Are you ready to stand out in your next interview? Understanding and preparing for Underglaze Decoration interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Underglaze Decoration Interview

Q 1. Explain the difference between underglaze and overglaze decoration.

The key difference between underglaze and overglaze decoration lies in the timing of application relative to the glazing process. Underglaze decoration is applied before the clear glaze is applied to the bisque-fired pottery. Overglaze, conversely, is applied after the clear glaze has been fired. This difference significantly impacts the final look, durability, and firing process.

Think of it like painting a wall: underglaze is like painting the wall before you put up wallpaper (the glaze), while overglaze is like painting the wallpaper itself. The underglaze becomes fused with the clay body during the high-temperature glaze firing, resulting in a more durable, scratch-resistant decoration that’s part of the pottery’s structure. Overglaze, being on top of the glaze, is more susceptible to scratching and wear.

Q 2. Describe your experience with various underglaze application techniques (e.g., brushwork, stamping, sponging).

My experience encompasses a wide range of underglaze application techniques. Brushwork allows for incredibly detailed and expressive designs, from fine lines to broad washes of color. I’ve used this extensively for floral motifs and landscapes, carefully controlling the pressure and amount of paint for varied effects. Stamping offers a quick and efficient method for repeating patterns or creating textured surfaces. I’ve experimented with various custom-made stamps, as well as commercially available ones, to achieve different aesthetic results.

Sponging is a technique I find particularly useful for creating subtle, blended washes of color or textural effects. The porosity of the sponge allows for a unique and unpredictable application, adding organic character to the piece. For instance, I used sponging to create a beautiful ombré effect on a collection of ceramic bowls, transitioning smoothly from dark to light blue.

Q 3. What are the challenges of achieving consistent color application in underglaze decoration?

Achieving consistent color application in underglaze decoration presents several challenges. The main hurdle is the inherent variability of the bisque ware itself. Porosity, even within a single batch of bisque, can differ, impacting how the underglaze is absorbed and ultimately affecting the final color intensity. The thickness of the application also plays a critical role. A too-thin application might result in faint coloration, while an overly thick application can lead to cracking or uneven drying.

Environmental factors such as humidity can also influence drying and therefore color consistency. Careful control of the application pressure, paint consistency, and even the temperature and humidity of the workspace are crucial for achieving consistent results. This often involves meticulously testing the underglaze on test tiles before applying it to the final piece to get a sense of its behavior.

Q 4. How do you ensure the proper adhesion of underglaze to the ceramic bisque?

Proper adhesion of underglaze to the ceramic bisque depends heavily on the quality of the bisque itself and the surface preparation. The bisque should be clean, free of dust and any other contaminants. A slightly absorbent bisque is generally ideal as it allows for better penetration of the underglaze. Applying a thin layer of underglaze is preferable to reduce the chance of cracking during firing.

Using a high-quality underglaze specifically designed for the type of clay being used is also critical. Some underglazes have additives to improve adhesion. Furthermore, appropriate firing temperature and duration are vital for proper fusing of the underglaze to the clay body. A poorly fired piece will result in poor adhesion and potential flaking of the design.

Q 5. Describe your experience with different types of underglaze paints and their properties.

I’ve worked with a wide variety of underglaze paints, each with unique properties. For example, some underglazes are known for their vibrant, intense colors, while others produce more muted tones. Some have a high level of opacity, completely covering the underlying clay, while others are more translucent, allowing some of the clay’s color to show through. The particle size of the pigments within the underglaze also impacts the final texture and finish.

The binding agents used in the underglaze formulation also influence its properties. Certain underglazes might be more prone to cracking if applied too thickly, while others might be more flexible and less susceptible to this problem. Understanding these nuances is crucial for achieving the desired aesthetic and ensuring the longevity of the decoration.

Q 6. What is the importance of kiln temperature and firing time in underglaze decoration?

