Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Understanding of Baking Processes interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Understanding of Baking Processes Interview

Q 1. Explain the process of making yeast dough, including the role of each ingredient.

Making yeast dough is a fascinating process of controlled fermentation. It involves combining several key ingredients that interact in specific ways to produce a light and airy final product. Let’s break down the role of each ingredient:

- Flour: Provides the structure. The protein in flour, gluten, forms a network when hydrated and kneaded, creating the dough’s framework. Different flour types (bread flour, all-purpose, etc.) have varying protein levels, influencing the strength and elasticity of the dough.

- Yeast: The leavening agent. Yeast is a living organism that consumes sugars in the dough, producing carbon dioxide gas as a byproduct. This gas creates air pockets, making the dough rise. We’ll discuss the differences between fresh and dry yeast later.

- Water: Hydrates the flour, allowing gluten development and activating the yeast. The temperature of the water is crucial; too hot will kill the yeast, too cold will slow down fermentation.

- Salt: Controls yeast activity, adds flavor, and strengthens the gluten structure. It prevents the dough from rising too quickly and unevenly.

- Sugar (Optional, but often used): Provides food for the yeast, accelerating fermentation and contributing to browning and flavor development. Too much sugar can inhibit yeast activity.

- Fat (Optional, such as butter or oil): Adds flavor, tenderness, and richness to the dough. It also helps prevent the gluten from becoming too strong, resulting in a softer crumb.

The process typically involves mixing the ingredients, kneading the dough to develop gluten, allowing it to rise (bulk fermentation), shaping the dough, and allowing it to rise again (proofing) before baking.

Q 2. Describe the different types of oven spring and how they are achieved.

Oven spring refers to the final rise a dough undergoes in the oven’s heat. There are two main types:

- Immediate Oven Spring: This is the rapid expansion of the dough in the first few minutes of baking. It’s driven by the expansion of gases (carbon dioxide and steam) already trapped within the dough structure. Think of it like a balloon suddenly placed in a hot room.

- Delayed Oven Spring: This is a slower rise that occurs later in the baking process. It’s mainly caused by the steam generated from the evaporation of water within the dough. This steam pushes the dough’s structure upwards, contributing to the final height and volume.

Achieving optimal oven spring involves careful control of factors like fermentation time, dough hydration, and oven temperature. Under-fermented dough might have less oven spring, while over-fermented dough might collapse.

Q 3. What are the key differences between using fresh and dry yeast?

Fresh and dry yeast are both types of Saccharomyces cerevisiae, but they differ in their form, activation, and storage:

- Fresh Yeast (Cake Yeast): Comes in a compressed block. It has a higher moisture content and is more perishable, needing refrigeration. It typically activates quickly in warm water with a little sugar. It usually gives a slightly more intense flavor than dry yeast.

- Dry Yeast (Active Dry and Instant): Comes in granular form. It has a much lower moisture content and a longer shelf life. Active dry yeast requires rehydration in warm water before use; Instant yeast can be added directly to dry ingredients.

The choice between fresh and dry yeast often comes down to availability, convenience, and recipe requirements. Some recipes specifically call for one type over the other because of the different flavors and activation rates.

Q 4. How do you troubleshoot a cake that has sunk in the center?

A cake that has sunk in the center usually indicates a problem with either insufficient structure or uneven baking. Here’s a troubleshooting guide:

- Insufficient Levening: Ensure you used the correct amount of leavening agent (baking powder or baking soda). Old leavening can lose its potency.

- Overmixing: Overmixing develops too much gluten, resulting in a tough cake that can sink. Mix only until the ingredients are just combined.

- Oven Temperature: Too low an oven temperature can result in a cake that doesn’t rise properly. Use an oven thermometer to verify your oven’s accuracy.

- Uneven Baking: Rotate the cake halfway through baking to ensure even heating.

- Incorrect Ingredients: Using the wrong type or amount of fat (butter, oil), or using too much liquid can lead to a cake that sinks. Always carefully measure ingredients.

If you suspect a particular issue, try adjusting that aspect in your next attempt. Keeping a baking journal is very helpful to track changes.

Q 5. Explain the Maillard reaction and its importance in baking.

The Maillard reaction is a chemical reaction between amino acids and reducing sugars that occurs when food is heated. It’s responsible for the characteristic browning and complex flavors developed in baked goods (and many other cooked foods).

Think of the beautiful golden-brown crust of a loaf of bread or the rich color of a perfectly baked cookie. That’s the Maillard reaction in action! It creates hundreds of different flavor compounds, contributing significantly to the overall aroma and taste profile. The reaction is highly temperature-dependent; it typically begins around 140°C (284°F) and intensifies at higher temperatures. Factors like moisture content and pH also influence its rate and extent.

Q 6. What are the effects of gluten development on bread texture?

Gluten development is crucial for bread texture. Gluten, a protein complex formed from glutenin and gliadin, creates the dough’s elasticity and strength. The extent of gluten development directly impacts the final bread’s characteristics:

- Well-developed gluten: Results in a strong, elastic dough that can trap gases during fermentation, leading to a high loaf volume with a chewy, airy crumb (inside texture). The crust will be more crisp.

- Under-developed gluten: Leads to a weak, gummy dough that doesn’t hold its shape well, resulting in a low-volume loaf with a dense, compact crumb. The crust may be slightly softer.

- Over-developed gluten: Can produce a tough, hard, and less flavorful bread. The dough becomes overly strong and less extensible, making it difficult to shape.

Techniques like kneading (by hand or machine) control the level of gluten development.

Q 7. How does fermentation affect the flavor and texture of bread?

Fermentation, the process where yeast consumes sugars and produces carbon dioxide and other byproducts, profoundly affects bread’s flavor and texture:

- Flavor: Fermentation generates various organic acids, alcohols, and esters that contribute complex flavors to the bread. These flavors range from subtly sweet and fruity to tangy and nutty, depending on the type of yeast, fermentation time, and other ingredients.

- Texture: The carbon dioxide produced during fermentation creates the air pockets within the bread’s crumb structure, resulting in a lighter and airier texture. The longer the fermentation, the more developed the flavors and the softer the texture, though there is a balance to be achieved to prevent over-fermentation.

