling?

I’m familiar with various types of wiring and cabling, from basic copper conductors in residential settings to specialized cables used in high-voltage and industrial applications. This includes different insulation types (PVC, XLPE, Teflon), conductor sizes (AWG), and shielding methods. I understand the importance of selecting the appropriate type of cable for its intended purpose based on voltage, current, and environmental conditions. I also possess expertise in working with armored cables, fiber optic cables, and control cables. Understanding the differences is crucial for electrical safety; for instance, using the wrong cable type could lead to overheating, insulation failure, or even fire. For example, I’ve experienced situations where using a cable not rated for the high temperature of a motor caused premature failure and necessitated a replacement.

Q 20. How do you identify and replace faulty components in electrical circuits?

Identifying and replacing faulty components involves a systematic approach. It starts with isolating the problem area by using testing equipment like multimeters and clamp meters to check voltage, current, and resistance. Visual inspection often reveals obvious signs of failure such as burnt components, loose connections, or physical damage. Once the faulty component is identified (e.g., a capacitor, resistor, or breaker), it’s essential to de-energize the circuit completely using proper lockout/tagout procedures before attempting any repairs. The faulty component is then replaced with a suitable replacement, paying close attention to specifications and ratings. After the replacement, the circuit is tested again to verify proper function and safety. Detailed documentation of the process is maintained. For instance, I recently replaced a faulty circuit breaker in a panel after identifying a high resistance across its terminals, confirming my initial diagnosis with a multimeter and replacing it with a unit of the same rating to ensure optimal performance.

Q 21. What are your preferred methods for documenting troubleshooting procedures?

My preferred methods for documenting troubleshooting procedures involve using a combination of digital and physical records. Digital documentation includes creating detailed reports with photographs and circuit diagrams using software like Microsoft Word and specialized electrical CAD programs. This allows me to create a clean, easy-to-read report with all the necessary information. I maintain comprehensive logs of all troubleshooting activities, including the date, time, location, equipment involved, the issue encountered, the steps taken to resolve it, and any parts replaced. These logs are stored securely and are accessible for future reference. Sometimes, hand-written notes on site are followed up with a more formal typed report. These methods help maintain a historical record, aiding in future troubleshooting and preventative maintenance. This rigorous record-keeping helps ensure accuracy and accountability. This also assists in analyzing trends and making improvements in preventative maintenance strategies.

Q 22. Describe your experience with preventative maintenance of electrical systems.

Preventative maintenance is crucial for ensuring the longevity and safety of electrical systems. It involves regularly inspecting components for wear and tear, loose connections, and potential hazards before they escalate into major problems. My experience encompasses a wide range of preventative measures, from visually inspecting wiring and connections for damage and corrosion to performing thermal imaging scans to detect overheating components. I’m proficient in testing circuit breakers, grounding systems, and safety devices to ensure they are functioning correctly. We also perform regular cleaning of electrical panels and equipment to prevent dust buildup, which can lead to overheating and fire hazards. In industrial settings, this might involve checking the insulation resistance of motors and cables using a megger. For instance, I once prevented a major outage at a manufacturing plant by discovering a loose connection in a high-voltage switchgear during a routine inspection – a minor repair that averted costly downtime.

- Visual inspections of wiring, connections, and equipment

- Testing of circuit breakers and safety devices

- Thermal imaging scans to detect overheating

- Insulation resistance testing (megger testing)

- Cleaning of electrical panels and equipment

Q 23. How do you troubleshoot intermittent electrical problems?

Troubleshooting intermittent electrical problems requires a systematic and patient approach. These problems are notoriously difficult because they don’t consistently reproduce. My strategy typically begins with careful observation and documentation. I’ll start by precisely documenting when the problem occurs, noting any environmental factors that might be contributing (temperature changes, humidity, vibration), and the exact symptoms experienced. Next, I’ll use diagnostic tools such as multimeters to measure voltage, current, and resistance at various points in the circuit. I might also employ specialized equipment like logic analyzers or oscilloscopes for more complex scenarios involving digital signals or high-frequency components. Intermittent issues are often caused by loose connections, failing components experiencing degradation (such as capacitors drying out or resistors changing value with temperature), or even environmental factors like moisture causing short circuits. I’ll systematically check each connection, testing for continuity and isolating suspect components until the root cause is identified.

For example, I once tracked down an intermittent power failure in a computer network that turned out to be caused by a faulty connector on a server’s power supply. The connector only failed under specific load conditions, making it difficult to diagnose initially. Using a combination of observation, multimeter testing, and careful physical inspection, I was able to isolate the faulty component and restore the network’s stability.

Q 24. Explain your understanding of Ohm’s Law and its application in troubleshooting.