Kiln temperature and firing time are absolutely critical in underglaze decoration. The firing process fuses the underglaze to the clay body, permanently bonding the decoration to the ceramic piece. If the temperature is too low, the underglaze might not fuse properly, leading to chipping or flaking. If it’s too high, it could lead to color alteration or even damage the glaze.

The firing time is equally important, as it ensures that the heat penetrates the piece evenly and the underglaze is fully vitrified. Insufficient firing time can result in weak adhesion, while excessive firing time can cause over-firing issues. Precise temperature control and adherence to the manufacturer’s firing schedule for the specific underglaze being used are crucial for achieving predictable and consistent results.

Q 7. How do you troubleshoot problems such as crazing or bleeding of underglaze colors?

Crazing, the appearance of fine cracks in the glaze, is often caused by a mismatch between the glaze and the clay body’s thermal expansion rates. It’s less directly related to the underglaze itself but can be exacerbated by applying the underglaze too thickly. Bleeding, where the underglaze colors run together, often indicates either insufficient drying time before glazing or the use of underglazes that are incompatible.

Troubleshooting involves careful analysis. For crazing, it might require a change in glaze or a thinner application of underglaze. For bleeding, ensuring the underglaze is fully dry before glazing is crucial, and testing for compatibility between different underglaze colors beforehand is essential. Using a higher-quality underglaze with improved binding agents can reduce these issues. Careful record-keeping of materials and processes is vital to identify the source of the problem and avoid repeating it.

Q 8. Explain your experience with color mixing and matching in underglaze decoration.

Color mixing in underglaze decoration is both an art and a science. It’s not simply about combining colors; it’s about understanding how they interact with each other and the ceramic body during firing. My experience spans years of experimentation and meticulous record-keeping. I approach color mixing systematically, starting with a base color and gradually adding small amounts of other colors until I achieve the desired hue and value. I rely heavily on color wheels and understand the principles of primary, secondary, and tertiary colors. For instance, if I need a specific shade of green, I might start with a yellow underglaze and slowly introduce varying amounts of blue until I arrive at the exact green I envision. This is not a one-size-fits-all approach; the specific underglaze brand and the clay body itself affect the final color. Each batch of clay can exhibit slight variations, meaning a color recipe needs tweaking to maintain consistency. This necessitates constant testing and refinement to achieve the precise desired results. I also have a vast library of color samples meticulously documented with their recipes, which are invaluable in maintaining consistent results over time. It’s a process that requires patience, precision, and a keen eye for detail.

Q 9. Describe your process for creating a design transfer for underglaze application.

Creating a design transfer for underglaze application usually involves a few key steps. I start with the initial design, often created digitally using software like Adobe Illustrator. This allows for precise control and easy scaling for different ceramic pieces. Once the design is finalized, I can choose from several transfer methods. One common approach is to print the design onto decal paper using a high-resolution inkjet printer using special underglaze-compatible inks. This decal paper is then carefully applied to the ceramic piece, and after it’s cured properly, I can gently rub away the backing paper, leaving behind the design in underglaze on the ceramic body. Another method involves screen printing, where a silk screen stencil of the design is used to apply underglaze directly onto the ceramic. This method is more suitable for high-volume production and repetitive designs. Regardless of the method, I always prioritize precision and cleanliness during the transfer process to ensure crisp lines and a clean application of the underglaze. Any smudges or imperfections will be visible after firing. Finally, I ensure the underglaze is applied at the correct thickness to avoid cracks or bleeding during the firing process.

Q 10. How do you maintain the quality and consistency of your underglaze work?

Maintaining the quality and consistency of my underglaze work involves meticulous attention to detail at every stage. This starts with sourcing high-quality underglaze paints from reputable suppliers. I carefully record each batch number and manufacturer, allowing traceability in case of any issues. Consistent application techniques are paramount. I use the same pressure and brushstrokes for each piece, avoiding any variation that could impact the outcome. This often involves using guides and templates. Moreover, keeping my brushes clean, storing them properly, and maintaining a consistent working environment helps ensure even application. Regular testing and calibrating color mixes prevents variations in color from batch to batch. I frequently create test pieces using different underglaze batches or firing cycles. This provides a check on color accuracy and consistency. Finally, I meticulously maintain detailed records of the entire process, documenting everything from the clay body used to the exact kiln settings. This documentation allows me to replicate successful results and diagnose and resolve any inconsistencies.