Different fermentation techniques (bulk fermentation, proofing) impact the final product. A longer, slower fermentation generally enhances the flavors and improves the bread’s digestibility and overall quality. It allows for the production of more complex flavors and creates a softer crumb.

Q 8. Describe the proper techniques for kneading different types of dough.

Kneading develops gluten, the protein network responsible for the structure and texture of bread. The technique varies depending on the dough’s hydration (water content) and desired outcome.

- Lean Doughs (low hydration, e.g., bread dough): Requires a vigorous kneading action. Imagine pushing, folding, and turning the dough, repeating the process for 8-10 minutes until it becomes smooth and elastic. This develops strong gluten strands for a chewy crumb.

- Rich Doughs (high hydration, e.g., brioche dough): Needs a gentler approach. Use a ‘slap and fold’ method, gently stretching and folding the dough, incorporating air without overworking it. Overkneading will tear the gluten structure, leading to a tough crumb. This results in a softer, airier texture.

- No-Knead Doughs: Relies on slow fermentation to develop gluten naturally, minimizing the need for direct kneading. This requires longer fermentation times, but results in a unique, open crumb structure.

Think of kneading as a workout for the dough. Lean doughs need a tough workout, while richer doughs prefer a more gentle approach.

Q 9. Explain the importance of proper ingredient measurements in baking.

Precise ingredient measurements are paramount in baking because baking is a science, relying on specific ratios of ingredients to achieve desired outcomes. Unlike cooking, where some adjustments are permissible, variations in baking can significantly impact the final product.

- Flour: Different types of flour have varying protein content, which directly impacts gluten development and the final product’s texture. Inaccurate flour measurement affects gluten formation and creates inconsistent rise.

- Liquids (water, milk, eggs): Liquid content significantly affects dough’s hydration and gluten development. Too much liquid yields a sticky, unworkable dough; too little results in a dry, crumbly product.

- Leavening Agents (baking soda, baking powder, yeast): These control the rise of the baked goods. Incorrect measurements can lead to a flat, dense product (under-leavened) or an overly airy, crumbly product (over-leavened).

- Sugar and Fats: Sugar and fat affect moisture, texture, and flavor. Incorrect amounts can lead to a dry cake, tough cookies, or a bland taste.

Imagine building a house – you can’t just roughly estimate the amount of bricks or cement. Similarly, precise measurements ensure the perfect ‘structure’ in your baked goods.

Q 10. How do you ensure consistent baking results across multiple batches?

Consistency in baking across batches is achieved through careful planning, precise measurement, and controlled process parameters.

- Standardized Recipes: Use precisely written recipes with specific weights and measures rather than volumetric measurements (cups).

- Ingredient Quality: Source high-quality, consistent ingredients.

- Environmental Control: Maintain a consistent baking environment—oven temperature, humidity, and altitude can all influence baking results.

- Equipment Calibration: Regularly calibrate ovens and scales to ensure accurate measurements.

- Process Documentation: Keeping detailed notes on each batch, including ingredient details and process parameters, helps in troubleshooting and identifying areas for improvement.

Think of it like a scientific experiment: reproducibility is key. Standard operating procedures help in replicating results.

Q 11. What are the signs of over- and under-mixing dough?

Over- and under-mixing are easily identifiable through observing the dough’s characteristics.

- Under-mixed Dough: Appears lumpy and uneven in texture. Gluten development is insufficient, resulting in a tough and dense final product. For example, bread will have a poor rise and a gummy texture.

- Over-mixed Dough: Feels excessively smooth and elastic and can be very difficult to handle. The gluten network has been over-developed and can shrink during baking, leading to a tough and chewy final product. For example, bread will have a dense, tough texture and an uneven crumb.

Imagine kneading bread dough: under-kneaded dough is like an uncooked piece of meat – stiff and tough, while over-kneaded dough is like chewing a really tough piece of meat – too much work to break apart.

Q 12. Describe the different methods of proofing dough.

Proofing, or fermentation, is crucial for developing flavor and texture in yeast-leavened dough. There are several methods:

- Bulk Fermentation: After kneading, the dough is placed in a lightly oiled bowl, covered, and allowed to rise in a warm place (ideally 75-80°F) until doubled in size. This allows for significant gluten development and flavor enhancement.

- Cold Proofing: The dough is refrigerated after bulk fermentation, slowing down the yeast activity and extending fermentation. This gives a more nuanced flavor and improved texture.

- Proofing in Pans: After shaping, the dough is placed in pans and allowed to proof again before baking, allowing for a final rise and giving the baked good its final volume and shape.

Think of proofing as giving the yeast time to do its work, creating a light and airy texture.

Q 13. How do you prevent a cake from drying out?

Preventing cake from drying out involves managing moisture content during baking and storage.

- Proper Baking Time and Temperature: Overbaking is a common cause of dryness. Use a toothpick test to check for doneness; it should come out clean.

- Appropriate Fat and Liquid Ratios: Sufficient fat and liquid contribute to moisture retention. The right balance keeps the cake moist and prevents it from becoming dry.

- Proper Storage: Store cakes in airtight containers at room temperature or in the refrigerator. A slice of cake stored properly can retain moisture better for longer periods.

- Cake Glaze or Frosting: A layer of frosting helps to seal in moisture and adds additional moisture to the cake

Imagine a sponge: keeping it moist is key to its structure. Similarly, moisture is crucial for keeping a cake moist and tender.

Q 14. What are the different types of fats used in baking and their effects on the final product?

Different fats have unique properties that affect the final product’s texture, flavor, and moisture.

- Butter: Adds richness, flavor, and tenderness. It contributes to a moist crumb and a golden brown crust.

- Shortening: Produces a tender, flaky texture, especially in pastries. It has a higher melting point than butter and can be used for items needing a longer shelf-life

- Oils (vegetable, canola, olive): Create a moist and tender crumb. The type of oil can add flavor nuances. Olive oil, for instance, provides a distinct taste.

- Margarine: A butter substitute, providing a similar outcome, but the flavor can sometimes be slightly different from butter.