Ohm’s Law is fundamental to electrical troubleshooting. It states that the voltage (V) across a conductor is directly proportional to the current (I) flowing through it, and inversely proportional to its resistance (R). The formula is: V = I * R

This simple equation allows us to calculate any one of the three variables if we know the other two. In troubleshooting, we use it to verify component values, diagnose shorts, and check circuit integrity. For instance, if we measure a significantly lower voltage across a component than expected, considering the known current, Ohm’s Law suggests a higher than normal resistance – potentially indicating a faulty component.

Let’s say a motor isn’t working. If the voltage at the motor terminals is significantly lower than the supply voltage, and the current is low, Ohm’s law tells us there’s a high resistance somewhere. This points towards a problem in the wiring, or a potential problem with the motor itself.

Conversely, an unexpectedly high current draw might indicate a short circuit, which is dangerous and needs immediate attention. Ohm’s Law provides the quantitative framework for understanding these relationships.

Q 25. How do you troubleshoot problems with transformers?

Troubleshooting transformers involves understanding their basic operation and the potential points of failure. Transformers typically fail due to overheating, insulation breakdown, winding shorts, or core saturation. My troubleshooting approach involves a multi-step process:

- Visual Inspection: Checking for physical damage such as cracks, burns, or loose connections.

- Insulation Resistance Test (Megger): Measuring the insulation resistance of the windings to detect insulation breakdown.

- Winding Resistance Test: Measuring the resistance of individual windings to identify short circuits or open circuits.

- Turns Ratio Test: Checking the turns ratio of the transformer to ensure that it matches the specifications.

- No-Load Test: Measuring the no-load current and losses to identify core problems.

- Load Test: Performing a load test under controlled conditions to assess the transformer’s performance under load.

For example, if a transformer is overheating, a visual inspection might reveal loose connections or a damaged winding. A megger test can confirm insulation failure. Further testing could then pinpoint the location of the fault within the transformer’s windings.

Q 26. What is your experience with using specialized tools for electrical troubleshooting?

My experience with specialized tools for electrical troubleshooting is extensive. I’m proficient in using a variety of instruments, including:

- Multimeters: For measuring voltage, current, resistance, and continuity.

- Clamp Meters: For measuring current without disconnecting the circuit.

- Meggers: For measuring insulation resistance.

- Oscilloscope: For analyzing waveforms and identifying signal problems.

- Logic Analyzers: For analyzing digital signals in complex systems.

- Thermal Imagers: For detecting overheating components.

- Loop Testers: For locating faults in wiring circuits.

The choice of tool depends on the specific problem being addressed. A simple circuit might only require a multimeter, while troubleshooting a complex industrial system may involve multiple tools and techniques.

Q 27. How do you prioritize troubleshooting tasks in a busy environment?

Prioritizing troubleshooting tasks in a busy environment is crucial. I use a risk-based approach, prioritizing issues based on their potential impact and urgency. I consider factors such as:

- Safety: Any imminent safety hazards, such as exposed wiring or sparking equipment, take precedence.

- Criticality: Problems impacting essential systems or processes are prioritized over less critical issues.

- Downtime Costs: Problems causing significant downtime or production losses are prioritized.

- Ease of Repair: Quick fixes are often addressed first to free up time for more complex tasks.

I use a ticketing system to track issues, assign priorities, and monitor progress. This helps manage workflow and ensures that all issues are addressed systematically and efficiently. Using a structured approach allows me to work effectively, even under pressure.

Q 28. Describe a challenging electrical problem you solved and how you approached it.

One of the most challenging problems I encountered involved a sudden and complete power failure in a large data center. Initial investigations revealed no obvious causes. The problem was intermittent, occurring only during peak load. The complexity arose because of the sheer scale and redundancy of the system—many potential points of failure existed.

My approach was methodical. First, I systematically checked the main power supply, backup generators, and the uninterruptible power supplies (UPS) ensuring they were operating correctly. After finding no immediate problems, I utilized a network monitoring tool to analyze the power consumption trends, which pointed towards anomalies during high-demand periods. This led me to investigate the power distribution system, which revealed a faulty connection within a heavily loaded busbar. The loose connection caused intermittent arcing, which was not easily detected with standard tools. Using a specialized thermal imaging camera, I discovered the hot spot indicating a failing connection. The repair, while seemingly simple (tightening a connection), was only identified after an exhaustive investigation and application of various diagnostic tools.

This experience highlighted the importance of a thorough investigation, utilizing diverse diagnostic tools, and leveraging system monitoring data when troubleshooting complex systems.

Key Topics to Learn for Troubleshooting Electrical Problems Interview

- Electrical Safety Procedures: Understanding and applying safe work practices, including lockout/tagout procedures, personal protective equipment (PPE) usage, and hazard identification.