Q 11. What safety precautions do you take when working with underglaze materials?

Safety is my utmost priority when working with underglaze materials. Many underglaze pigments contain heavy metals, such as lead or cadmium, that can be toxic if inhaled or ingested. Therefore, I always work in a well-ventilated area, ideally equipped with a local exhaust ventilation system. I wear a dust mask to prevent inhalation of fine particles. Gloves are also essential to protect my skin from direct contact with the underglaze. Eye protection is critical to prevent splashing or dust getting into my eyes. I always follow the manufacturer’s instructions on safe handling and storage of the materials, and I am extremely careful with cleaning up any spills immediately. Furthermore, I make sure that my workspace is clean and organized to prevent accidents. Proper disposal of waste materials is also crucial; I always follow local regulations and guidelines for disposal of hazardous materials.

Q 12. Describe your experience with different types of brushes and their applications in underglaze decoration.

My brush collection reflects the versatility needed for underglaze work. I utilize a range of brushes, each suited for specific tasks. For fine detail work, I rely on fine sable brushes with a sharp point, allowing for precise lines and intricate designs. For larger areas, or washes of color, I employ broader, softer brushes, such as synthetic or hog bristle brushes. The size and shape of the brush significantly influence the texture and style of the application. For example, a flat brush might be perfect for creating sharp edges, while a round brush is ideal for applying dots or creating smooth blends. The choice of brush also depends on the viscosity of the underglaze; thicker underglazes require brushes with stiffer bristles, whereas thinner underglazes work well with softer brushes. I regularly maintain my brushes to ensure their shape and longevity. Regular cleaning prevents the underglaze from hardening and ruining the bristles.

Q 13. How do you adapt your techniques to different ceramic bodies?

Adapting techniques to different ceramic bodies is crucial for consistent results. Different clays have varying porosities and firing temperatures, which significantly affect how the underglaze interacts with the clay and how it looks once fired. For instance, a highly porous clay might absorb more underglaze, potentially resulting in a less vibrant color. A less porous clay might require a slightly thinner application to prevent cracking. To adapt, I conduct thorough testing on the specific clay body before beginning a project. I would create test tiles with various applications of underglaze, adjusting the thickness, number of coats, and color mixes. I also adjust firing parameters accordingly, such as temperature and firing time, based on the clay’s properties and desired effect. Accurate record-keeping of the results from these tests is essential for future projects using the same clay body. Each clay is different, and experimentation is key to mastering the underglaze techniques on each.

Q 14. What are your preferred methods for cleaning brushes and tools after underglaze application?

Cleaning brushes and tools promptly is critical to maintaining their quality and preventing underglaze build-up. Immediately after using a brush, I rinse it thoroughly under running water. For water-based underglazes, this usually suffices. For more stubborn residues, I use a mild soap specifically designed for artists’ brushes, ensuring it is thoroughly rinsed afterward. It’s very important to reshape the brush bristles after cleaning to maintain their form. I store the brushes standing upright or lying flat to prevent distortion. For other tools like palette knives, I use a damp sponge to remove excess underglaze, followed by a thorough rinse. I then allow the tools to dry completely before storing them. Regular cleaning and proper storage are essential to prolong the lifespan of my tools and ensure high-quality work. Neglecting this aspect can lead to ruined brushes and inconsistencies in underglaze application.

Q 15. Explain your experience with designing and executing intricate underglaze patterns.