Each fat acts like a different ingredient in a recipe, each adding its own unique properties and affecting the overall outcome in terms of taste, texture and quality.

Q 15. Explain the importance of temperature control in baking.

Temperature control is paramount in baking because it directly impacts the chemical reactions that occur during the baking process. Think of it like this: baking is a carefully orchestrated dance between heat and ingredients. Too little heat, and your goods won’t cook through; too much heat, and you’ll end up with burnt offerings. Different ingredients react differently to heat. For instance, gluten development in bread requires a specific temperature range, while delicate pastries need gentle heat to avoid over-browning. Precise temperature control ensures proper gluten development, even browning, and the desired texture and rise in baked goods. An oven thermometer is crucial for verifying your oven’s accuracy, as ovens often vary from their stated temperature.

For example, a slightly lower temperature might be needed for cakes to prevent them from becoming dry and tough while ensuring even cooking throughout. Conversely, a higher temperature is useful for creating a crisp crust on bread or cookies.

Career Expert Tips:

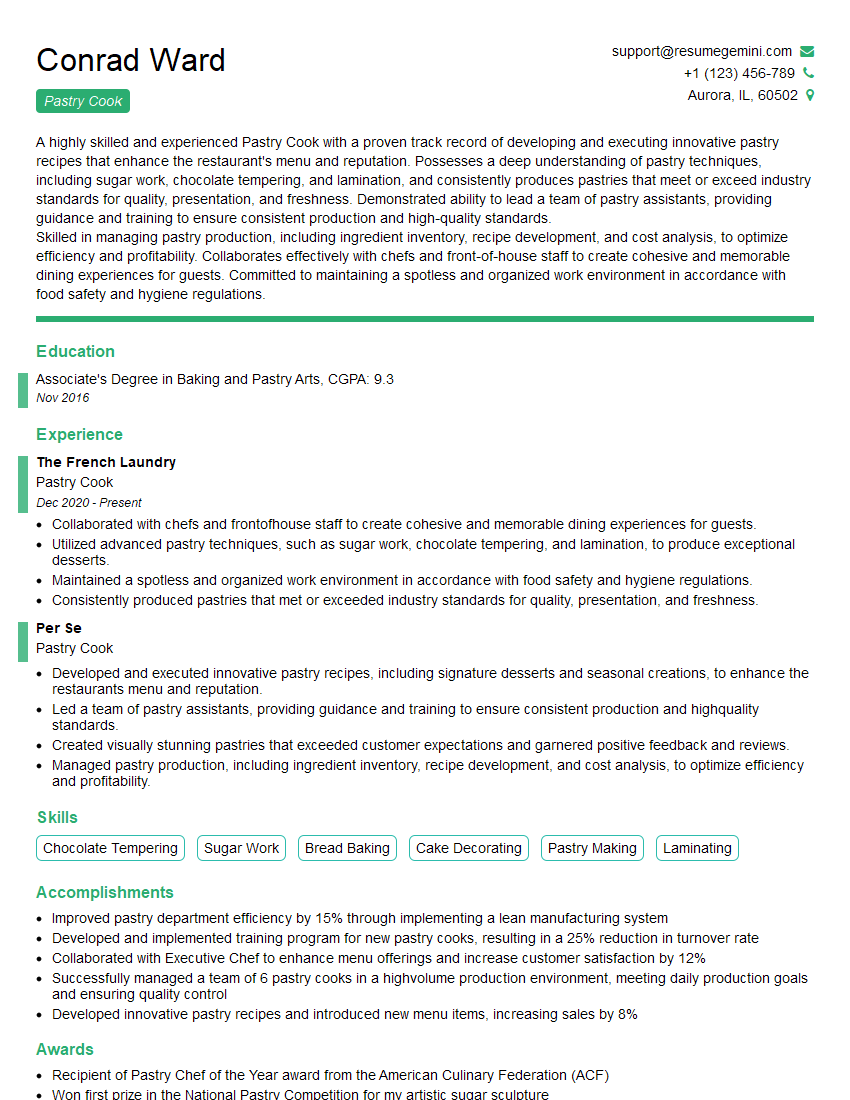

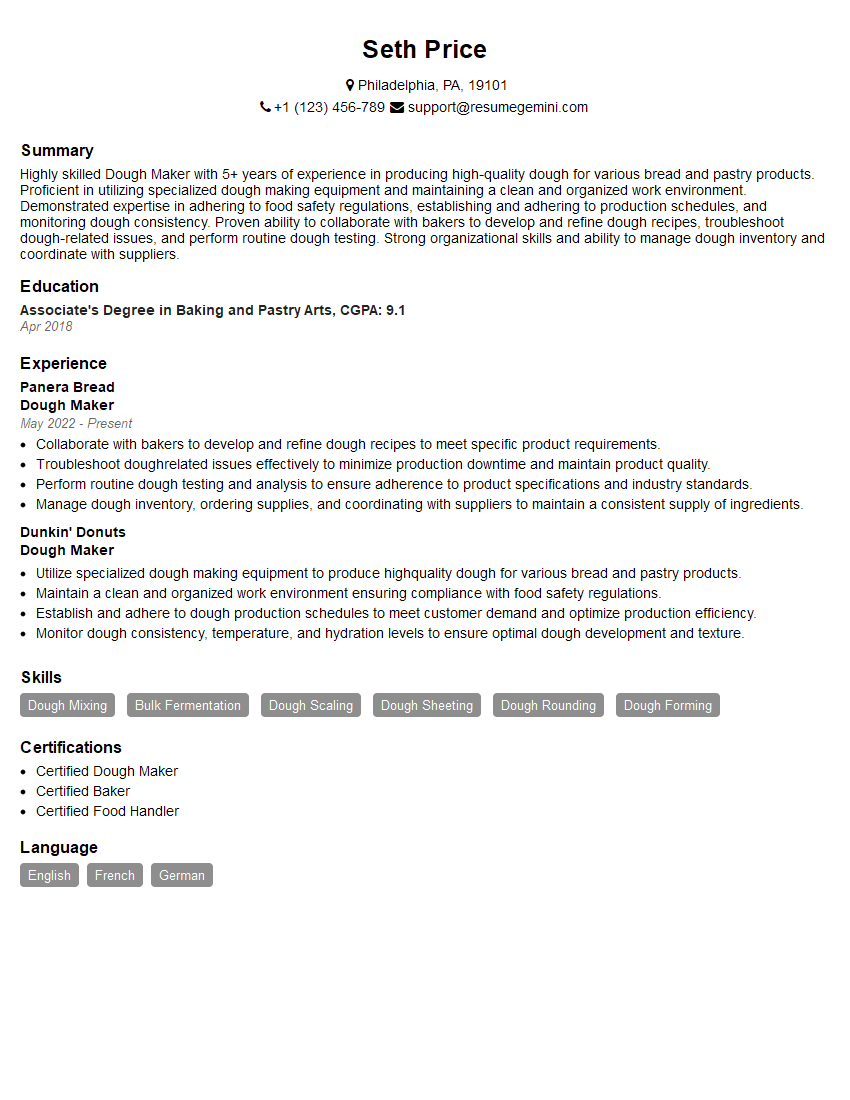

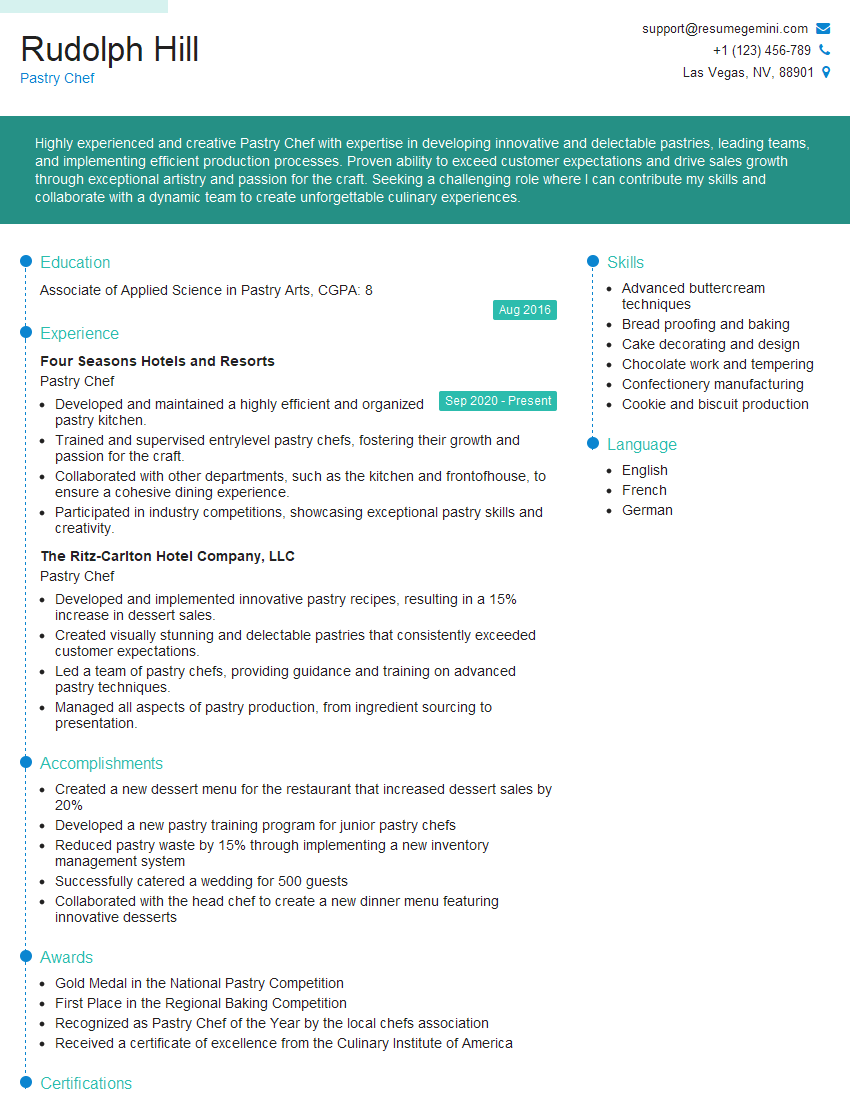

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor the baking process to ensure proper doneness?

Monitoring the baking process requires a multi-sensory approach. Visual cues are key: observe the rise, color, and texture changes. For instance, a cake is done when it springs back lightly when touched in the center, and a bread loaf should have a deep golden-brown crust. A reliable oven thermometer ensures the temperature remains consistent. However, visual cues are not always sufficient. The use of a digital thermometer is recommended to measure the internal temperature. Insert it into the thickest part of the baked good to ensure it has reached the appropriate temperature according to the recipe.