- Basic Electrical Theory: Solid grasp of Ohm’s Law, Kirchhoff’s Laws, series and parallel circuits, voltage, current, resistance, and power calculations. Practical application: Calculating voltage drop in a circuit to identify potential problems.

- Circuit Diagrams and Schematics: Reading and interpreting electrical schematics, identifying components, tracing circuits, and understanding their function. Practical application: Diagnosing a faulty circuit using a schematic.

- Testing and Measurement Techniques: Proficiency in using multimeters (both analog and digital) to measure voltage, current, and resistance. Understanding the use of other diagnostic tools like oscilloscopes (where applicable).

- Troubleshooting Methodologies: Employing systematic troubleshooting approaches, including the use of logic, process of elimination, and methodical testing to isolate faults. Practical application: Explaining your step-by-step process for identifying a short circuit.

- Common Electrical Faults: Identifying and diagnosing common problems like short circuits, open circuits, ground faults, blown fuses, and faulty components (switches, outlets, breakers).

- AC/DC Systems: Understanding the differences between AC and DC circuits and their applications. Practical application: Explaining the advantages and disadvantages of each in specific scenarios.

- Wiring and Cabling: Knowledge of different wire types and their applications, proper wiring techniques, and color coding standards. Practical application: Identifying different gauge wires and explaining their appropriate uses.

- Electrical Codes and Standards: Familiarity with relevant electrical codes (NEC – National Electrical Code, for example) and safety standards. Practical application: Explaining compliance with relevant codes in a specific scenario.

Next Steps

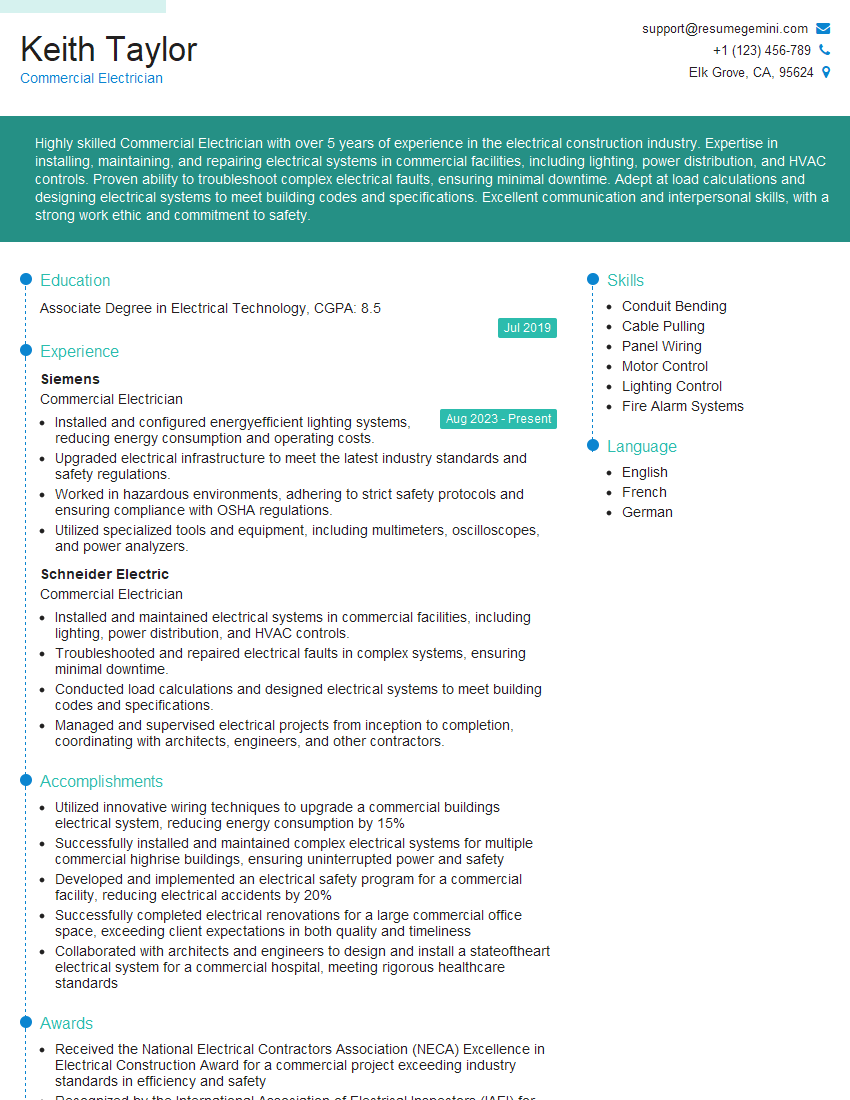

Mastering troubleshooting skills in electrical systems is crucial for career advancement in this in-demand field. A strong understanding of these concepts will significantly enhance your interview performance and open doors to exciting opportunities. To further improve your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to troubleshooting electrical problems are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good