Designing and executing intricate underglaze patterns requires a blend of artistic vision and technical skill. My experience spans over 15 years, encompassing a wide range of styles, from delicate floral motifs to complex geometric designs. I begin by sketching concepts, carefully considering the interplay of lines, shapes, and colors. Then, I translate these sketches into the chosen medium – whether it’s underglaze pencils for fine details or underglaze paints for broader washes. I pay close attention to the flow of the design, ensuring a harmonious balance across the piece. For instance, on a recent commission for a series of ceramic bowls, I developed a pattern based on repeating tessellations, each individually hand-painted and then kiln-fired to achieve the desired effect. The precision required for such work demands patience and meticulous attention to detail, which I’ve honed through years of practice.

One particular challenge I tackled involved creating a bespoke pattern for a large ceramic mural. The design incorporated hundreds of miniature birds, each requiring individually applied brushstrokes. I used a combination of underglaze pencils for the detailed bird anatomy and underglaze washes to create a subtle background wash that provided contrast and enhanced the birds’ appearance. The final result was a breathtaking piece that demonstrated the capabilities of underglaze decoration in a large format.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle color variations between batches of underglaze?

Color consistency is paramount in underglaze decoration. Variations between batches are inevitable due to factors like raw material sourcing and kiln firing temperatures. To mitigate this, I employ several strategies. First, I always purchase underglaze materials from reputable suppliers known for their quality control. Second, I meticulously document the specific batch number of each underglaze used in a project. Third, I create test tiles with each new batch to assess color and consistency before applying them to the final pieces. These test tiles are fired alongside the project pieces to ensure uniform results.

If subtle variations still persist, I utilize blending techniques to create a smooth transition between colors. If the variations are too significant, I might adjust the application technique or even use a different underglaze color from the same batch to match the existing ones. For example, in a recent project involving a set of teacups, slight variation in the blue underglaze occurred. Instead of discarding the entire set, I carefully adjusted my brushstrokes to soften the color shifts, resulting in a visually pleasing, if slightly variegated, final product, that had an almost antique appearance.

Q 17. Describe your experience with working under pressure and meeting deadlines.

Working under pressure and meeting deadlines is an integral part of my profession. I’ve developed strong time management and organizational skills to handle this effectively. I thrive in fast-paced environments and prioritize tasks to ensure timely completion. My approach involves detailed planning, breaking down large projects into smaller, manageable steps, and setting realistic deadlines for each. I always maintain open communication with clients, keeping them updated on progress and addressing potential delays proactively. A recent example was a large-scale order of custom-decorated tiles for a restaurant. The deadline was tight, but by efficiently organizing my workflow and delegating certain tasks where appropriate (like prepping the tiles), we successfully completed the project on time and to the client’s complete satisfaction.

Q 18. How do you manage your time effectively when working on multiple projects simultaneously?

Managing multiple projects simultaneously requires careful organization and prioritization. I utilize project management tools to track tasks, deadlines, and resources for each project. I dedicate specific blocks of time to each project based on their urgency and complexity, using a time-blocking technique. This prevents multitasking and enhances focus, leading to higher quality output. I also maintain detailed records of each project’s progress, making it easier to switch between them efficiently. This helps prevent errors and maintain the quality of my work regardless of workload.

Q 19. How do you handle feedback and critiques on your underglaze designs?

I value feedback and critiques as opportunities for growth. I actively seek constructive criticism from clients and colleagues alike. I listen attentively to their comments, analyze their suggestions, and assess their validity based on my own technical understanding and artistic vision. I believe open communication is crucial for creating a piece that aligns perfectly with the client’s needs and expectations. If modifications are required, I make those adjustments thoughtfully and demonstrably, always discussing it with the client.

For example, one client initially requested a bright, bold floral design. After the initial sketch review, they voiced concerns about the intensity of the colors and suggested a more subdued palette. I incorporated their feedback and created a revised design using softer hues. The final result was well received, demonstrating my ability to adapt and collaborate effectively. It’s a rewarding process to see how feedback can transform a design into something even better than the original vision.

Q 20. What is your experience with different kiln types and their effects on underglaze firing?