Beyond visual inspection, I also rely on the aroma. A bread’s characteristic aroma signifies its progress. The timing specified in the recipe is just a guide; it’s important to adjust according to visual and olfactory cues and internal temperature. This experience comes from years of baking and adapting to different ingredients and oven types.

Q 17. What are some common baking errors and how do you correct them?

Common baking errors stem from issues with ingredients, technique, and oven control. For instance, using old baking powder can result in flat cakes due to lost leavening power. Overmixing batter leads to tough cookies and cakes, while undermixing will result in uneven texture. Inconsistent oven temperatures produce unevenly baked products. Incorrect measurements of ingredients can also affect the final result.

- Solution: Always use fresh ingredients. Follow the recipe instructions carefully regarding mixing techniques and times. Utilize an oven thermometer to ensure accurate temperature and preheat adequately. Use a kitchen scale for precise ingredient measurements.

For example, if a cake is underbaked, it’ll be gummy in the center. The solution? Bake it a little longer, checking with a toothpick or thermometer. Conversely, if a cake is overbaked, it will be dry and crumbly. Here, the solution is to reduce the baking temperature or time.

Q 18. How do you adapt recipes for different oven types and sizes?

Adapting recipes for different oven types and sizes requires understanding how heat distributes. Convection ovens, for instance, cook faster and more evenly than conventional ovens. A recipe designed for a conventional oven will require a lower temperature and potentially shorter baking time in a convection oven. Likewise, the size of your baking pan influences baking time; a larger pan requires a longer baking time because the batter is spread thinner.

I usually begin by decreasing the temperature by 25 degrees Fahrenheit (approximately 15 degrees Celsius) for convection ovens. I then check for doneness earlier than the original recipe indicated, making adjustments as needed to ensure a perfectly baked product. It often requires some trial and error to find the perfect adjustment for a particular oven and pan size. I maintain detailed notes on all adjustments to refine my techniques.

Q 19. Describe your experience with different baking equipment.

My experience with baking equipment is extensive, ranging from standard kitchen appliances to specialized tools. I’m proficient with various ovens (conventional, convection, and even a deck oven), stand mixers, hand mixers, and various types of measuring tools. My experience with a deck oven, for instance, enabled me to understand heat distribution in a professional setting, providing insights that apply to all ovens. The ability to use a stand mixer with precision is vital for achieving the correct consistency in batters and doughs. My expertise in this area has helped me improve overall baking efficiency and product quality.

I also have experience with specialized tools like pastry bags, various types of pans (including silicone and non-stick), and temperature probes, all of which are crucial for achieving high-quality results in a variety of baking applications.

Q 20. Explain your experience with various baking techniques (e.g., lamination, creaming).

I’m well-versed in various baking techniques. Creaming, for instance, involves incorporating fat and sugar until light and fluffy, creating air pockets that contribute to a tender crumb in cakes and cookies. This process requires a deep understanding of the interaction between fat and sugar. Lamination, a technique used in puff pastry, involves repeatedly folding and rolling dough to create layers of butter and dough, which results in a flaky texture when baked. This demands precision and patience.

Other techniques I’m proficient in include the muffin method (combining wet and dry ingredients separately before gently mixing), the creaming method (described above), and the biscuit method (using cold ingredients to create a flaky texture). My experience with these techniques allows me to adapt recipes and create innovative baked goods.

Q 21. How do you maintain food safety and hygiene standards in a baking environment?

Maintaining food safety and hygiene is paramount in baking. I strictly adhere to principles of HACCP (Hazard Analysis and Critical Control Points) to minimize risks of contamination. This involves practices such as hand washing, proper food storage, and using clean equipment and utensils. I regularly sanitize my work surfaces and equipment, ensuring that all ingredients are stored at correct temperatures and handled with care.

Furthermore, I’m aware of cross-contamination risks and implement measures to prevent this, such as using separate cutting boards and utensils for raw and cooked ingredients. My commitment to food safety and hygiene ensures that I produce high-quality baked goods that are safe for consumption. This extends to practicing First-In, First-Out (FIFO) inventory management to ensure ingredient freshness and minimize waste.

Q 22. How do you manage inventory and order supplies in a bakery?

Inventory management in a bakery is crucial for smooth operations and minimizing waste. It involves a multi-step process beginning with forecasting demand. I utilize historical sales data, upcoming events (like holidays or local festivals), and seasonal trends to predict ingredient needs. This forecast informs my ordering schedule. I employ a first-in, first-out (FIFO) system for perishable goods like fresh fruit and dairy, ensuring older items are used before they expire. We maintain a detailed inventory list, updated regularly, using either a spreadsheet or a dedicated inventory management software. This allows us to track stock levels, identify low-stock items, and place timely orders with our suppliers. Regular inventory checks help identify spoilage and prevent losses. For example, if we notice a particular item is consistently expiring before we can use it, we adjust our order quantity downwards or switch suppliers to find a fresher product.

For ordering supplies, I establish strong relationships with reliable suppliers, negotiating prices and securing consistent delivery schedules. I compare prices and quality from different suppliers to optimize cost-effectiveness. Creating a standardized purchase order template ensures consistent communication and avoids errors. Regular communication with suppliers regarding lead times and potential shortages helps prevent delays and stockouts. Critical supplies, like yeast or specific types of flour, are often ordered with extra buffer stock to account for unexpected demand or supply chain issues. This proactive approach ensures we always have the necessary ingredients to meet customer demands.

Q 23. Describe your experience with different types of flour and their properties.

My experience encompasses a wide range of flours, each with unique characteristics influencing baking outcomes. Bread flour, with its high protein content (typically 12-14%), is ideal for creating strong gluten development, resulting in chewy, textured breads. Cake flour, on the other hand, has a lower protein content (around 8%), yielding tender, delicate cakes. All-purpose flour falls somewhere in between, suitable for a variety of applications but not always ideal for specialized needs. I’ve also worked extensively with whole wheat flour, which imparts a nutty flavor and denser texture due to the presence of bran and germ. Pastry flour, lower in protein than all-purpose, creates flaky pastries. Understanding the protein content is key; higher protein means more gluten development, while lower protein results in a more tender product. I’ve learned to adjust recipes based on the specific flour I’m using, sometimes adding vital wheat gluten to boost protein in all-purpose flour for bread-making or using techniques like the creaming method with cake flour to achieve maximum tenderness.

Furthermore, I am familiar with specialty flours like rye, which lends a distinct flavor and creates dense, dark breads. Understanding how each flour’s properties influence gluten development, texture, and flavor is fundamental to creating high-quality baked goods.

Q 24. How do you ensure consistent quality control throughout the baking process?

Consistent quality control is paramount in baking. It starts with meticulous ingredient measurement using calibrated scales and measuring cups. Following standardized recipes precisely is crucial, avoiding deviations that could impact the final product. Maintaining consistent baking temperatures is achieved through the use of accurate thermometers and regular oven calibration. We monitor baking time carefully, making adjustments as needed based on visual cues and internal temperatures (using a thermometer). Each baked item undergoes a quality check before packaging, examining for proper rise, texture, color, and overall appearance. Regular equipment maintenance is also vital; faulty ovens or mixers can directly affect product quality.

We implement a system of taste testing and feedback loops. Each batch is evaluated to ensure consistency in flavor and texture. Employee training on quality control standards is crucial; every baker needs to understand and apply these standards consistently. We keep detailed records of each batch, including ingredients, baking times, and temperature, allowing us to track performance and identify areas for improvement. Addressing inconsistencies promptly is key to maintaining high standards. For instance, if a batch of cookies is consistently coming out too soft, we carefully analyze factors like oven temperature, baking time, and ingredient proportions before making necessary adjustments to the recipe or baking process.