My experience with different kiln types and their effects on underglaze firing is extensive. I’ve worked with electric kilns, gas kilns, and even some traditional wood-fired kilns. Each kiln type offers unique characteristics that affect the final result. Electric kilns provide consistent and precise temperature control, making them ideal for achieving predictable results. Gas kilns offer rapid firing cycles, but require careful monitoring to avoid uneven heating. Wood-fired kilns create unique atmospheric conditions that can lead to unexpected yet beautiful effects on the underglaze, adding variations in color and texture.

Understanding these nuances is critical for achieving the desired outcome. For example, a specific underglaze might require a slightly lower firing temperature in a gas kiln compared to an electric kiln to prevent discoloration. My experience allows me to adapt my firing schedules and techniques to each kiln type, ensuring optimal results regardless of the equipment used.

Q 21. Explain your familiarity with different types of underglaze pencils and paints.

My familiarity with various underglaze pencils and paints is comprehensive. I frequently use a range of brands and types, each offering different properties. Underglaze pencils are excellent for fine lines and detailed work, offering precision that’s difficult to achieve with paints. I prefer brands known for their smooth application and vibrant color saturation. Underglaze paints, on the other hand, are better suited for larger areas and washes. I select paints based on their opacity, flow, and the desired final effect (matte, glossy, etc.).

For example, when painting delicate floral patterns, I might use a fine-tipped underglaze pencil to outline the petals and then fill in the areas with the appropriate underglaze paints, achieving a blend of detail and smooth color transitions. Different brands have different pigment concentrations, so the same color may appear different depending on the manufacturer. My experience allows me to skillfully blend different brands and types to achieve the desired aesthetic and maintain consistent quality throughout a project.

Q 22. Describe your experience with sgraffito and other carving techniques in underglaze decoration.

Sgraffito, a scratching technique, and other carving methods are integral to underglaze decoration, allowing for the creation of intricate designs and textures. My experience spans a wide range, from delicate linework achieved by carefully scoring the underglaze layer with a variety of tools like needles, scribes, and even sharpened bamboo sticks, to more robust carving with specialized gouges to create deep relief. I’ve utilized these techniques on both functional ware like mugs and bowls, and artistic pieces like sculptural vessels. For example, I once created a series of plates depicting stylized floral patterns, using sgraffito to reveal a contrasting underlayer of color beneath the initial underglaze application. The depth of the carving drastically influences the final look; a shallow scratch will create a subtle effect, while a deep carve will create a more dramatic contrast.

Beyond sgraffito, I’m proficient in various carving techniques including incising (creating lines), gouging (removing larger areas of material), and even employing stamps for repetitive patterns. The choice of technique depends heavily on the desired design and the scale of the project. For fine details, sgraffito is ideal, whereas larger areas might benefit from gouging. I always test my carving techniques on a scrap piece of bisque ware first to ensure the desired effect before applying it to the finished piece.

Q 23. What is your process for maintaining clean and organized workspaces?

Maintaining a clean and organized workspace is paramount for efficiency and preventing mistakes in underglaze decoration. My process is meticulous and multi-layered. I begin by designating specific areas for different tasks: one for mixing underglazes, one for applying them, one for cleanup. Each station has its own dedicated tools and supplies. This prevents cross-contamination and makes it easier to locate everything I need. For example, I use separate palettes for each color to avoid mixing. After each use, tools are immediately cleaned with a damp sponge, then a final rinse. Palettes are scrubbed clean, and larger spills are addressed instantly.

I also utilize a variety of storage solutions, from labeled containers for underglaze powders to drawers for brushes and stencils. Everything has a place, and everything is in its place. My workspace is regularly decluttered; at the end of each workday, I wipe down all surfaces and dispose of waste properly. This systematic approach ensures that I’m always ready to begin working with a clear, organized, and safe workspace.

Q 24. How do you calculate the amount of underglaze required for a given project?

Calculating the amount of underglaze needed depends on several factors: the size and shape of the piece, the desired coverage, the thickness of the application, and the absorption rate of the bisque ware. There isn’t a single formula, but a combination of experience and estimation is crucial. I often start with a test piece, applying underglaze to a similar surface area, and then accurately measure how much was used. This provides a good baseline.