Q 25. How do you handle stressful situations during peak baking hours?

Peak baking hours can be incredibly demanding, but effective strategies are crucial to manage stress. Prioritization is key; I focus on tasks with the tightest deadlines first. A well-organized workspace and efficient workflow are essential; maintaining a clean and organized environment reduces stress and improves efficiency. I involve my team proactively, assigning tasks effectively and ensuring clear communication to avoid confusion during rush periods. Maintaining a positive attitude and fostering a supportive team environment is essential – teamwork under pressure is invaluable. I also anticipate peak demands; forecasting helps us plan staffing levels and prepare sufficient ingredients in advance. Having contingency plans in place for unexpected issues is crucial, such as equipment malfunctions or unexpected rush orders. Taking short breaks to recharge is also important; a few minutes away from the intense activity can significantly improve focus and prevent burnout. Finally, practicing mindfulness and stress-reduction techniques outside of work contributes to better overall management.

Q 26. What is your experience with different types of sugar and their effects on baking?

Different sugars contribute unique properties to baked goods. Granulated sugar, the most common, provides sweetness and structure. Brown sugar, containing molasses, adds moisture and a caramel-like flavor. Powdered sugar, finely ground, is ideal for icings and dusting, offering a smooth texture. In baking, sugar’s role is multifaceted; it affects browning (through the Maillard reaction), texture (by influencing gluten development and moisture content), and shelf life. For example, using brown sugar in a cake results in a moister crumb, while granulated sugar might be preferred for a crisp cookie. I also utilize corn syrup, providing moisture and preventing crystallization in candies. Invert sugar, a mixture of glucose and fructose, inhibits crystallization and produces a smoother texture in confections. Understanding the functionalities of different sugars is crucial; choosing the appropriate type depends on the desired outcome – a moist cake versus a crisp cookie, for instance, will require different types of sugar.

Q 27. Explain your understanding of different baking formulas and scaling recipes.

Baking formulas are essentially mathematical representations of recipes, expressing ingredient proportions as percentages of the total flour weight. This allows for easy scaling of recipes to different batch sizes. Understanding these formulas is crucial for consistent results regardless of the desired quantity. For example, a basic formula might be: 100% flour, 60% water, 20% fat, 10% sugar, etc. These percentages remain constant even if we double or halve the recipe. Scaling a recipe is straightforward using this method; simply multiply all percentages by the desired scaling factor (e.g., multiply all ingredients by 2 to double the recipe).

I’m proficient in converting weight-based recipes (which are more accurate) to volume-based recipes and vice versa, though I prefer weight measurements for precision. I understand how changes in ingredient ratios affect the final product, which allows me to make informed adjustments based on desired texture or flavor. For example, increasing the fat percentage in a cookie recipe results in a more tender texture, while decreasing water in a bread recipe can lead to a firmer crumb. My knowledge of these principles ensures consistent and predictable results across different batch sizes.

Q 28. Describe your experience with decorating and presenting baked goods.

Decorating and presenting baked goods is an essential part of the baking process; it enhances the visual appeal and elevates the customer experience. My expertise includes a range of techniques, from simple icing and dusting to more elaborate piping, fondant work, and ganache creations. I’m proficient in using various tools, such as piping bags, spatulas, and decorating tips, to achieve different designs and textures. I’ve experience with creating beautiful cakes, cupcakes, cookies, and other pastries. I consider the overall aesthetic, including color palettes, texture contrasts, and the overall theme or occasion when designing decorations. For instance, I’ve crafted intricately decorated wedding cakes using fondant and piped buttercream designs, as well as created simple yet elegant designs for everyday pastries.

Proper presentation also involves careful packaging, maintaining product integrity and enhancing visual appeal. Using appropriate containers and packaging materials ensures that the finished products reach the customer in pristine condition. Attention to detail in every aspect, from the smallest detail in the decoration to the choice of packaging, results in a superior customer experience and showcases the quality of the baked goods.

Key Topics to Learn for Understanding of Baking Processes Interview

- Flour Properties & Functionality: Understanding different types of flour (e.g., bread flour, cake flour), their protein content, and how it impacts gluten development and final product texture.

- Leavening Agents: Mastering the roles of yeast, baking powder, and baking soda; knowing how to select the appropriate leavening agent for different recipes and troubleshooting issues related to insufficient or excessive leavening.

- Mixing Methods: Familiarizing yourself with various mixing techniques (e.g., creaming, kneading, folding) and their impact on dough and batter structure, gluten development, and final product characteristics.

- Baking Temperatures & Times: Understanding the critical role of oven temperature and baking time in achieving optimal texture, color, and flavor. Being able to explain how these factors vary depending on the recipe and the type of oven used.

- Fermentation Processes: Knowing the science behind yeast fermentation, its impact on flavor development, and troubleshooting common fermentation problems (e.g., slow rise, uneven rise).

- Understanding Gluten Development: Explain the process of gluten formation, its importance in bread making, and how to control gluten development for different desired textures.

- Troubleshooting Baking Issues: Demonstrating your ability to diagnose and solve common baking problems (e.g., tough bread, flat cakes, uneven browning) by understanding the underlying causes.

- Safety and Sanitation in a Baking Environment: Highlighting your knowledge of proper food handling, hygiene practices, and safety procedures in a professional baking setting.

- Baking Equipment and Tools: Demonstrating familiarity with various baking equipment (ovens, mixers, etc.) and tools, and their proper usage and maintenance.

- Recipe Scaling and Adaptation: Showcasing your ability to adjust recipes for different batch sizes and understanding the impact of ingredient changes on the final product.

Next Steps

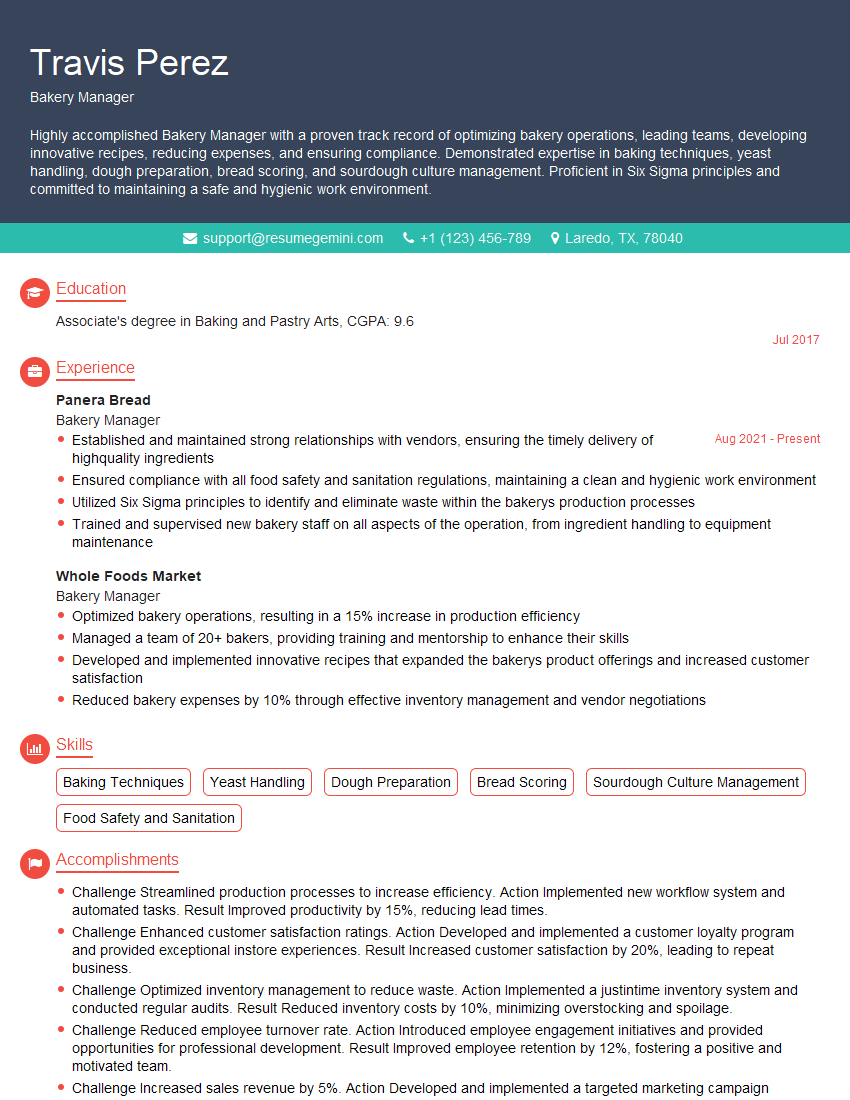

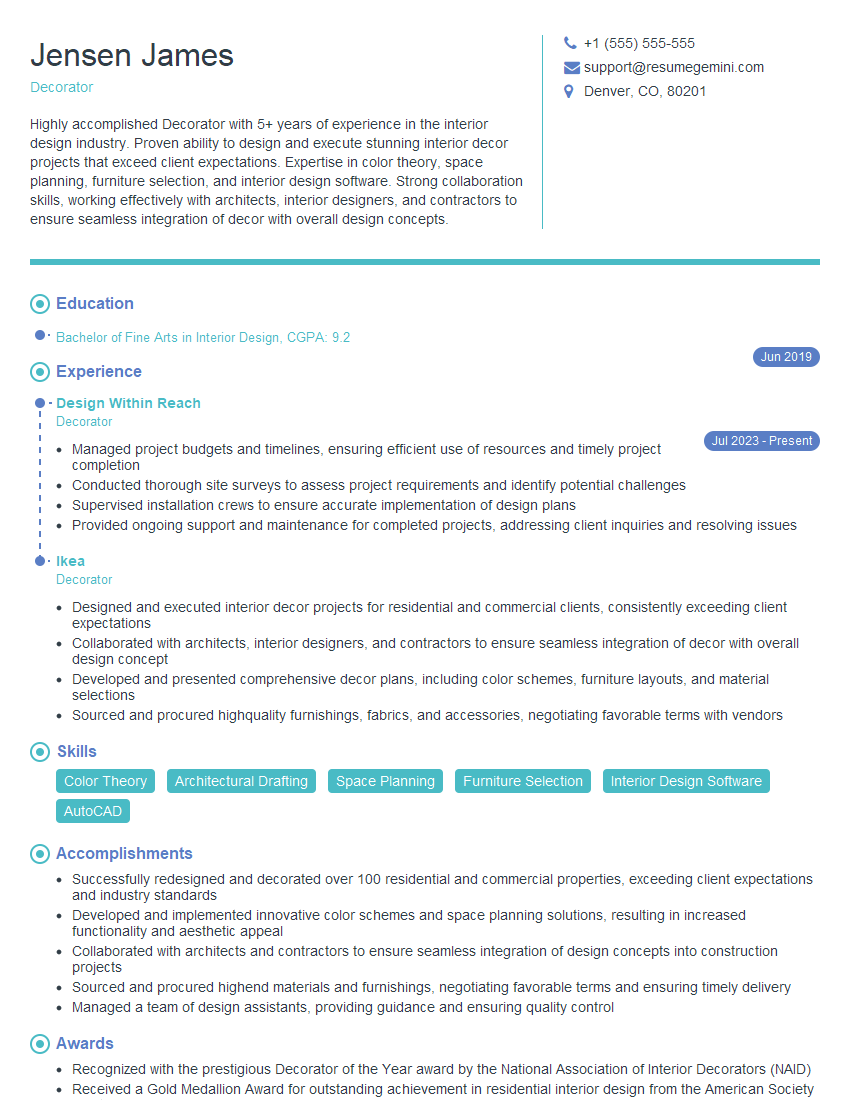

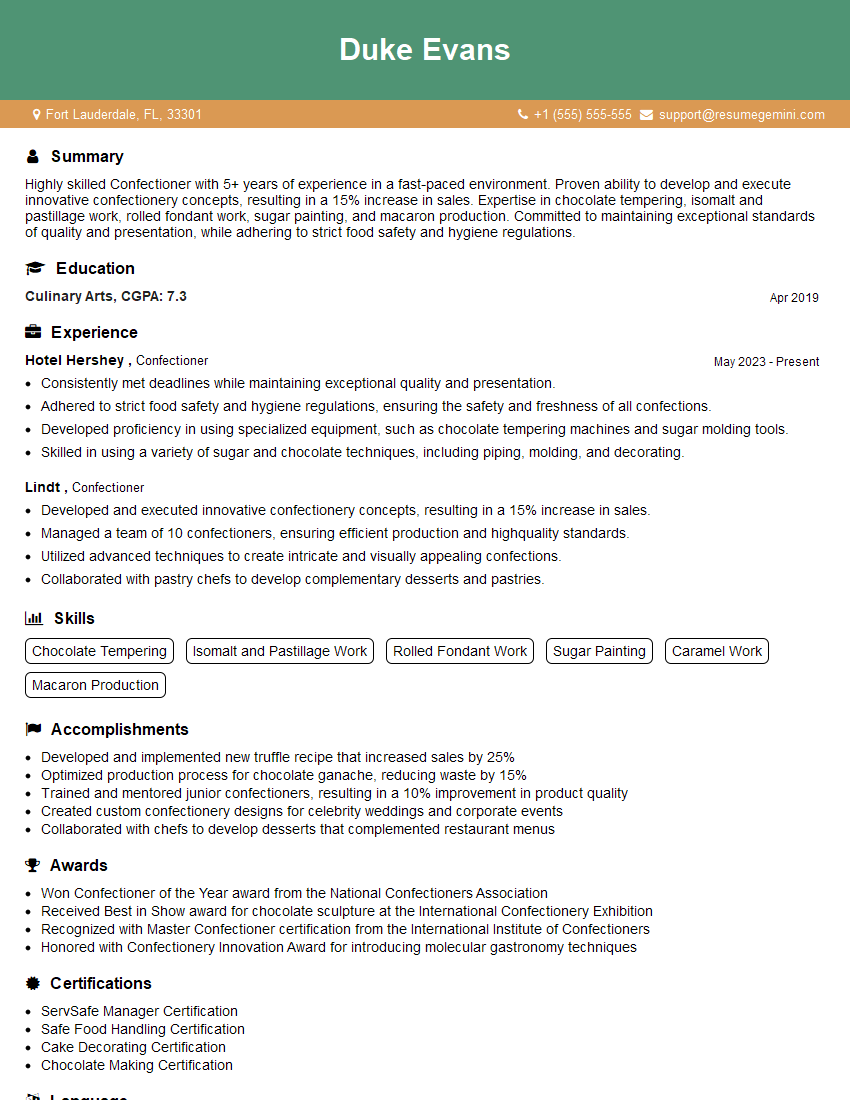

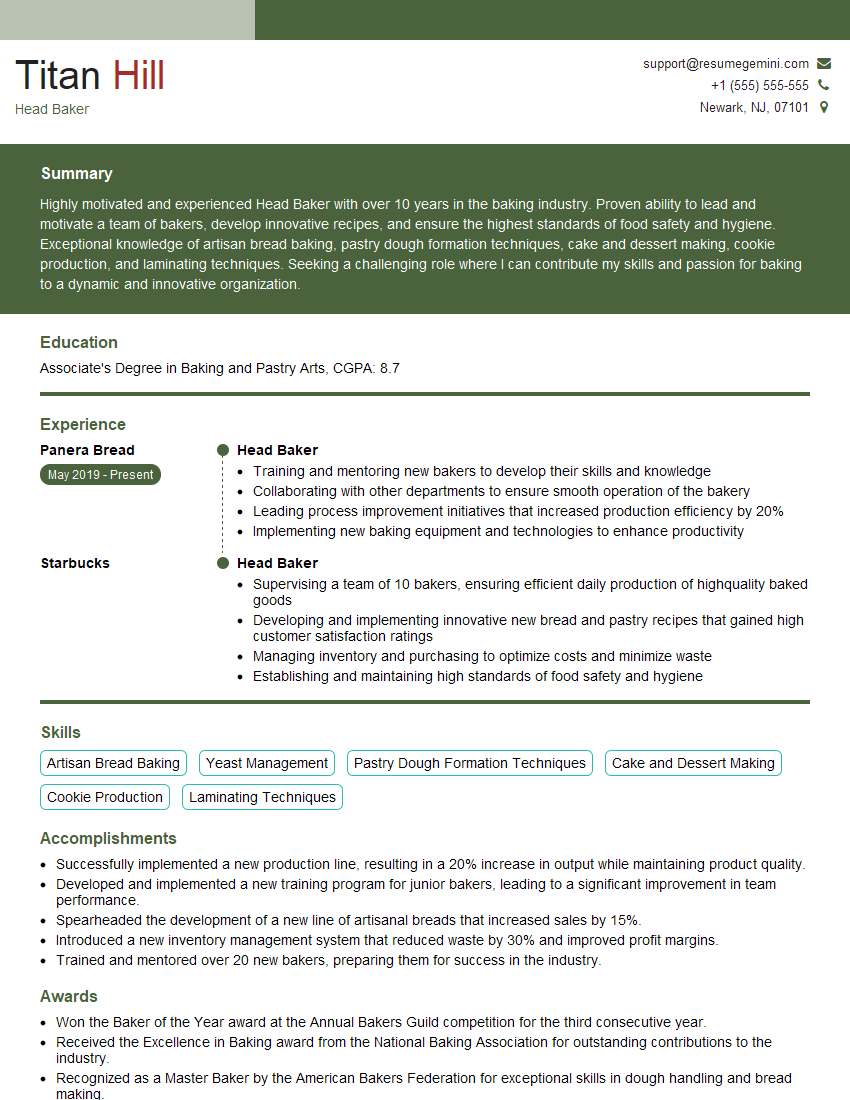

A deep understanding of baking processes is crucial for career advancement in the culinary arts, opening doors to specialized roles and increased earning potential. To maximize your job prospects, crafting an ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Understanding of Baking Processes to guide you in showcasing your expertise. Take the next step towards your dream baking career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good