For larger projects, I use a combination of methods. First, I estimate the total surface area of the pieces to be decorated. This might involve calculating the area of individual shapes, and adding them up. Then, I consider the desired coverage – a single thin coat will require significantly less underglaze than multiple layers or a thick application. I factor in the absorption of the bisque itself; porous clay will absorb more underglaze than a denser clay body. Finally, I add a safety margin of 10-15% to account for potential losses during application and clean-up.

Q 25. What are your skills in using design software for underglaze creation?

I’m proficient in several design software packages, including Adobe Illustrator and Photoshop. I use these tools extensively for creating digital designs which are then either printed onto stencils or used as visual guides for hand-painting. For example, I’ll create intricate vector designs in Illustrator, ensuring smooth curves and sharp lines, ideal for precise stencil cutting. Photoshop’s capabilities are useful for color manipulation and experimenting with different color palettes before applying them to the pottery.

My skillset extends beyond creating the initial designs. I can utilize software to modify and refine existing patterns, create seamless repeating motifs, and adjust the size and proportions of elements to fit various pieces of pottery. I can even incorporate digital imagery into my underglaze designs by adjusting contrast and saturation for optimal results on the bisque.

Q 26. Describe your experience with stenciling and masking techniques in underglaze decoration.

Stenciling and masking are essential techniques for achieving clean, crisp lines and patterns in underglaze decoration. My experience involves using various materials, including acetate, vinyl, and even laser-cut stencils depending on the complexity and scale of the design. For intricate designs, I prefer laser-cut stencils for precise lines. For simpler, larger-scale designs, hand-cut stencils or masking tape might be sufficient. The process usually begins by securing the stencil firmly to the bisque using low-tack adhesive. The underglaze is then applied evenly over the stencil using a sponge or brush, taking care to avoid bleeding.

Masking allows for more complex arrangements and negative space designs. I use masking fluid or tape to protect areas from underglaze while painting other portions. For instance, I might mask off areas to create fine white lines against a colored background, or to create intricate shapes within a larger design. After applying the underglaze, the stencils or masking materials are carefully removed, revealing the finished pattern. It’s critical to use low-tack materials to avoid damaging the clay surface.

Q 27. How do you manage color consistency across large production runs?

Maintaining color consistency across large production runs is crucial for maintaining quality and brand identity. My approach is multifaceted. First, I always use pre-weighed underglaze powders to ensure accuracy, mixing them using calibrated scales and consistent water-to-powder ratios. I maintain detailed batch records, including specific powder weights, water volume, and mixing times for each color. This level of documentation is vital for ensuring reproducibility.

Additionally, I use consistent application techniques, whether hand-painting, airbrushing, or stenciling. Regular calibration of equipment like airbrushes ensures even application. I check the consistency of the underglaze throughout the process to avoid color variation caused by settling or thickening. If a color seems off, I always refer back to my batch records to correct the mix and ensure consistent color throughout the production run. I also employ test tiles throughout the process to verify color consistency before applying the underglaze to the final piece.

Q 28. What are some of the common mistakes to avoid in underglaze decoration?

Several common mistakes can compromise the quality of underglaze decoration. One frequent error is using too much water when mixing underglazes, leading to a muddy appearance and uneven application. Another common issue is applying underglaze too thickly, which can lead to cracking or peeling during firing. Conversely, applying it too thinly can result in weak or faded colors. Also, failing to properly clean brushes and tools can lead to color contamination, affecting the integrity of the final design. Inadequate cleaning can affect the next piece’s color and pattern.

Ignoring the bisque ware’s absorption rate can also cause problems. Highly absorbent bisque might soak up underglaze excessively, leading to uneven color or loss of vibrancy. And finally, inconsistent firing temperatures can drastically alter color and result in poor adhesion. These are some of the areas where attention to detail and a careful methodology are key to success.

Key Topics to Learn for Underglaze Decoration Interview

- Underglaze Color Properties: Understanding the characteristics of different underglaze colors, including their opacity, vibrancy, and behavior during firing.

- Application Techniques: Mastering various application methods such as brushing, sponging, stamping, and airbrushing, and understanding their impact on the final product.

- Design & Composition: Developing strong compositional skills to create visually appealing and balanced designs suitable for ceramic surfaces.

- Glaze Interaction: Knowing how underglaze interacts with different glazes, including potential issues like crazing or color shifts during firing.

- Kiln Firing Processes: Understanding the effects of different firing temperatures and schedules on underglaze colors and overall piece durability.

- Troubleshooting & Quality Control: Identifying and resolving common issues such as bleeding, pinholes, or uneven color application.

- Health & Safety: Familiarity with proper handling and disposal of underglaze materials and adherence to safety protocols in a studio environment.

- Production & Efficiency: Understanding efficient workflows for decorating multiple pieces, balancing speed and quality.

- Color Mixing & Matching: Developing skills in mixing underglaze colors to achieve desired shades and effects.

- Design Software Familiarity (if applicable): Demonstrating proficiency in relevant design software for creating digital artwork for transfer onto ceramic pieces.

Next Steps

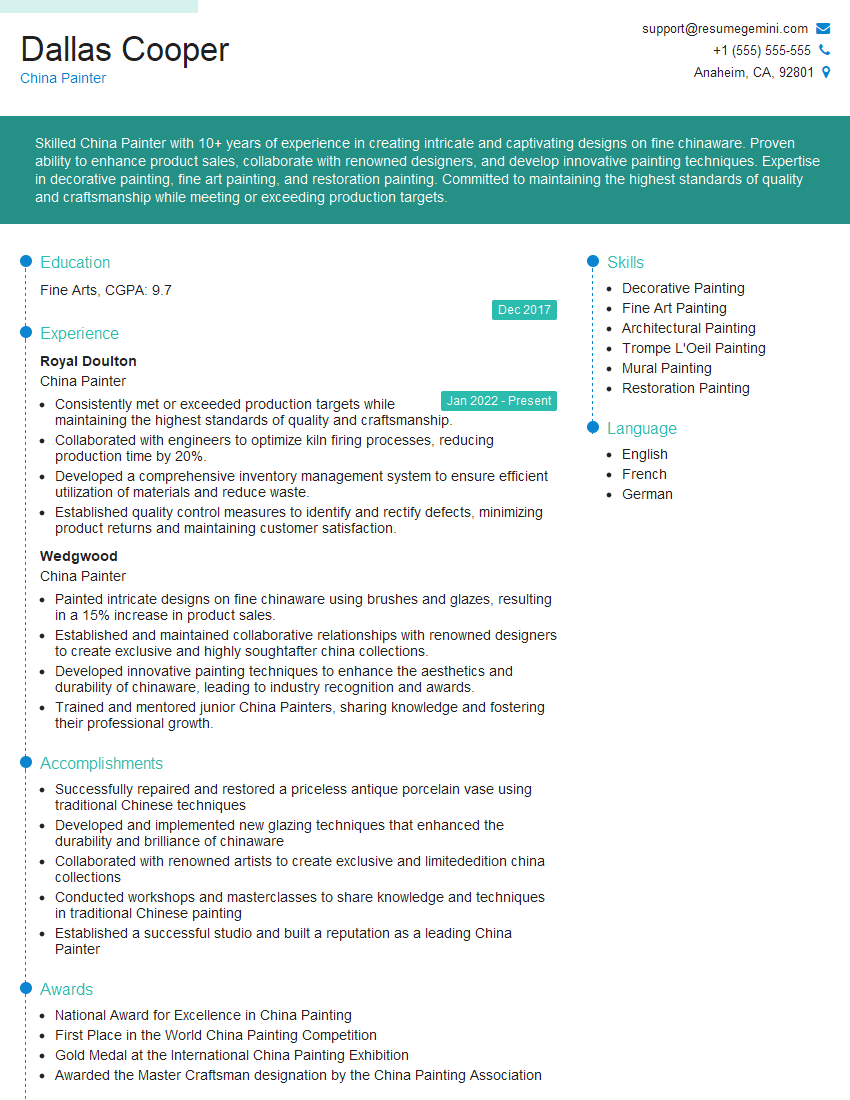

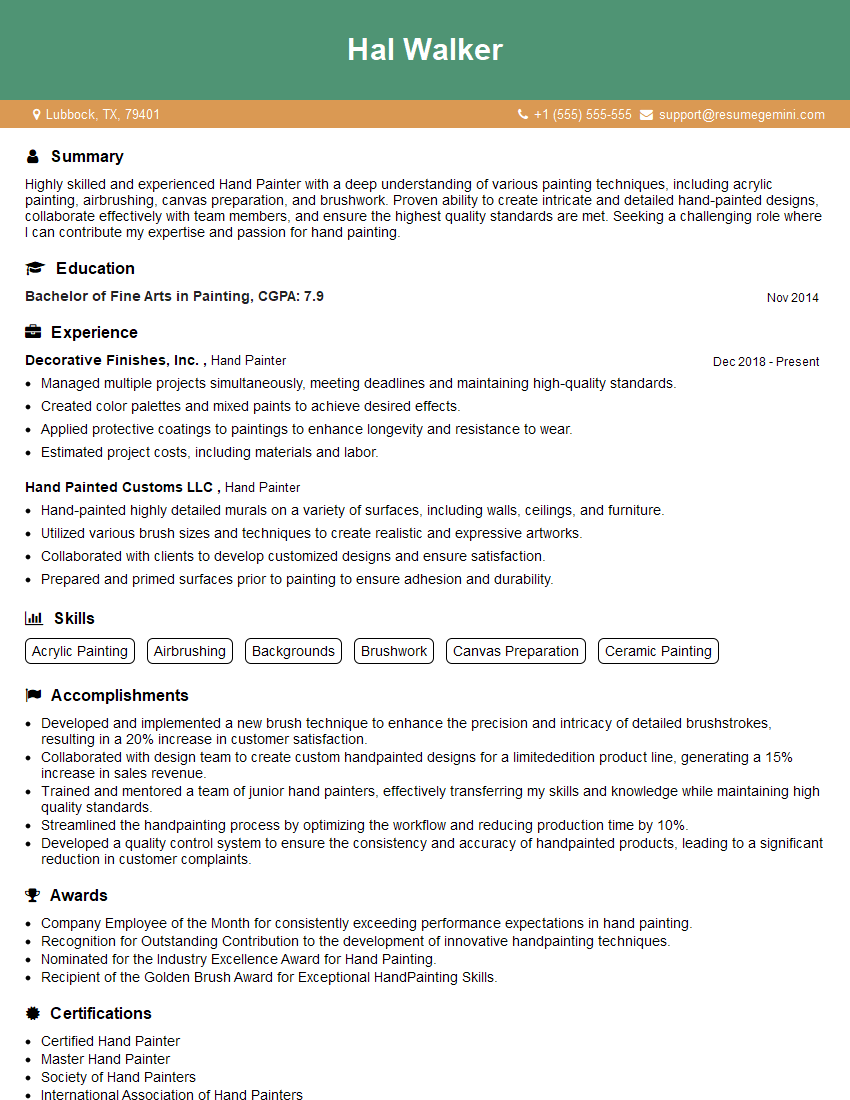

Mastering Underglaze Decoration opens doors to exciting career opportunities in ceramics, pottery studios, and even larger-scale production facilities. To stand out in a competitive job market, a well-crafted resume is essential. An ATS-friendly resume will ensure your qualifications are highlighted effectively for potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume that showcases your skills and experience in Underglaze Decoration. ResumeGemini offers the tools and resources you need to craft a compelling application. Examples of resumes tailored to Underglaze Decoration are available to help guide your creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good